Winding machine

A technology of winding machine and rotating mechanism, which is applied in the direction of packing/bundling items, packaging, wrapping items, etc. It can solve the problems of not being able to meet the needs, unsightly appearance, and difficult welding, etc., to achieve reasonable structure, avoid duplication of labor, and reduce workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

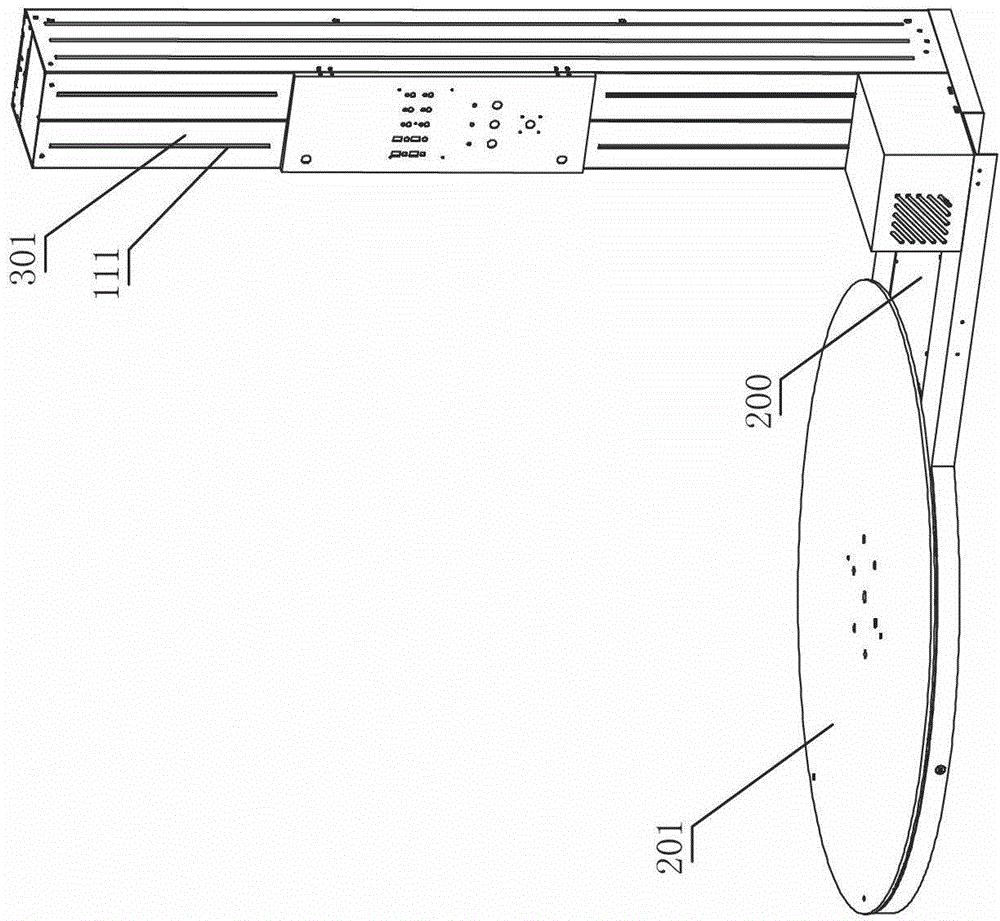

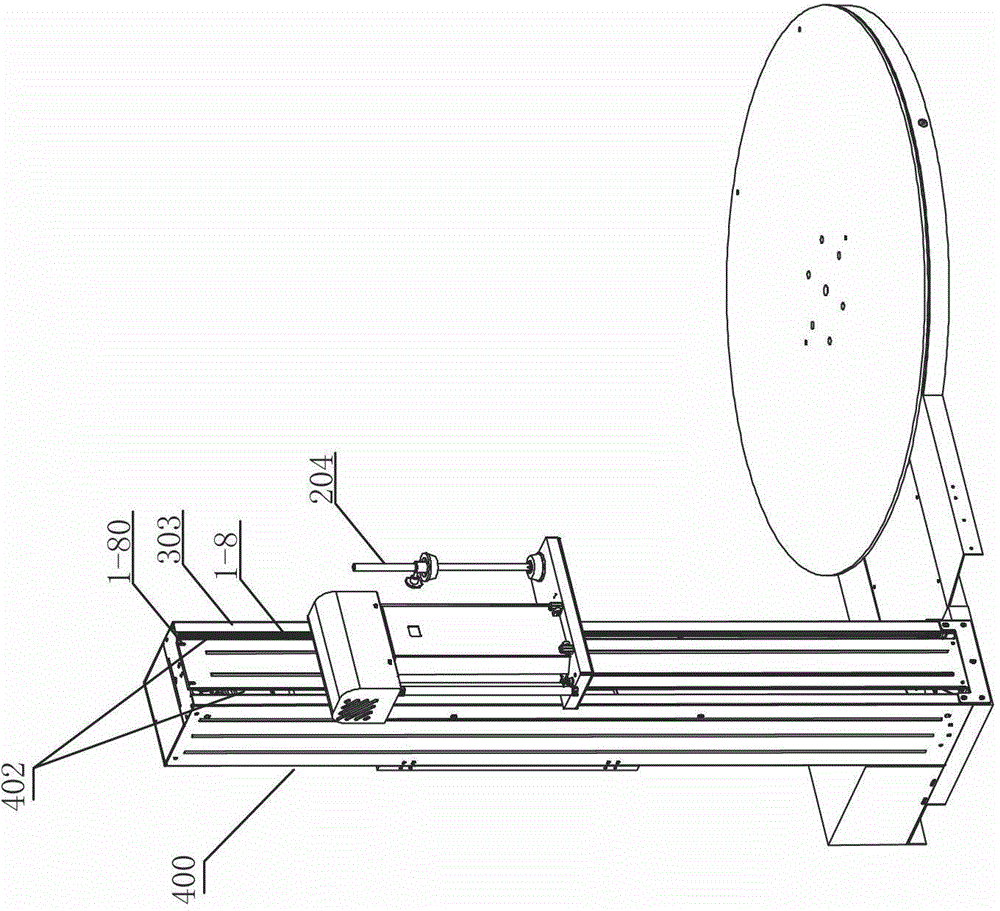

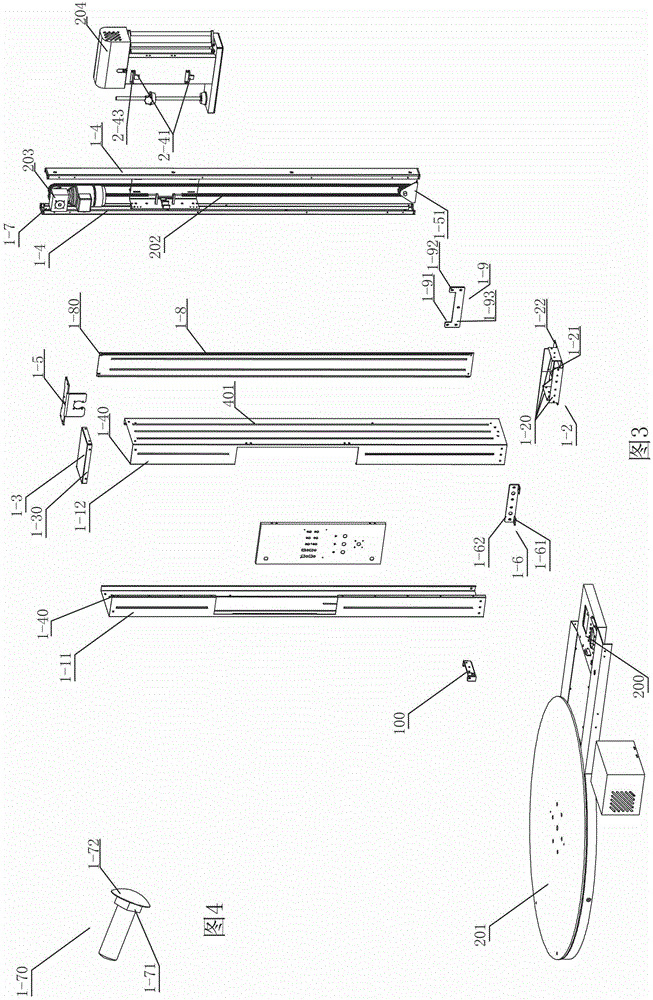

[0063] With reference to the accompanying drawings, especially the Figure 1-4 . The winding machine provided by the present invention includes a column, a winding machine base 200 , a rotating mechanism 201 and a liftable film frame 204 , and the rotating mechanism is used to carry the articles to be wound.

[0064] The central column of the winding machine provided by the present invention includes a column shell main body, the bottom of the column shell main body is hinged with the winding machine base 200 through the first connecting piece 100, and the column shell body is composed of the first column cover plate 1-11 and the second column cover plate. The two column cover plates 1-12 are connected into a column shape; the winding machine column is also provided with a column bottom inner connector 1-2, and the column bottom inner connector 1-2 has a column contour shaping surface 1-20, and the The cross-sectional profile of the column is a rectangle or a rectangle with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com