Concrete beam-STC combination bridge-face structure and construction method thereof

A technology of concrete beams and composite bridge decks, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of large differences between physical properties and structural properties, poor bonding, and no consideration of STC, etc., to improve fatigue resistance Destructive ability, small thickness, and the effect of avoiding erosion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

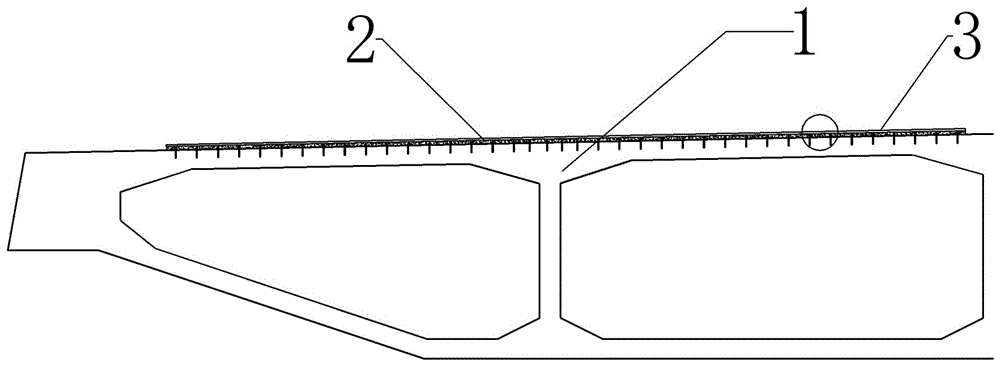

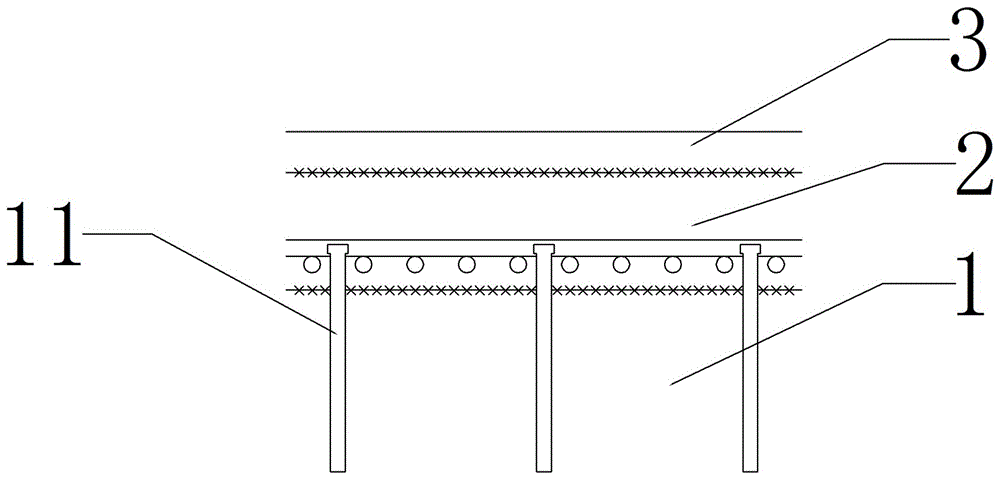

[0081] Embodiment 1, the present invention comprises the beam top layer 1, the STC layer 2 and the studs 11 fixedly connected with the beam top layer 1 and the STC layer 2 respectively at both ends, the beam top layer 1 body is a concrete structure layer; on the beam top layer 1 upper surface Fixing holes are arranged and distributed according to the principle of mechanics, and pegs 11 are fixed in each fixing hole. The upper part of the pegs 11 protrudes from the upper surface of the beam top layer 1, and the height of the upper part of the pegs 11 protruding from the upper surface of the beam top layer 1 is smaller than the STC layer 2. The thickness of the beam top layer 1 is laid on the STC layer 2, so that the two ends of the studs 11 are fixedly connected with the beam top layer 1 and the STC layer 2 respectively, forming an integral concrete beam-STC composite bridge deck structure, see Figure 1 to Figure 2 .

[0082] The stud 11 of the present invention can adopt the ...

Embodiment 2

[0084] Embodiment 2, the beam top layer 1 of the present invention is the top plate of the bridge, and the spacing of the fixing holes arranged on the upper surface of the beam top layer 1 is scientifically designed and arranged according to the principles of mechanics. The preferred spacing between the fixing holes is 10-40 cm, and the best The best spacing is 15~30cm to ensure that all parts of the top layer of the beam are evenly stressed. The pegs 11 can be implanted in the top layer of the beam 1 in a manner similar to planting bars, that is, firstly drill fixing holes on the upper surface of the top layer 1 of the beam, and then fill the fixing holes with inorganic glue, the inorganic glue includes cement inorganic glue with good durability etc., to ensure that it is consistent with the life of the bridge, and then the peg 11 is inserted into the fixing hole, and the peg 11 is firmly connected with the top layer of the beam through the adhesive. refer to Figure 1 to Fi...

Embodiment 3

[0085] Embodiment 3, the STC layer 2 of the present invention includes steel mesh and ultra-high-performance concrete, and the steel mesh can be directly laid on the upper surface of the beam top layer 1, and the steel bars in the steel mesh can also be connected or overlapped with the pegs 11, The ultra-high-performance concrete completely covers the studs 11 and the entire reinforcement mesh on the upper surface of the top layer 1 of the protruding beam. The spacing between the reinforcement bars in the reinforcement mesh can be equal, and the reinforcement bars in the reinforcement mesh can also be formed perpendicular to each other. Mesh, the ultra-high performance concrete wraps the studs 11 and the steel mesh, so that the ultra-high performance concrete completely covers the studs 11 and the steel mesh to form a whole, see Figure 1 to Figure 2 , and the rest are combined with any other embodiment of the present invention or two or more embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com