Heat treatment process of niobium-containing steel for axles of motor train unit

A technology for steel for axles and EMUs, applied in the field of alloy steel, can solve the problems of low toughness and fatigue performance, no heat treatment process parameters, low fatigue strength, etc., to improve the combination of strength and toughness, and excellent fatigue resistance , Improve the effect of fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in detail below, which is a preferred embodiment among various implementations of the present invention.

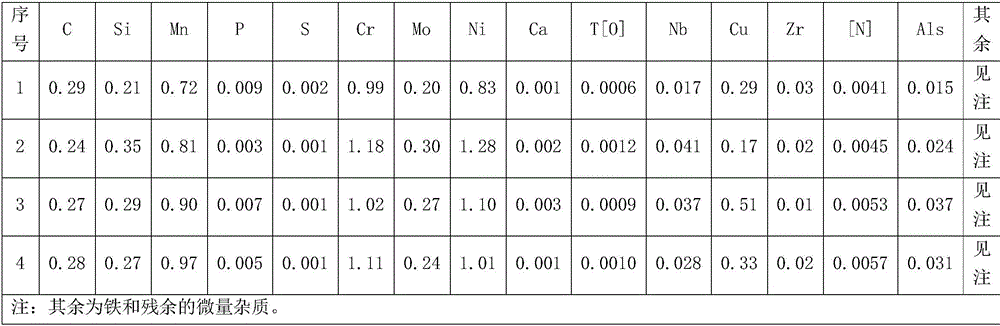

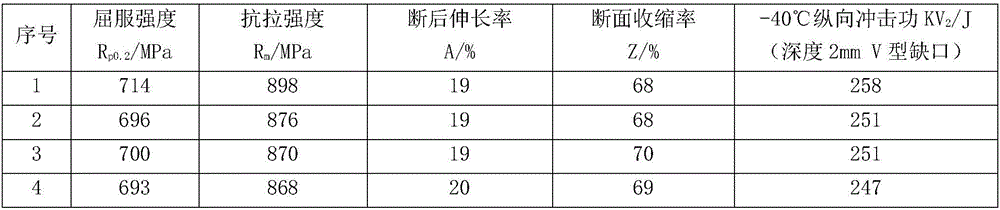

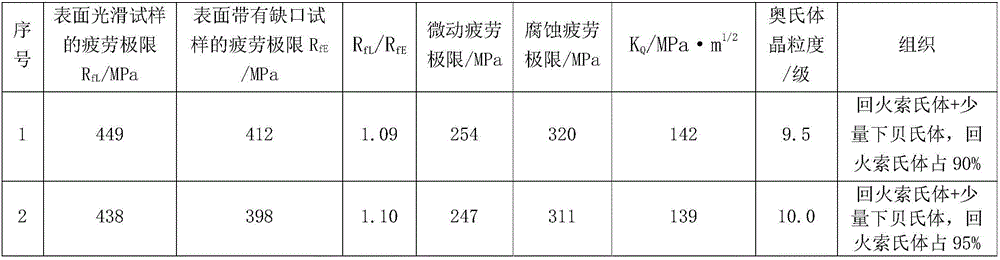

[0021] In a preferred embodiment, a heat treatment process for a niobium-containing EMU axle steel includes the following steps: (1) First quenching: heating the niobium-containing high-speed EMU axle steel to a temperature of 870-900° C. The heating and holding time in the temperature section is calculated according to 1.5-2.0min / mm, followed by cooling; (2) The second quenching: heating the steel for axles of high-speed EMUs containing niobium to a temperature of 850-880°C, and the heating and holding time in this temperature section is as follows: 1.5-2.0min / mm calculation, followed by cooling; (3) Tempering: heating the niobium-containing high-speed EMU axle steel to a temperature of 620-680°C, and the heating and holding time at this temperature range is calculated as 2-2.5min / mm, Then cool. In step (1), heat at 80°C / h to a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com