Patents

Literature

71results about How to "Improve resistance to fatigue damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

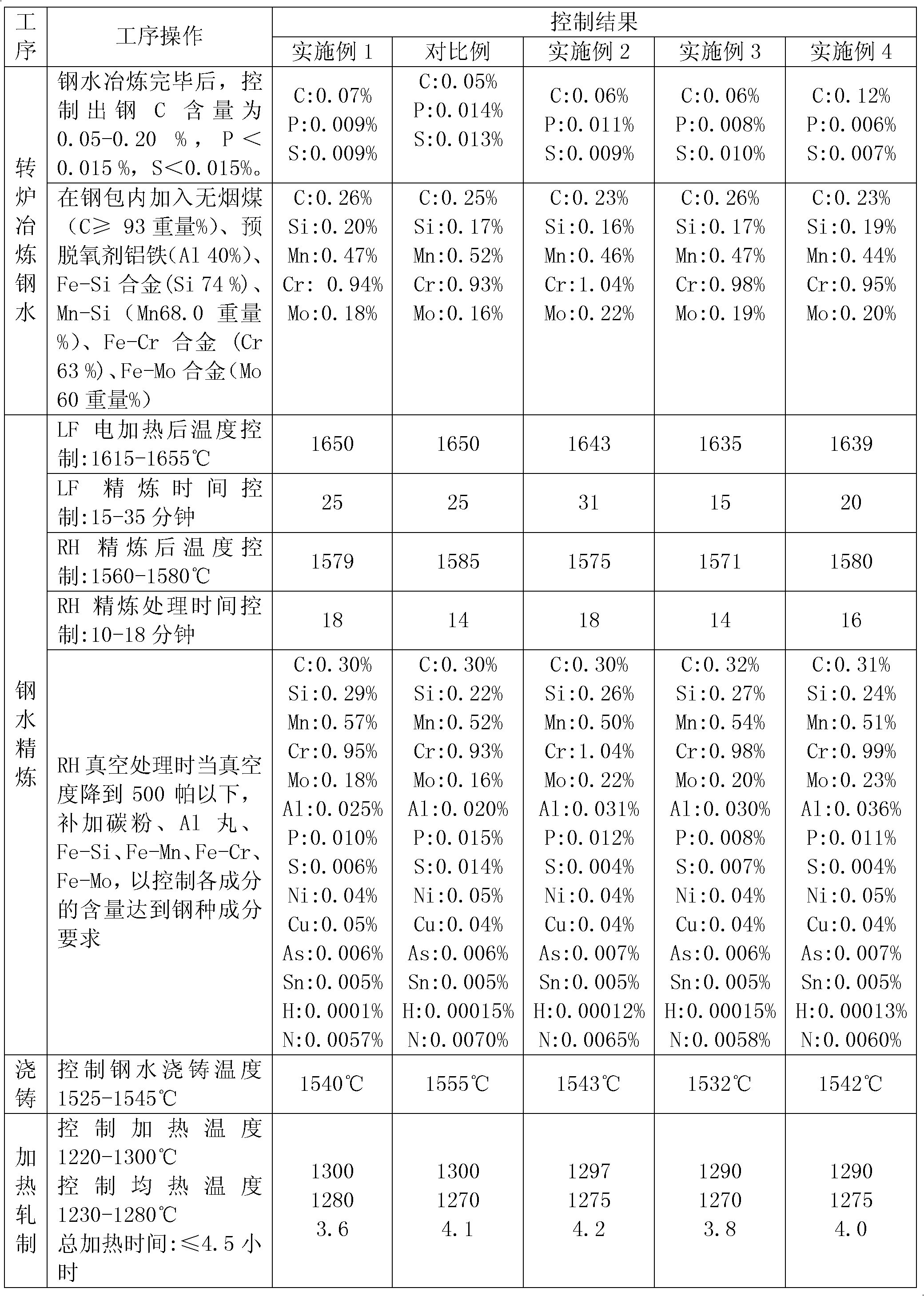

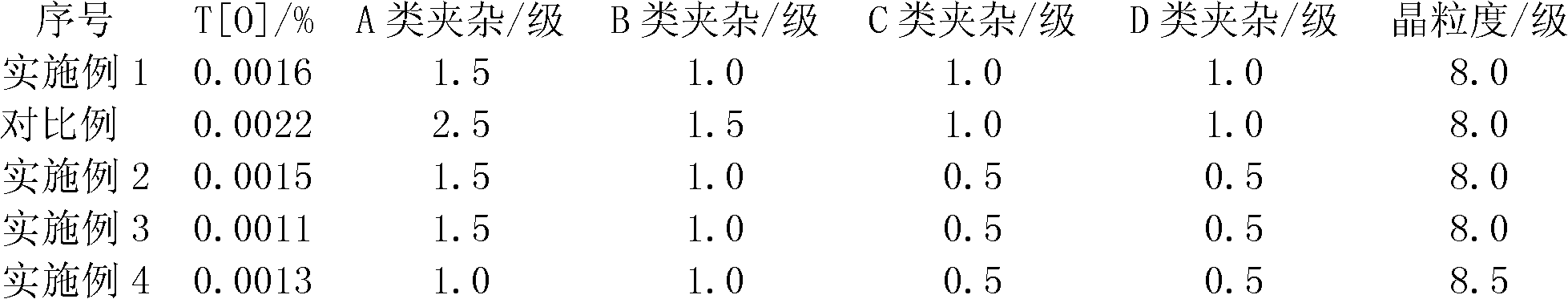

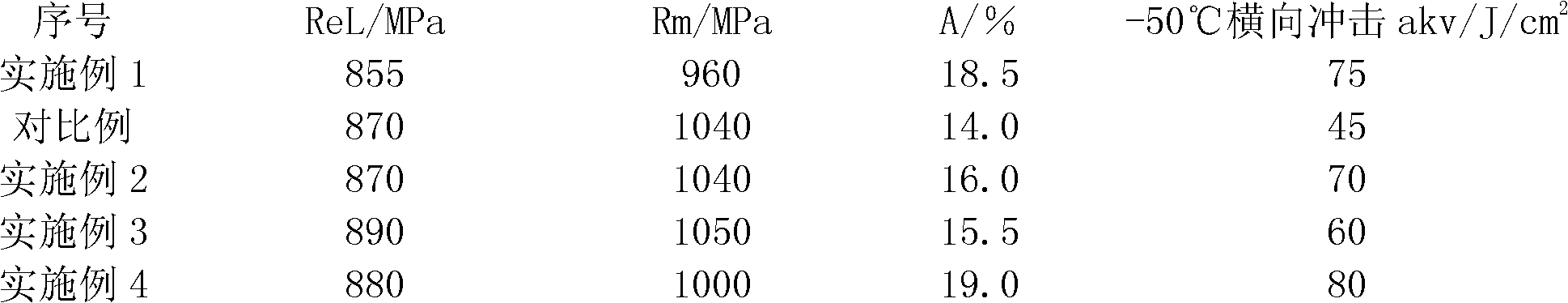

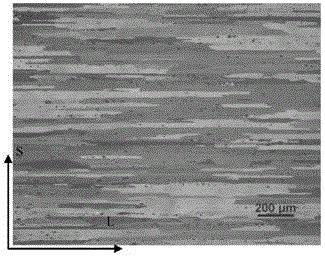

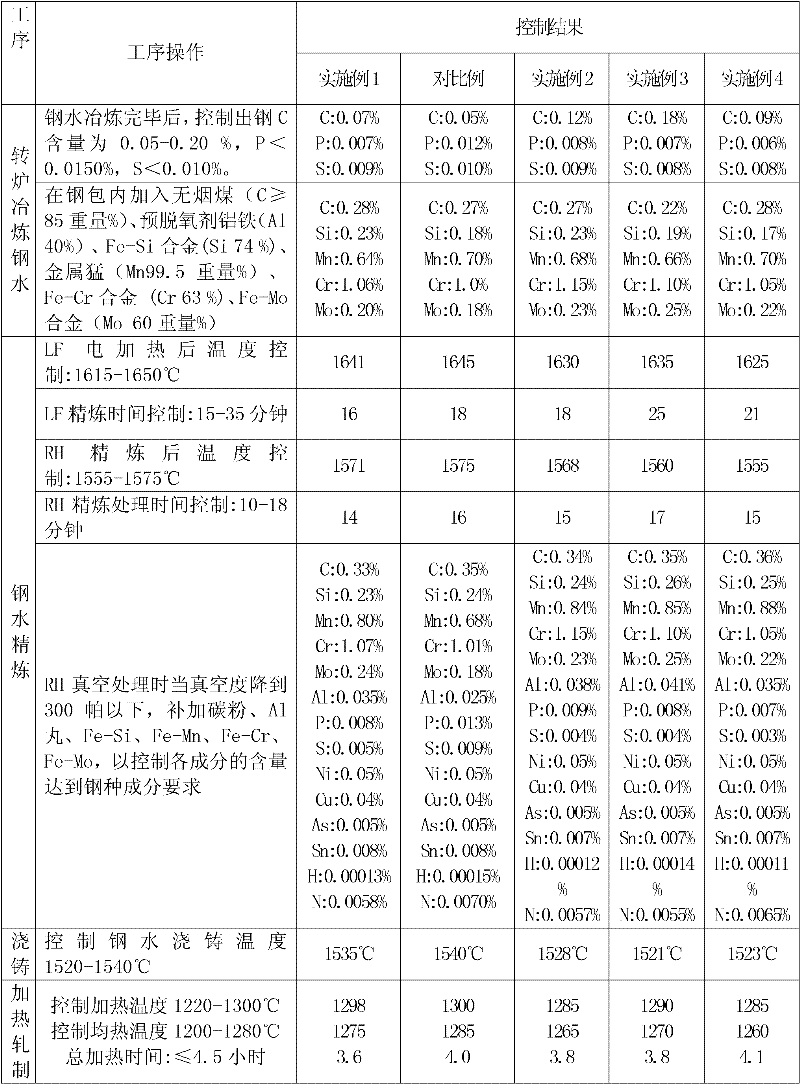

Hot-rolled section steel for gas cylinder and production method thereof

The invention belongs to the field of steel production and relates to hot rolled steel section for gas cylinders and a production method thereof. The technical problem to be solved by the invention is to provide the hot rolled steel section for gas cylinders and improve the quality and comprehensive mechanical performance of hot rolled steel section for gas cylinders. The hot rolled steel sectionfor gas cylinders comprises the following components in percentage by weight: 0.25 to 0.32 percent of C, 0.15 to 0.35 percent of Si, 0.40 to 0.60 percent of Mn, 0.8 to 1.05 percent of Cr, 0.15 to 0.25 percent of Mo, 0.02 to 0.04 percent of Al, less than or equal to 0.015 percent of P, less than or equal to 0.015 percent of S, less than or equal to 0.020 percent of P and S, less than or equal to 0.2 percent of Ni, less than or equal to 0.15 percent of Cu, less than or equal to 0.015 percent of Sn, less than or equal to 0.015 percent of As, less than or equal to 0.0002 percent of H, less than or equal to 0.009 percent of N, less than or equal to 0.0020 percent of T[O], and the balance of Fe. The steel disclosed by the invention can achieve high and stable comprehensive mechanical performance through simple tempering heat treatment.

Owner:PANZHIHUA IRON AND STEEL +3

Machining technology for improving fatigue damage resisting performance of 2xxx aluminum alloy plate

ActiveCN105483579AImproved resistance to fatigue damageImprove resistance to fatigue damageAviationFatigue damage

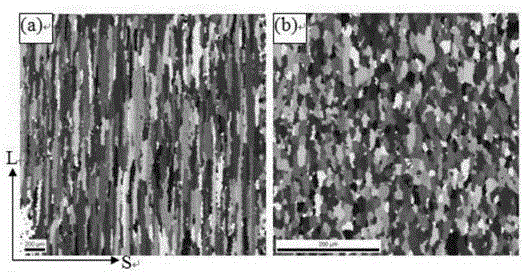

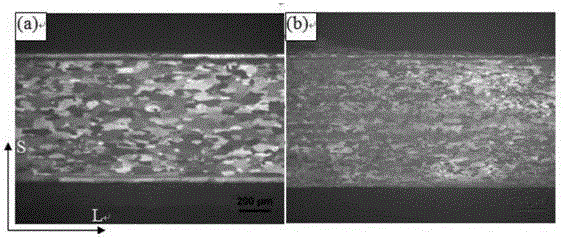

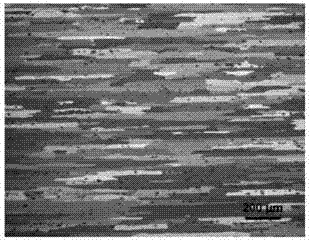

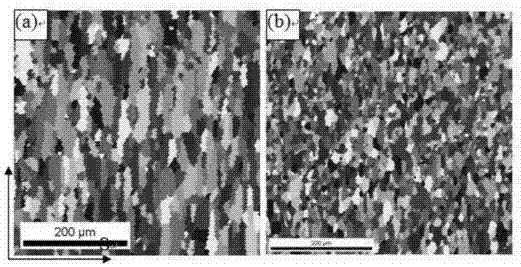

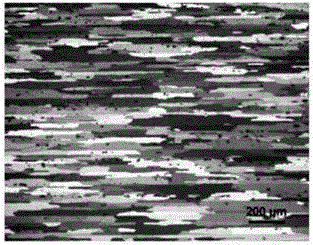

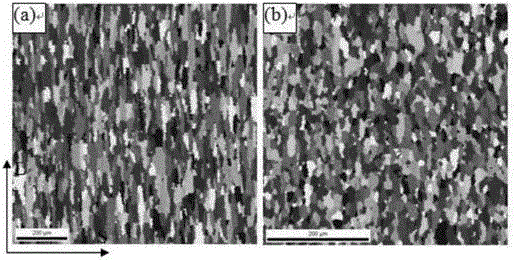

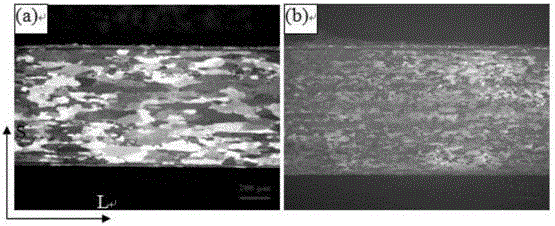

The invention relates to a machining technology for improving the fatigue damage resisting performance of a 2xxx aluminum alloy plate. The machining technology comprises the following steps that 1, alloy is subjected to burdening smelting and is cast into an ingot casting; 2, the ingot casting is sequentially subjected to homogenization treatment, surface milling and aluminum cladding, preheating is carried out, and a hot rough-rolled plate is manufactured; 3, the hot rough-rolled plate is subjected to hot finishing and cold rolling deformation to the thickness of the finished plate; 4, recrystallization pre-annealing treatment is carried out, temperature is raised to 300-450 DEG C at the average speed of 10-300 DEG C / h or within 1.0-45 h, and heat preservation is carried out for 1-20 h; 5, solid solution hardening treatment is carried out, the solid solution temperature is 480-505 DEG C, and heat preservation time is 3-60 min; and 6, the plate is straightened, and natural ageing is carried out to the stable state. According to the machining technology, recrystallization pre-annealing treatment is added so that the L-ST section grain average equivalent diameter and grain length-width ratio of the plate can be effectively controlled, and the tensile mechanical property and fatigue crack spreading rate of the plate can both meet the AMS 4296 aviation standard requirement.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD +1

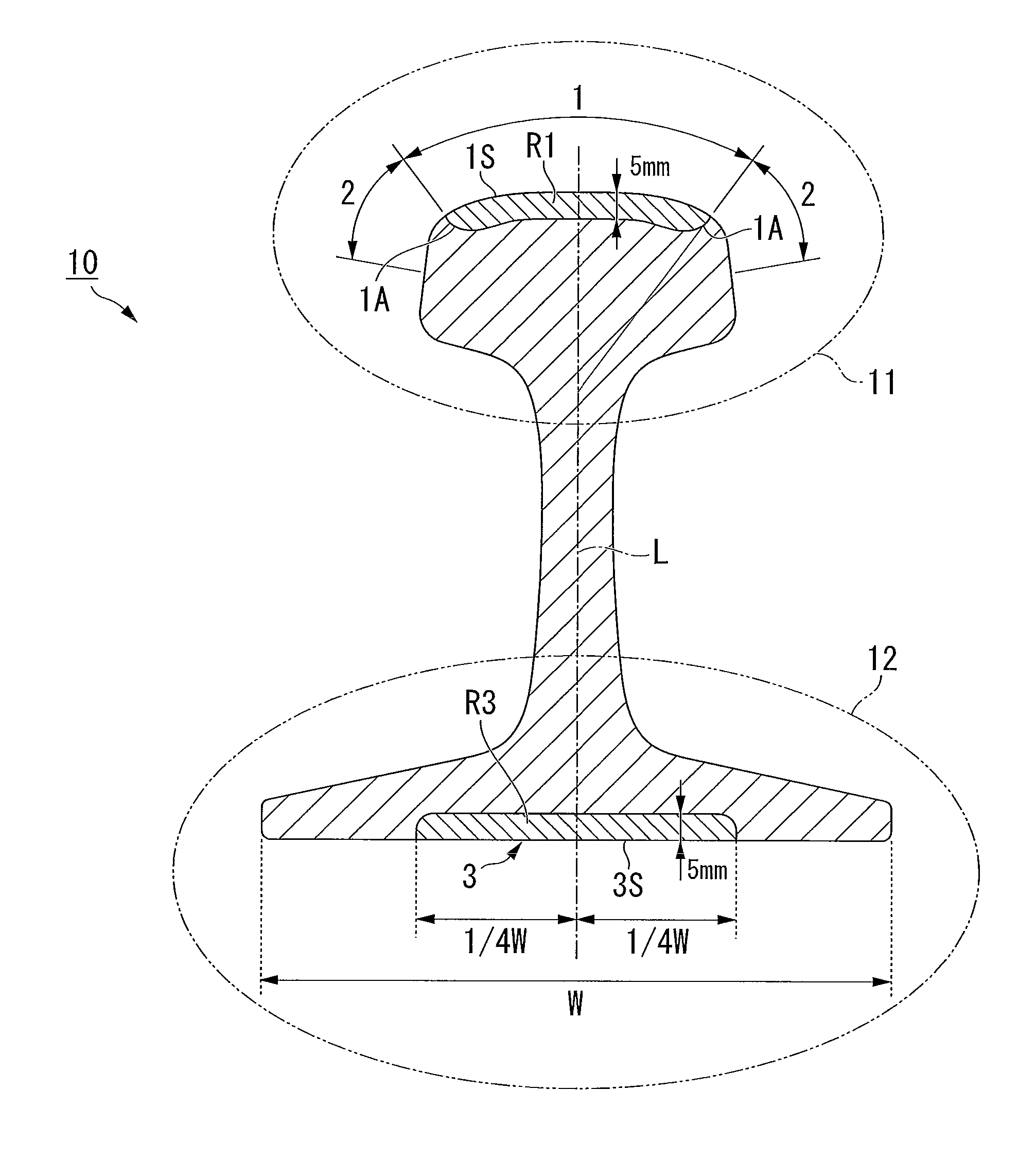

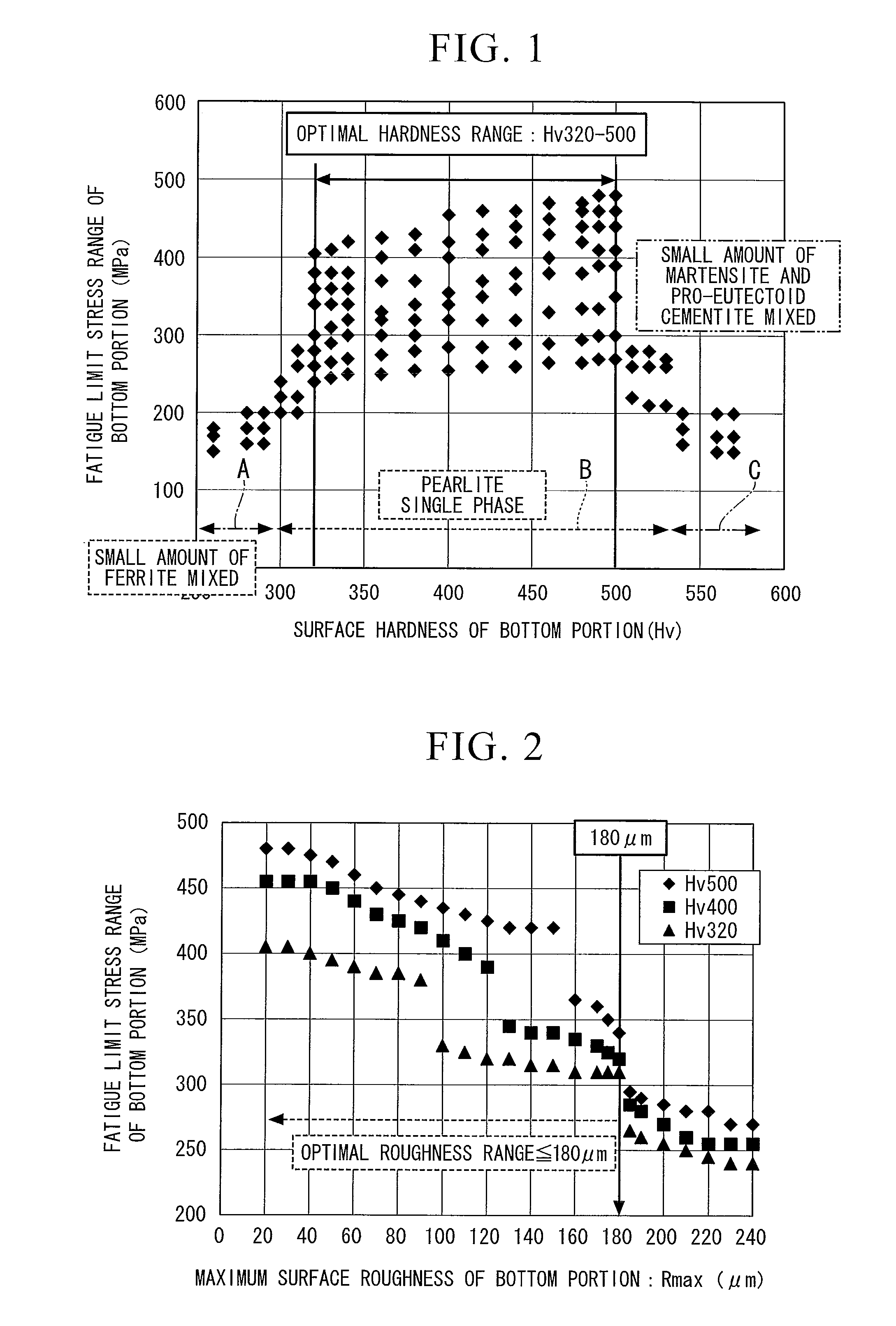

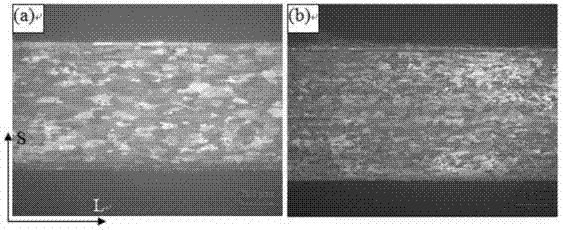

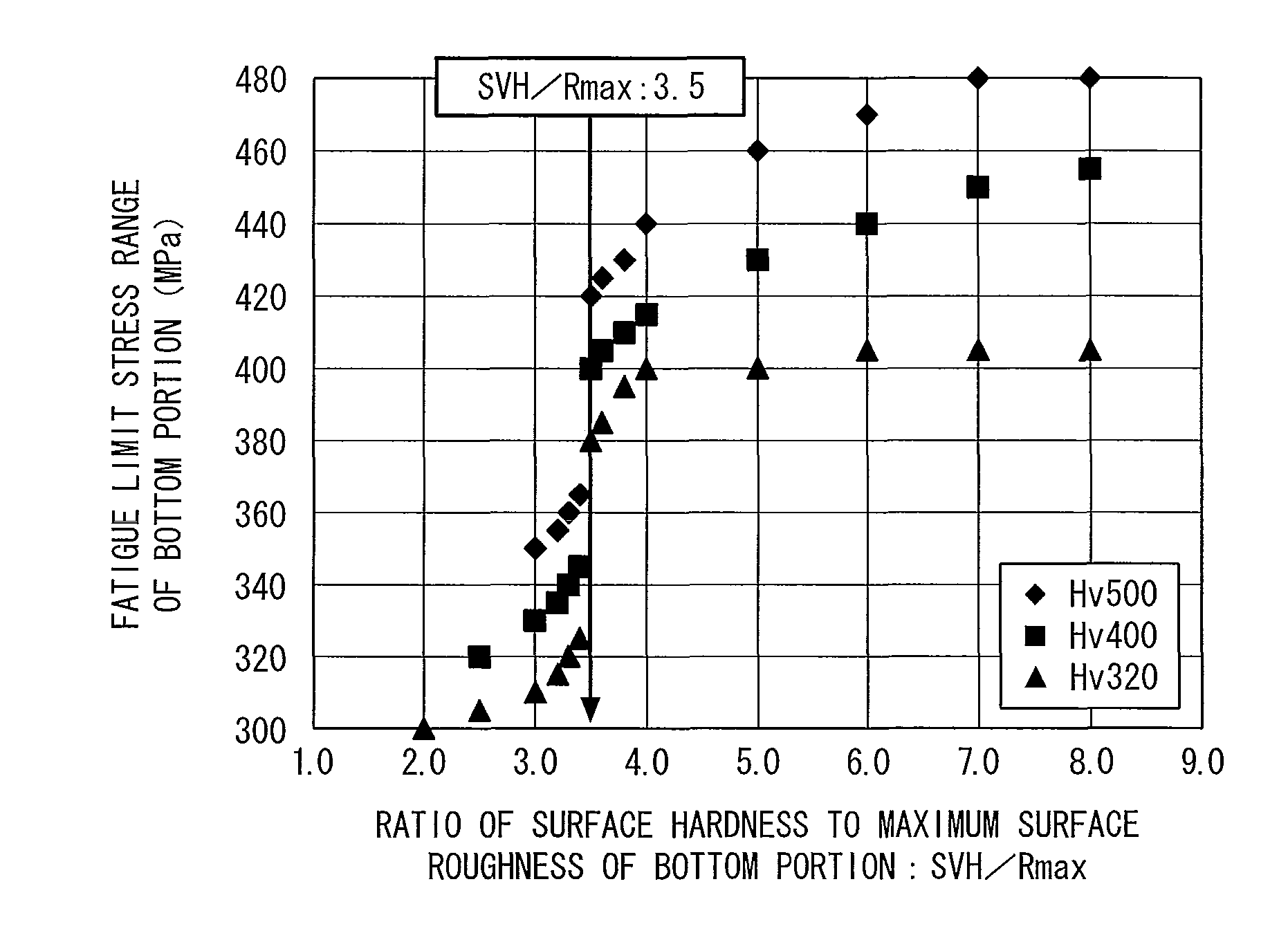

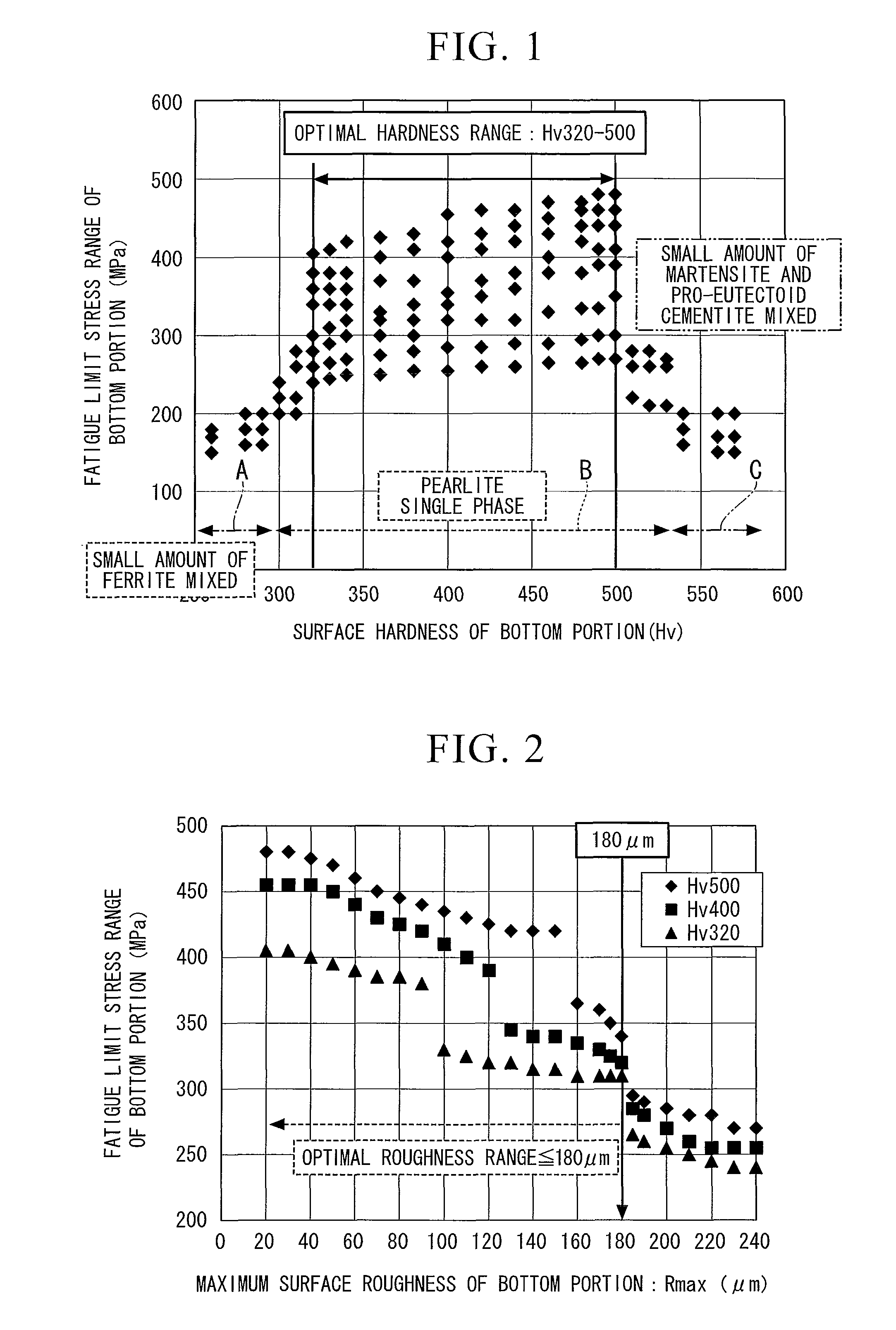

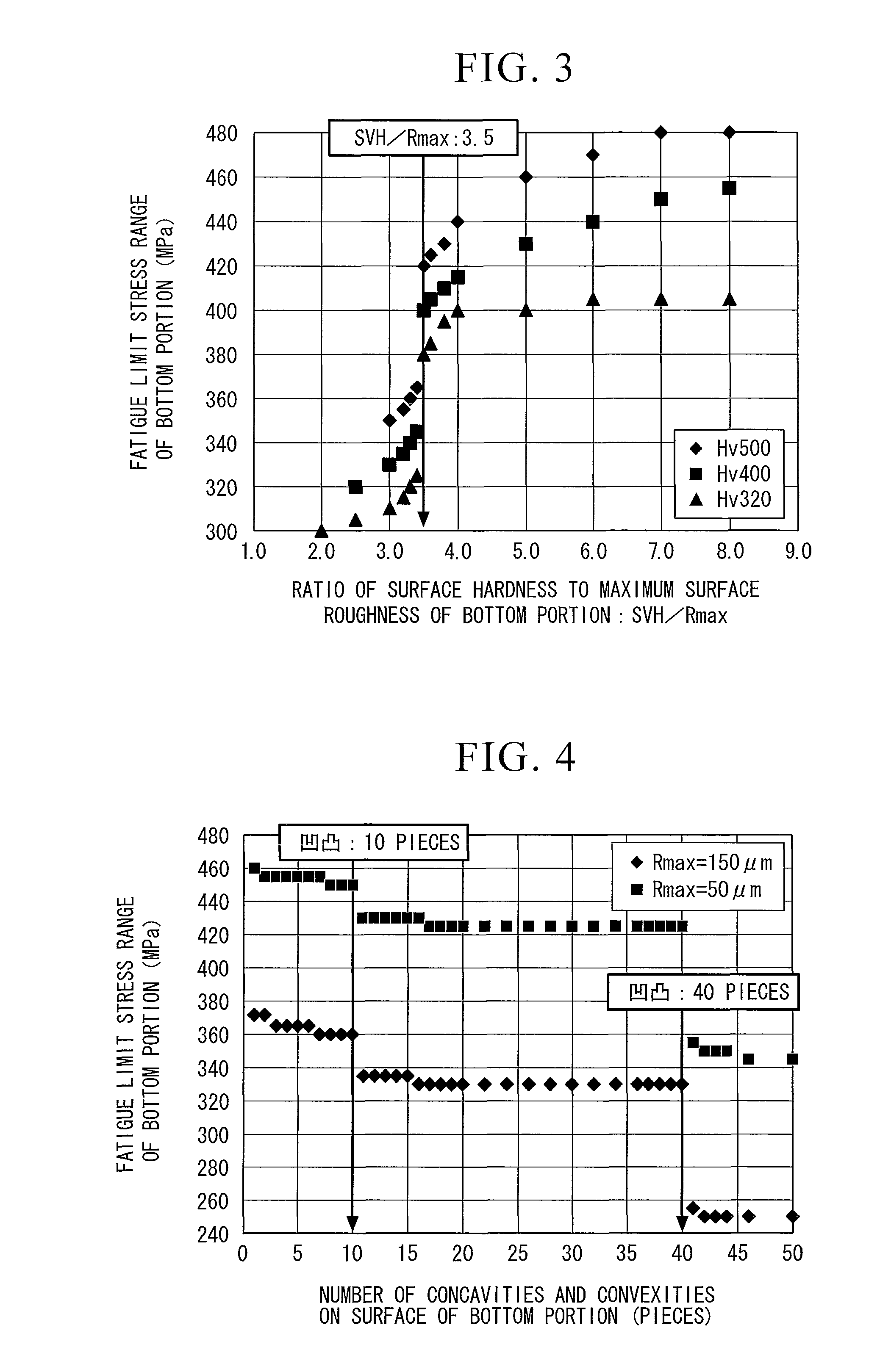

Pearlite rail

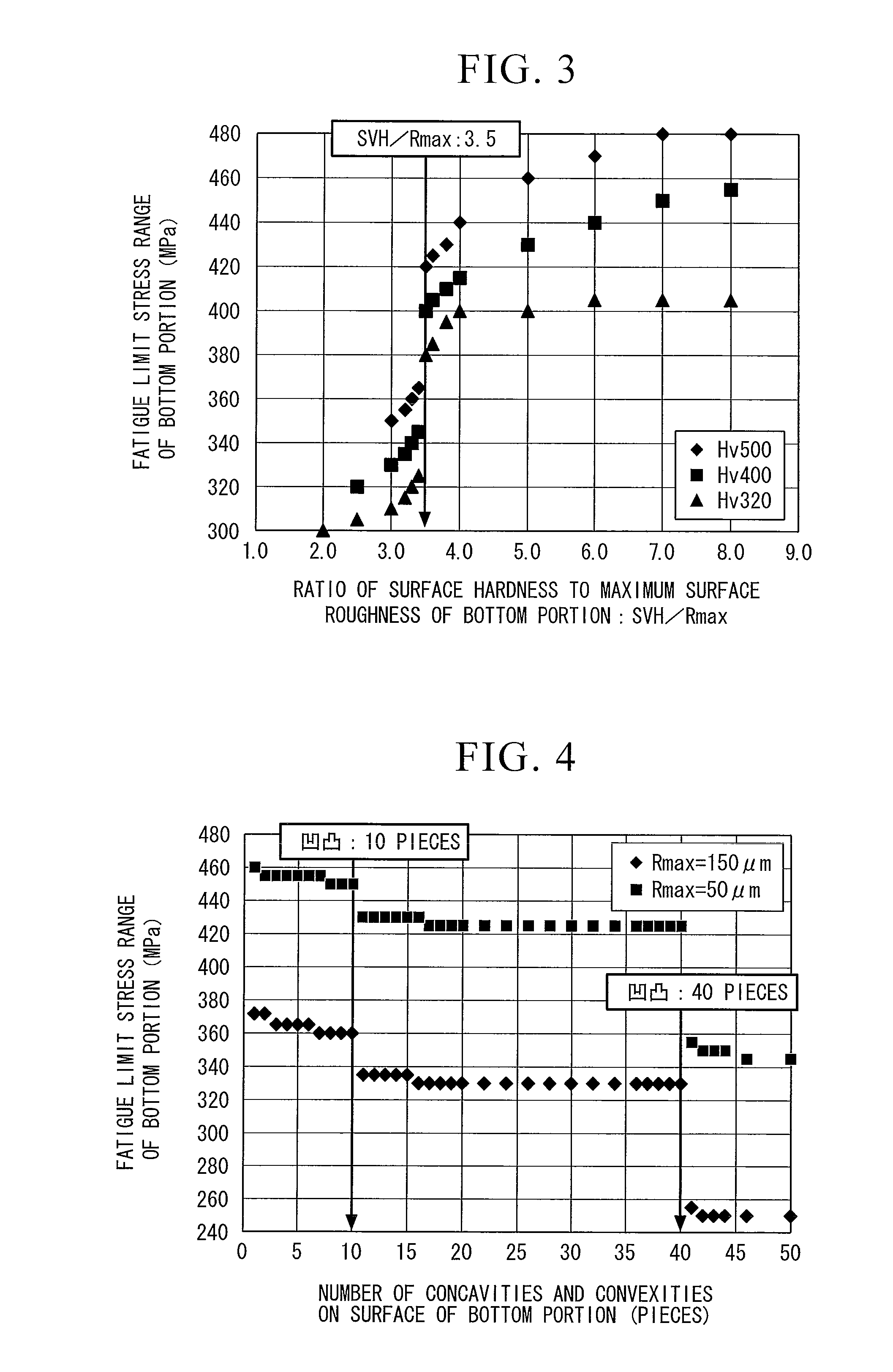

ActiveUS20110226389A1Maintain hardness (strength)Improve resistance to fatigue damageFurnace typesHeat treatment furnacesMetallurgySurface roughness

A pearlite rail contains, by mass %, 0.65 to 1.20% of C; 0.05 to 2.00% of Si; 0.05 to 2.00% of Mn; and the balance composed of Fe and inevitable impurities, wherein at least part of the head portion and at least part of the bottom portion has a pearlite structure, and the surface hardness of a portion of the pearlite structure is in a range of Hv320 to Hv500 and a maximum surface roughness of a portion of the pearlite structure is less than or equal to 180 μm.

Owner:NIPPON STEEL CORP

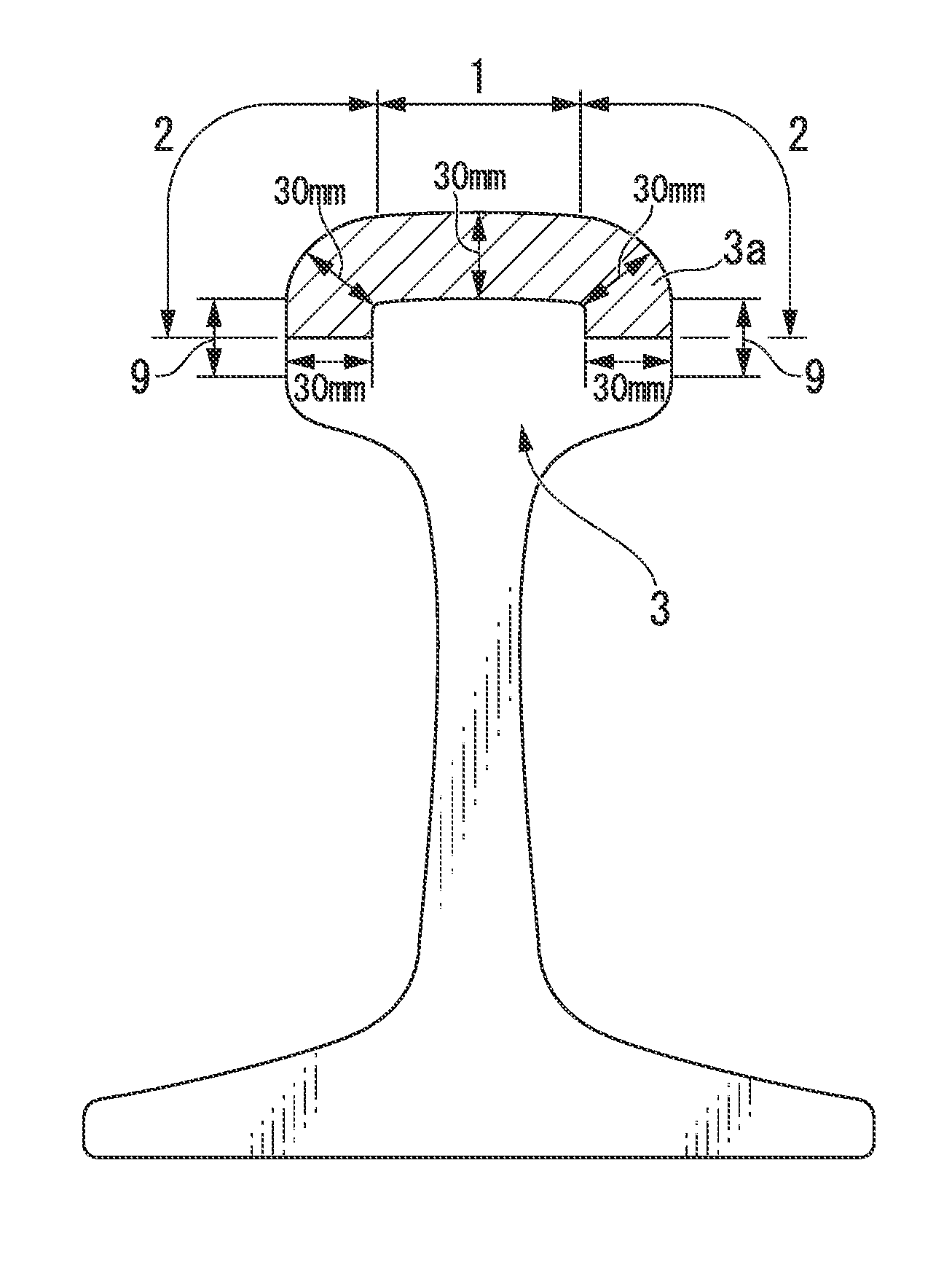

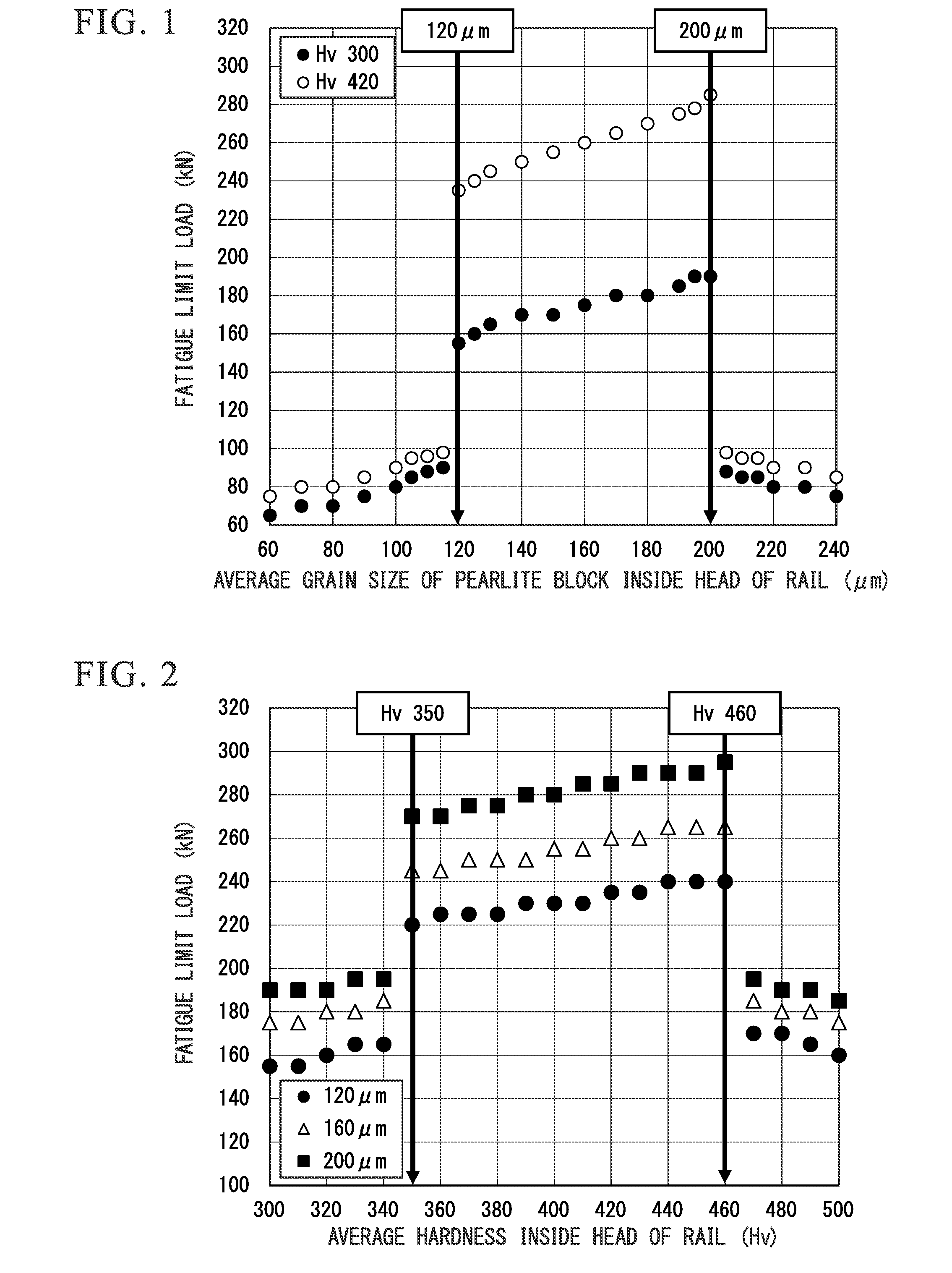

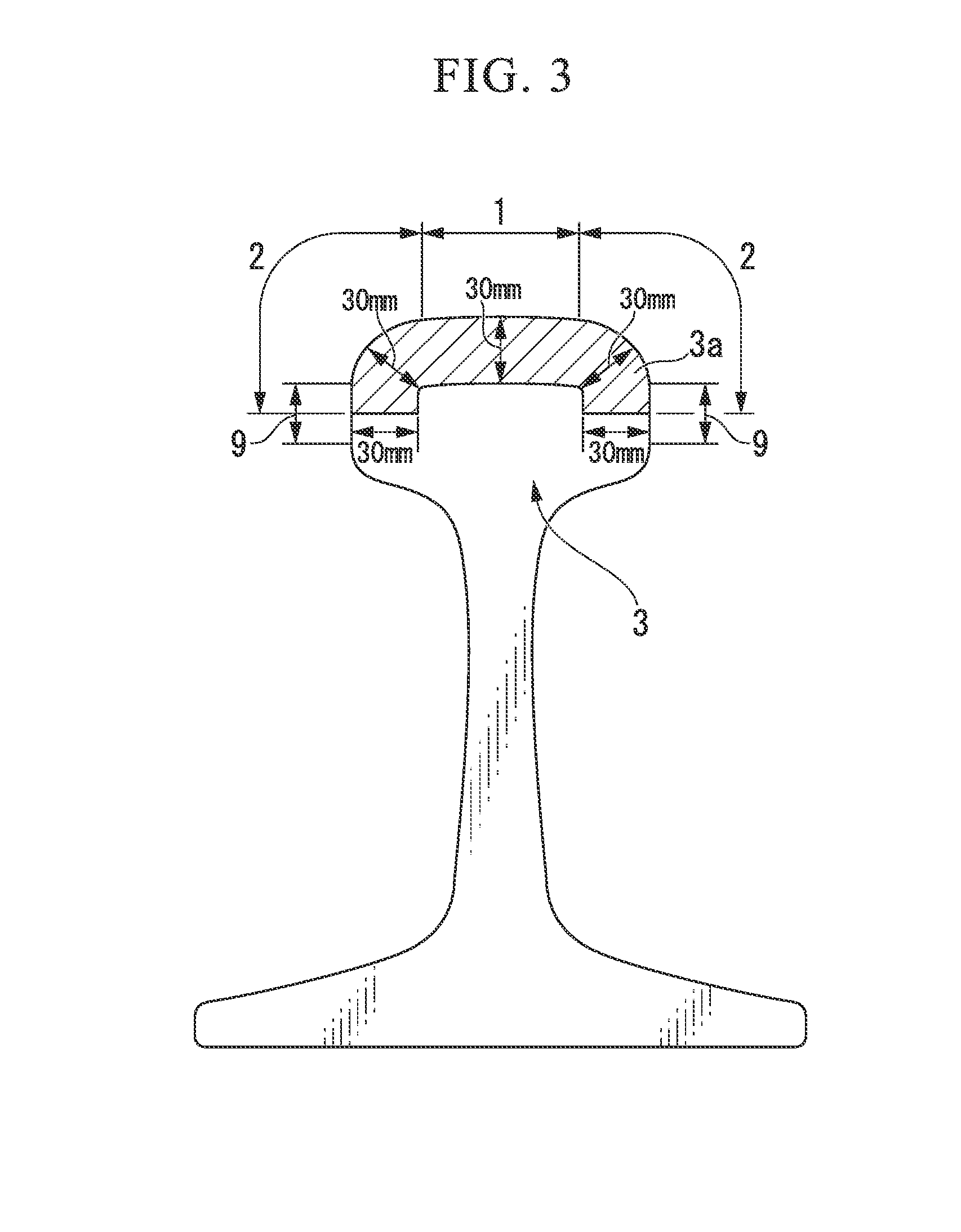

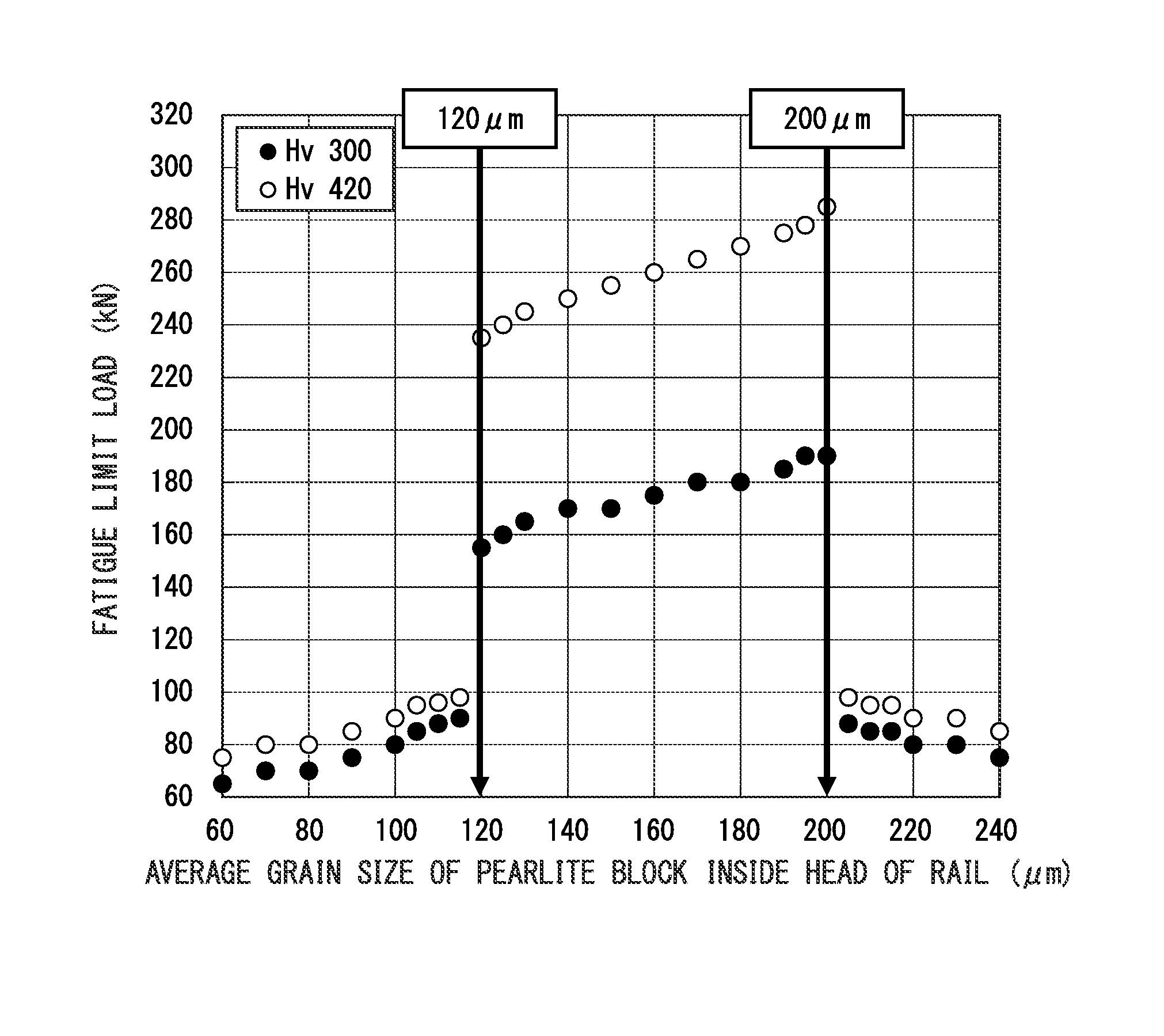

Rail

ActiveUS20150136864A1Improve fatigueExtended service lifeRailsFurnace typesMetallurgyMaterials science

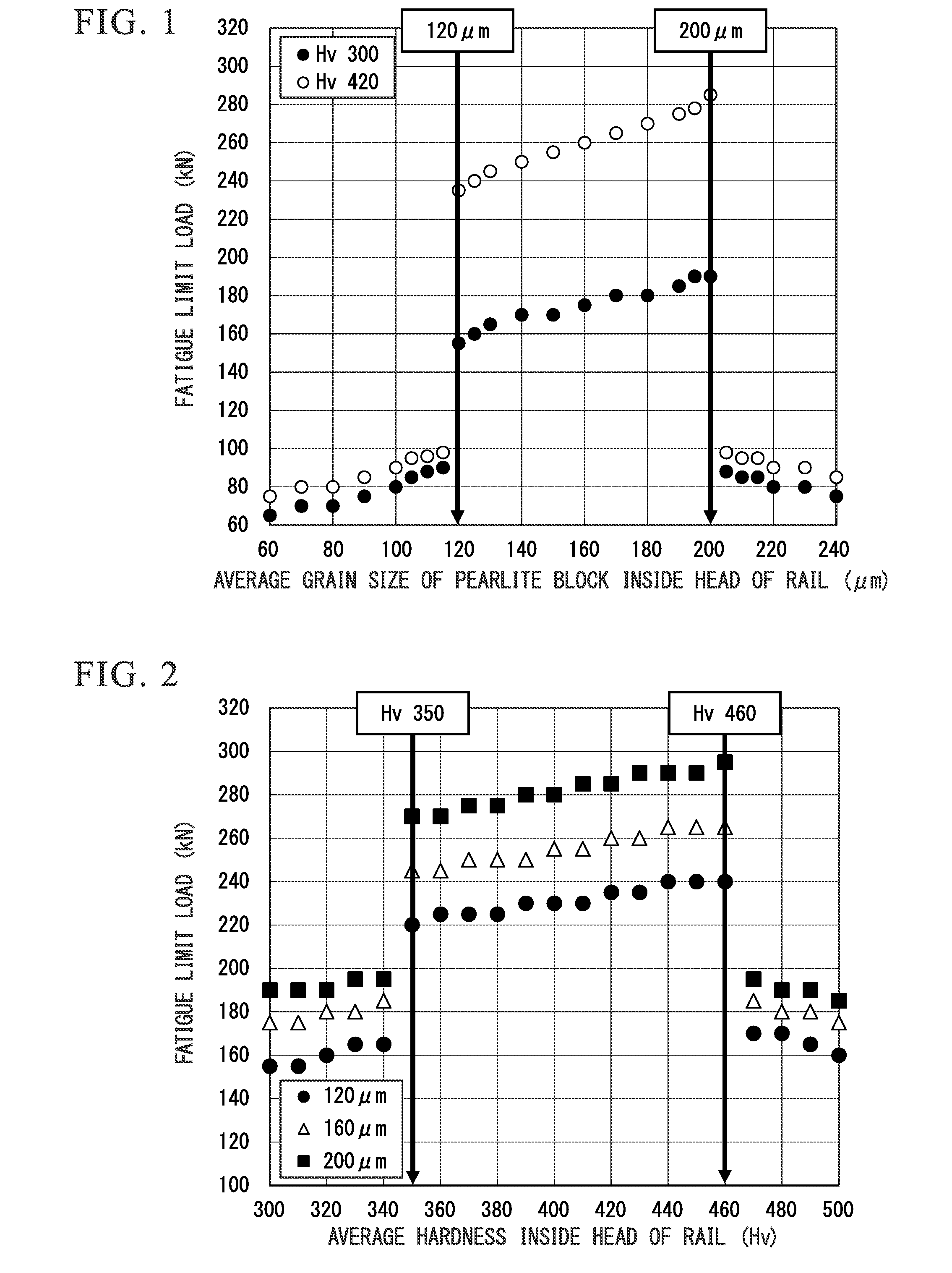

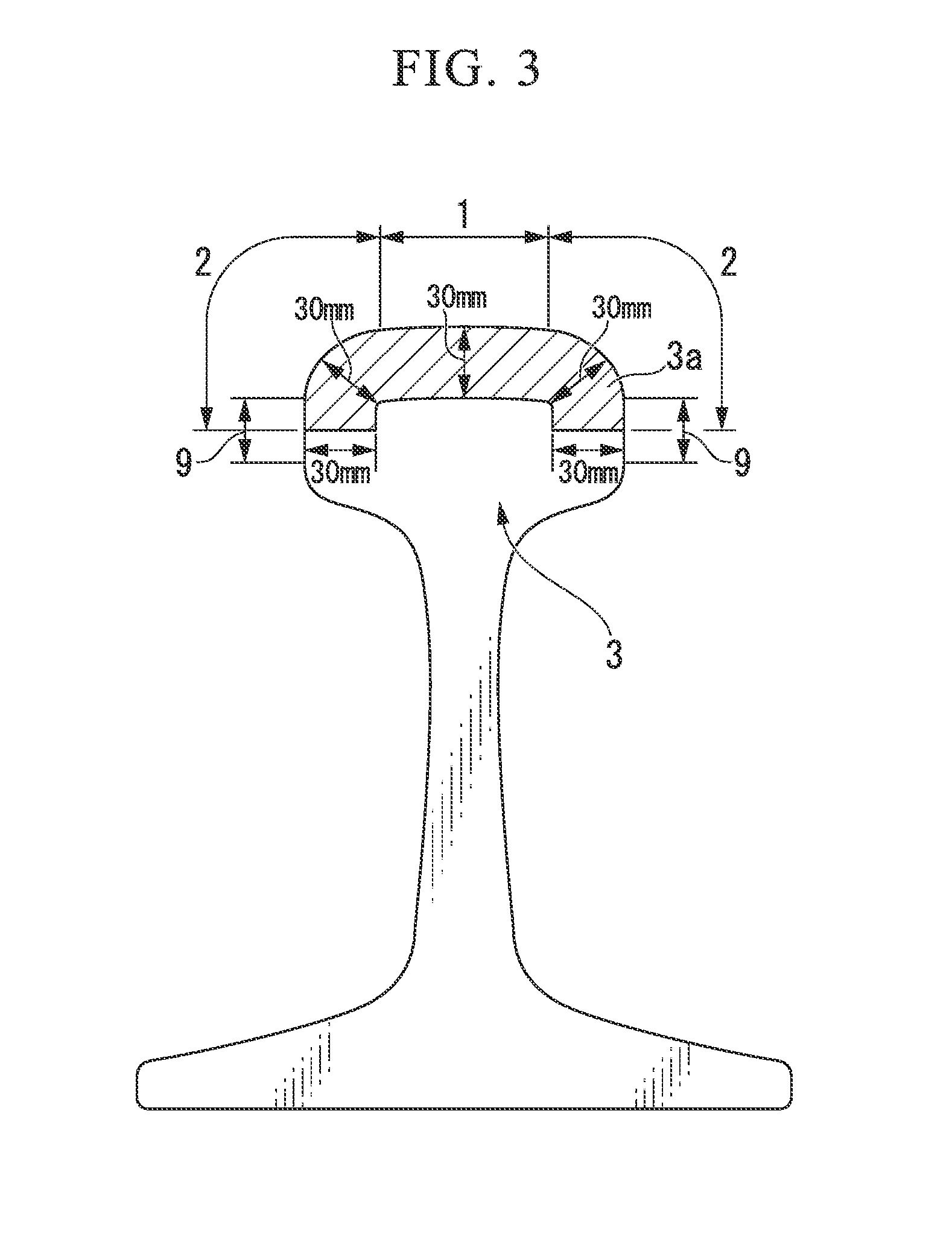

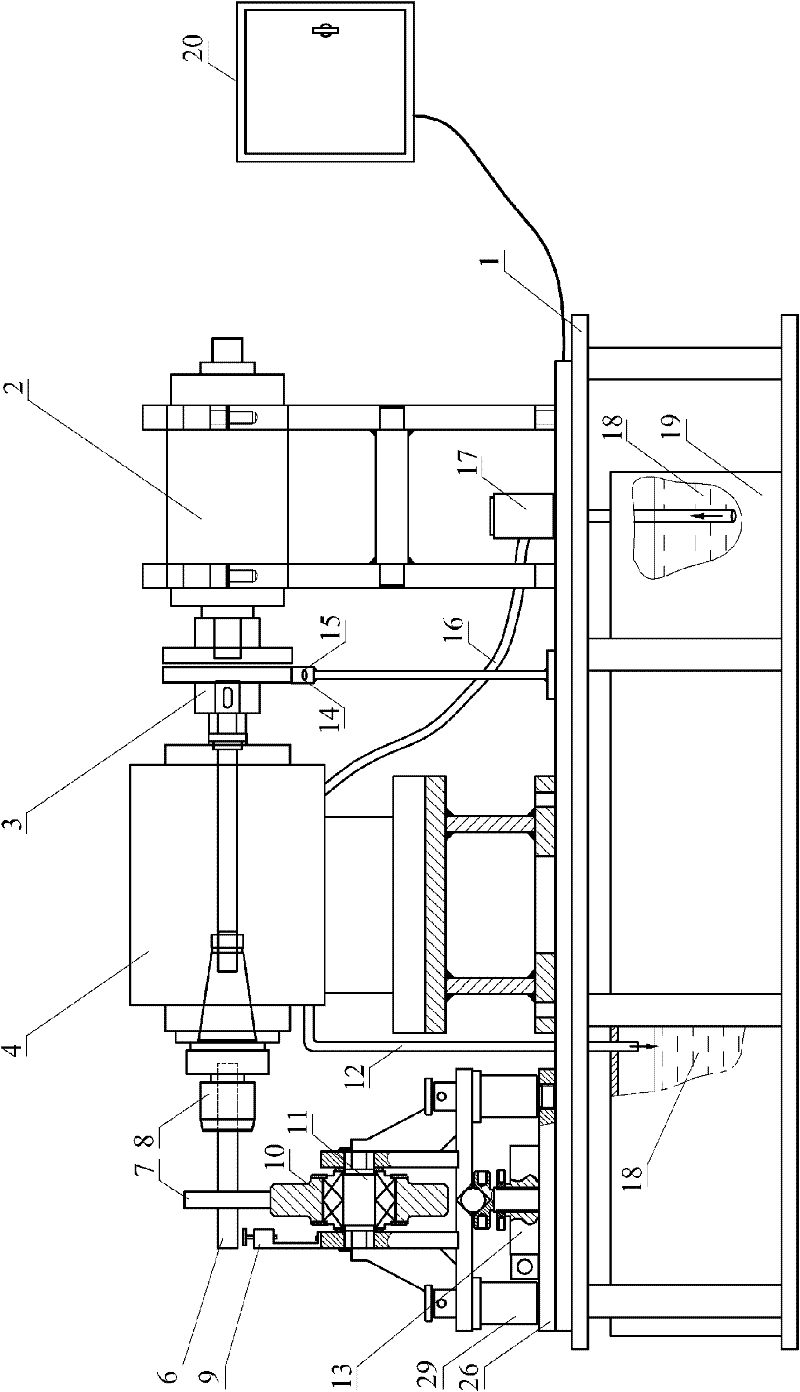

A rail is provided in which in a range from a surface of a head of the rail to a depth of 30 mm, 95% or more of a structure is composed of a pearlite structure by area %, and in a range with a depth of 20 mm to 30 mm from the surface of the head of the rail, an average grain size of a pearlite block in a transverse section is 120 μm to 200 μm.

Owner:NIPPON STEEL CORP

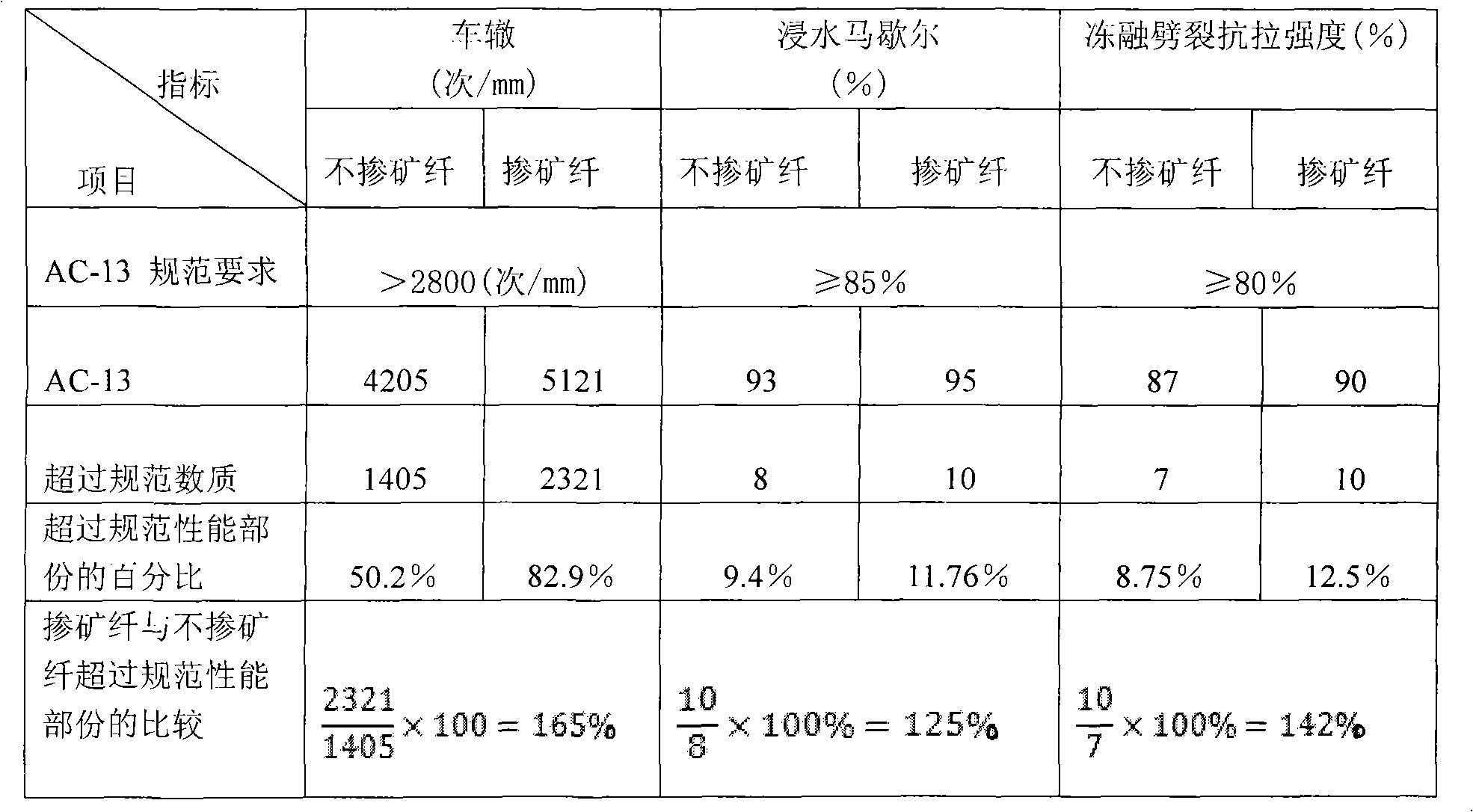

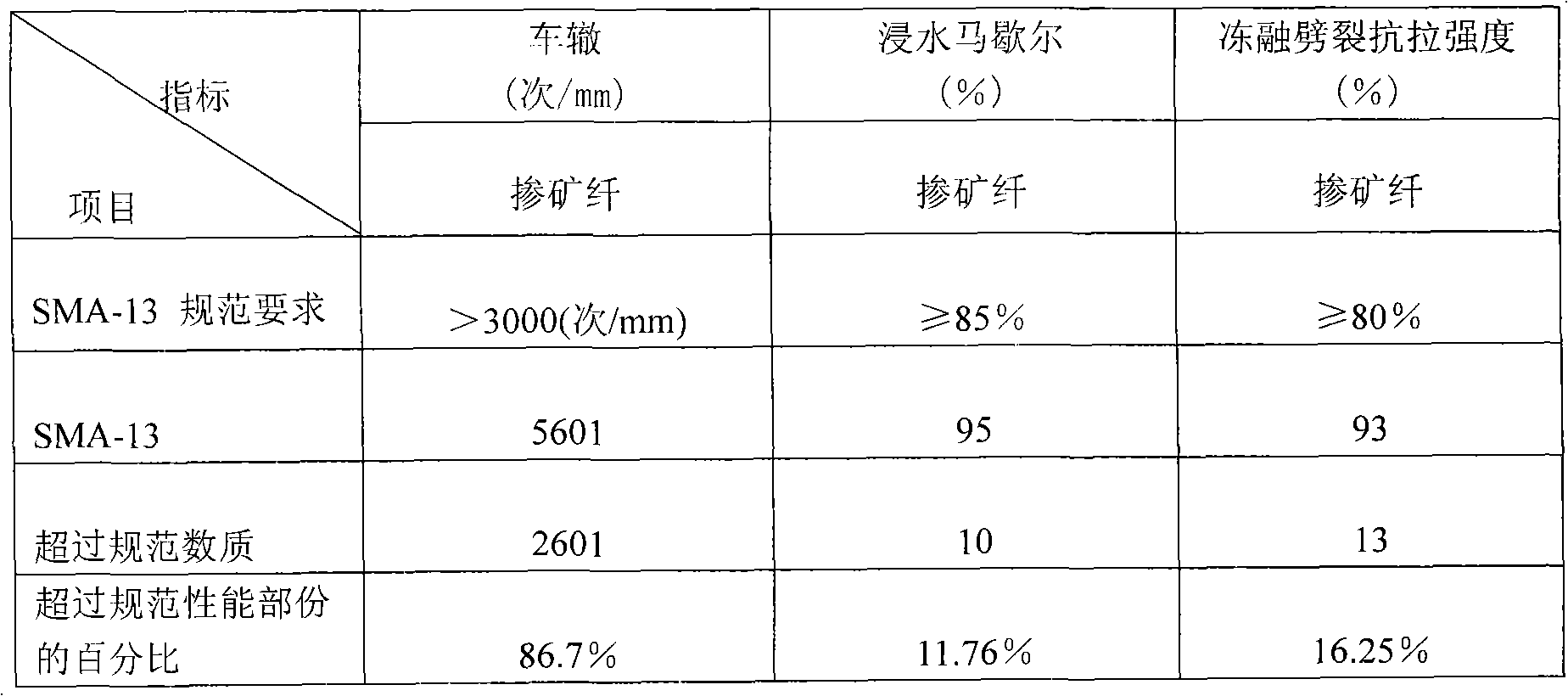

Basalt mineral fiber used for asphalt concrete

InactiveCN101255011AImprove high temperature resistance to rutting deformationExtended service lifeBasaltChemical composition

A basalt mineral fiber used in asphalt concrete prepared by minerals such as the basalt, has the following chemical compositions by weight proportion: 42-48.3% of SiO2, 11-16.2% of Al2O3, 8-12.8% of CaO, 11-14% of MgO, 4.8-8.6% of FemOn and 0.8-2.3% of TiO2, and 4.6-7.8% of other components (K2O, NaO, B2O3, Cr2O3 and MnO2); the average particle size of the fiber is 4mm-8mm and the average fiber diameter is 0.004mm-0.006mm. By integrating proper fiber and the asphalt concrete, the high-temperature rut deformation resistant performance, low-temperature cracking resistant performance and fatigue damage resistant performance of the asphalt concrete road surface is greatly improved, the early-stage water damage of the road surface is effectively prevented and the service life of the road surface is greatly prolonged.

Owner:肖菁

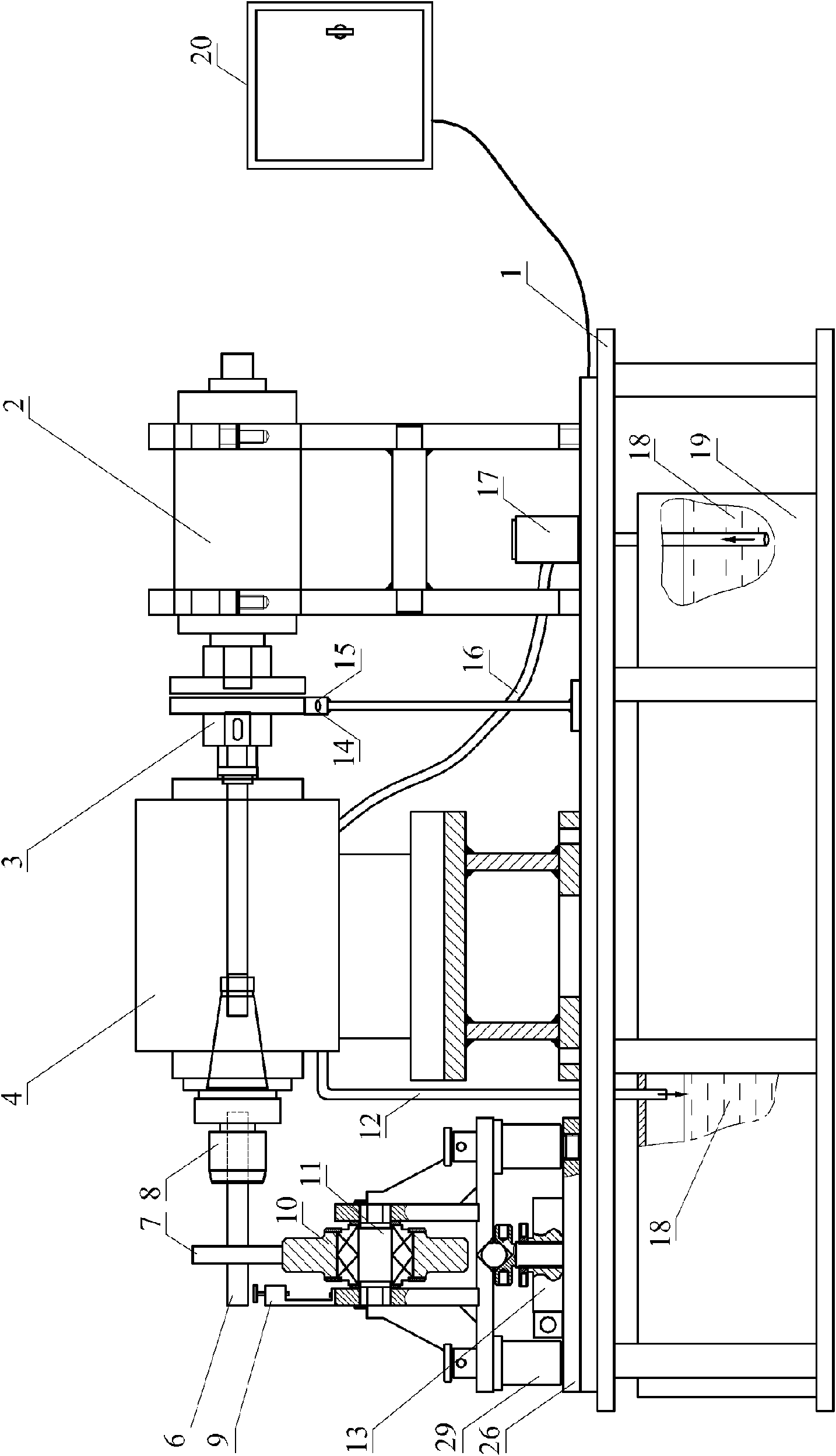

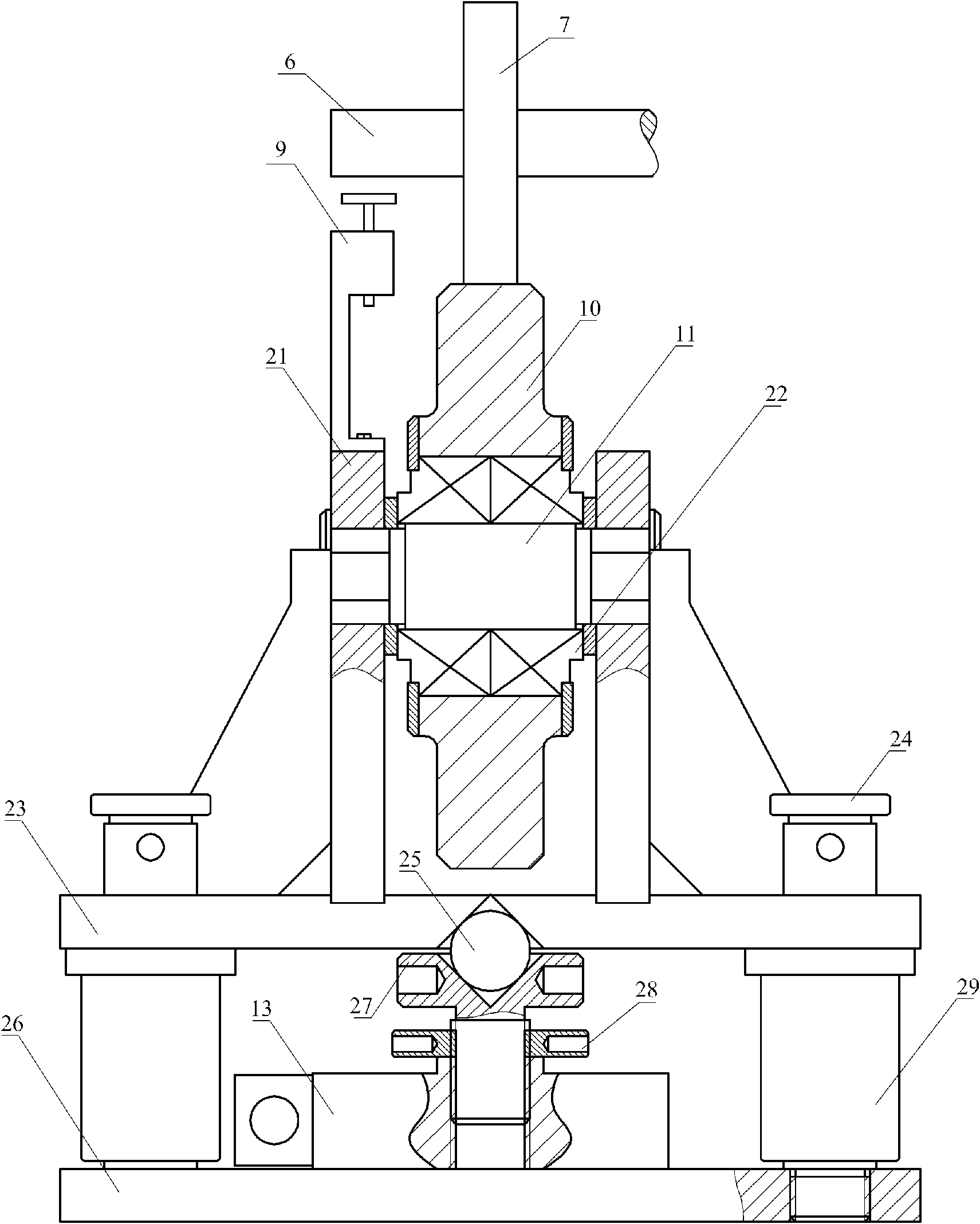

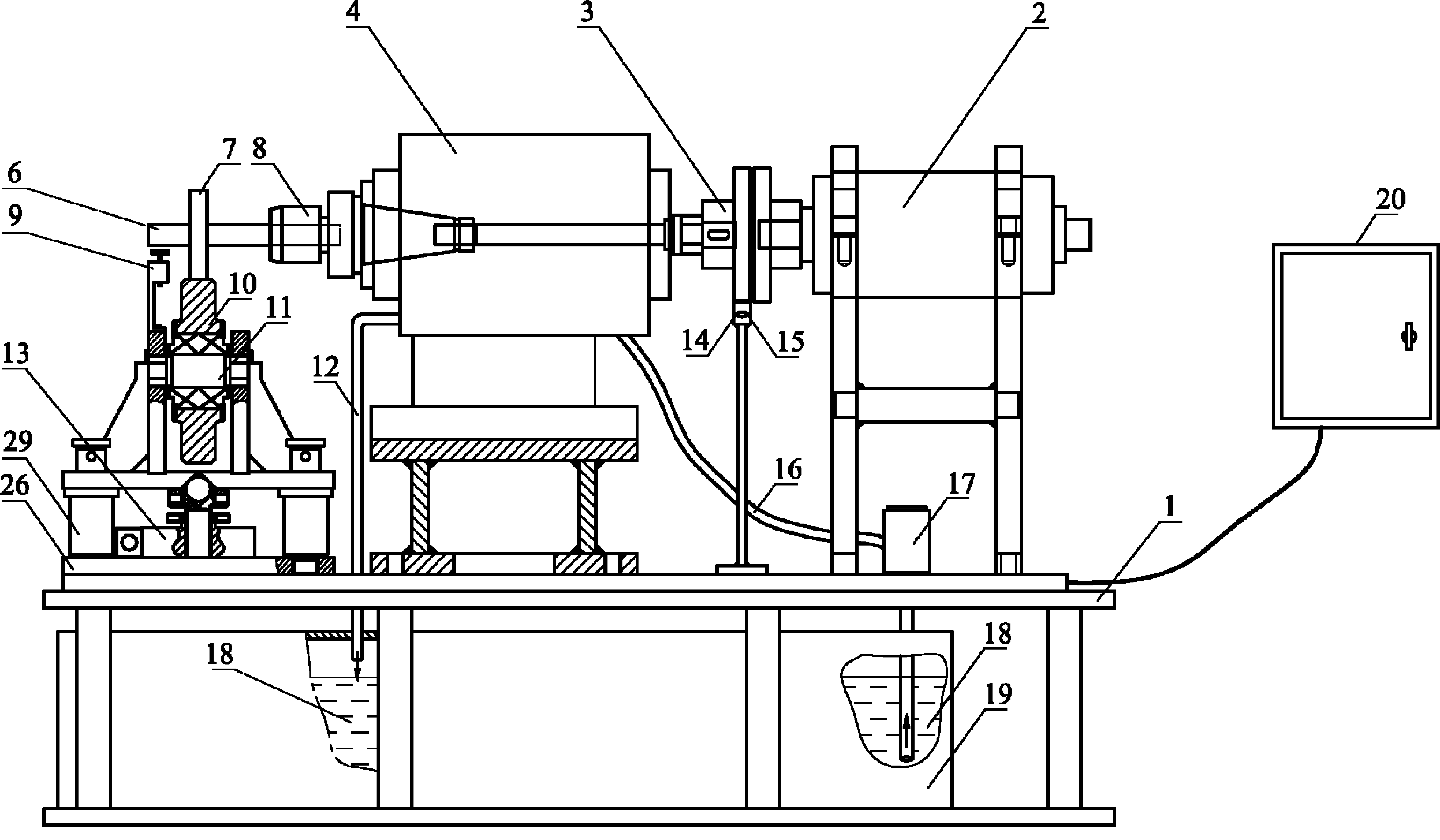

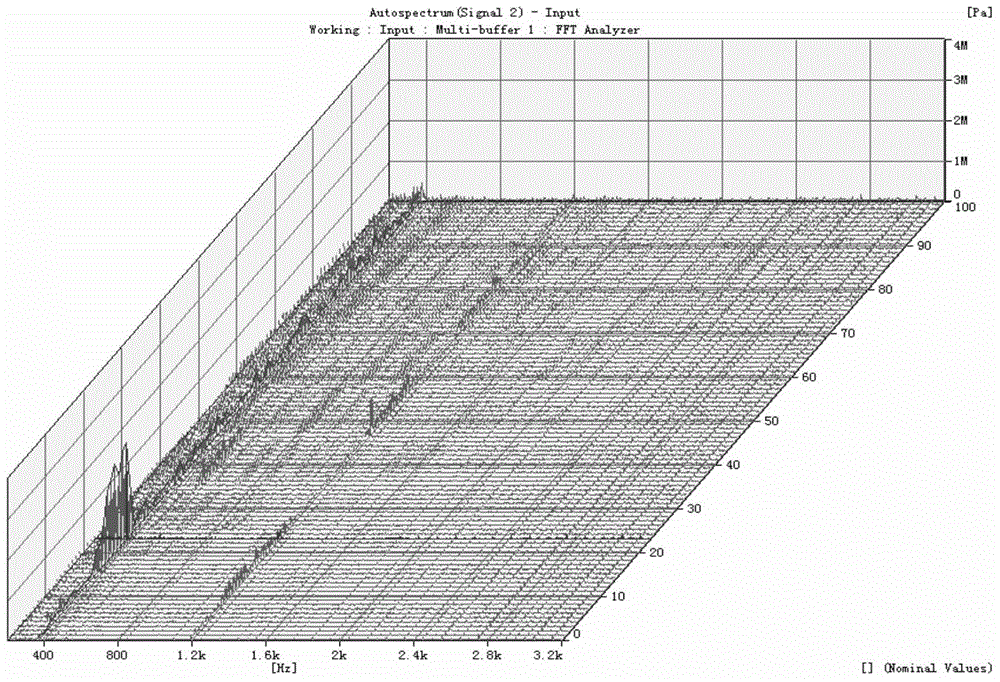

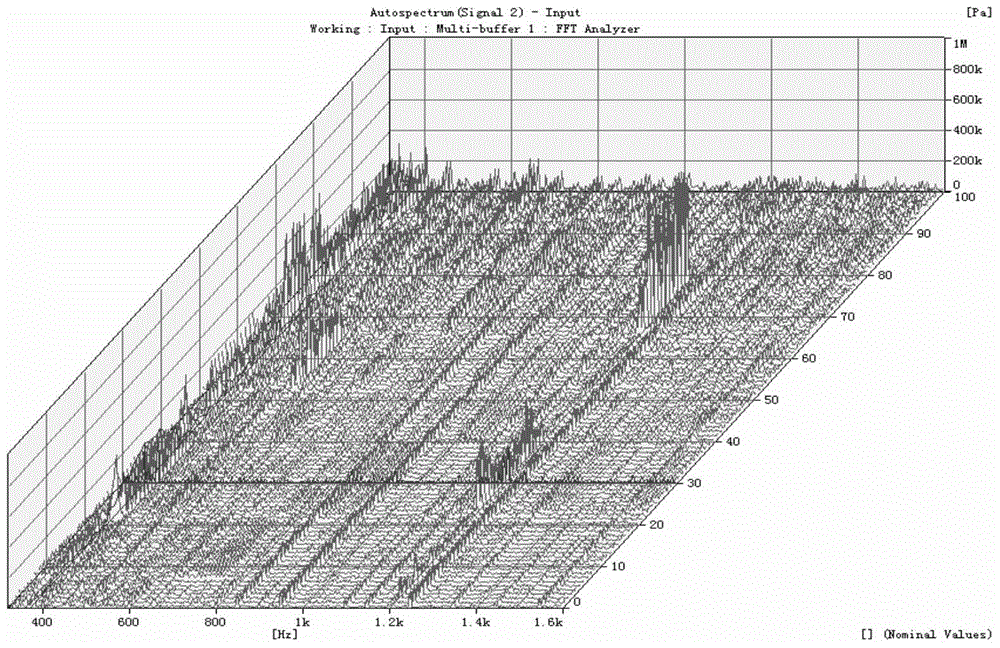

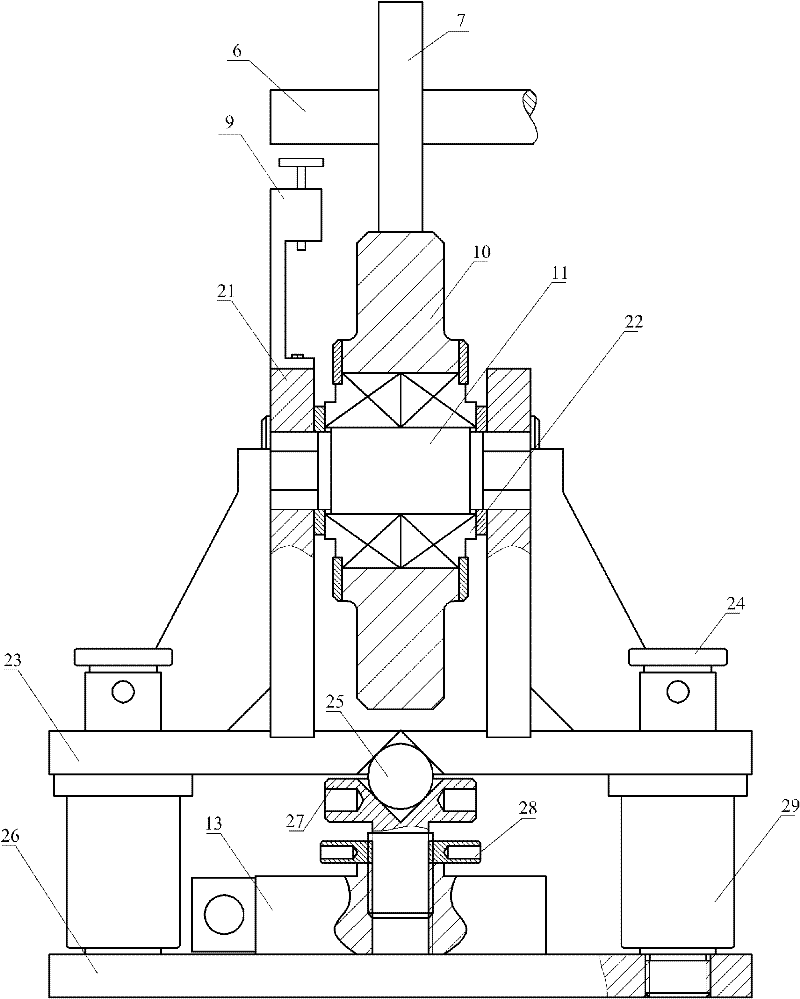

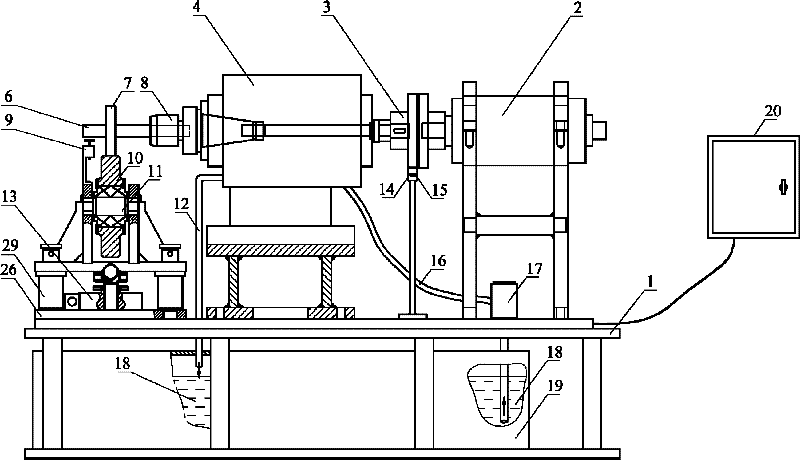

Proportional test device for rotating bending fatigue of train wheel axle

InactiveCN102103056AImproved resistance to fatigue damageThe axle is well protectedMaterial strength using repeated/pulsating forcesSelf lockingEngineering

The invention relates to a proportional test device for the rotating bending fatigue of a train wheel axle. A base is provided with an electric spindle controlled by a data acquisition and control system; the electric spindle is connected with a spring collet through a coupler and an axle box filled with cooling oil; the spring collet clamps the axle of a wheel axle sample; a rotating speed sensor and a revolution sensor are arranged beside the coupler; the wheel of the wheel axle sample is contacted with a driven wheel below; the axle of the driven wheel is arranged on a driven wheel bracket; a guide sleeve of the driven wheel bracket is sleeved on a guide pillar of a sensor base; a threaded hole of a pressure sensor of the sensor base is connected with an adjusting upright post; the upper end of the adjusting upright post is contacted with the lower surface of a bottom plate of the driven wheel bracket; and the middle part of the adjusting upright post is provided with a self-locking threaded ring. The test device can conveniently simulate the rotating bending fatigue damage of the train wheel axle under the action of a complex alternating load so as to provide a more reliable and accurate test basis for improving the fatigue damage resistance of the wheel axle and better protecting the wheel axle.

Owner:SOUTHWEST JIAOTONG UNIV

Flux-cored wire for repair cold-rolling support roll operational layer and preparation method thereof

InactiveCN101391352AImprove wear resistanceImprove crack resistanceWelding/cutting media/materialsSoldering mediaCrack resistanceHardness

The invention belongs to the welding material field, in particular relates to a flux-cored welding wire used in the restoration of the operation layer of a cold roll bearing roller and a preparation method thereof. The technical problem to be solved is to provide a welding material used for repairing the operation layer of a cold roll bearing roller. The weld overlay metal is of high hardness, and good wear resistance, crack resistance and anti-fatigue and anti-destructiveness performance. The core of the flux-cored welding wire is composed of the following component by weight percentage: C 0.30-0.40%, Si 0.50-1.0%, Mn 0.70-1.0%, Cr 2.5-3.5%, Ni 0.4-1.0%, Mo 0.5-1.7%, V 0.30-0.60%, Nb 0.03-0.10%, Ti 0.01-0.025%, W 0.80-1.9%, Re 0.05- 0.50%, S <= 0.035%, P<=0.035%, and a remnant amount of Fe. The application of the welding wire in the cold roll bearing roller welding achieves the requirements of the weld surfacing restoration.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

High-capacity high-pressure gas cylinder steel and production method thereof

The invention belongs to the field of iron and steel production, and in particular relates to large capacity high pressure gas cylinder steel and a production method thereof. The invention aims at solving the technical problems of providing the large capacity high pressure gas cylinder steel and improving the quality and comprehensive mechanical properties of the large capacity high pressure gas cylinder steel. The large capacity high pressure gas cylinder steel provided by the invention comprises the following components in percentage by weight: 0.33-0.38 percent of carbon, 0.15-0.35 percentof silicon, 0.80-0.90 percent of manganese, 1.05-1.2 percent of chromium, 0.20-0.30 percent of molybdenum, 0.02-0.04 percent of aluminum, not more than 0.010 percent of phosphorus, not more than 0.008 percent of sulfur, not more than 0.015 percent of phosphorus and sulfur, not more than 0.2 percent of nickel, not more than 0.15 percent of copper, not more than 0.015 percent of stannum, not more than 0.015 percent of arsenic, not more than 0.0002 percent of hydrogen, not more than 0.007 percent of nitrogen, not more than 0.0020 percent of T[0], and the balance of ferrum. Only through simple quenching and tempering heat treatment, good and stable comprehensive mechanical properties of the steel provided by the invention can be obtained so that the steel can be used for manufacturing large capacity steel cylinders.

Owner:PANZHIHUA IRON AND STEEL +3

Production method of prestressed concrete corrugated sheet pile

The invention relates to a production method of a prestressed concrete corrugated sheet pile. The method is characterized by including: preparing concrete mixture; producing reinforcement cages; die-filling; prestress tensioning; concrete pouring and vibration forming; prestress tension releasing and die removing; conveying the overall die to an assembling pedestal, using a special automatic opening-closing device to open the lateral die so as to take out a finished sheet pile, cleaning the dies, apply demolding agent, and turning to the next production procedure; examining and putting into storage. The production method is high in production efficiency and low in energy consumption, work environments are improved, labor intensity of workers is lowered, and the products are stable in quality, high in safety coefficient and good in mechanical performance.

Owner:张武 +1

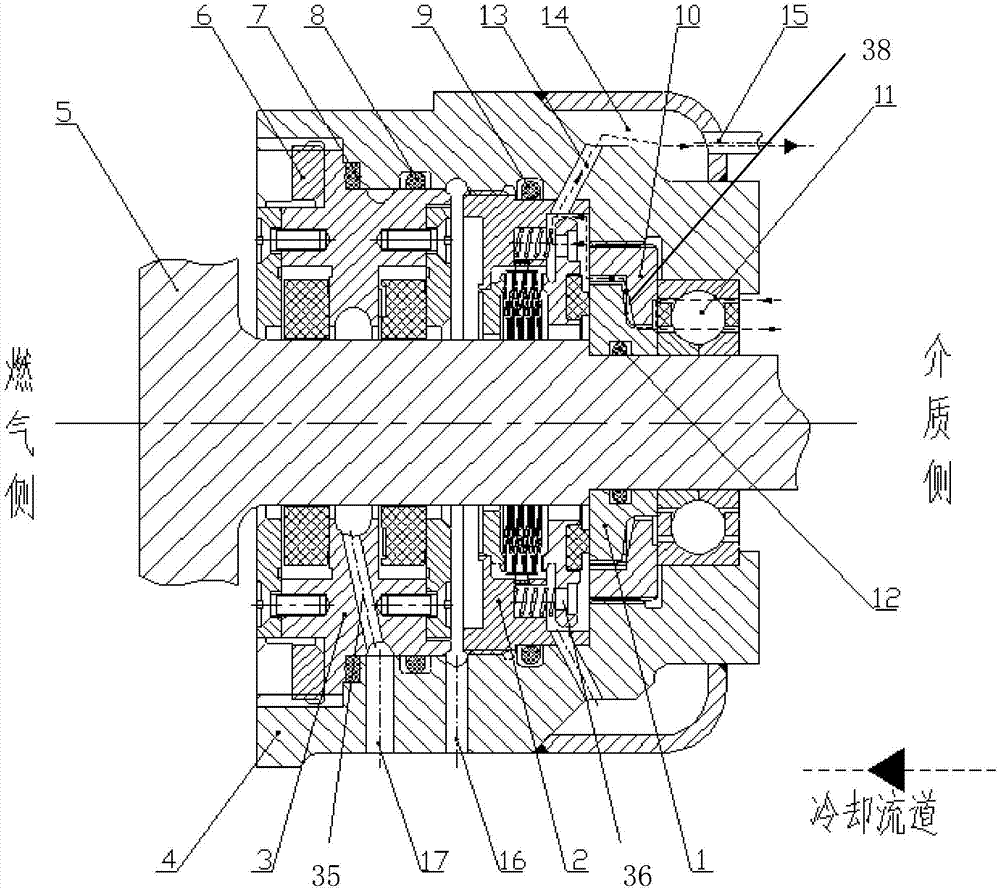

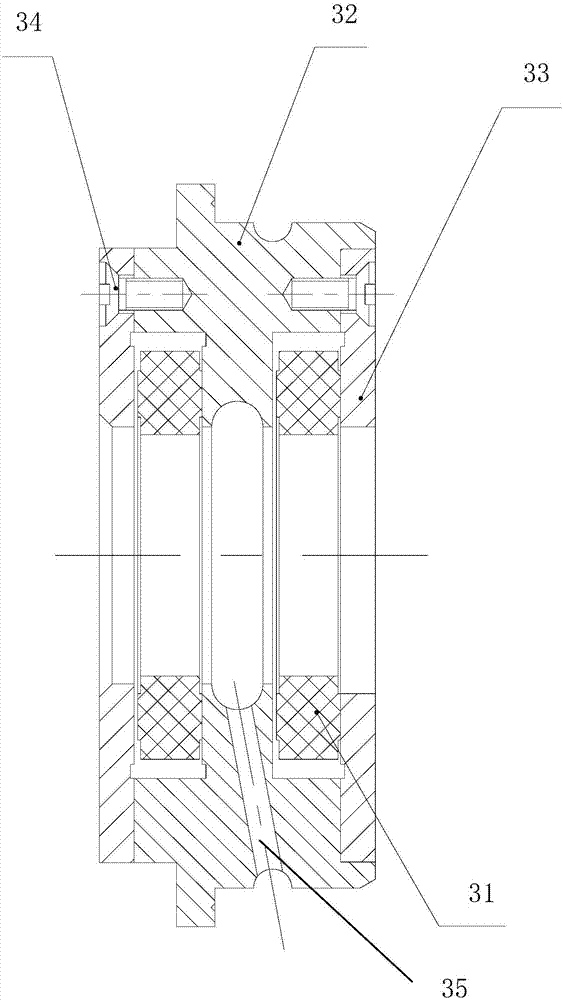

Combined mechanical seal device

ActiveCN107387261AAvoid meetingSimple systemPump componentsNuclear energy generationRubber ringEngineering

The invention particularly relates to a combined mechanical seal device which comprises a moving ring, a static ring assembly, a static ring housing, a floating ring assembly and an O-shaped rubber ring. The static ring assembly is arranged in the static ring housing and comprises an end face block assembly, a rotation-preventing pin, a spring and a damping belt. The end face block assembly comprises a static ring, a static ring seat, a film box assembly and a rear ring which are arranged in sequence. The damping belt is located in an annular groove of the inner surface of the static ring housing. The floating ring assembly comprises a floating ring, a cover plate and a floating ring housing, wherein the floating ring penetrates through a rotor to be arranged in the floating ring housing, and a cover plate penetrates through a rotor to be fixedly arranged on two sides of the floating ring housing respectively. A cooling backflow channel comprises a bearing axial gap, a gap between the moving ring and a pressing ring, a static ring seat balance hole gap, a radial gap between a static ring seat and the static ring housing, a backflow channel I, an accumulated liquid cavity and a backflow channel II which are communicated in sequence. The combined mechanical seal device achieves long-service-life, low-friction and zero-leakage work of a mechanical seal under the working conditions of high temperature and high pressure.

Owner:XIAN AEROSPACE PROPULSION INST

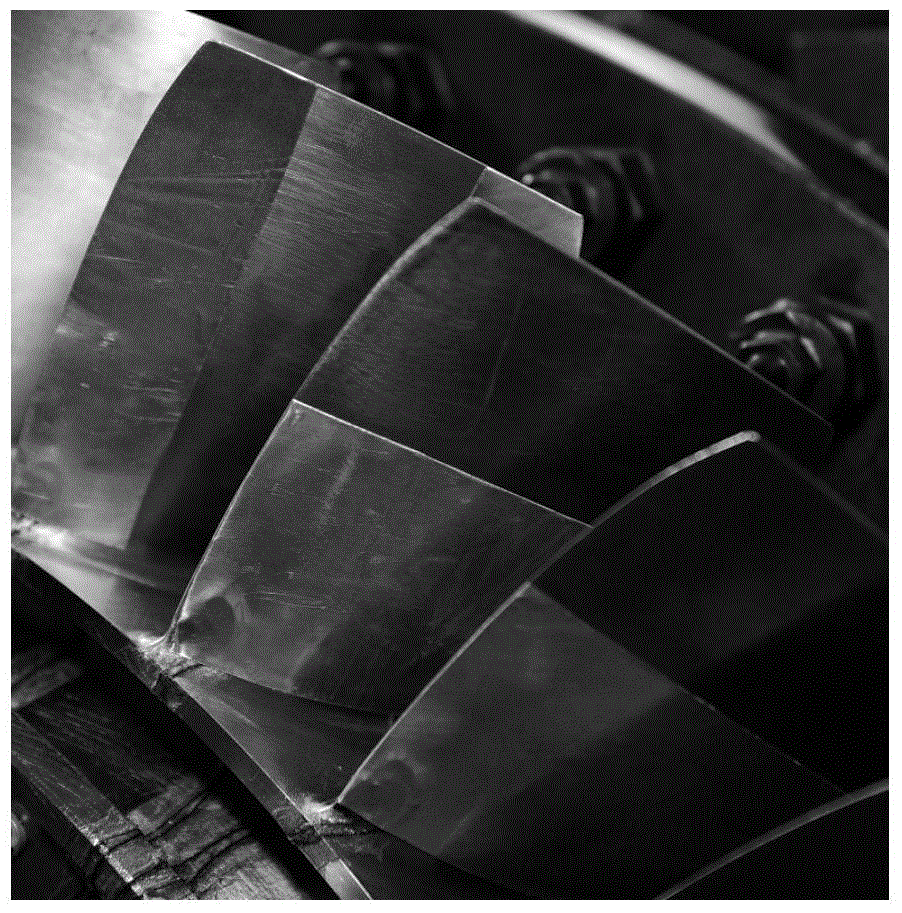

Topological optimization method for constraining and damping blades of aeroengine

InactiveCN104573199AReduce vibration stressBest damping effectSpecial data processing applicationsMesh gridEngineering

The invention relates to a topological optimization method for constraining and damping blades of an aeroengine. The method comprises the following steps: taking lightweight aluminum foil as a constraining material, sequentially sticking a viscoelastic material and the constraining material onto the surface of each blade of the aeroengine, carrying out constraining and damping processing on the blades, and establishing finite element models of the constrained and damped blades; carrying out modal analysis on the constrained and damped blades according to the finite element models of the constrained and damped blades, and filtering sensitivity of constrained and damped cell units by adopting an independent grid filtering technology; solving an optimization model by adopting an asymptotic optimization algorithm, programming an optimization program, searching for the optimal layout of a constraining and damping material on each blade, and cutting and regularizing optimized layout, so as to adapt to engineering application. The method has the advantages that the aim of achieving the maximal aeroengine blade damping vibration reduction effect with the minimal damping material additionally-added amount is realized, so that the vibration stress of the blades of the aeroengine is remarkably lowered, and the fatigue damage resistance of the blades is improved.

Owner:AECC SHENYANG ENGINE RES INST +1

Flywheel crack repair method

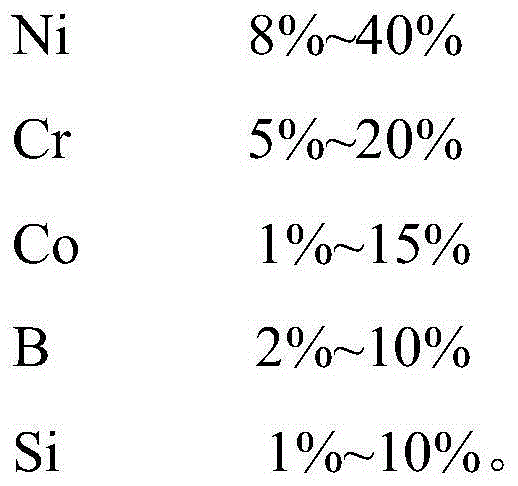

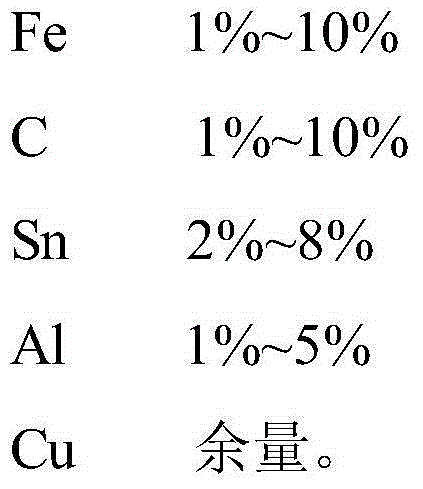

ActiveCN104162761AStrength Improvement and EnhancementImproved and increased shear strengthMolten stateAlloy

The invention discloses a flywheel crack repair method. The flywheel crack repair method includes the following steps of firstly, conducting grinding in the direction of a crack with the crack as the center to form a groove, and conducting milling at certain intervals in the direction perpendicular to the groove to form a plurality of ditch grooves, wherein the depth of the ditch grooves is larger than or equal to one third of the depth of the groove; secondly, drilling through holes with the starting point and the ending point of the crack as the circle centers; thirdly, conducing bead welding in the ditch grooves through stainless steel electrodes, wherein the height of bead welding ranges from one half to two thirds of the depth of the ditch grooves; fourthly, preheating a flywheel to the temperature of 600 DEG C to 800 DEG C, pouring molten-state nickel-cobalt- molybdenum-manganese-base alloy into the rest of the space of the through hole and the rest of the space of the groove, and conducting cooling at the room temperature; fifthly, machining and removing the redundant dead welding material and the redundant pouring material till the size is qualified. The flywheel crack repair method is simple in repair process and good in repair effect; the repaired flywheel is long in service life, and the flywheel crack repair method is suitable for repairing the crack of the flywheel in batches.

Owner:青岛海之冠汽车配件制造有限公司

Processing technology for improving fatigue damage resistance of 2xxx series aluminium alloy plate

ActiveCN105441839AImproved resistance to fatigue damageImprove resistance to fatigue damageFatigue damageQuenching

The invention relates to a processing technology for improving fatigue damage resistance of a 2xxx series aluminium alloy plate. The processing technology comprises the following steps that (1) an alloy is subjected to batching and smelting and is cast to form an ingot; (2) the ingot is sequentially subjected to homogenizing treatment, face milling, aluminium cladding and preheating, and is made into a hot rough-rolled plate; (3) the hot rough-rolled plate is subjected to hot finish rolling, different technologies are implemented according to the plates requiring different exit thicknesses, and a cold final rolling reduction rate of the plate is controlled; (5) solid solution quenching treatment is carried out with the solid solution temperature being 480-505 degrees and the heat preservation time being 3-60min; and (6) the plate is straightened, and is subjected to natural aging till a stable state is reached. By controlling the cold final rolling reduction rate of the plate, the grain average equivalent diameter and the grain length-width ratio of the L-ST cross section of the plate can be controlled effectively, and the tensile mechanical property and the fatigue-crack propagation speed of the plate can meet the requirements of AMS (Aerospace Material Specification) 4296.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD +1

Pearlite rail

ActiveUS8361246B2Maintain hardness (strength)Improve resistance to fatigue damageFurnace typesHeat treatment furnacesMetallurgySurface roughness

A pearlite rail contains, by mass %, 0.65 to 1.20% of C; 0.05 to 2.00% of Si; 0.05 to 2.00% of Mn; and the balance composed of Fe and inevitable impurities, wherein at least part of the head portion and at least part of the bottom portion has a pearlite structure, and the surface hardness of a portion of the pearlite structure is in a range of Hv320 to Hv500 and a maximum surface roughness of a portion of the pearlite structure is less than or equal to 180 μm.

Owner:NIPPON STEEL CORP

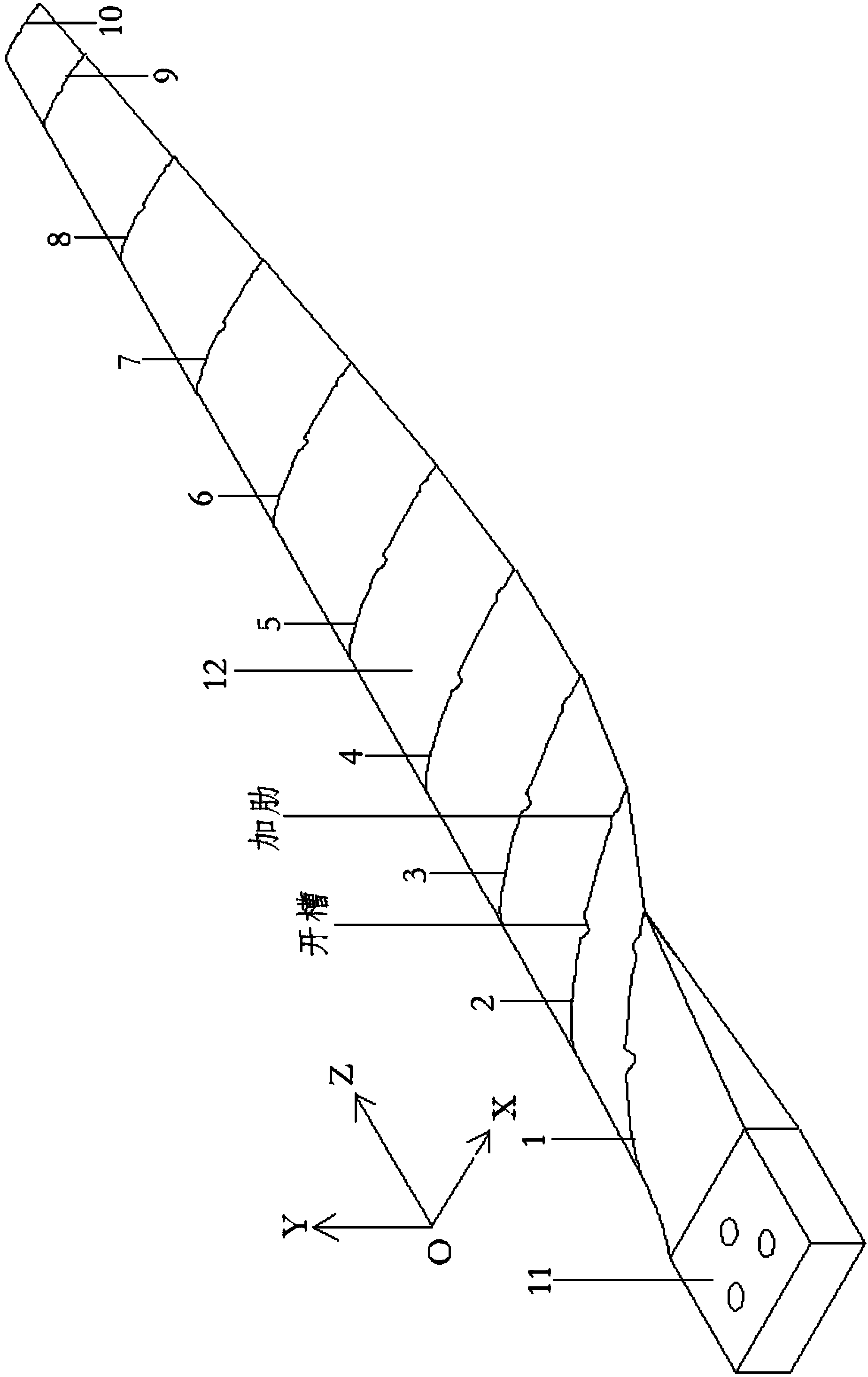

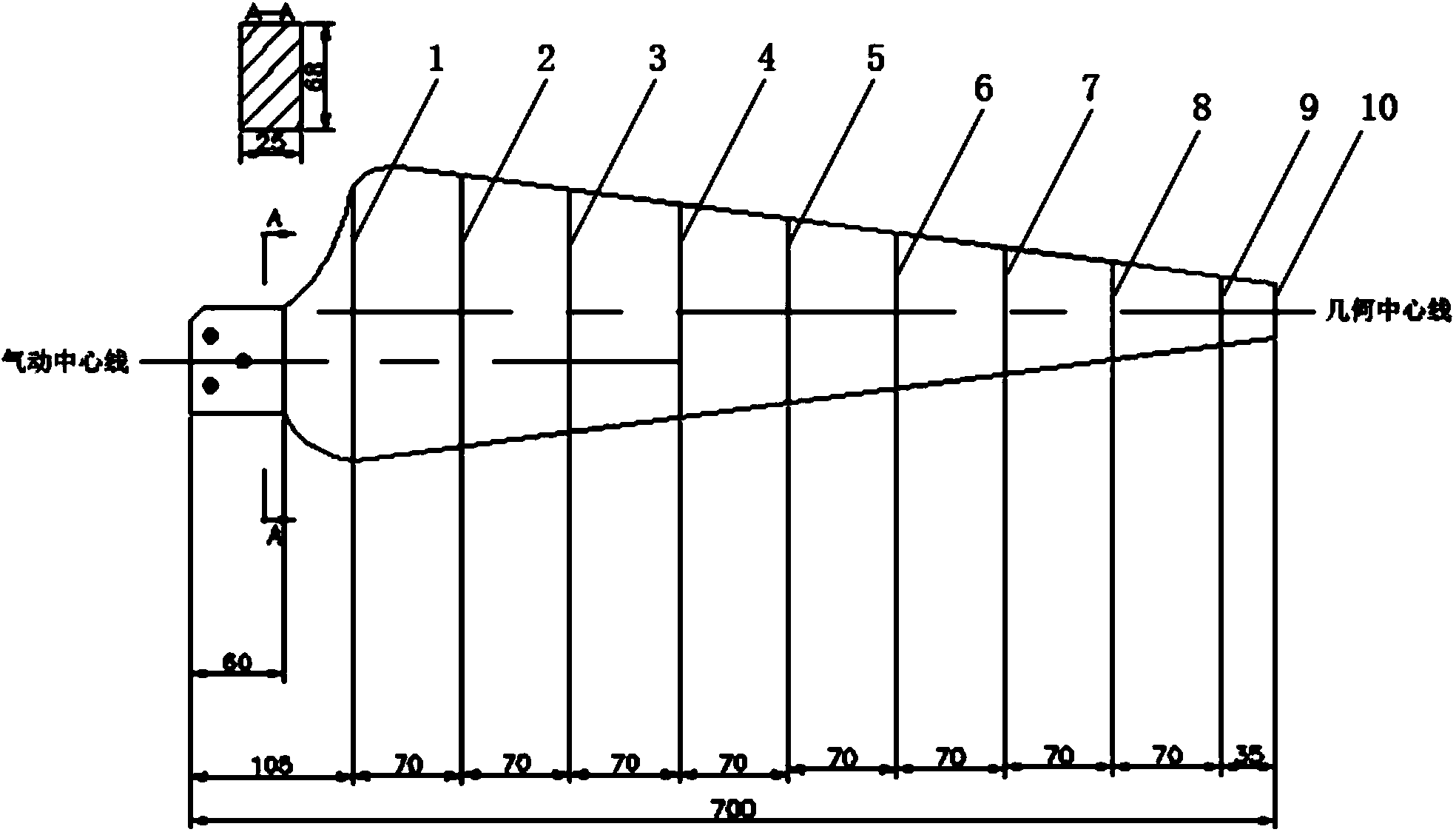

Ribbed and grooved type wind turbine blade

InactiveCN103410657ASuitable for useImprove output stabilityMachines/enginesWind energy generationFatigue damageTurbine blade

The invention discloses a ribbed and grooved type wind turbine blade and belongs to the technical field of wind power utilization. The surface of the wind turbine blade is formed by ten airfoil-shaped surface airfoil-shaped curves through continuous smooth transition. Each airfoil-shaped surface airfoil-shaped curve is composed of two parts, namely a leeside curve body and a windward side curve body, and each leeside curve body is provided with a downward-concave curve and an upward-convex curve. Ten airfoil-shaped surfaces are sequentially arranged in the blade unfolding direction, and grooved and ribbed structures are formed on the surface of the blade after smooth transition of the downward-concave curves and the upward-convex curves of the leeside curve bodies of the ten airfoil-shaped surfaces. The ribbed and grooved structures on the surface of the blade can effectively resist bending deformation caused by conventional vibration of the blade, and fatigue damage resistant capacity of the blade is improved obviously. Meanwhile, the grooved and ribbed structures on the surface of the blade do not enable pneumatic performance of the blade to be lowered, but the blade has good pneumatic performance.

Owner:INNER MONGOLIA UNIV OF TECH

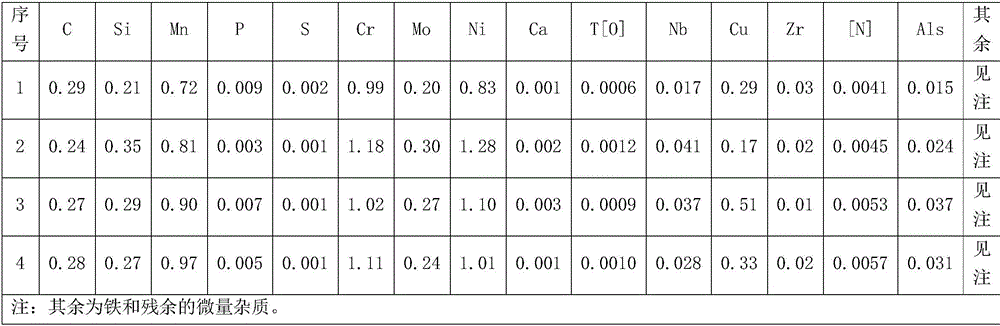

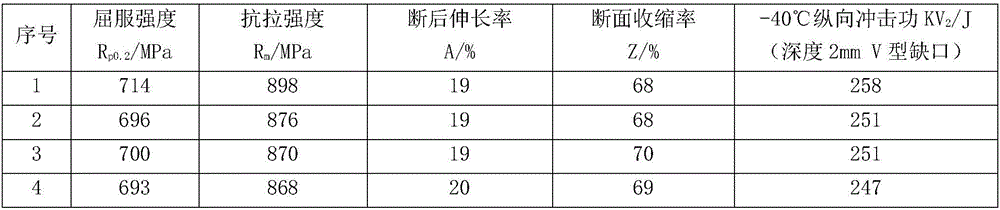

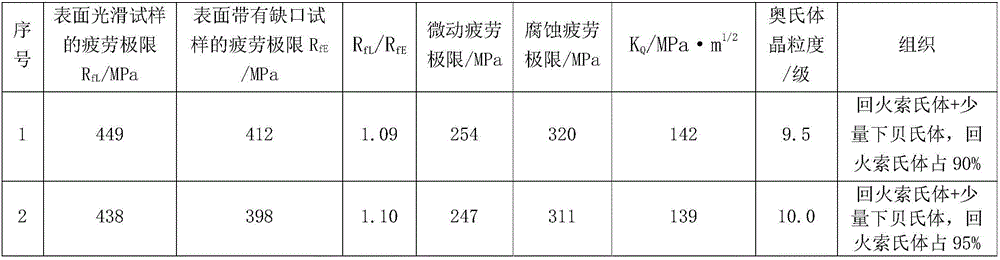

Heat treatment process of niobium-containing steel for axles of motor train unit

ActiveCN105838989AImprove toughnessImprove plasticityFurnace typesHeat treatment furnacesFatigue damageNiobium

The invention relates to a heat treatment process of niobium-containing steel for axles of a motor train unit. The heat treatment process comprises the following steps of firstly, primary quenching: heating the niobium-containing steel for the axles of the motor train unit to be 870 to 900DEG C, calculating the heating and heat preservation time of the temperature section according to 1.5 to 2.0min / mm, and subsequently cooling; secondly, secondary quenching: heating the niobium-containing steel for the axles of the motor train unit to be 850 to 880DEG C, calculating the heating and heat preservation time of the temperature section according to 1.5 to 2.0min / mm, and subsequently cooling; and thirdly, tempering: heating the niobium-containing steel for the axles of the motor train unit to be 620 to 680DEG C, calculating the heating and heat preservation time of the temperature section according to 2 to 2.5min / mm, and subsequently cooling. The steel for the axles obtains excellent fatigue damage resistance and lower cost while high strength is obtained.

Owner:MAANSHAN IRON & STEEL CO LTD

Processing technique for improving fatigue damage resistance of 2XXX series aluminum alloy plate

ActiveCN105603340AImproved resistance to fatigue damageImprove resistance to fatigue damageAviationFatigue damage

The invention relates a processing technique for improving fatigue damage resistance of a 2XXX series aluminum alloy plate, comprising the following steps: (1), burdening and smelting an alloy, and casting to obtain an ingot; (2), subjecting the ingot sequentially to homogenizing, surface milling and aluminum cladding, and preheating to obtain a hot roughed plate; (3), subjecting the hot roughed plate to hot finishing and cold rolling deformation to finished plate thickness; (4), carrying out recovery pre-annealing at 250-320 DEG C, and holding the temperature for 2-20 h; (5), carrying out solid solution quenching at 480-505 DEG C, and holding the temperature for 3-60 min; (6), straightening a plate, and naturally ageing to a stable state. By adding the recovery pre-annealing treatment, it is possible to effectively control grain average equivalent diameter and grain length-width ratio of L-ST section of the plate, so that both tensile mechanical property of the plate and fatigue crack growth rate thereof meet the requirements of AMS 4296 aviation standards.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD +1

Long-service-life Chinese lute string

InactiveCN104658514ASolve problems such as stress crackingHigh strengthStringed musical instrumentsFatigue damageAlloy

The invention discloses a long-service-life Chinese lute string. The Chinese lute string is of a laminated composite structure, an inner core of the laminated composite structure is a steel wire, an intermediate layer is coated on the outer surface of the inner core, and a nylon outer layer is arranged on the outer surface of the intermediate layer; a coating is arranged on the outer surface of the steel wire inner core, and the coating is a metal ceramic composite coating; the intermediate layer is a copper-based alloy layer; and the inner core of the laminated composite structure is a steel wire twisted rope formed by combining a single steel wire or a plurality of steel wires. The coating is arranged to ensure that the strength and elastic modulus of the inner core can be effectively increased, so that the fatigue damage resistance of the inner core can be improved, and original cracks on the surface of the inner core can be prevented from being further expanded to cause breakage under the condition that the Chinese lute string is played repeatedly for a plurality of times for a long term; and meanwhile, because components of the coating comprise both metals and ceramics, the playing tone of the Chinese lute string disclosed by the invention has the characteristic of bright metal sound, and also has the characteristic of relatively mild and soothing sound produced by the ceramics.

Owner:HUNAN CITY UNIV

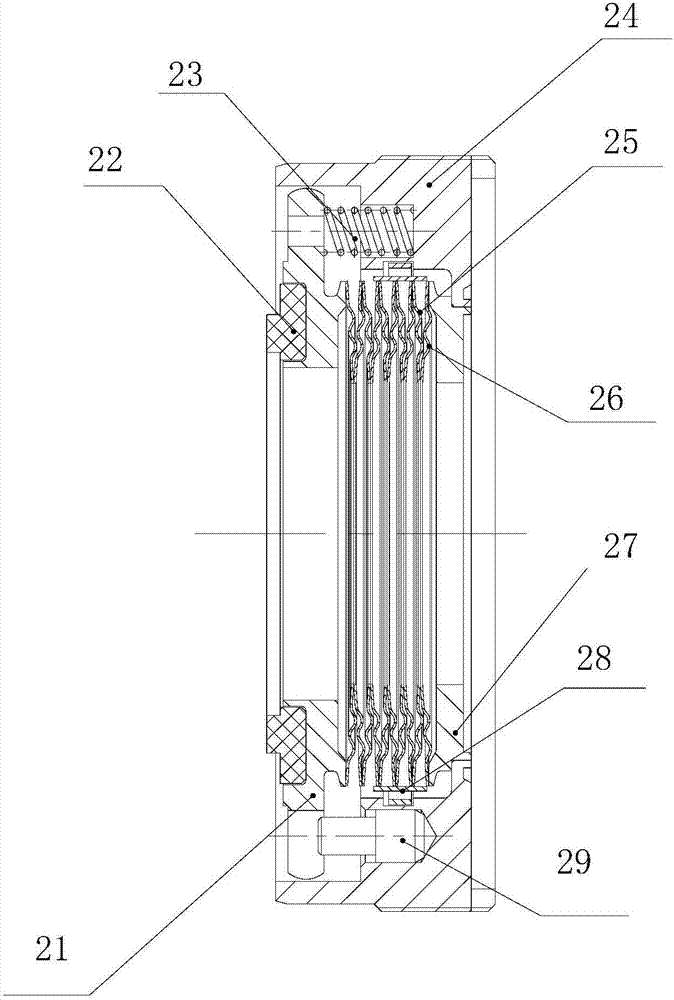

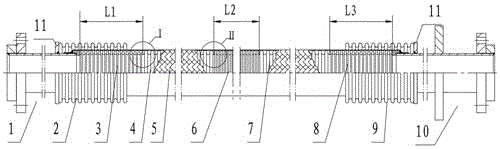

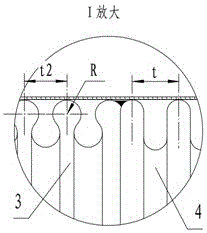

Oxygen blowing metal hose long in service life

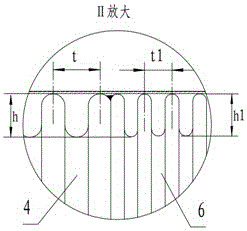

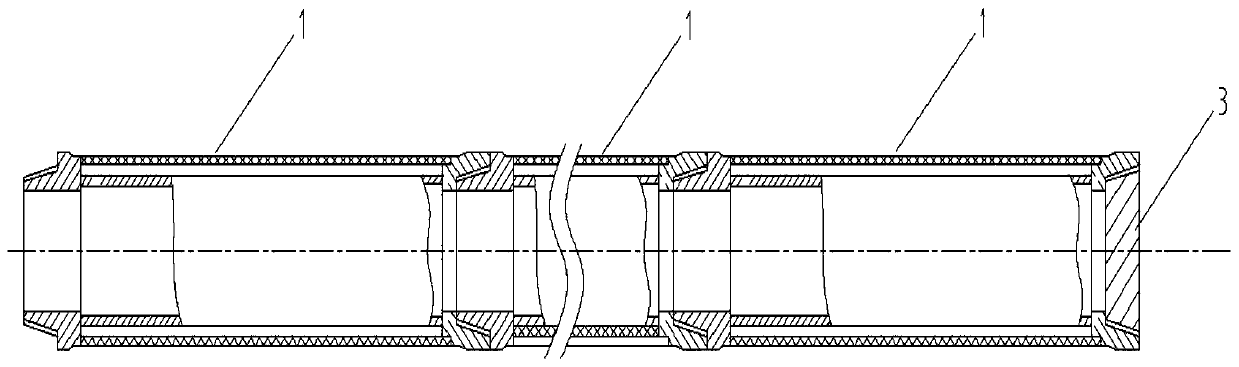

ActiveCN105673980AExtended service lifeImprove flexibilityPipeline expansion-compensationWave shapeEngineering

An oxygen blowing metal hose long in service life comprises a corrugated pipe, and a first joint and a second joint are arranged at the two ends of the corrugated pipe; the outer side of the corrugated pipe is wrapped with a metal net body, and the corrugated pipe is of a five-segment type structure formed by sequentially connecting a first pressure-resisting segment, a first transition segment, a high-flexibility segment, a second transition segment and a second pressure-resisting segment; the first pressure-resisting segment and the second pressure-resisting segment on the two sides of the corrugated pipe are in omega shapes; and the high-flexibility segment located in the middle portion of the corrugated pipe is in a deep-U-shaped wave shape, and the first transition segment and the second transition segment are in U-shaped wave shapes. According to the characteristics that the two sides of the corrugated pipe are bad in working condition and large in bearing pressure, the pressure-resisting segments in the omega shapes are arranged on the two sides of the corrugated pipe; according to the characteristic that due to insufficient flexibility, the dynamic bending portion of the middle segment of the corrugated pipe is prone to being damaged, the middle segment of the corrugated pipe is designed to be the high-flexibility segment in the deep-U-shaped wave shape; and through the improvement, the service life of the oxygen blowing metal hose is greatly prolonged, the maintenance and replacement time is greatly shortened, and improvement of steel smelting efficiency is facilitated.

Owner:石家庄巨力科技股份有限公司

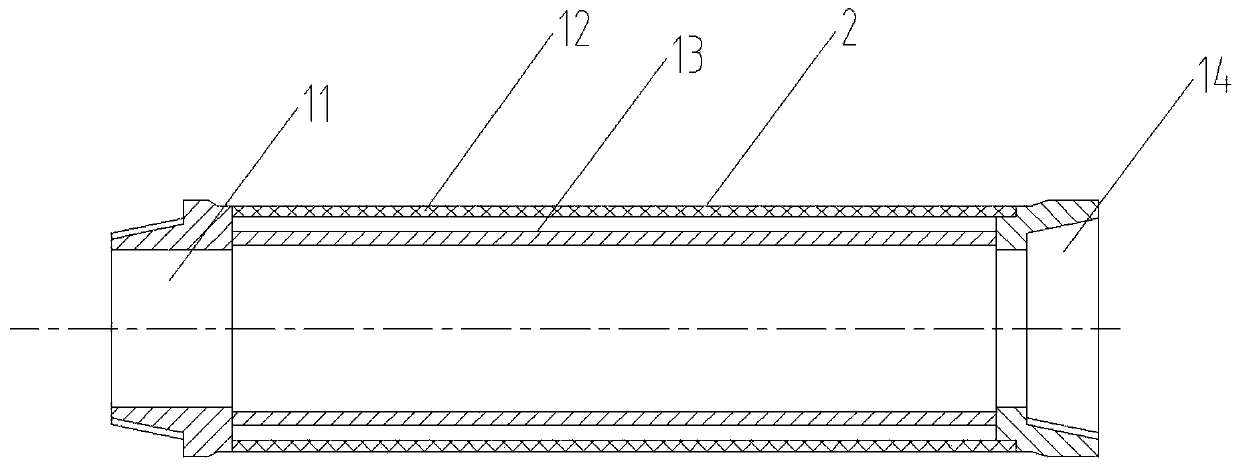

Combined high-strength fatigue-resistant metal composite filtering core

InactiveCN110433570AHigh mechanical strengthSmall circulation resistanceMembrane filtersFiltration separationHigh intensityMetal

The invention discloses a combined high-strength fatigue-resistant metal composite filtering core, which comprises a plurality of filtering units connected sequentially, wherein the filtering unit comprises a filtering pipe section, both ends of the filtering pipe section are respectively connected to an outer pipe joint and an inner pipe joint, the inner pipe joint of the filtering unit on the end portion is connected to a plug, the filtering pipe section comprises a support pipe and a metal filtering cylinder sleeved on the support pipe, and the support pipe is provided with a hole. According to the present invention, the combined high-strength fatigue-resistant metal composite filtering core has characteristics of high mechanical strength and low flow resistance; under the instantaneousimpact and frequent back-blowing condition under high back-blowing pressure, the filtering core can ensure the rigidity and the integrity of the metal filtering cylinder so as to enhance the structural strength and the fatigue damage resistance of the filtering core; and the filtering core is easy to assemble so as to effectively reduce the maintenance frequency during the production operation and prolong the service life.

Owner:WESTERN BAODE TECH CO LTD

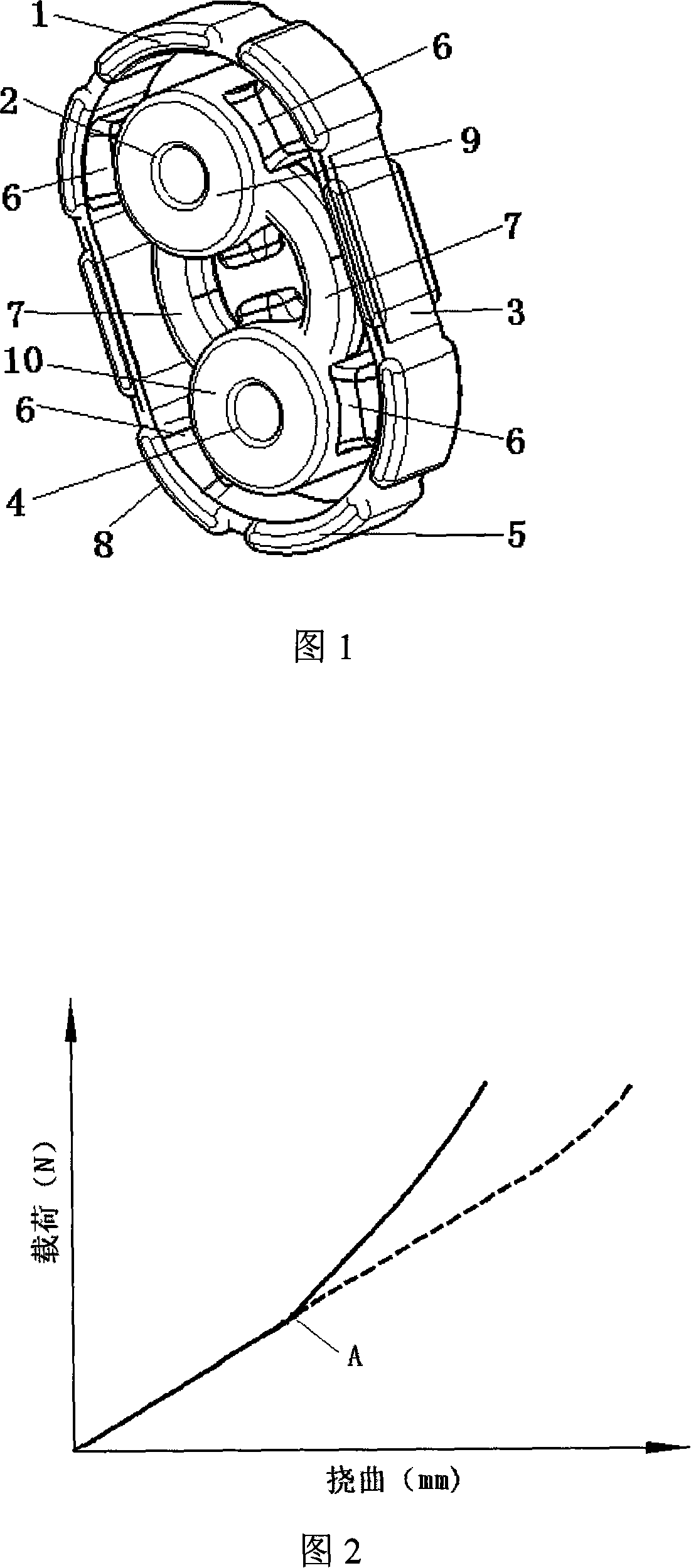

Automobile exhaust system mounting hanger

ActiveCN101088792APrevent rubber from overstretchingExtended service lifePropulsion unit gas exhaustAutomotive engineeringFatigue resistance

The present invention discloses one kind of automobile exhaust system mounting hanger. One metal frame is set around the hanger, the automobile body installation unit and the exhaust pipe installation unit; and the automobile body installation unit and the exhaust pipe installation unit are fixed through supporting and connecting parts of rubber onto the metal frame. Compared with available technology, the present invention has the advantages of long service life, good vibration reducing performance, high fatigue resistance, etc.

Owner:安庆福莱克斯动力科技有限公司

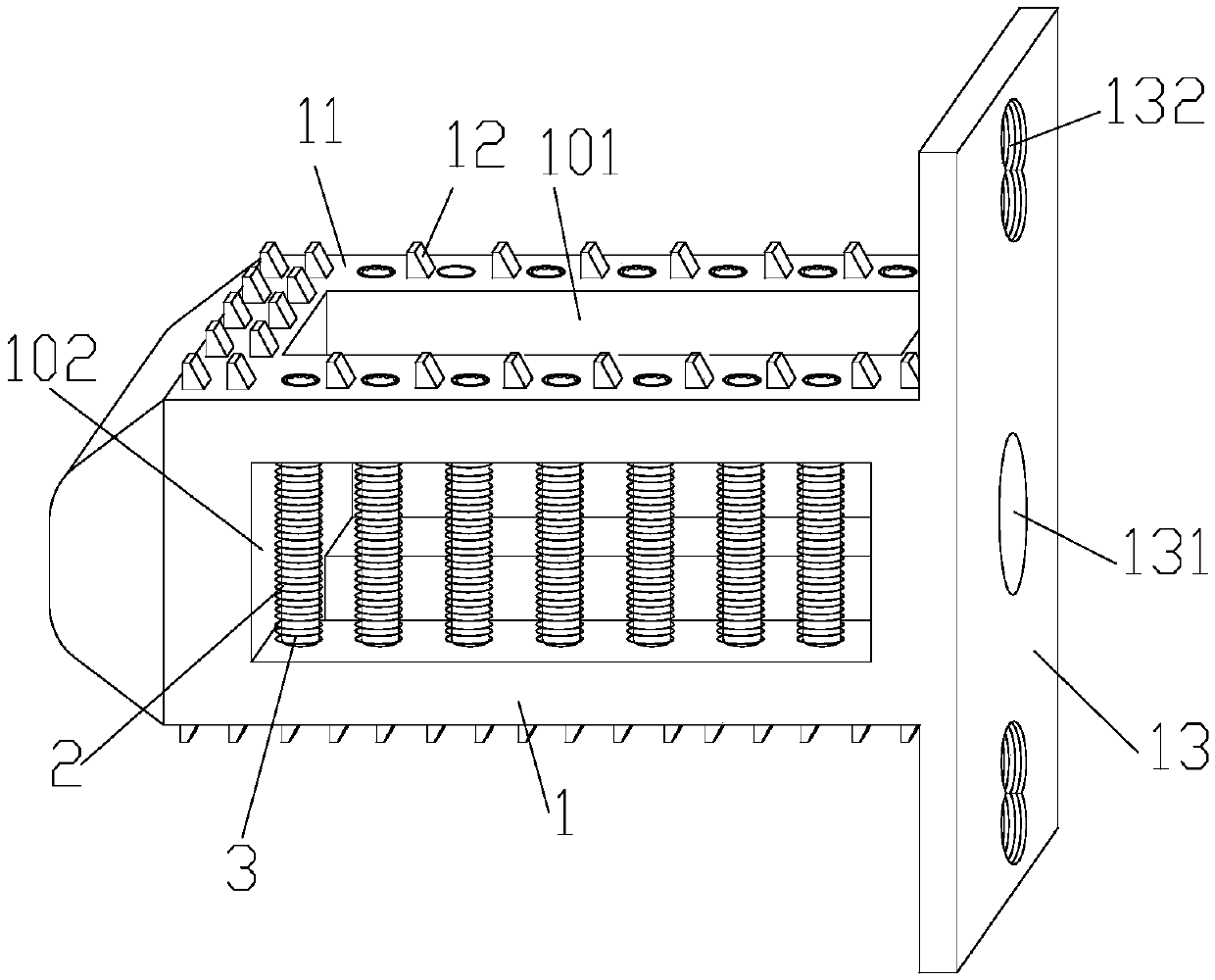

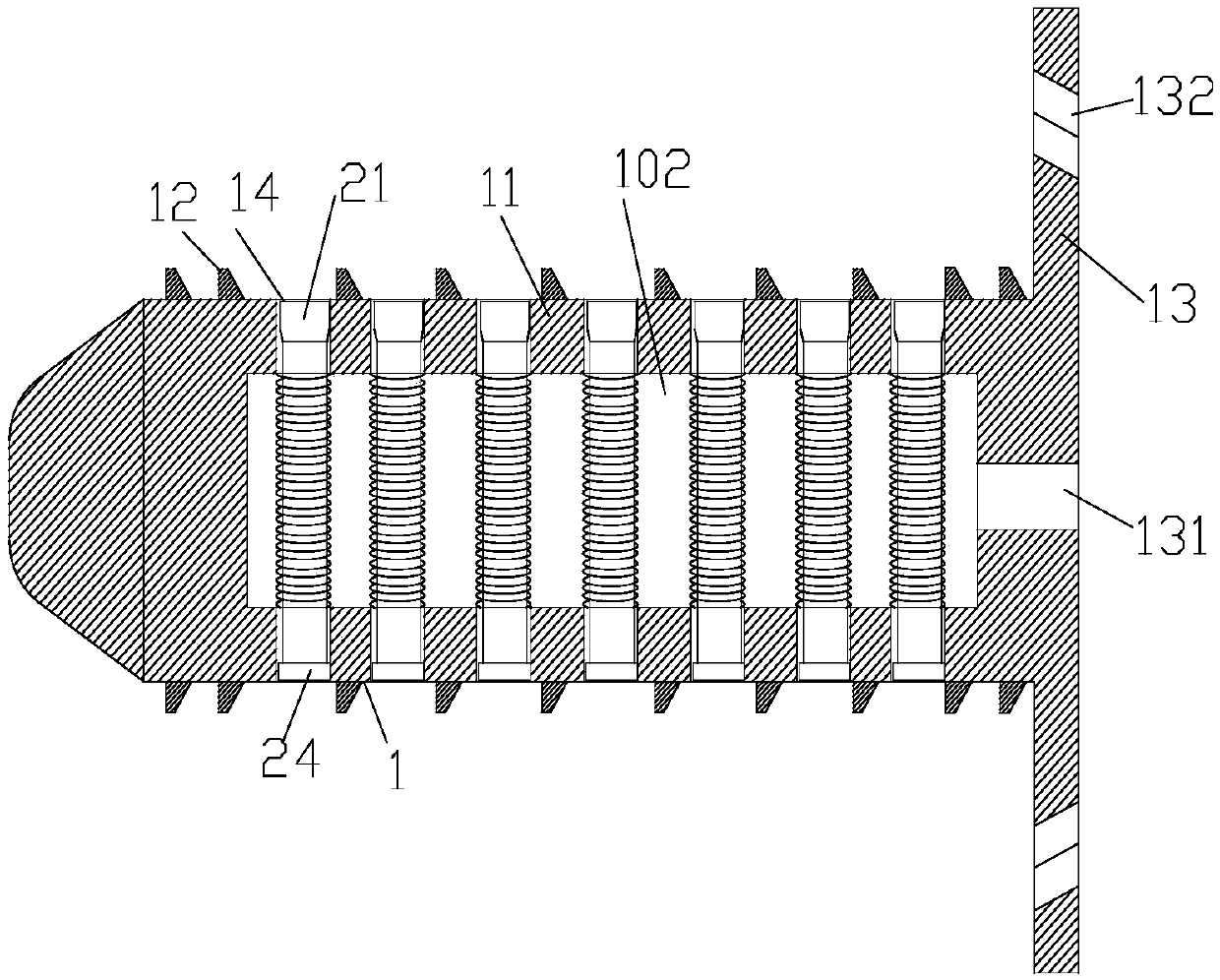

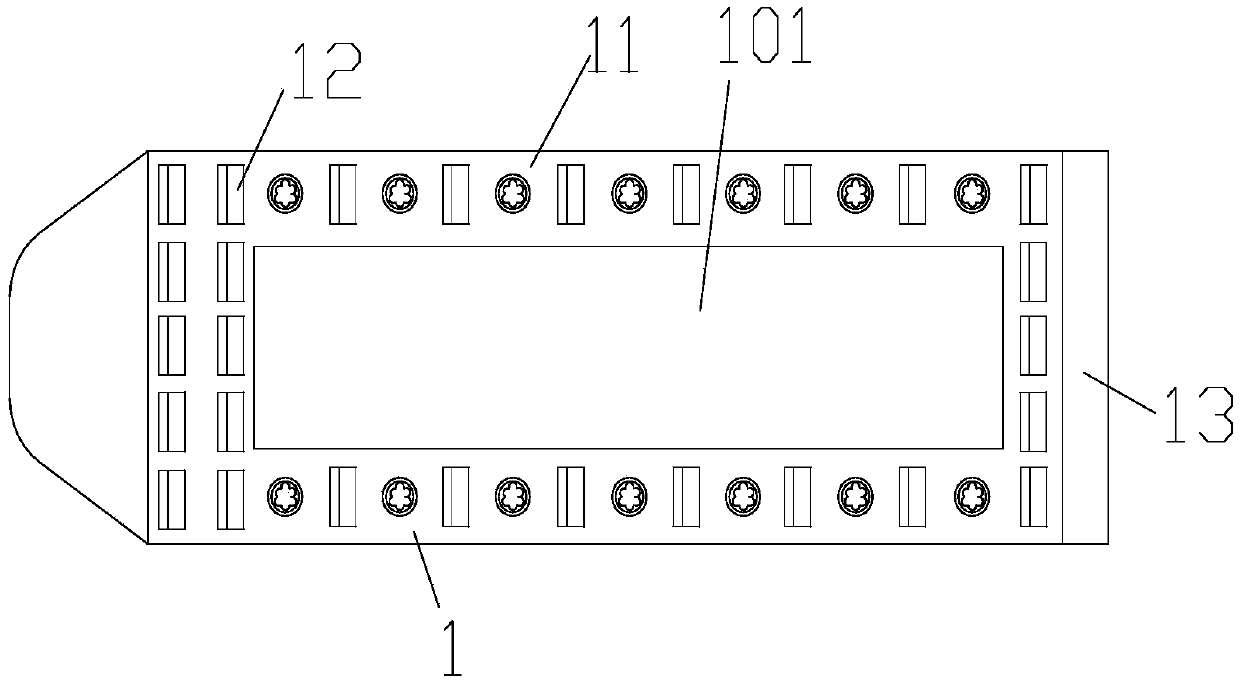

Lumbar vertebra interbody fusion cage and application thereof

InactiveCN110478091AImprove resistance to fatigue damageAvoid chippingSpinal implantsSpinal cageLumbar intervertebral disc

The invention discloses a lumbar vertebra interbody fusion cage and application thereof. The lumbar vertebra interbody fusion cage comprises a fusion cage body, the left end of the fusion cage body isa tapered wedge-shaped implant end, a tail plate is arranged on the right end part of the fusion cage body, a penetrating central bone grafting hole is formed in the top of the fusion cage body, a penetrating side hole is formed in the vertical surface of the fusion cage, the central bone grafting hole and the side hole divide the fusion cage body into four cross beams, compression energy dissipating devices are fixed between the cross beams, anti-skid protrusions are arranged on the top surface and the bottom surface of the fusion cage body, 8-shaped screw holes are formed in the upper end and the lower end of the tail plate, and the middle of the tail plate is provided with a repair bone grafting hole penetrating through the central bone grafting hole. According to the interbody fusioncage, a strong-column and weak-beam structure is adopted, a high-strength interbody body fusion cage made of metal materials does not need to be used, and an elastic module of the high-strength metalinterbody body fusion cage can be achieved; the anti-fatigue rupture performance of the interbody fusion cage is better; the interbody body fusion cage is combined with a vertebra screw to limit the axial torsional movement of the lumbar intervertebral disc, and thus the fracture of the interbody fusion cage is avoided.

Owner:THE AFFILIATED HOSPITAL OF PUTIAN UNIV (THE SECOND HOSPITAL OF PUTIAN CITY)

Preparation method for aluminum alloy resistant to fatigue damage for building template

The invention discloses a preparation method for aluminum alloy resistant to fatigue damage for a building template and relates to the field of building engineering materials. The preparation method includes the steps of melting aluminum ingots prior to heating molten aluminum ingots to 660-680 DEG C, descumming, uniformly mixing Si, Fe, Cu, Mn, Mg, Zn, Ti, Cr, Ni, Mo, V and B and adding an obtained mixture into a furnace for smelting; adding refining agents into a melt for refining and standing for 30-60 minutes; taking out from the furnace to cast to obtain a casting blank; placing the casting blank into a melting furnace, heating the casting blank to 720-730 DEG C, stirring for 10-15 minutes after complete smelting, refining at the temperature of 715-730 DEG C, standing for 10-20 minutes and then casting to obtain a cast ingot; subjecting the cast ingot to homogenization treatment at the temperature of 550-570 DEG C; subjecting the homogenized cast ingot to mist cooling to enable the homogenized cast ingot to be below 180 DEG C, and air cooling to the room temperature. The preparation method solves the problems of poor weatherability and low corrosion resistance of existing aluminum alloy for the building template.

Owner:LIUZHOU PUYA TRADE

Rail

A rail is provided in which in a range from a surface of a head of the rail to a depth of 30 mm, 95% or more of a structure is composed of a pearlite structure by area %, and in a range with a depth of 20 mm to 30 mm from the surface of the head of the rail, an average grain size of a pearlite block in a transverse section is 120 μm to 200 μm.

Owner:NIPPON STEEL CORP

Proportional test device for rotating bending fatigue of train wheel axle

InactiveCN102103056BImprove resistance to fatigue damageImprove the protective effectMaterial strength using repeated/pulsating forcesFatigue damageElectricity

The invention relates to a proportional test device for the rotating bending fatigue of a train wheel axle. A base is provided with an electric spindle controlled by a data acquisition and control system; the electric spindle is connected with a spring collet through a coupler and an axle box filled with cooling oil; the spring collet clamps the axle of a wheel axle sample; a rotating speed sensor and a revolution sensor are arranged beside the coupler; the wheel of the wheel axle sample is contacted with a driven wheel below; the axle of the driven wheel is arranged on a driven wheel bracket; a guide sleeve of the driven wheel bracket is sleeved on a guide pillar of a sensor base; a threaded hole of a pressure sensor of the sensor base is connected with an adjusting upright post; the upper end of the adjusting upright post is contacted with the lower surface of a bottom plate of the driven wheel bracket; and the middle part of the adjusting upright post is provided with a self-locking threaded ring. The test device can conveniently simulate the rotating bending fatigue damage of the train wheel axle under the action of a complex alternating load so as to provide a more reliable and accurate test basis for improving the fatigue damage resistance of the wheel axle and better protecting the wheel axle.

Owner:SOUTHWEST JIAOTONG UNIV

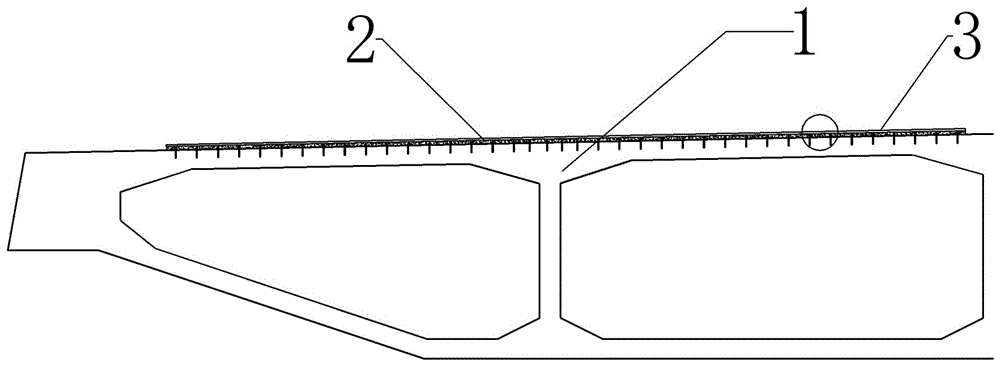

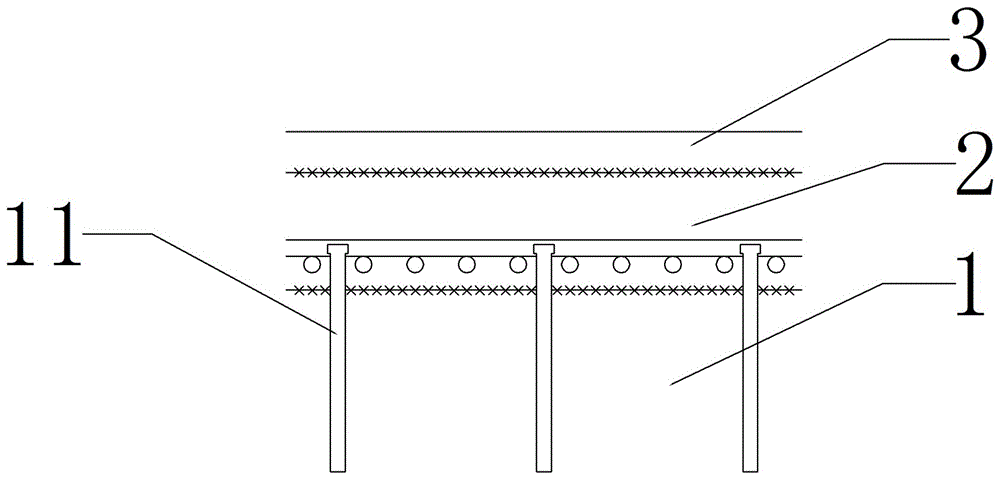

Concrete beam-STC combination bridge-face structure and construction method thereof

InactiveCN106087740AReasonable structureIncreased durabilityBridge structural detailsBridge erection/assemblyBridge engineeringConcrete beams

The invention discloses a concrete beam-STC combination bridge-face structure and a construction method thereof. The technical problems that an existing structure is unreasonable, the material performance is free of high quality, the construction technology is low in efficiency, and the structure function is incomplete are mainly solved. The concrete beam-STC combination bridge-face structure and the construction method thereof in the technical scheme are characterized in that the concrete beam-STC combination bridge-face structure comprises a beam top layer (1), an STC layer (2) and bolt nails (11), wherein the two ends of the bolt nails (11) are fixedly connected with the beam top layer (1) and the STC layer (2) respectively, and a body of the beam top layer (1) is a concrete structure layer; the bolt nails (11) are implanted into the upper surface of the beam top layer (1), the upper portions of the bolt nails (11) protrude out of the upper surface of the beam top layer (1), and the height, protruding out of the upper surface of the beam top layer (1), of the upper portions of the bolt nails (11) is smaller than the thickness of the STC layer (2); the STC layer (2) is laid on the beam top layer (1) to form the whole concrete beam-STC combination bridge-face structure. The concrete beam-STC combination bridge-face structure is mainly applied to bridge engineering construction and later stage maintenance and repairing construction of bridge engineering.

Owner:HUNAN ZHONGLU HUACHENG BRIDGE TECH CO LTD

Processing technology to improve fatigue damage resistance of 2××× aluminum alloy plate

The invention relates to a machining technology for improving the fatigue damage resisting performance of a 2xxx aluminum alloy plate. The machining technology comprises the following steps that 1, alloy is subjected to burdening smelting and is cast into an ingot casting; 2, the ingot casting is sequentially subjected to homogenization treatment, surface milling and aluminum cladding, preheating is carried out, and a hot rough-rolled plate is manufactured; 3, the hot rough-rolled plate is subjected to hot finishing and cold rolling deformation to the thickness of the finished plate; 4, recrystallization pre-annealing treatment is carried out, temperature is raised to 300-450 DEG C at the average speed of 10-300 DEG C / h or within 1.0-45 h, and heat preservation is carried out for 1-20 h; 5, solid solution hardening treatment is carried out, the solid solution temperature is 480-505 DEG C, and heat preservation time is 3-60 min; and 6, the plate is straightened, and natural ageing is carried out to the stable state. According to the machining technology, recrystallization pre-annealing treatment is added so that the L-ST section grain average equivalent diameter and grain length-width ratio of the plate can be effectively controlled, and the tensile mechanical property and fatigue crack spreading rate of the plate can both meet the AMS 4296 aviation standard requirement.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD +1

Formula of low-heat anti-fatigue base rubber and preparation method of formula

InactiveCN108752653ALow resistance to fatigue damageImprove resistance to fatigue damageSpecial tyresFatigue damagePolymer science

The invention belongs to the technical field of rubber formulae and in particular relates to a formula of low-heat anti-fatigue base rubber and a preparation method of the formula. The formula of low-heat anti-fatigue base rubber comprises the following components in parts by weight: 80-100 parts of natural rubber, 0-20 parts of cis-polybutadiene, 15-25 parts of carbon black N330, 15-30 parts of nano clay, 4-5 parts of ZnO, 1.9-2.1 parts of citric acid, 2-3 parts of an anti-aging agent, 1.0-1.8 parts of sulfur, 1-2 parts of an accelerant and 0.2-0.5 part of a scorch retarder CTP. Through two procedures of master refining and final refining, mixed rubber of the formula of the low-heat anti-fatigue base rubber can be obtained. By adopting the formula provided by the invention, low heat of the mixed rubber can be maintained, meanwhile, the anti-fatigue damage properties of the base rubber can be improved, and the durability of the rubber can be improved.

Owner:JIANGSU GENERAL SCI TECH

Preparation method for controlling non-quenched and tempered steel large particle inclusions

InactiveCN111411188AReduce H and O contentReduce H contentManufacturing convertersSmelting processAlloy

The invention discloses a preparation method for controlling non-quenched and tempered steel large particle inclusions. The preparation method for controlling the non-quenched and tempered steel largeparticle inclusions comprises the following steps that (1) converter smelting is carried out, specifically, in the process of converter smelting, the converter end point C mass percent content is controlled to be greater than or equal to 0.10% or the tapping TSO oxygen level is less than or equal to 300 ppm, and the tapping temperature is greater than or equal to 1600 DEG C; and (2) converter tapping is carried out, specifically, converter bottom stirring is started before molten steel tapping, the oxidation of molten steel and the P content of the molten steel are reduced; and carbon powderis added for pre-deoxygenation in the tapping early stage, then a deoxidizer, an alloy and slag are added for deoxidize alloying in sequence, the whole process of nitrogen blowing is kept in deoxidizing alloying process, and a double stop way is adopted for tapping in the tapping later stage to strictly control roughing slag. Non-quenched and tempered steel can stably control the total oxygen below 15 ppm and the H content below 1.5 ppm, the H and O content in the steel are effectively reduced, the product quality is improved, the steel produced for automobiles has low full O, H and high purity level, and the non-quenched and tempered automobile steel with excellent anti-fatigue damage performance is ensured.

Owner:NANJING IRON & STEEL CO LTD

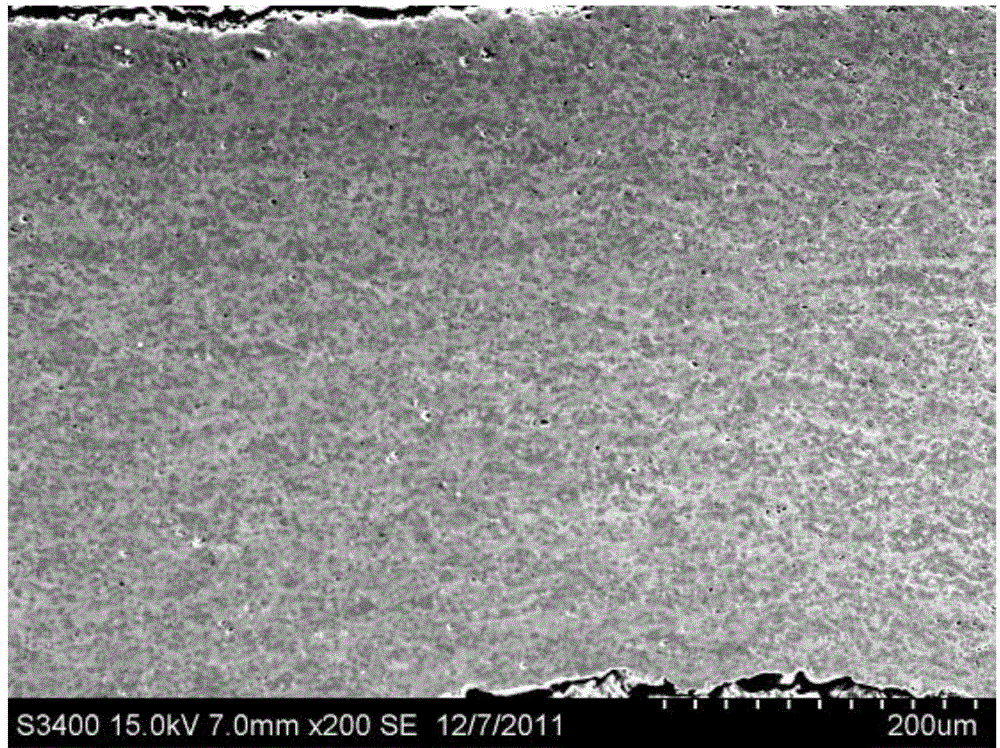

Alpha+beta type titanium alloy based on cold forming composite low-temperature nitriding treatment and nitriding layer forming method thereof

ActiveCN112410722AImprove resistance to fatigue damageIncreasing the thicknessSolid state diffusion coatingFatigue damageCold formed

The invention relates to the technical field of titanium alloy nitriding, in particular to an alpha+beta type titanium alloy based on cold forming composite low-temperature nitriding treatment and a nitriding layer forming method thereof. The nitriding layer forming method comprises the following steps that quenching, cold forming and low-temperature nitriding are sequentially conducted on the alpha+beta type titanium alloy, and a nitriding layer is formed on the surface of the alpha+beta type titanium alloy, wherein the accumulated deformation amount of cold forming is 10%-65%; and the temperature of the low-temperature nitriding is 400-600 DEG C. By the adoption of the method, the millimeter-scale super-thick nitriding layer can be formed on the surface of the alpha+beta type titanium alloy, the hardness gradient can be adjusted and controlled, the plasticity and toughness of an alloy matrix structure and the abrasion resistance of the titanium alloy can be remarkably improved, the fatigue damage resistance of the nitriding layer is improved, and the service life of a product is prolonged.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com