Hydraulic steering gear

A hydraulic steering gear and rotor technology, applied in hydraulic steering gear, engine seals, engine components, etc., can solve the problems of increasing resistance during steering, large steering torque of steering gear, etc., to reduce friction and preload, reduce Power steering input torque, effect outstanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

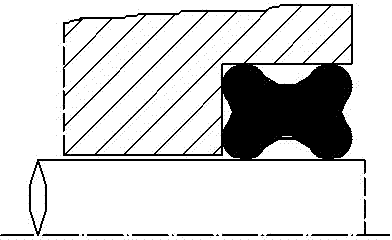

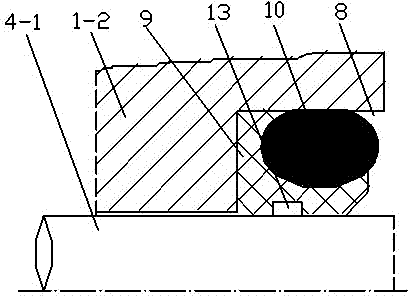

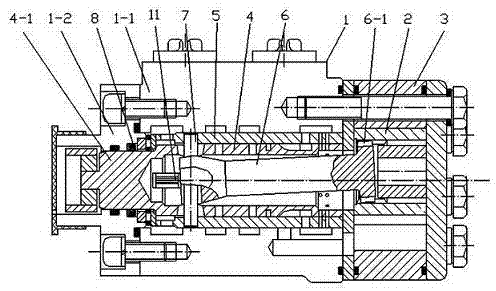

[0020] The low torque hydraulic steering gear of the present embodiment is as image 3 As shown, the housing 1-1 with the oil inlet and the oil outlet is fixedly connected with the end cover 1-2 to form the valve body 1, one end of which is fixedly connected with the stator 3 equipped with the cycloid rotor 2, and the valve body 1 is installed The valve core 4 extending out of the front shaft 4-1 and the valve sleeve 5 forming a channel switching valve with it. The linkage shaft 6 passes through the inner hole of the spool 4 . One end of the linkage shaft 6 has an external tooth 6 - 1 engaged with the inner spline of the rotor 2 , and the other end is connected with the valve core 4 through a radial pin 7 . The surface of the inner hole where the valve body 1 cooperates with the front shaft 4-1 is formed with an annular sealing groove 8 with one side open, that is, the annular sealing groove 8 is located at the stepped end surface of the valve body 1 . Such as figure 2 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com