Revolving shaft with muffling cam

A cam and shaft technology, applied in the field of opening and closing connection between the upper and lower covers, can solve the problems of unstable size, high cost, low yield, etc., to reduce manufacturing precision, eliminate abnormal sound, and easy to process and manufacture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

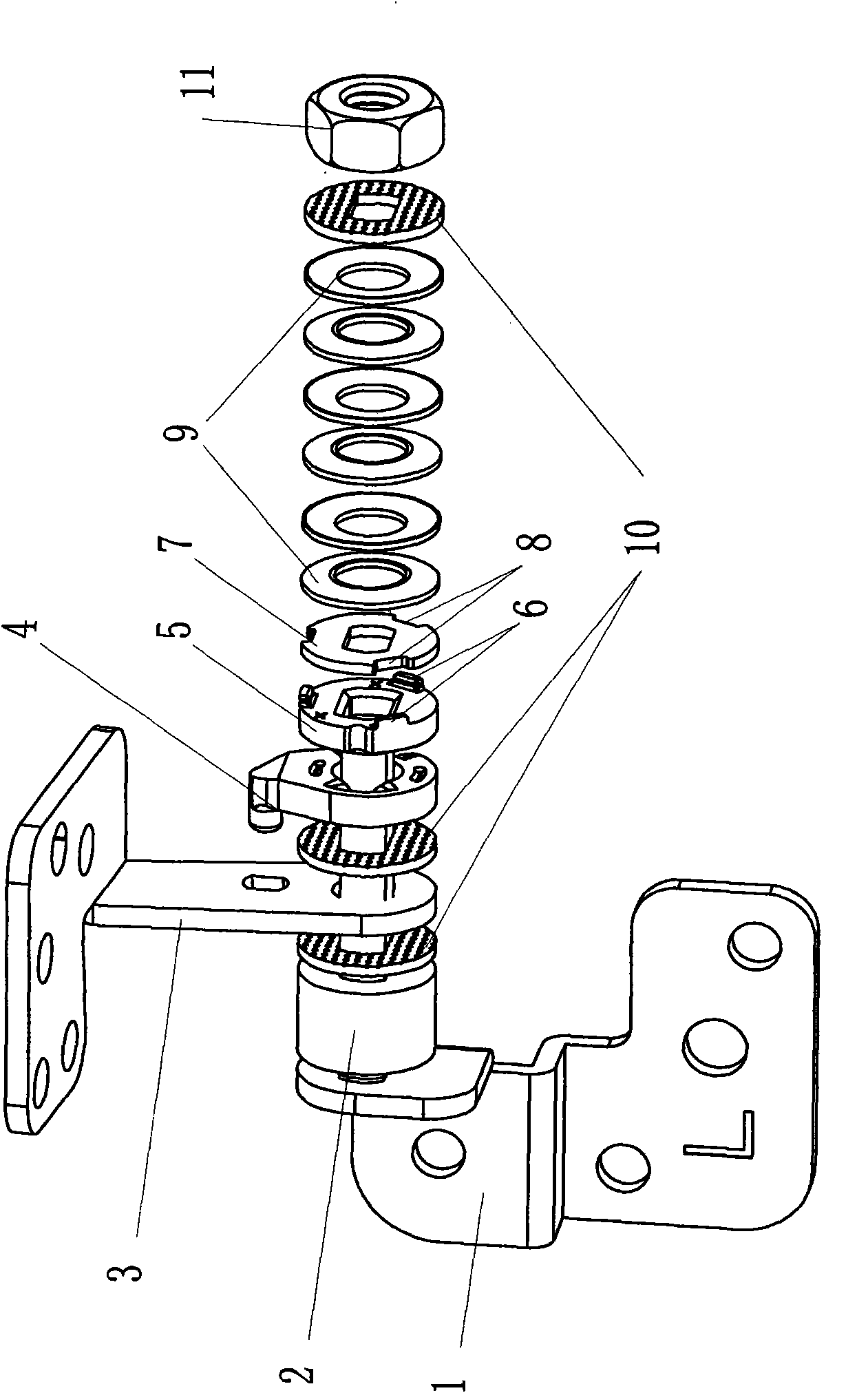

[0008] Depend on figure 1 It can be seen that the rotating shaft with the silencer cam in the present invention includes a bearing frame 3, a concave wheel 4, a cam 5 and a plurality of shrapnels 9 sequentially installed on the rotating shaft 2. Fastening, wherein a sound-absorbing sheet 7 is provided between the cam 5 and the shrapnel 9, three arc-shaped grooves 8 are evenly distributed on the outer circumference of the sound-absorbing sheet 7, and three arc-shaped grooves 8 are arranged on the outer circumference of the cam 5. The tongue piece 6 that arc-shaped groove 8 fits, and promptly cam 5 tightly cooperates and blocks sound-absorbing piece 7, makes both become one. At the same time, on the rotating shaft 2 , gaskets 10 are provided on both sides of the support frame 3 and between the elastic piece 9 and the nut 11 . Noise-absorbing sheet 7 is made of SK7 material.

[0009] During use, because the groove 8 on the cam 5 and the groove 8 on the sound-absorbing sheet 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com