Method for uniformly polishing optical device

A uniform technology for optical devices, applied in grinding/polishing equipment, grinding/polishing safety devices, working carriers, etc., can solve problems such as edge collapse, uneven flatness of optical devices, and unguaranteed product uniformity, etc., to achieve The effect of eliminating edge collapse, reducing the difficulty of fitting, and small friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

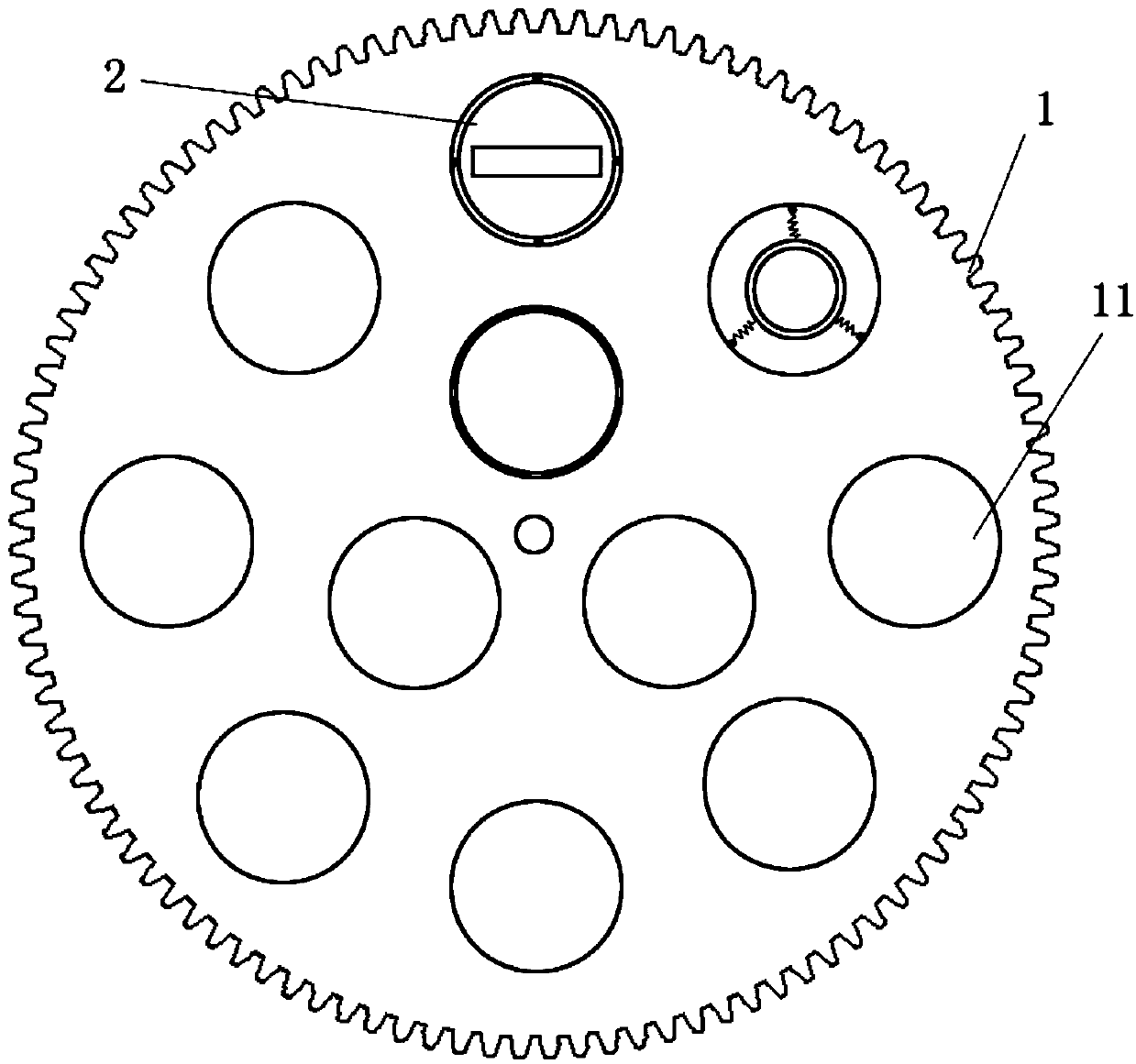

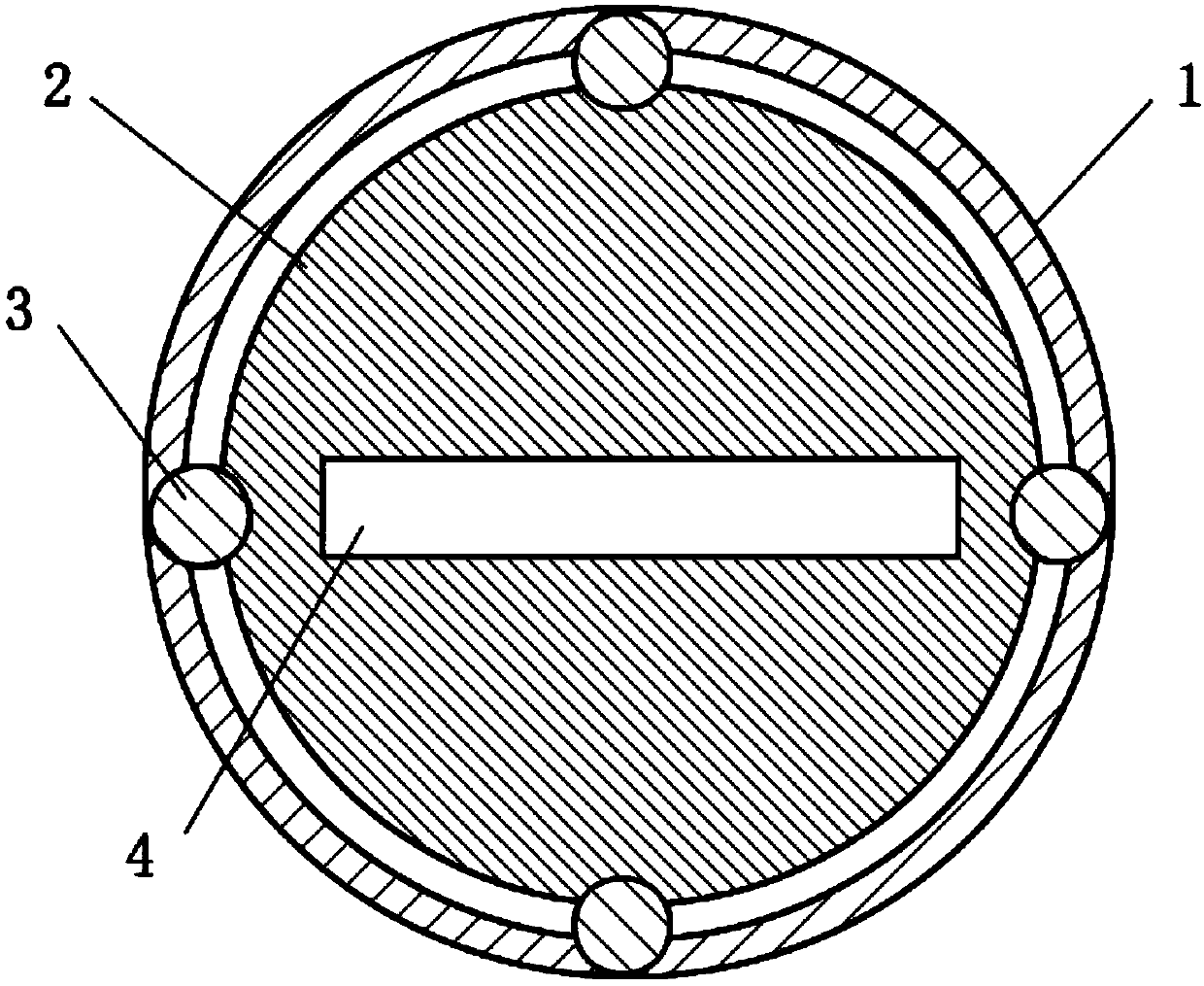

[0028] Such as figure 1 As shown, this embodiment is composed of a star wheel 1 and a processing cavity 2. The star wheel 1 is provided with a grinding hole 11, and the grinding hole 11 rotates around the center of the star wheel 1 during the grinding process. figure 2 It is a schematic diagram of the coordination of the planetary wheel 1 and the machining cavity 2. The planetary wheel 1 is provided with an annular raceway that matches with the ball 3, and the other end of the ball 3 is set in the notch of the machining cavity 2 (also can be set In a circular ring raceway), and the star wheel 1 does not touch the processing cavity 2, the processing cavity 2 is provided with a rectangular station 4, when contemporary workpieces are placed in the station for polishing, the star wheel 1 follows the polishing machine The driving gear rotates, because there is friction between the machining part and the grinding disc that prevents the machining part from rotating in the rotation dire...

Embodiment 2

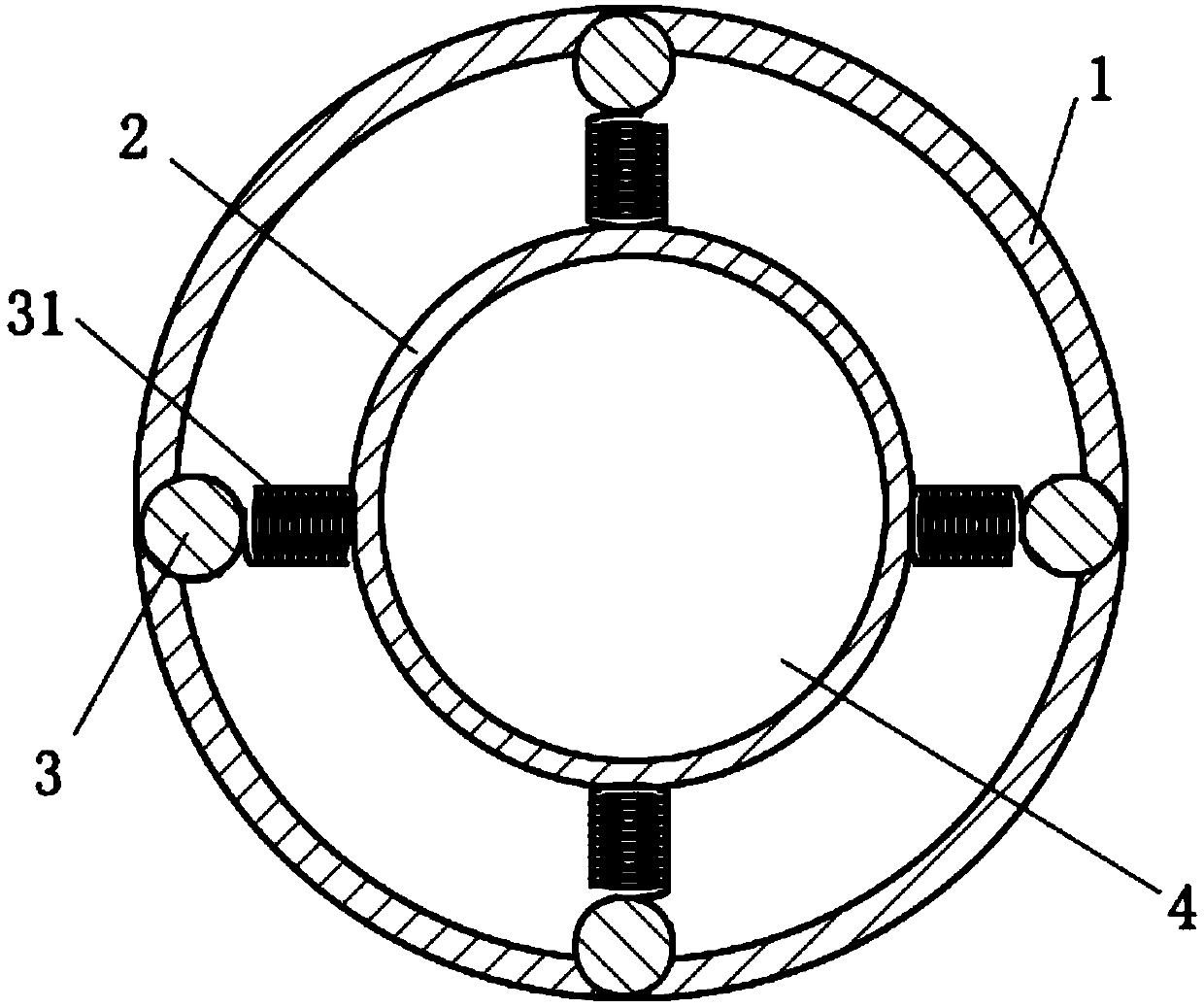

[0034] Such as image 3 As mentioned, this embodiment is basically the same as Embodiment 1, the difference is that the processing cavity 2 and the ball 3 are connected by an elastic member 31, wherein the natural length of the elastic member 31 is equal to the interval between the processing cavity 2 and the ball 3, thereby reducing the processing Matching requirements between cavity 2 and ball 3. When the grinding starts, the machining cavity is shifted relative to the center of the planetary wheel due to uneven force, so that the positions of the substitutive workpieces are shifted in different parts and the grinding is carried out on different paths.

Embodiment 3

[0036] Such as figure 1 As shown, the star wheel 1 is in direct contact with the processing cavity 2, and a lubricating layer is provided between the two. The lubricating layer can be alkyd resin, epoxy resin or acrylic resin, or a little less than 5% metal can be added to the above materials Oxide to increase wear resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com