Cutout cock for rail car

A technology for rail vehicles and plug doors, applied to railway car body parts, transportation and packaging, pneumatic brakes, etc., to achieve the effect of wide ambient temperature range and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiment of the present invention is illustrated below in conjunction with accompanying drawing, but should not be limited to following embodiment:

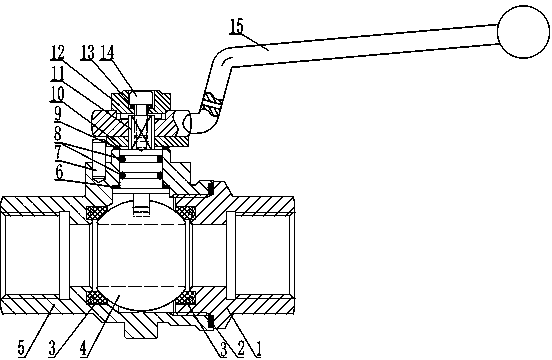

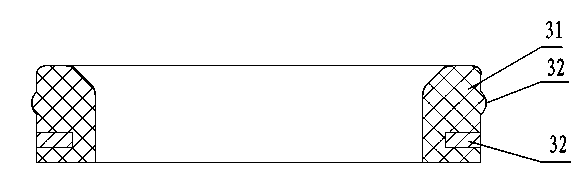

[0028] according to figure 1 As shown, a cut-off cock for a rail vehicle, its structure includes a ball core 4 for opening and cutting off the air supply pipeline, and a special rubber composite ball gasket 3 is attached to both sides of the ball core 4 and is formed by a cock body 5 Pressed with the joint 1 and in the plug body 5, the joint gasket 2 seals between the plug body 5 and the joint 1; the valve stem 11 is installed on the upper part of the ball core 4, and a Double O-ring 8 is sealed, and the contact surface between the valve stem 11 and the end surface of the plug body 5 is padded with a polytetrafluoroethylene valve stem lower flat gasket 6 to reduce the friction force between the valve stem 11 and the end surface of the plug body 5; The upper end surface of 5 is covered with a flat pad 9 on the valve ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com