Silver-bearing Al-Cu-Mg alloy and heat treatment method for silver-bearing Al-Cu-Mg alloy to obtain high-strength P structure

A heat treatment method, al-cu-mg technology, applied in the field of aluminum alloy heat treatment, can solve the problems of unfavorable alloy fatigue resistance, stress concentration, crack propagation across grain boundaries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

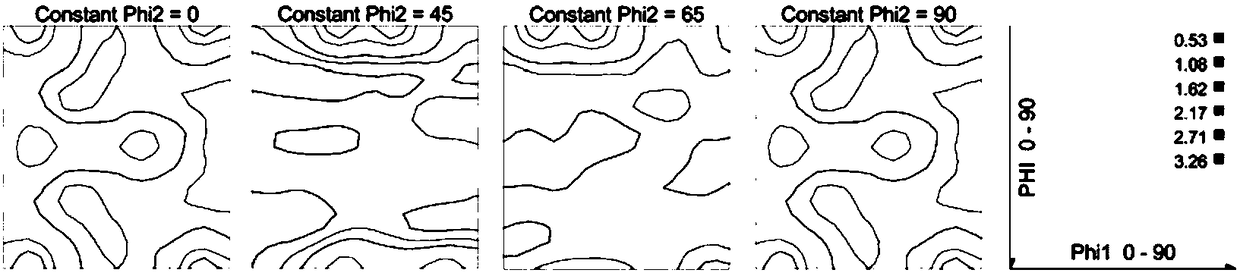

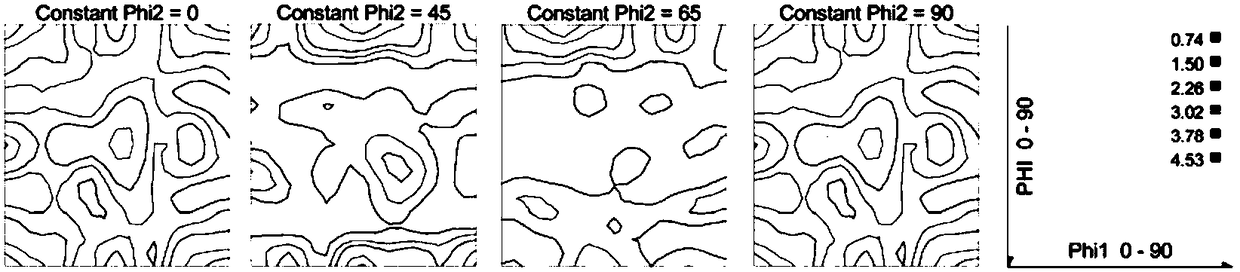

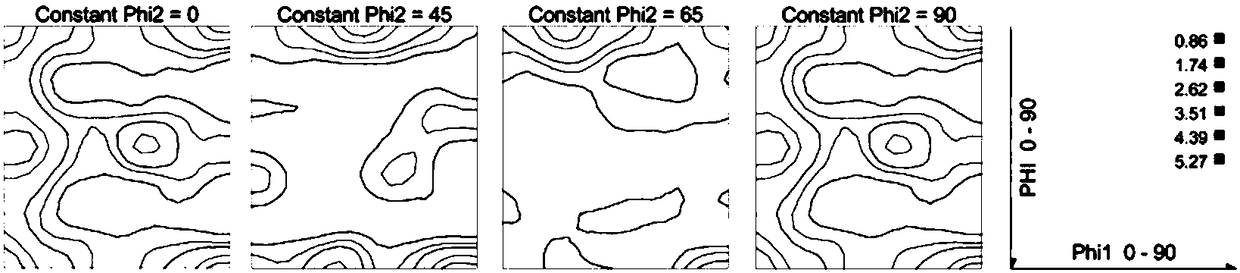

Image

Examples

Embodiment 1

[0051] The composition of alloy 1 is: 3.6% Cu, 1.2% Mg, 0.5% Ag, 0.7% Mn, 0.03% Ti, and the balance is Al. After recrystallization and annealing at 300°C for 240 minutes, the hot-rolled sheet was solid-dissolved at 510°C for 20 minutes, quenched in water, and then subjected to natural aging treatment for 96 hours. The tensile properties of the aged sheet were: tensile strength 474MPa, yield strength 302MPa, The elongation rate is 19.7%, and the anti-fatigue performance is: ΔK=30MPam 1 / 2 , da / dN=5.74×10 -3 mm / cycle.

Embodiment 2

[0053] The composition of alloy 2 is: 4.0% Cu, 1.0% Mg, 0.8% Ag, 0.4% Mn, 0.08% Ti, and the balance is Al. After recrystallization and annealing at 350°C for 180 minutes, the hot-rolled sheet was solid-dissolved at 500°C for 50 minutes, quenched in water, and then subjected to natural aging treatment for 96 hours. The tensile properties of the aged sheet were: tensile strength 469MPa, yield strength 314MPa, The elongation rate is 22.5%, and the anti-fatigue performance is: ΔK=30MPam 1 / 2 , da / dN=3.84×10 -3 mm / cycle.

Embodiment 3

[0055] The composition of alloy 3 is: 4.5% Cu, 1.8% Mg, 0.3% Ag, 1.2% Mn, 0.15% Ti, and the balance is Al. After recrystallization and annealing at 400°C for 120 minutes, the hot-rolled sheet was solidified at 490°C for 80 minutes, quenched in water, and then subjected to natural aging treatment for 96 hours. The tensile properties of the aged sheet were: tensile strength 460MPa, yield strength 295MPa, The elongation rate is 23.2%, and the anti-fatigue performance is: ΔK=30MPam 1 / 2 , da / dN=2.46×10 -3 mm / cycle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com