Processing technique for improving fatigue damage resistance of 2XXX series aluminum alloy plate

A technology of anti-fatigue damage, aluminum alloy plate, applied in the field of non-ferrous metal material engineering, to achieve a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

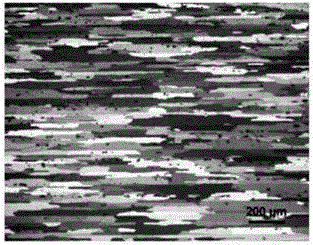

[0036] According to the element ratio of 4.32wt.% Cu, 1.35wt.% Mg, 0.61wt.% Mn, 0.08wt.% Fe, 0.06wt.% Si, 0.03wt.% Ti, the 2524 aluminum alloy with a size of 400×1620×2500mm was cast Ingot. The alloy ingot was subjected to 498°C / 32h homogenization treatment, face milling, aluminum cladding, 480°C / 8h preheating, and then hot rough rolling at 480°C, followed by hot finish rolling to 6.0mm. The hot finish-rolled plate is kept at 290°C for 4h, and then undergoes solution quenching at 496°C / 50min, straightening treatment and natural aging for more than 96h. The process flow is as follows figure 1 shown. Test the tensile mechanical properties of the final finished plate, and test the fatigue crack growth rate of the plate according to GB / T6398-2000 and AMS4296 standards.

Embodiment 2

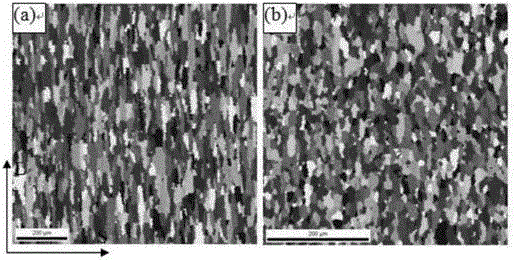

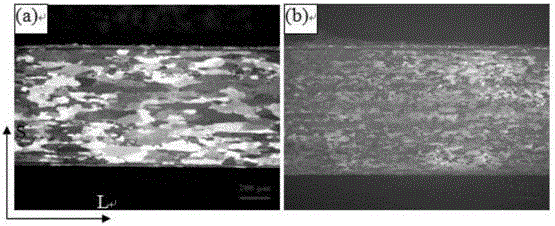

[0038]According to the element ratio of 4.32wt.% Cu, 1.35wt.% Mg, 0.61wt.% Mn, 0.08wt.% Fe, 0.06wt.% Si, 0.03wt.% Ti, the 2524 aluminum alloy with a size of 400×1620×2500mm was cast Ingot. The ingot was subjected to 498°C / 32h homogenization treatment, face milling, aluminum cladding, 480°C / 8h preheating, and then hot rough rolling at 480°C, followed by hot finish rolling to 6.0mm. The hot finish rolling plate is deformed to 2.5mm by cold final rolling at a reduction rate of 58%, and the cold final rolling plate is kept at 270°C for 8h, then solution quenched at 496°C / 25min, and naturally aged for more than 96h after straightening , the process such as figure 2 shown. Test the mechanical properties of the final finished plate, and test the fatigue crack growth rate of the plate according to GB / T6398-2000 and AMS4296 standards.

Embodiment 3

[0040] According to the element ratio of 4.32wt.% Cu, 1.35wt.% Mg, 0.61wt.% Mn, 0.08wt.% Fe, 0.06wt.% Si, 0.03wt.% Ti, the 2524 aluminum alloy with a size of 400×1620×2500mm was cast Ingot. The ingot was subjected to 498°C / 32h homogenization treatment, face milling, aluminum cladding, 480°C / 8h preheating, and then hot rough rolling at 480°C, followed by hot finish rolling to 6.0mm. The hot finish rolling plate is deformed to 2.5mm by cold final rolling at a reduction rate of 58%, and the cold final rolling plate is kept at 290°C for 4h, then solution quenched at 496°C / 25min, and naturally aged for more than 96h after straightening treatment , the process such as figure 2 shown. Test the mechanical properties of the final finished plate, and test the fatigue crack growth rate of the plate according to GB / T6398-2000 and AMS4296 standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com