Installing anti-rotating locating tool and method for automobile wire harness bonding iron terminal

A technology for automotive wiring harnesses and terminals, which is applied in the direction of manufacturing tools and workpiece clamping devices, can solve the problems of increasing the structural design of grounding terminals, increasing the weight and cost of terminals, and requiring boundary parts, so as to improve the efficiency of process installation and reduce the Terminal weight, effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the present invention will be further described:

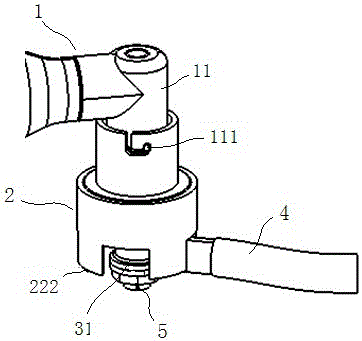

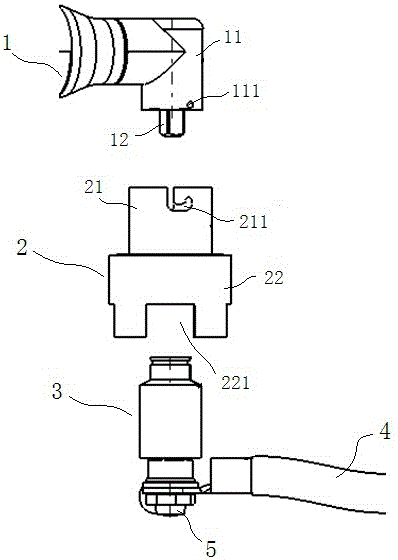

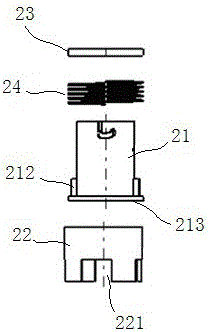

[0023] Figure 1 to Figure 3 Shown is an anti-rotation positioning tool for installing an automobile wire harness ground terminal, including a torque gun 1 , a positioning sleeve 2 and a sleeve 3 . Torque gun 1 is used to provide tightening torque. The positioning sleeve 2 is used to fix the position of the ground terminal 4 of the wiring harness. The sleeve 3 is used to connect the torque gun 1 and the bolt or nut used to fasten the ground terminal 4 of the wire harness to transmit the fastening torque. In this embodiment, the sleeve 3 is used to connect the torque gun 1 and the fastening bolt 5 . The positioning sleeve 2 is a hollow structure, the sleeve 3 is located in the positioning sleeve 2, the driving square head 12 of the torque gun 1 is inserted downward into the positioning sleeve 2 and connected with the upper end of the sleeve 3, the lower part of the sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com