Flanged connection component

A technology for connecting components and flanges, which is applied in the direction of flange connections, pipes/pipe joints/fittings, passing components, etc., which can solve the problems of easy sealing failure, reduce bolt pre-tightening force, etc., to overcome sealing failure and simple structure , Improve the effect of reliability and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

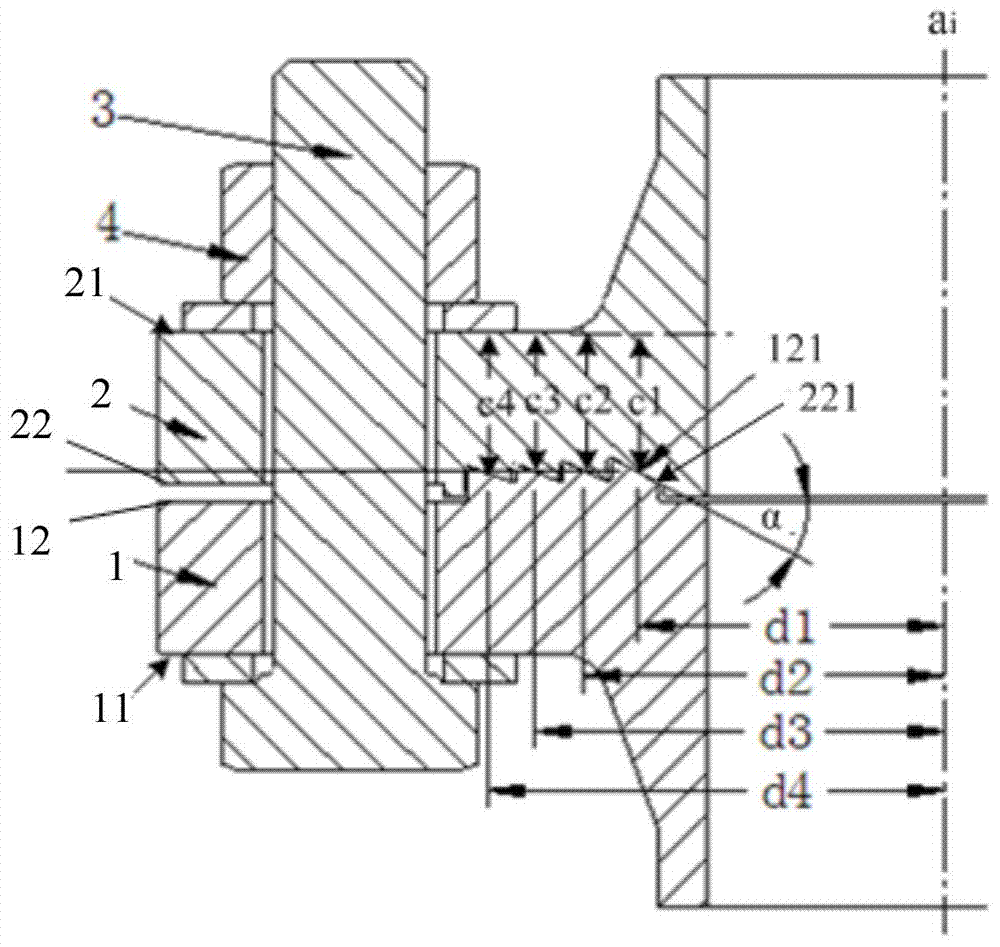

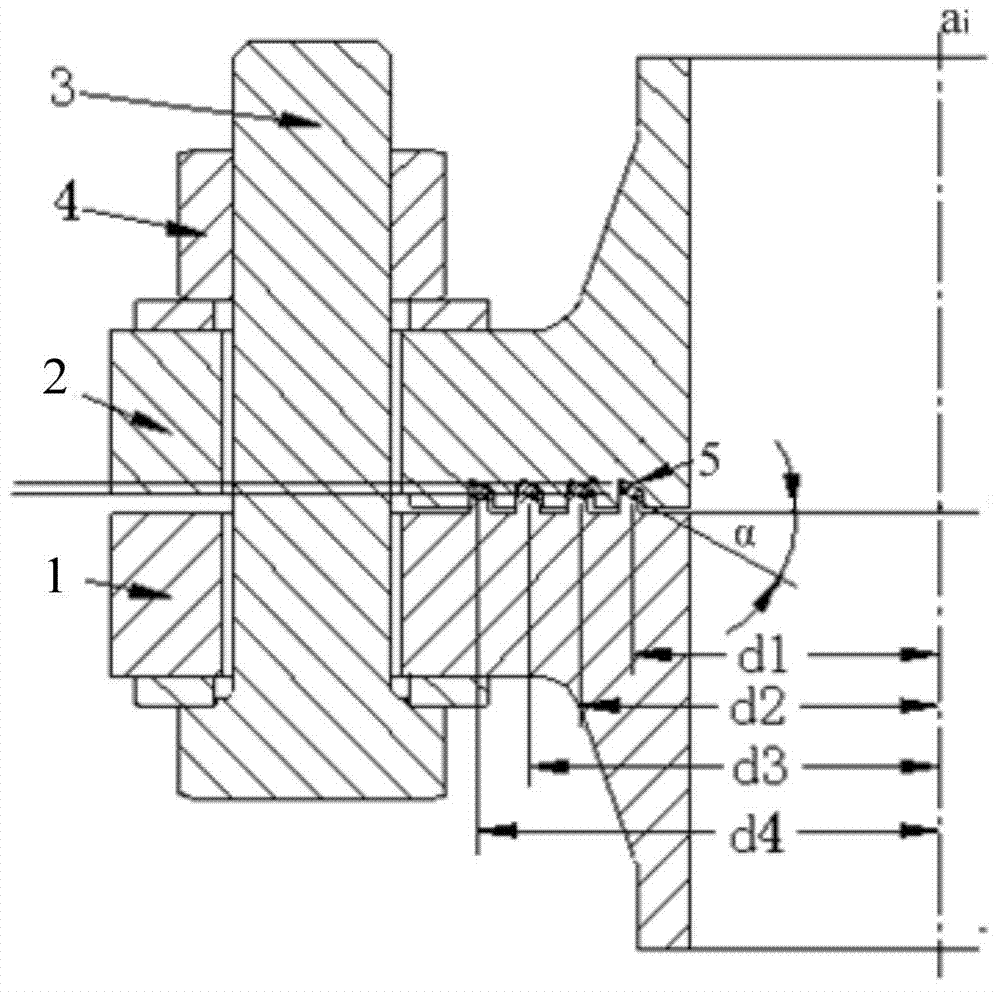

[0022] exist figure 1 In the shown embodiment, the flange connection assembly of the present invention includes a circular first flange 1 and a second flange 2, and the first flange 1 and the second flange 2 are relatively a central axis a i Axially aligned and butted against each other by bolts 3 and nuts 4.

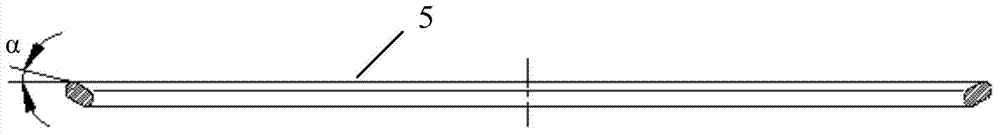

[0023] Such as figure 1 As shown, the first flange 1 has an opposite first base plane 11 and a first abutment surface 12, and the second flange 2 has an opposite second base plane 21 and a second abutment surface 22, wherein the two bases The planes 11, 21 are far away from and parallel to each other, and the two abutting surfaces 12, 22 are butted and matched with each other. Different from conventionally designed butt joints that are planar, the first butt joint 12 here includes four joints arranged between the bolt 3 and the central a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com