Overhead escape device of light rail

An escape device and light rail technology, applied in life-saving equipment, building rescue, etc., can solve the problems of no high-altitude escape device, etc., and achieve the effects of clear deceleration principle, easy maintenance, and simple and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

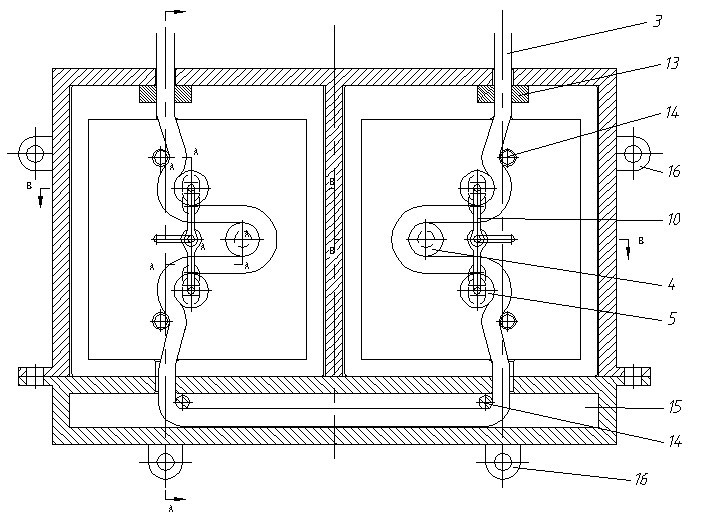

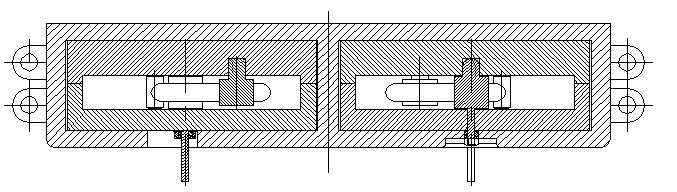

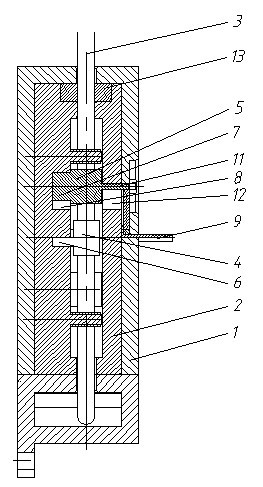

[0024] The present invention will be further described below in conjunction with accompanying drawing.

[0025] see figure 1 , figure 2 with image 3 As can be seen from the figure, the light rail high-altitude escape device of the present invention includes an outer shell 1 and an inner shell 2 located in the outer shell, and an escape rope 3 for escapees is arranged in the inner shell 2, and the two ends of the escape rope 3 Pass out from the same side of the inner shell 2 and the outer shell 1 and face downward when in use. A deceleration mechanism for decelerating the escape rope in use is provided in the inner shell, and the deceleration mechanism is mainly composed of a fixed friction block 4 and two moving friction blocks 5 that are both circular. The fixed friction block 4 is provided with a positioning pin 6, and the inner wall of the inner shell is provided with a positioning hole corresponding to the positioning pin, and the positioning pin is inserted into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com