Control valve for oil atomizer

A fuel injector and control valve technology, which is used in machines/engines, fuel injection devices, engine components, etc., can solve the problem of increased difficulty in control valve control by electromagnets, insufficient reliability, durability, and high-cost replacement and maintenance. Cost and other issues, to achieve the effect of shortening the matching length, reducing the quality and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

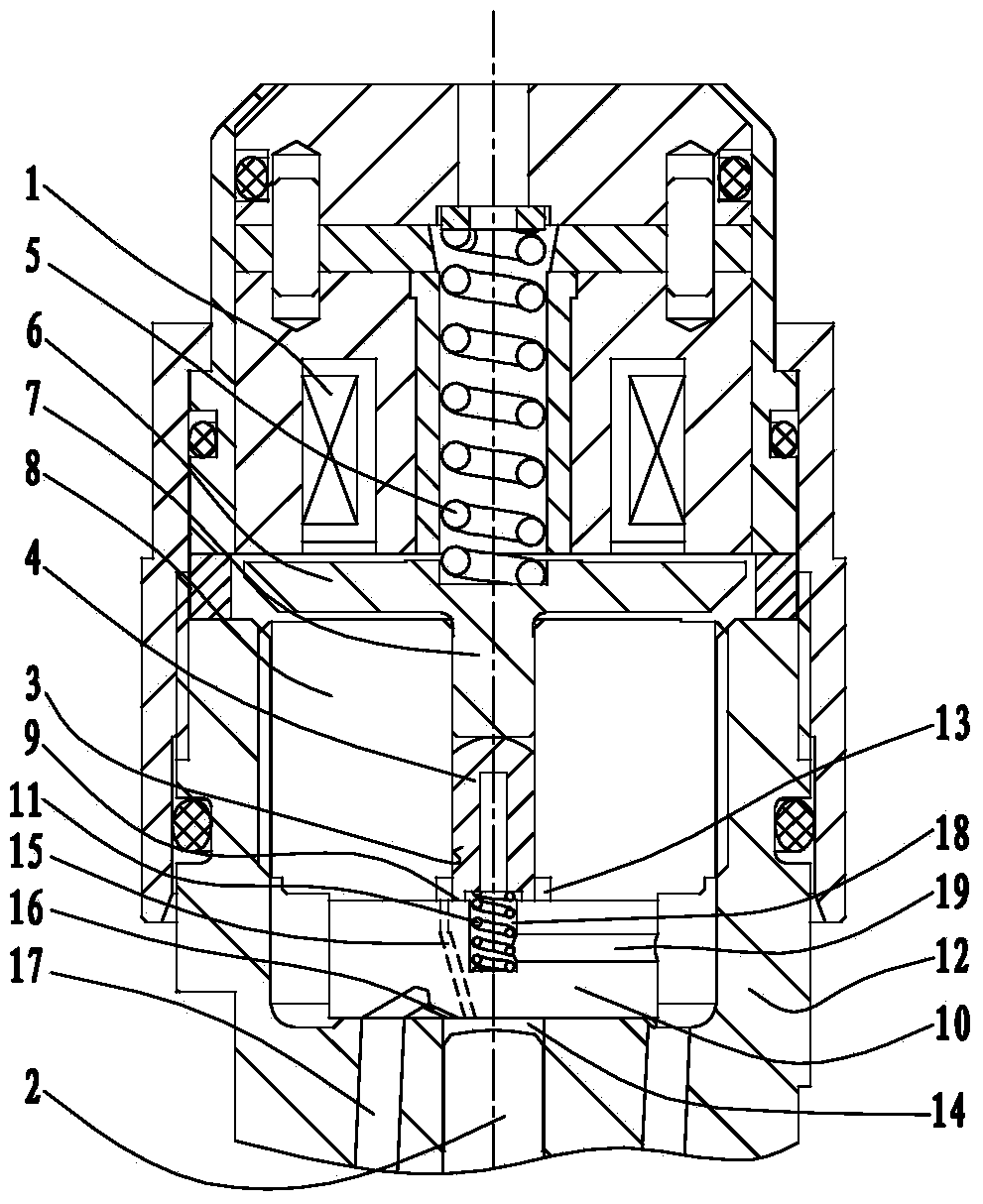

[0025] Such as figure 1 As shown, the control valve for the fuel injector of embodiment 1 is mainly composed of an electromagnet 1, a sealing pin 4, an electromagnet spring 5, an armature 6, an armature guide rod 7, a control valve seat 8, a throttle orifice 10, The auxiliary spring 11 is composed of the injector body 12; the electromagnet 1 is connected to the upper end of the injector body 12, and the electromagnet spring 5 in the electromagnet 1 presses down on the armature 6; the control valve seat 8 is installed on the injector In the concave cavity on the upper part of the body 12, the center of the control valve seat 8 is provided with a control valve seat inner hole 3, and the armature guide rod 7 is placed in the control valve seat inner hole 3 and can move axially; the throttle orifice 10 is arranged on the control valve seat. Below the seat 8, the fuel inlet passage 16 on the throttle orifice 10 communicates with the fuel inlet passage 17 on the injector body 12; t...

Embodiment 2

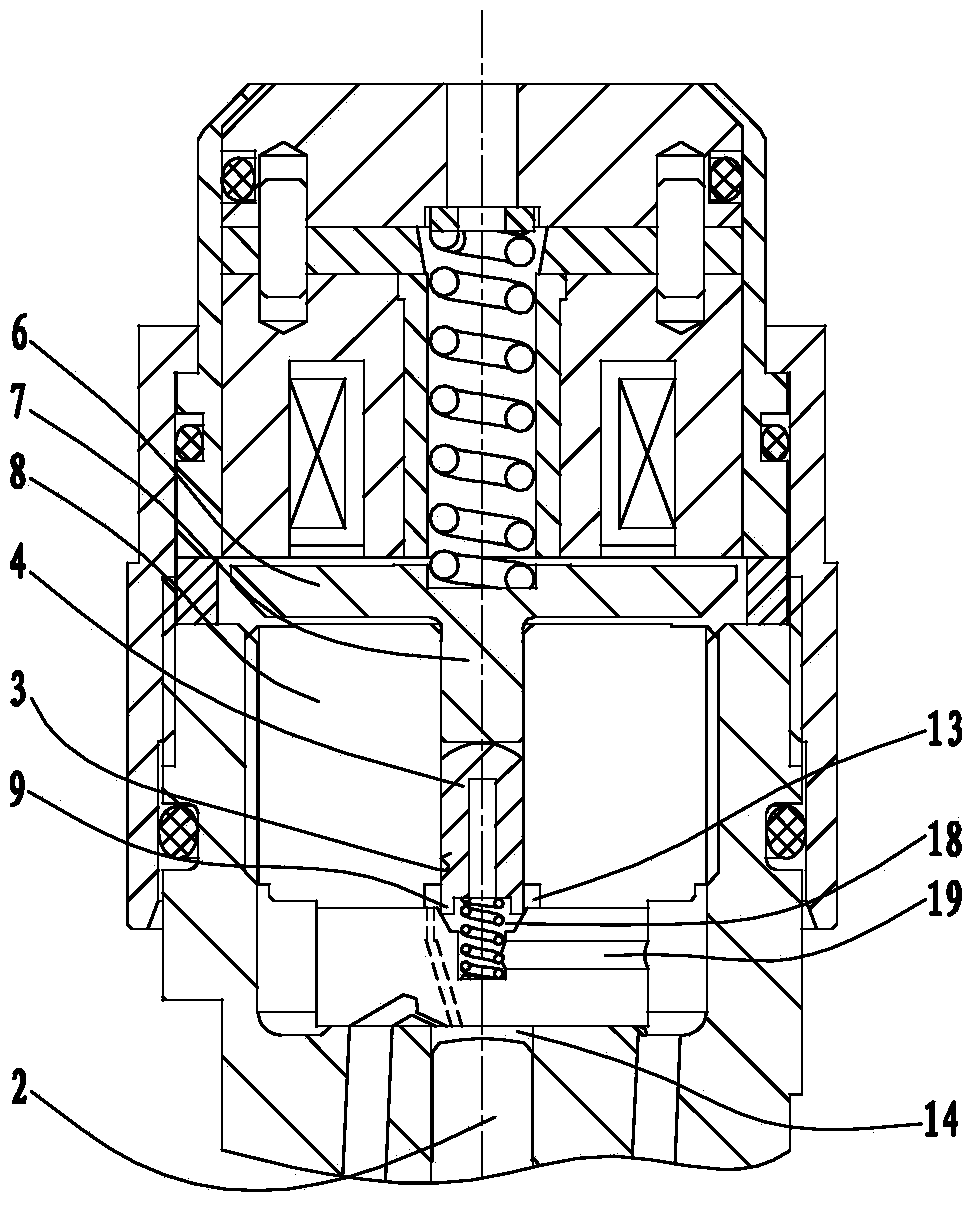

[0029] Such as figure 2 As shown, the difference between the control valve in embodiment 2 and the control valve in embodiment 1 lies in the structure of the support surface at the upper end of the throttle orifice 10 and the support surface at the lower end of the closing part 9 .

[0030] exist figure 1 In the shown embodiment, the support surface at the upper end of the throttle orifice 10 is a conical concave surface, the support surface at the lower end of the closing part 9 is a high-precision plane or conical surface, and the high-precision plane or conical surface is in contact with the sealing pin 4 The outer circular surfaces of the two meet to form a circular intersecting line, and the circular intersecting line presses down on the conical concave surface of the throttle orifice 10 to form a high-pressure sealing fit.

[0031] In order to make the leakage of high-pressure fuel in the valve chamber 13 small, the pressure of the closing part 9 on the conical concav...

Embodiment 3

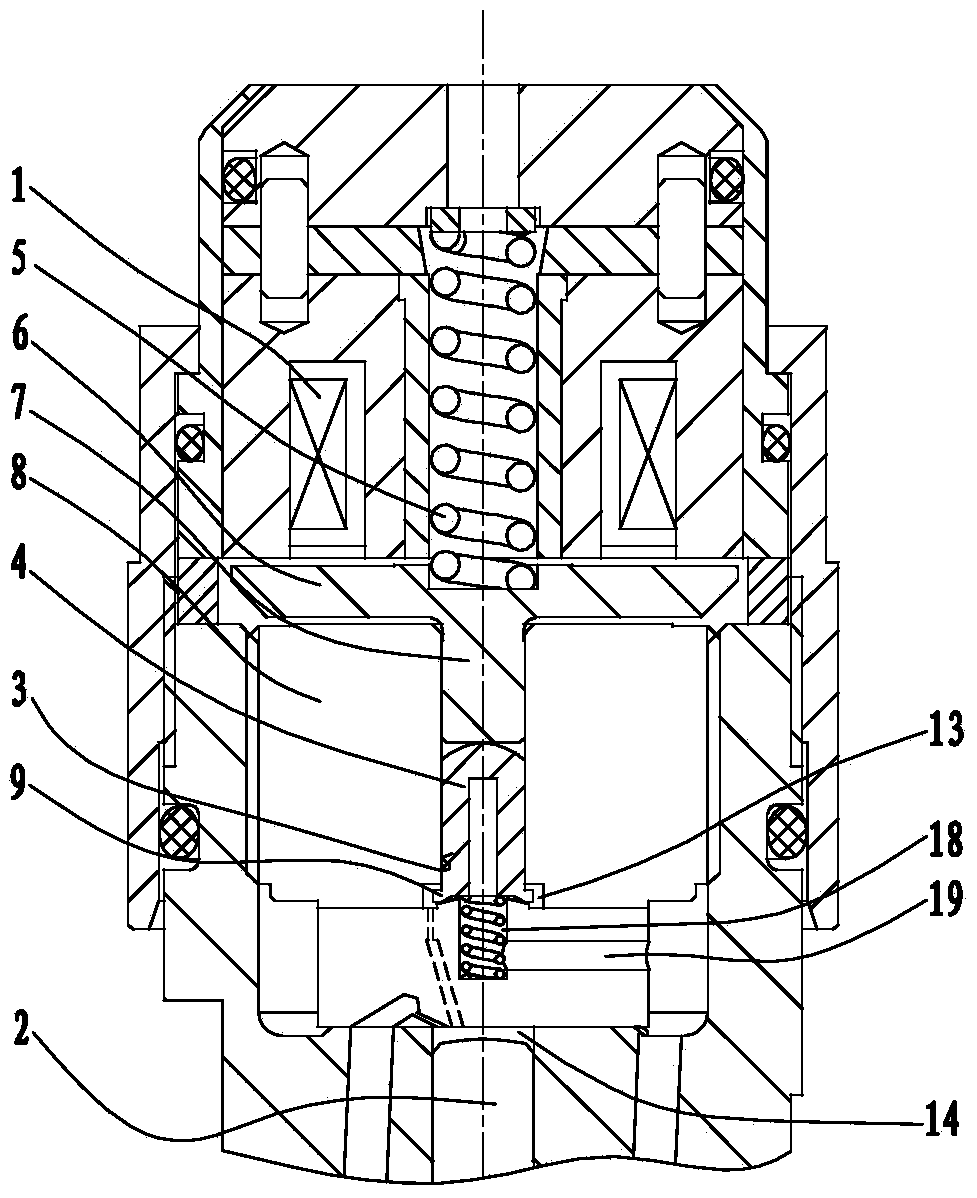

[0033] Such as image 3 As shown, the difference between the control valve in Embodiment 3 and the control valve in Embodiment 1 lies in the structure of the upper support surface of the throttle orifice 10 and the lower support surface of the closing part 9 .

[0034] exist image 3 In the shown embodiment, the support surface at the upper end of the throttle orifice 10 is a high-precision spherical convex surface, the closing part 9 is an annular platform formed by extending the lower end of the sealing pin 4 outward, and the sealing surface at the lower end of the closing part 9 is Continuing the connection of the plane and the conical surface, the plane and the conical surface meet to form a circular intersecting line, and the circular intersecting line presses down on the spherical convex surface of the throttle orifice 10 to form a high-pressure sealing fit.

[0035] In order to make the leakage of high-pressure fuel in the valve chamber 13 small, the pressure of the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com