Motor rotor penetrating device

A technology of rotor and moving device, which is applied in the direction of adjusting/balancing rotor, manufacturing stator/rotor body, etc., can solve the compression damage of stator iron core and slot wedge, stator iron core slot wedge damage and falling off, stator iron core or motor rotor compression Deformation damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

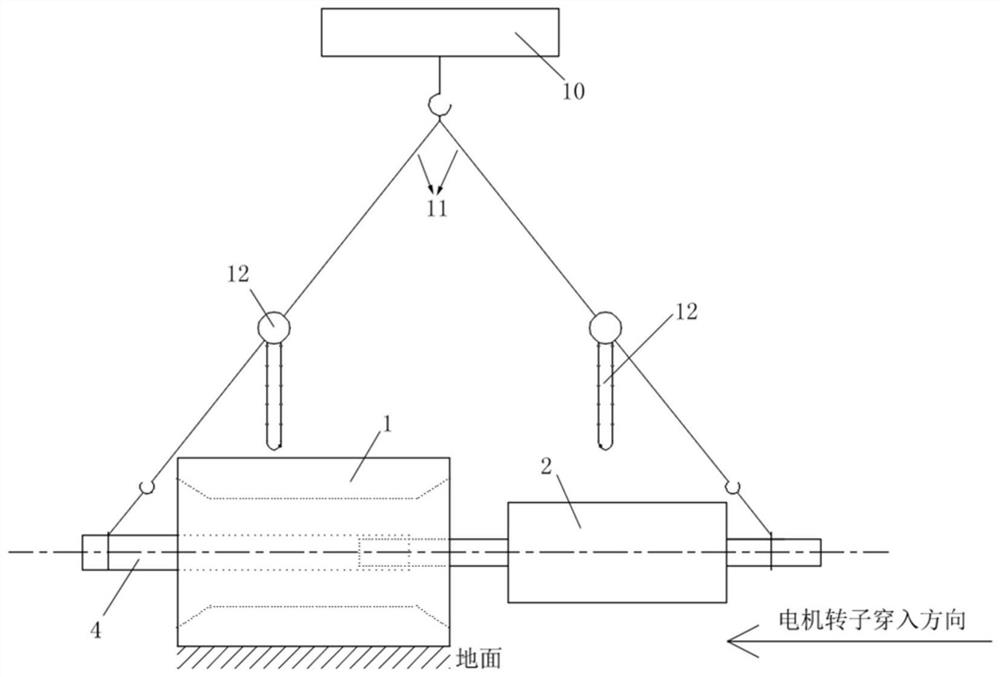

[0041] During the existing motor overhaul process, such as figure 1 As shown, the motor rotor 2 is hoisted by using the workshop crane 10 and the wire rope 11, and the motor rotor 2 is moved axially by jogging the workshop crane 1, so that the motor rotor 2 penetrates the motor stator 1, and the chain hoist 12 on the wire rope 11 is used to move the motor rotor 2. Adjust the level of the motor rotor 2 during the movement of the rotor 2. However, there are many certainties and deficiencies in the existing hoisting and threading back technology.

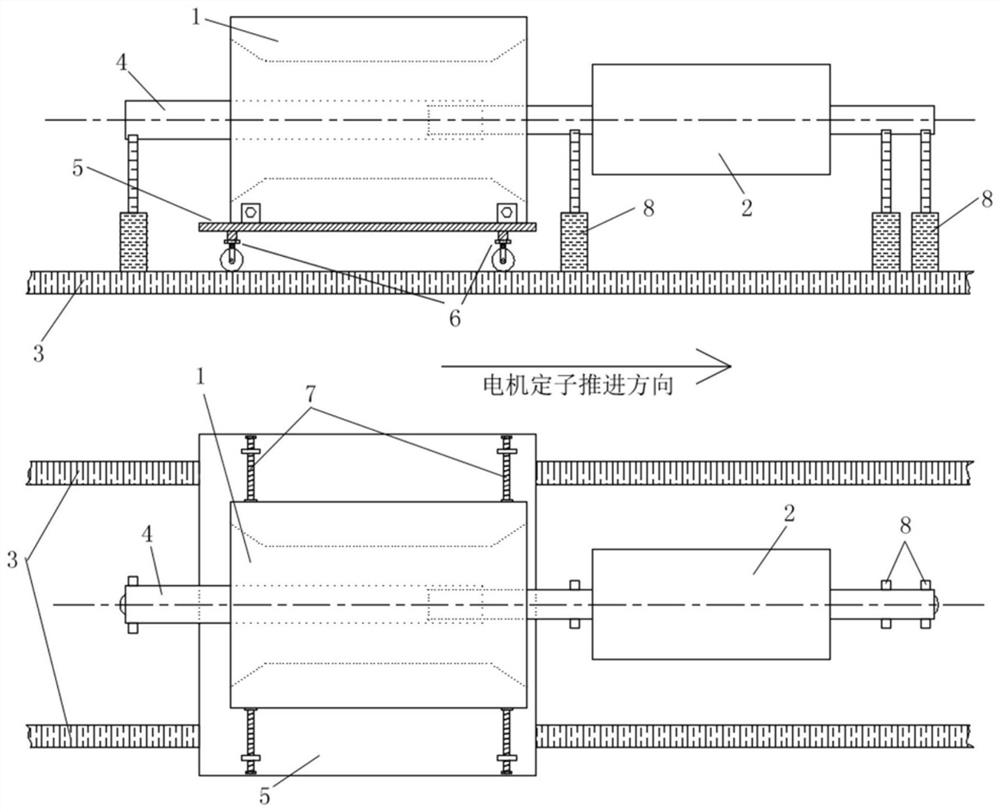

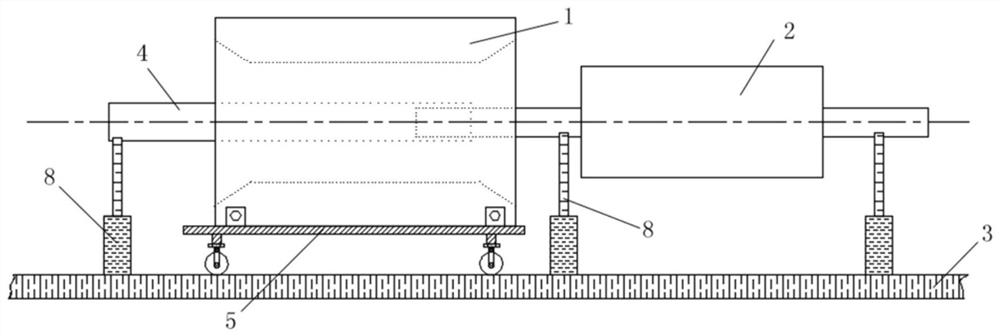

[0042] The application provides a motor through the rotor device, the side view and the top view are as follows figure 2 As shown, it includes a guide rail 3, a dummy shaft sleeve 4, a stator moving device 5 and a rotor supporting device, the stator moving device 5 moves back and forth along the guide rail 3, and the rotor supporting device is used to support the motor rotor 2; the stator moving device 5 includes a storage plate and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com