Axial positioning device of crushing roller

An axial positioning and crushing roller technology, applied in grain processing and other directions, can solve the problems of crushing roller installation, maintenance difficulties, poor reliability of equipment operation, etc., and achieve the effects of quick installation and maintenance, reduced preload force, and reliable locking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

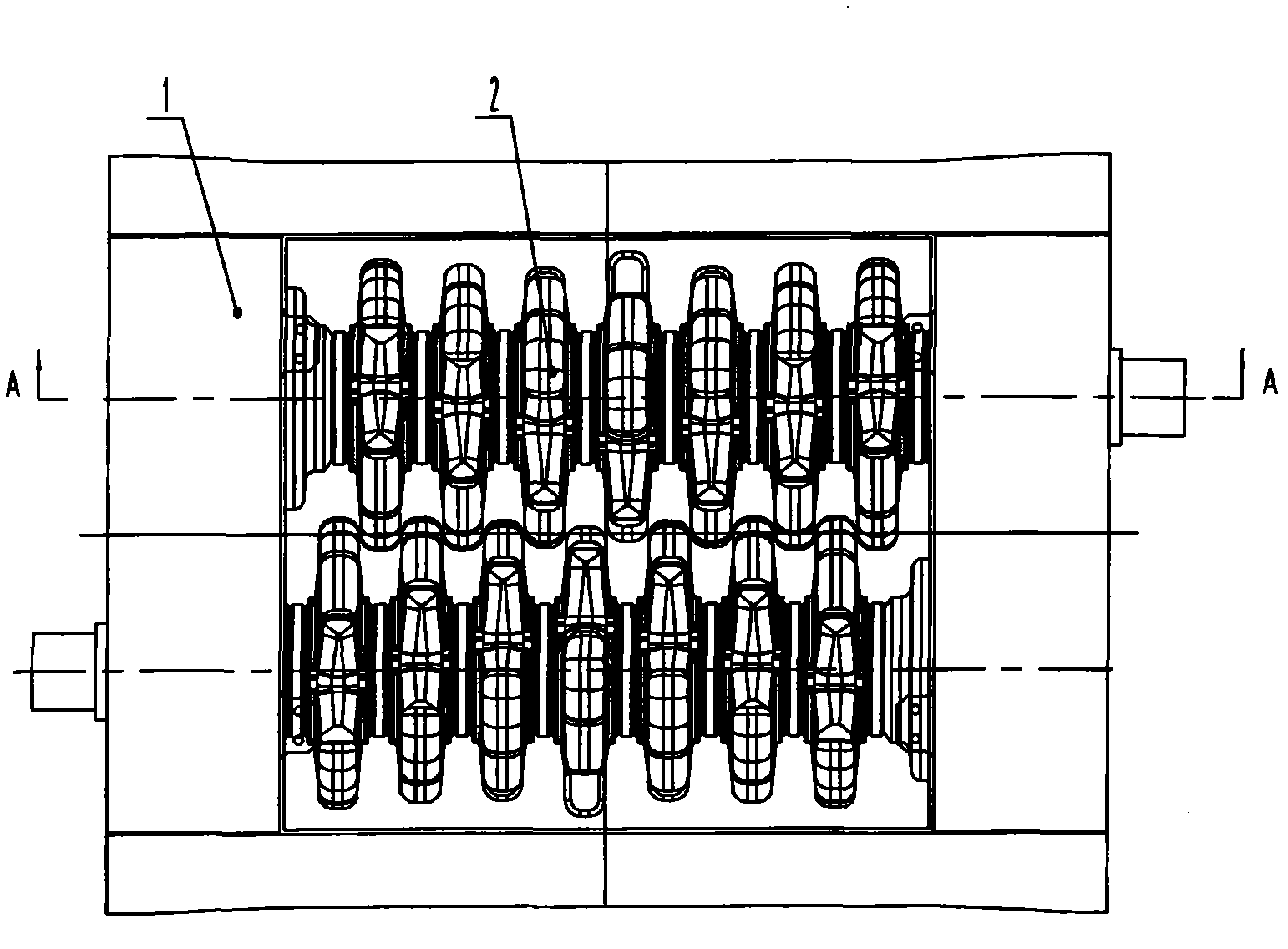

[0044] Such as figure 1 As shown, the structure of the double-toothed roller crusher body includes a crusher box assembly 1 and a pair of symmetrically arranged crushing rollers 2 .

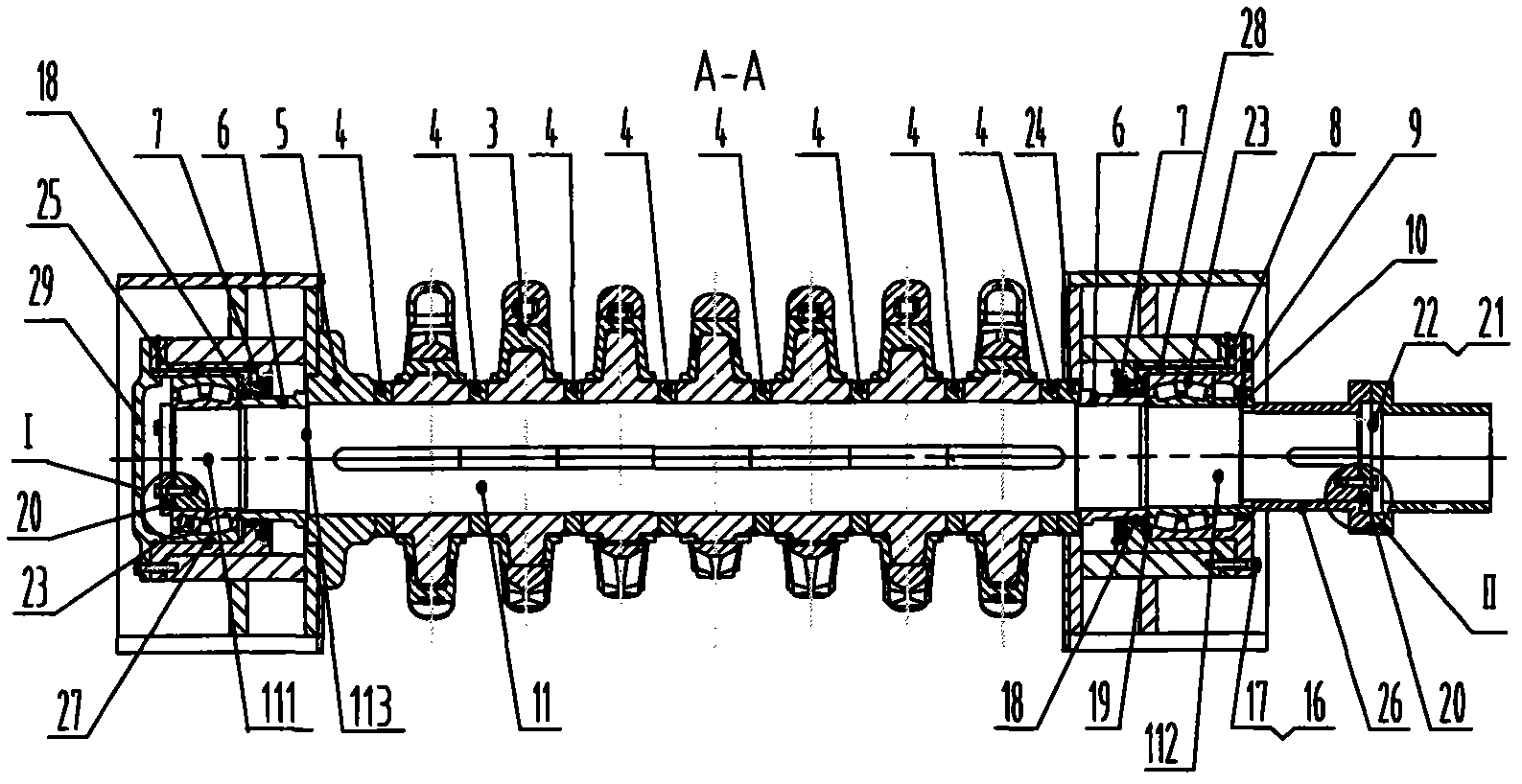

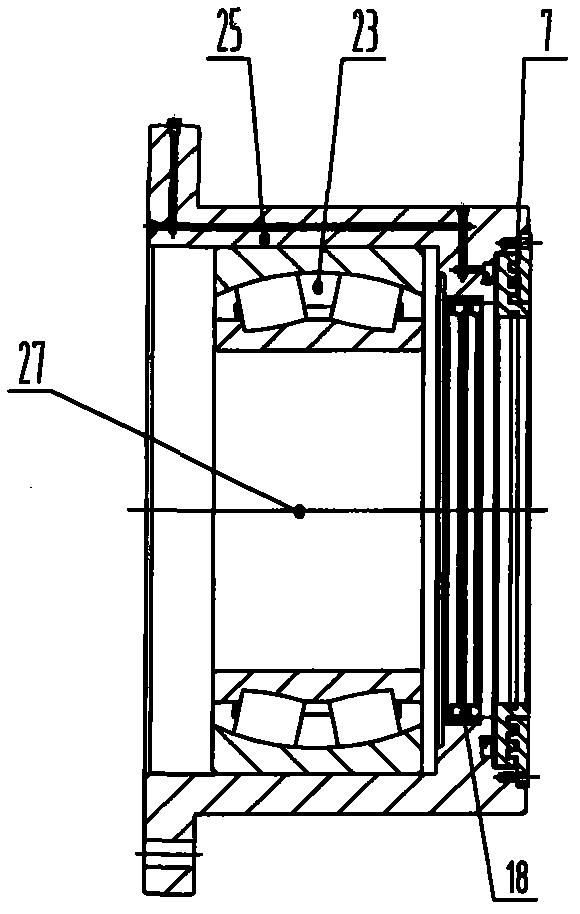

[0045] Such as image 3 , 4, 8, 9, 10, 11, 12, and 13 show an axial positioning device for a crushing roller. The crushing roller includes: a roller shaft 11, several gear ring assemblies 3 installed in the middle of the roller shaft 11, arranged on A number of No. I spacer rings 4 between the gear ring assemblies 3, No. II spacer rings 5, No. III spacer rings 6, and floating end bearing seat assemblies 27 are successively set on the floating end of the roller shaft 11. The fixed end of the roller shaft 11 is sequentially fitted with the No. V spacer ring 24, the No. III spacer ring 6, the fixed end bearing housing assembly 28, the No. IV spacer ring 10, and the axial positioning devices installed at both ends of the roller shaft 11 , characterized in that: the axial positioning device include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com