Full automatic bottle blowing technology for heat resistant bottle and bottle blowing machine for implementing said technology

A fully automatic, heat-resistant technology, applied in the field of plastic bottle manufacturing process and its equipment, can solve the problems of differences in thermal stability of plastic bottles, increase production costs, reduce production efficiency, etc., achieve simple and reasonable processes and equipment, and reduce production costs. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

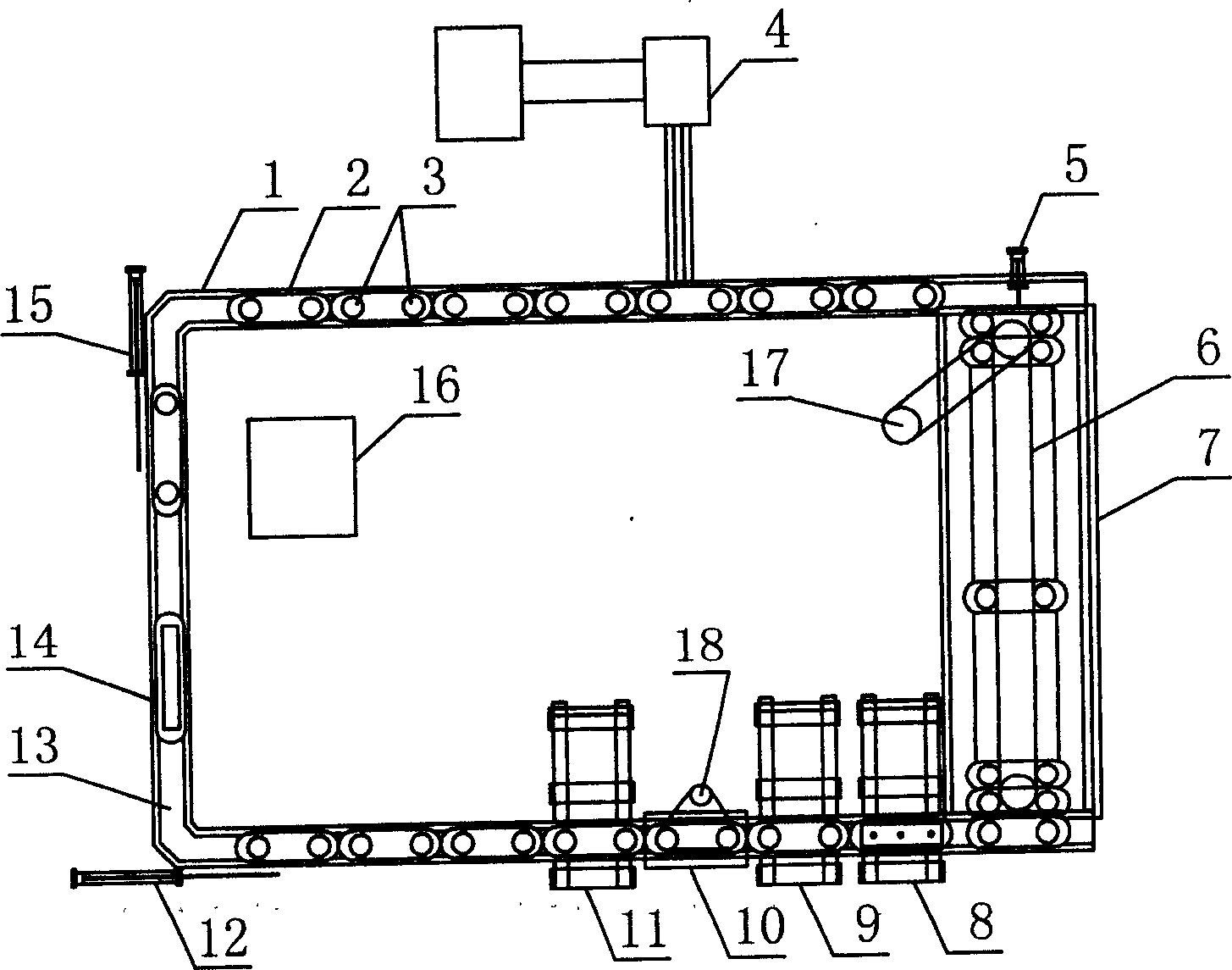

[0016] The bottle blowing machine includes a rack 1, a feeding device 4 connected to each other, a ring conveying track 13 and a heating device 7 and a bottle stripping mechanism 14 are installed on the rack 1 and the ring conveying track 13 is installed with front and back follower Two sets of inner chucks 3 for holding the preform are installed on the slide 2, and the inner chucks 3 can also be more than two sets. The preform is fed in by the feeding device 4, is clamped by the inner chuck 3, and moves circularly along the track 13. A chain 6 meshing with the inner chuck 3 is arranged between the two inner chucks 3 in the heating device 7. The chain 6 rotates and cooperates with the motor 17 through the sprocket at both ends, so that the preform continuously rotates when it advances and ensures that it is evenly heated. On the rear part of the heating device 7 on the frame 1, a medium temperature mold 8, a high temperature mold 9, a secondary heating device 10, and a medium temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com