Clamping type feedback lever

A feedback lever and clamping technology, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of high manufacturing precision, difficult machining, and hidden dangers of falling off, so as to reduce processing difficulty, The effect of eliminating bad influence and eliminating negative influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

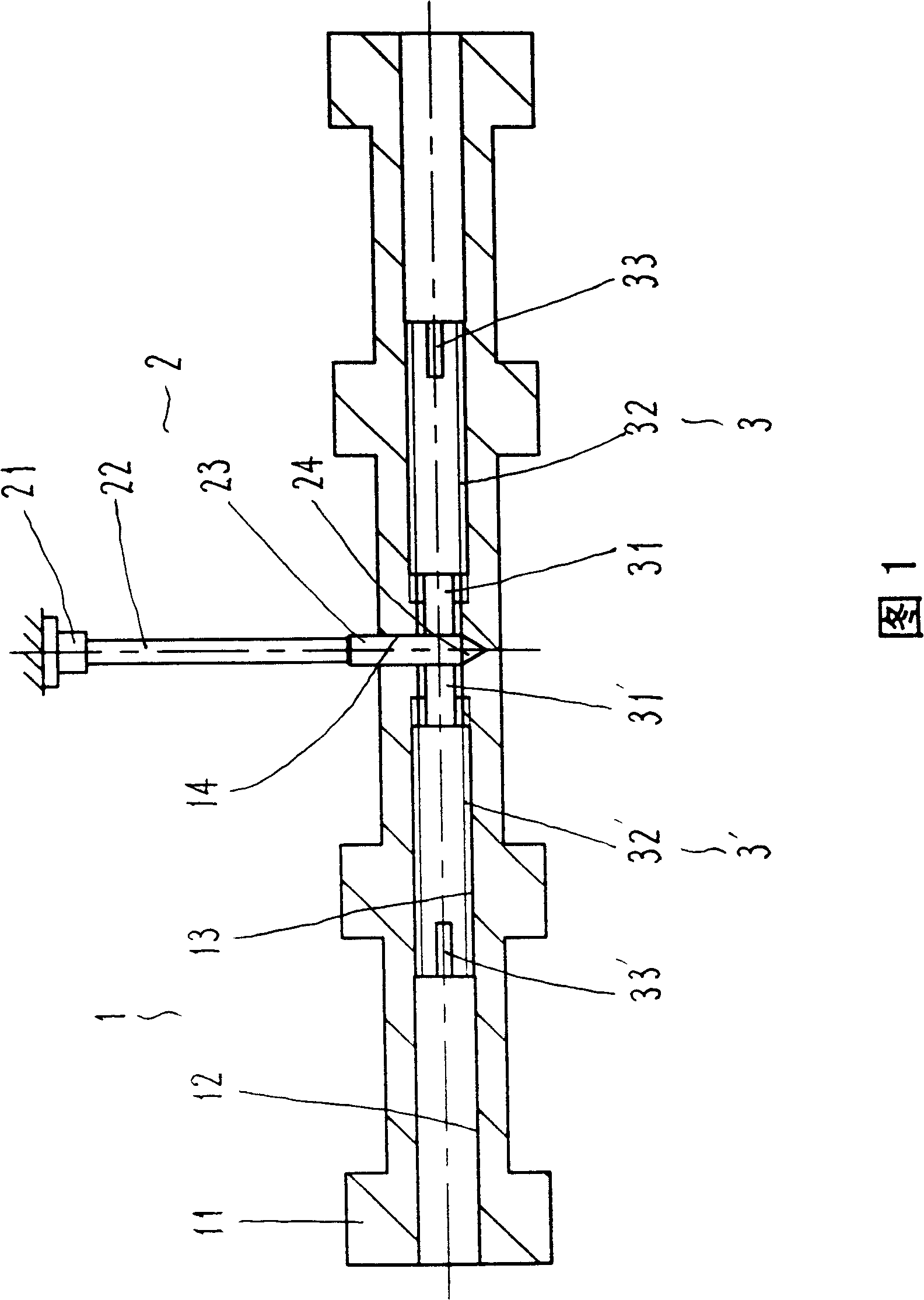

[0011] Referring to Fig. 1, the clamping feedback lever includes a spool 1, a feedback lever 2 and two clamping screws 3, 3'.

[0012] The valve core 1 has the same or similar external structure as the existing structure. The feature of the present invention is that a through hole 12 is arranged on the axial center line of the valve core body 11 of the valve core 1, and the diameter of the middle part of the through hole 12 is slightly smaller. A screw hole 13 is provided, and the screw hole 13 can also be a symmetrical section, and a through hole with a diameter slightly larger or the same as the thread root diameter of the screw hole 13 is connected between the two sections, and an accommodating hole is arranged in the middle of the through hole 12 14. The center line of the receiving hole 14 is perpendicular to the center line of the through hole 12 and intersects. The receiving hole 14 passes through the through hole 12 and a tapered hole is drilled on its inner wall.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com