Al-Cu-Mg alloy with high-strength GoSS+P texture and excellent fatigue resistance and technology

An anti-fatigue, high-strength technology, which is applied in the field of Al-Cu-Mg alloy and thermal processing technology, can solve the problem that the formation temperature range of Goss texture and P texture is quite different, which has not been reported, and achieves the homogenization temperature Effects of time optimization, improvement of fatigue resistance, and reduction of segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

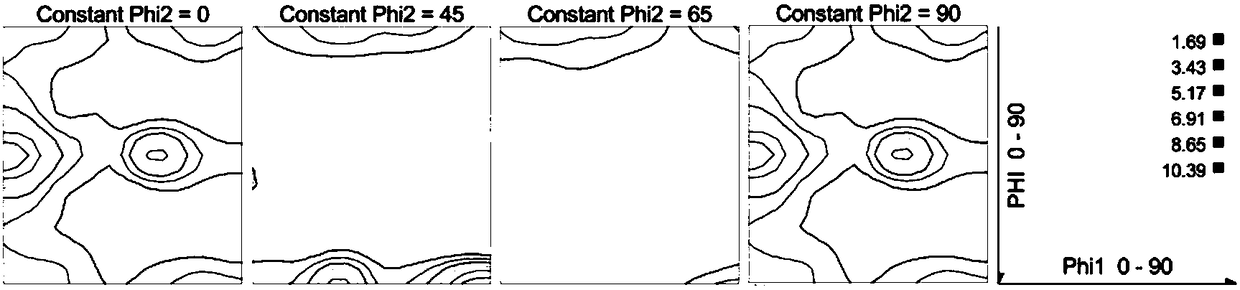

[0067] Example 1 (Goss+P: 19.04)

[0068] The composition of the alloy is 4.5% Cu, 1.2% Mg (Cu / Mg=3.7), 0.5% Mn, 0.06% Ti, 0.05% Fe, 0.05% Si, and the rest is aluminum. After the ingot was homogenized at 495°C / 48h, it was then hot-rolled at 485°C with a deformation of 96% for 80s, and then recrystallized annealed at 330°C for 240min, and then solidified at 490°C / 30min. The tensile properties of the aging plate obtained after solution quenching and natural aging treatment for 96 hours are: tensile strength is 429Mpa, yield strength is 297Mpa, elongation is 23.3%, fatigue performance is: ΔK=30MPam 1 / 2 , da / dN=1.4×10 ~3 mm / cycle.

Embodiment 2

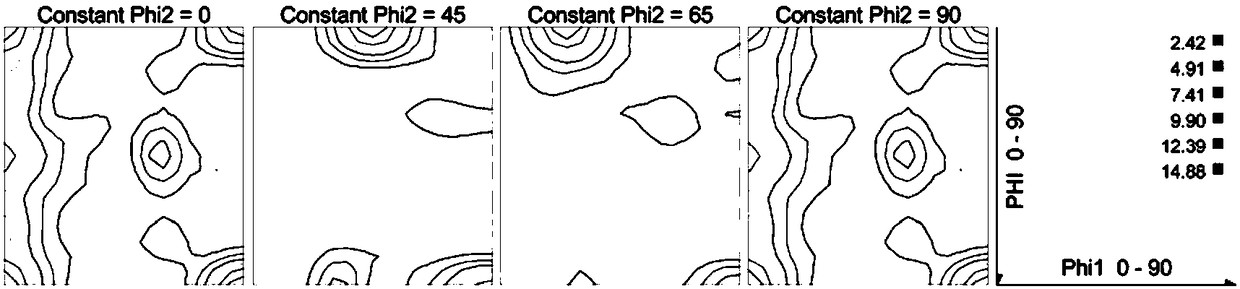

[0069] Example 2 (Goss+P: 19.80)

[0070] The composition of the alloy is 4.4% Cu, 1.5% Mg (Cu / Mg=2.9), 0.4% Mn, 0.08% Ti, 0.03% Fe, 0.05% Si, and the rest is aluminum. After the ingot was homogenized at 475°C / 48h, it was then hot-rolled at 490°C with a deformation of 92% for 70s, and then recrystallized annealed at 320°C for 240min, and then solidified at 490°C / 50min. The tensile properties of the aging plate obtained after solution quenching and natural aging treatment for 96 hours are: tensile strength is 446Mpa, yield strength is 302Mpa, elongation is 24.3%, fatigue performance is: ΔK=30MPam 1 / 2 , da / dN=1.3×10 ~3 mm / cycle.

Embodiment 3

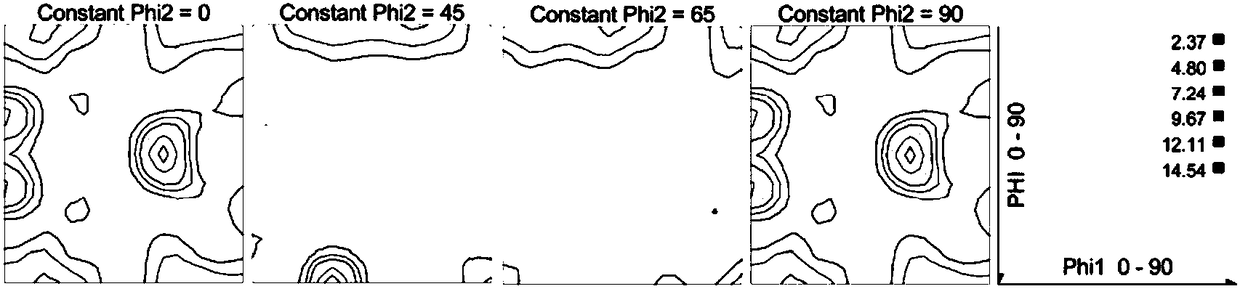

[0071] Example 3 (Goss+P: 19.34)

[0072] The composition of the alloy is 4.2% Cu, 1.20% Mg (Cu / Mg=3.5), 0.8% Mn, 0.05% Ti, 0.05% Fe, 0.02% Si, and the rest is aluminum. After the ingot was homogenized at 495°C / 48h, it was then hot-rolled at 490°C with a deformation of 85% for 50s, and then recrystallized annealed at 340°C for 150min, and then solidified at 480°C / 70min. The tensile properties of the aging plate obtained after solution quenching and post-natural aging treatment for 96 hours are: tensile strength is 442Mpa, yield strength is 295Mpa, elongation is 21.6%, fatigue performance is: ΔK=30MPam 1 / 2 , da / dN=1.5×10 ~3 mm / cycle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com