Caster seat for adjusting ground clearance

A technology of ground clearance and caster seat, which is applied in the direction of road cleaning, construction, cleaning methods, etc., can solve the problems of low work efficiency in adjusting the ground clearance of trolleys, the inability to realize step-by-step adjustment, and large amount of machining, so as to save manpower , Extensive practicability, the effect of small amount of mechanical processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

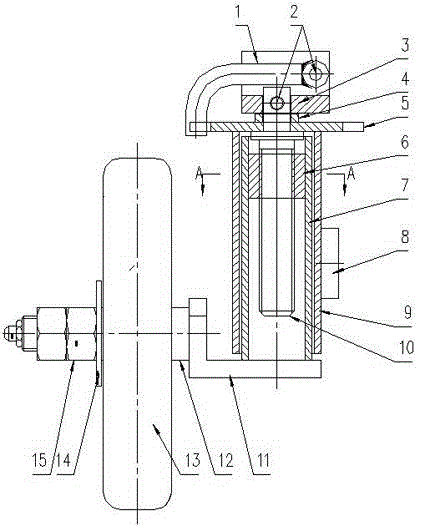

[0025] Further illustrate the present invention below in conjunction with accompanying drawing.

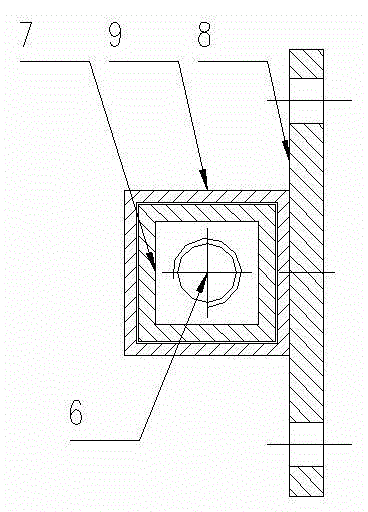

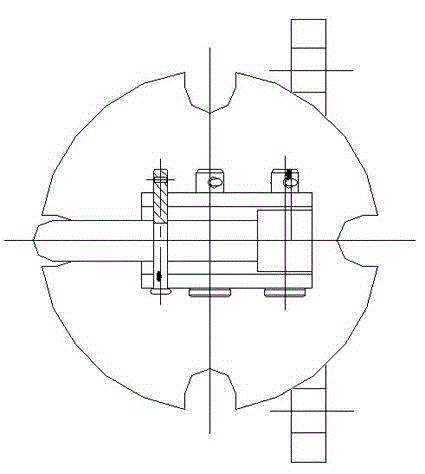

[0026] like figure 1 As shown, the caster seat for adjusting the ground clearance is characterized in that it includes a turning handle, a turning groove, a wire seat, a lead screw, an axle, and a rubber wheel. The turning handle is connected with the turning groove through a pin shaft, and the turning groove is connected through a pin shaft It is connected with the screw, the screw is a cylinder, the screw is connected with the screw seat through the external thread, the outer wall of the screw seat is welded on the seat cover, the outer wall of the seat cover is provided with a guide sleeve, and the upper end of the guide sleeve is welded with a cover plate I The lower end of the guide sleeve is welded with an "L"-shaped support, the side wall of the guide sleeve is welded with a fixed seat, the "L"-shaped support is welded to the wheel shaft, and the rubber wheel is fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com