Alpha+beta type titanium alloy based on cold forming composite low-temperature nitriding treatment and nitriding layer forming method thereof

A low-temperature nitriding, titanium alloy technology, applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of increased grain size, poor wear resistance of titanium alloys, and reduced matrix toughness, etc. Conducive to the overall cold forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment takes the TC4 titanium alloy sheet as the processing object, and the specific steps are as follows:

[0055] Quenching treatment: put TC4 titanium alloy in a vacuum furnace, keep at 850℃ for 50min, and cool with circulating water at 15℃;

[0056] Cold forming: After quenching, cold forming is carried out at room temperature, and the deformation amount is 30% to obtain TC4 titanium alloy sheet;

[0057] Workpiece cleaning: Use sandpaper to polish the surface of the workpiece, and perform ultrasonic cleaning in acetone solution;

[0058] Low-temperature nitriding: place the cleaned workpiece in a pulsed plasma furnace, and the atmosphere selected in the nitriding process is N 2 and H 2 Two kinds of gas infiltration agents, the flow ratio is 1:1, N 2 , H 2 The flow rate is 0.21m 3 / h, the voltage is 650V, the pressure rise rate is 0.13P / min, the duty cycle is 45%, the nitriding temperature is 480℃, and the holding time is 16h;

[0059] Thermal diffusi...

Embodiment 2

[0065] The difference between Example 2 and Example 1 is that the deformation amount of cold forming is 20%, and the nitriding time is 14h.

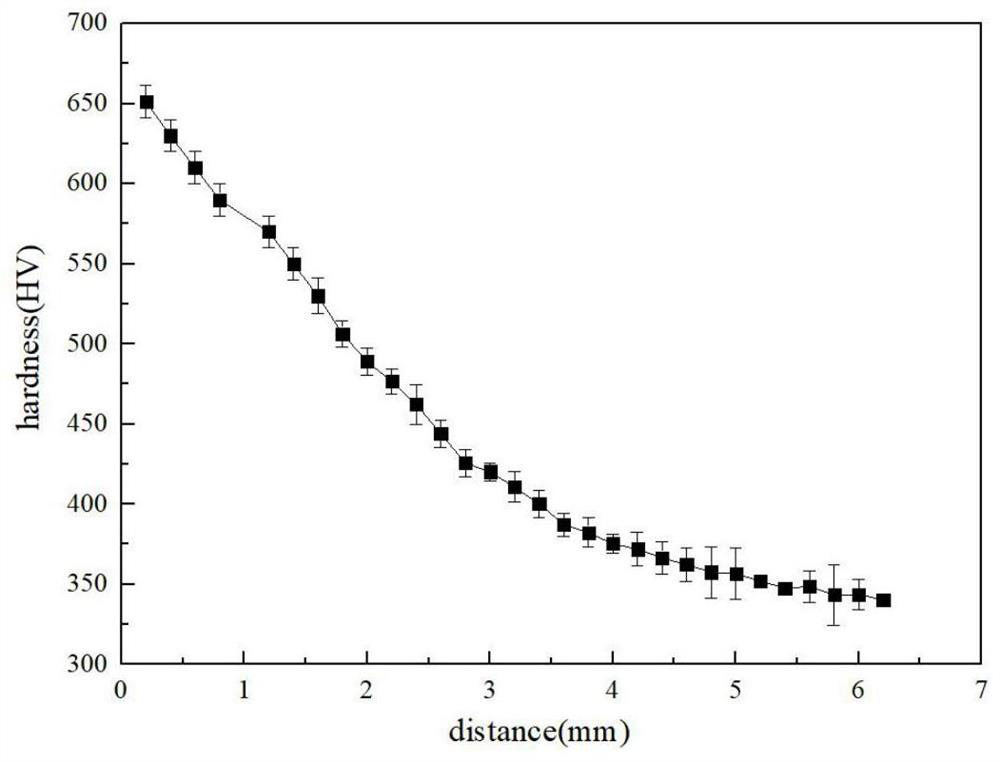

[0066] The nitrided workpiece obtained after low-temperature nitriding in Example 2 and the nitrided workpiece obtained after thermal diffusion treatment were tested. After thermal diffusion treatment, the surface N concentration of the TC4 alloy is 19%, the core concentration is 15.6%, the thickness of the infiltrated layer is 3.6mm, the friction coefficient is 0.39, and the surface hardness reaches 632HV. After the thermal diffusion treatment, the hardness of the matrix changes in steps. ,like Figure 4 shown.

Embodiment 3

[0068] The difference between Example 3 and Example 1 is that the deformation amount of cold forming is 40%, and the nitriding time is 18h.

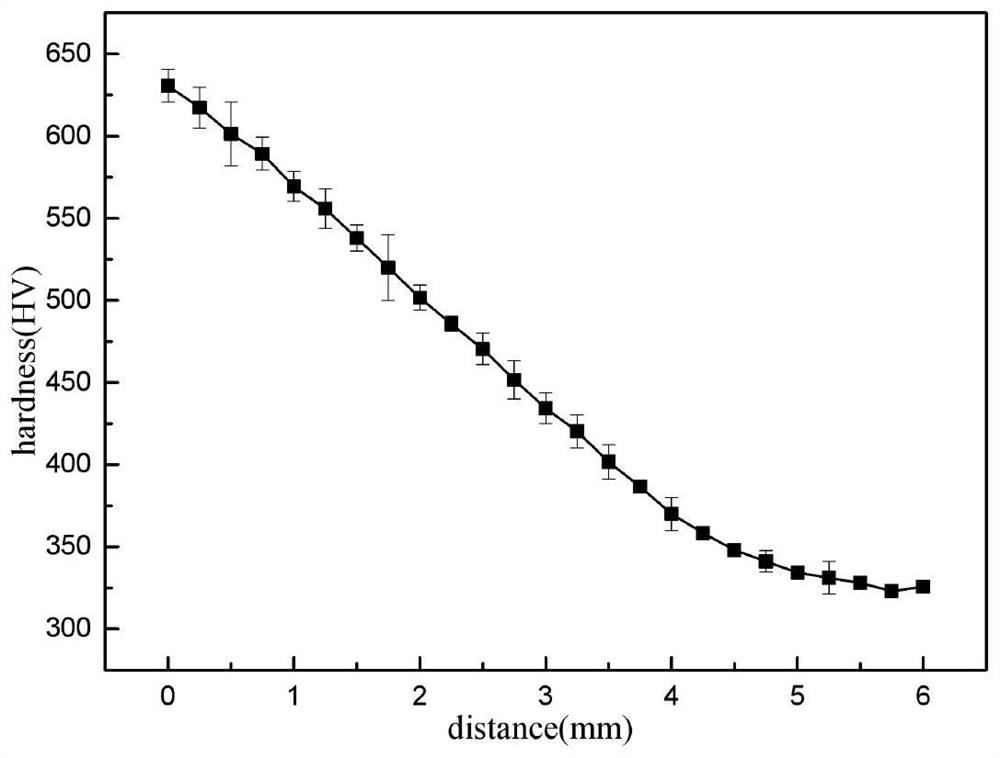

[0069] The nitrided workpiece obtained after low-temperature nitriding in Example 3 and the nitrided workpiece obtained after thermal diffusion treatment were tested. The results showed that the thickness of the nitrided workpiece after low-temperature nitridation in Example 3 was 3 mm, and the surface N concentration was 26.9%; after the thermal diffusion treatment, the surface N concentration of the TC4 alloy is 25%, the core concentration is 22.3%, the thickness of the infiltrated layer is 4.4mm, the friction coefficient is 0.24, and the surface hardness reaches 661HV. like Figure 5 shown.

[0070] The comprehensive properties of the products of Examples 1 to 3 are far superior to those of the incoming TC4 titanium alloy (the hardness is 310HV and the friction coefficient is 0.69). It can be seen that the hardness and wear resistanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Permeable layer thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com