Constant force support lifting frame for support lifting of thermal power pipelines

A technology for thermal pipelines, supports and hangers, which is applied in the directions of pipeline supports, pipes/pipe joints/pipes, mechanical equipment, etc., can solve problems such as inability to combine and cannot meet performance requirements, and achieves convenient installation and maintenance, high precision, and simple process. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

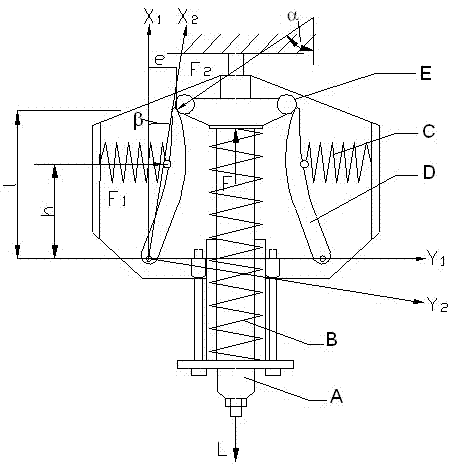

[0012] Control attached figure 1 , The structure is that the main spring B is installed on the load tube A, the main spring B is fixed by the main spring pressure plate, the auxiliary spring C is installed on the two inner sides of the outer frame of the constant force support and hanger, and the outer frame is installed with 2 knives through the rotating shaft The auxiliary spring C on both sides is connected to the knife-shaped guide rail through the auxiliary spring pressure plate. The load tube is connected to the knife-shaped guide rail by two sets of rollers E. When the load tube is subjected to external force, the roller E moves up and down along the knife-shaped guide rail. , The main spring is compressed. At different positions of the movement, the swing of the knife-shaped guide rail causes the auxiliary springs on both sides to be compressed or stretched. Their combined force in the vertical direction changes linearly due to the special shape of the knife-shaped guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com