Latching device for a rotationally or translationally movable operating element

A technology of a stop device and an operating element, which is used in devices, measuring devices, control devices, etc. to prevent/restrict/restore the movement of parts of the control mechanism, which can solve problems such as labor and achieve reduced wear, long service life, and reduced wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

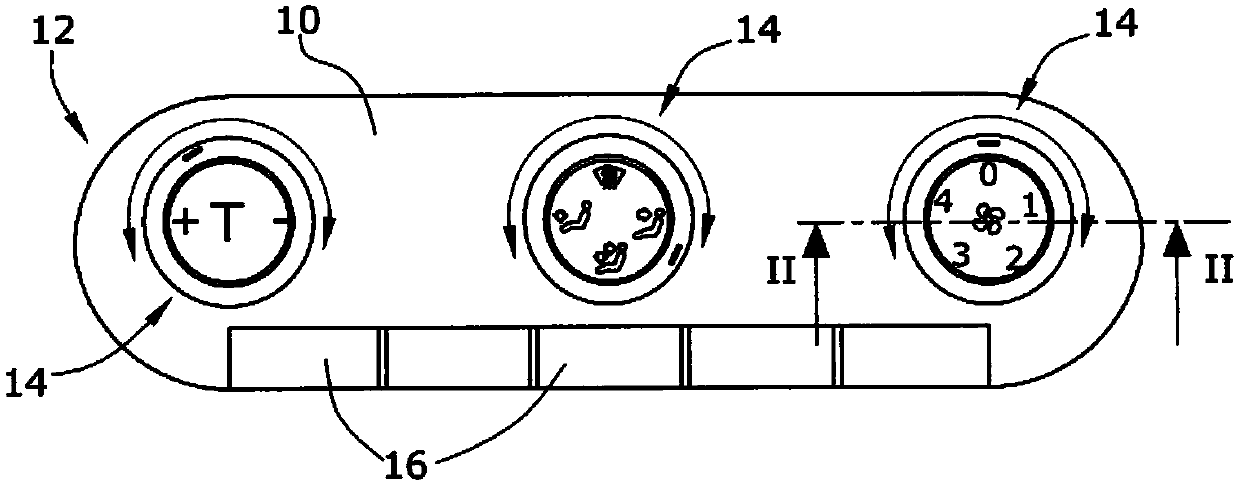

[0062] figure 1 A top view of a front panel 10 of an operating unit 12 for an air-conditioning or heating system of a motor vehicle is shown. Also shown are three rotary regulators 14 for regulating temperature, air distribution and blast intensity. Furthermore, operating unit 12 also has various keys 16 . The three rotary actuators 14 also have stop devices, which serve on the one hand to maintain the currently assumed rotary position and, on the other hand, to provide an acoustic and tactile feedback of the adjustment to the person actuating the rotary actuators. With the help of Figures 2 to 11 The construction of the locking device according to the first exemplary embodiment is explained in detail.

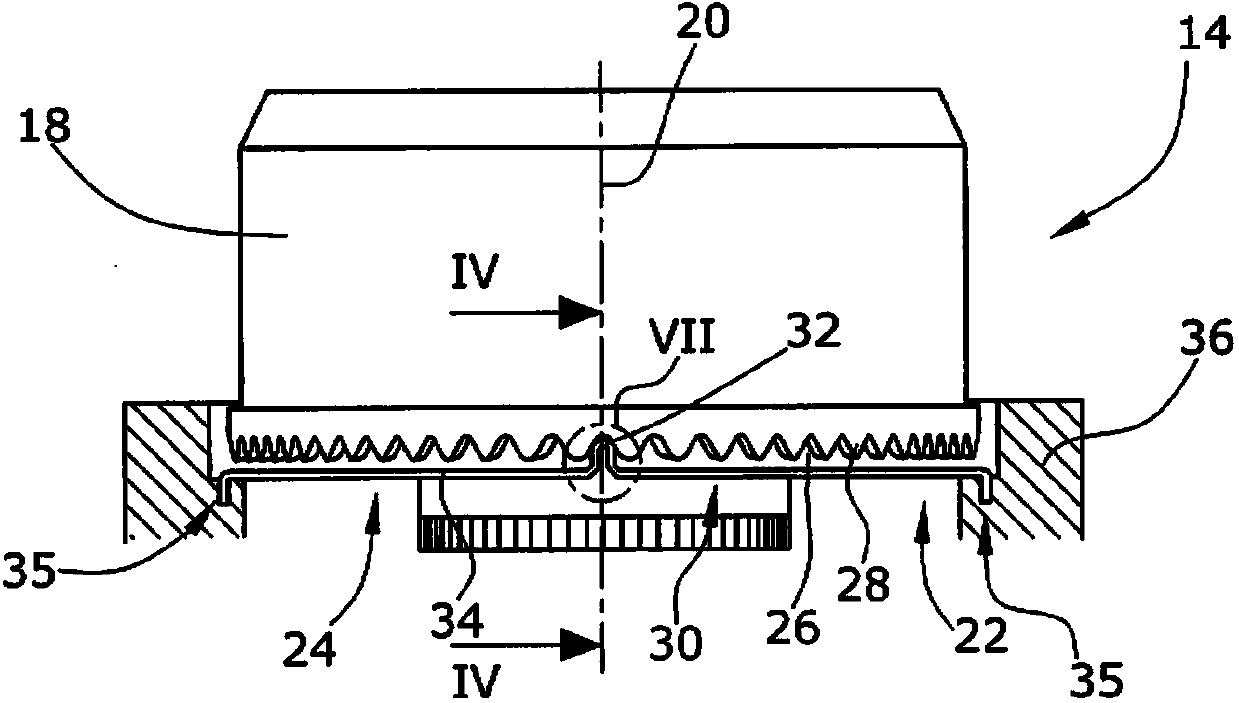

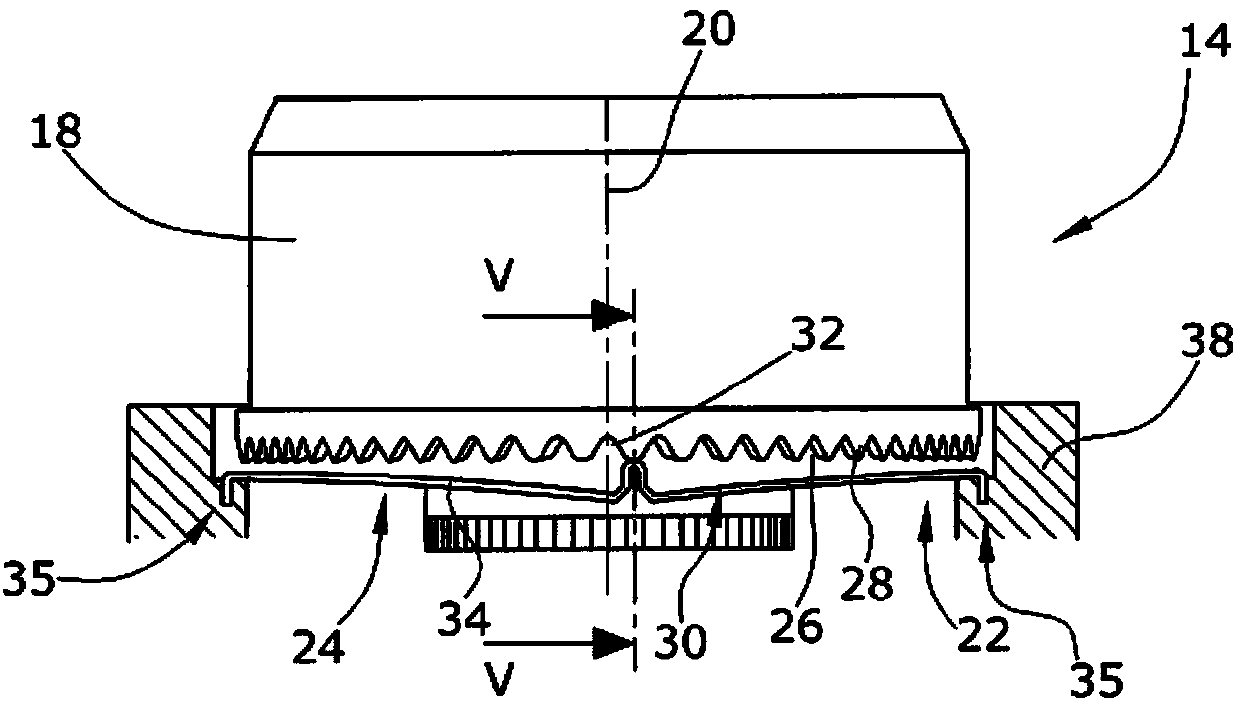

[0063] Each rotary adjuster 14 has a rotary operating element 18 , which is mounted rotatably about an axis of rotation 20 . On the lower axial end side 22 , the rotary operating element 18 has a locking link 24 which extends on the end side along the circumference of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com