Method for making civil work engineering structure layer using domestic incinerator slag

A technology of domestic waste incineration and engineering structure, which is applied in the field of comprehensive utilization of domestic waste incineration slag, can solve the problems of unfavorable popularization and application, large investment, complicated process, etc., and achieve the effect of improving project quality, simple and reasonable process, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

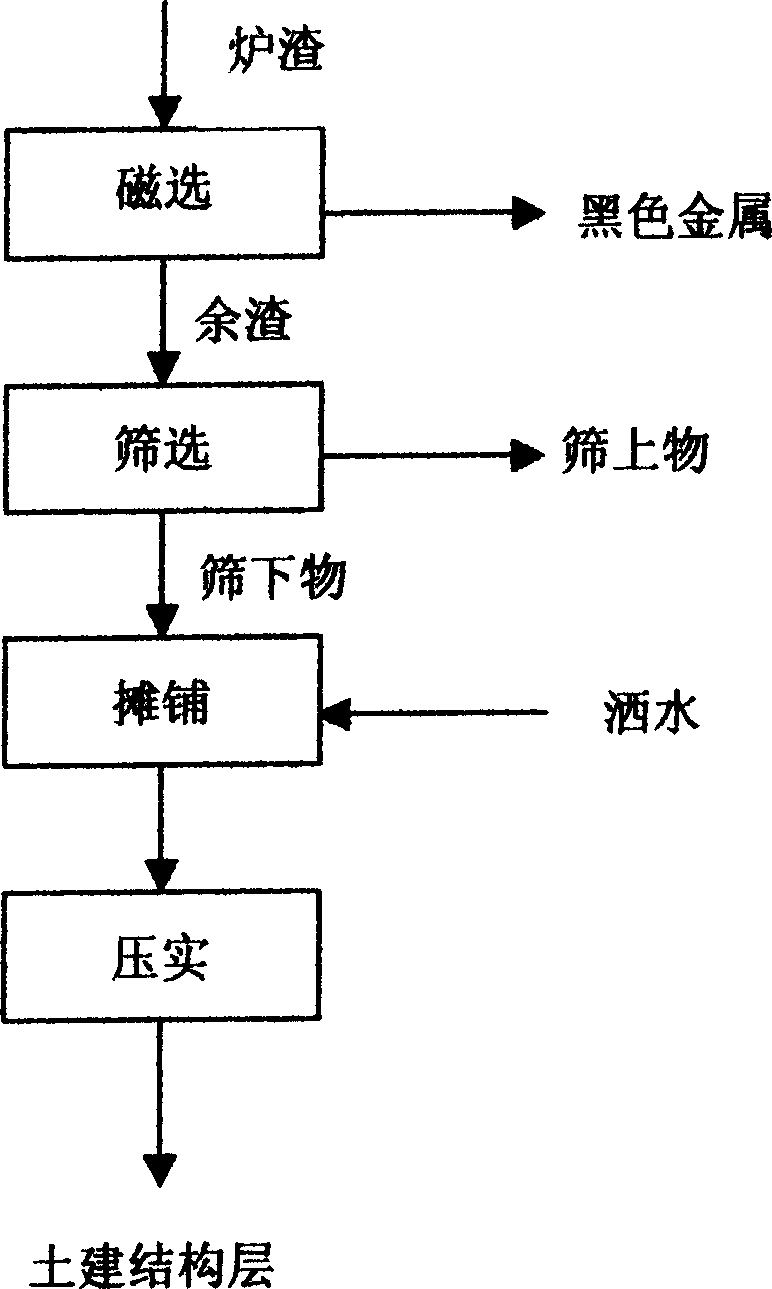

[0011] Please refer to attached picture. The domestic garbage incineration slag of the present invention is firstly subjected to magnetic separation to separate ferrous metals, and the ferrous metals can be further recycled. The remaining incineration slag is then sorted by vibrating screen for particle size, and the oversize can be landfilled or further sorted and recovered. The underscreen material can be used as the covering material of municipal road subgrade and landfill site. When it is applied, it should be paved and watered first, then compacted, and finally form a stable civil structure layer.

[0012] The magnetic separation equipment of the first step of the present invention can choose the magnetic separation drum, which is installed on the upper end drum position of the inclined belt conveyor (replacing the original drum), and the original domestic waste incineration slag is evenly fed to the lower end of the belt conveyor, When the belt is carried to the upper o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com