Transmission mechanism of bidirectional automatic gearbox

A technology of automatic transmission and transmission mechanism, which is applied in the field of machinery, can solve problems such as insufficient coordination, poor working stability of the transmission device, and insufficient cooperation between the blocking part and the abutting part, so as to ensure stability, improve stability, The effect of reducing coordination requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

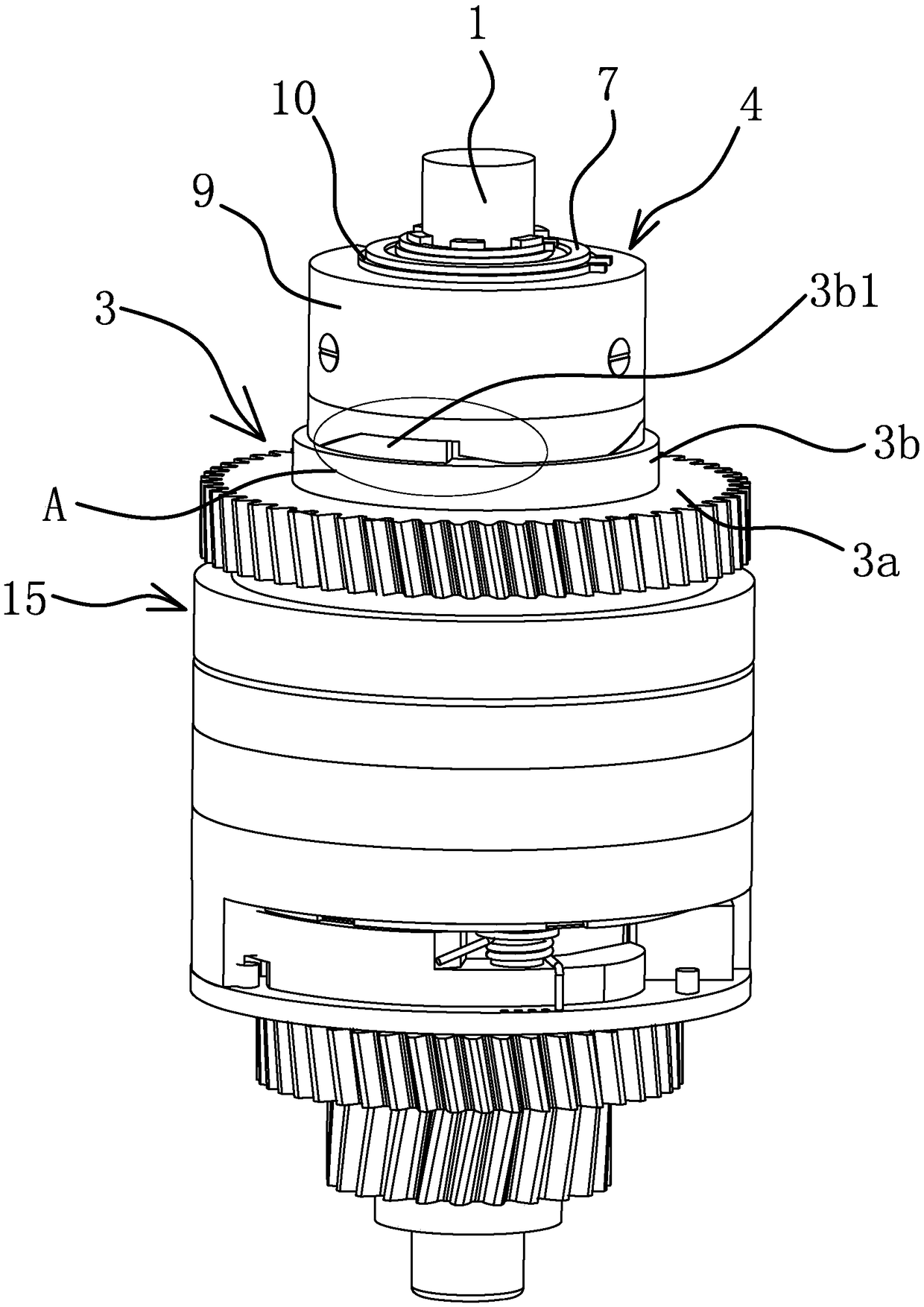

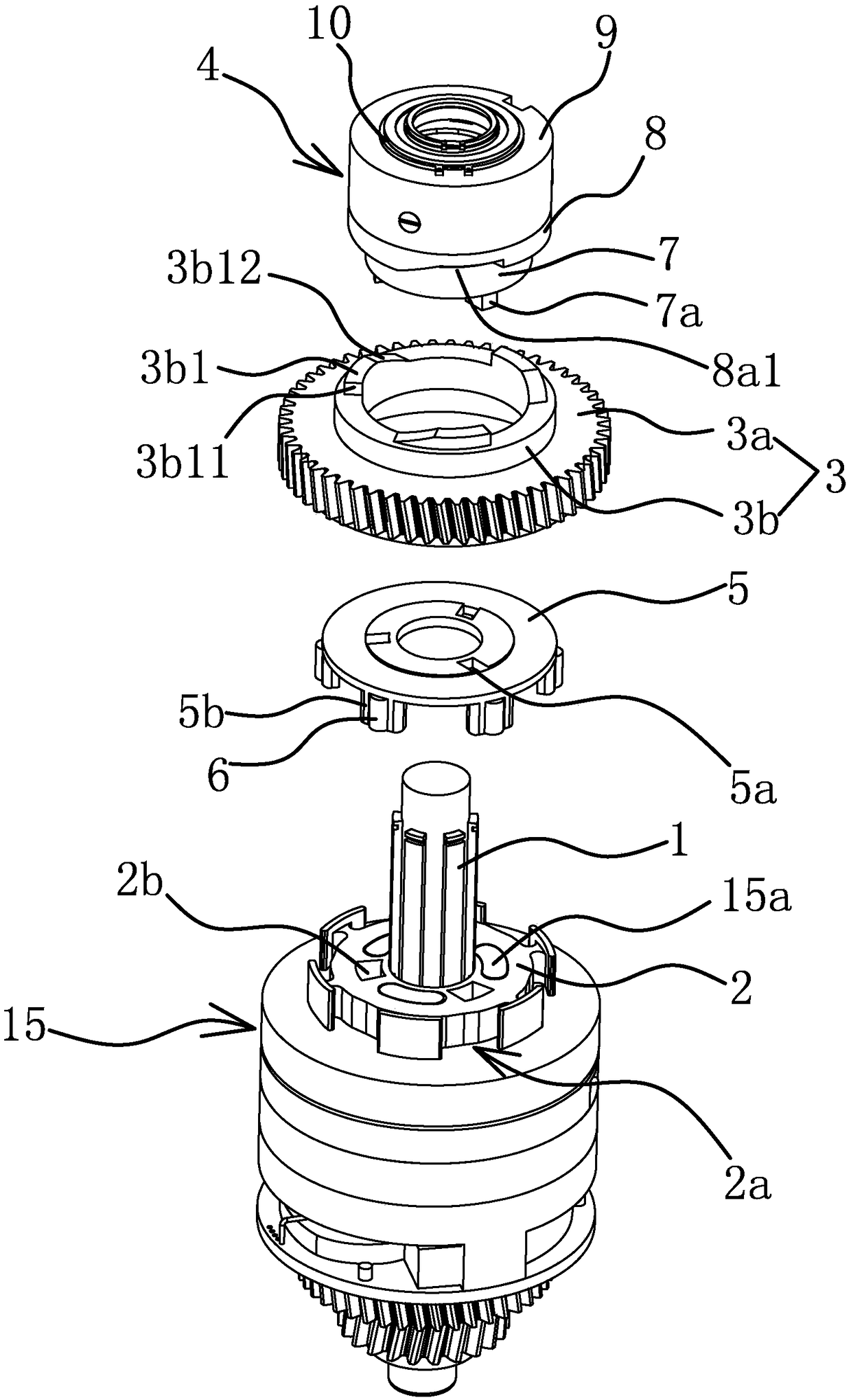

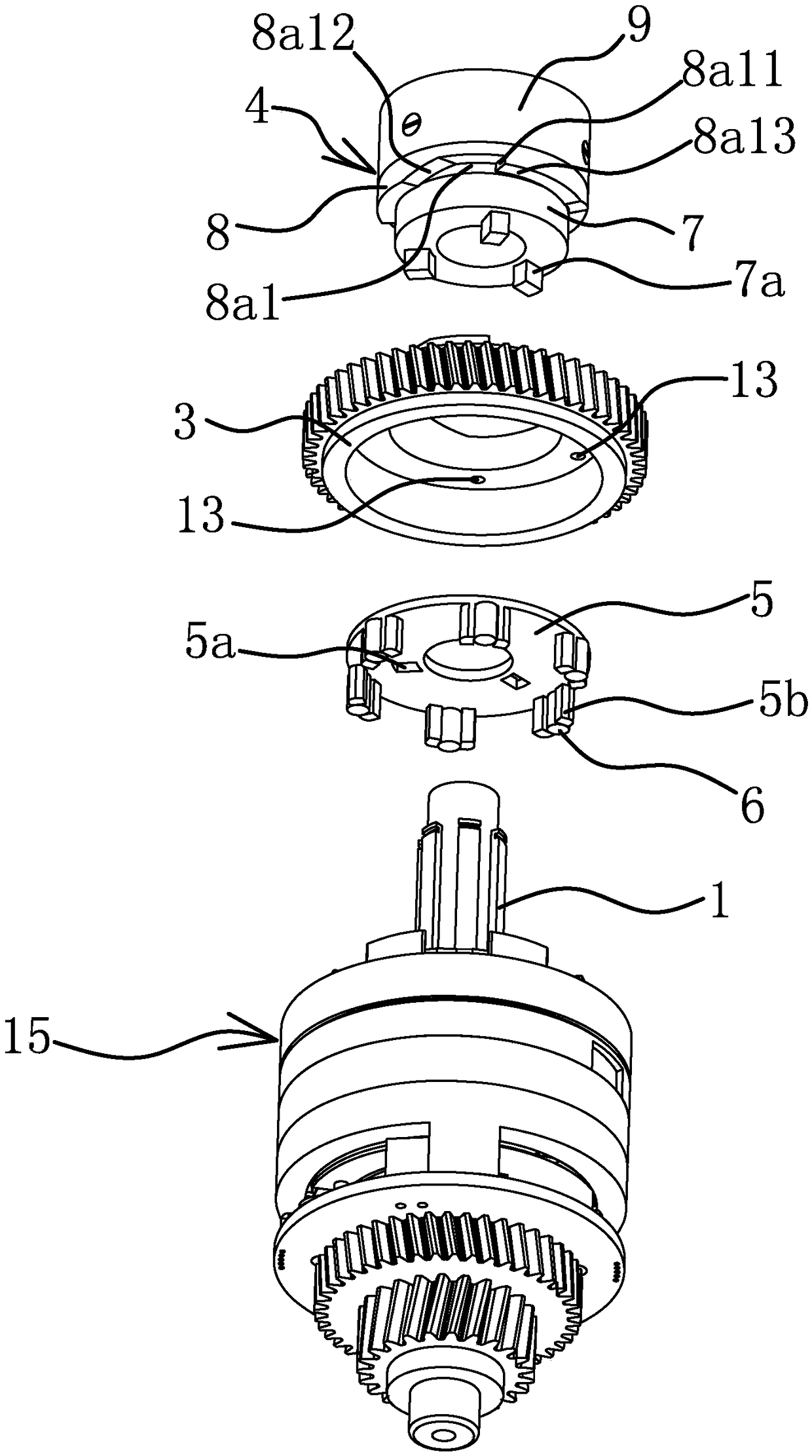

[0046] like figure 1 , figure 2 , image 3 and Figure 11 As shown, a transmission mechanism of a two-way automatic transmission includes a main shaft 1 and an inner ring 2 and a coupling sleeve 4 both sleeved on the main shaft 1. An output gear is fixed on the main shaft 1. The inner ring 2 is in the shape of a ring and the inner ring 2 and the main shaft 1 are fixed in the circumferential direction, and the inner ring 2 is covered with a ring-shaped outer ring 3, and the joint sleeve 4 and the outer ring 3 are provided between the joint sleeve 4 and the outer ring 3. When the outer ring 3 rotates in the direction of making the vehicle reverse The disengagement structure moves away from the outer ring 3, and the main shaft 1 is provided with a large spring 14 that enables the coupling sleeve 4 to approach the outer ring 3.

[0047] like figure 2 As shown, the main shaft 1 is provided with a second gear transmission structure 15 (the specific structure of the second gear...

Embodiment 2

[0063] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the friction structure includes a magnet embedded on the inner side wall of the positioning ring 9, and the ring body 8a of the matching ring 8 is adsorbed by the magnet. On the positioning ring 9. The attraction force of the magnet to the ring body 8a is relatively small, and when the vehicle moves forward or reverses, the magnet has no effect. When the vehicle switches from reverse to forward, since the inclined guide surface 8a13 is provided between the vertical surface 8a11 inside the notch 8a1 and the lower end surface of the annular shoulder 8b, when the outer ring 3 just rotates to the vertical surface on the outside of the block 3b1 When the right angle between the abutment surface 3b11 and the upper end surface of the block 3b1 abuts against the guide surface 8a13, the suction force of the magnet on the mating ring 8 can just...

Embodiment 3

[0065] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference is that in this embodiment, the positioning structure includes a number of protrusions arranged on the inner top wall of the outer ring 3 and a number of protrusions arranged on the upper end surface of the coupling plate 5 along the circumferential direction. The shape of the protruding head is the same as that of the groove and the protruding head has elasticity, the number of the protruding heads is less than the number of the grooves, each groove is continuously distributed and there is a circular arc transition between two adjacent grooves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com