A Method of Improving the Fatigue Resistance of Al-cu-mg Alloy

An al-cu-mg, anti-fatigue technology, applied in the processing of Al-Cu-Mg alloy, improving the anti-fatigue performance of Al-Cu-Mg alloy, can solve the problem of cost, inconvenience of industrial production, low density of Gaussian texture, etc. problem, to achieve the effect of simple and reasonable process and high fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

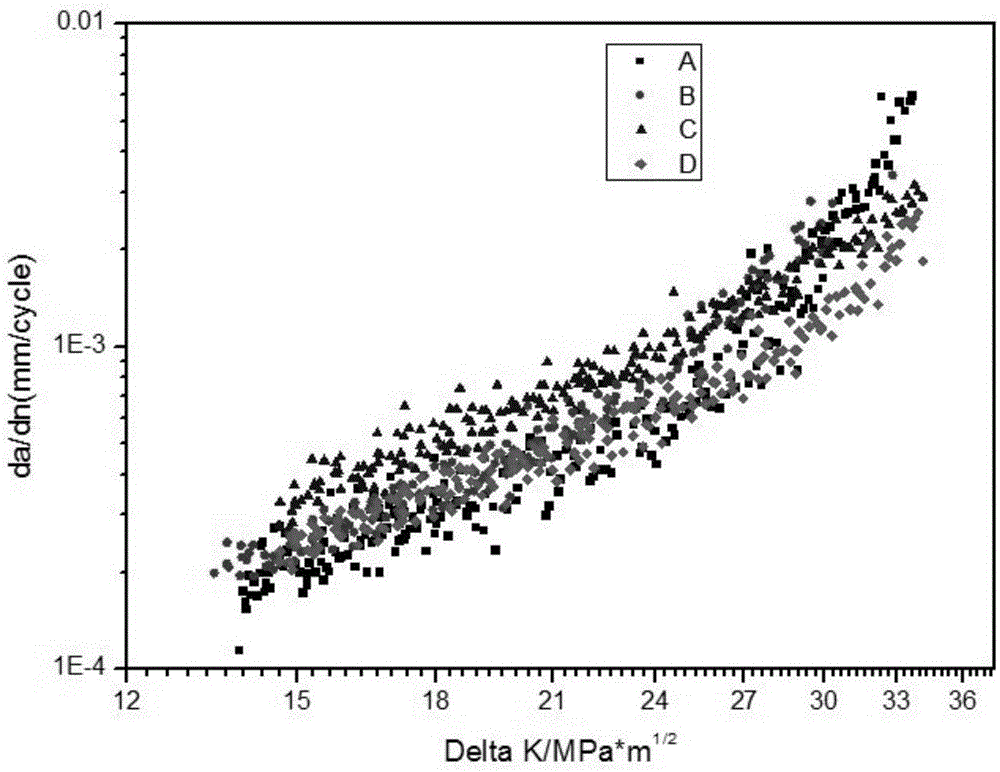

[0041]The alloy composition is: 3.8%Cu, 1.0%Mg, 0.3%Mn, and the balance is Al-Cu-Mg alloy homogenized. After the ingot is kept at 430°C for 1 hour, it is directly hot-rolled with 70% deformation. Then, it was subjected to air solution treatment at 470°C for 1 hour and water quenched, followed by cold rolling with 80% deformation, and then subjected to 470°C salt bath solution treatment for 20 minutes and then natural aging treatment after water quenching. The tensile strength is 456MPa, the yield strength is 327MPa, and the elongation is 23%. When the stress expansion factor ΔK=33MPa*m 1 / 2 , the expansion rate of the alloy is 0.00595mm / cycle respectively.

Embodiment 2

[0043] The alloy composition is: 4.4%Cu, 1.3%Mg, 0.45%Mn, the balance is Al-Cu-Mg alloy homogenized, after the ingot is kept at 440°C for 1 hour, it is directly hot-rolled with 70% deformation. After that, cold rolling with 80% deformation is carried out, followed by annealing treatment at 400°C for 1 hour, and then natural aging treatment after water quenching for 20 minutes in a salt bath at 490°C. The tensile strength is 476MPa, the yield strength is 334MPa, and the elongation is 23.2%. When the stress expansion factor ΔK=33MPa*m 1 / 2 , the expansion rate of the alloy was 0.00335mm / cycle.

Embodiment 3

[0045] The alloy composition is: 4.9% Cu, 1.5% Mg, 0.8% Mn, and the Al-Cu-Mg alloy with the balance of Al is homogenized. After the ingot is heated at 440°C for 1 hour, it is directly hot-rolled with 70% deformation. Then air solution treatment at 490°C for 1 hour and water quenching followed by cold rolling with 80% deformation, followed by natural aging treatment at 490°C salt bath for 20 minutes after water quenching. The tensile strength is 475MPa, the yield strength is 331MPa, and the elongation is 22.3%. When the stress expansion factor ΔK=33MPa*m 1 / 2 , the expansion rate of the alloy was 0.0043mm / cycle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com