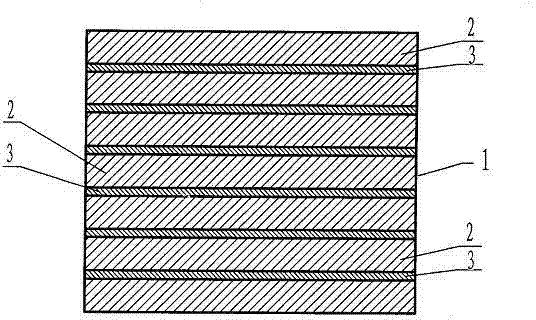

Organic clay rubber composite material for laminated rubber supporting seat and preparation process thereof

A technology of laminated rubber bearing and organoclay, applied in the rubber field, can solve the problems affecting the quality and service life of rubber bearing products, affecting the safety and durability of bridge structures, etc., and achieve excellent anti-aging performance and excellent mechanical properties. , the effect of strong interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

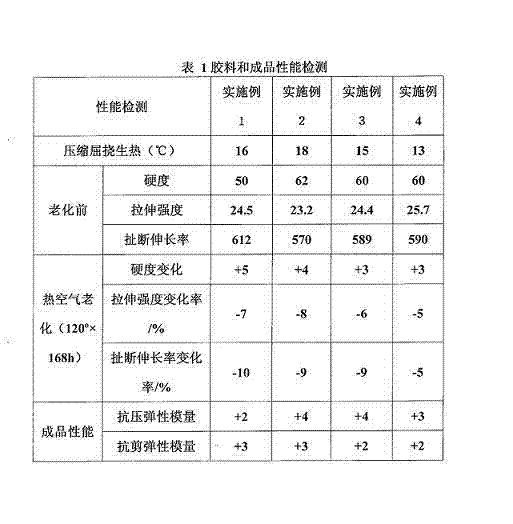

Examples

Embodiment 1

[0036] The preparation process of the organoclay rubber composite material for the laminated rubber bearing of the present invention comprises the following steps:

[0037] Step 1 Preparation of organoclay-rubber composites for unvulcanized laminated rubber bearings

[0038] In the first small step, 100 parts by weight of rubber is masticated on a double-roller open mill, and the roller distance is adjusted to 1mm, and 3 triangular bags are made by the wrapping rollers, and then 3 parts by weight of organic clay and 10 parts by weight of carbon black are added. Mechanical intercalation is carried out on the machine, 3 knives each on the left and right, and 5 triangle bags are made;

[0039] The second small step is to put the sizing material in the first small step into the internal mixer, add 10 parts by weight of activating agent and 4 parts by weight of anti-aging agent successively, pressurize the top bolt; wait until the temperature of the rubber material in the internal ...

Embodiment 2

[0044] The preparation process of the organoclay rubber composite material for the laminated rubber bearing of the present invention comprises the following steps:

[0045] Step 1 Preparation of organoclay-rubber composites for unvulcanized laminated rubber bearings

[0046] In the first small step, 100 parts by weight of rubber is masticated on a double-roller open mill, and the roller distance is adjusted to 1mm, and 3 triangle bags are made by the wrapping roller, and then 11.5 parts by weight of organic clay and 17 parts by weight of carbon black are added. Mechanical intercalation is carried out on the machine, 3 knives each on the left and right, and 5 triangle bags are made;

[0047] The second small step is to put the sizing material in the first small step into the internal mixer, add 8 parts by weight of active agent and 3 parts by weight of anti-aging agent successively, pressurize the top bolt; At 110°C, raise the bolt and keep it for 10 seconds, then add 33 parts b...

Embodiment 3

[0052] The preparation process of the organoclay rubber composite material for the laminated rubber bearing of the present invention comprises the following steps:

[0053] Step 1 Preparation of organoclay-rubber composites for unvulcanized laminated rubber bearings

[0054] The first small step is to plasticize 100 parts by weight of rubber on a double-roller open mill, adjust the roller distance to 1mm, wrap the rolls into 3 triangle bags, then add 20 parts by weight of organic clay and 24 parts by weight of carbon black, Mechanical intercalation is carried out on the machine, 3 knives each on the left and right, and 5 triangle bags are made;

[0055] The second small step is to put the rubber in the first small step into the internal mixer, add 6 parts by weight of active agent and 2 parts by weight of anti-aging agent successively, pressurize the top bolt; wait until the temperature of the rubber in the internal mixer rises to At 120°C, raise the bolt and keep it for 12 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com