Patents

Literature

80results about How to "Reduced fit requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for detecting human faces, device and remote teller machine system

ActiveCN106407914AReduced fit requirementsHigh speedComplete banking machinesAutomatic teller machinesPattern recognitionLight spot

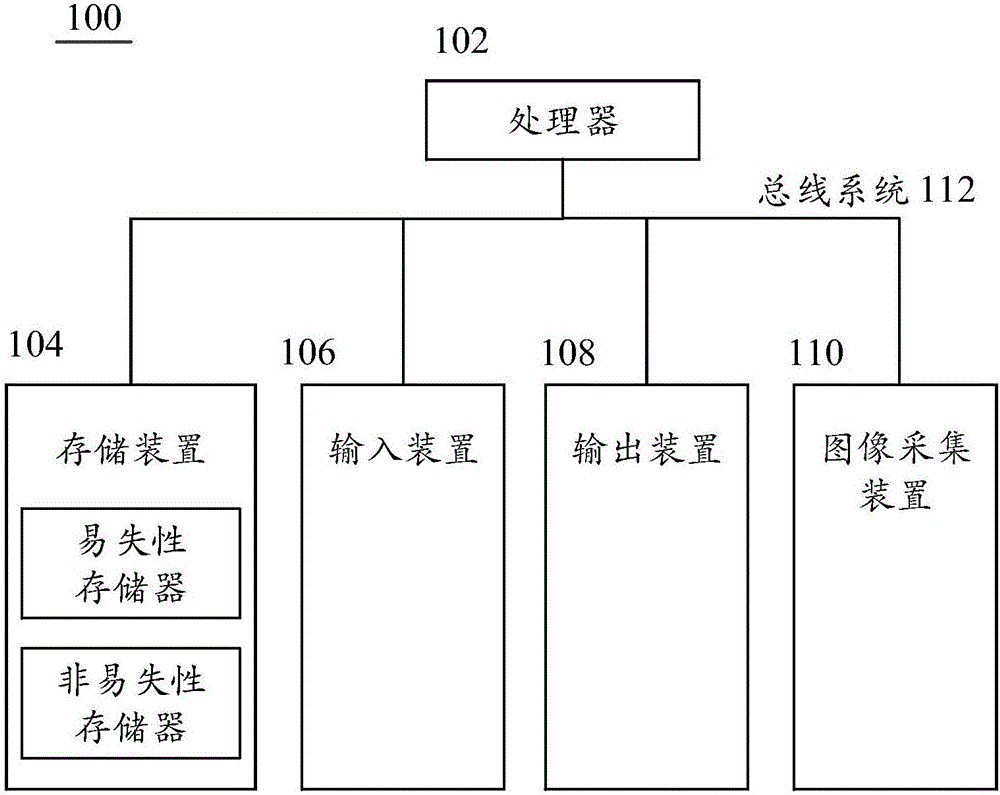

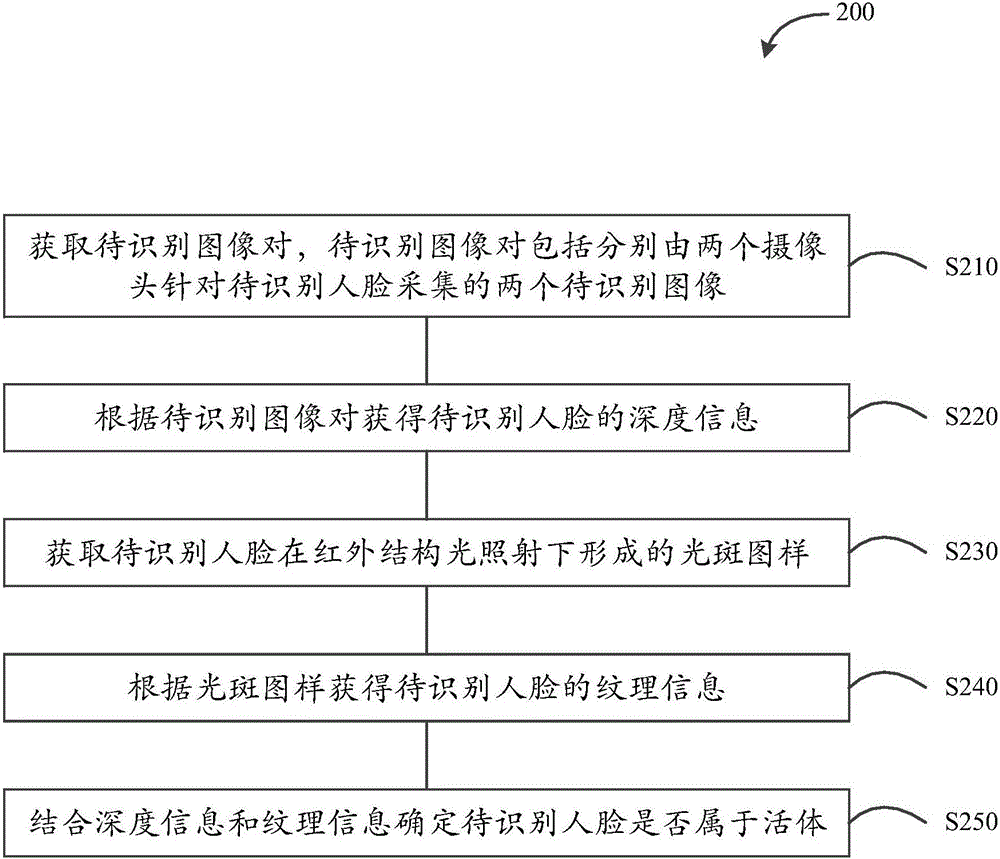

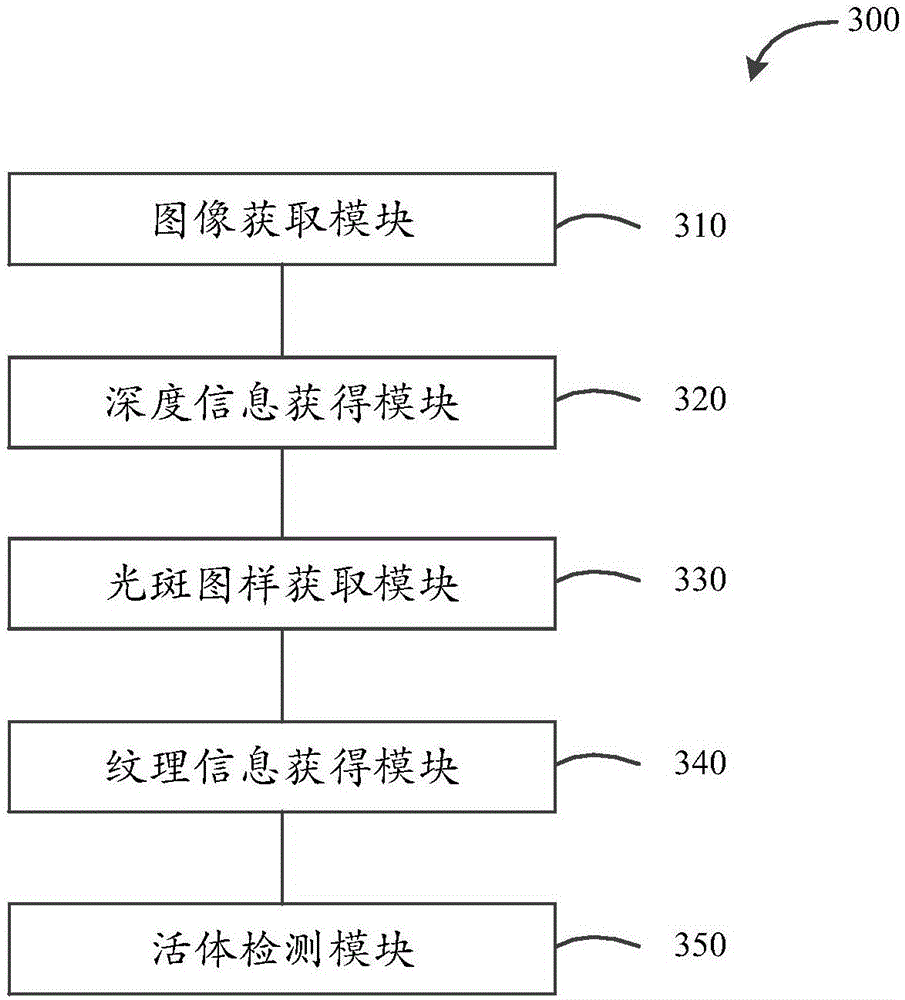

The present invention provides a method for detecting human faces, a device for detecting human faces and a remote teller machine system. The method includes the following steps that: an image pair to be recognized is acquired, wherein the image pair to be recognized includes two images to be recognized which are acquired by two cameras according to a human face to be recognized respectively; the depth information of the human face to be recognized is obtained according to the images to be recognized; a light spot pattern formed by the human face to be recognized under the illumination of an infrared structure is obtained; the texture information of the human face to be recognized is obtained according to the light spot pattern; and whether the human face to be recognized is a living body is determined based on the depth information and the texture information. The method, the device and the remote teller machine system have the advantages of low cooperation requirements, high speed and high security.

Owner:BEIJING KUANGSHI TECH +1

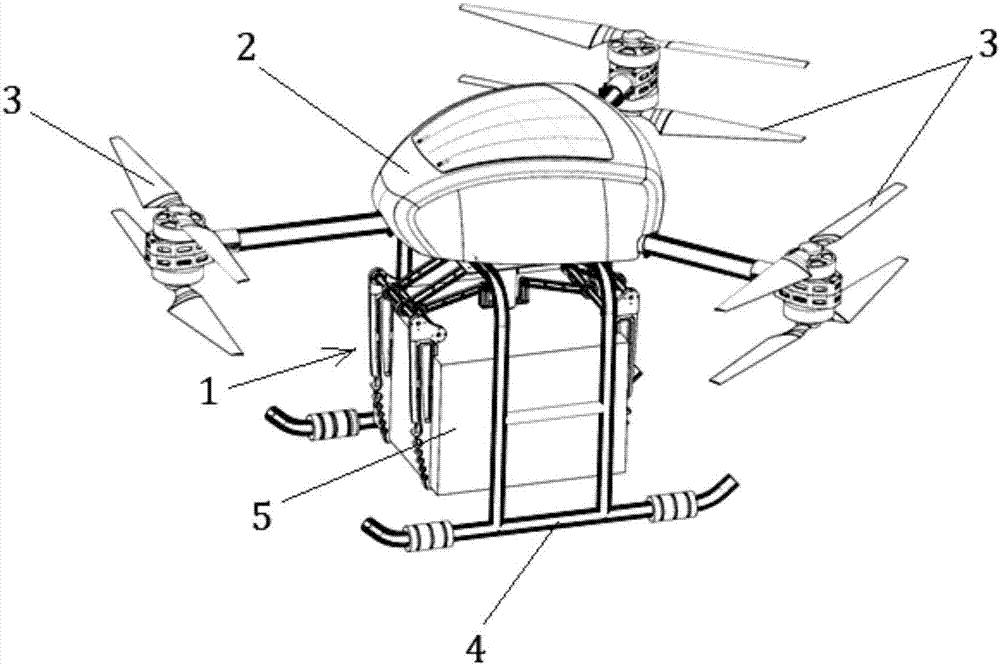

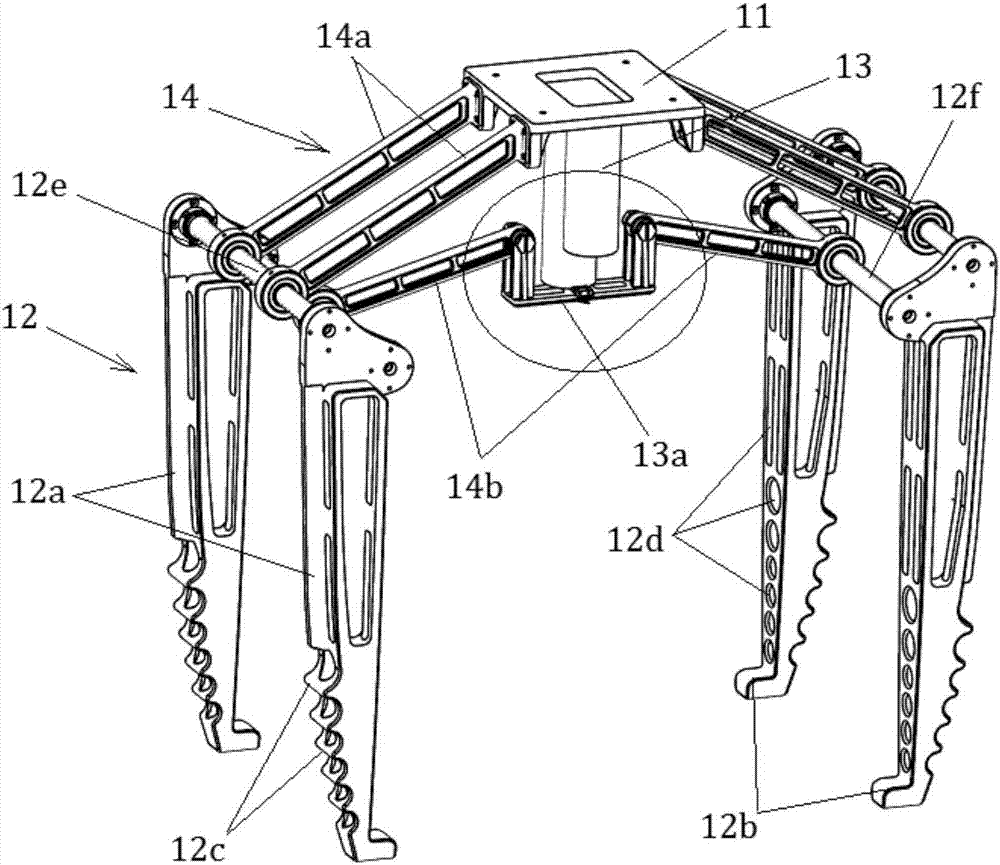

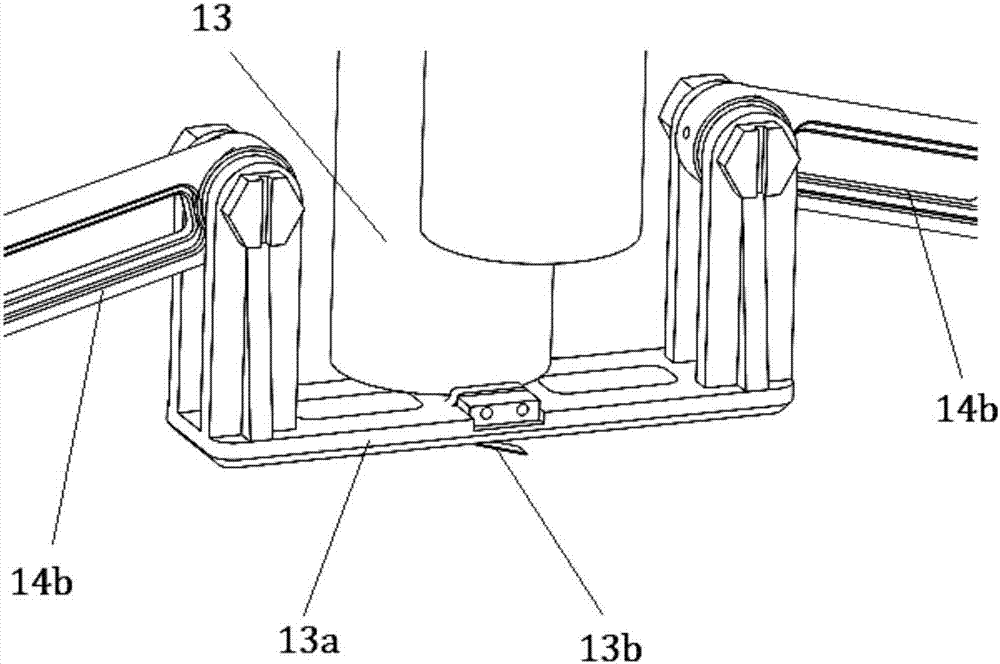

Automatic unloading carrier and unmanned aerial vehicle

PendingCN106892119AImprove carrying capacityAchieve releaseGripping headsRemote controlled aircraftUncrewed vehicleEngineering

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

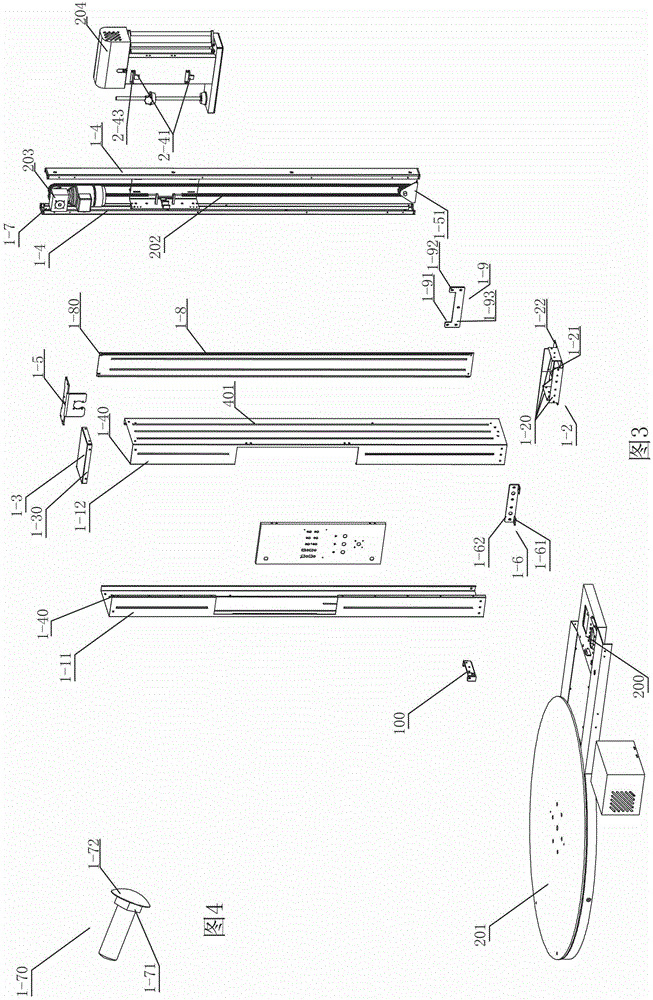

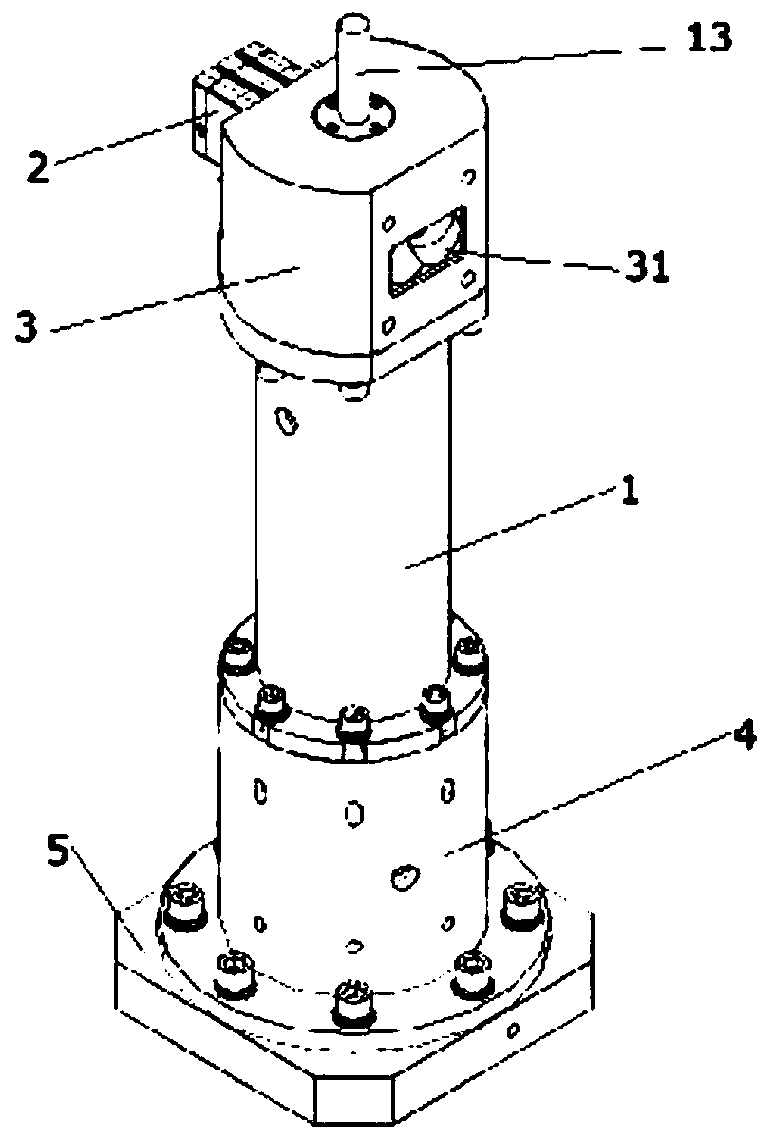

Winding machine

ActiveCN103332316AReasonable structureEliminates welding operationsWrappingWinding machineEngineering

The invention provides a winding machine. The winding machine comprises a stand column, a winding machine base, a rotary mechanism and a membrane frame, wherein the bottom of a stand column shell main body is hinged with the winding machine base through a first connection piece, and the stand column shell main body and the winding machine base are connected through a first stand column cover plate and a second stand column cover plate to form a column shape; the winding machine is provided with a stand column bottom inner side connection piece and the inner side connection piece is provided with a stand column outline sizing surface; the stand column is internally provided with a hoisting device supporting frame; the lower end of the supporting frame is connected with the bottom inner side connection piece; the upper end of the supporting frame is connected with a top mounting rack of a hoisting device; a bottom mounting rack of the hoisting device is connected with the bottom inner side connection piece; all the parts are connected by using bolts or screws; and a groove opening for hoisting movement is reserved on the stand column shell main body between the first stand column cover plate and the second stand column cover plate. The winding machine disclosed by the invention is reasonable in structure; a main body structure of the stand column can be assembled in a manufacturing factory by using the bolts or the screws and is hinged with the winding machine base, so as to avoid welding operation; and the winding machine is beautiful in appearance and is applicable to installation and debugging, and transportation.

Owner:HANGZHOU YOUNGSUN INTELLIGENT EQUIP

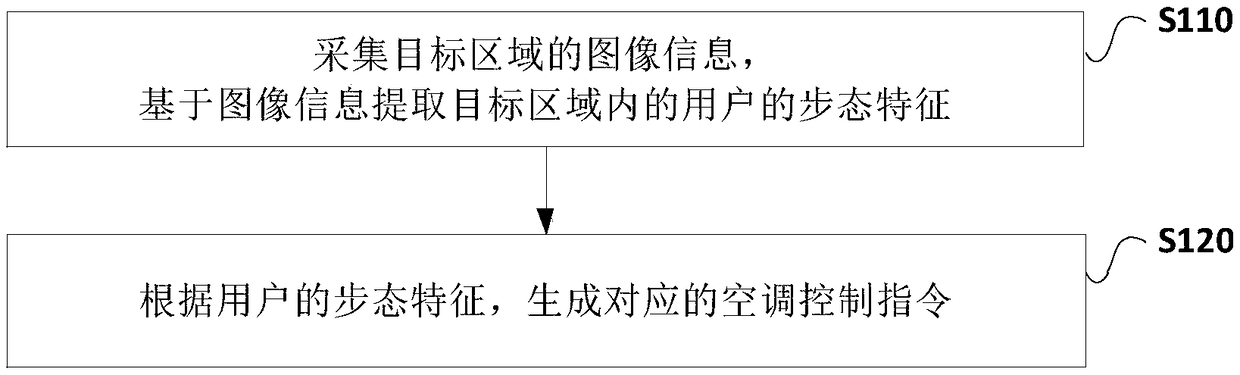

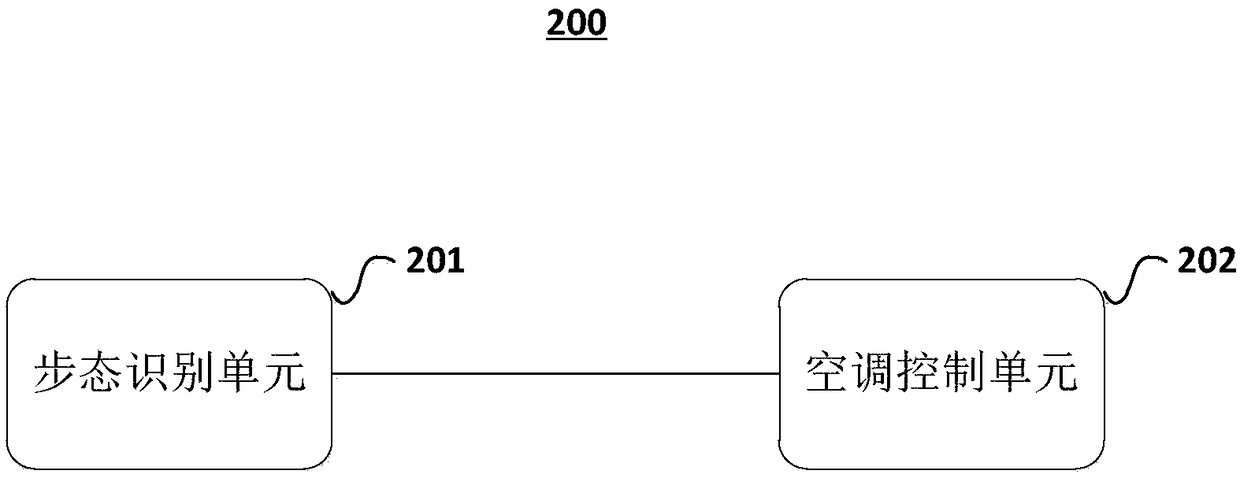

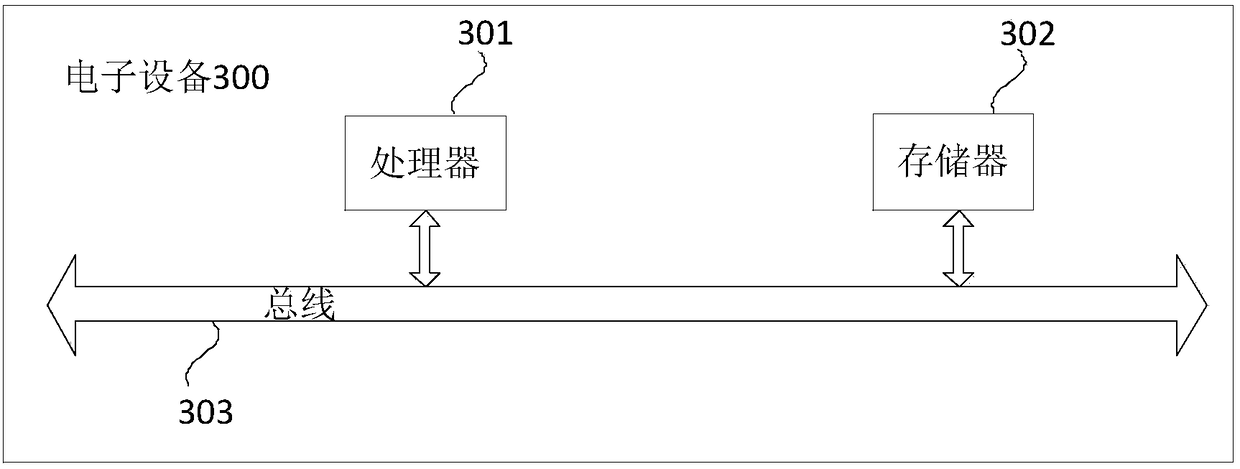

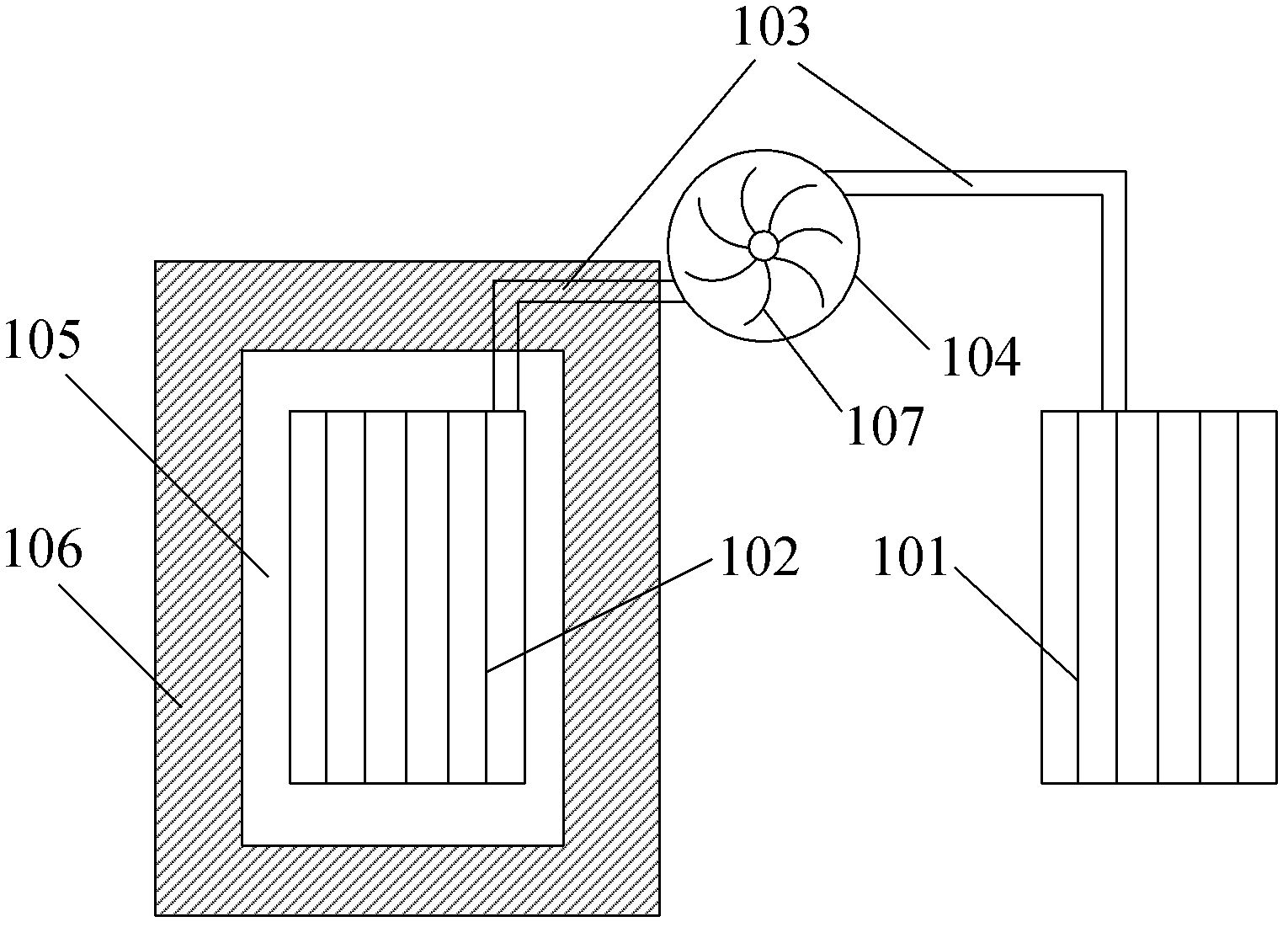

Control method and device of air conditioning system

ActiveCN108224691AReduced fit requirementsImprove experienceMechanical apparatusSpace heating and ventilation safety systemsAir conditioningGait

The invention provides a control method and device of an air conditioning system. The method comprises the following steps: acquiring image information of a target area; extracting gait characteristics of a user within the target area based on the image information; and generating a corresponding air conditioner control command based on the gait characteristics of the user. The method is used forperforming the abovementioned method. With the adoption of the method and the device, the requirements on user supporting are decreased, and moreover, personal service is supplied to the user, and thus the user experience is increased.

Owner:WATRIX TECH CORP LTD

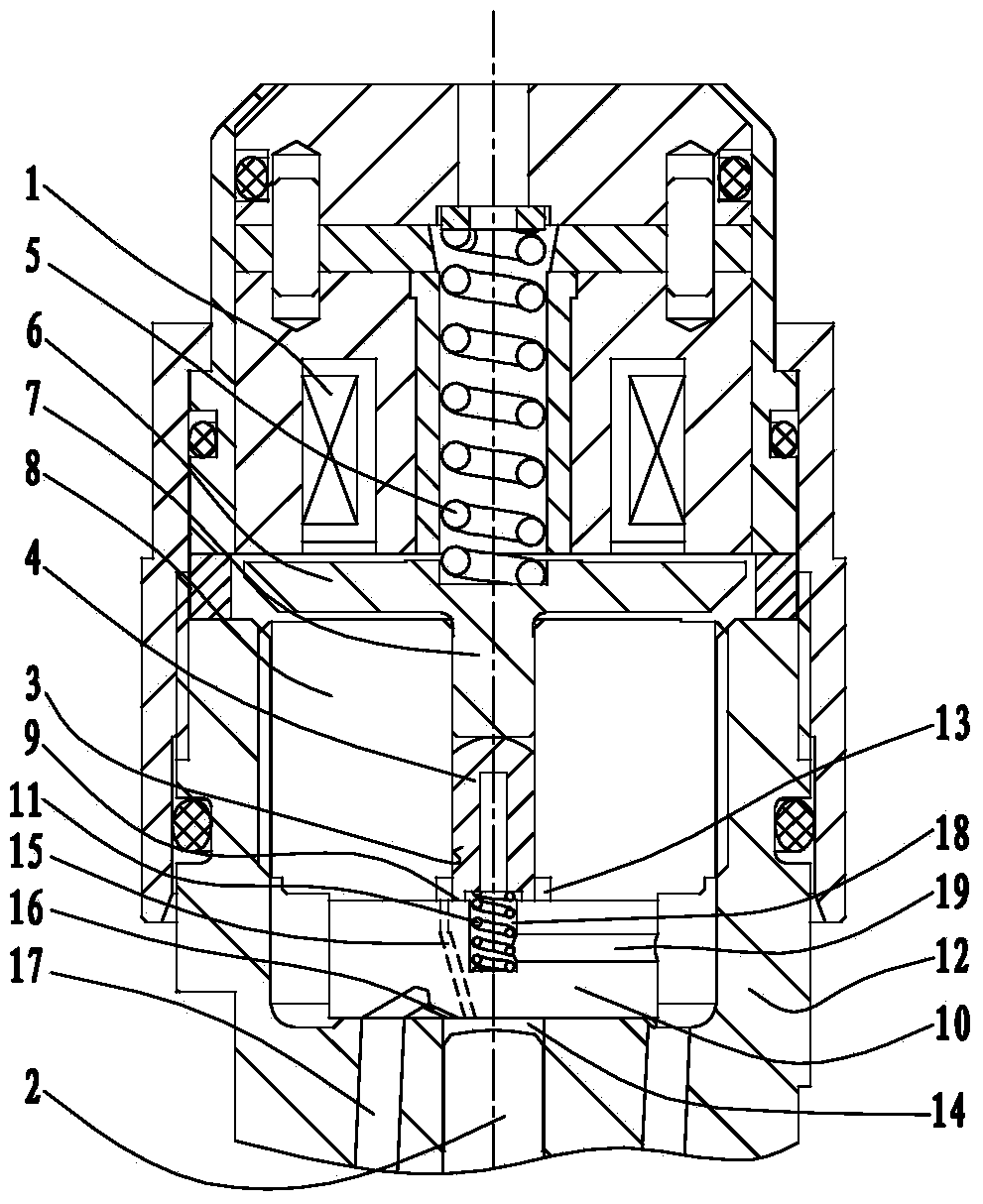

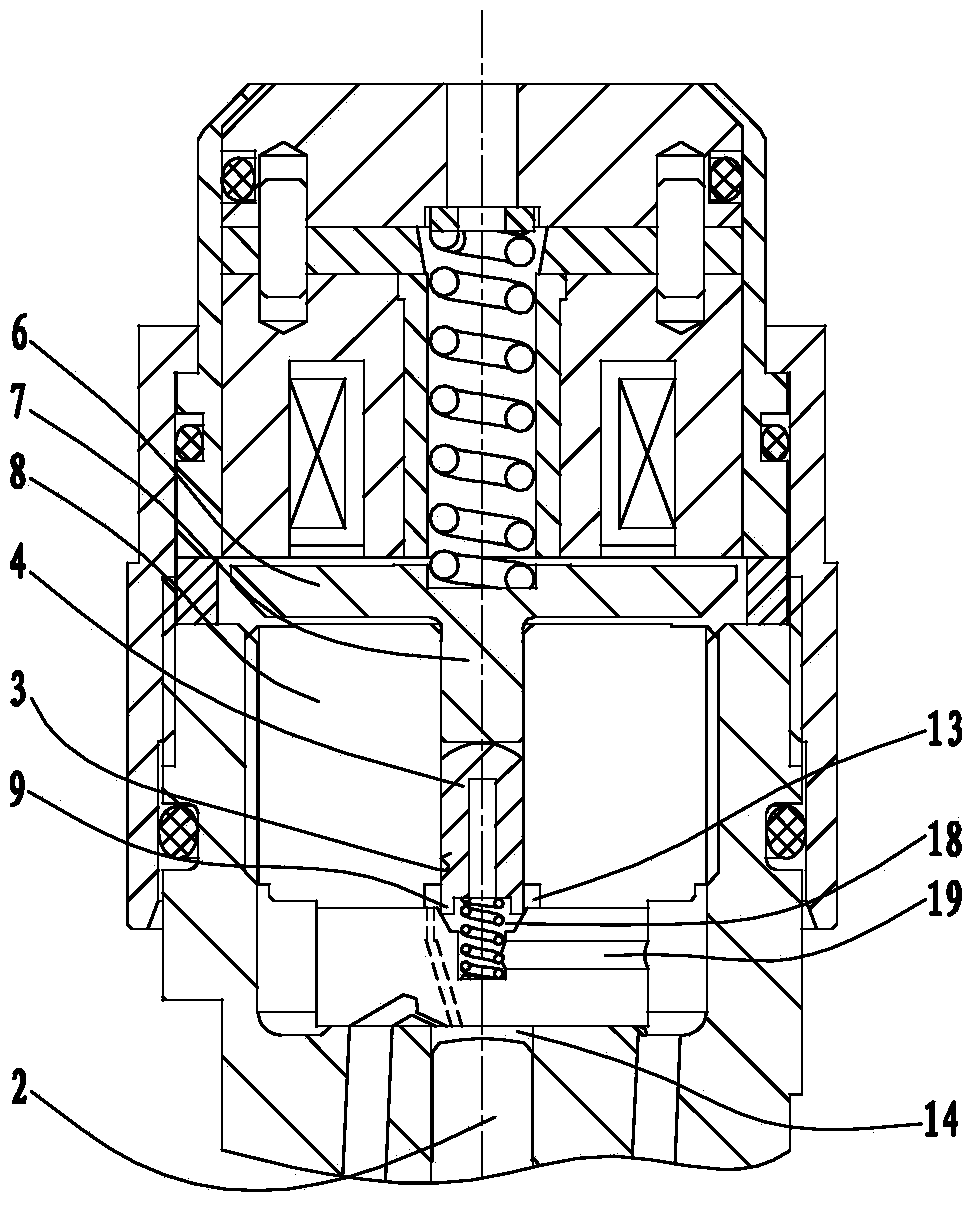

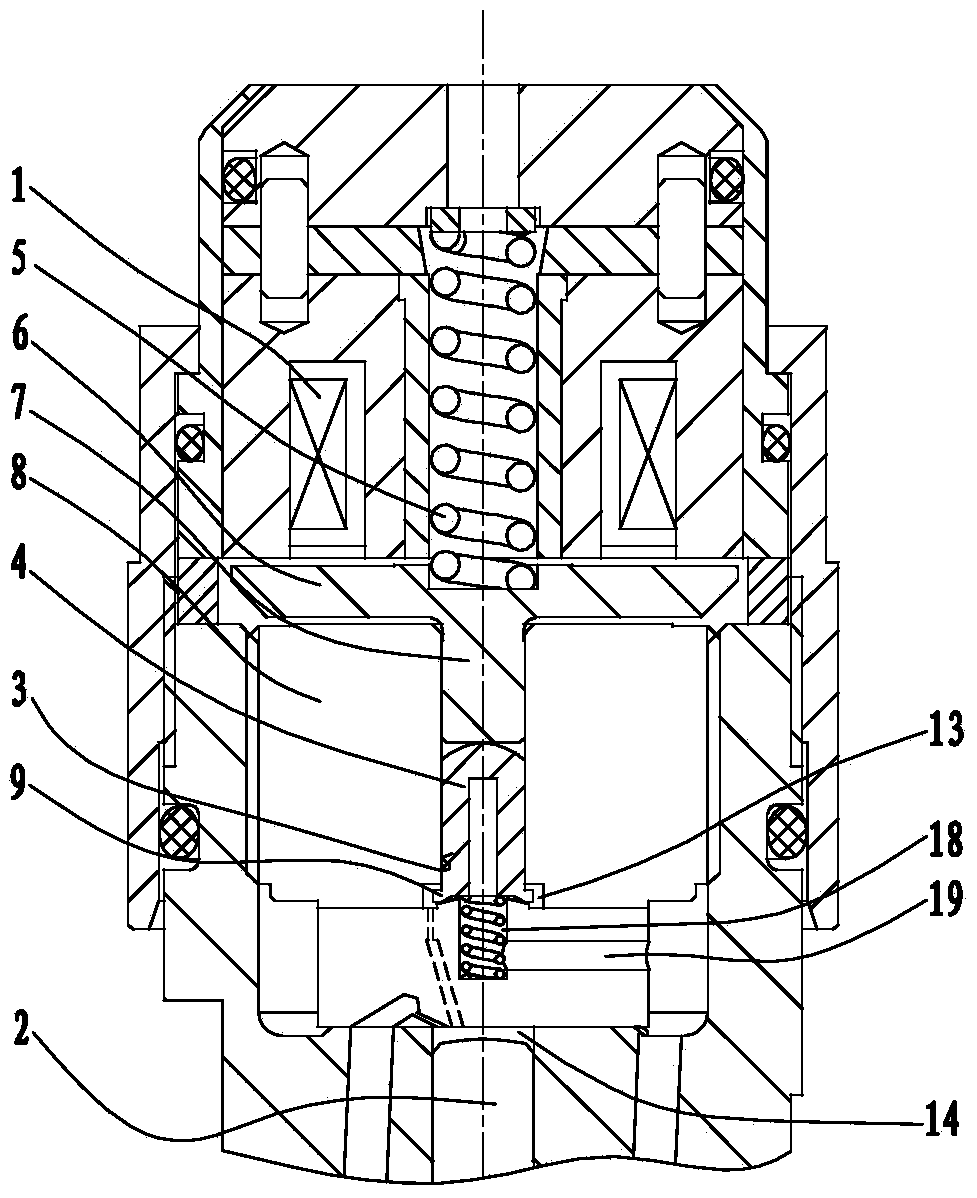

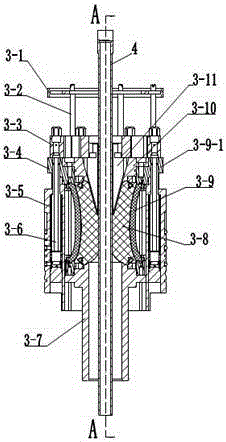

Step mechanical speed changer without power transmission interruption during gear shift

ActiveCN101806359ATorsional Vibration and Noise MitigationReduced fit requirementsControlled membersGearing controlClutchVariator

The invention relates to a step mechanical speed changer without power transmission interruption during gear shift. The common gear shift composite set (synchronizer or shift sleeve assembly) of a step mechanical speed changer is replaced by a polymorphic controllable clutch assembly which is controlled by an actuating component and has the functions of a free-wheel or overdrive clutch. The free-wheel clutch, which is used as the basic part for mechanical transmission, can be improved in a controllable way to obtain the polymorphic controllable clutch, so that the clutch can be switched among multiple working positions in a partially or totally controlled way. The polymorphic controllable clutches in all the gears are controlled, combined and switched in a reasonable way, thereby realizing the function of no power transmission interruption during bidirectional gear shift.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

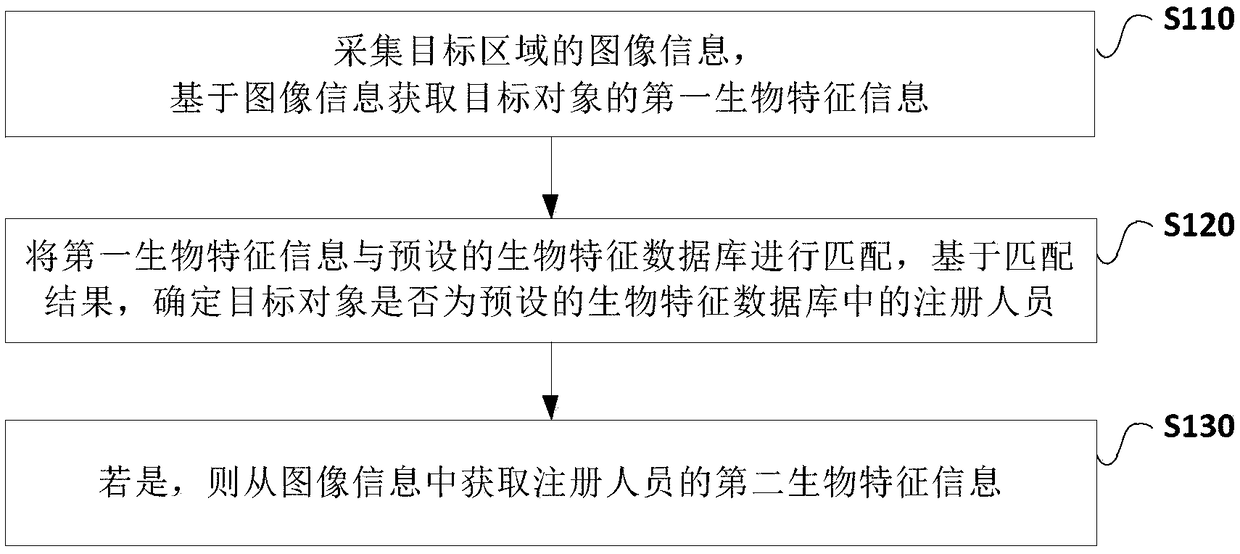

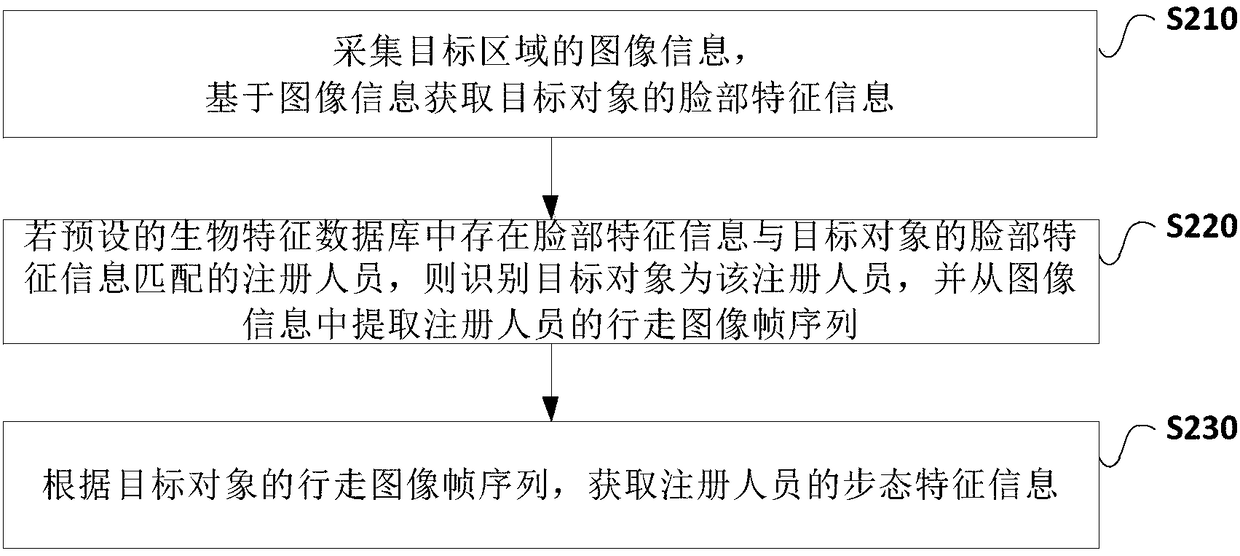

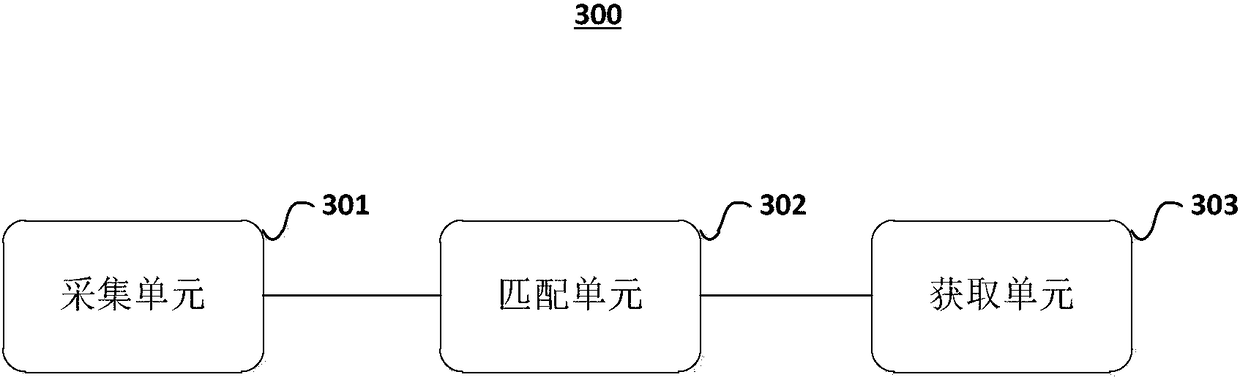

Bio-feature information obtaining method and apparatus

ActiveCN108171138AImprove accuracyImprove acquisition efficiencyMultiple biometrics useBiometric dataData mining

The invention provides a bio-feature information obtaining method and apparatus. The method comprises the steps of collecting image information of a target region, and based on the image information,obtaining first bio-feature information of a target object; matching the first bio-feature information with a preset bio-feature database, and based on a matching result, determining whether the target object is a registered person in the preset bio-feature database or not; and if yes, obtaining second bio-feature information of the registered person in the image information. The apparatus is usedfor executing the method. According to the method and the apparatus provided by the invention, the cooperation requirements of the registered person can be lowered; and the accuracy and efficiency ofobtaining the bio-feature information can be improved.

Owner:银河水滴科技(宁波)有限公司

Overhead escape device of light rail

InactiveCN101898015ASimple structureDeceleration principle is clearBuilding rescueStatic frictionLight rail

The invention discloses an overhead escape device of a light rail. The device comprises an outer shell and an inner shell positioned in the outer shell, wherein an escape rope is arranged in the inner shell and two ends of the escape rope run through the same side of the outer shell and inner shell; a retarding mechanism is arranged in the inner shell and mainly comprises a round static friction block and two round kinetic friction blocks; the two movable friction blocks are symmetrically positioned on two sides of a centre line of the static friction block; the escape rope sequentially winds over one movable friction block, the static friction block and the other movable friction block; and the centre of the static friction block deviates for a certain distance from the connection line of the centres of the two movable friction blocks so that the escape rope forms a certain wrap angle with the kinetic friction blocks. The device has the advantages of low cost, convenient use, simple structure, reliable performance and convenient maintenance. The required time for the whole landing process is short and the device can be repeatedly and uninterruptedly used so that many people can conveniently and quickly escape.

Owner:CHONGQING UNIV OF TECH

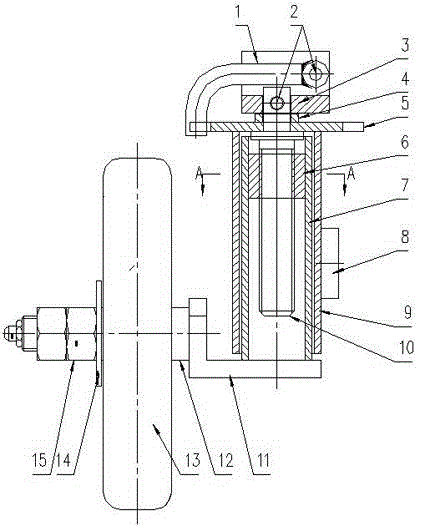

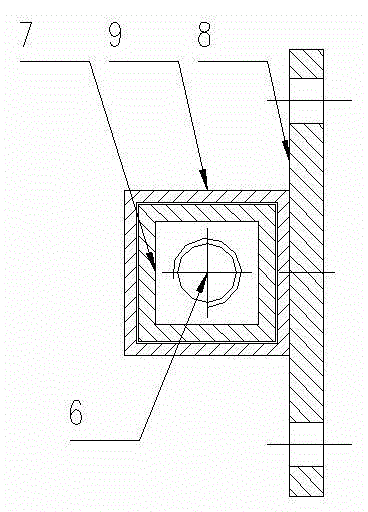

Control valve for oil atomizer

ActiveCN104265532AOpen quicklyQuick closeFuel injection apparatusMachines/enginesEngineeringControl room

The invention relates to a control valve for an oil atomizer. The control valve comprises electromagnets, a sealing bolt pin, electromagnet springs, an armature, an armature guide rod, control valve bases, a restriction orifice and an oil atomizer body. The control valve is characterized in that the sealing bolt pin is arranged in inner holes of the control valve bases; a high-pressure sealing face is formed by the outer circle surface of the sealing bolt pin and the inner holes of the control valve bases; a valve chamber is defined by the sealing bolt pin, the control valve base and the restriction orifice and is communicated with a control chamber through an oil outlet path; the sealing bolt pin is in rigid connection with the armature guide rod and is pressed on a supporting face at the upper end of the restriction orifice under downward elastic force of the electromagnet springs; a closed portion is arranged on the lower end face of the sealing bolt pin; a high-pressure sealing face is formed by the supporting face of the lower end of the closed portion and the supporting face of the upper end of the restriction orifice; a blind hole is formed in the center of the restriction orifice; an oil returning cavity is formed between the blind hole and the lower end face of the sealing bolt pin and is communicated with an oil returning channel. The control valve can be closed only through small spring pre-tightening force.

Owner:CHINA FAW LIMITED WUXI FUEL INJECTIONEQUIP RES INST +1

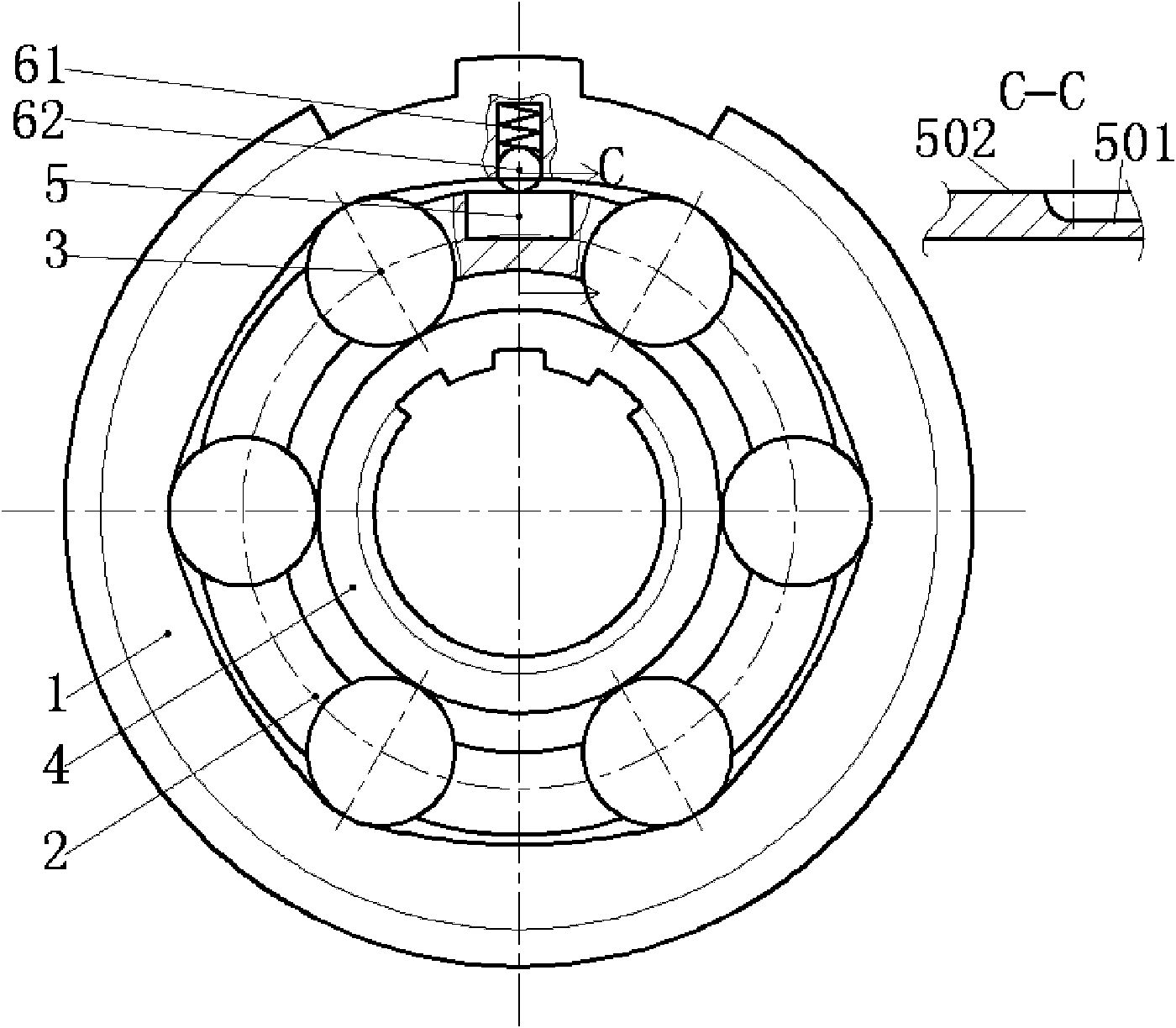

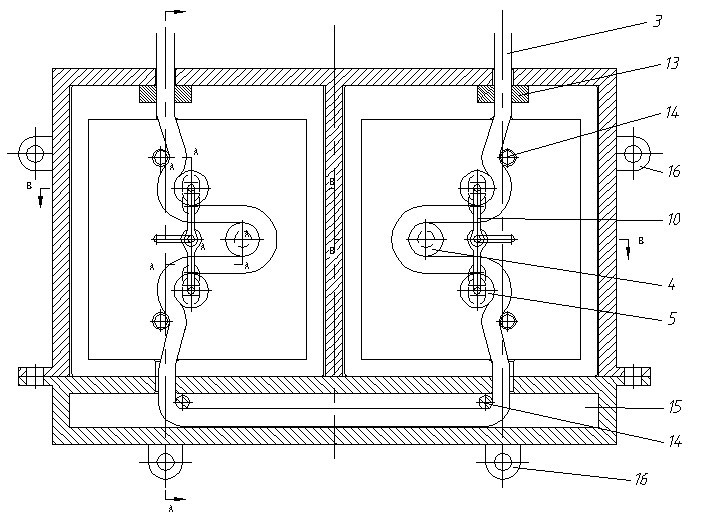

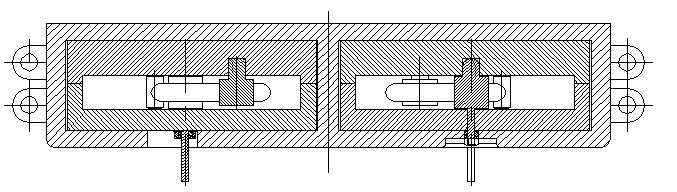

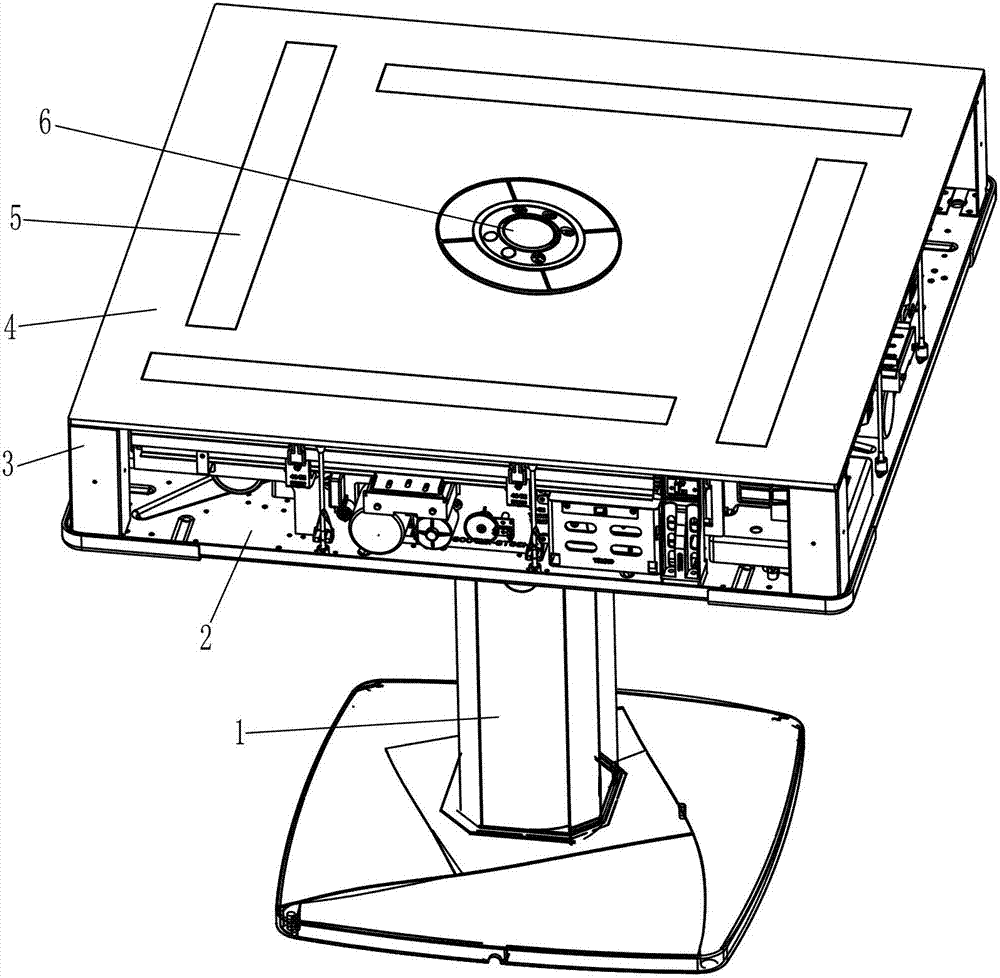

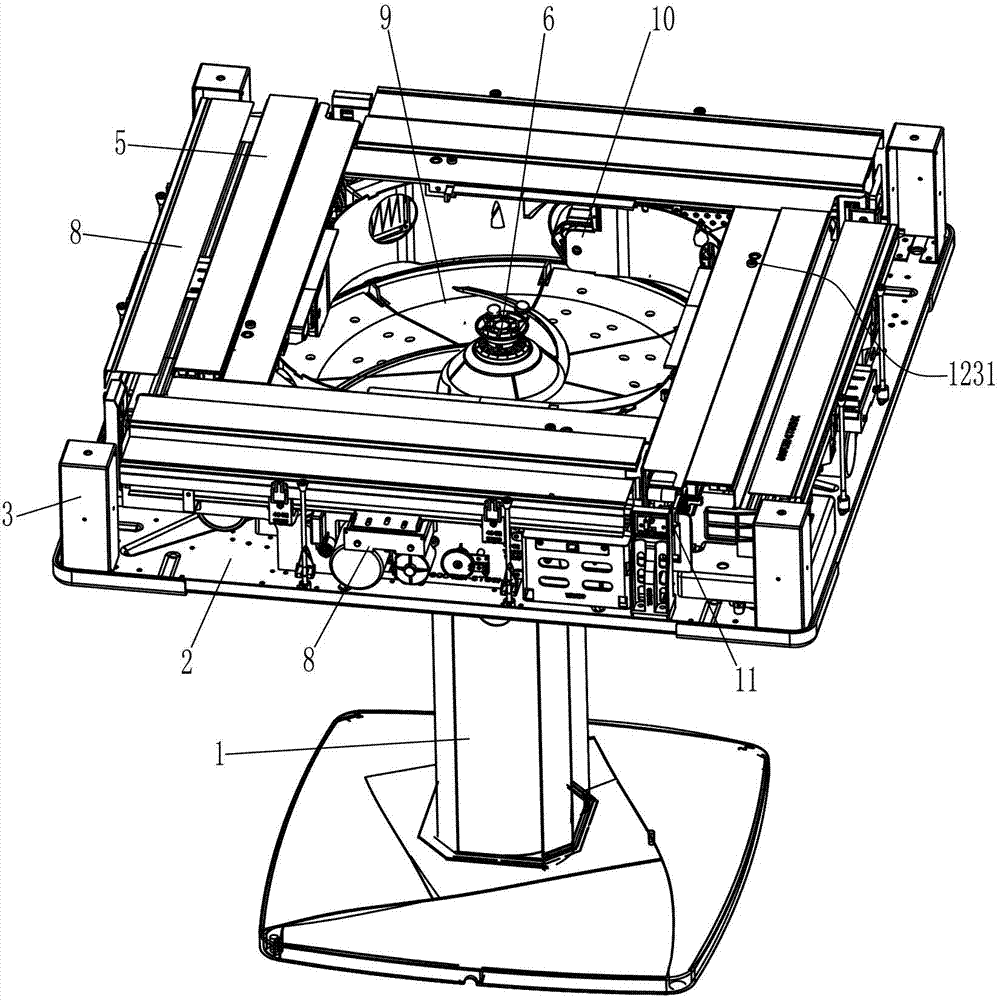

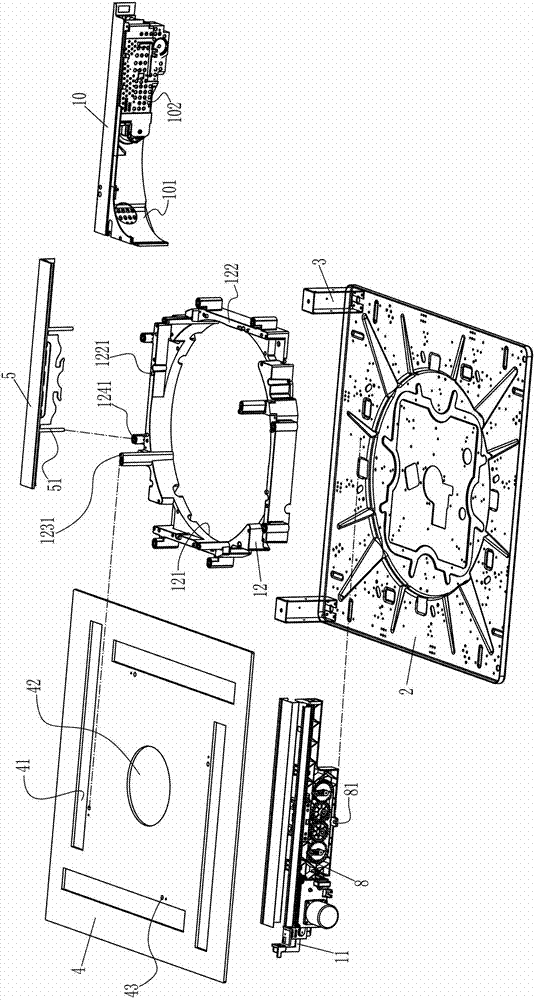

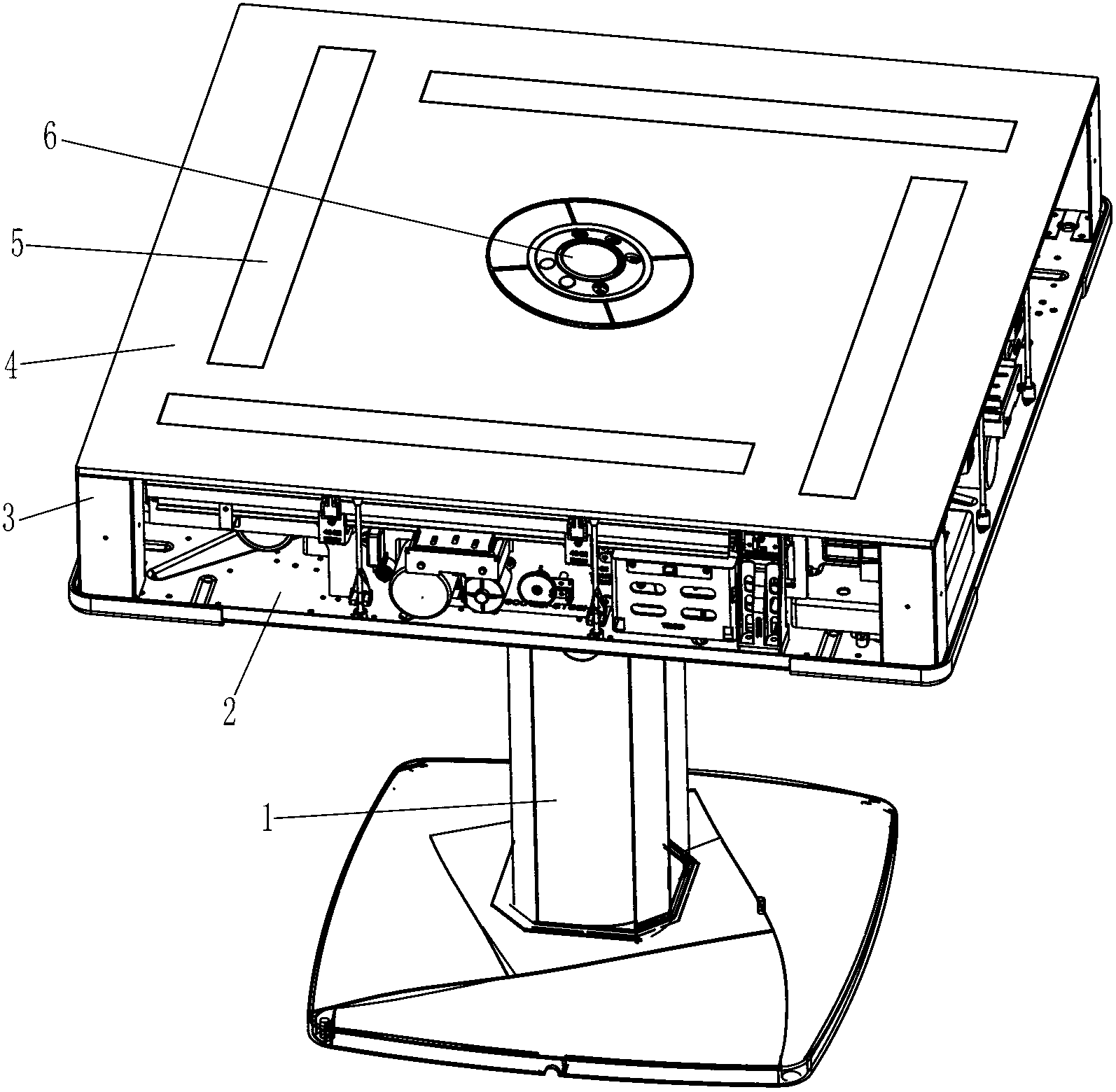

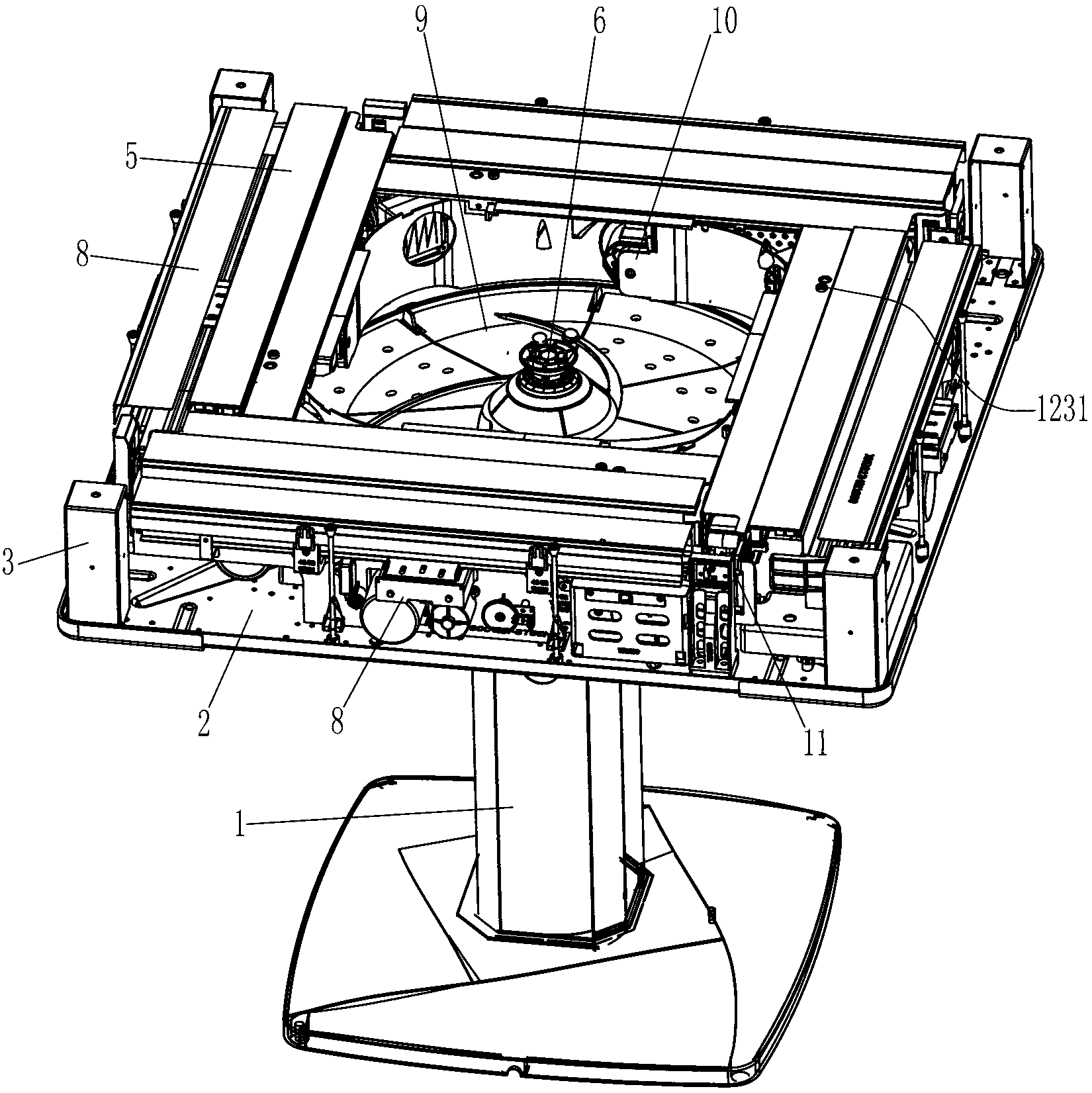

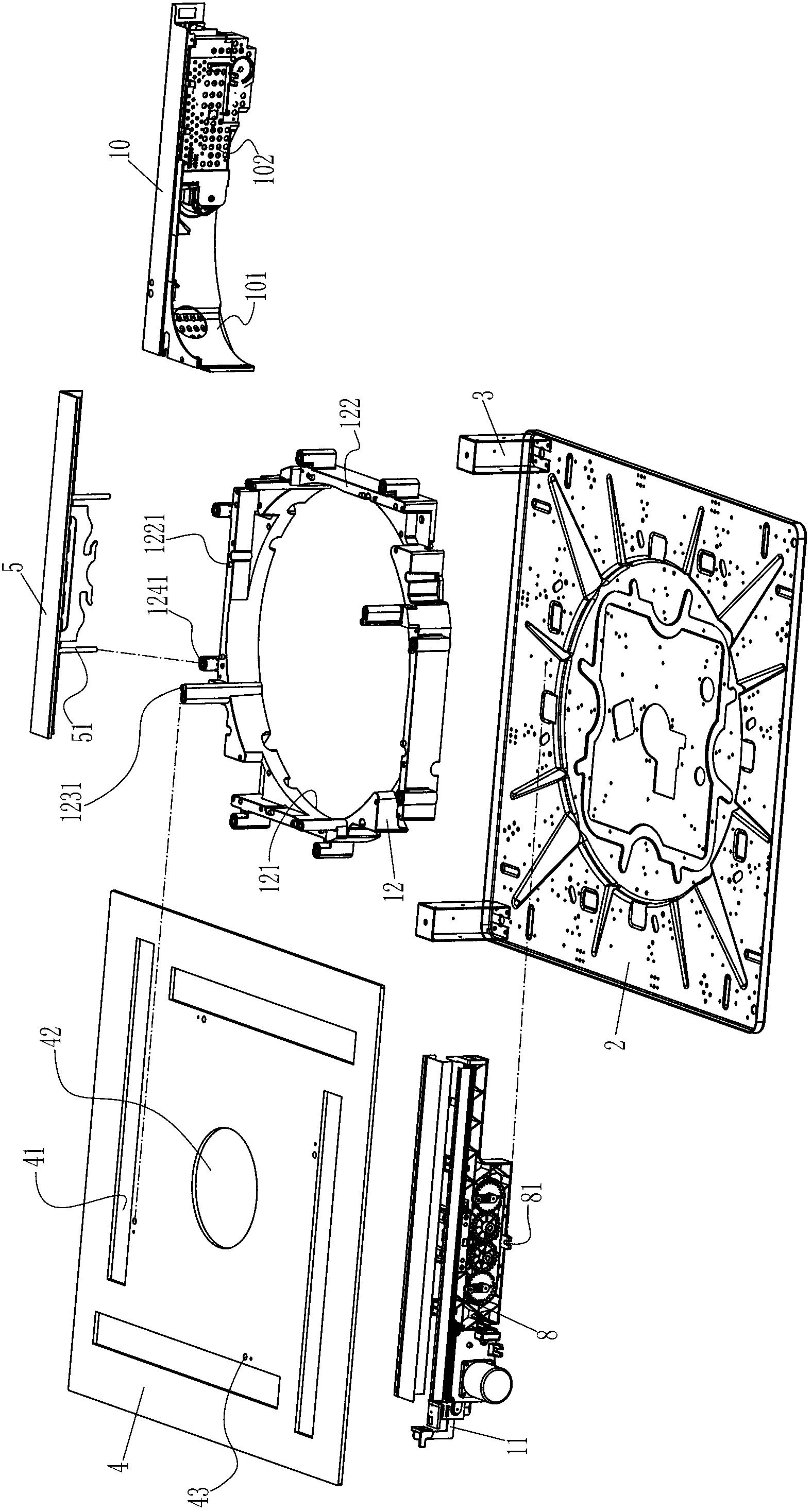

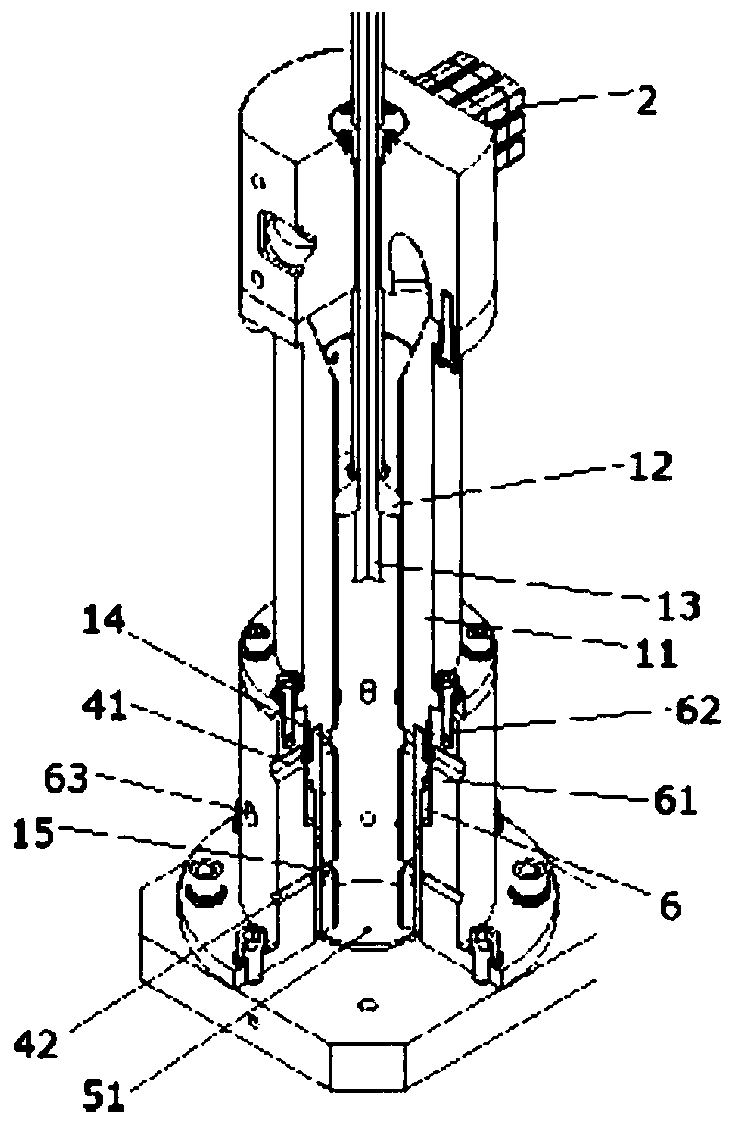

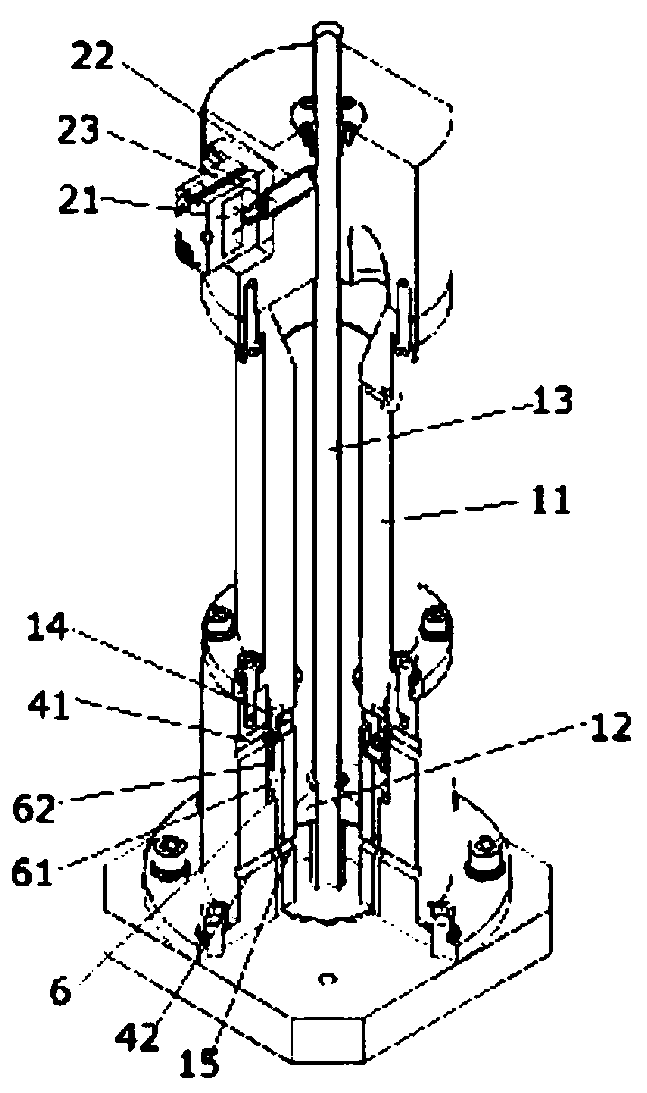

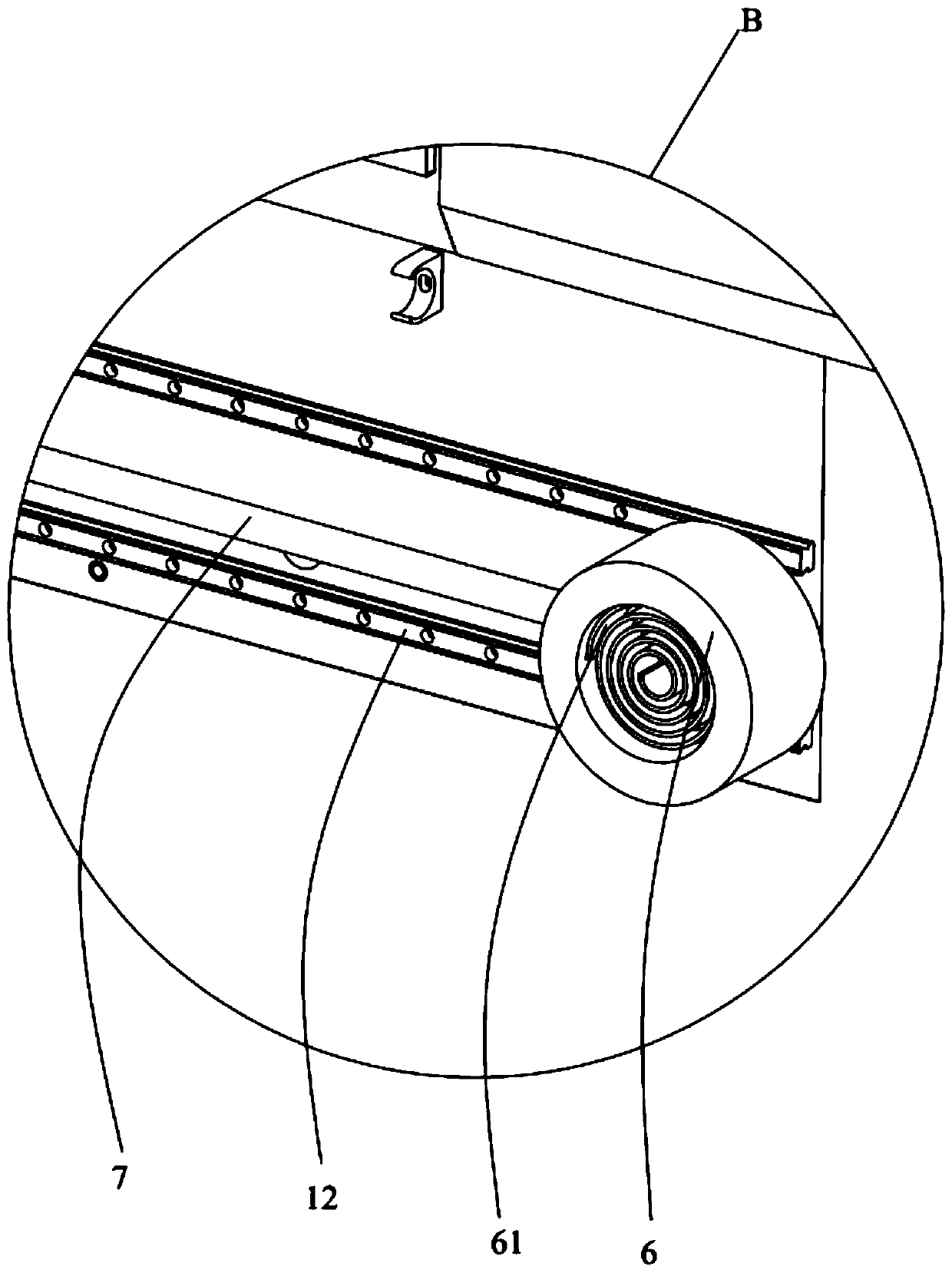

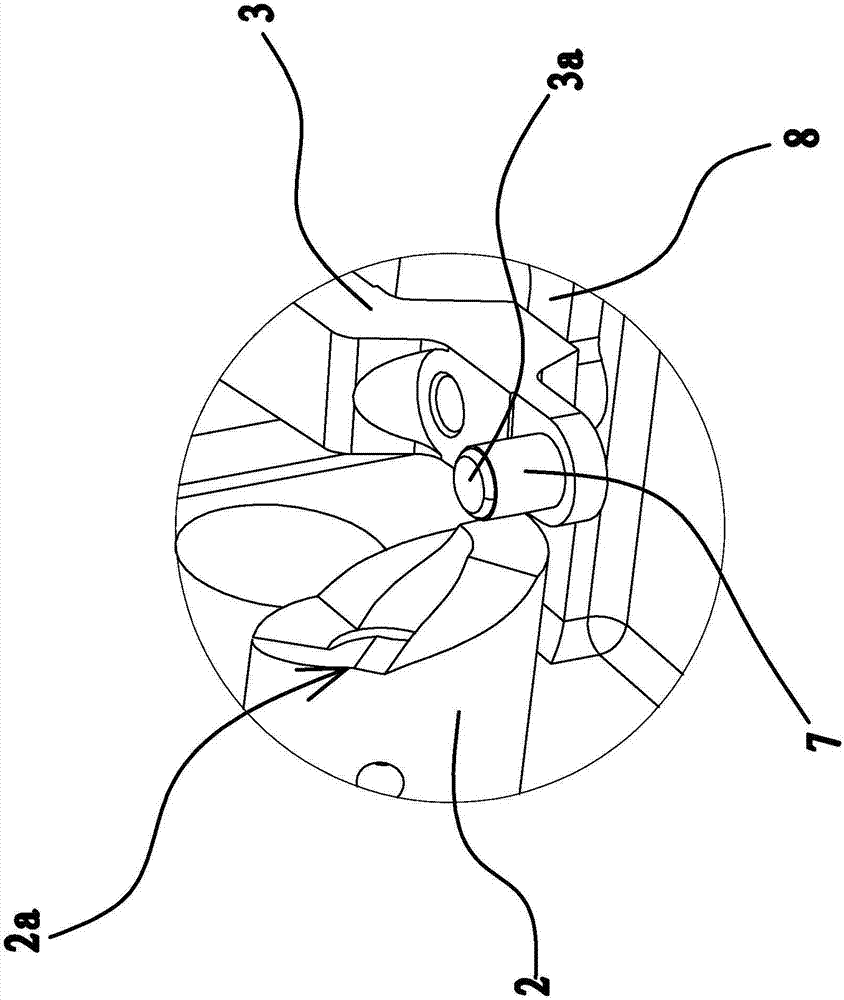

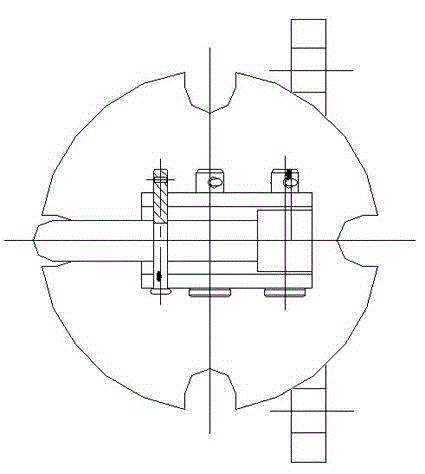

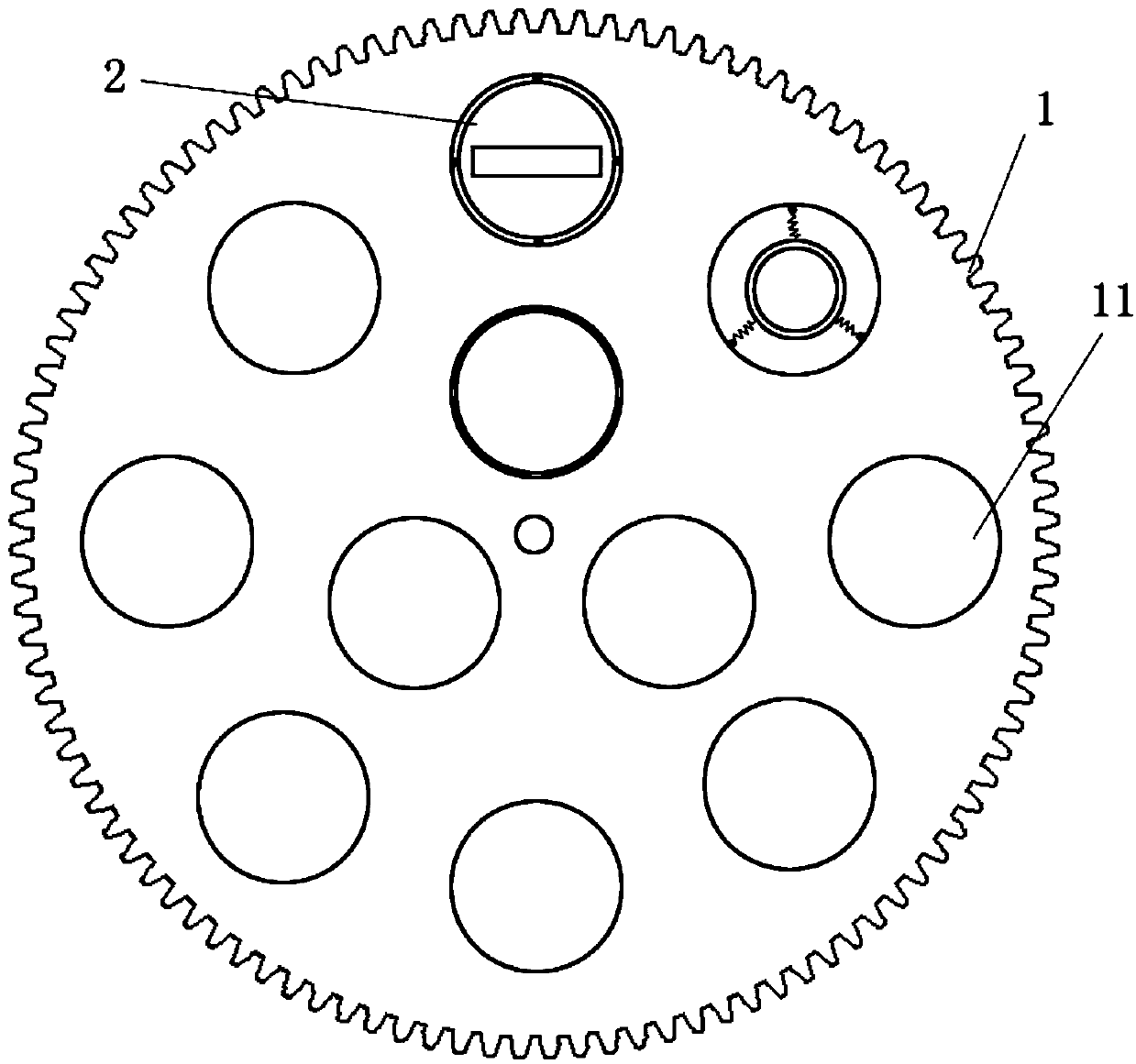

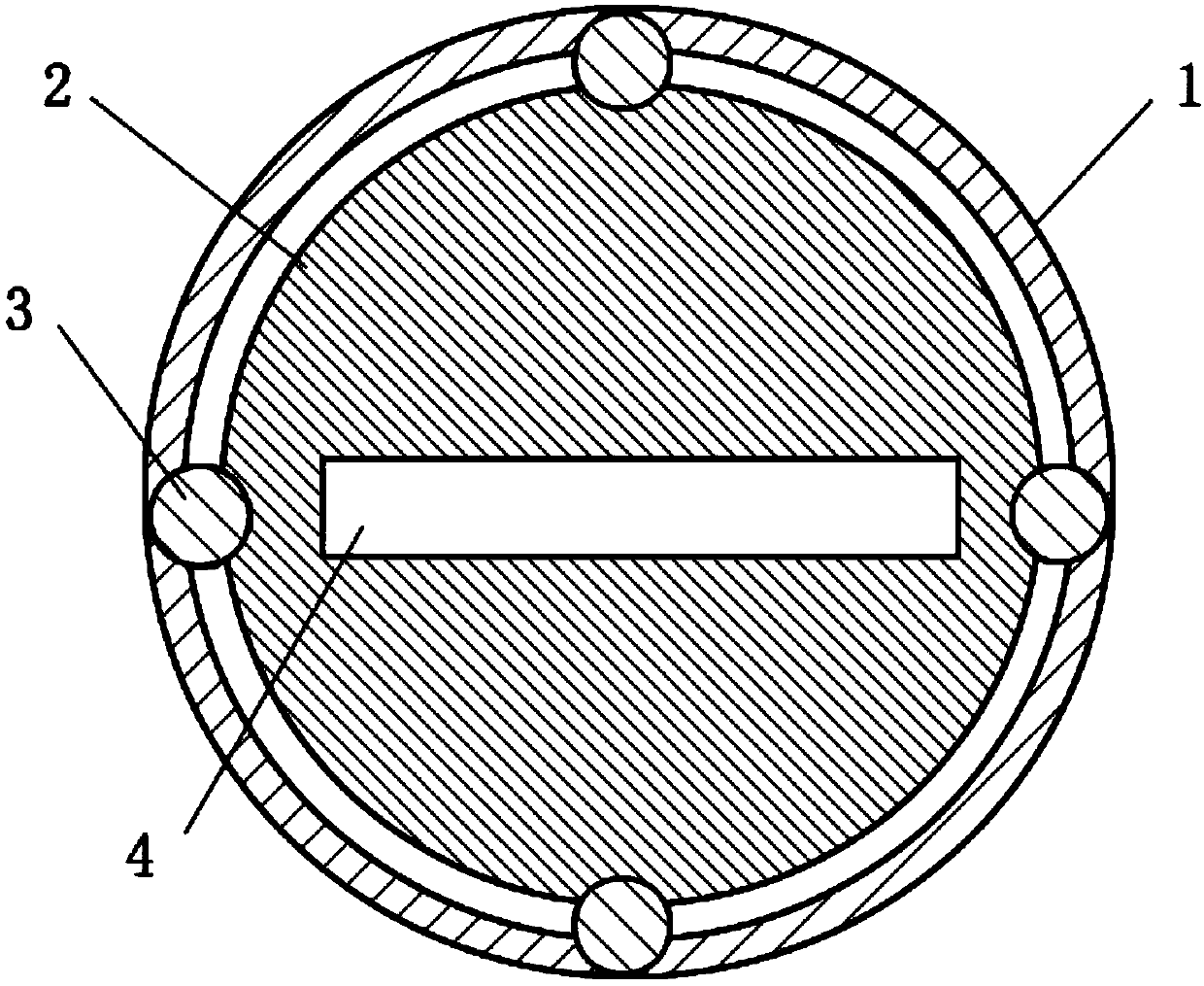

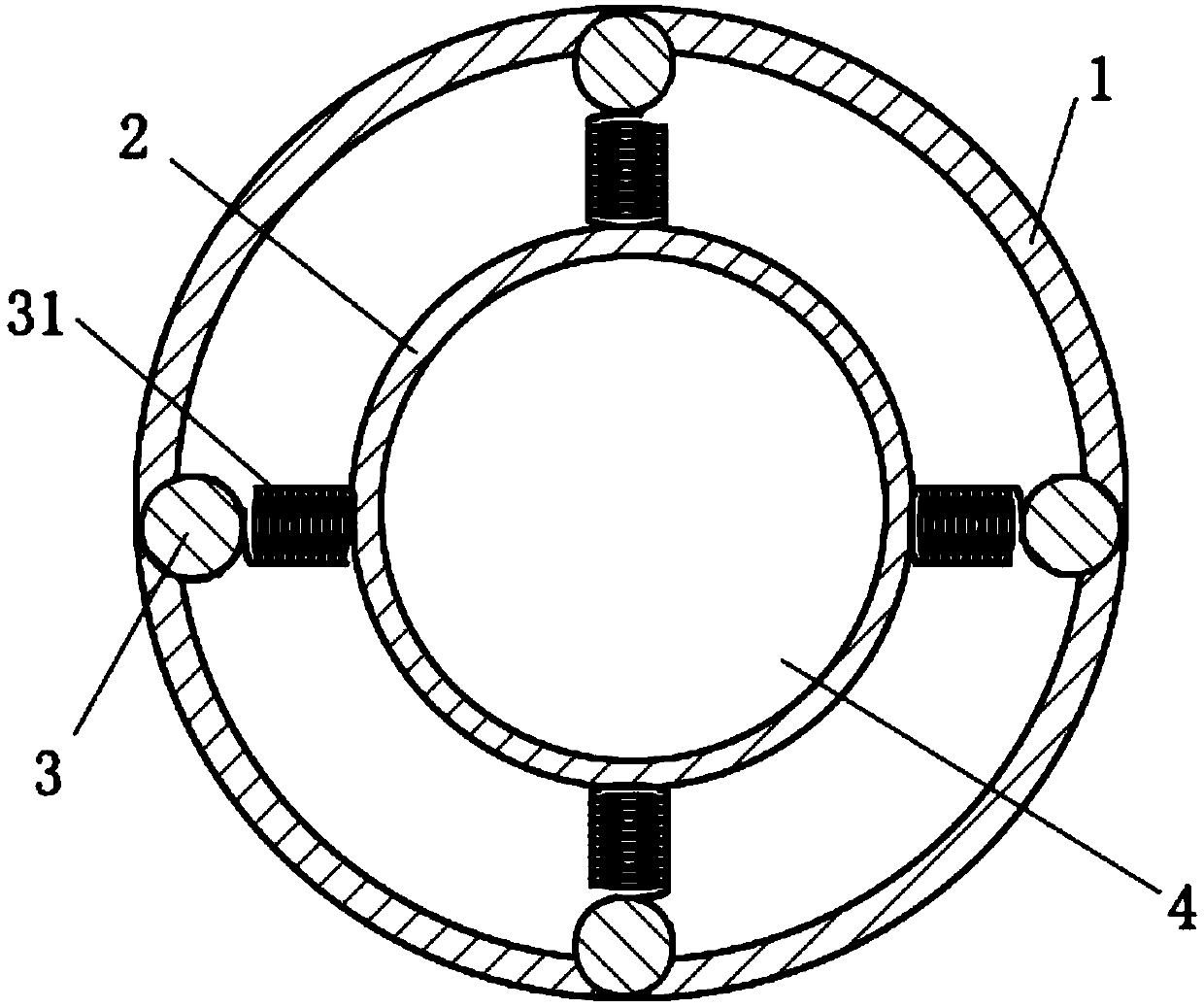

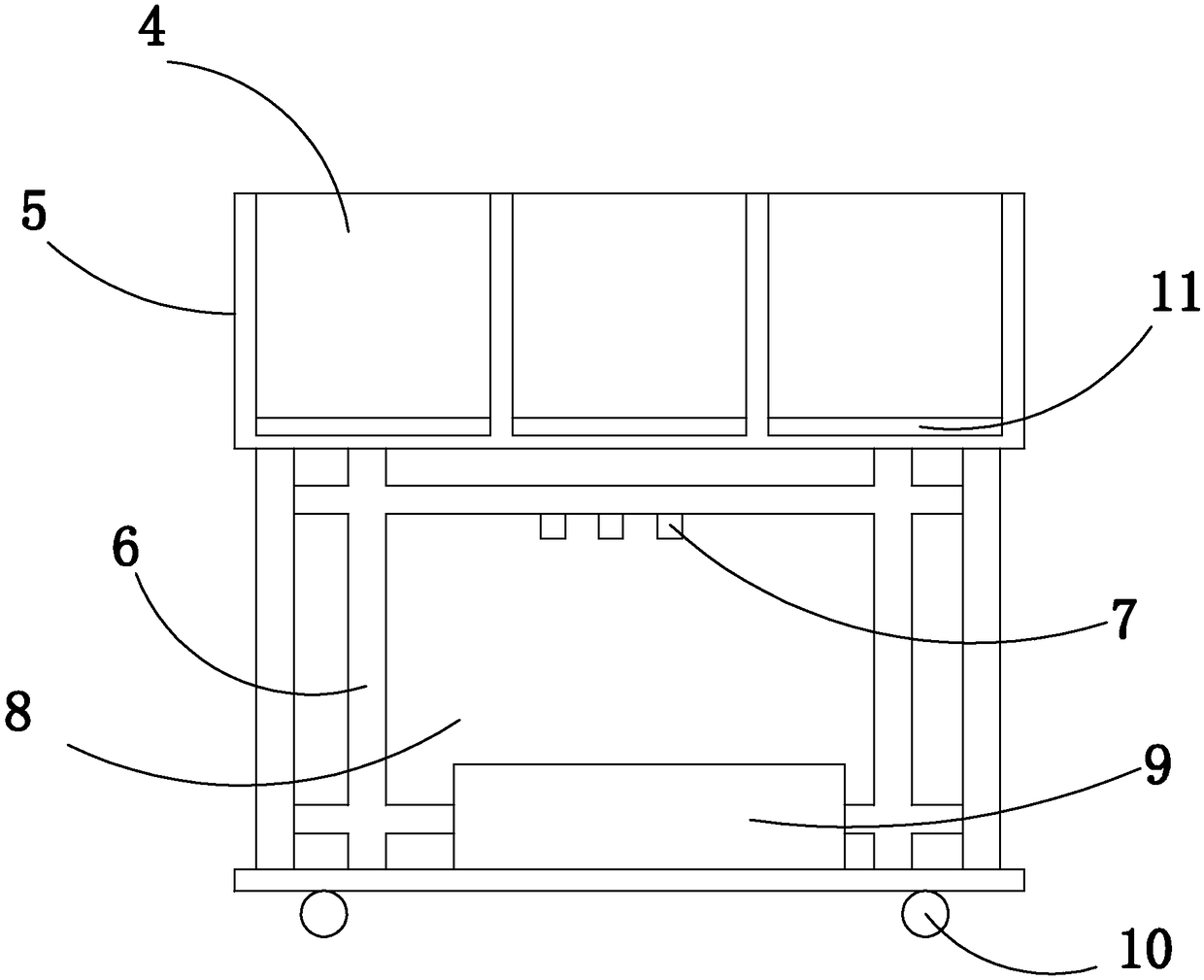

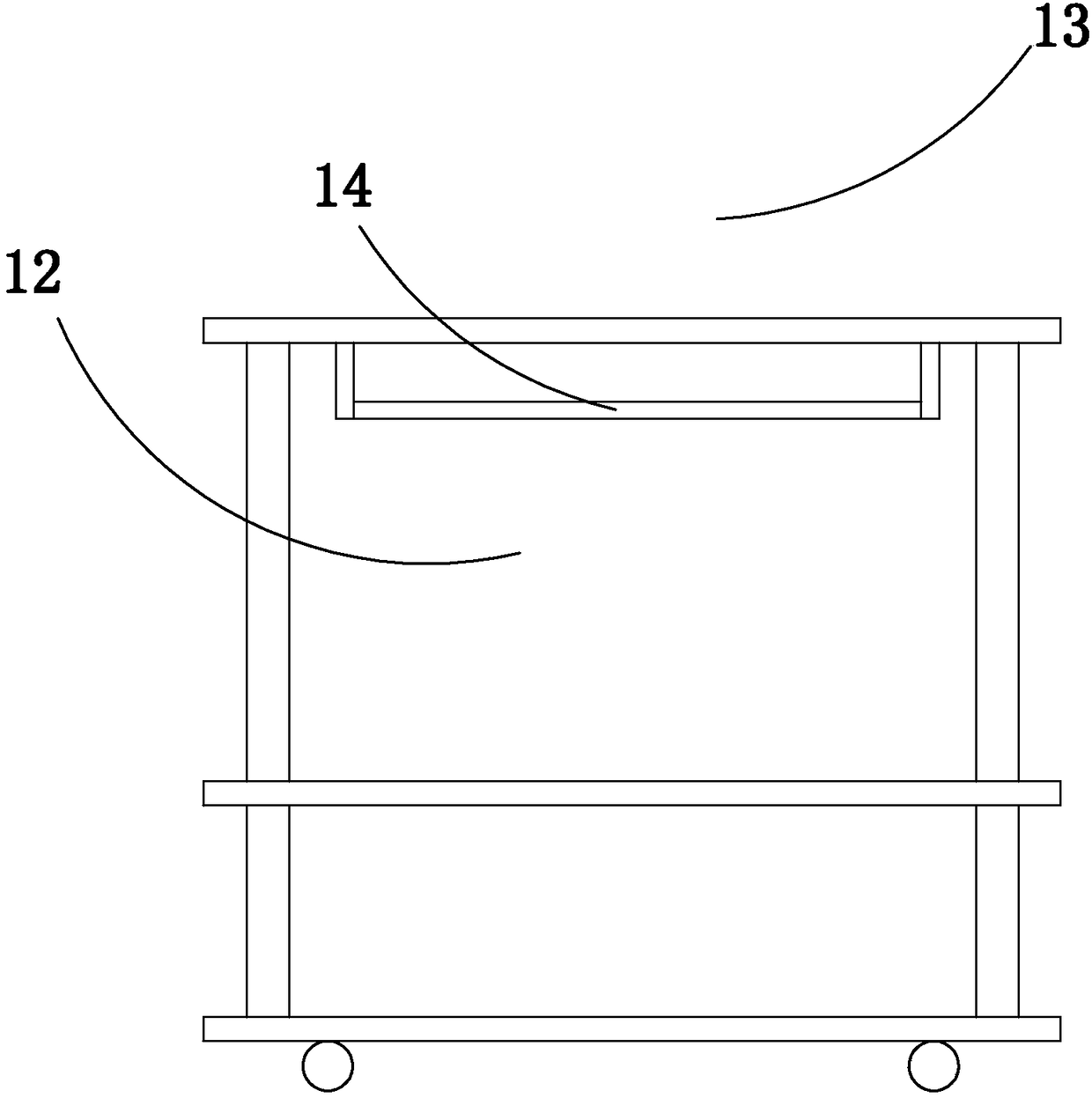

Mahjong machine

ActiveCN103239861BCooperate accuratelyPrecise positioningIndoor gamesEngineeringMechanical engineering

The invention discloses a mahjong machine which comprises a base plate, panels, mahjong lifting support plates, a mahjong shuffling plate, mahjong taking and conveying mechanisms and a mahjong pushing and lifting mechanism. Four mahjong taking and conveying mechanisms and four mahjong lifting support plates are installed on a conveying base which is an integrally-formed part provided with four groups of positioning and installing portions. The four groups of positioning and installing portions are centrally symmetrical, each group of positioning and installing portions comprises a conveying and installing portion, a panel installing portion and a guiding shaft seat portion, wherein the conveying and installing portions and the mahjong taking and conveying mechanisms achieve positioning and are locked and fixed through fasteners, and the top ends and panels of the panel installing portions achieve positioning. The guiding shaft seat portions are arranged on the outer sides of the conveying and installing portions, two guiding rods under the mahjong lifting support plates are respectively and vertically inserted into two shaft holes of the guiding shaft seat portions, and the mahjong pushing and lifting mechanism pushes the mahjong lifting support plates to lift. By means of the technical scheme, the panels and the mahjong lifting support plates are positioned on the same part, accordingly the matching requirement of the panels and the mahjong lifting support plates is guaranteed, machine adjustment is decreased, the matching accuracy is improved, and the deformation influence is reduced.

Owner:浙江承驰科技有限公司

Mahjong machine

The invention discloses a mahjong machine which comprises a base plate, panels, mahjong lifting support plates, a mahjong shuffling plate, mahjong taking and conveying mechanisms and a mahjong pushing and lifting mechanism. Four mahjong taking and conveying mechanisms and four mahjong lifting support plates are installed on a conveying base which is an integrally-formed part provided with four groups of positioning and installing portions. The four groups of positioning and installing portions are centrally symmetrical, each group of positioning and installing portions comprises a conveying and installing portion, a panel installing portion and a guiding shaft seat portion, wherein the conveying and installing portions and the mahjong taking and conveying mechanisms achieve positioning and are locked and fixed through fasteners, and the top ends and panels of the panel installing portions achieve positioning. The guiding shaft seat portions are arranged on the outer sides of the conveying and installing portions, two guiding rods under the mahjong lifting support plates are respectively and vertically inserted into two shaft holes of the guiding shaft seat portions, and the mahjong pushing and lifting mechanism pushes the mahjong lifting support plates to lift. By means of the technical scheme, the panels and the mahjong lifting support plates are positioned on the same part, accordingly the matching requirement of the panels and the mahjong lifting support plates is guaranteed, machine adjustment is decreased, the matching accuracy is improved, and the deformation influence is reduced.

Owner:浙江承驰科技有限公司

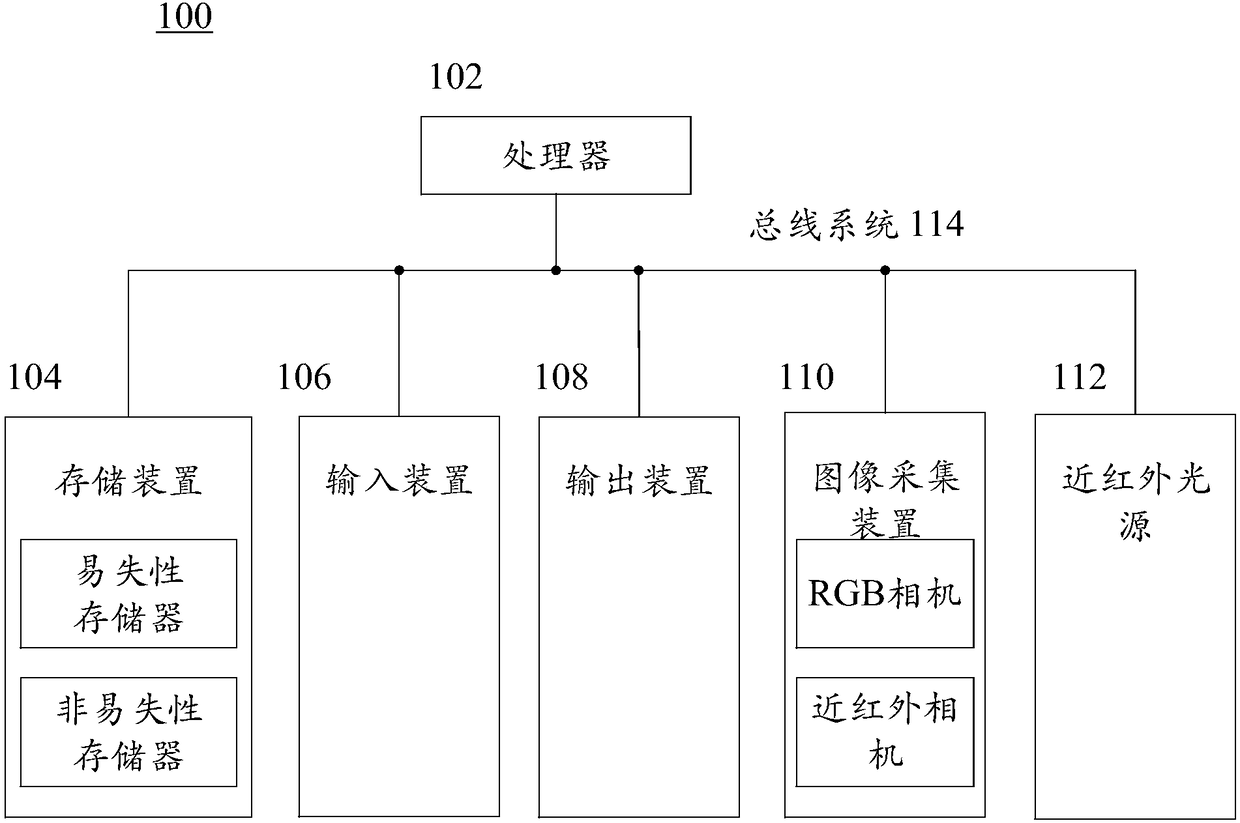

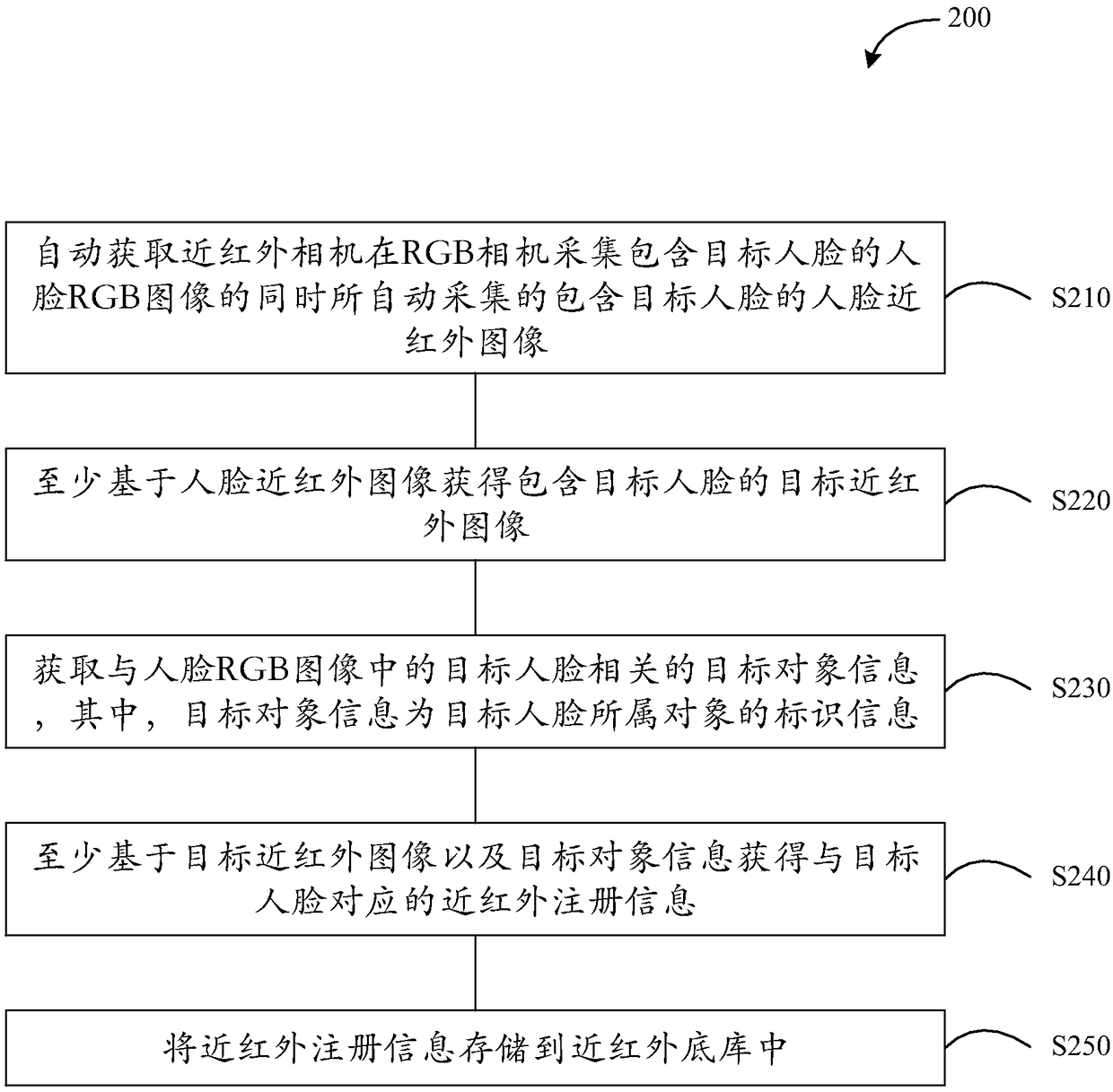

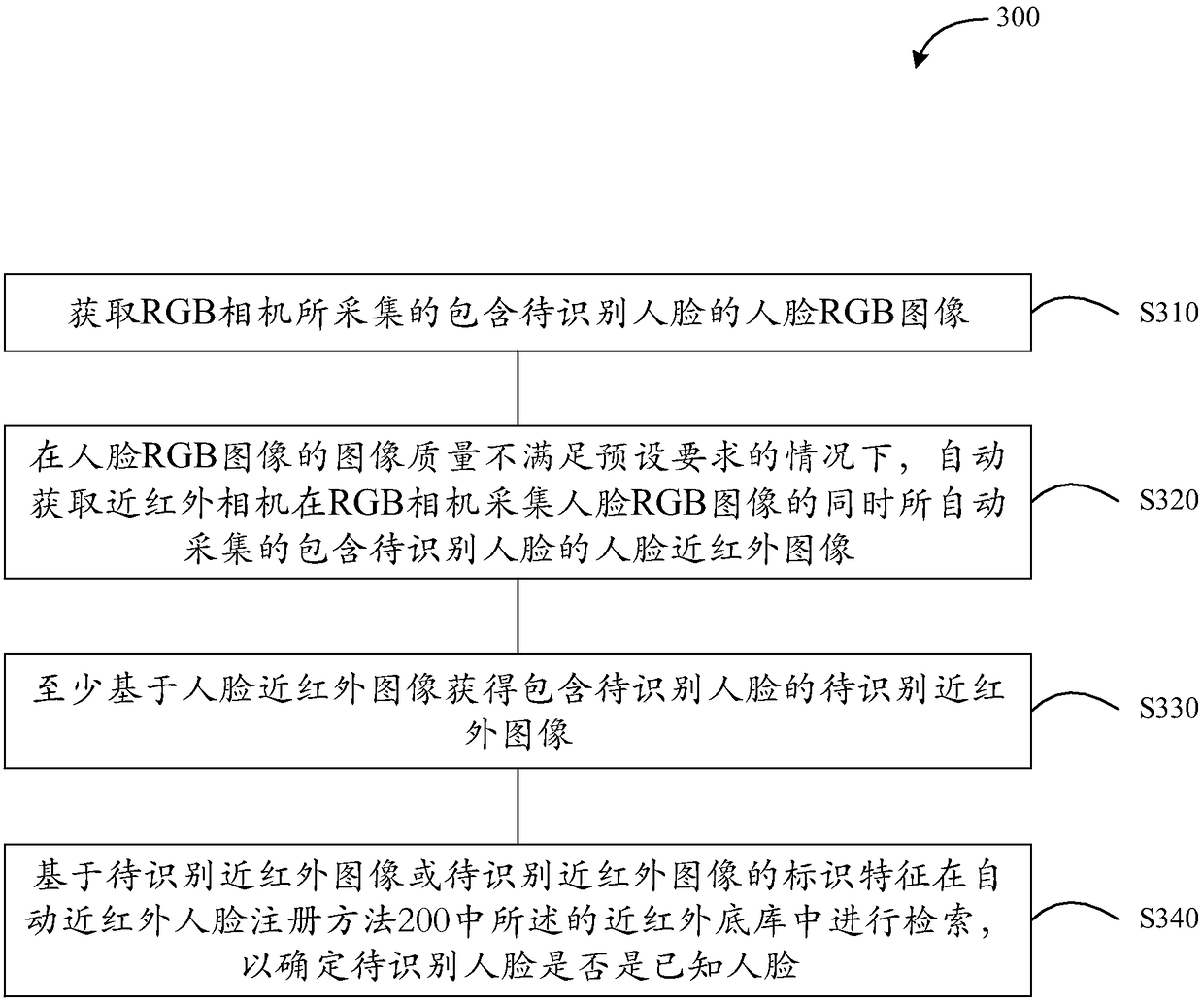

Automatic near-infrared face registration and recognition method, device and system and storage medium

ActiveCN108875476AReduced fit requirementsImprove experienceCharacter and pattern recognitionRgb imagePatient registration

The embodiment of the invention provides an automatic near-infrared face registration method and device, an automatic near-infrared face recognition method and device and a storage medium. The automatic near-infrared face registration method comprises the steps that S210, a face near-infrared image which contains a target face and is automatically collected by a near-infrared camera while an RGB camera collects a face RGB image containing the target face is automatically acquired; S220, a target near-infrared image containing the target face is obtained at least based on the face near-infraredimage; S230, target object information relevant to the target face in the face RGB image is acquired, wherein the target object information is identification information of an object having the target face; S240, near-infrared registration information corresponding to the target face is obtained at least based on the target near-infrared image and the target object information; and S250, the near-infrared registration information is stored into a near-infrared base library. In this way, the requirement on user cooperation is low, user experience is good, and the face recognition rate is high.

Owner:BEIJING KUANGSHI TECH +1

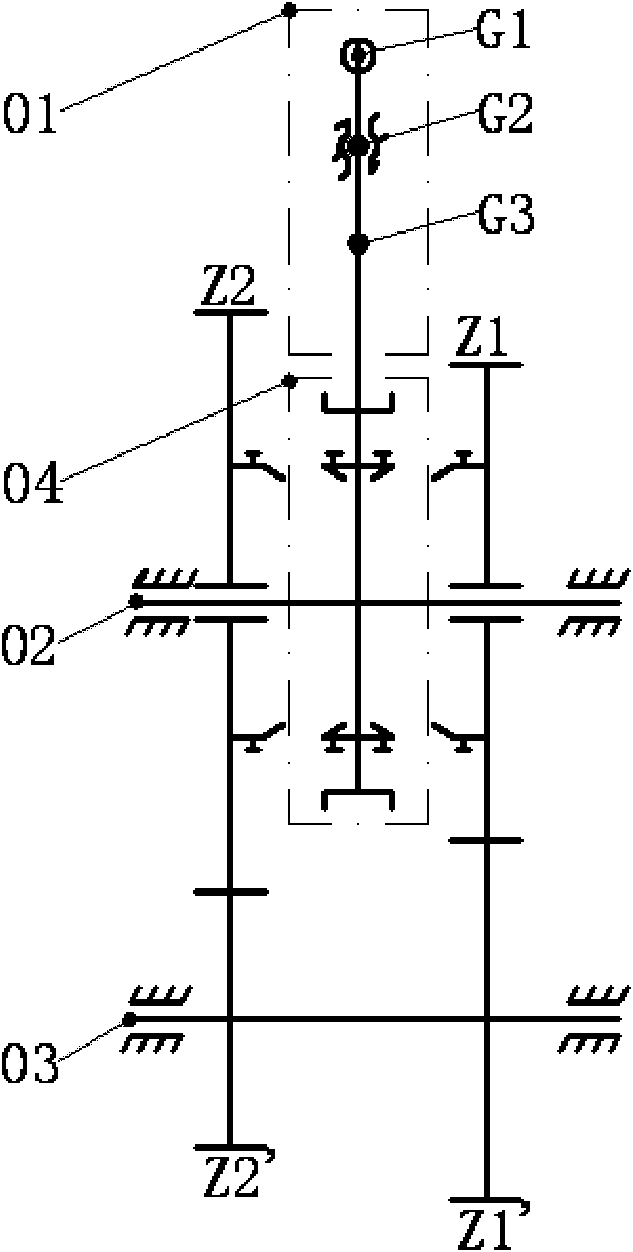

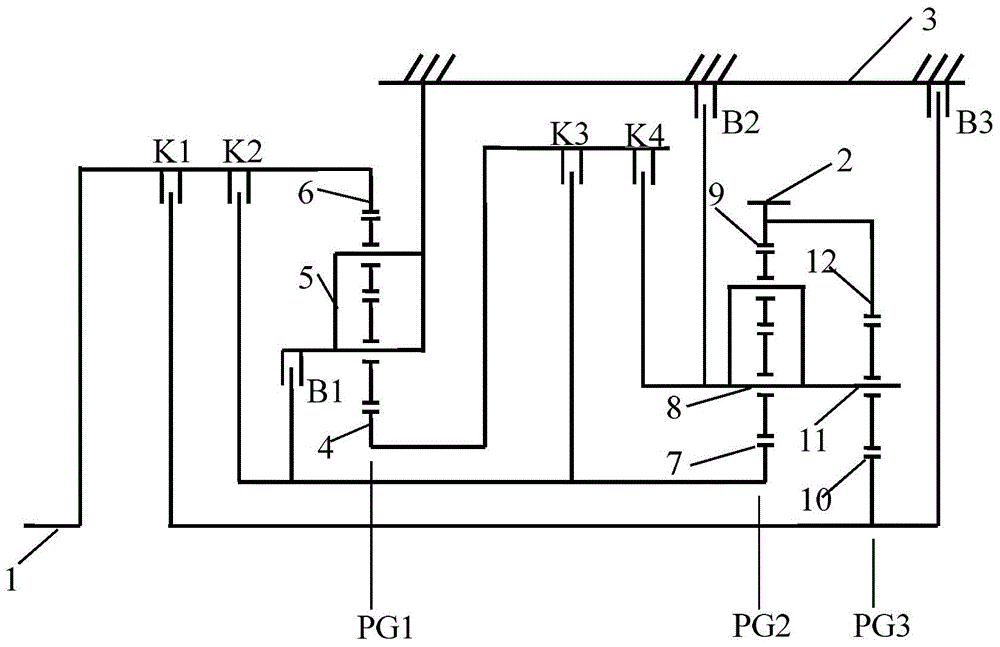

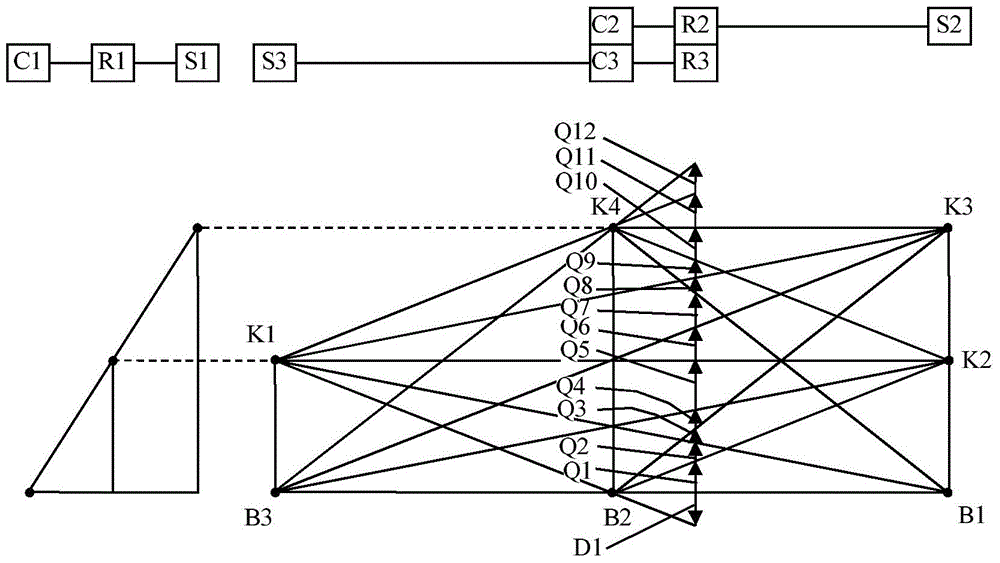

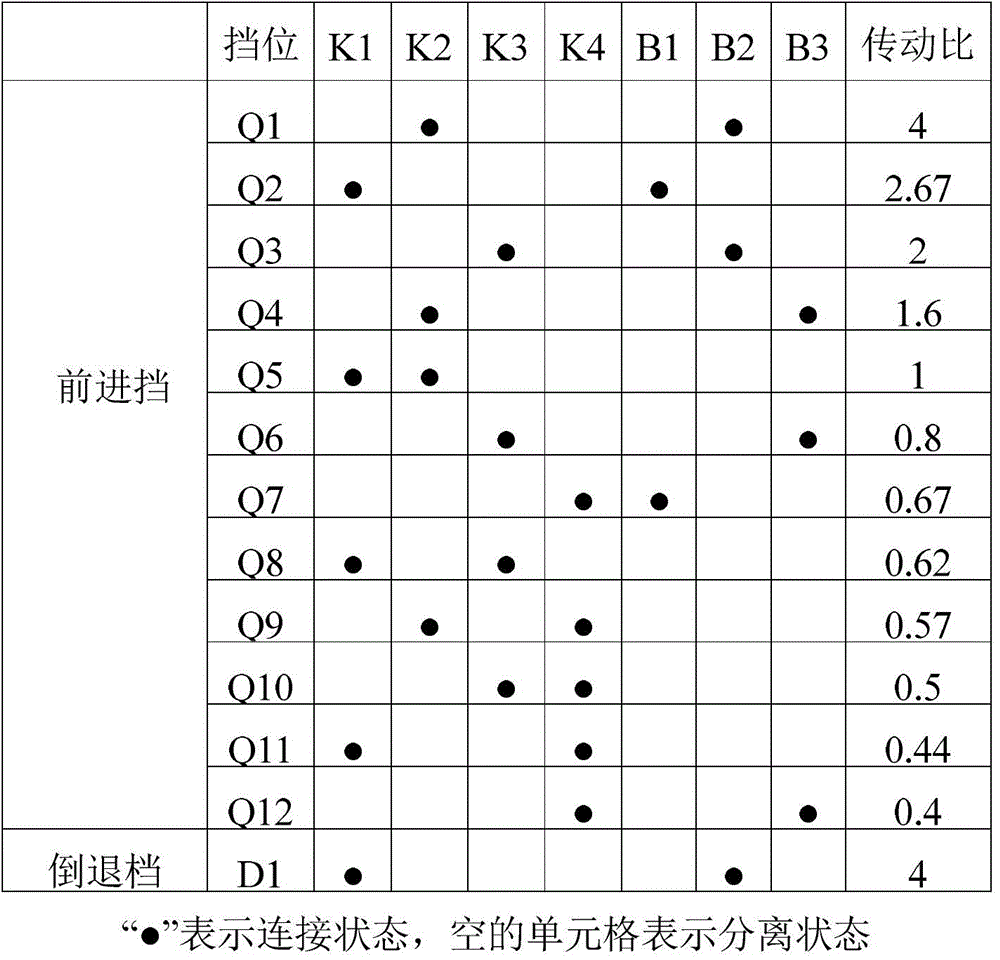

Automatic gearbox

InactiveCN104896041AReduce complexitySimple designToothed gearingsTransmission elementsAutomatic transmissionEngineering

The invention discloses an automatic gearbox which comprises an input shaft, a first planetary gear mechanism, a second planetary gear mechanism, a third planetary gear mechanism, an output shaft, a first clutch, a second clutch, a third clutch, a fourth clutch and a second brake. A first gear ring is connected with the input shaft, a first planetary frame is fixedly connected with a gearbox shell, a second planetary frame is fixedly connected with a third planetary frame, the output shaft is fixedly connected with a second gear ring and a third gear ring and parallel to the input shaft, the first clutch is freely connected with the input shaft and a third sun gear, the second clutch is freely connected with the input shaft and a second sun gear, the third clutch is freely connected with a first sun gear and the second sun gear, the fourth clutch is freely connected with the first sun gear and the second planetary frame, the second planetary frame is freely fixed to the gearbox shell by the aid of the second brake, and transmission gears are determined according to the connecting state of two fastening mechanisms. The automatic gearbox is more compact in structure and wider in speed ratio range, and is provided with more gears and at most provided with twelve forward gears and one reverse gear.

Owner:NANNING UNIV

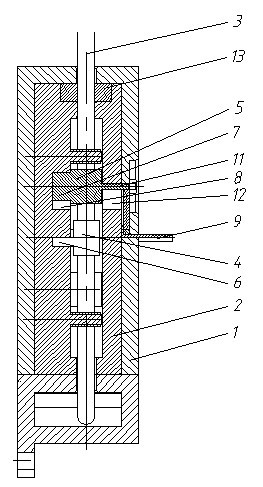

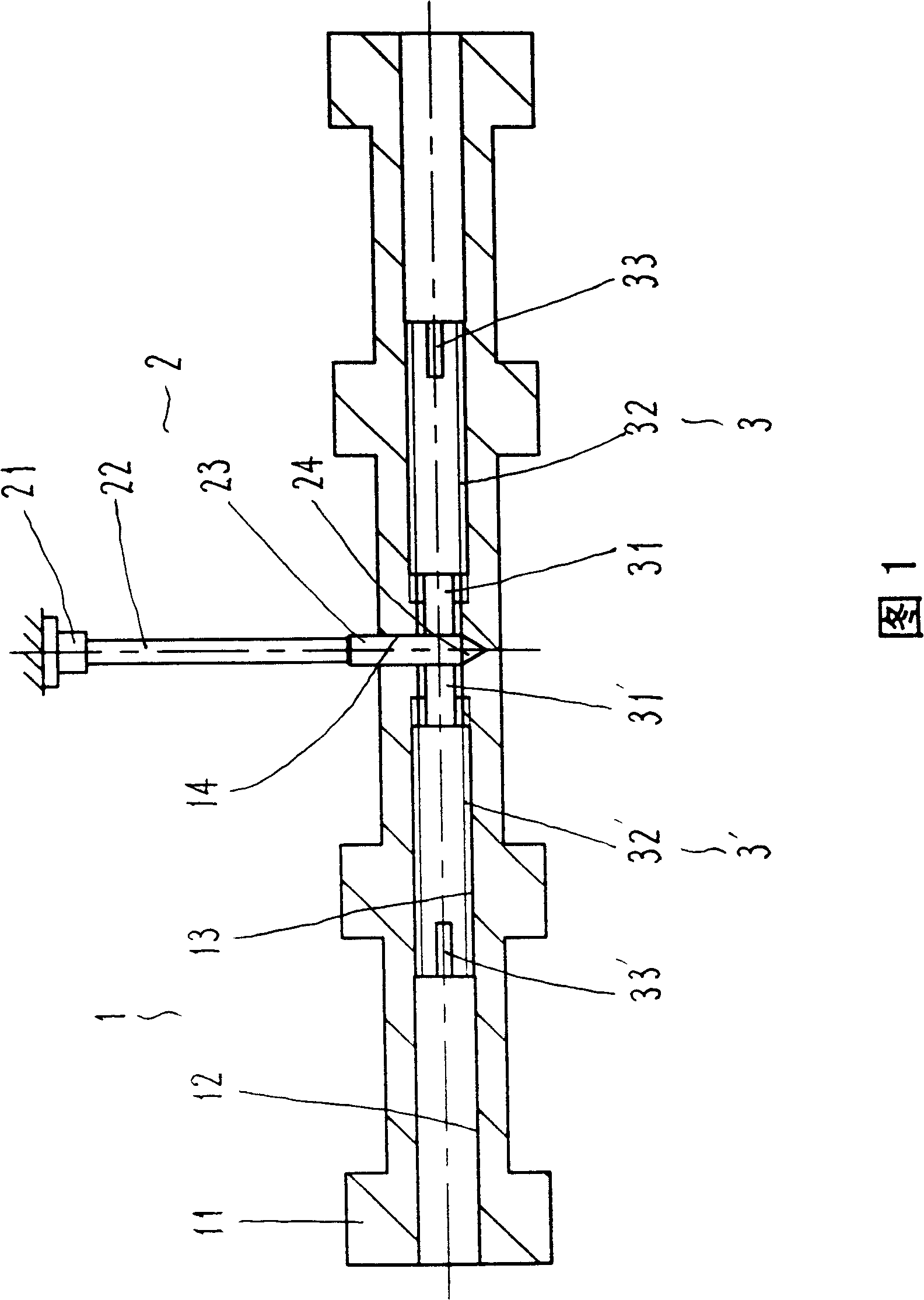

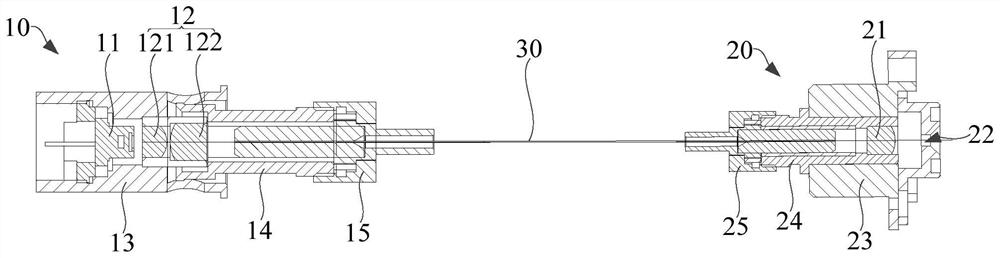

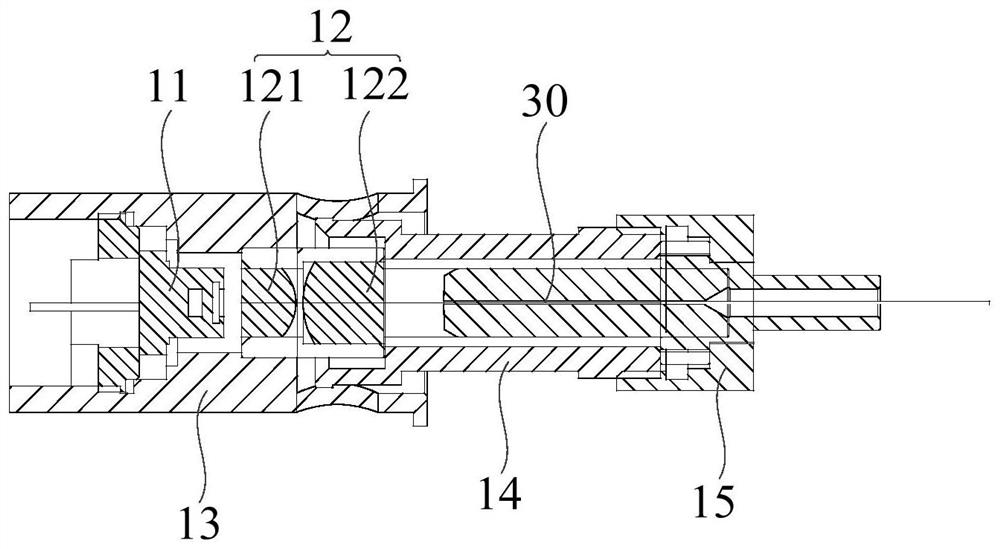

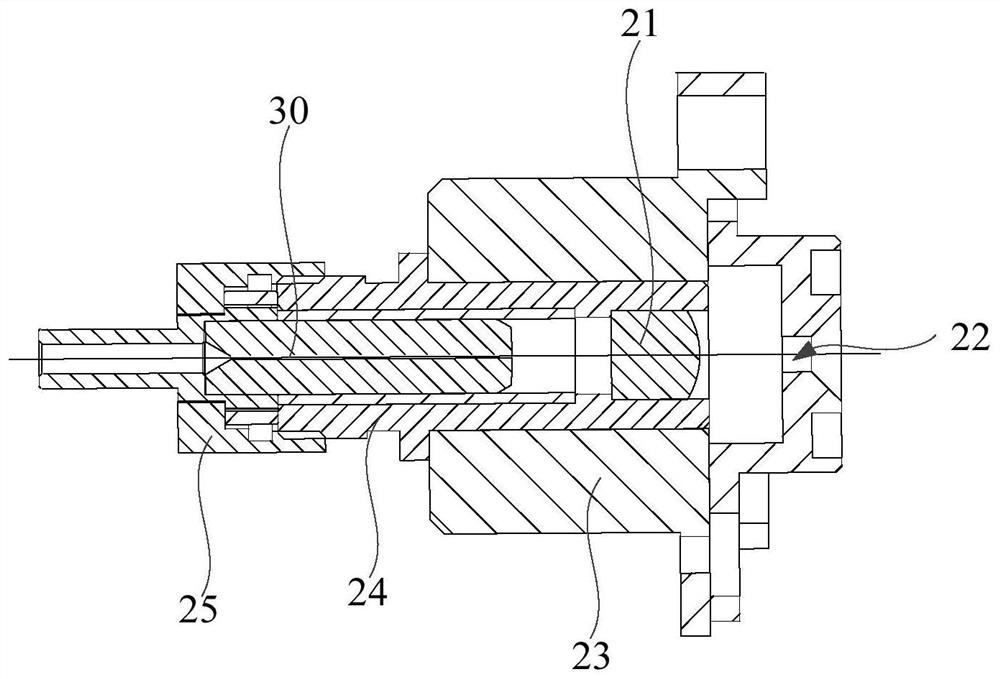

Clamping type feedback lever

InactiveCN101245795AEasy to keep clampedEliminate negative effectsServomotor componentsElectro hydraulicEngineering

The invention provides a clamp typed feedback rod which mainly solves the technical problems of improving manufacture process and enhancing the performance of a servo valve, etc. The technical proposal of the clamp typed feedback rod is that a valve core is provided with a screw hole in the axial direction; one end of the feedback rod passes through the valve core and vertically passes through the screw hole; two clamping screws are respectively screwed in the screw hole; the ends of the two clamping screws respectively pushes against the external surface at the two sides of the feedback rod. the clamp typed feedback rod is suitable for various electro-hydraulic servo valves.

Owner:中国船舶重工集团公司第七0四研究所

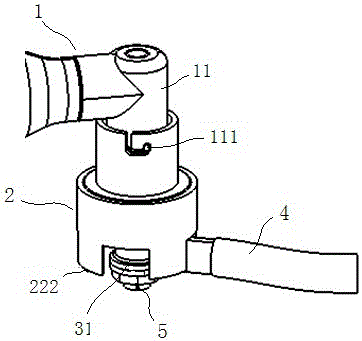

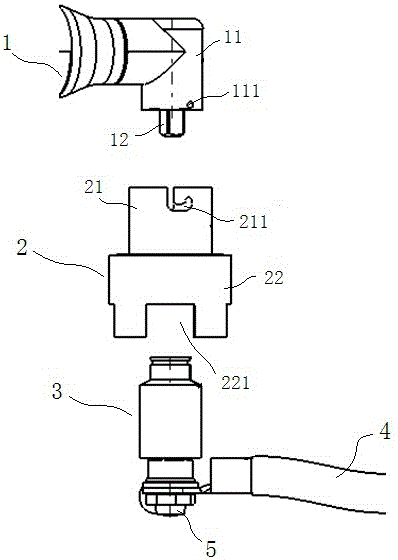

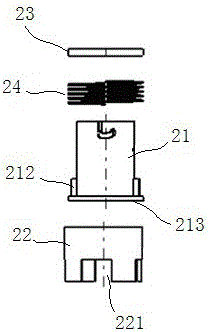

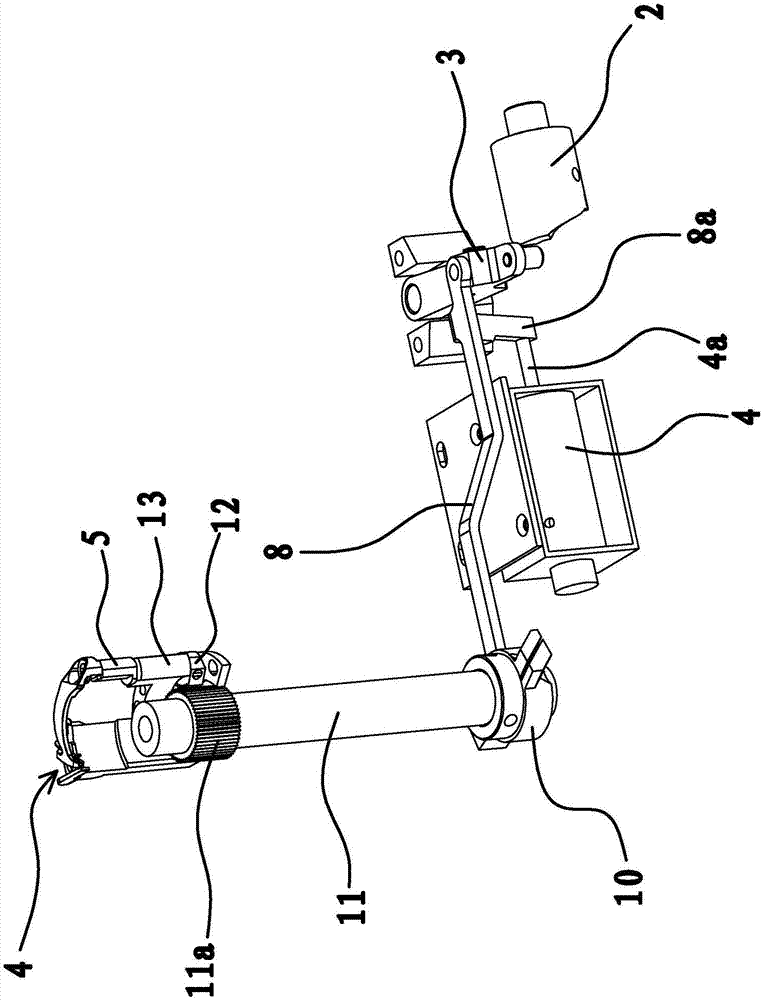

Installing anti-rotating locating tool and method for automobile wire harness bonding iron terminal

The invention relates to an installing anti-rotating locating tool and method for an automobile wire harness bonding an iron terminal. The tool and method are characterized that the tool comprises a torque gun (1), a locating sleeve head (2) and a sleeve (3); the locating sleeve head (2) is of a hollow structure, a driving square head (12) of the torque gun (1) is inserted into the locating sleeve head (2) and connected with one end of the sleeve (3), and a bolt or a nut used for fastening a wire harness putting up iron terminal (4) is matched with the other end of the sleeve (3); and the locating sleeve head (2) is used for fixing the location of the wire harness putting up iron terminal (4) and preventing the wire harness putting up iron terminal (4) from rotating, and the sleeve (3) is used for connecting the driving square head (12) of the torque gun (1) with the bolt or the nut to transmit tightening torque. Installing the anti-rotating locating tool and method for the automobile wire harness putting up the iron terminal can simplify the structure of the wire harness putting up iron terminal (4), relieve the weight of the terminal and lower the cost. The method is suitable for the standardization connection of the bolt and the nut and tool professionalization. The installing efficiency of technology is improved and a wiring harness is neat and orderly after being installed.

Owner:CHERY AUTOMOBILE CO LTD

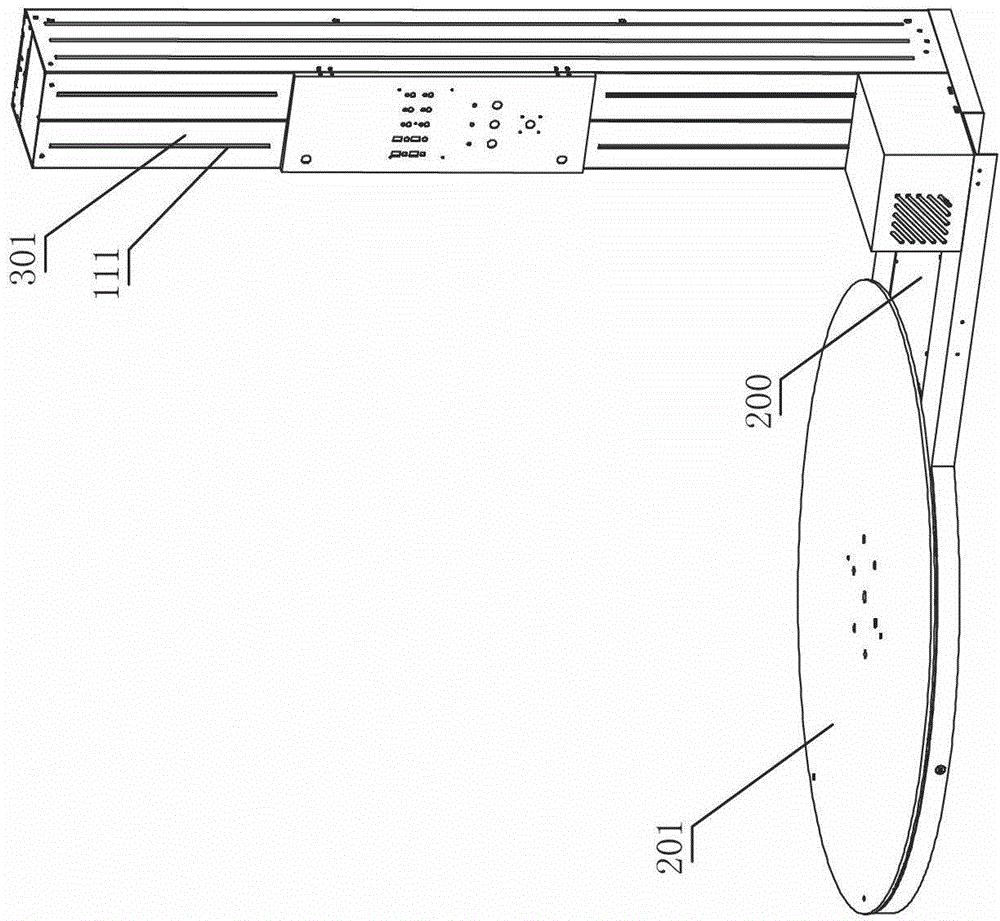

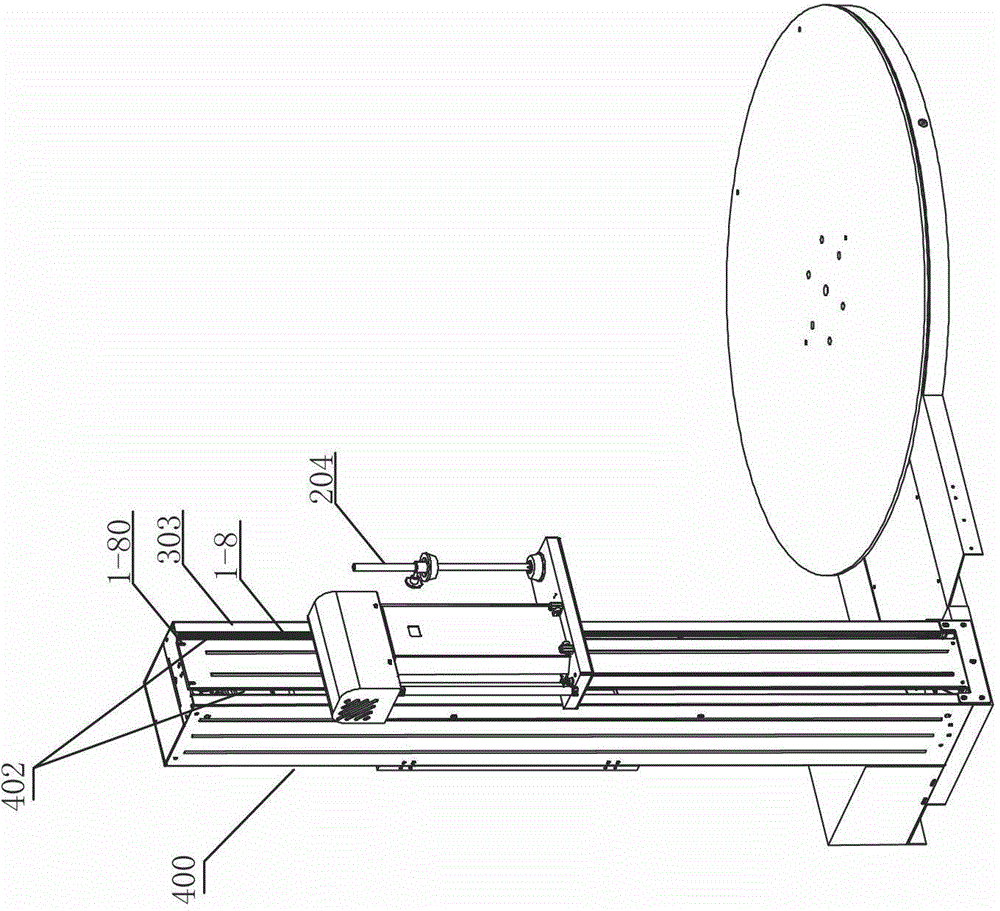

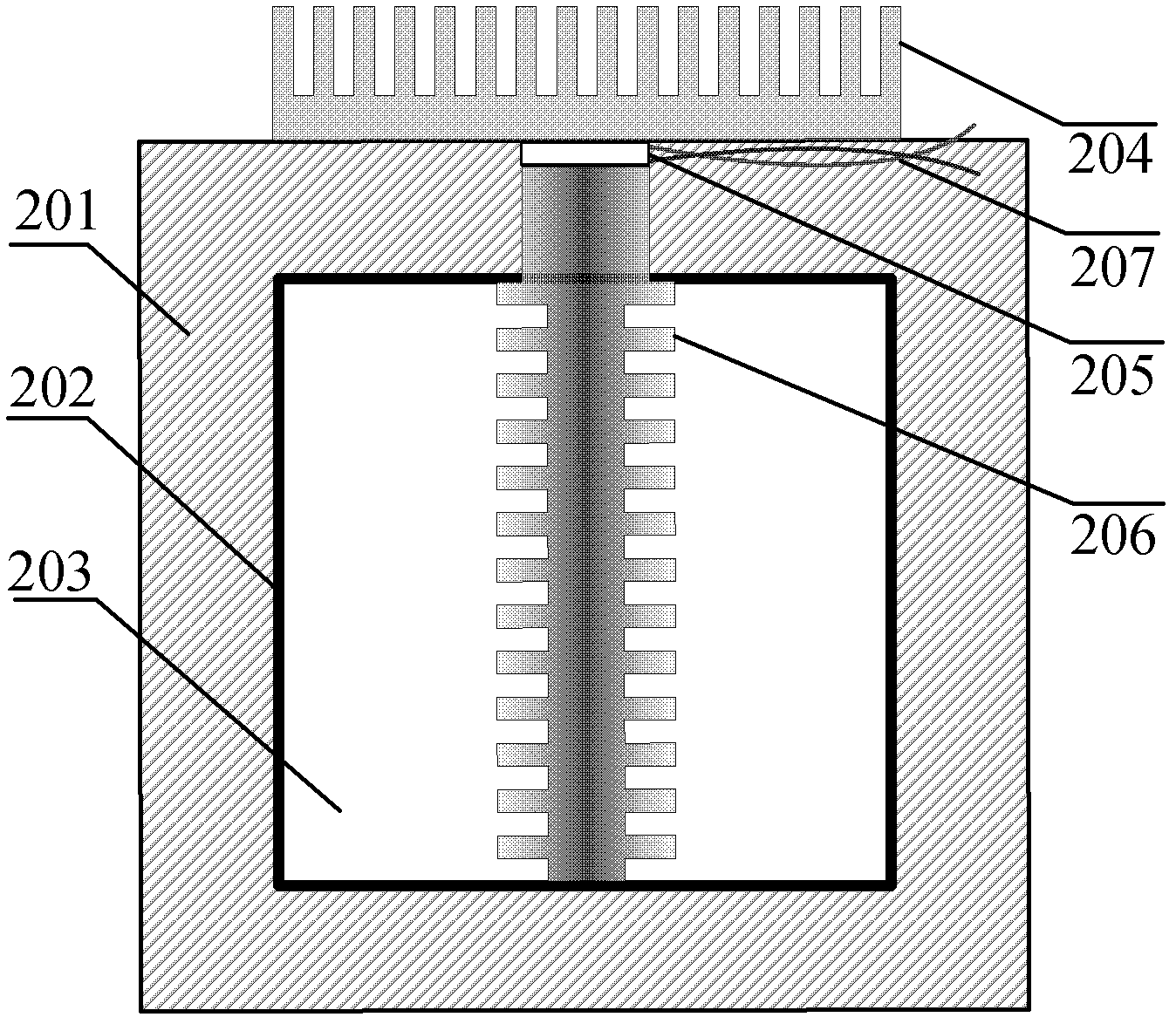

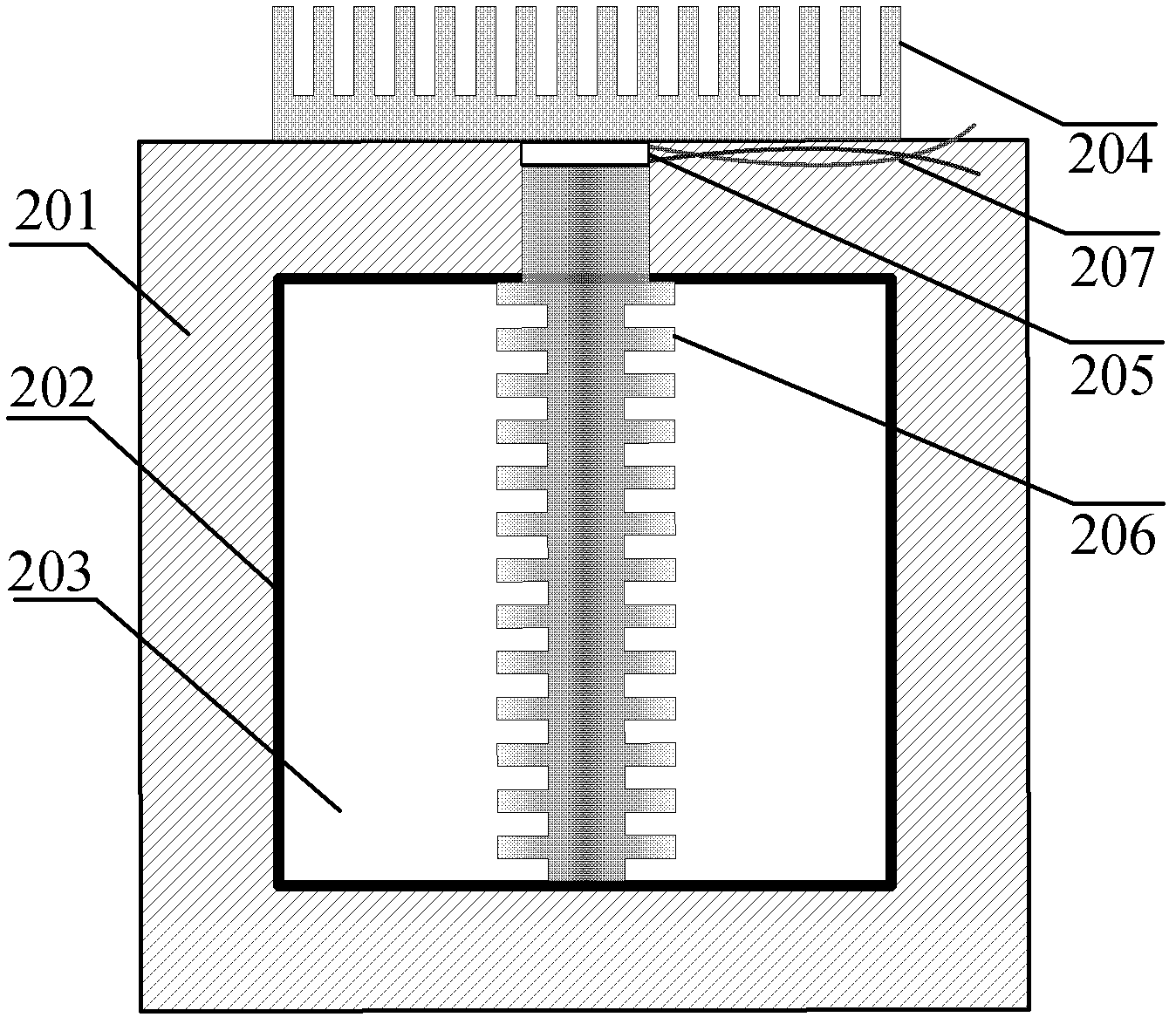

Atmospheric temperature difference power generation device

InactiveCN102545715AAvoid the link of mechanical energy conversionImprove thermal power generation efficiencyGenerators/motorsThermoelectric devicesInsulation layerAtmospheric air

The invention discloses an atmospheric temperature difference power generation device, which mainly solves the problems of low efficiency and heat utilization rate, poor stability and the like of the conventional device. The device comprises a heat storage box (201) with a heat insulation layer (202), an external heat exchange fin (204), an internal heat exchange fin (206), and a semiconductor temperature difference power generation sheet (205) between the external heat exchange fin (204) and the internal heat exchange fin (206), wherein a liquid heat storage working medium (203) of which the temperature slowly changes along with fluctuation of air temperature is filled in the heat storage box (201); after long-term accumulation and counteracting of heat, the temperature of the liquid heat storage working medium (203) tends to be an average air temperature; and dynamic temperature difference between dynamic air temperature and average air temperature is formed inside and outside the heat storage box (201), is fed into the two ends of the semiconductor temperature difference power generation sheet (205) through the external heat exchange fin (204) and the internal heat exchange fin (206) and is further converted into voltage which is directly proportional to the dynamic temperature difference and output. The device has the characteristics of high efficiency and heat utilization rate and continuous electric energy output and can be used for providing power for low-power-consumption electronic equipment such as a distributed wireless sensor node for a long time.

Owner:XIDIAN UNIV

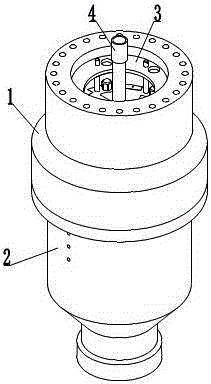

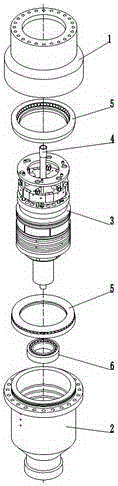

Annular preventer for drilling and workover in oil field

The invention provides an annular preventer for drilling and workover in an oil field, belonging to the technical field of drilling equipment. The annular preventer for drilling and workover in the oil field comprises an upper end cover, a shell and a preventer core, wherein the upper end cover is assembled with the shell through a bolt component; the preventer core is arranged in a cavity enclosed by the upper end cover and the shell; a slip assembly, a vertically-arranged packing element and a rigid torsion transfer drum are arranged in the preventer core; a packing element upper torsion conduction shaft and a packing element lower torsion conduction shaft are respectively arranged at the upper and lower ends of the packing element; the packing element upper torsion conduction shaft is of a hollow structure, and the inner wall of the packing element upper torsion conduction shaft is a circular conical surface matched with the slip assembly; and the torsion transfer drum sleeves outside the packing element. The annular preventer for drilling and workover in the oil field has the characteristics of strong high pressure resistance, good universality and long working life and is suitable for conventional down-hole operation, operation under pressure and under-balanced drilling operation.

Owner:韩咏利

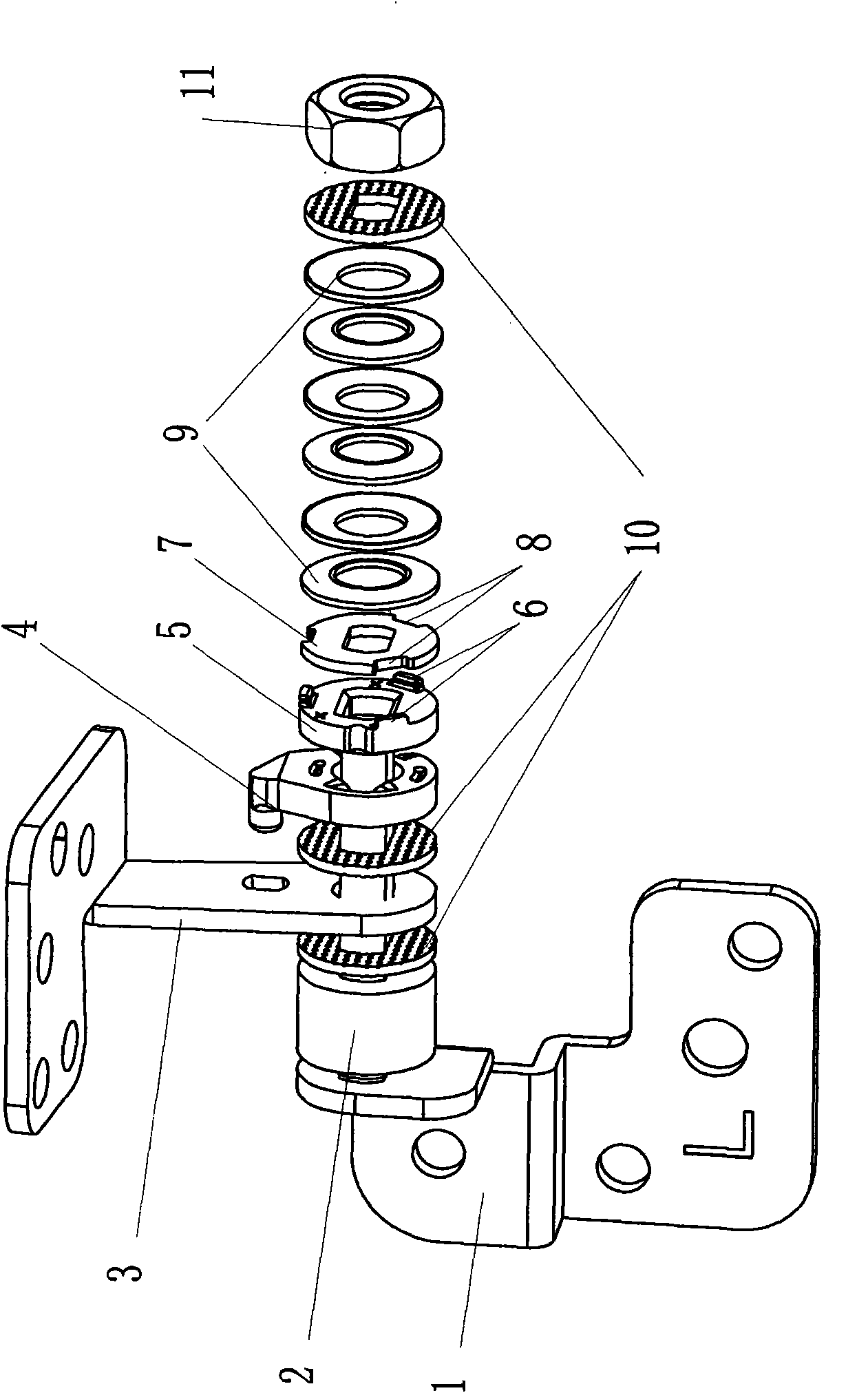

Revolving shaft with muffling cam

InactiveCN101555899AReduce manufacturing precisionReduced fit requirementsPivotal connectionsCamScrew cap

The invention relates to a revolving shaft with a muffling cam, comprising a staddle, a concave wheel, a cam and a plurality of spring plates, which are arranged in sequence on the revolving shaft; one end of the revolving shaft is fixedly connected with a fixing bracket, the other end thereof is tightly fixed by screw caps, wherein a muffling piece is arranged between the cam and the spring plate, at least three arc grooves are arranged on the external circumference of the muffling piece in an evenly distributed manner, at least three tongue pieces are arranged on the external circumference of the cam, which are assembled with the three arc grooves. The muffing piece is added between the cam and the spring plate on the revolving shaft and the muffing piece and the cam are tightly assembled into a whole by the tongue pieces and the grooves; in the way, the matching demand between the cam and the revolving shaft is lowered, thus reducing the requirement on the manufacturing precision of the cam and lowering the cost. The muffling piece is manufactured by pressing, is easy to process and manufacture and can be exactly assembled with the cam, thus realizing the effect of eliminating the abnormal sound.

Owner:ZHEJIANG VOSO SCI TECH

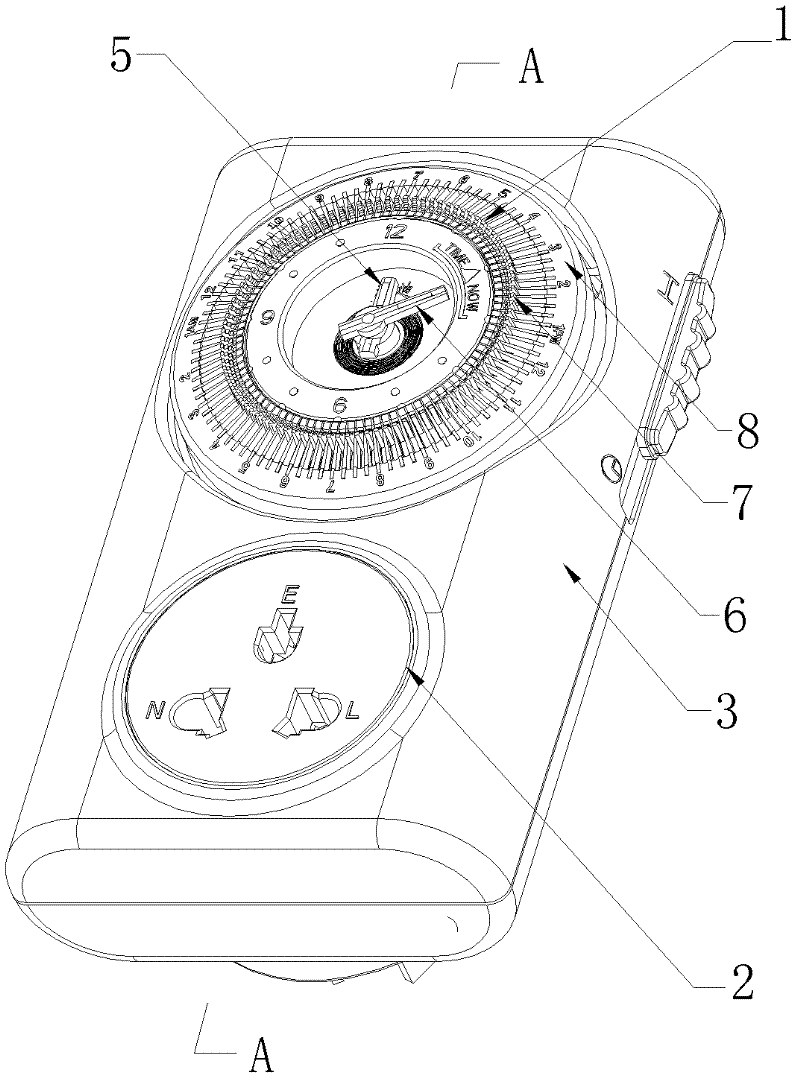

Timer with clock function

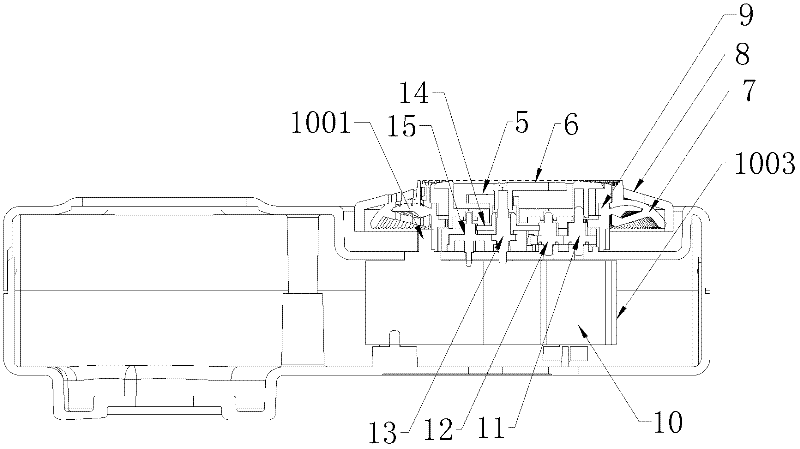

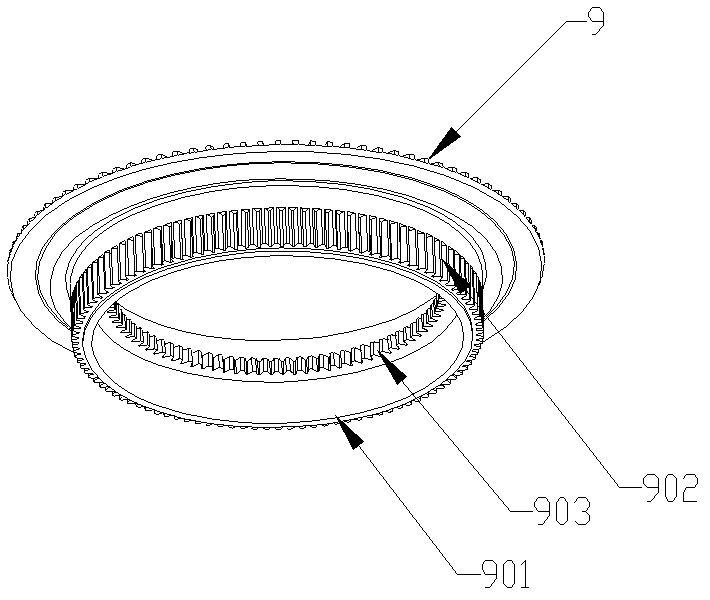

InactiveCN102646548AReduce installation stepsReduce in quantityTime-programme switchesEmbedded systemGear transmission

The invention discloses a timer with a clock function. The timer comprises a driving device for supplying power, a timing device for setting a time alarm, a gear transmission system for conducting power of the driving device to the timing device, and a micro-switch for switching on / off a power supply plug / socket under the control of the timing device, wherein the timing device comprises an inserting sheet for setting a timing point, an index ring for mounting the inserting sheet, and a scale ring for fixing the inserting sheet on the index ring; the gear transmission system is connected with a pointer for indicating the time alarm; the pointer comprises an hour needle and a minute needle; and the driving device drives the gear transmission system through the index ring. The driving device provided by the scheme is in an integrated structure, so that a motor and each reducing gear are mounted in a shell and are output through a power output shaft. Therefore, the complex steps for mounting the driving device are reduced; the stability of the timer is enhanced; and the cost and the matching and precision requirements on an element process can be reduced. The driving device drives the timing device through the index ring and thus the timing efficiency of the timer is improved.

Owner:NINGBO MIDEAY ELECTRICAL APPLICANCE CO LTD

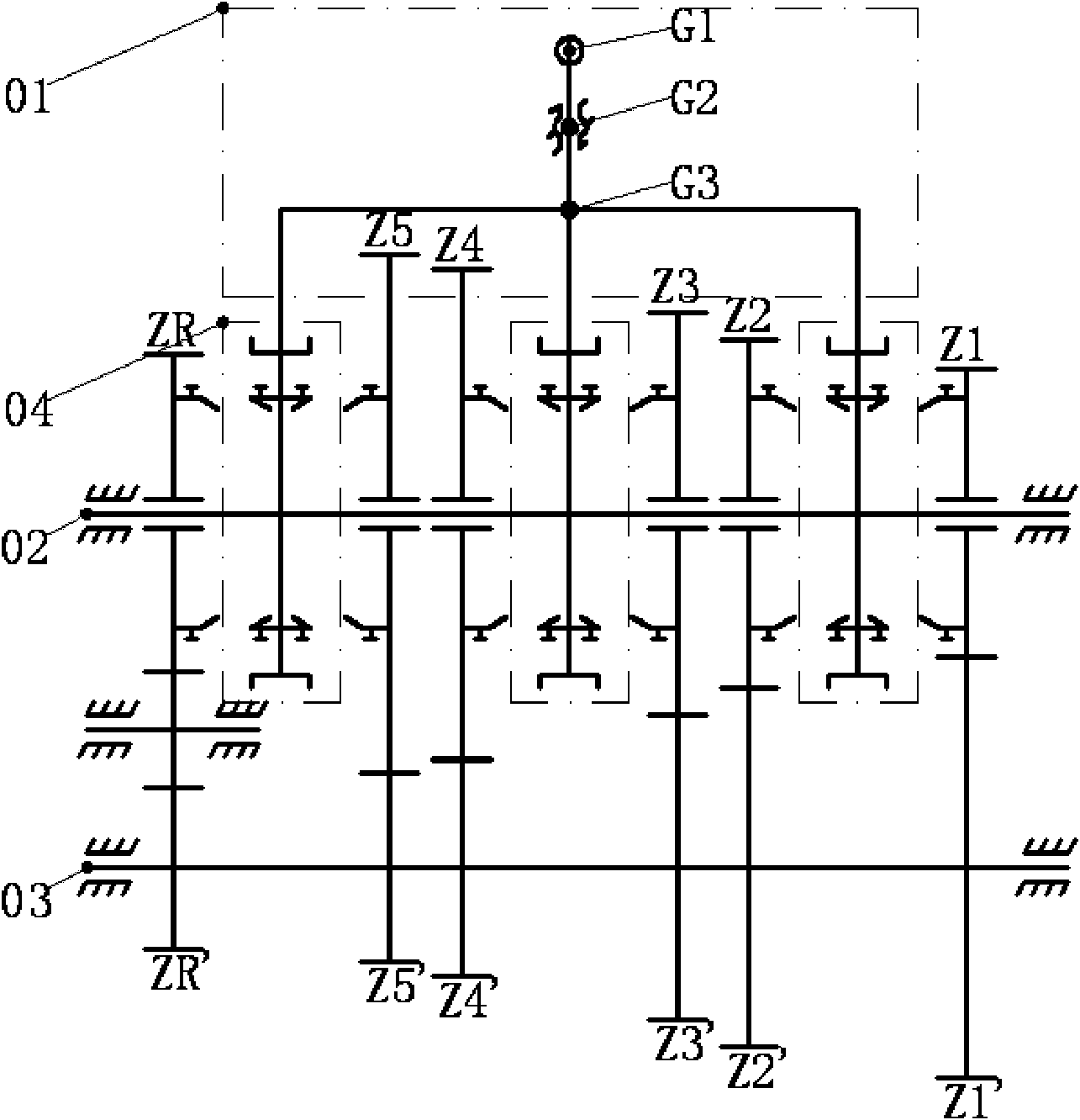

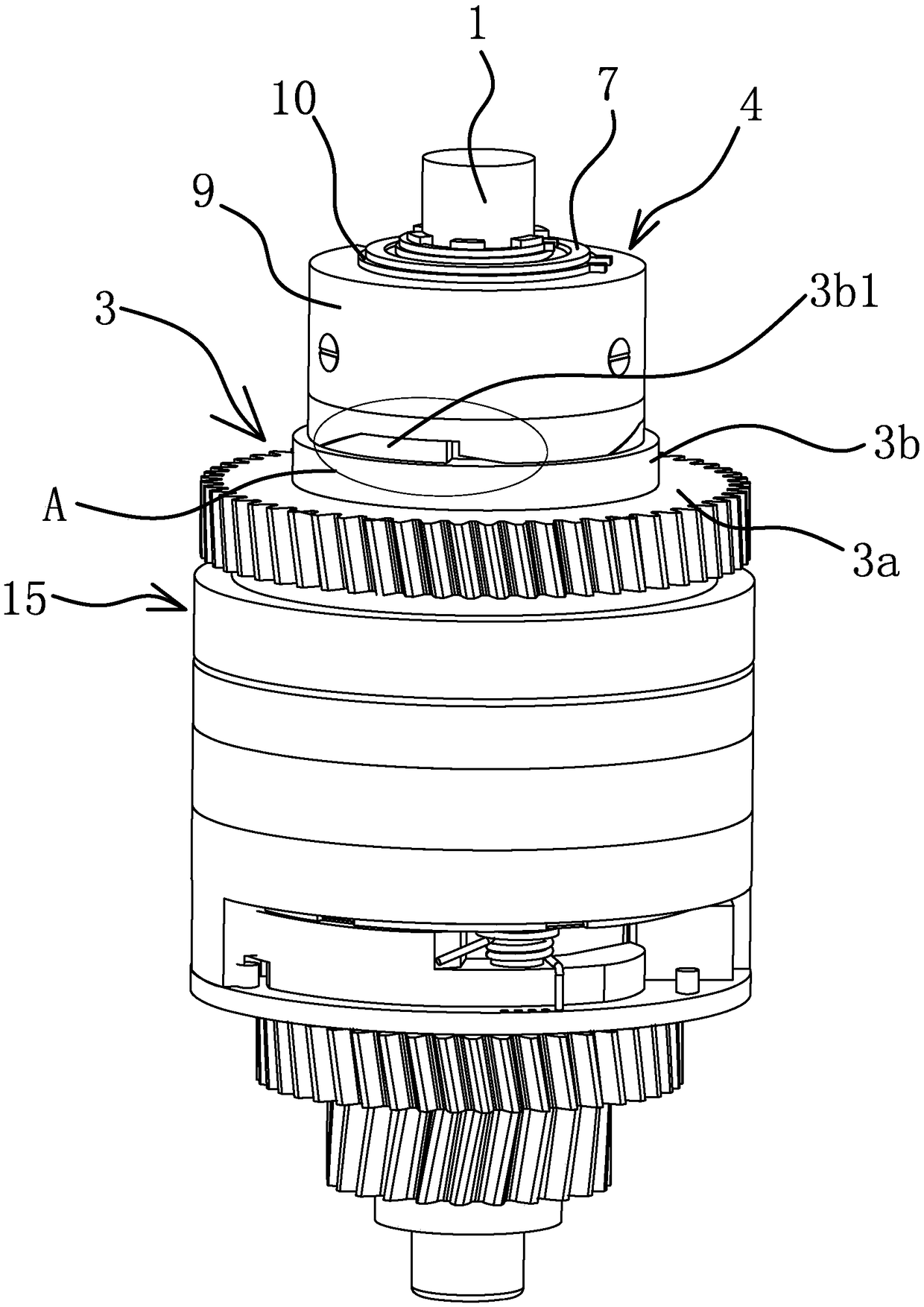

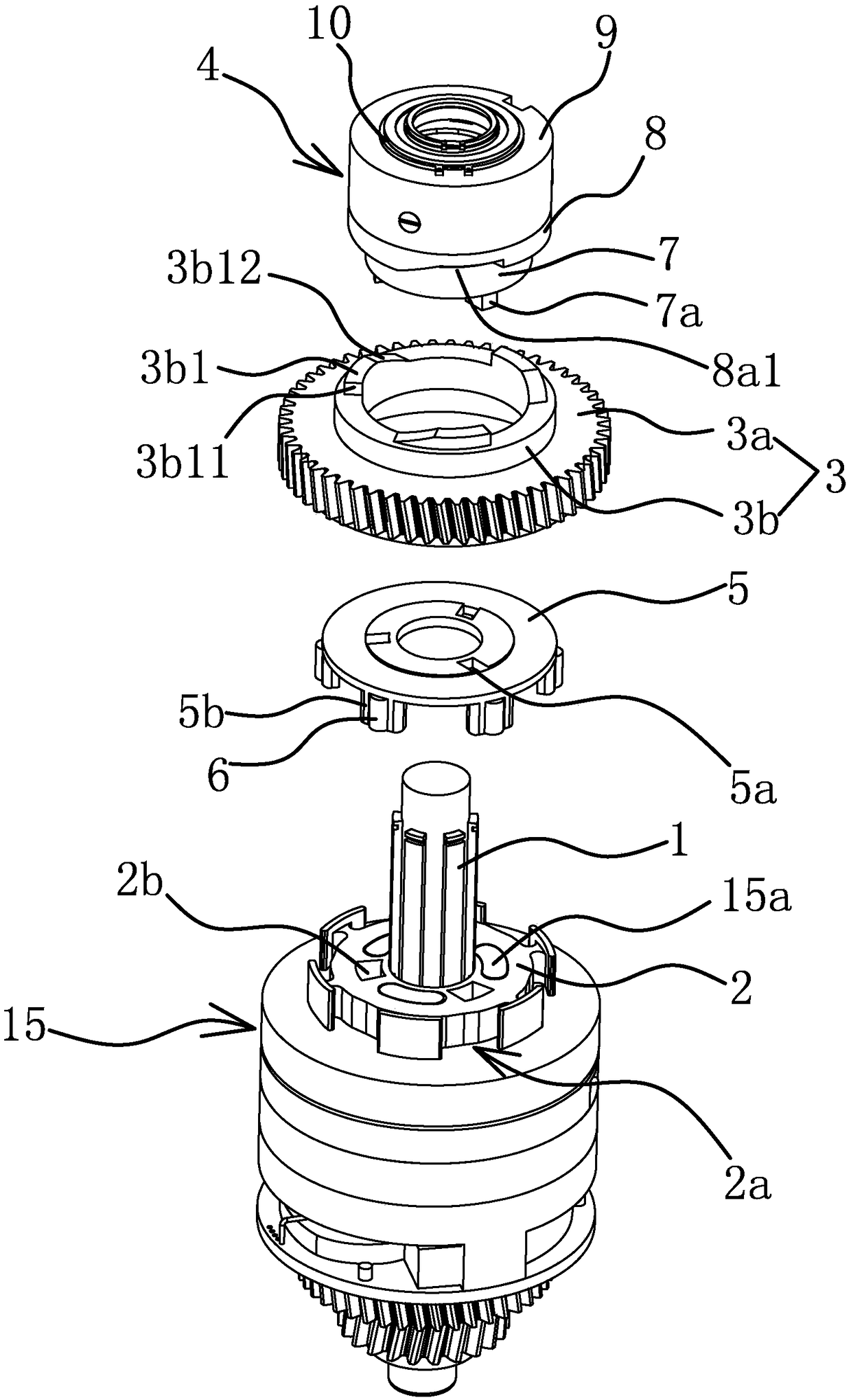

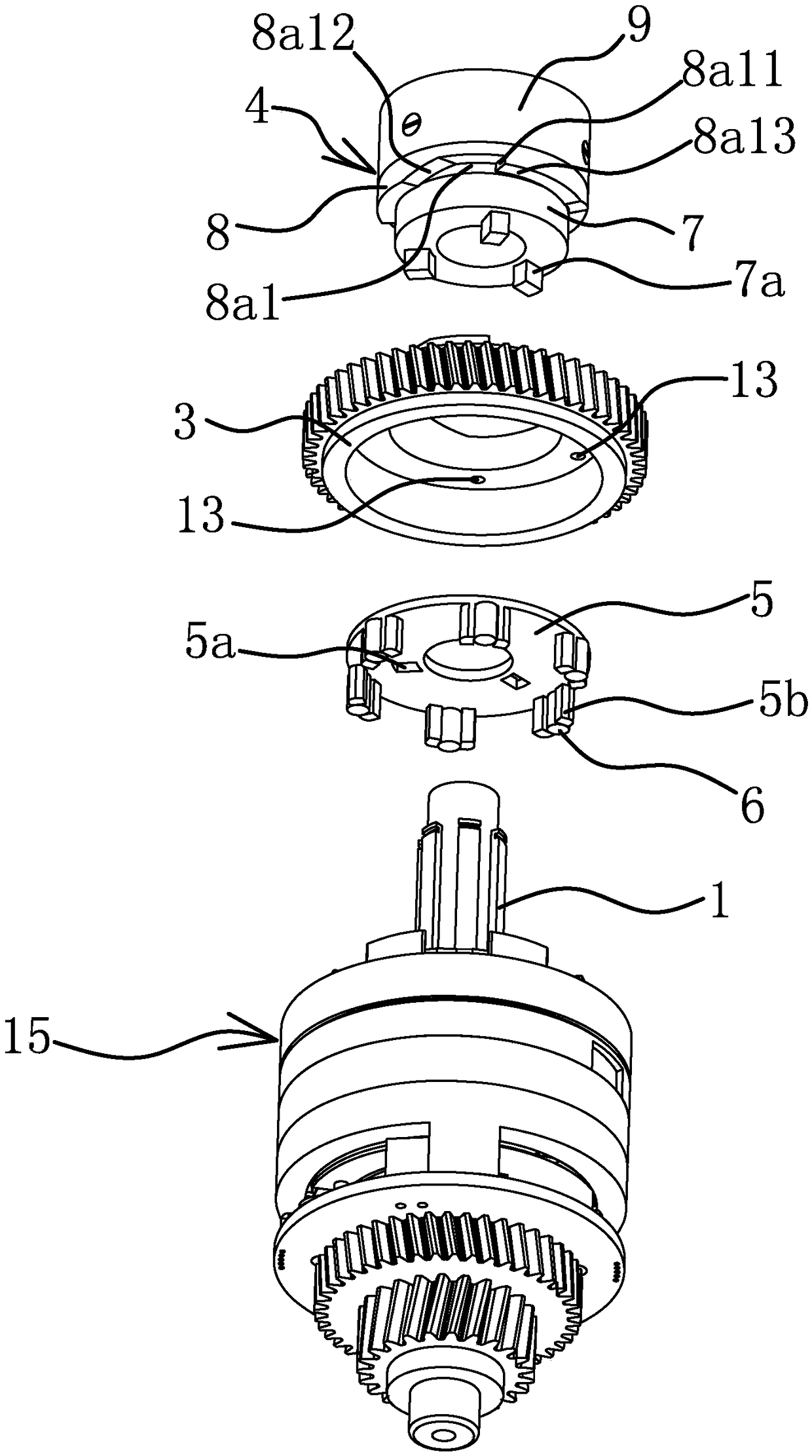

Transmission mechanism of bidirectional automatic gearbox

ActiveCN109386577AImprove stabilityReduced fit requirementsToothed gearingsAutomatic transmissionEngineering

The invention provides a transmission mechanism of a bidirectional automatic gearbox and belongs to the technical field of machinery. The transmission mechanism solves the problem of low work stability of existing bidirectional automatic gearboxes. The transmission mechanism comprises a main shaft, an inner ring circumferentially fixed to the main shaft, an outer ring sleeving the inner ring and acombining sleeve sleeving the main shaft; a disengagement structure is arranged between the outer ring and the combing sleeve, the outer ring is internally connected with a connecting disc through apositioning structure circumferentially, avoidance segments and first combining segments are arranged on the outer side of the inner ring, first rolling columns are positioned on the connecting disc,and the lower end of the combining sleeve penetrates through the connecting disc and is inserted into the upper end face of the inner ring. When the outer ring rotates in a forward movement directionof a car, the first rolling columns are located at the avoidance segments, and the inner ring and the outer ring slip. When the outer ring rotates in a reverse movement direction of the car, the lowerend of the combing sleeve is retracted into the connecting disc, and the connecting disc drives the first rolling columns to move to the first combining segments and makes the inner ring circumferentially connected with the outer ring. The transmission mechanism has the advantages of being high in work stability, simple in structure and the like.

Owner:屠申富 +1

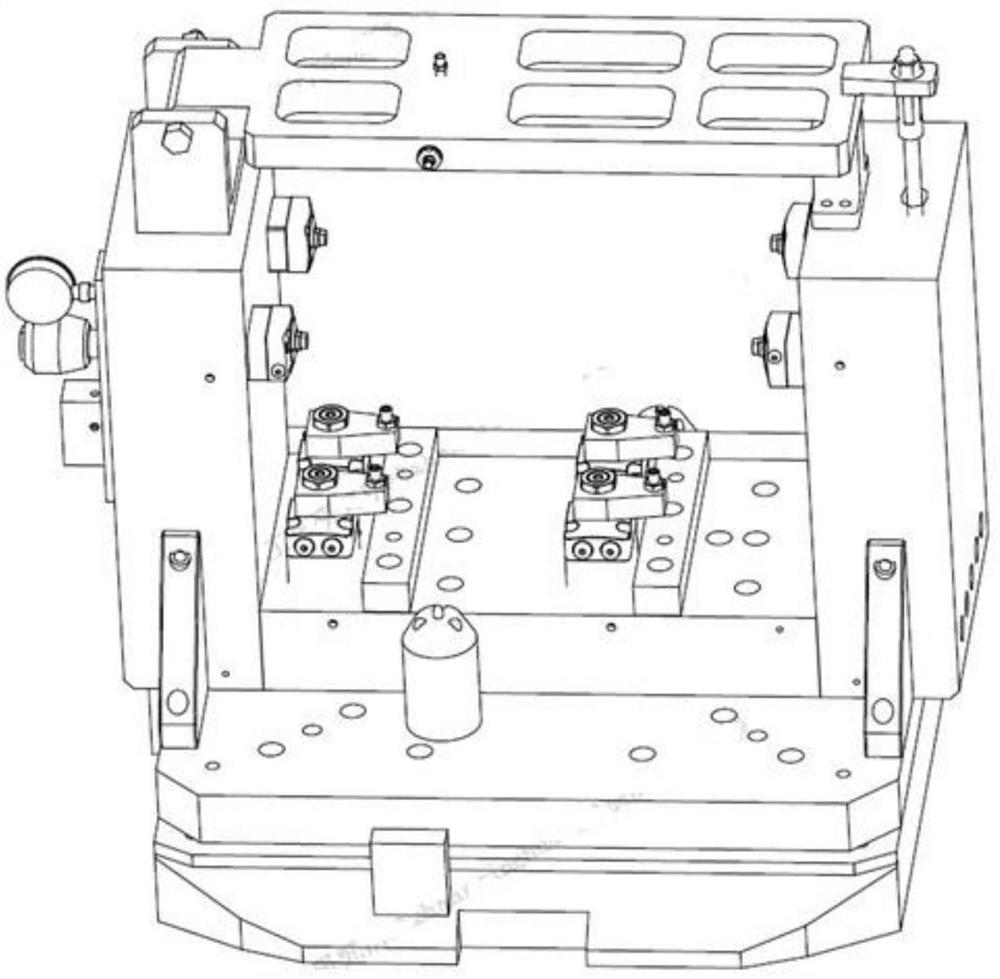

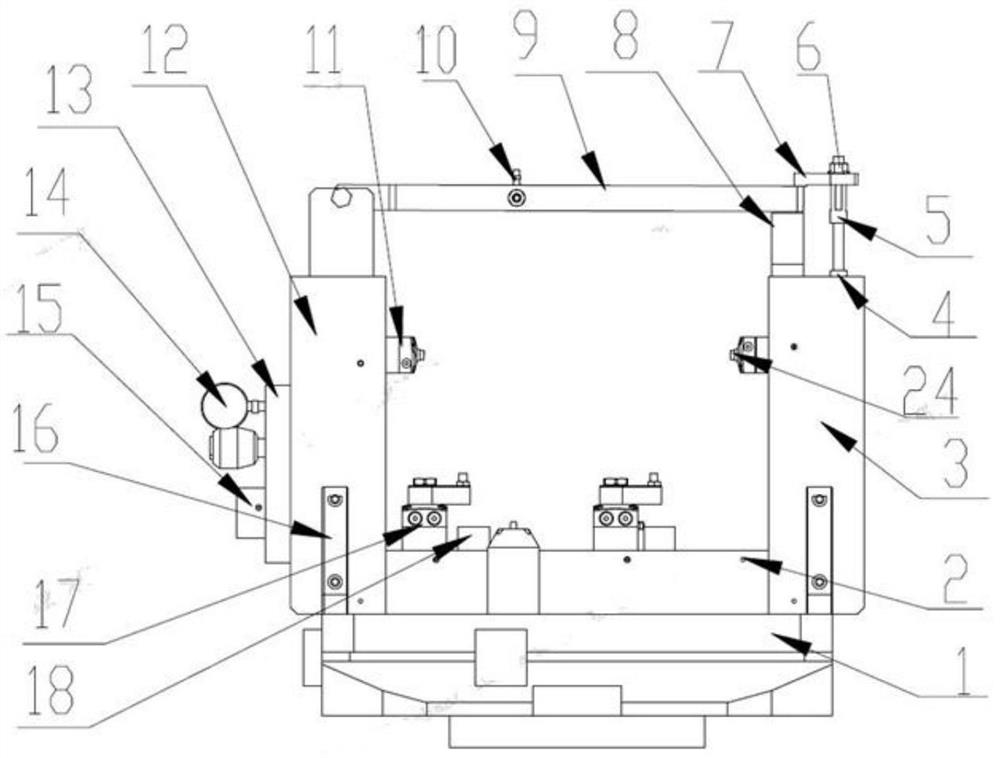

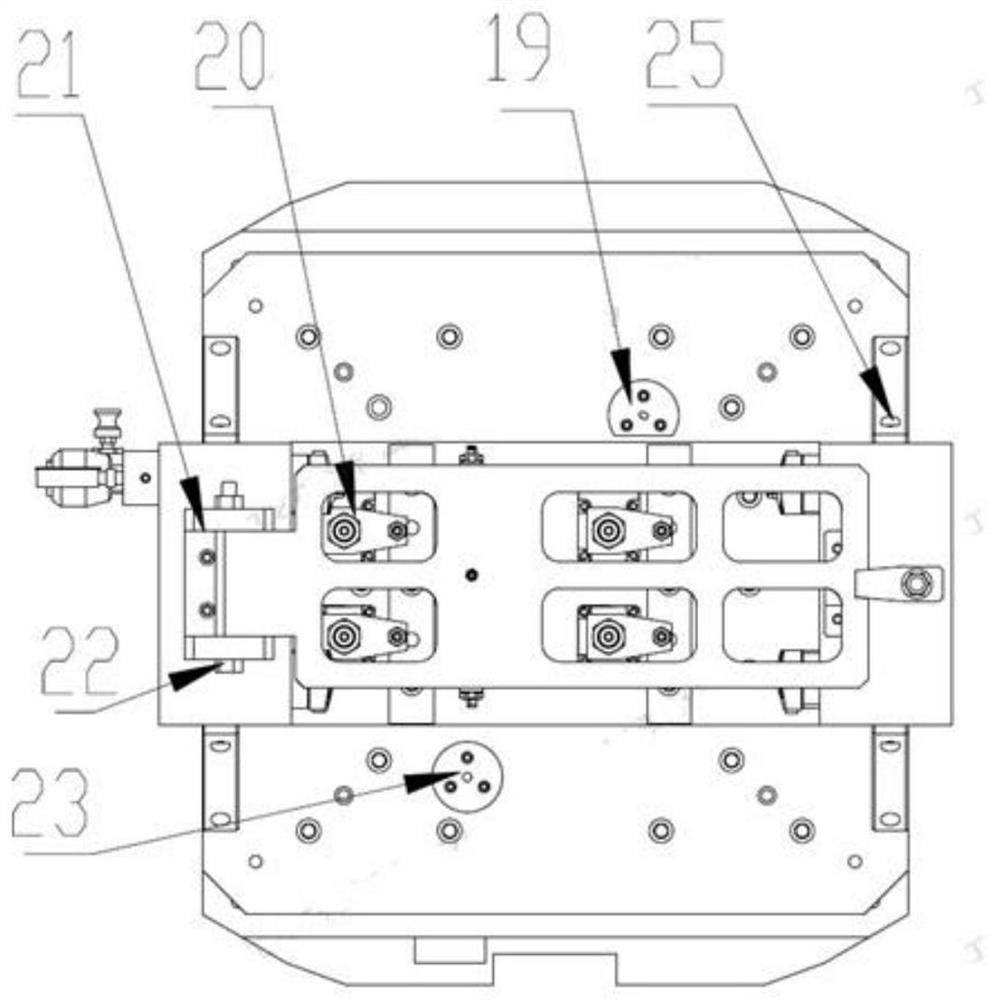

Thin-wall box clamp mechanism

ActiveCN113084561AShorten the timeReduce labor intensityPositioning apparatusMetal-working holdersMachining processMechanical engineering

The invention discloses a thin-wall box clamp mechanism which comprises a base assembly, a positioning mechanism, a hydraulic fixing mechanism and a pressing mechanism; the base assembly comprises a positioning plate, a left side plate and a right side plate which are connected in a U shape, and the inner side of the base assembly is used for containing a workpiece; the positioning mechanism is mounted on the upper side of the base assembly and is used for positioning the workpiece; the hydraulic fixing mechanism is arranged on the inner side of the base assembly; the pressing mechanism is mounted on the upper sides of the left side plate and the right side plate and connected with the left side plate and the right side plate; and the positioning mechanism, the hydraulic fixing mechanism and the pressing mechanism make contact with the periphery of the workpiece correspondingly, and multi-point pressing is conducted on the workpiece. The thin-wall box clamp mechanism adopts an ingenious mechanical structure, the mechanism is simple in structure, low in matching requirement, convenient for machining, low in cost and convenient and labor-saving in assembling, in the workpiece clamping process, one-face two-pin positioning and hydraulic clamping are achieved, pressing force is adjusted through pressure, and deformation of a workpiece in the machining process is avoided.

Owner:XUZHOU XCMG DRIVELINE TECH CO LTD

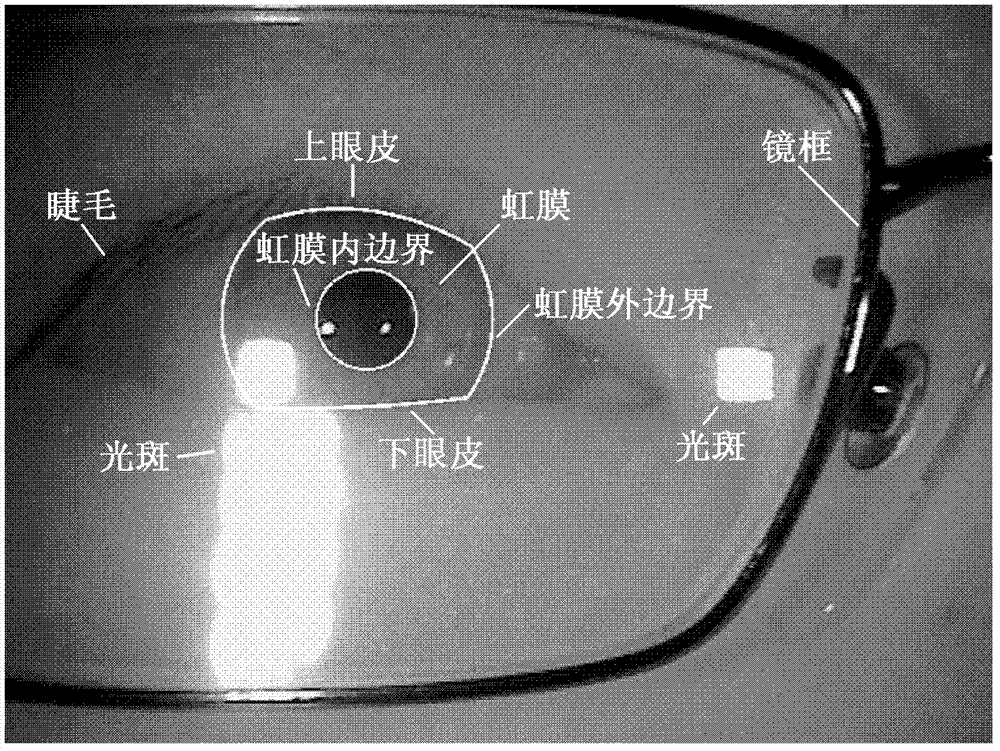

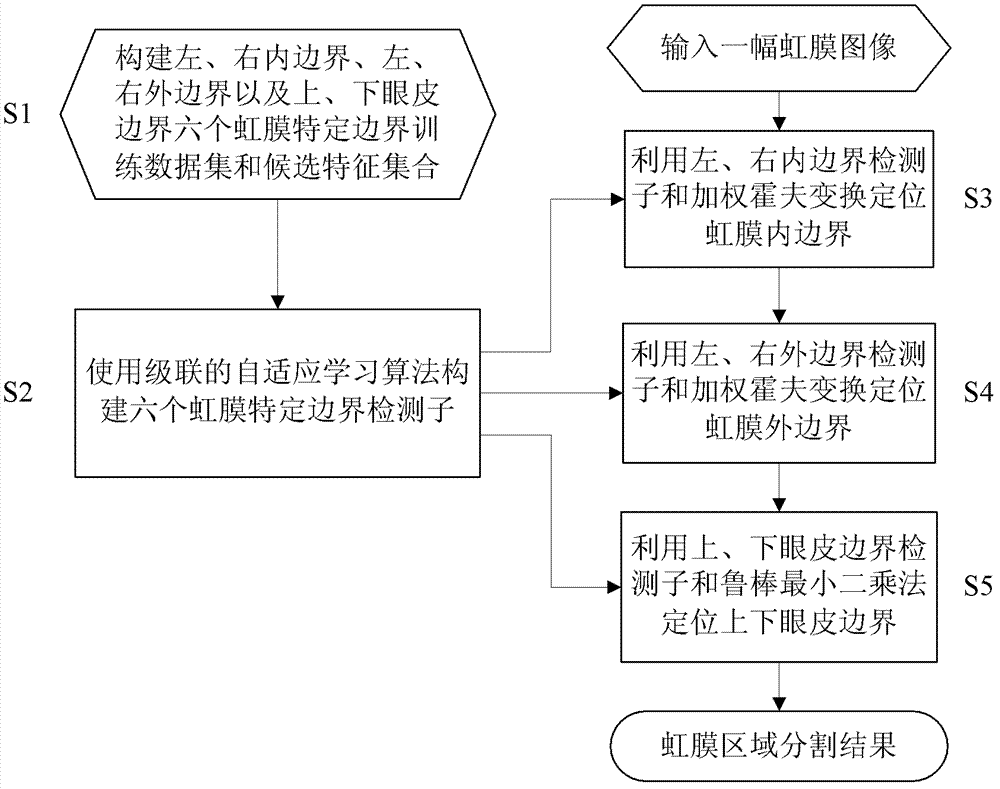

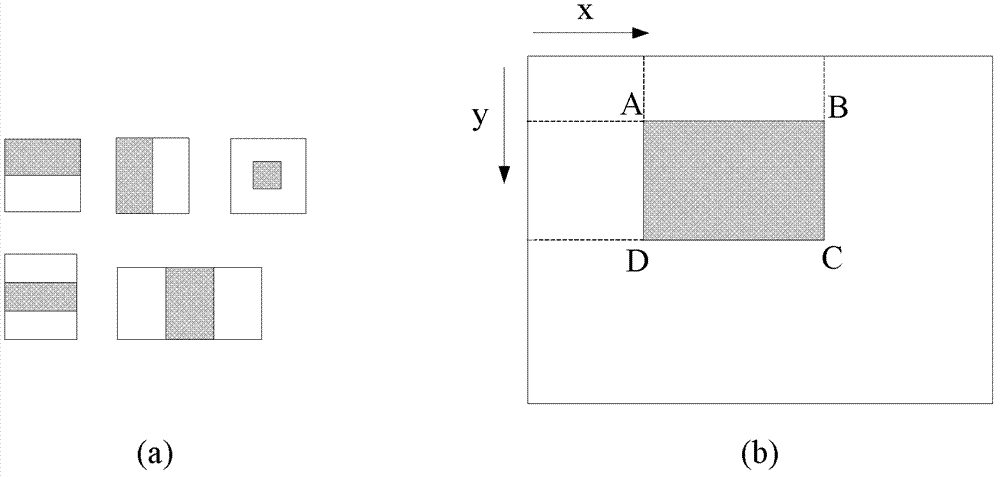

Robust iris region segmentation method based on specific boundary detectors

ActiveCN102629319BCalculation speedDetection speedCharacter and pattern recognitionFeature setData set

The invention discloses a robust iris region segmentation method based on specific boundary detectors, which comprises the following steps: S1, constructing a left and right inner boundary, left and right outer boundary and upper and lower eyelid boundary iris specific boundary training data set and a candidate feature set; S2, constructing the six iris specific boundary detectors by using a cascaded self-adaptive learning algorithm; S3, positioning an iris inner boundary by utilizing the left and right inner boundary detectors and weighted Hough transform; S4, positioning an iris outer boundary by utilizing the left and right outer boundary detectors and the weighted Hough transform; and S5, positioning an upper eyelid boundary by utilizing the upper and lower eyelid boundary detectors and a robust least square method. By utilizing the robust iris region segmentation method, an iris effective area can be accurately segmented in an iris image containing a lot of noise, so that the accuracy, the robustness and the usability of an iris identification system are improved. The robust iris region segmentation method can be widely applied to various application systems for identity recognition and security defense by using iris recognition.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

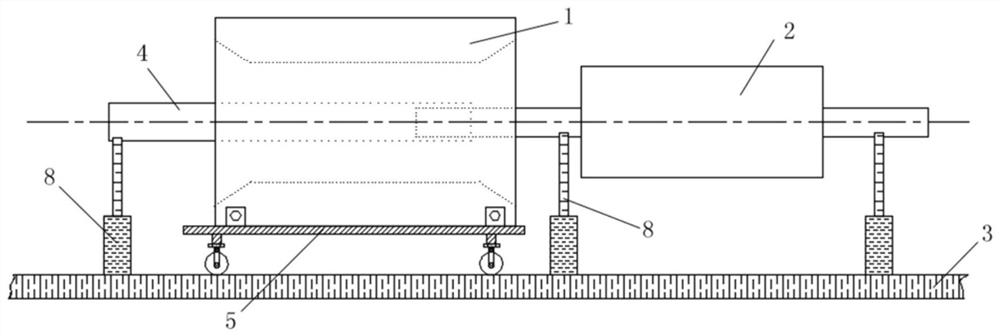

Simple pneumatic lifting and rapid releasing vertical automatic impact cylinder

InactiveCN111504822AReduced fit requirementsReduce frictional resistanceMaterial strength using repeated/pulsating forcesHigh accelerationEngineering

The invention discloses a simple pneumatic lifting and rapid releasing vertical automatic impact cylinder which comprises a high-pressure gas gun used for generating high-acceleration impact force, animpact cylinder body and a control cylinder. The impact cylinder comprises a cylinder body, a piston and a piston rod, the piston is fixedly mounted on the piston rod, and the piston is used for receiving high pressure generated by the high-pressure gas gun to drive the piston rod to move at a high speed in the cylinder body; the control cylinder is used for providing controllable braking for thepiston rod. The simple pneumatic lifting and rapid releasing vertical automatic impact cylinder can be suitable for realizing a high-acceleration impact mechanical environment test, the test condition is easy to meet, the cost is low, the use is convenient, and the excitation of the high-acceleration impact mechanical environment can be safely and reliably realized by multiple times of repetition.

Owner:CHONGQING UNIV OF ARTS & SCI

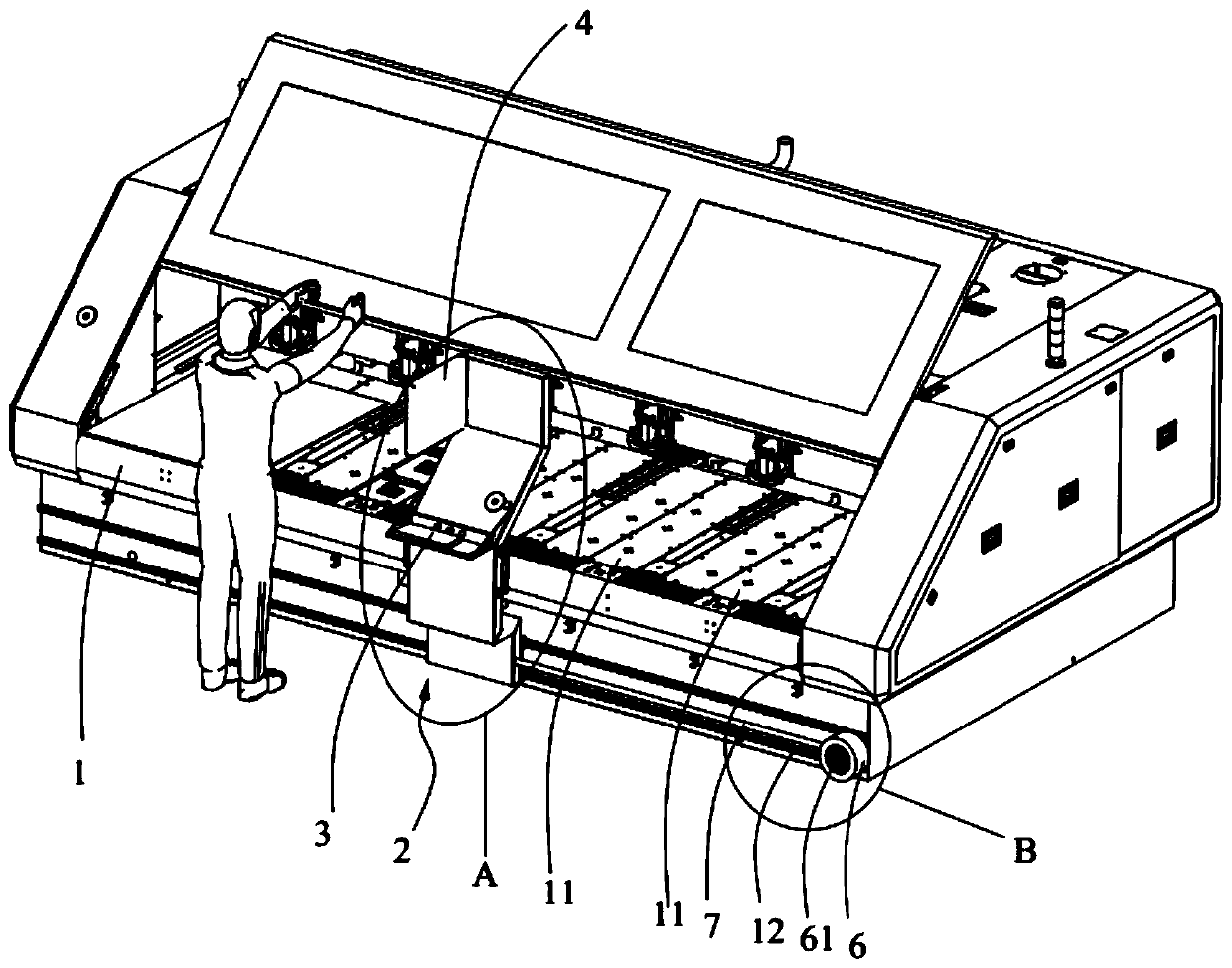

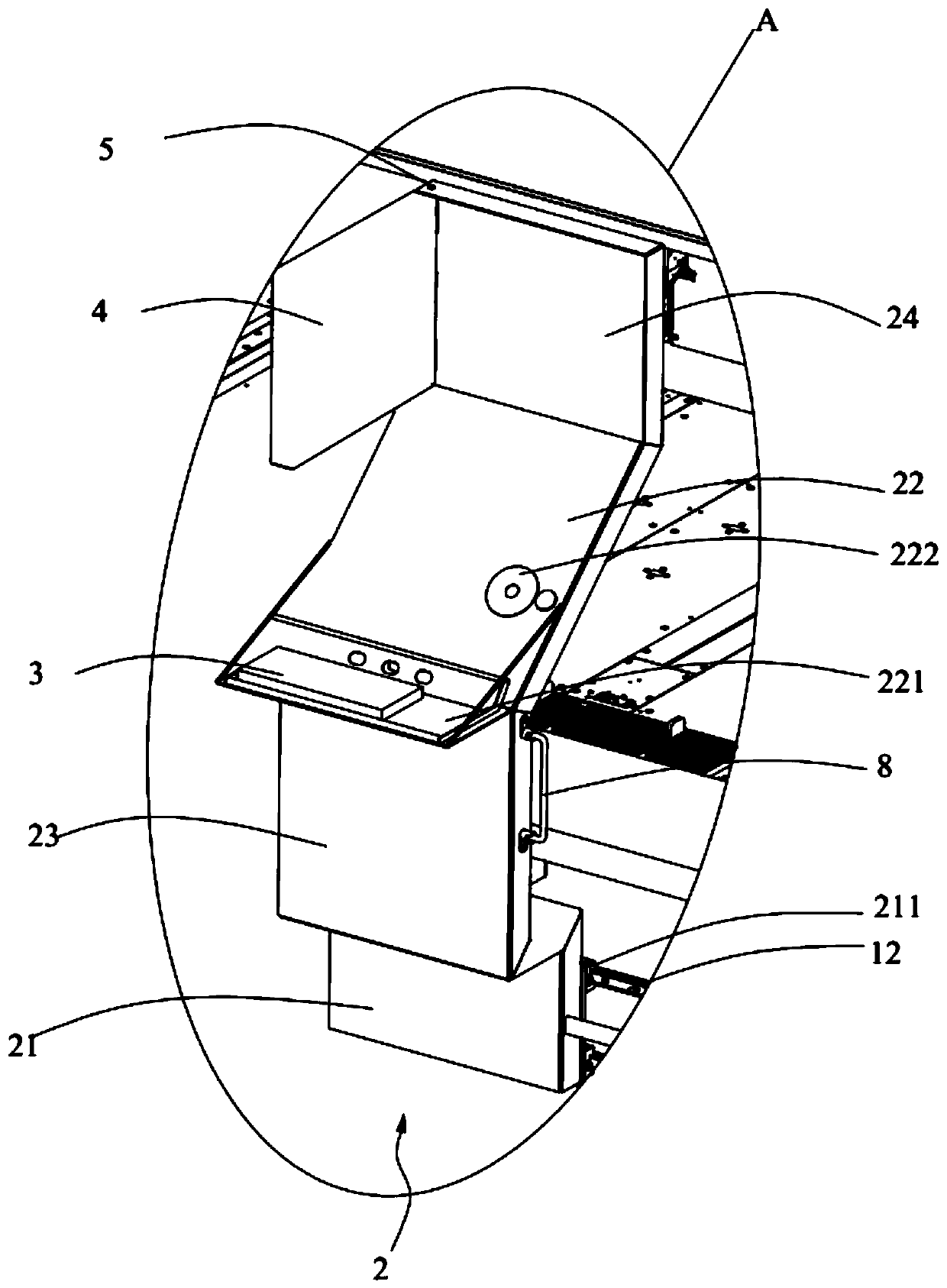

Drilling and routing machine and production line

PendingCN111573190AAvoid moving back and forthReduced fit requirementsMechanical conveyorsProduction lineControl engineering

The invention belongs to the technical field of PCB production and machining, and discloses a drilling and routing machine and a production line. The drilling and routing machine comprises a base andan operation tray; multiple workbenches are arranged on the base in parallel at intervals; an operation assembly and a display screen are arranged on the operation tray, and the display screen is electrically connected to the operation assembly; and the operation tray is configured to be arranged in a sliding mode relative to the base so that the operation tray can be selectively arranged right opposite to the workbenches. According to the drilling and routing machine, the operation tray can be pushed to slide relative to the base to the required station position, and only one operator is needed to complete monitoring in front of the station and perform commanding and adjusting in front of the operation tray at the same time, so that manpower resources are saved, the production cost is effectively reduced, and the production efficiency is improved; and meanwhile, compared with the prior art, the machine has the beneficial effects that the requirement for cooperation between two operators for completing work is reduced, work errors caused by cooperation deviation between the two operators are reduced, danger in the production process is reduced, and the safety and reliability are improved.

Owner:SUZHOU VEGA TECH CO LTD

Marking and positioning device and exposure machine

PendingCN111889891ASimple structureHigh precisionPhotomechanical exposure apparatusMicrolithography exposure apparatusLight beamEngineering

The invention relates to a marking and positioning device and an exposure machine. The marking and positioning device comprises a light source head, a marking head and an optical fiber. The light source head comprises a light source and a coupling lens. The marking head comprises a collimating lens. The light incident end of the optical fiber is connected with the light source head. The light outlet end of the optical fiber is connected with the marking head. A light beam emitted by the light source head is output after passing through the coupling lens, the optical fiber and the collimating lens in sequence. By means of the scheme, the marking and positioning device can realize high-precision marking and positioning, and is simple in overall structure, low in cost, stable in performance and high in cost performance.

Owner:ZHONGSHAN AISCENT TECH

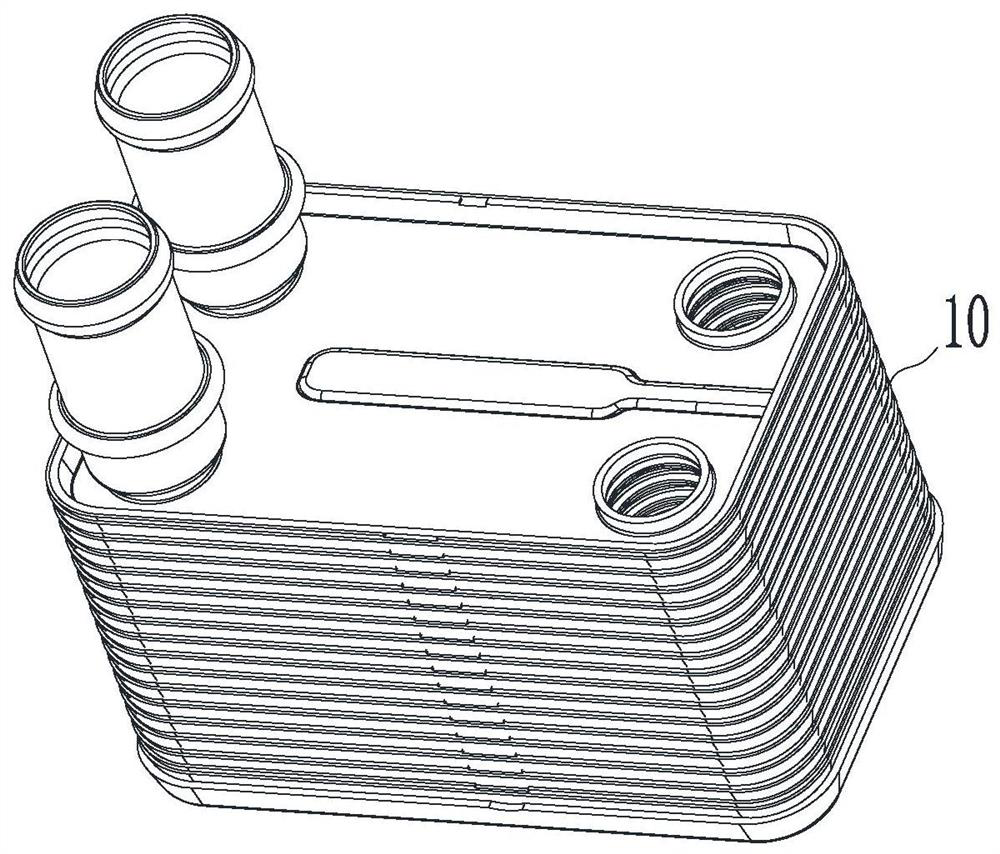

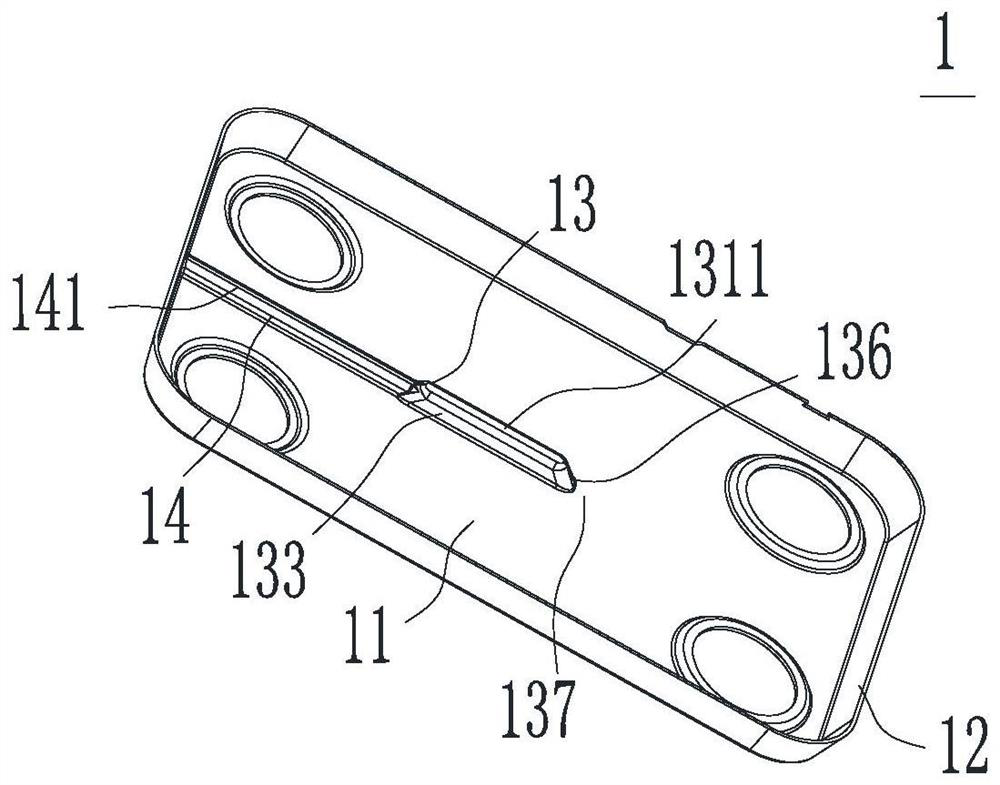

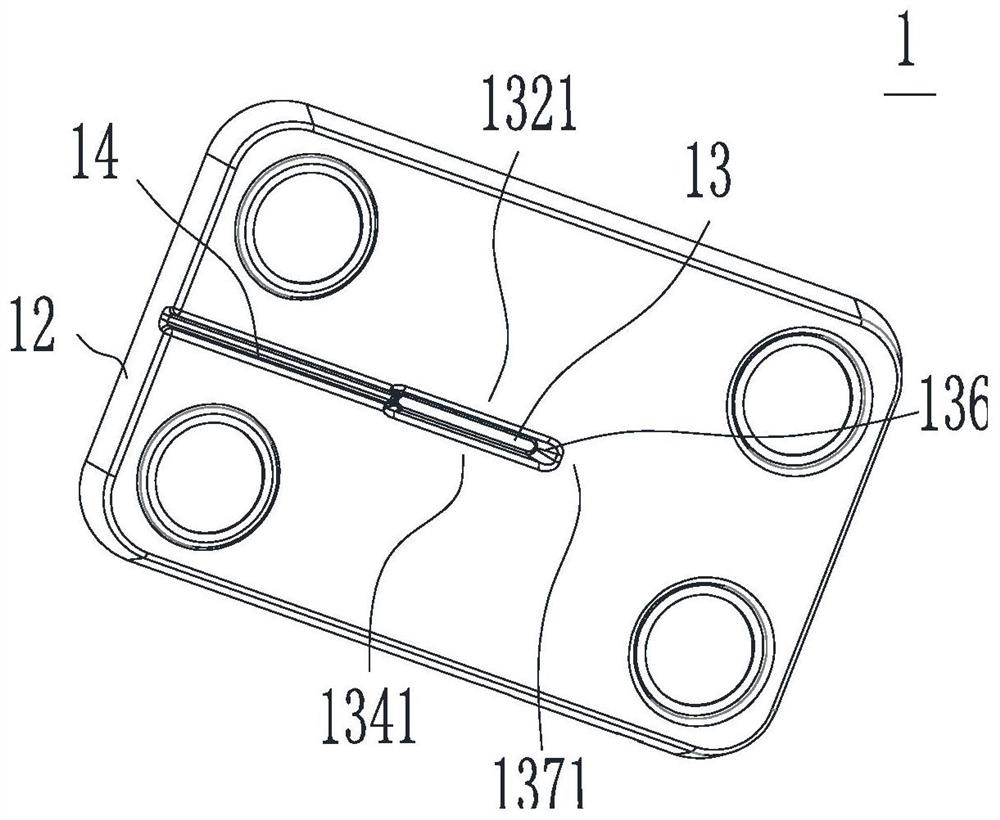

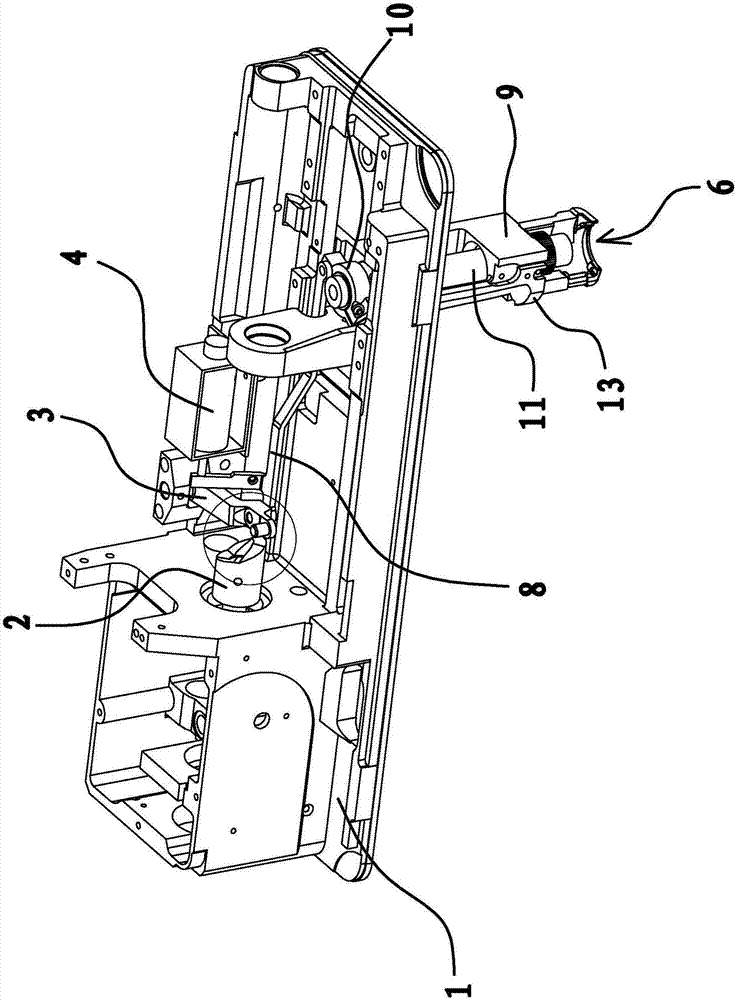

Heat exchanger

PendingCN114688897AReduced fit requirementsEasy to installLaminated elementsStationary plate conduit assembliesPhysicsHeat exchanger

The heat exchanger comprises a core body, the core body comprises a first plate sheet and a second plate sheet, the core body is provided with a first fluid channel and a second fluid channel, the first fluid channel comprises a first inter-plate channel, the second fluid channel comprises a second inter-plate channel, the core body is provided with a first isolation part and a second isolation part, the first isolation part is located on the first plate sheet, and the second isolation part is located on the second plate sheet. The first isolation part is provided with a first welding part, a second welding part and a first main body part, the first welding part is provided with a first welding surface, and the first welding surface is welded and fixed with a second plate sheet adjacent to one side of the first plate sheet, so that the first isolation part divides the first inter-plate channel part into a first inter-sub-plate channel and a second inter-plate channel; the second welding part is provided with a second welding surface, and the second welding surface is welded and fixed with a second plate adjacent to the other side of the first plate, so that the second isolation part divides the second inter-plate channel part into a third inter-sub-plate channel and a fourth inter-sub-plate channel. Matching requirements of the isolation part can be reduced, installation is easy, and processing is convenient.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

Thread trimming mechanism of sewing machine

ActiveCN107419448AThere will be no seam off-lineReduced fit requirementsNeedle severing devicesEngineeringHinge point

The invention provides a thread trimming mechanism of a sewing machine and belongs to the technical field of machines. The problem that the cooperative stability of an existing tread trimming mechanism of the sewing machine is poor is solved. The thread trimming mechanism of the sewing machine comprises a thread trimming knife, a swing rod driving piece, a swing rod and a thread trimming cam, wherein the swing rod is hinged to the sewing machine, and the thread trimming cam can rotate. The swing rod is located between the thread trimming cam and the swing rod driving piece, a transmission structure is arranged between the swing rod and the thread trimming knife, and the transmission structure can drive the thread trimming knife to swing and trim thread when the swing rod swings. The thread trimming cam is in a sleeve shape or in a columnar shape, a cam surface is arranged at one end of the thread trimming cam, the swing rod abuts against the cam surface, and when the thread trimming cam rotates, the swing rod can swing around the hinged point under the action of the cam surface.

Owner:ZHEJIANG ZOJE SEWING MACHINE

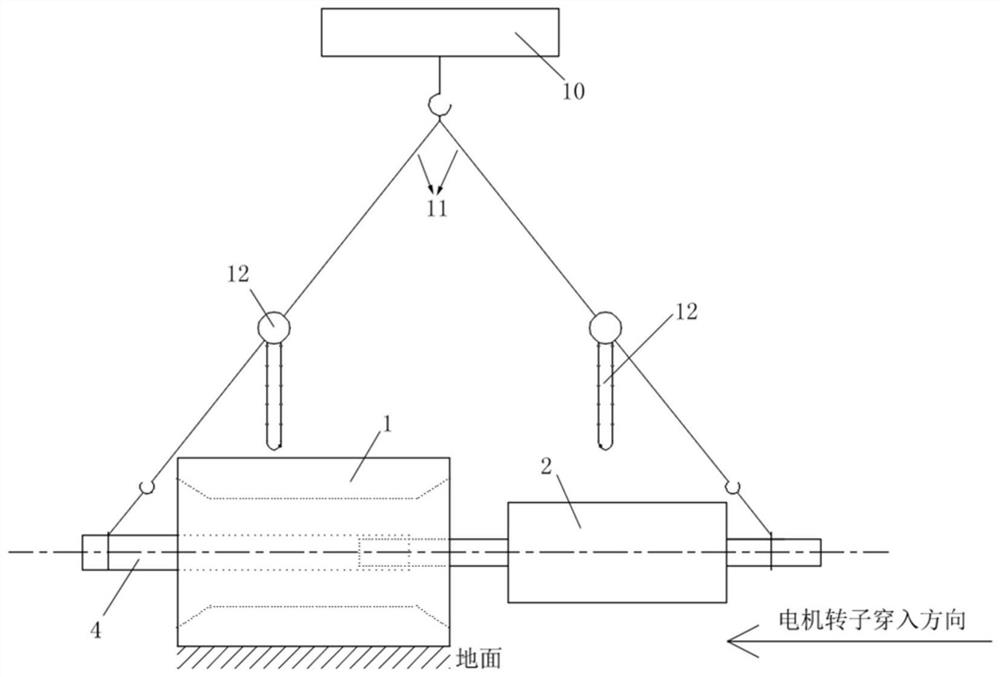

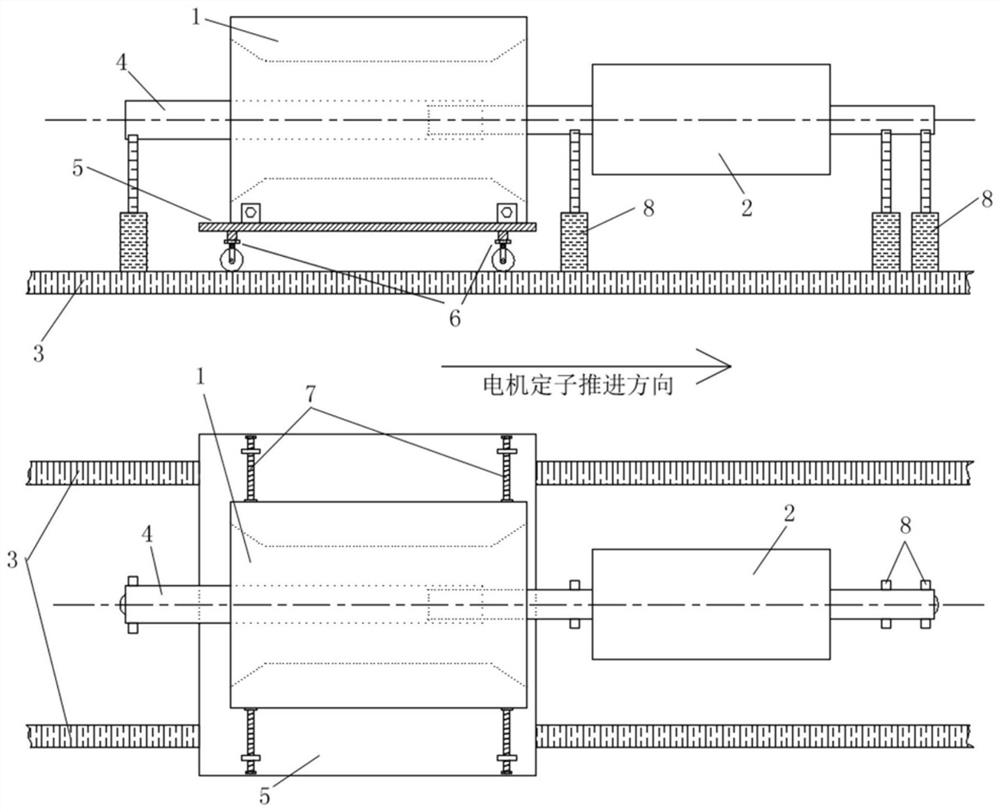

Motor rotor penetrating device

PendingCN113381569AAvoid damageAvoid rubbingManufacturing stator/rotor bodiesCentering/balancing rotorsElectric machineClassical mechanics

The invention relates to a motor rotor penetrating device. The device comprises a guide rail, a dummy shaft sleeve, a stator moving device and a rotor supporting device; the rotor supporting device is used for supporting a motor rotor; the stator moving device comprises an object placing plate and a moving assembly; the moving assembly moves back and forth along the guide rail; a horizontal adjusting mechanism is arranged between the moving assembly and the object placing plate; a motor stator is placed on the object placing plate; a limiting and positioning mechanism is arranged on the object placing plate; and the rotor supporting device comprises a plurality of supporting frames, and the arrangement positions and the heights of the supporting frames can be adjusted. According to the motor rotor penetrating device, the motor rotor is supported by the supporting frames and the height of the motor rotor is adjusted, so that the central lines of the motor stator and the motor rotor can be aligned, the motor stator is driven by the stator moving device to move along the guide rail, and the motor rotor can easily penetrate into the motor stator, and collision and abrasion between the motor stator and the motor rotor are avoided, and structural damage of the motor stator and the motor rotor is effectively prevented.

Owner:HUANENG TAICANG POWER GENERATION CO LTD

Caster seat for adjusting ground clearance

The invention discloses a caster seat for adjusting a ground clearance. The caster seat for adjusting the ground clearance comprises a rotating handle, a rotating groove, a screw seat, a screw rod, a wheel axle and a rubber wheel, wherein the rotating handle is connected with the rotating groove through a pin shaft; the rotating groove is connected with the screw rod through a pin shaft; the screw rod is a cylinder; the screw rod is connected with the screw seat through an external thread; the outer wall of the screw seat is welded on a seat sleeve; the outer wall of the seat sleeve is provided with a guide sleeve; the upper end of the guide sleeve is welded with a cover plate I; the lower end of the guide sleeve is welded with an L-shaped support; a fixed seat is welded on the side wall of the guide sleeve; the L-shaped support is welded together with the wheel axle; and the rubber wheel is fixed on the wheel axle through a nut and a cover plate. According to the invention, through tightening the rotating handle, the cylindrical screw rod is driven by the rotating handle to rotate, the rotation motion of the screw rod is converted into up-and-down motion and the distance between the bottom end of the screw rod and the seat sleeve is vertically adjusted so that the clearance between a trolley and the ground is adjusted. Therefore, the caster seat for adjusting the ground clearance has the advantages that the structure of the caster seat is simple, the operation of the caster seat is convenient, the caster seat realizes a guiding function, the efficiency is increased, labor is saved, the safety factor of the caster seat is high, and the caster seat also realizes wide practicability.

Owner:QINGDAO ALLITE AUTO TECHNIC

Method for uniformly polishing optical device

ActiveCN107685284AReduce the difficulty of cooperationEliminate edge collapseWork carriersGrinding/polishing safety devicesEngineeringMechanical engineering

The invention relates to a method for uniformly polishing an optical device. The method comprises the steps of 1, putting a planetary wheel into a polisher; 2, putting the optical device into a machining cavity, wherein the machining cavity is formed in a polishing hole of the planetary wheel and can freely rotate relative to the polishing hole; 3, starting polishing, wherein the planetary wheel rotates with a driving wheel of the polisher and has the rotation speed w1, the machining cavity rotates with the planetary wheel and the optical device and has the rotation speed w2, and w1 is not equal to w2. According to the technical scheme, in the polishing process, the grinding paths which all parts of the optical device pass by are basically the same.

Owner:台州市正大光学有限公司

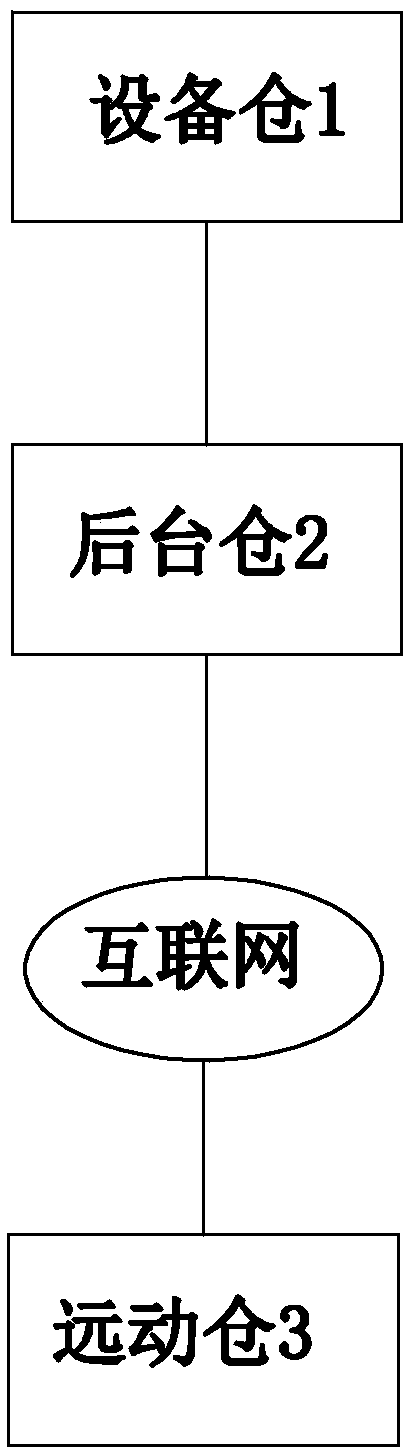

Dynamic simulation platform for substation automation system and signal checking method

ActiveCN109510306AReduce staffingReduced fit requirementsEmergency protective circuit arrangementsInformation technology support systemDynamic simulationDynamic simulation model

The invention relates to a dynamic simulation platform for a substation automation system. The dynamic simulation platform is characterized by comprising an equipment bin, a background bin and a telecontrol bin which are sequentially connected, the equipment bin and the background bin are arranged at the same place, the background bin is connected with the telecontrol bin through the network, theequipment bin includes an equipment power supply area located at the bottom, a secondary circuit area located at the back and a protective device area located at the top, the background bin includes adisplay area located at the top and a monitoring host area located at the middle, the telecontrol bin includes a telecontrol power supply area located at the bottom, a switch area located at the middle and a telecontrol device area located at the top. The dynamic simulation platform has the advantages of less personnel investment, high checking accuracy, short checking time, high efficiency, simple and convenient operation and accurate and visual signal checking.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD JINHUA POWER SUPPLY CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com