Bearing device for wheel

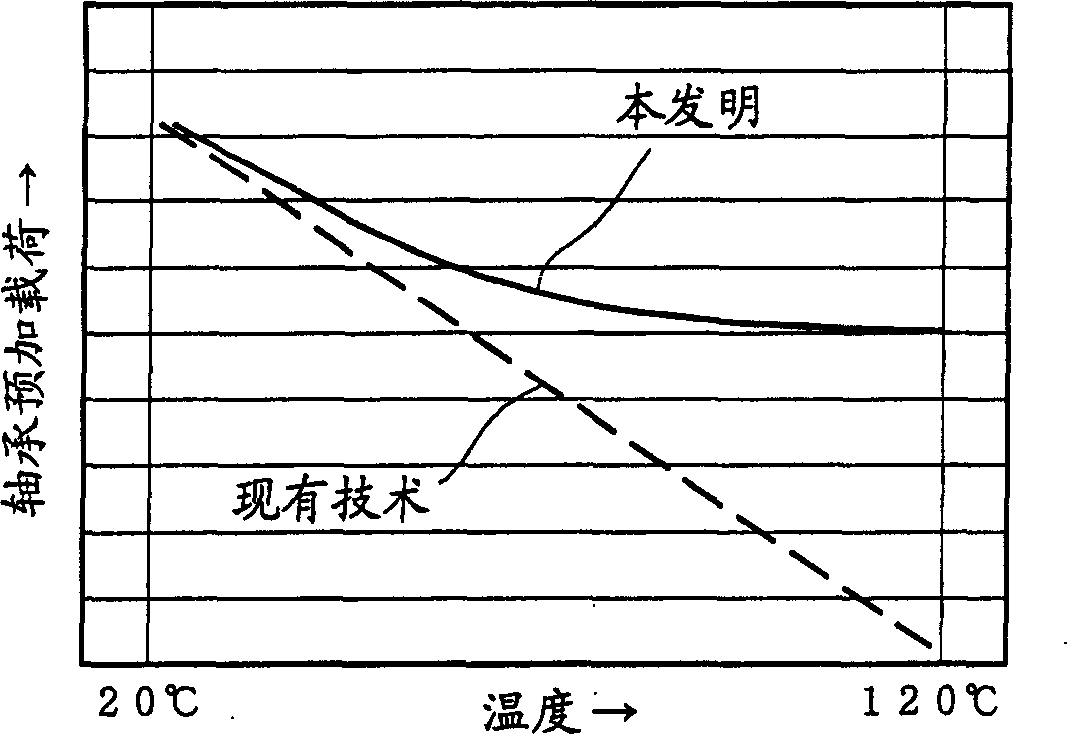

A bearing device, wheel bearing technology, applied in the directions of axles, wheels, bearing components, etc., can solve problems such as no existing technology, and achieve the effects of preventing creep, restraining the reduction of fitting interference, and restraining the change of bearing stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0038] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

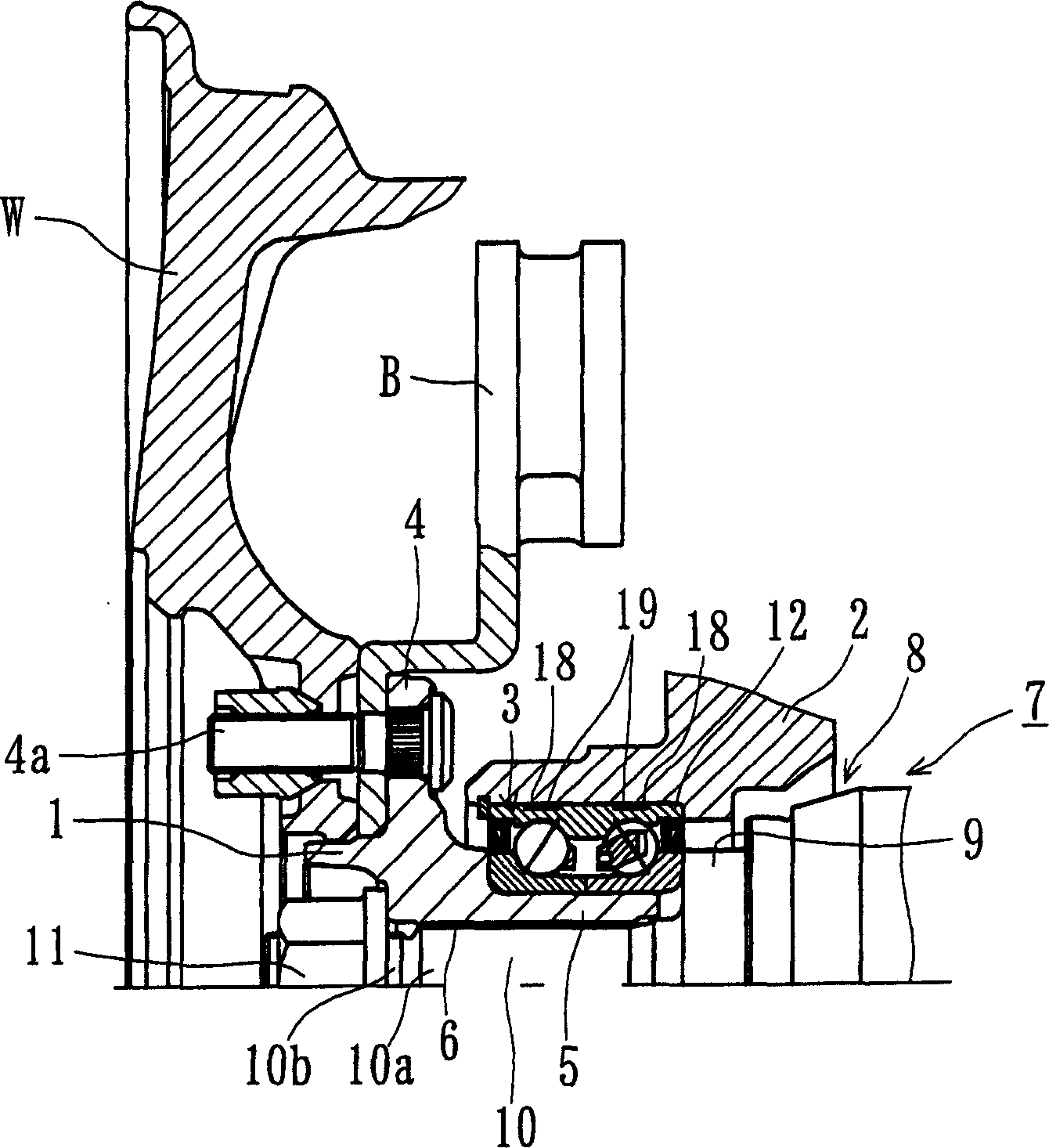

[0039] figure 1 A first embodiment of the bearing device for a wheel of the present invention is shown. In the following description, the term device "outside" means the side that is located outside the vehicle body when the bearing device is mounted on the vehicle body, and the term device "inside" represents a side that is located inside the vehicle body when the bearing device is mounted on the vehicle body. side.

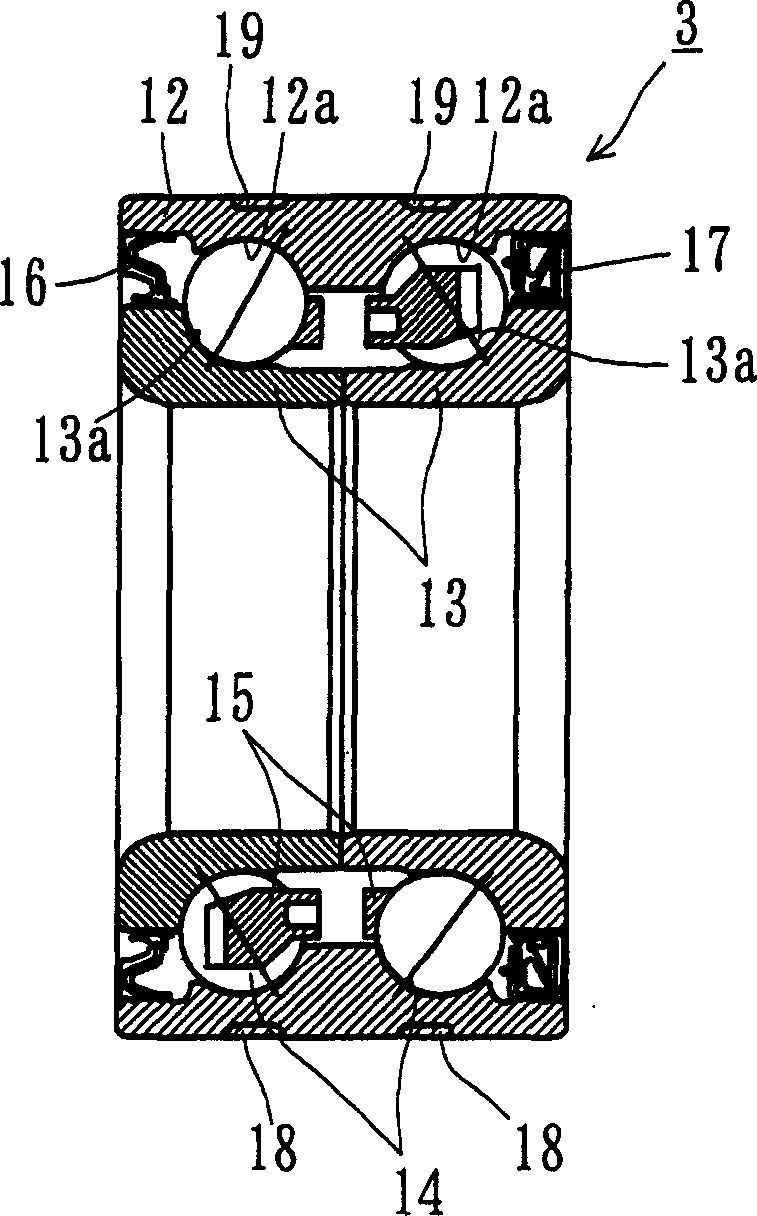

[0040] figure 1The shown bearing device for a wheel of the present invention includes a wheel hub 1 as a main component, and a wheel bearing 3 for rotatably supporting the wheel hub 1 with respect to a steering knuckle 2 . Hub wheel 1 is made of medium carbon steel (eg S53C) containing 0.40-0.80% carbon by weight and includes wheel mounting flange 4 for mounting wheel "W" and brake disc "B" at the outboard end , and a small-diameter ...

no. 2 example

[0050] Figure 4 It is a longitudinal view showing a second embodiment of the bearing device for a wheel of the present invention. This embodiment differs from the first embodiment only in the structure of the outer ring, so the same reference numerals are used to denote the same parts having the same functions as those used in the first embodiment.

[0051] In this wheel bearing 20 , a single annular groove 22 is formed on the outer peripheral surface of an outer ring 21 . The annular groove 22 is formed at the axial center of the outer peripheral surface of the outer ring 21 so that it spans the double row outer raceway surface 12a. The annular groove 22 is filled with a resin band 23 formed by injection molding a heat-resistant thermoplastic synthetic resin based on PA11 (polyamide 11).

[0052] Since the resin band 23 in this second embodiment is formed in the same manner as that of the first embodiment, although the thermal expansion of the knuckle 2 is greater than tha...

no. 3 example

[0054] Figure 5 It is a longitudinal view showing a third embodiment of the bearing device for a wheel of the present invention. This embodiment differs from the first embodiment only in the structure of the wheel bearing, so the same reference numerals are used to denote the same parts having the same functions as those used in the first embodiment.

[0055] In this bearing arrangement for a wheel, a wheel bearing 24 is press-fitted onto the cylindrical portion 5 of the wheel hub 1 and is fixed by being sandwiched between the wheel hub 1 and the shoulder 9 of the outer joint part 8 . The desired bearing preload is obtained by tightening the tightening nut 11 to the threaded portion 10b formed on the end of the shank 10 with a predetermined tightening torque. The wheel bearing 24 is press-fitted into the knuckle 2 formed of light metal such as aluminum alloy with predetermined interference.

[0056] Such as Figure 6 As shown, a wheel bearing 24 has an outer ring 25 , a pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com