Patents

Literature

36results about How to "Prevent narrowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

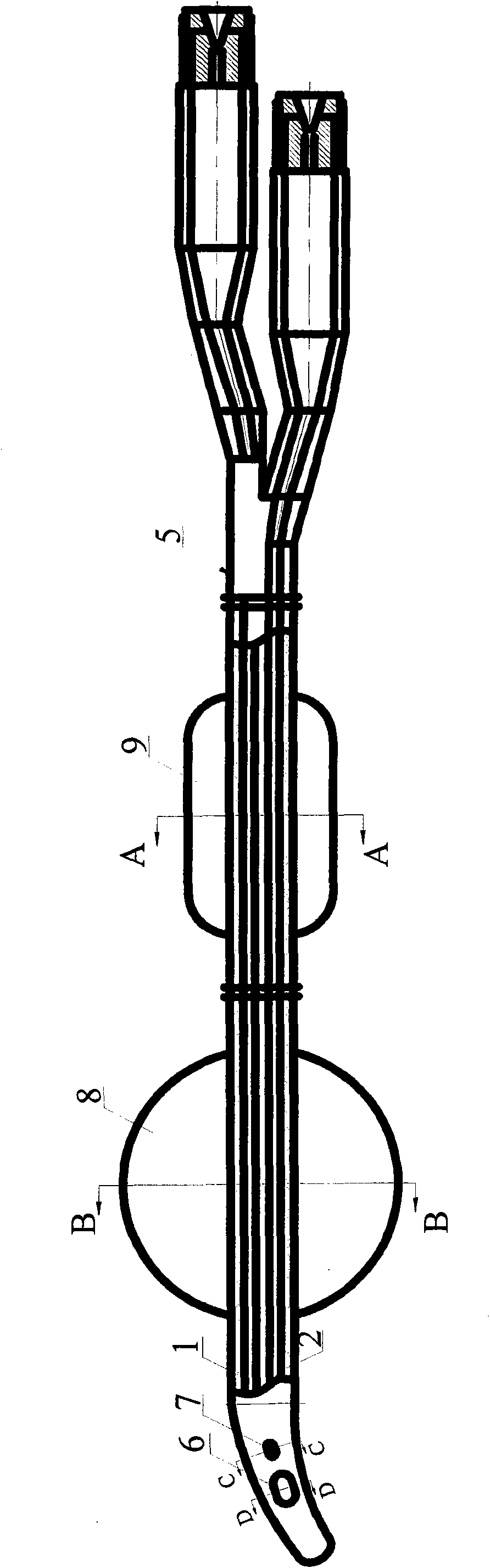

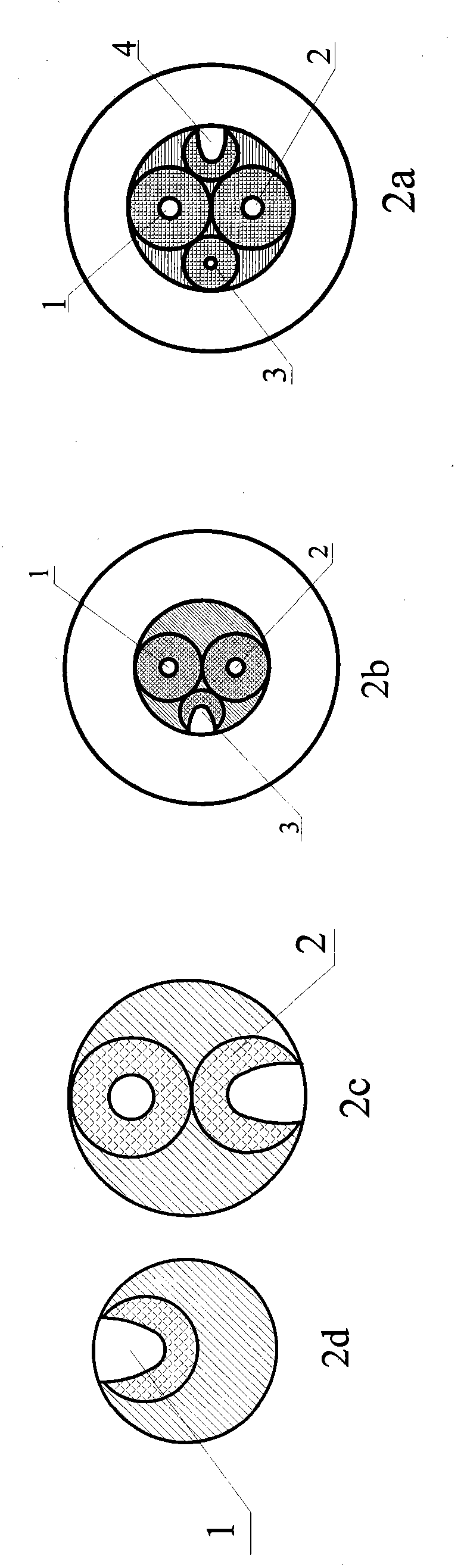

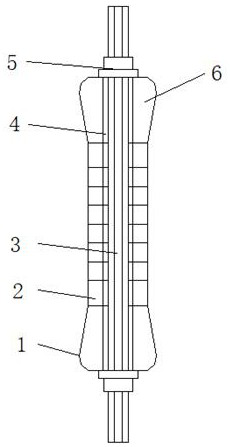

Locally expanding balloon catheter

InactiveCN101862500AUniform expansionUniform and consistent pressure hemostasisStentsBalloon catheterUrethraBalloon catheter

The invention discloses a locally expanding balloon catheter, comprising a catheter body, wherein the middle part of the catheter body is sleeved with an expanding capsule body the wall of which is connected with the catheter body in a sealing manner; a fluid passage is arranged in the catheter body, the front port of the fluid passage is communicated with the expanding capsule body, the tailing port of the fluid passage extends to the tailing end face of the catheter body, and a first one-way valve is arranged at the tailing part of a first fluid passage. The invention has moderate thickness, can provide sufficient support and expansion and does not generate excessive pressure on urethra mucosa and external orifice of urethra to cause patients to fell discomfort or even cause new iatrogenic stenosis. The invention is a thinner silicone catheter before fluid is injected into the expanding capsule, and can expand to a required size after a certain amount of fluid is injected. The invention can play the role of local hemostasis by compression at early period after surgery, and has the functions of local intermittent expansion during the period of catheter retention.

Owner:NANJING BENQ HOSPITAL CO LTD

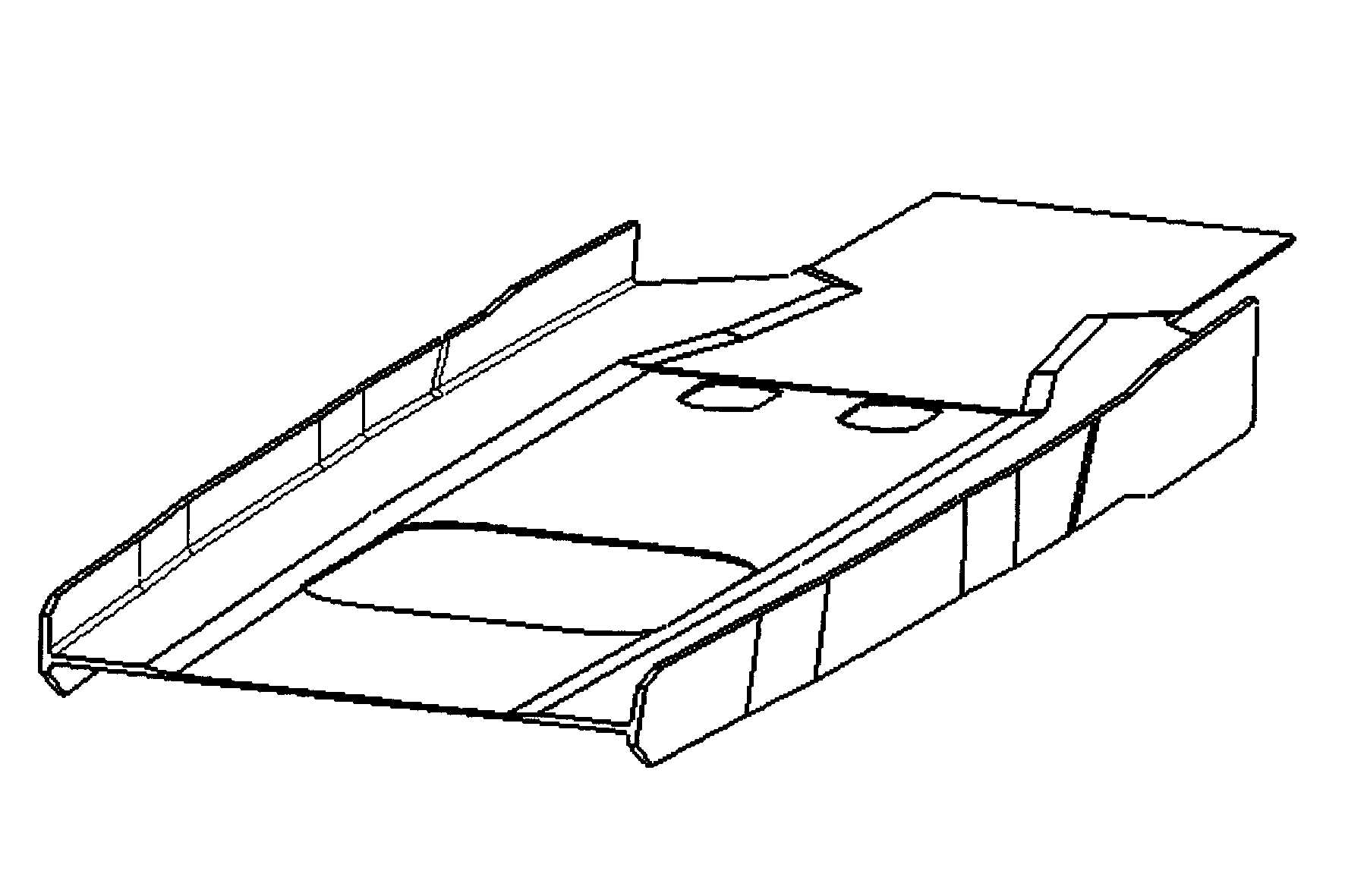

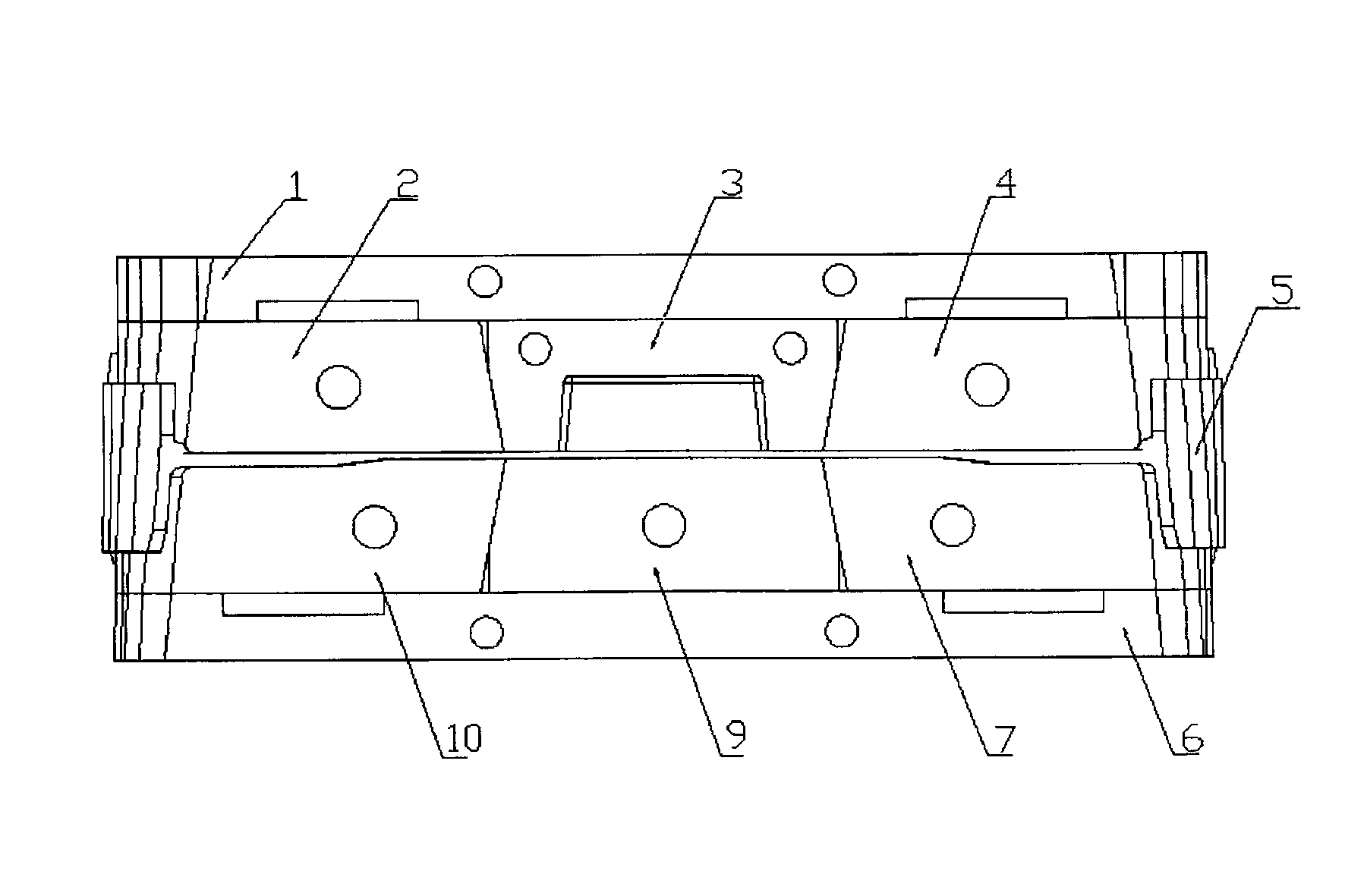

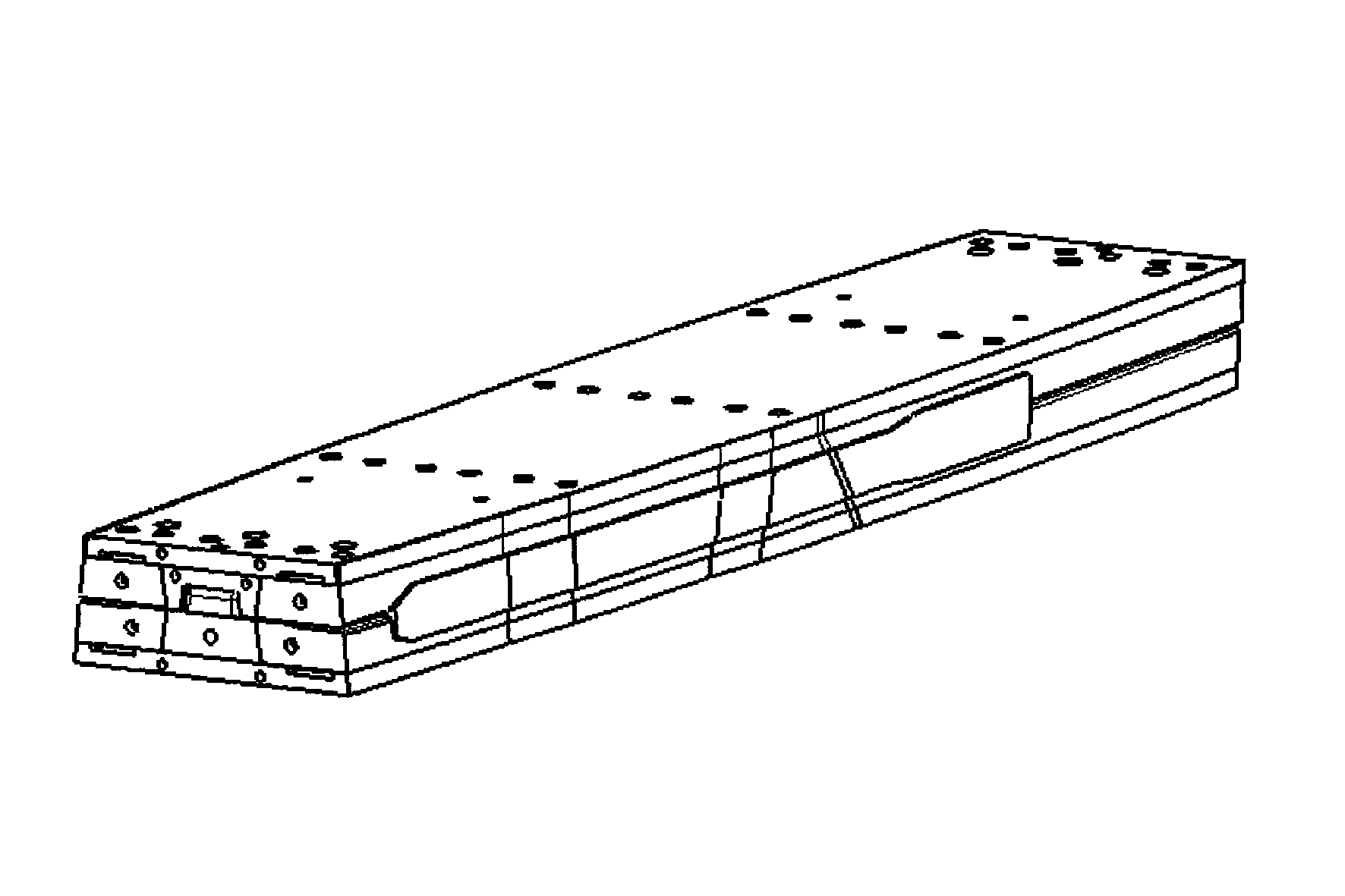

Processing method of long-narrow composite material molding part assembling mould

The invention relates to a processing method of a long-narrow composite material molding part assembling mould. The processing method of the long-narrow composite material molding part assembling mould comprises the following steps of: (1) processing an upper bottom plate and a lower bottom plate; (2) processing a long-narrow clamp plate: (2.1) reserving the margin of 3mm for the thickness and the width; (2.2) carrying out thermal treatment; (2.3) leveling by a bench worker, planning and milling the upper and lower surfaces to be parallel, and reserving a margin of 1mm; and (2.4) numerically processing a matching profile in the width direction and reserving a margin of 1mm; (3) carrying out overall processing on the assembled upper and lower long-narrow clamp plates: (3.1) trimming the involution gaps between three clamp plates respectively; (3.2) grinding two planes in the thickness direction of the overall grinding; and (3.3) numerically processing the upper and lower profiles to meet the dimensional requirement, and then polishing the profiles by bench workers. By using the processing method, the problems that the long-narrow composite material assembling part deforms and the connection of the contact surfaces is poor, the processing precision of the long-narrow assembling mould is improved, and the production efficiency is greatly enhanced.

Owner:SHENYANG AIRCRAFT CORP

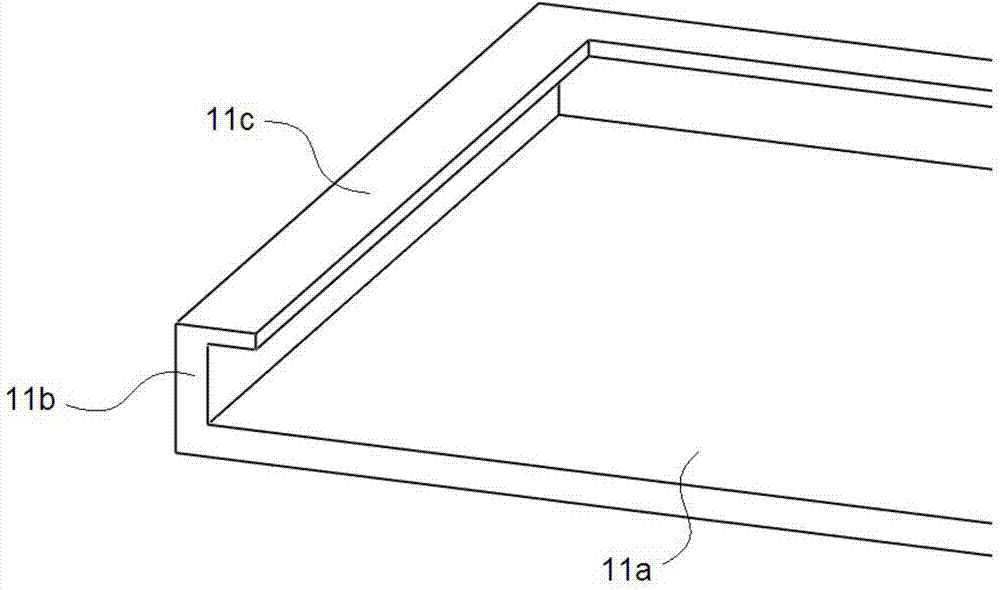

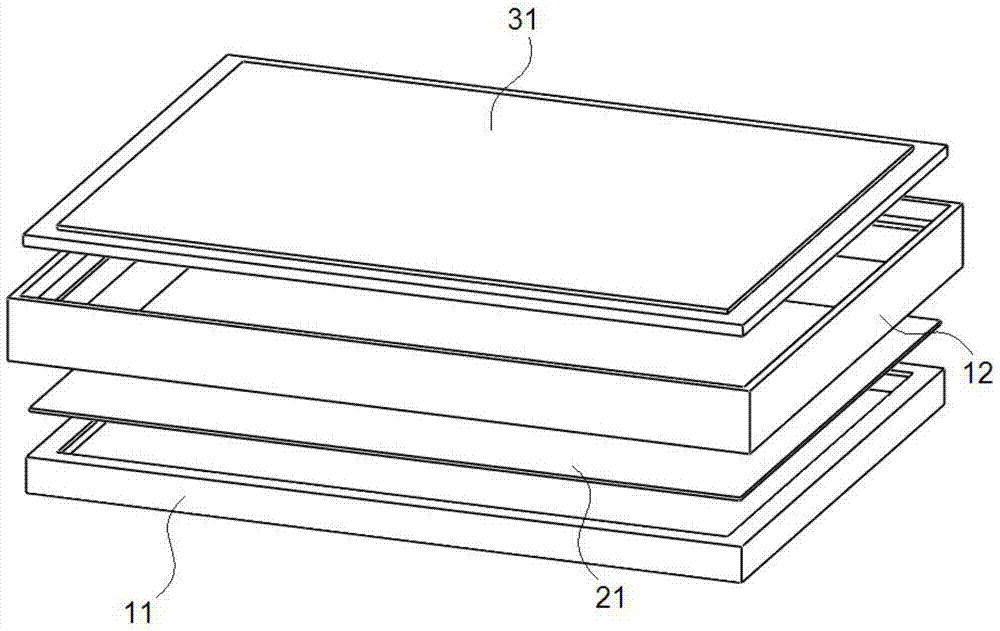

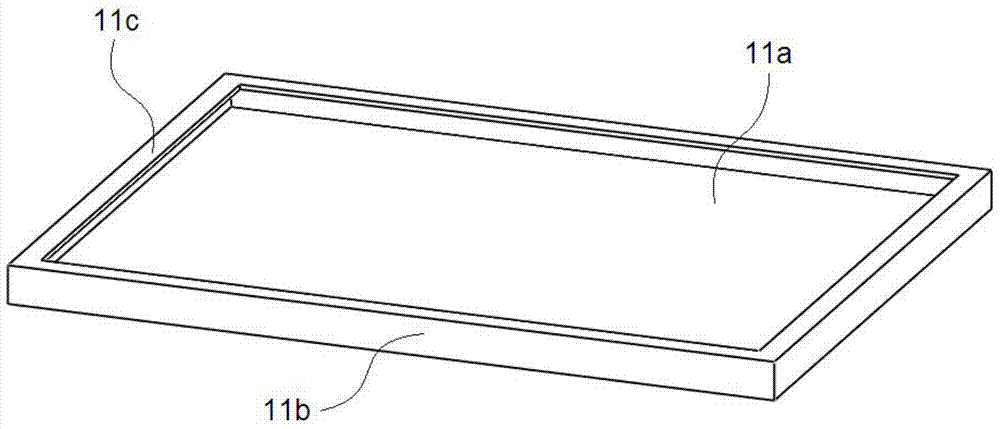

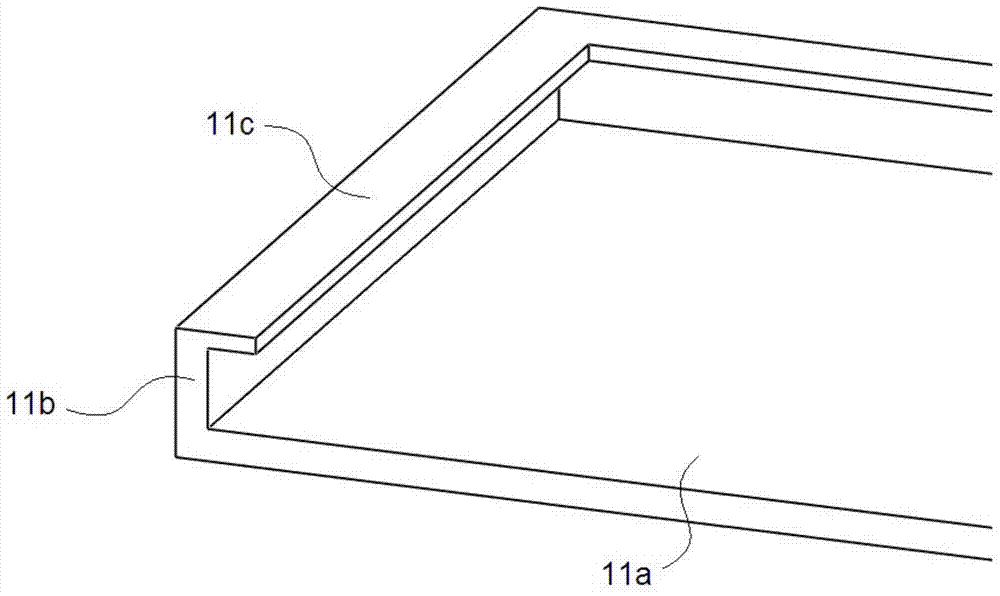

Backlight module and display device

ActiveCN104763944AAvoid badAvoid narrowingPlanar light sourcesPoint-like light sourceDisplay deviceEngineering

The invention discloses a backlight module and a display device. The backlight module comprises a back plate and a rubber frame. The back plate comprises a bottom plate and side walls located on the edge of the bottom plate. The rubber frame is arranged on the side walls and provided with a first supporting part for arranging a display panel. A second supporting part is arranged on the side walls. A groove for arranging an optical film is formed between the first supporting part and the second supporting part. The set distance between the bottom of the groove and the valid display area of the display panel is larger than the set distance between the bottom of the display panel and the bottom of the optical film. By means of the backlight module and the display device, the problem that in a narrow frame display device, edge bright lines are not good can be solved.

Owner:BOE TECH GRP CO LTD +1

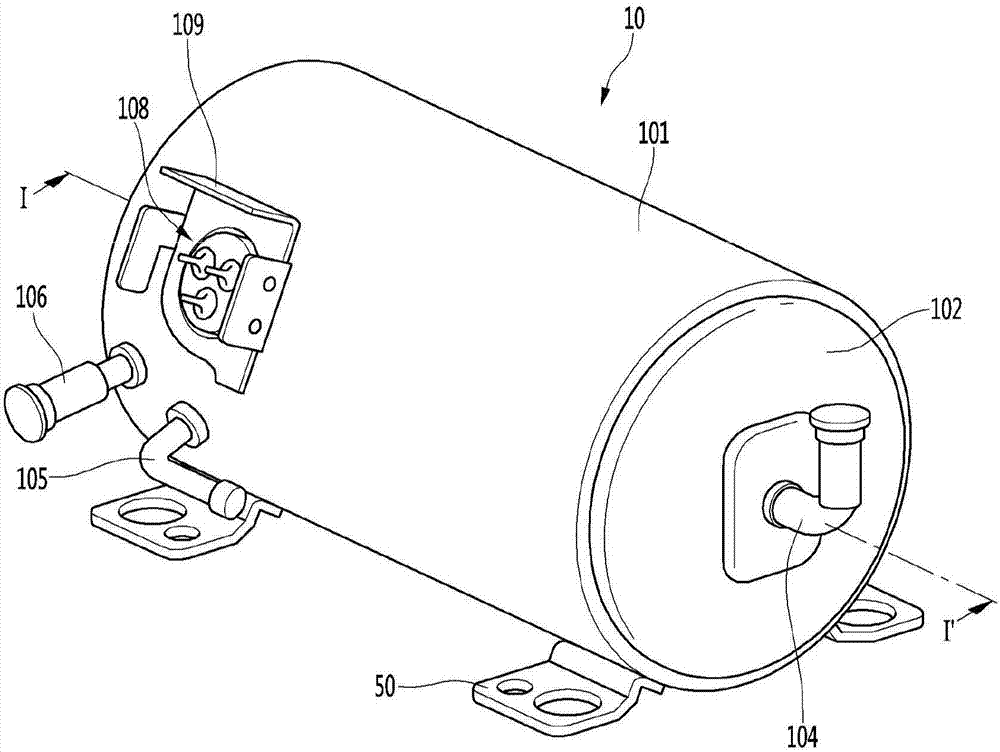

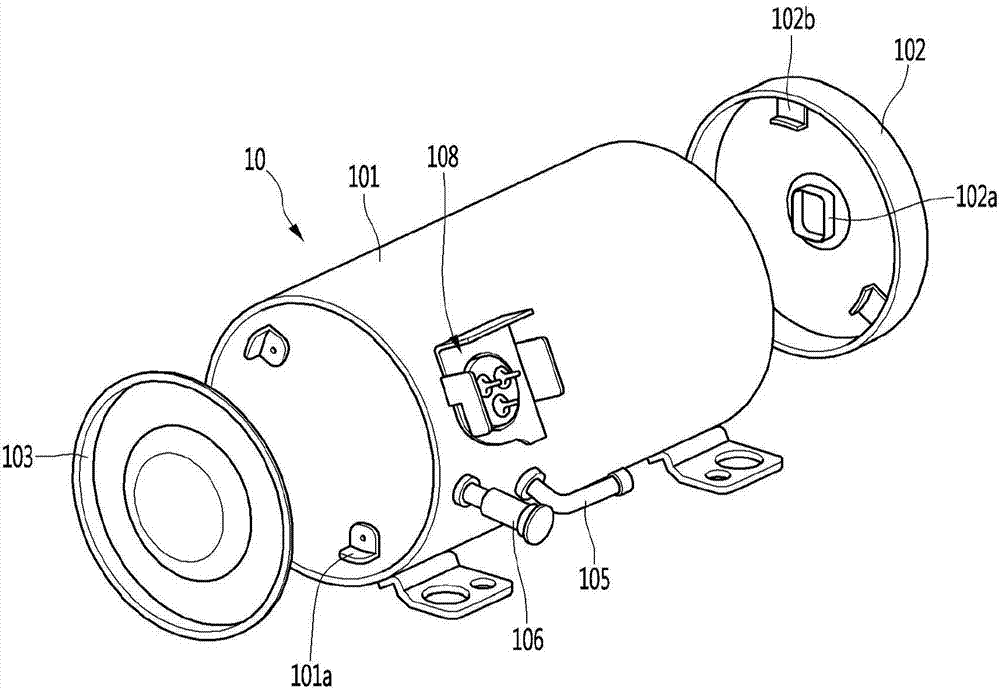

Linear compressor

ActiveCN107339216AReduce sizeIncreased internal storage spacePositive displacement pump componentsPiston pumpsLinear compressorEngineering

A linear compressor is provided. The linear compressor may include a frame coupled to a cylinder, a gas hole defined in the frame, and a gas pocket that communicates with the gas hole and transfers a refrigerant gas to the cylinder.

Owner:LG ELECTRONICS INC

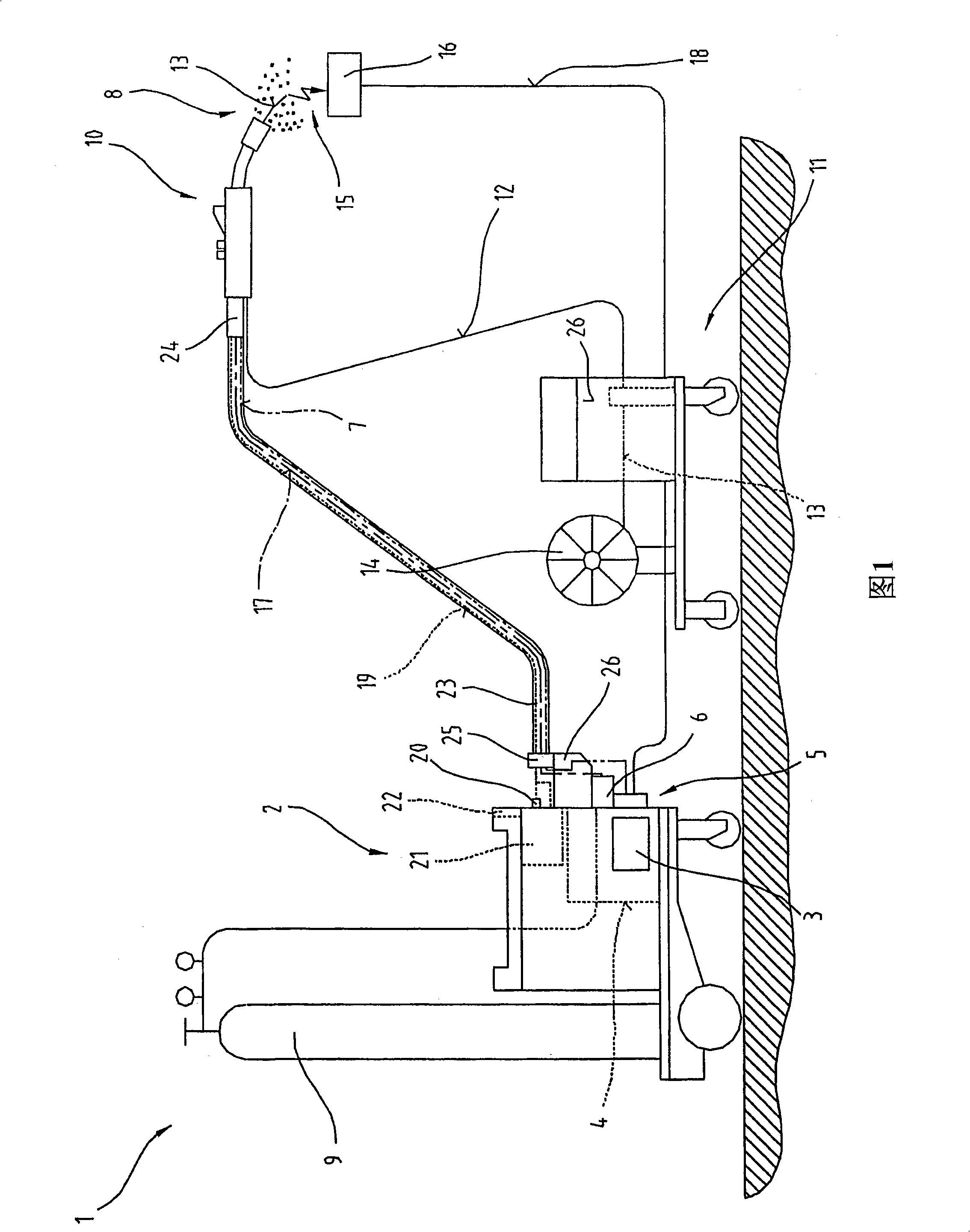

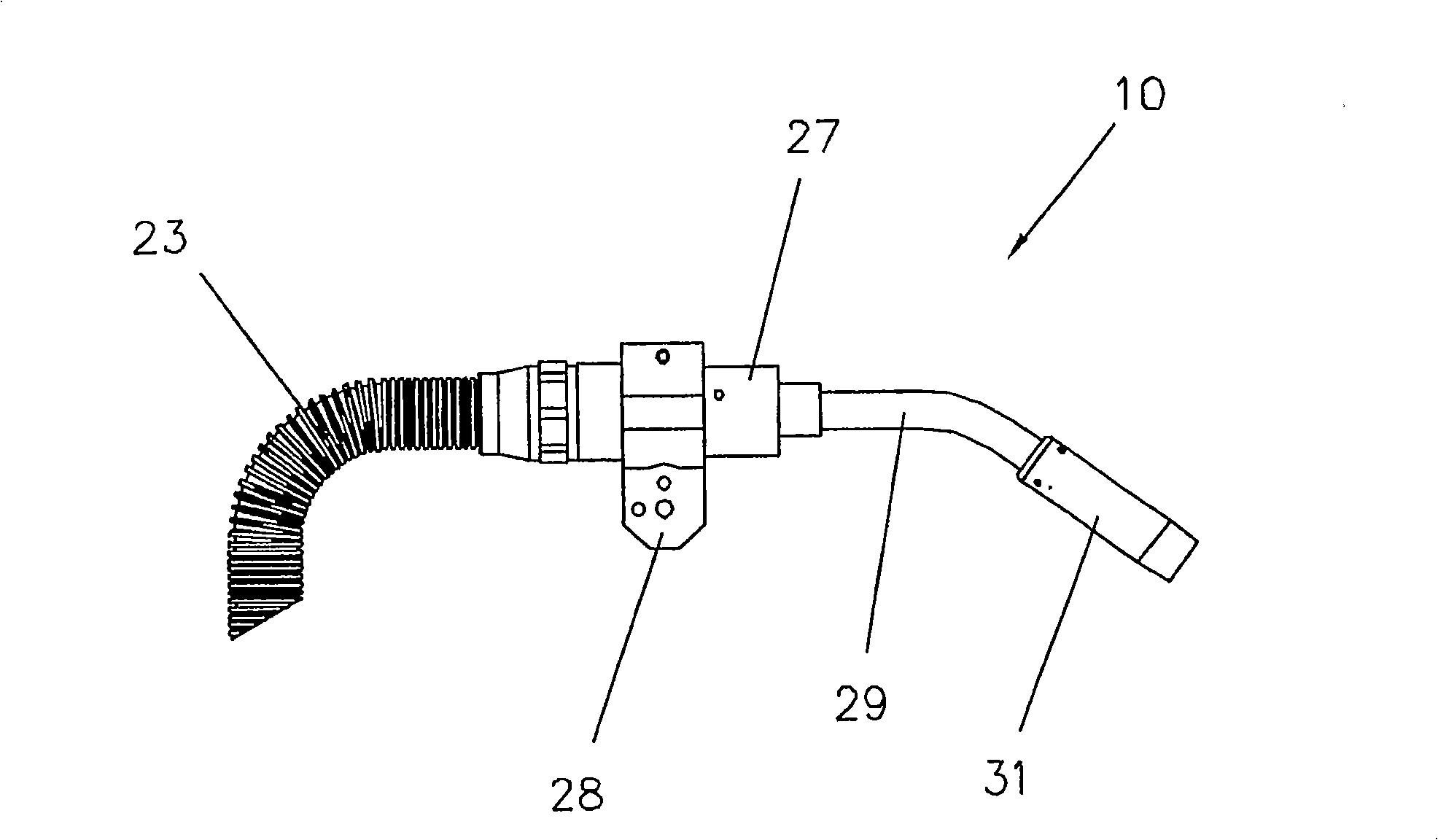

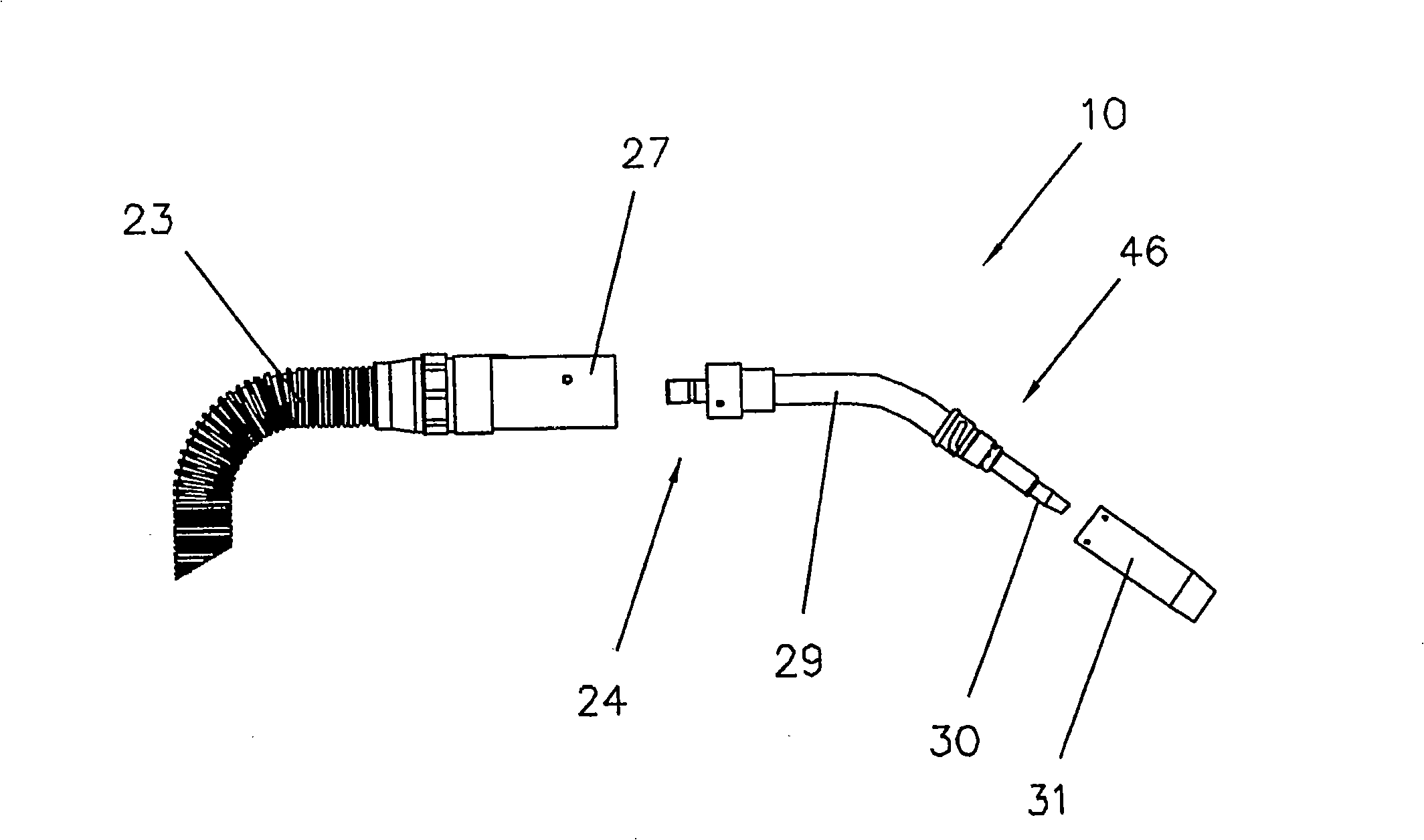

Welding torch and end piece and also contact tube for a welding torch

ActiveCN101331000AImprove conductivityAchieve deflectionSupport devices with shieldingElectrode accessoriesMechanical engineeringWelding torch

The invention relates to a welding torch (10) having a torch body (46) in which at least one device (32) for feeding a welding wire (13) and a contact tube (30) having a bore (33) and a guide bore (34), running concentrically thereto, for guiding the welding wire (13) in the direction of a workpiece (16) are arranged, wherein the welding wire (13) can be supplied with electrical energy via the contact tube (30), wherein one end of the feed device (32) is arranged in the guide bore (34) of the contact tube (30) and is provided with an electrically conductive end piece (36) having a bore (40) for the welding wire (13). To provide such a welding torch (10) in which the durability or the service life of the wearing parts, in particular of the contact tube (30), is prolonged, provision is made for the end piece (36) of the feed device (32) to be movably arranged in the guide bore (34) of the contact tube (30).

Owner:FRONIUS INTERNATIONAL GMBH

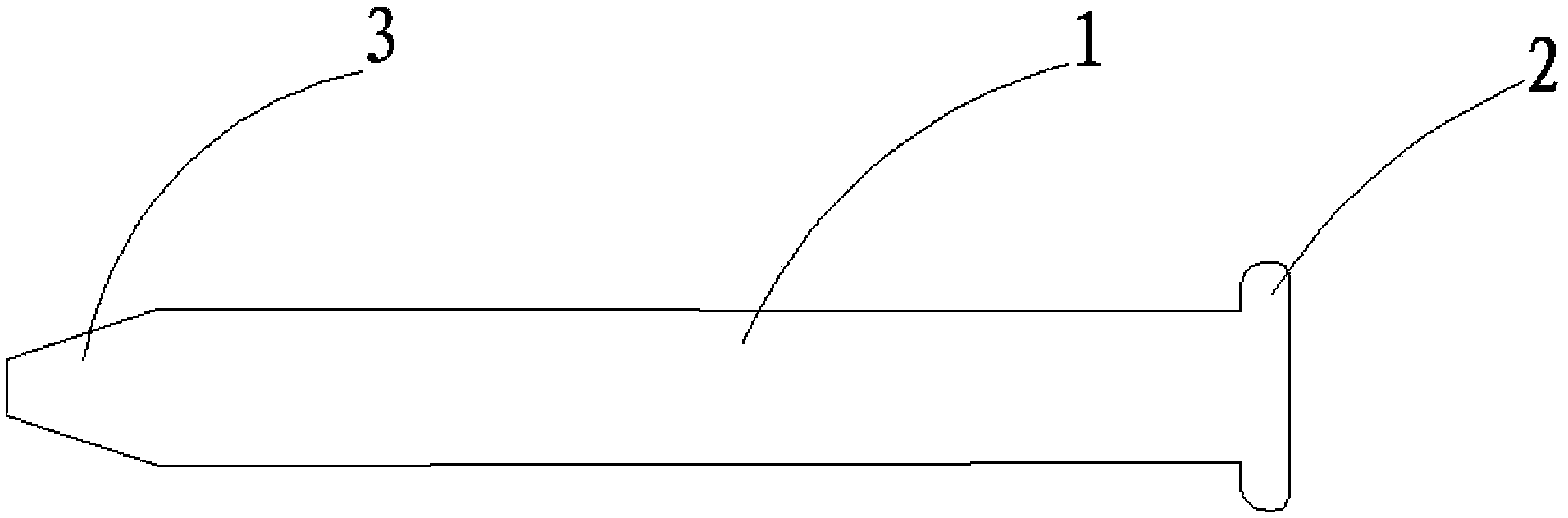

Lacrimal ductile blocking core

The invention discloses a lacrimal ductile blocking core which comprises a blocking core tube body. One end of the blocking core tube body is provided with a taper-shaped tip. The other end of the lacrimal ductile blocking core tube is provided with a blocking core tip. The lacrimal ductile blocking core can be used for treating xerophthalmia conveniently, safely and stably, can prevent lacrimal passages from becoming narrow after acid and alkali burns, and can be taken out or planted into the lacrimal passages conveniently by tweezers.

Owner:GUANGZHOU VISBOR BIOTECHNOLOGY LTD

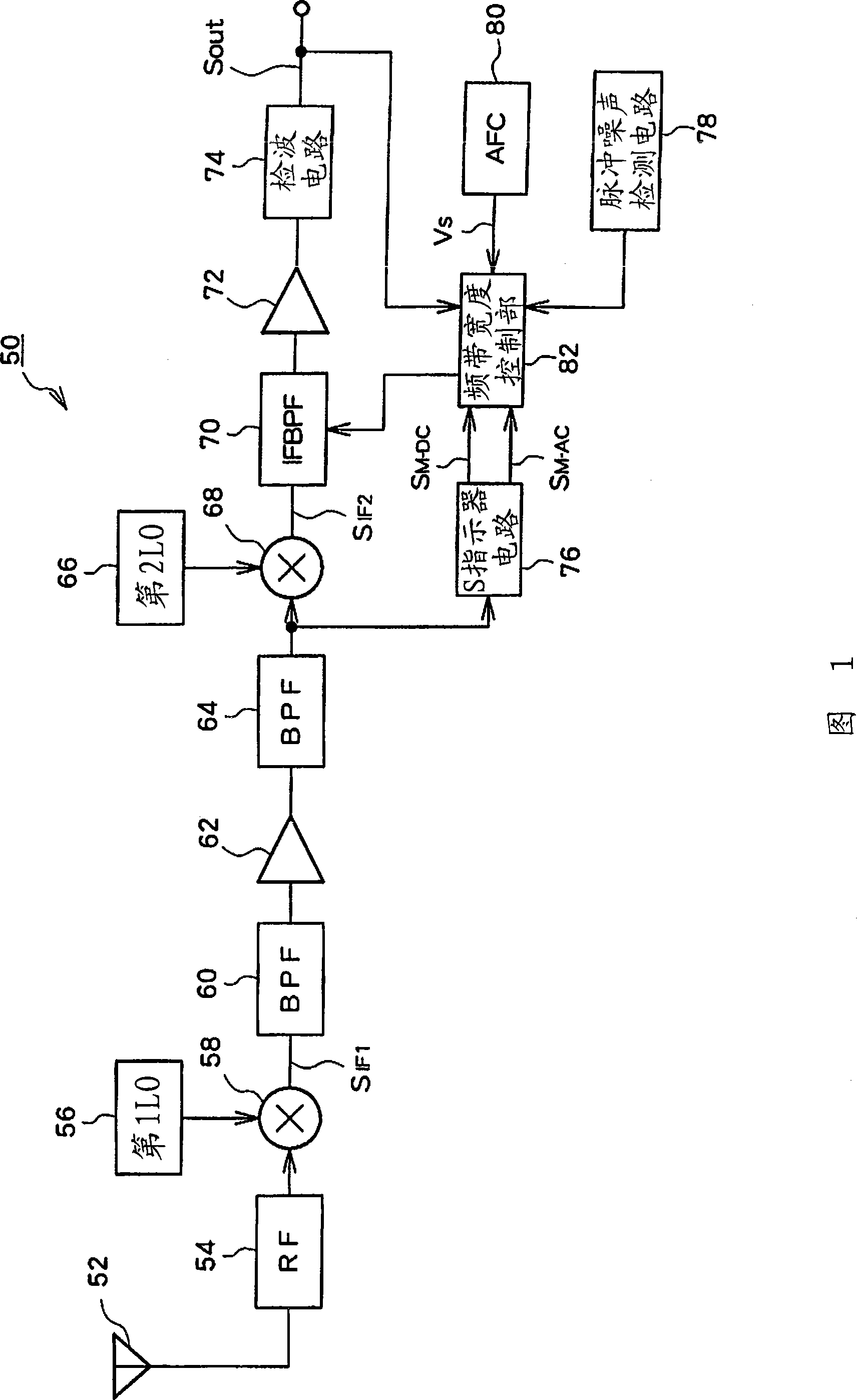

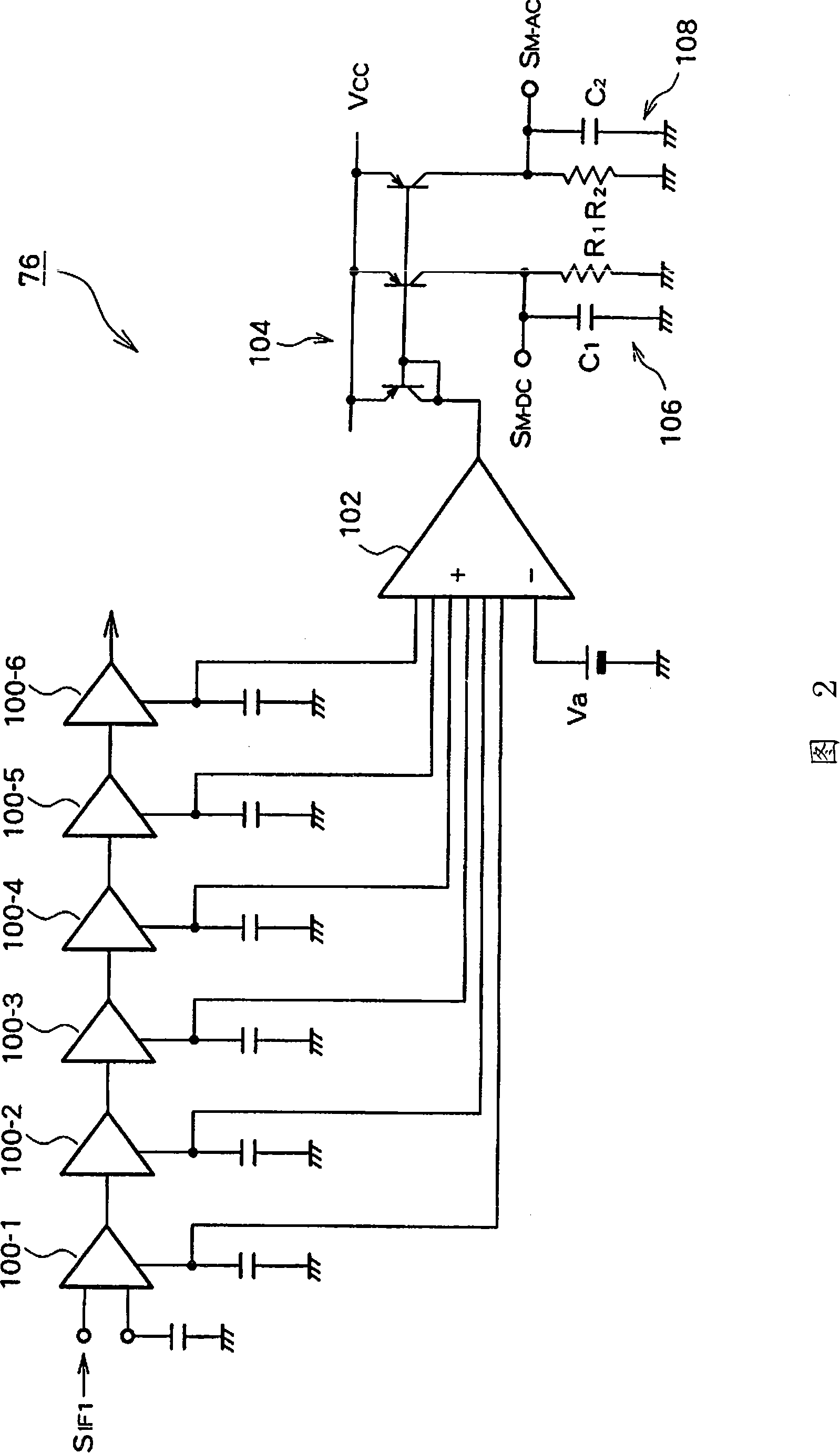

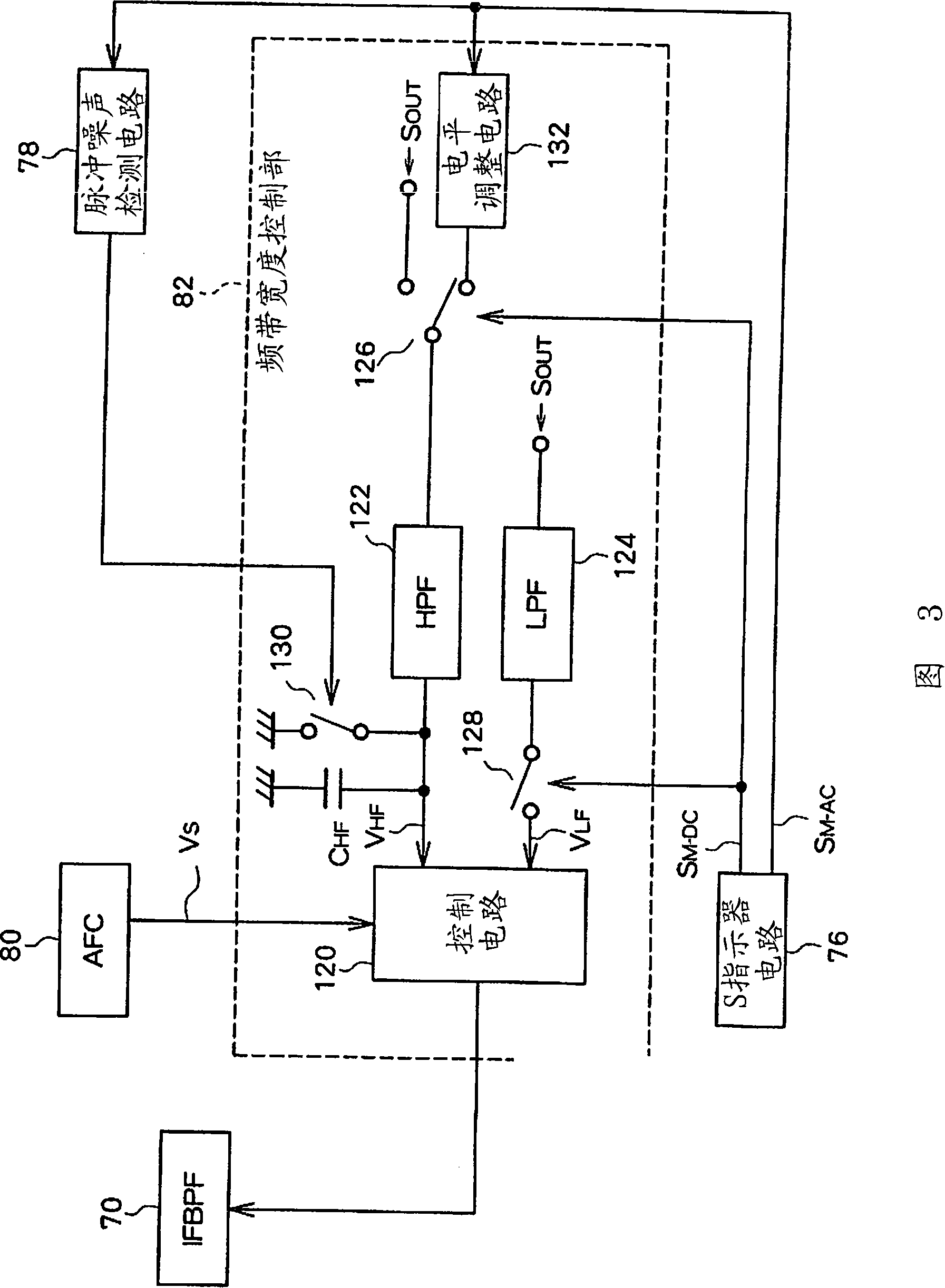

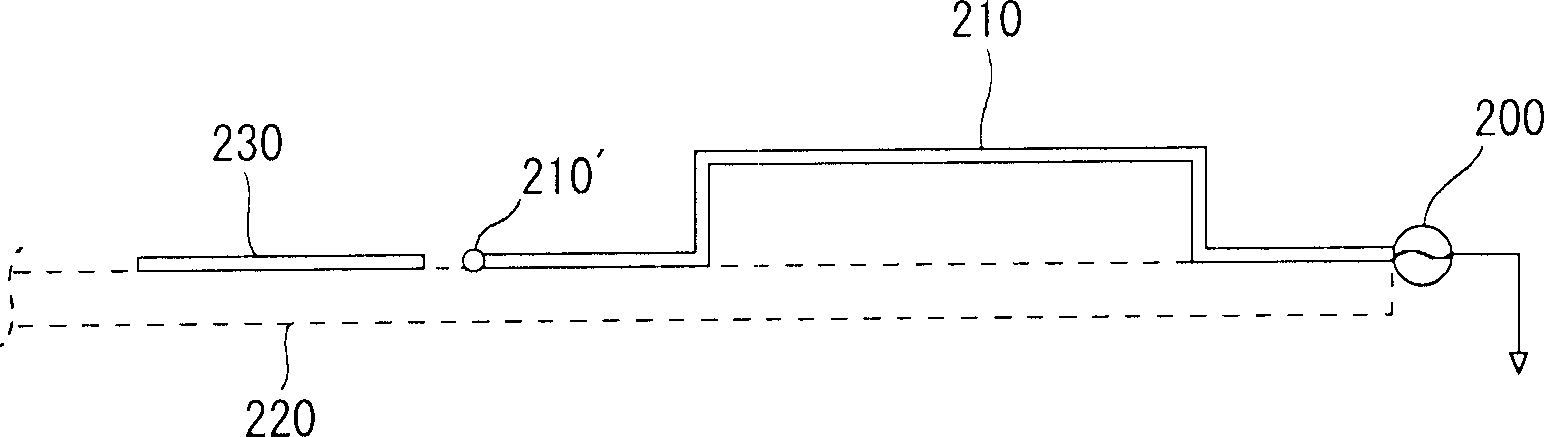

FM receiver

InactiveCN101252365AReduce noiseImprove interference characteristicsTransmissionBandpass filteringAdjacent-channel interference

An FM receiver that is suitable for reducing a transmission bandwidth W F of a bandpass filter to remove adjacent-channel interference, and increasing W F to prevent audio distortion. A detection output signal S OUT is inputted to an HPF 122 when a reception electric field strength signal S M-DC indicates an intermediate or stronger electric field. In a weak electric field, an AC component signal S M-AC , which is extracted from an intermediate signal S IF1 prior to detection and which has fewer high-pass noise components than S OUT , is inputted to the HPF 122. A control circuit 120 detects a case as an adjacent-channel interference state when a large amount of high-pass components passes through the HPF 122, and reduces W F of an IFBPF 70 in order to remove adjacent-channel interference. When a small amount of high-pass components is transmitted, W F is increased in order to minimize audio distortion. The relative detection output signal has more noise components in weak electric fields and has less noise in AC component signals, so that adjacent interference reliability is enhanced, and bandwidth control based thereon is implemented properly.

Owner:SANYO ELECTRIC CO LTD +1

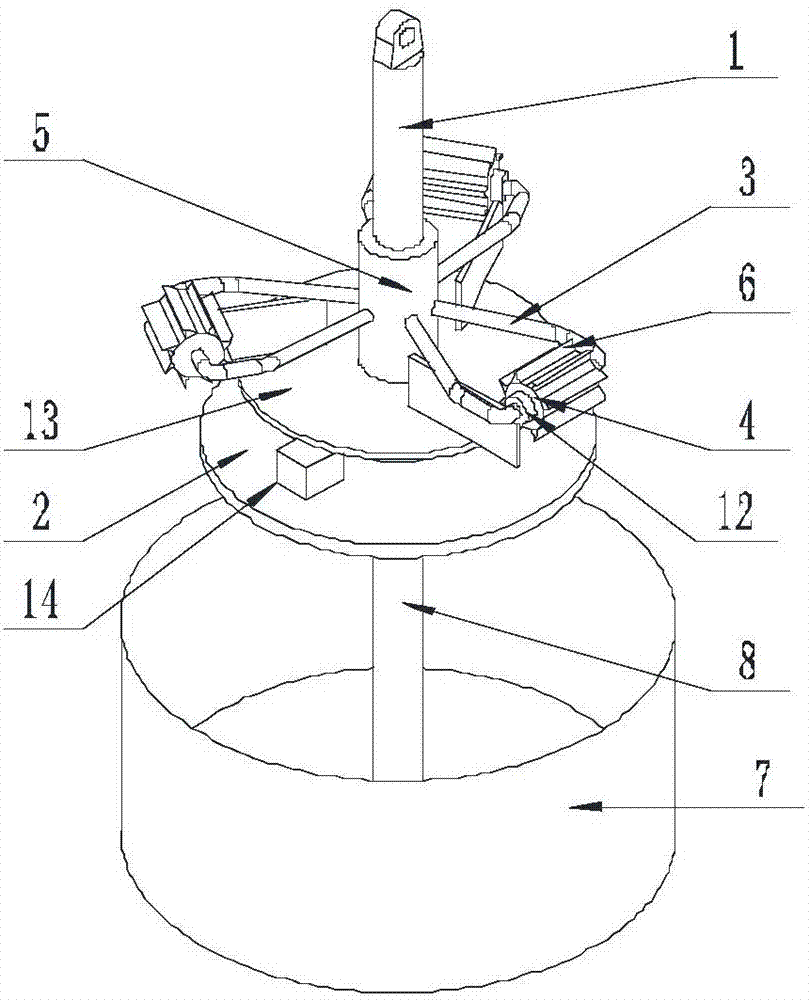

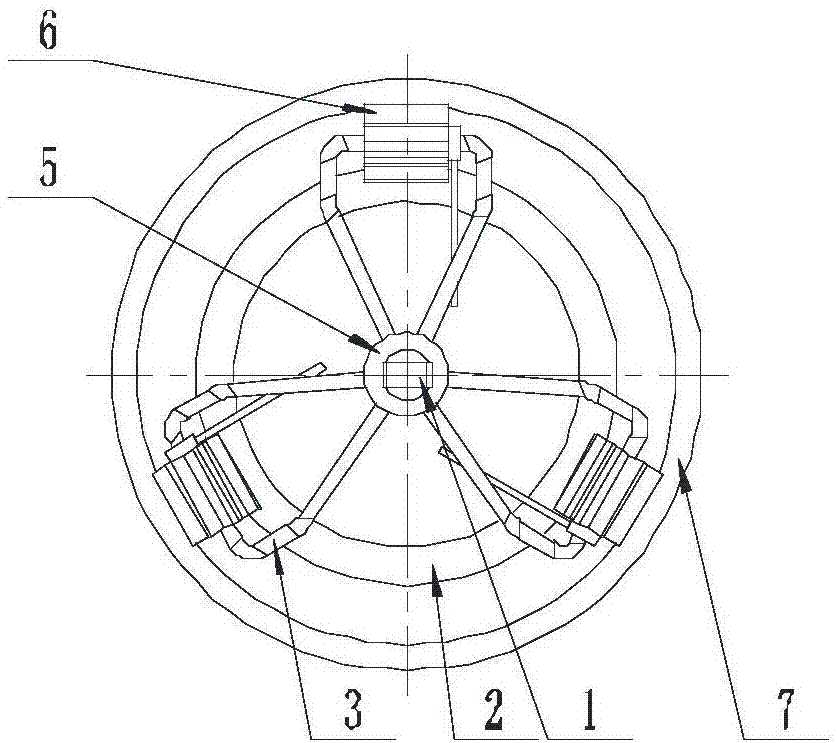

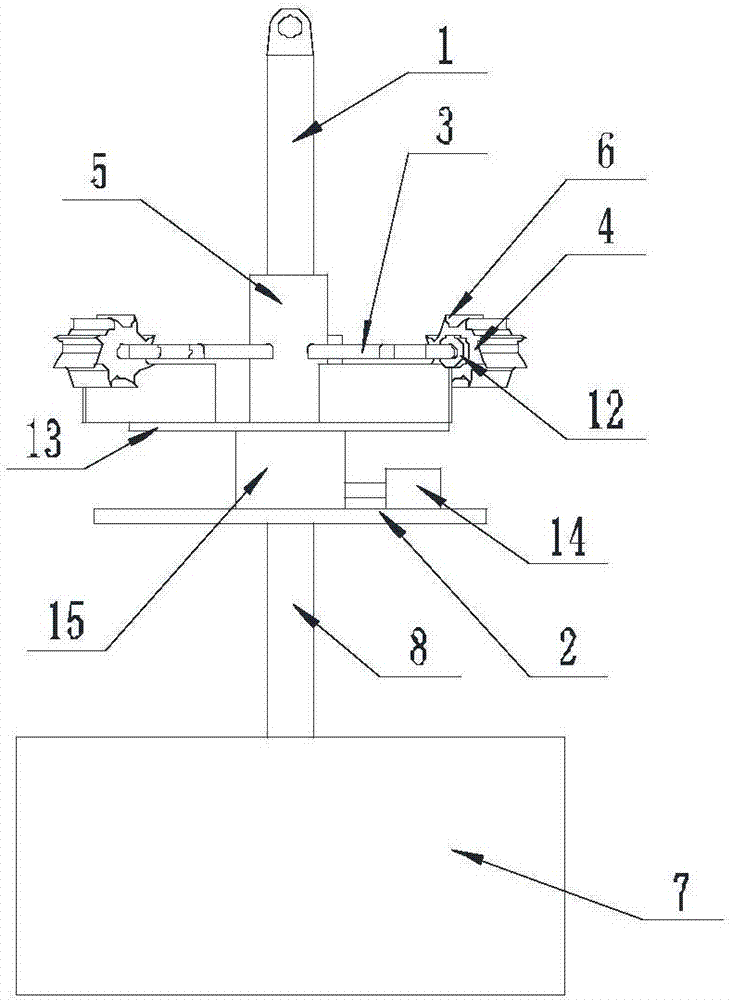

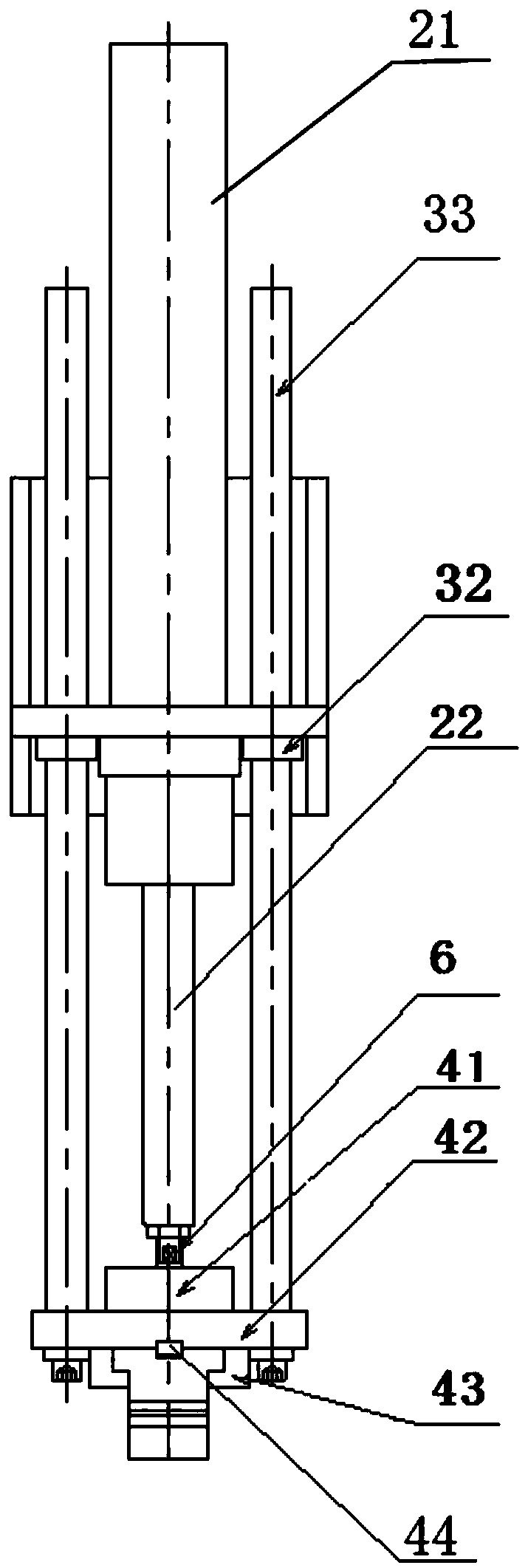

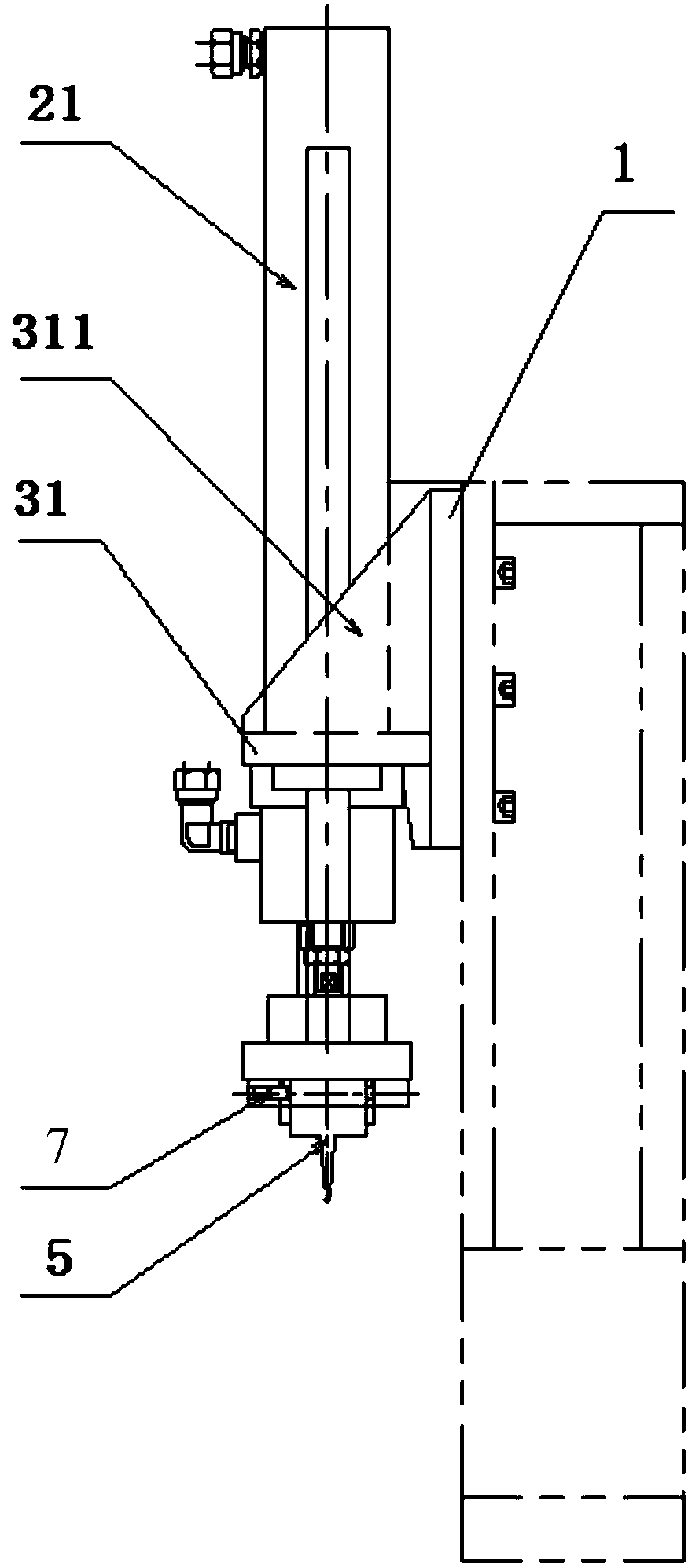

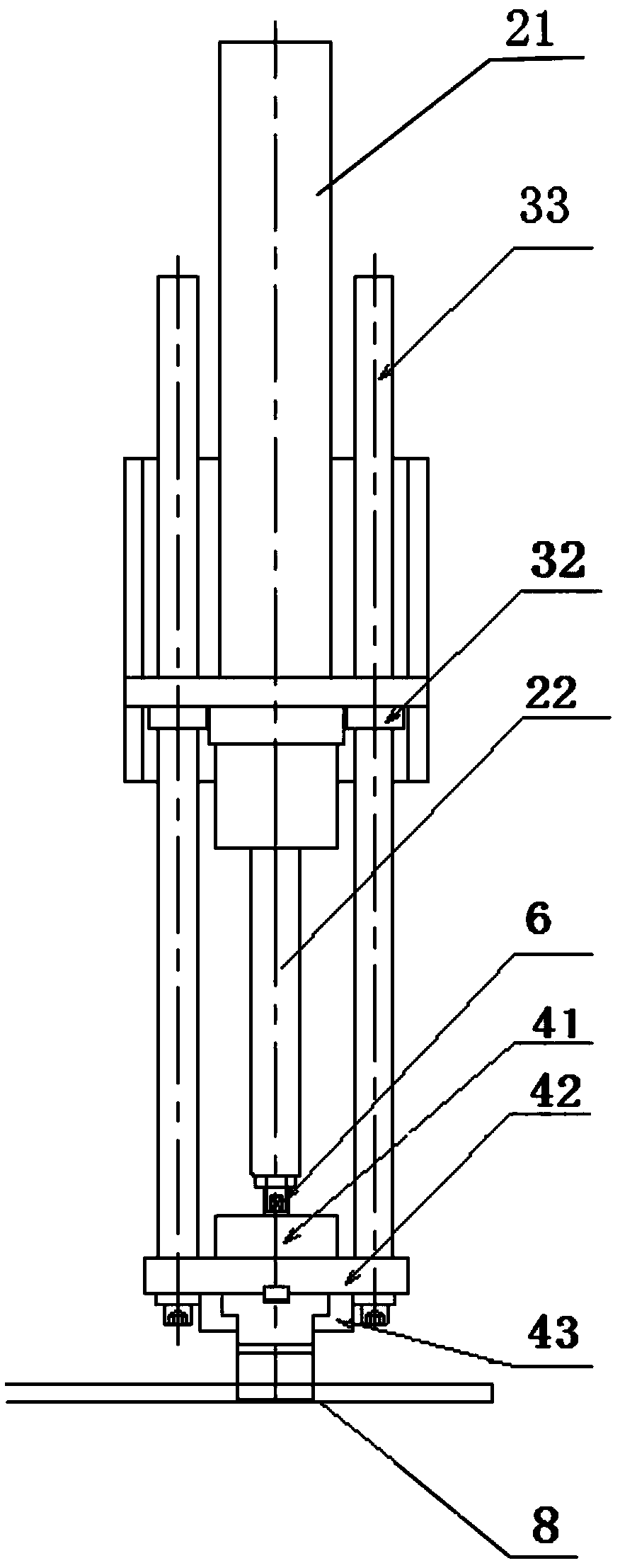

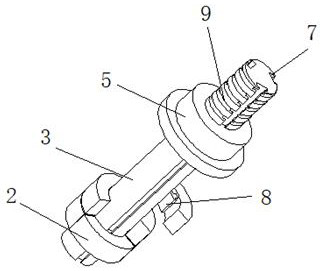

Device for preventing crude oil channel in oil well from being narrowed

InactiveCN107091068APrevent narrowingAvoid negative situations such as blockageCleaning apparatusWaxOil well

The invention discloses a device for preventing a crude oil channel in an oil well from being narrowed. The device for preventing the crude oil channel in the oil well from being narrowed comprises a suspending device and a wax removing assembly which are connected in sequence, the wax removing assembly comprises a connecting shaft, a support plate, a scraping knife assembly first driving device, a second driving device and a mounting cylinder, the connecting shaft is connected with the support plate, and the first driving device can rotate around an axial line of the connecting shaft; the scraping knife assembly comprises a support shaft and a support cylinder, one end of the support shaft is connected with the mounting cylinder, the other end of the support shaft penetrates through the support cylinder to be connected with the mounting cylinder, and the second driving device drives the support cylinder to rotate; the side wall of the support cylinder is provided with several scraping knifes. The suspending device puts the wax removing assemblies into the oil well which needs wax removal, then the first driving device and the second driving device are started to make the scraping knife remove wax on the wall of the oil well, which further avoids the generation of negative conditions that a crude oil flow channel is reduced, the oil pressure is increased, and an oil pipe is clogged to guarantee normal flow of crude oil and successful proceeding of crude oil exploitation.

Owner:SICHUAN XILIN OIL SUPPLIES EQUIP

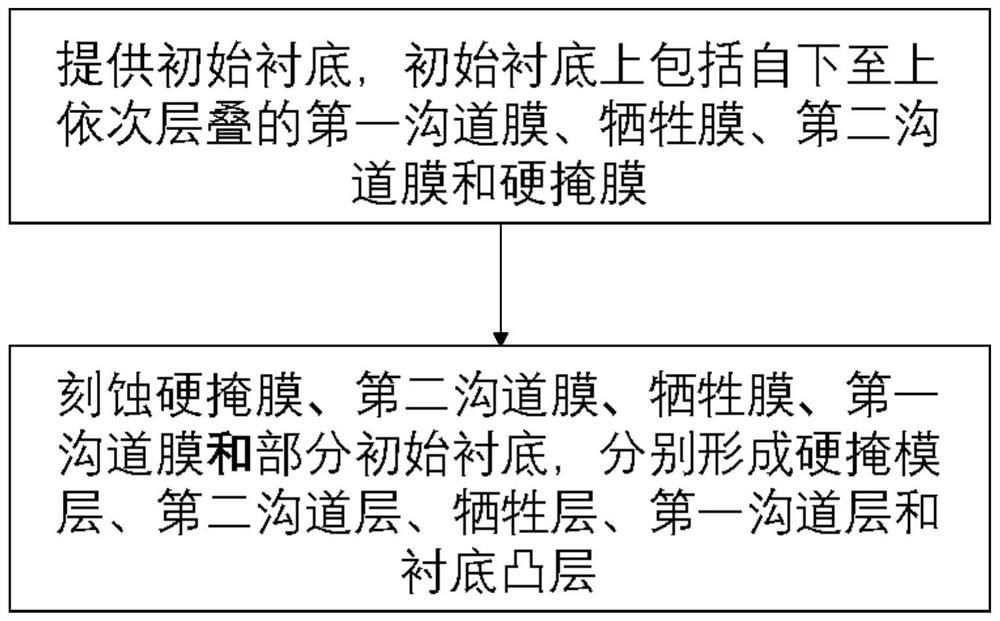

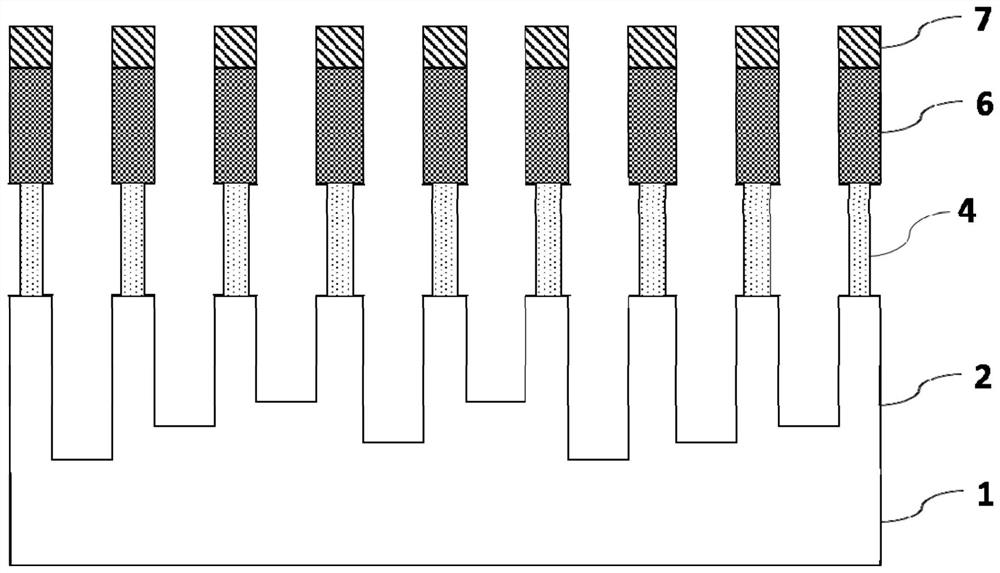

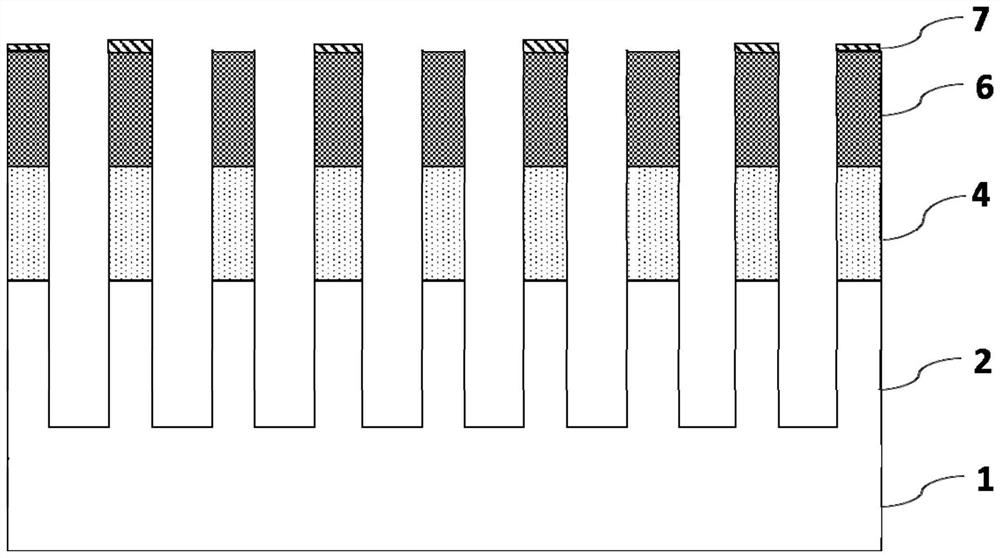

Semiconductor structure and forming method thereof

ActiveCN113539823AReduce typesRealize isolation protectionTransistorSemiconductor/solid-state device manufacturingSemiconductor structureEngineering

The invention discloses a semiconductor structure and a forming method thereof. The method comprises the steps that: an initial substrate is provided, wherein the initial substrate comprises a first sacrificial film, a first channel film, a second sacrificial film, a second channel film and a third sacrificial film which are sequentially stacked from bottom to top; the third sacrificial film and the second channel film are etched until the surface of the second sacrificial film is exposed to form a third sacrificial layer and a second channel layer; a first protection layer is formed on the side wall of the second channel layer; the second sacrificial film and the first channel film are etched until the surface of the first sacrificial film is exposed to form a second sacrificial layer and a first channel layer; a second protection layer is formed on the side wall of the second channel layer, the side wall of the second sacrificial layer and the side wall of the first channel layer; and the first sacrificial film and a part of the initial substrate are etched to enable the first sacrificial film to form a first sacrificial layer. According to the semiconductor structure and the forming method thereof disclosed by the invention, the CFET manufacturing process is improved, and the performance of the semiconductor structure is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

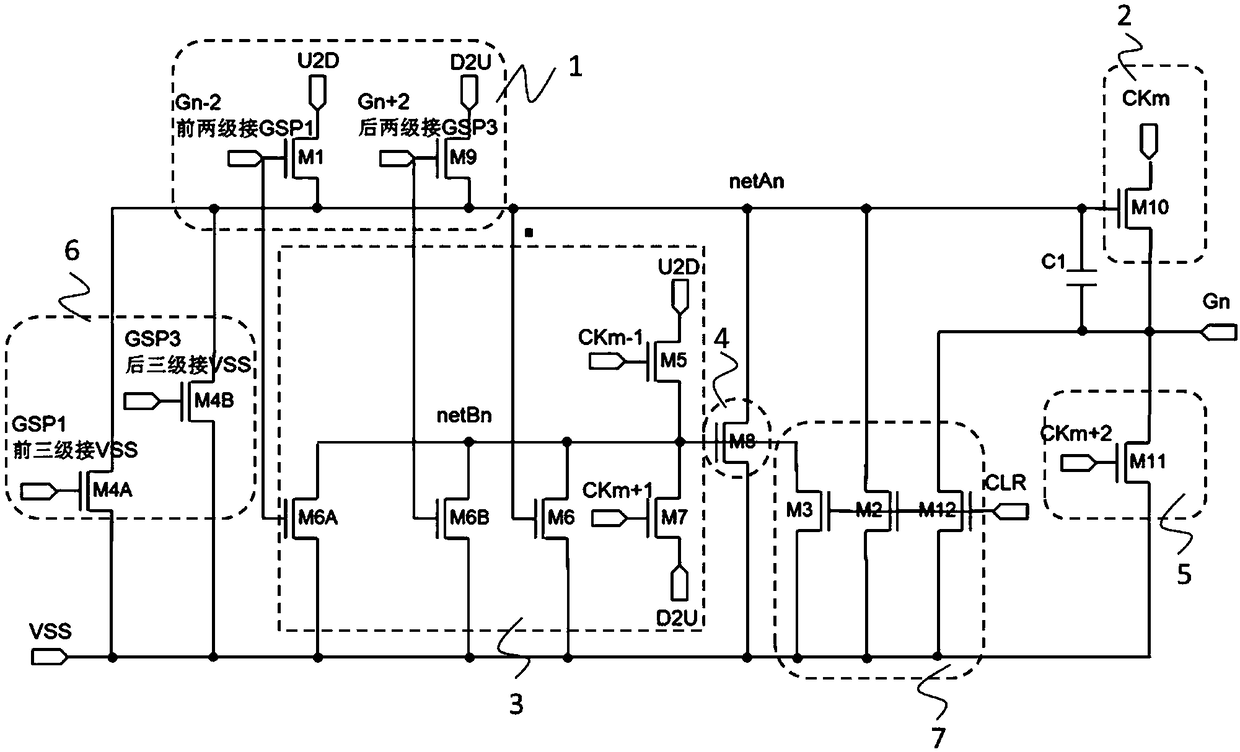

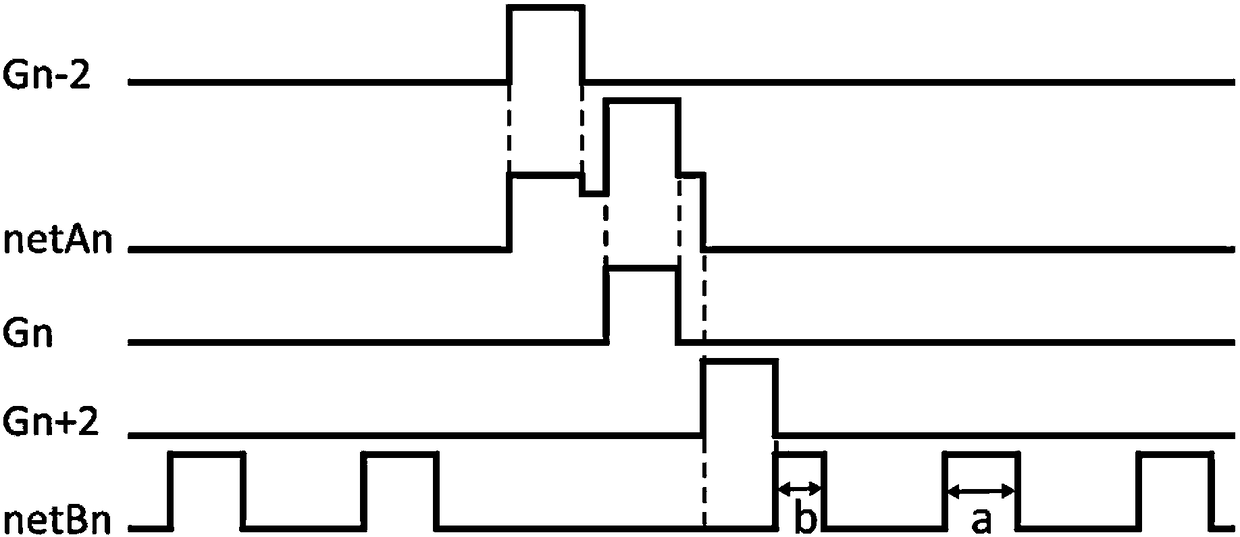

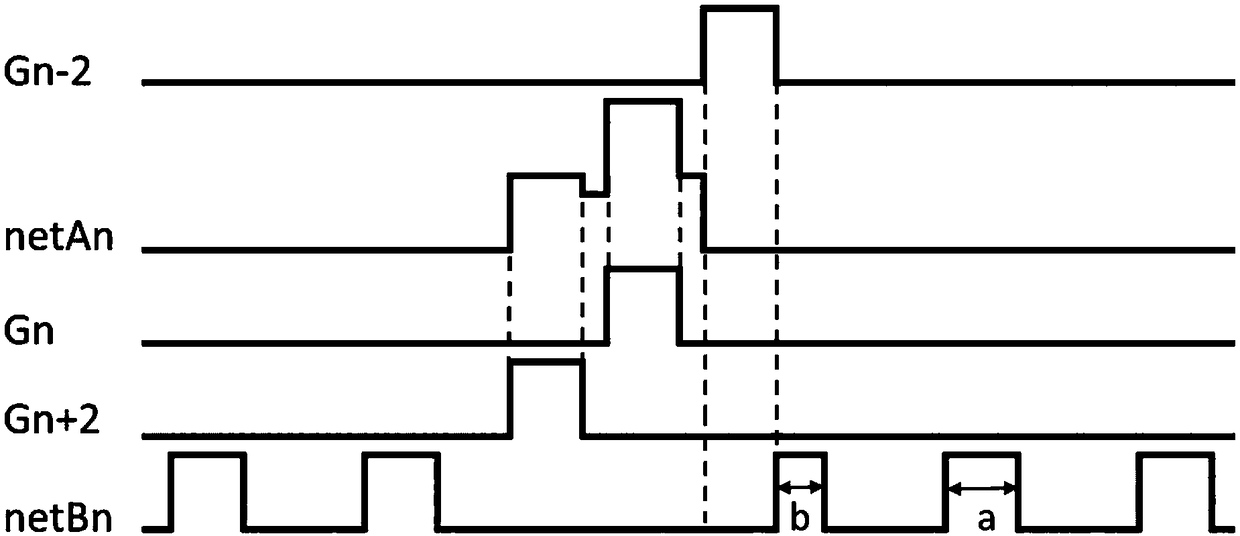

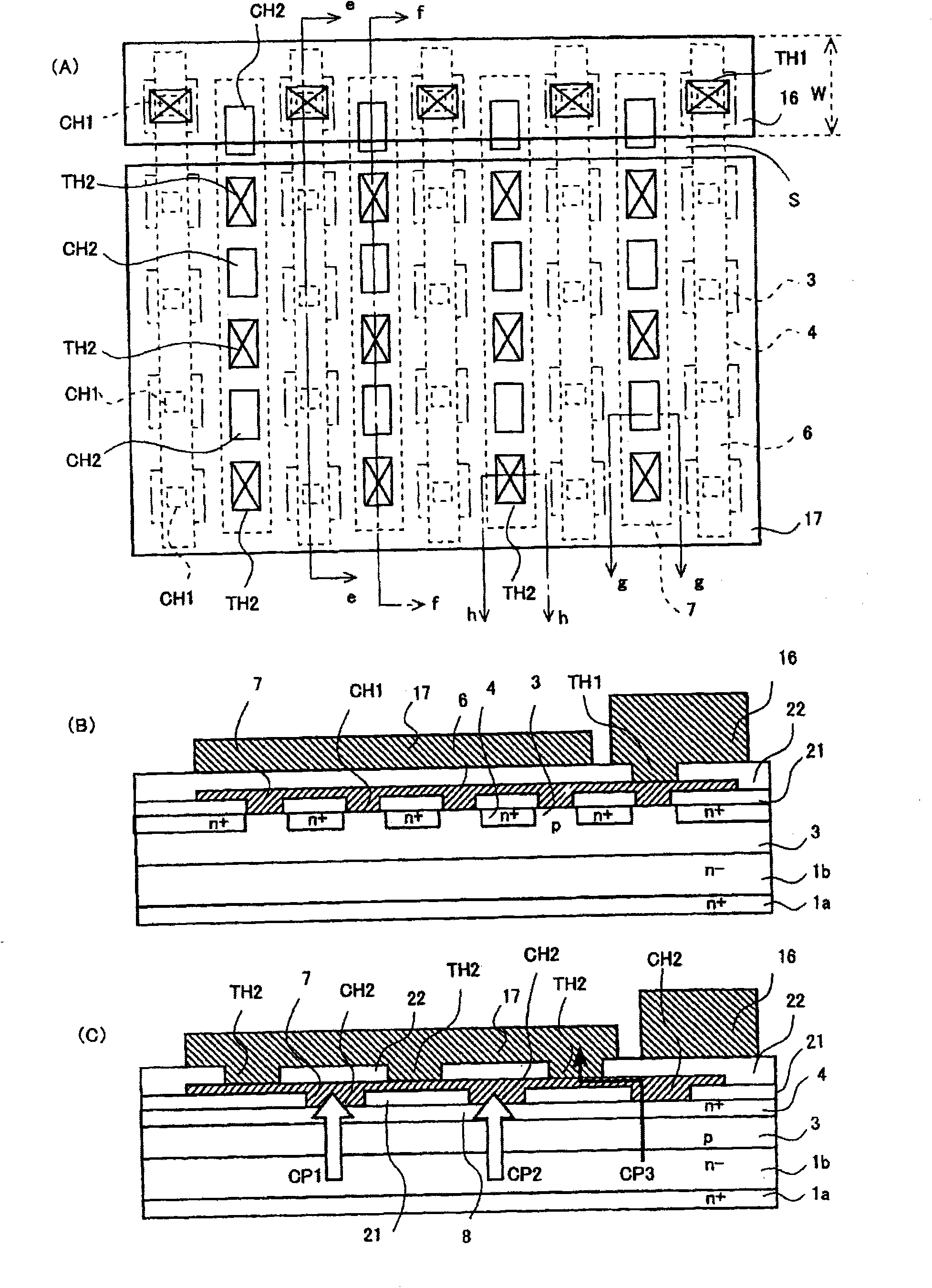

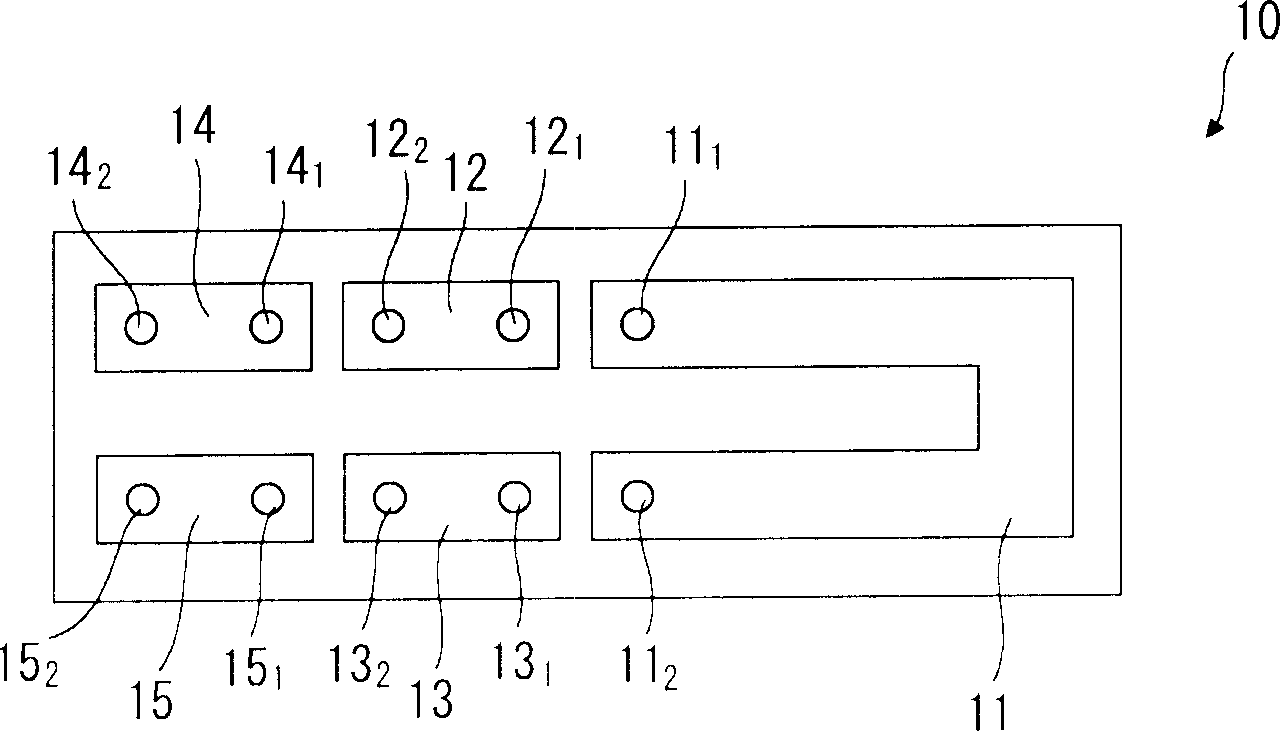

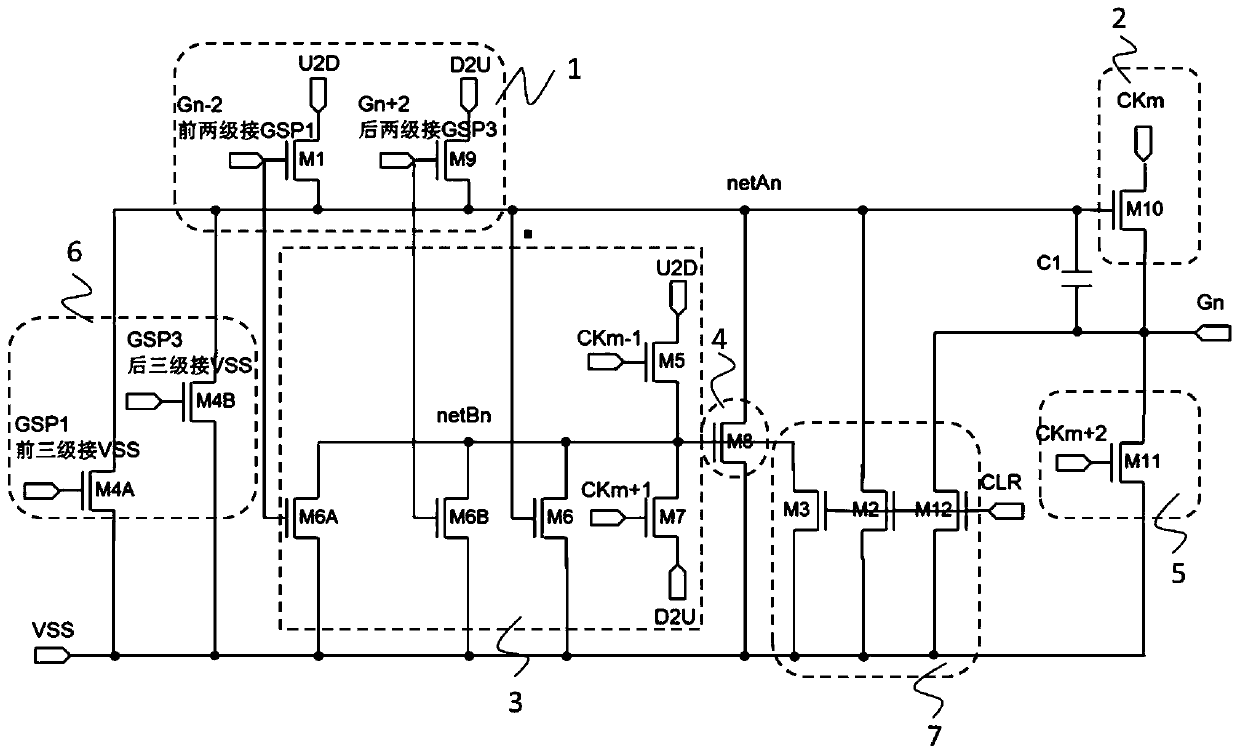

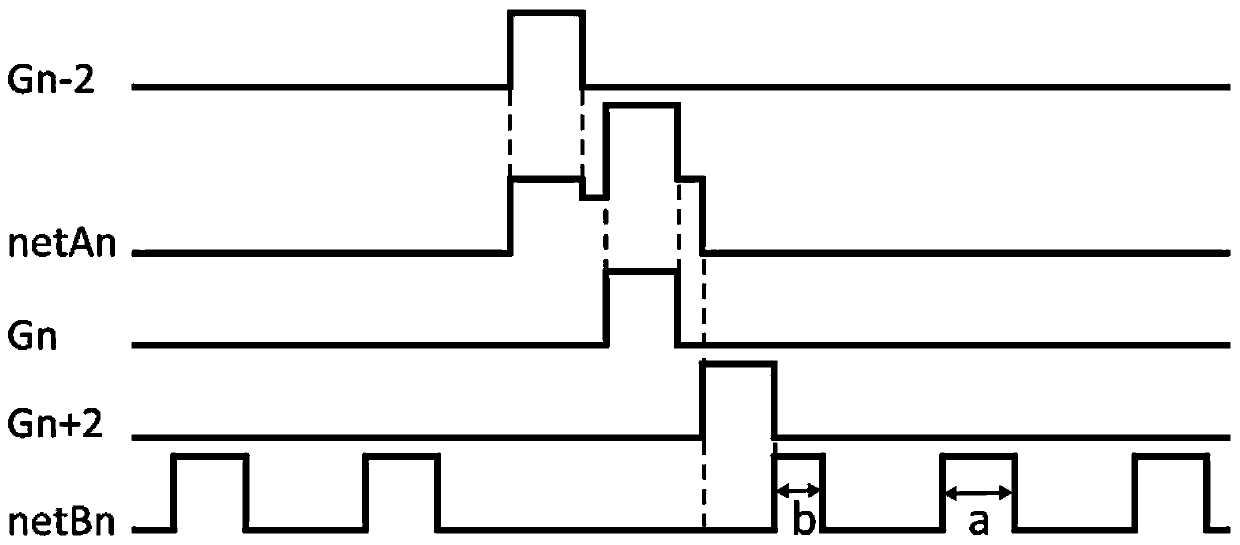

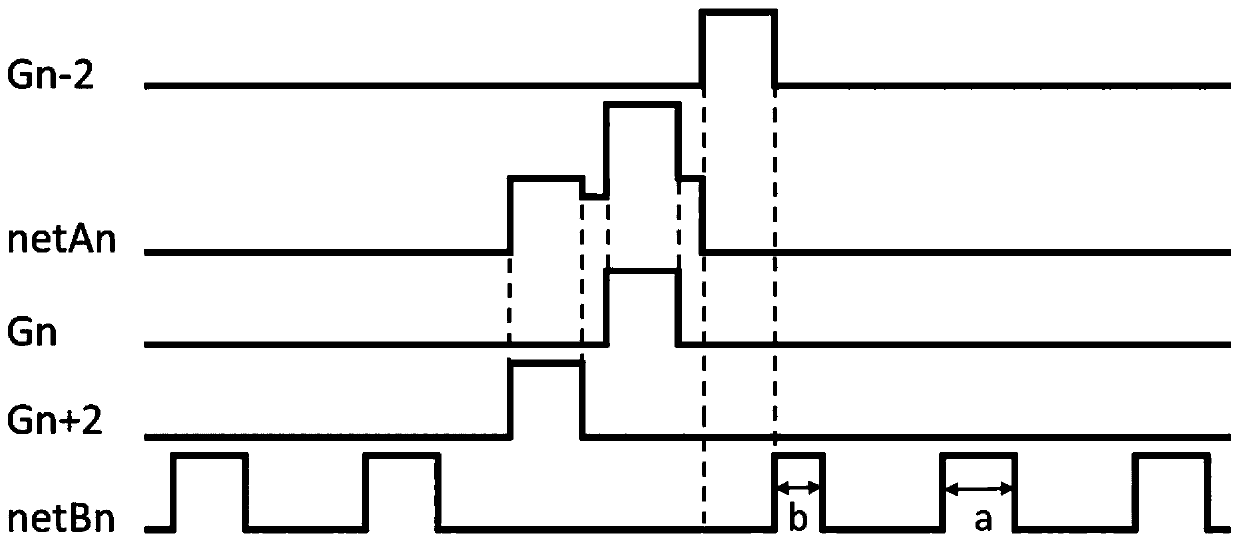

Gate driver monolithic (GDM)

ActiveCN108242228AImprove reliabilityPrevent narrowingStatic indicating devicesGate driverCircuit reliability

The invention discloses a gate driver monolithic (GDM) including N (N>4, and N is a positive integer) levels of driving circuit units. The nth(1< / =n< / =N, and n is a positive integer)-level driving circuit unit includes a pull-up control module, a pull-up module, a maintenance control node generation module, a pull-up control node maintenance module, and an output node maintenance module. The maintenance control node generation module inputs a forward scan control signal and a reverse scan control signal that are mutually inverted, and generates a maintenance control signal to control a maintenance control node, after the output of scan signals in the forward scan and the reverse scan, the first signal pulse width of the maintenance control node is the same as the preset width, the first pulse width of the maintenance control node is prevented from being narrowed, so that the pull-up control node maintenance module can immediately perform intermittent low-potential maintenance on a pull-up control node, the scan signal is prevented from being erroneously turned on, and the circuit reliability is improved.

Owner:NANJING CEC PANDA LCD TECH

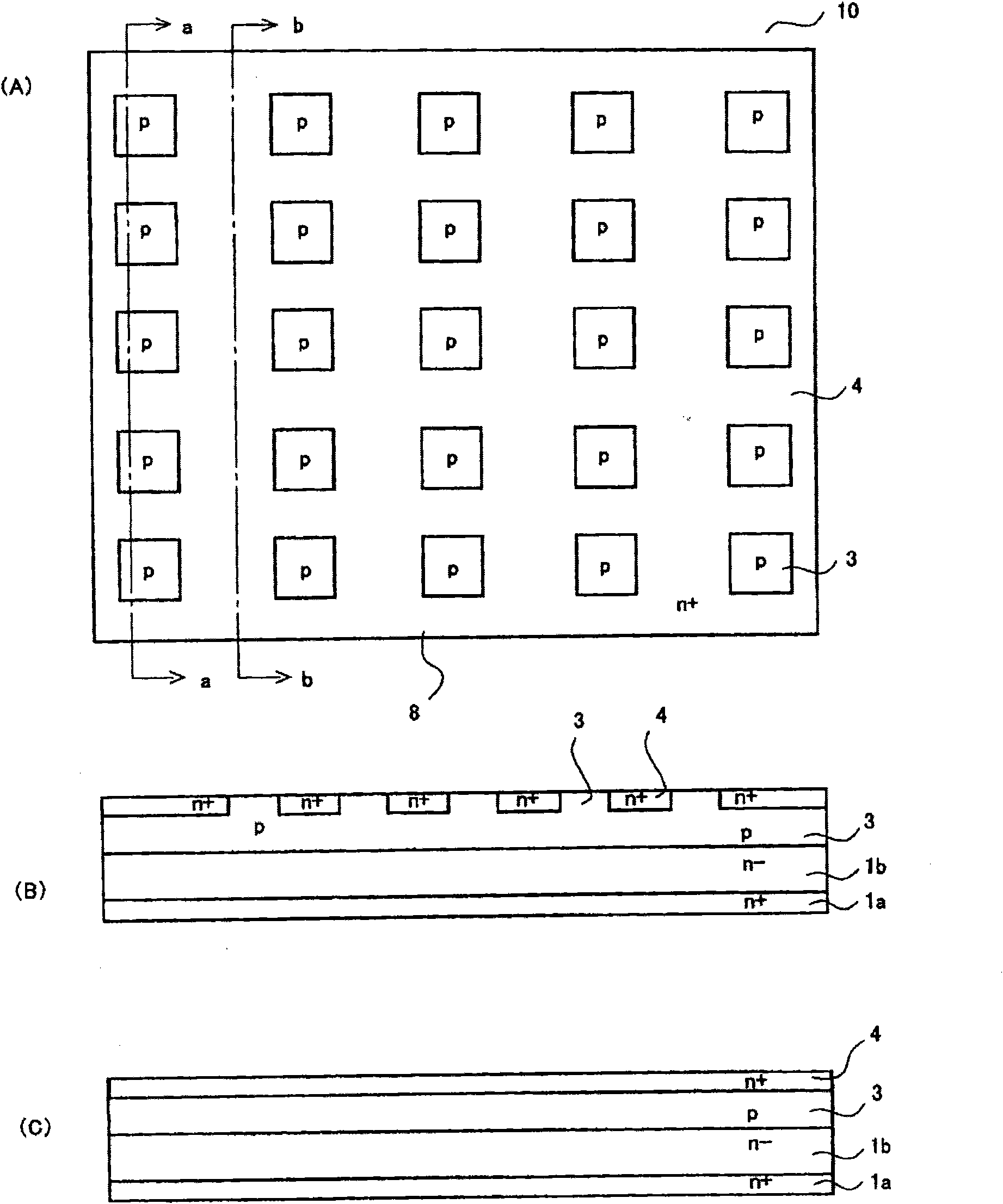

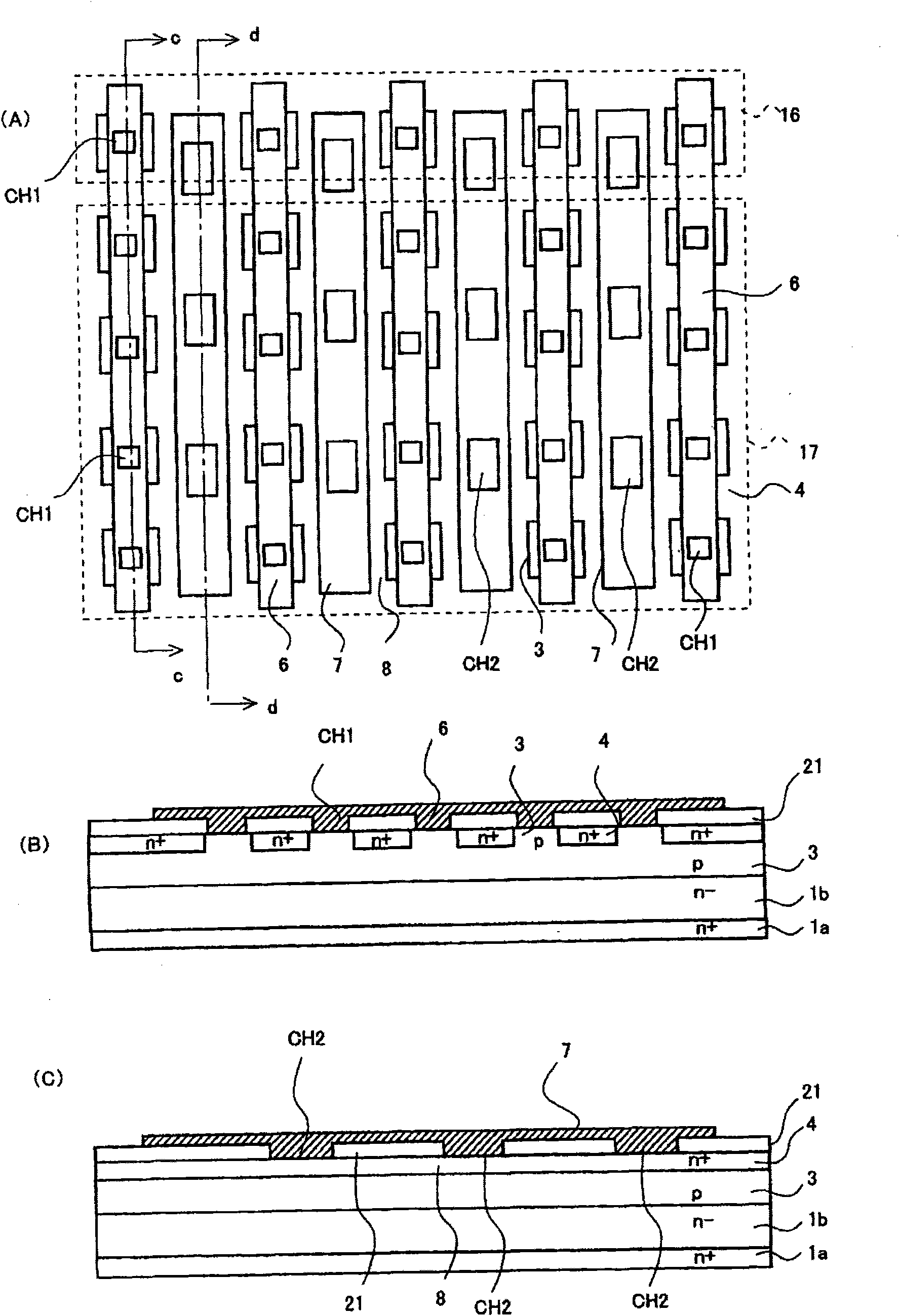

Semiconductor device

InactiveCN101661953AReduce bumpsInhibition of poor wettabilityTransistorSolid-state devicesMetal sheetHeight difference

A semiconductor device. In a discrete bipolar transistor with two layers of electrode structures, the emitter electrode in a first layer and the emitter region are connected via emitter contact holesof a first insulated film formed therebetween. The emitter electrode in the second layer and the emitter electrode in the first layer are connected via emitter through holes of a second insulated filmformed therebetween. Accordingly, the emitter contact holes and the emitter through holes are overlapped under the emitter electrode in the second layer so as to generate a height difference of a thickness of two insulated films. The height difference influences the surface of the emitter electrode in the second layer, thus producing bad adhesion owing to large bump when a metal sheet is bound onthe surface with a solder. Emitter contact holes formed under the emitter electrode in the first layer and emitter through holes formed thereon are arranged so as not to overlap each other, and, foreach emitter electrode, the multiple emitter contact holes and the multiple emitter through holes are provided so as to be separated from each other. Thereby, the top surface of an emitter electrode in a second layer is influenced by at most only a height difference of each emitter through hole formed in an insulated film having a larger thickness, and thus the flatness of the top surface of the emitter electrode in the second layer is improved. Accordingly, fixation failure of a metal sheet can be avoided.

Owner:SANYO ELECTRIC CO LTD +1

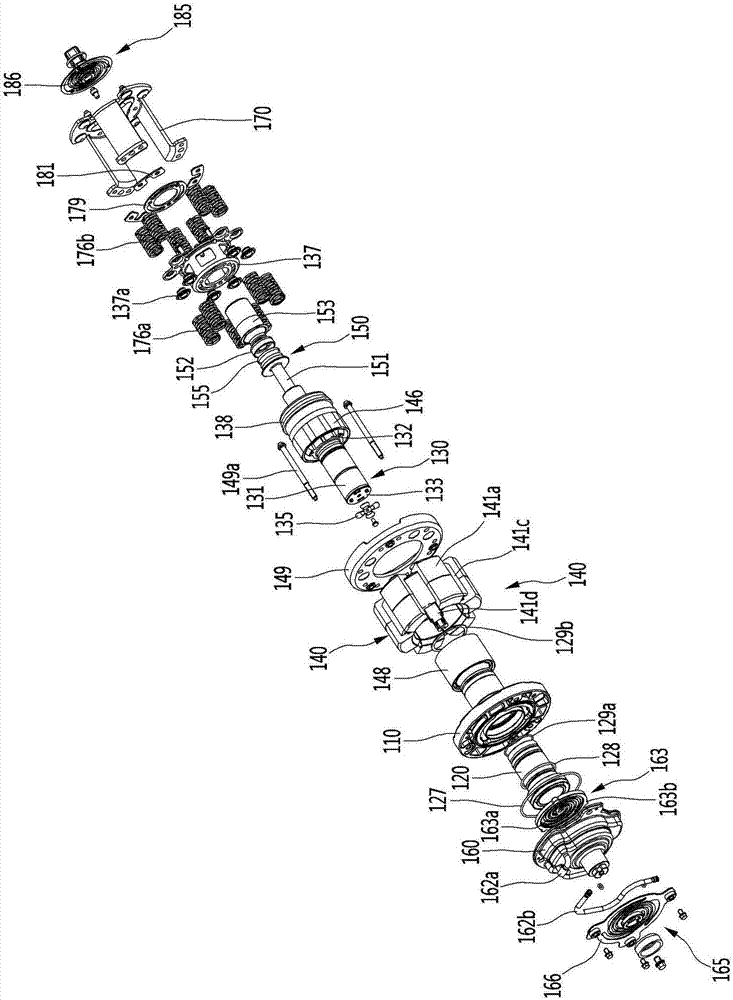

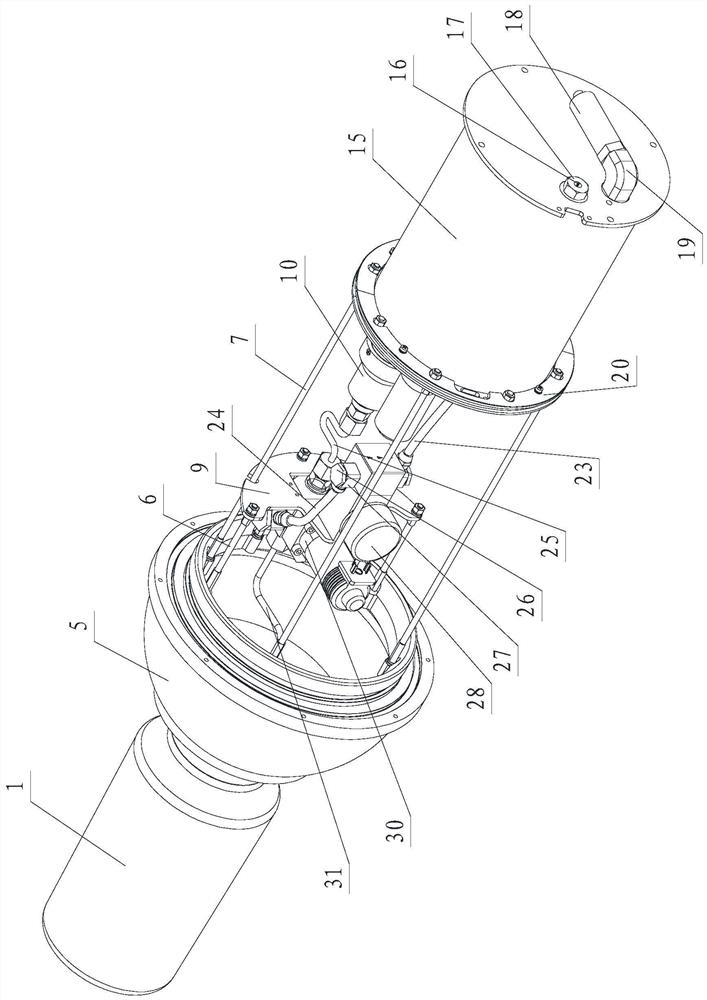

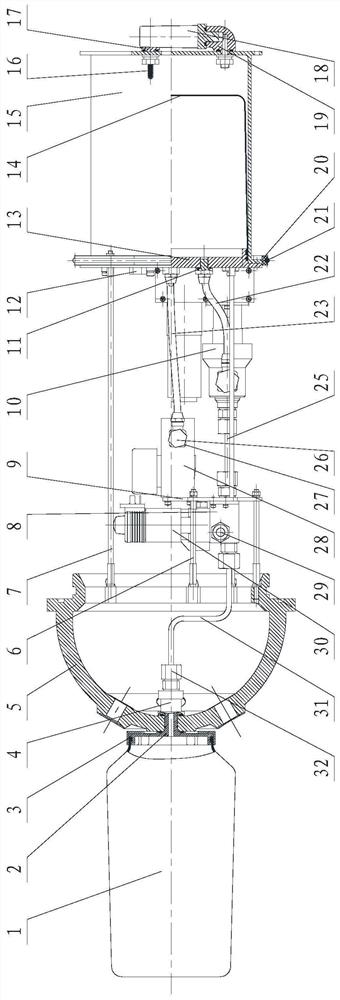

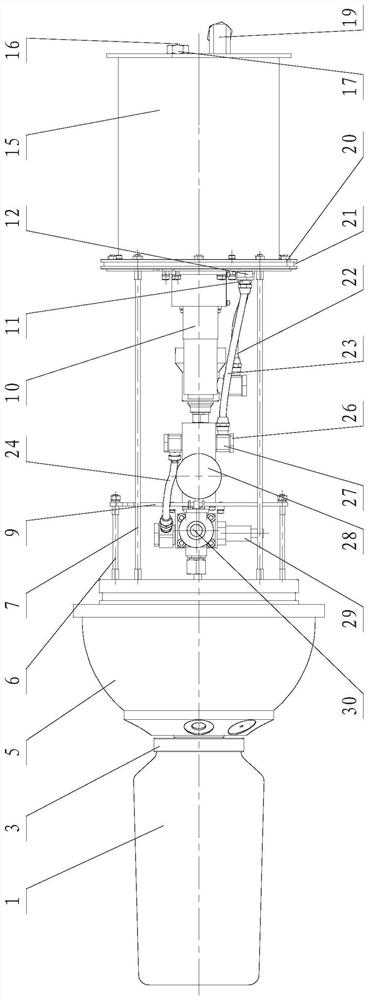

Buoyancy adjusting device for large-depth underwater robot

PendingCN112124539ALight in massThe overall structure is simple and reliableUnderwater vesselsUnderwater equipmentBuoyancy regulationEngineering

The invention relates to a buoyancy adjusting device for a large-depth underwater robot. The adjusting amount of hydraulic oil of the buoyancy adjusting device is detected by detecting changes of thetemperature and the pressure of inert gas in a closed cavity; and the inert gas with positive pressure is poured into an inner leather bag sealing barrel, so that an inlet of a high-pressure plunger pump has positive pressure, the problem that the self-suction capacity of the high-pressure plunger pump is poor is solved, and the working efficiency of the high-pressure plunger pump is improved. Double-pump combination is adopted, and different pumps are adopted for outward oil discharge and inward oil return, so that the energy consumption of a system is reduced, and the corresponding speed during low-pressure oil return is increased. A direct-current motor and the high-pressure plunger pump are arranged in parallel, so that the structure is more compact; and the high-pressure plunger pumpis installed in an oil immersion manner, the structural characteristics of the high-pressure plunger pump are fully combined, the installation size is minimized, the oil absorption efficiency is improved, and meanwhile the space is saved. According to the buoyancy adjusting device, through the structure design that a whole cage-shaped frame is matched with a core shaft, the stability of the wholestructure is met, and the light weight of the whole structure is achieved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Vertical wedge mechanism

PendingCN109108673AAvoidance and clampingExtended service lifeLarge fixed membersMaintainance and safety accessoriesSteel platesManual insertion

The invention discloses a vertical wedge mechanism. The vertical wedge mechanism comprises a machine frame, a driving cylinder assembly, a wedge block fixing assembly, a guide assembly and a wedge block, wherein the driving cylinder assembly comprises a cylinder body and a piston rod arranged in the cylinder body, the cylinder body is vertically connected with the machine frame, the piston rod isconnected with the wedge block fixing assembly in the vertical direction, the wedge block is vertically fixed on the wedge block fixing assembly, and the piston rod drives the wedge block fixing assembly to do reciprocating motion in the vertical direction along the guide assembly. The wedge block is driven by the piston rod of the driving cylinder to be inserted into the knife seam, manual insertion is replaced, time and labor are saved, and meanwhile, the service life of the cutter is prolonged, and the machining precision of the steel plate is improved.

Owner:江苏宁兴恒力智能设备有限公司

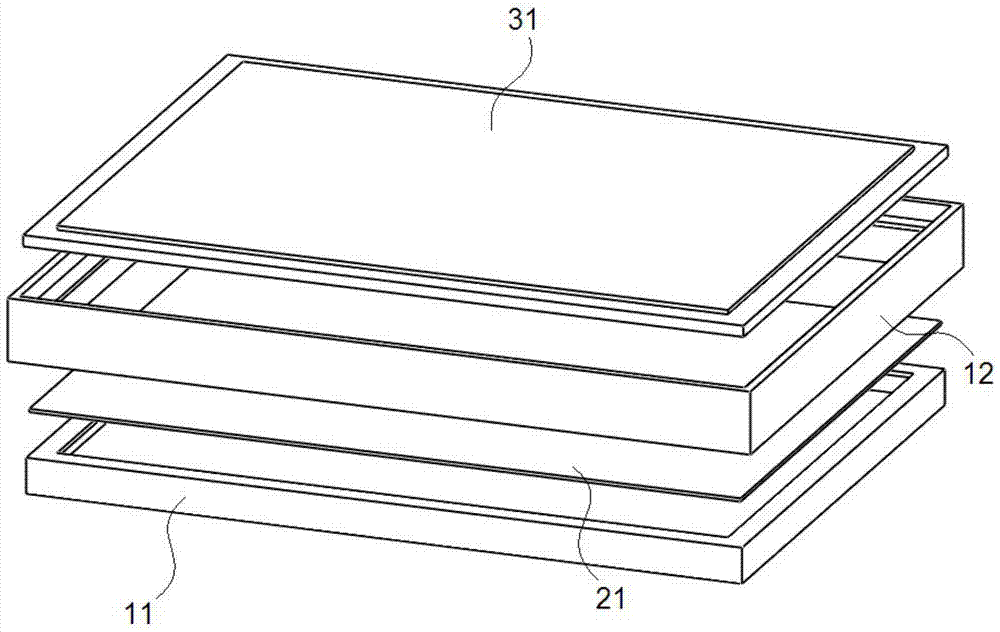

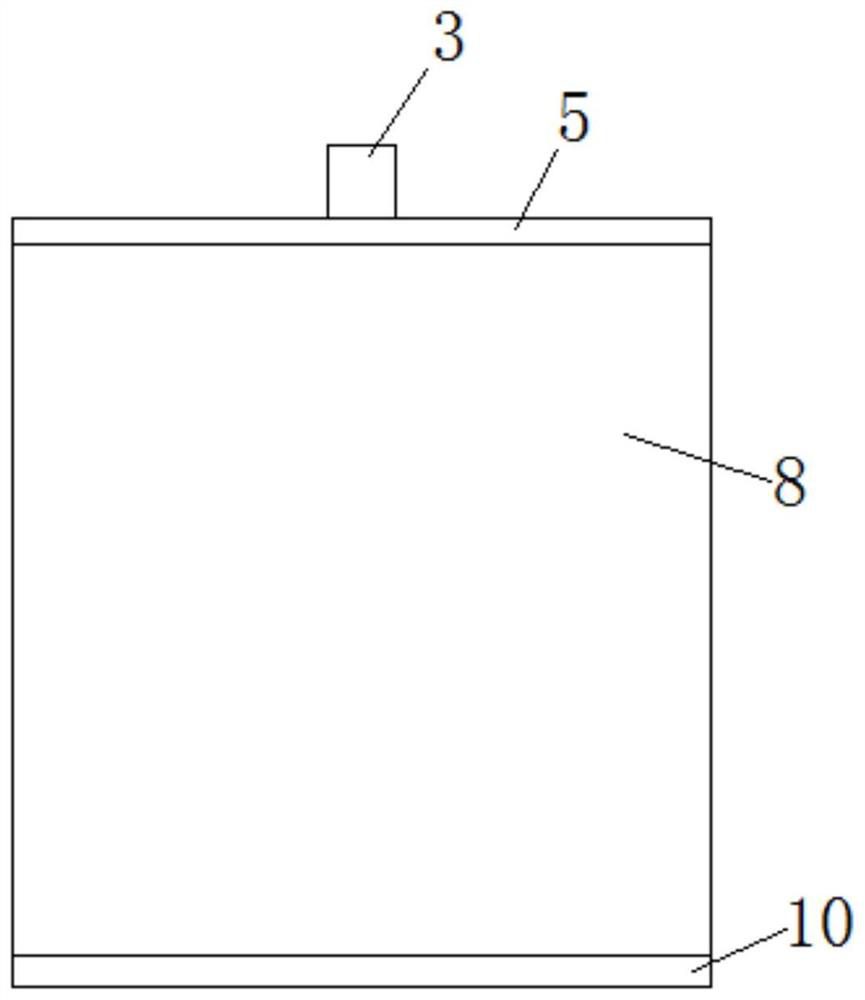

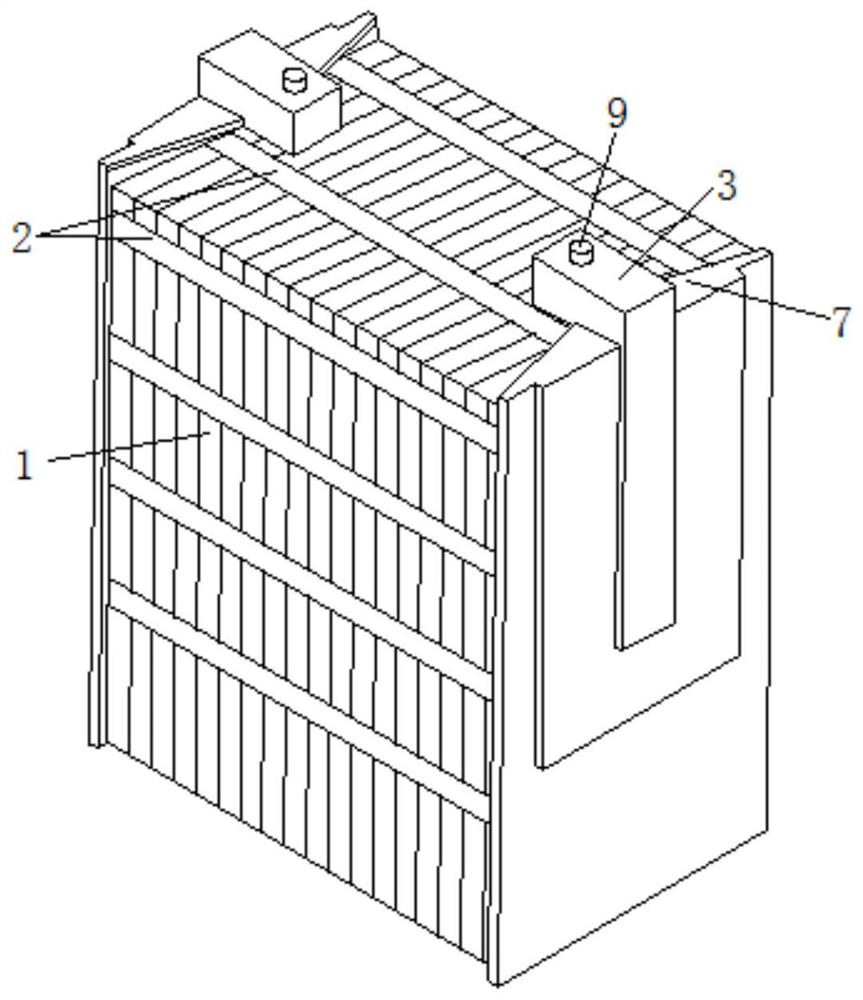

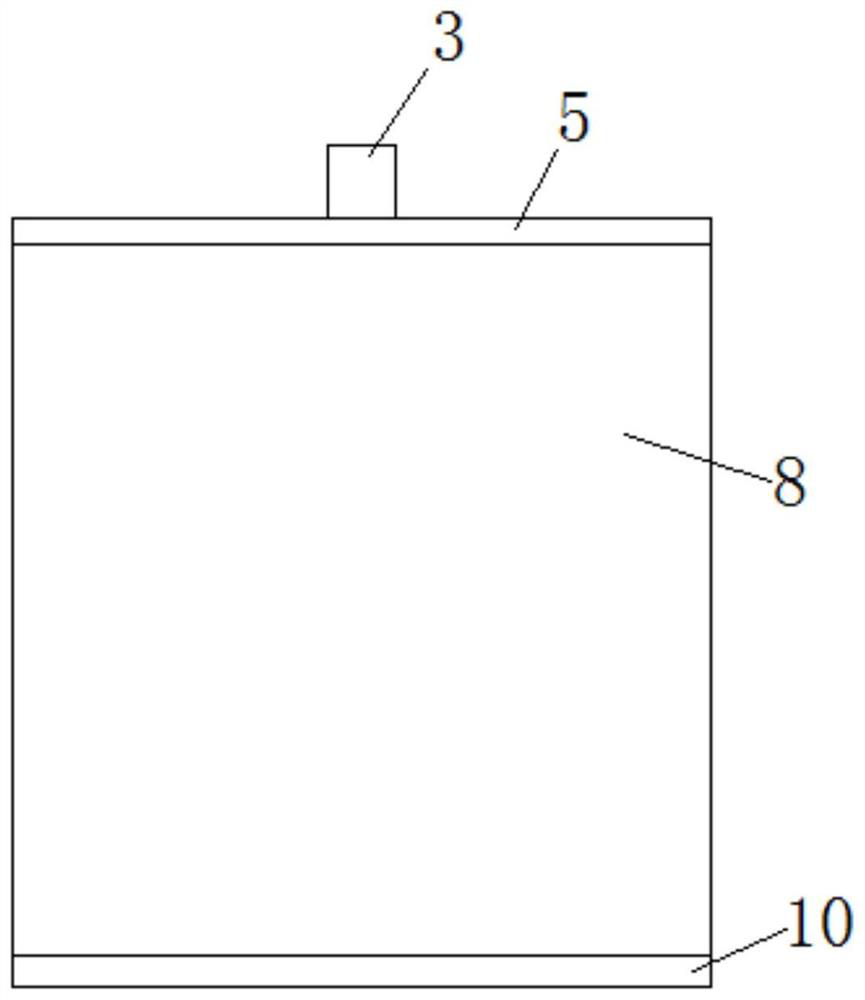

Stacked battery and production method of stacked battery

ActiveCN111740144AReduce shakingReduce softening and flakingLarge-sized flat cells/batteriesFinal product manufactureStructural engineeringMechanical engineering

The invention provides a stacked battery. The stacked battery comprises a polar plate group, pressure frames, tabs and a shell, the pressure frames wrap the polar plate group and are connected into awhole through buckles, so that the polar plate group is mounted into a whole by utilizing the pressure frames, the situation that the active substances are softened and peeled off due to shaking amongpolar plates in the use process of the polar plate group is reduced, and the shell is mounted outside the pressure frames, and further the pressure frames or the polar plate group can be further insulated through the shell and are prevented from being damaged by the outside in the use process of the battery. The polar plate group can be fixed through the pressure frames, so that the distance between the positive plates and the negative plates can be unified, the condition that conductive channels become narrower due to thickening the polar plate group caused by the excessive positive plates and negative plates is avoided, and each conductive channel in the electrode plate can ensure the effective utilization rate of active substances of the battery, and the service life of the battery canbe prolonged.

Owner:肇庆中特能科技投资有限公司

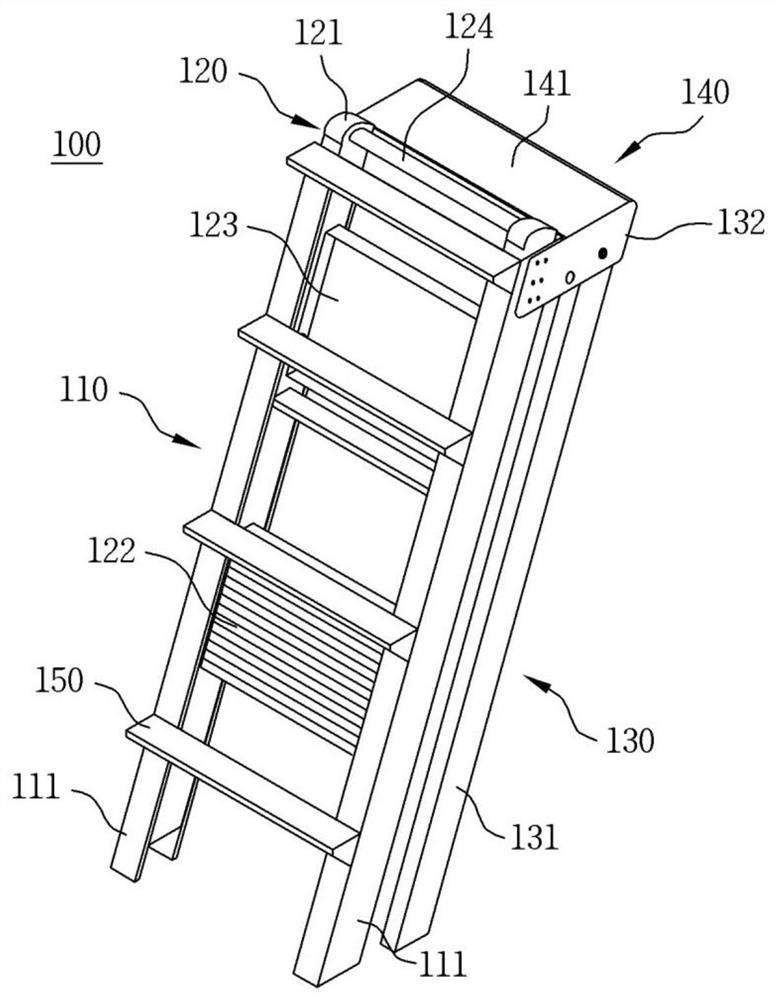

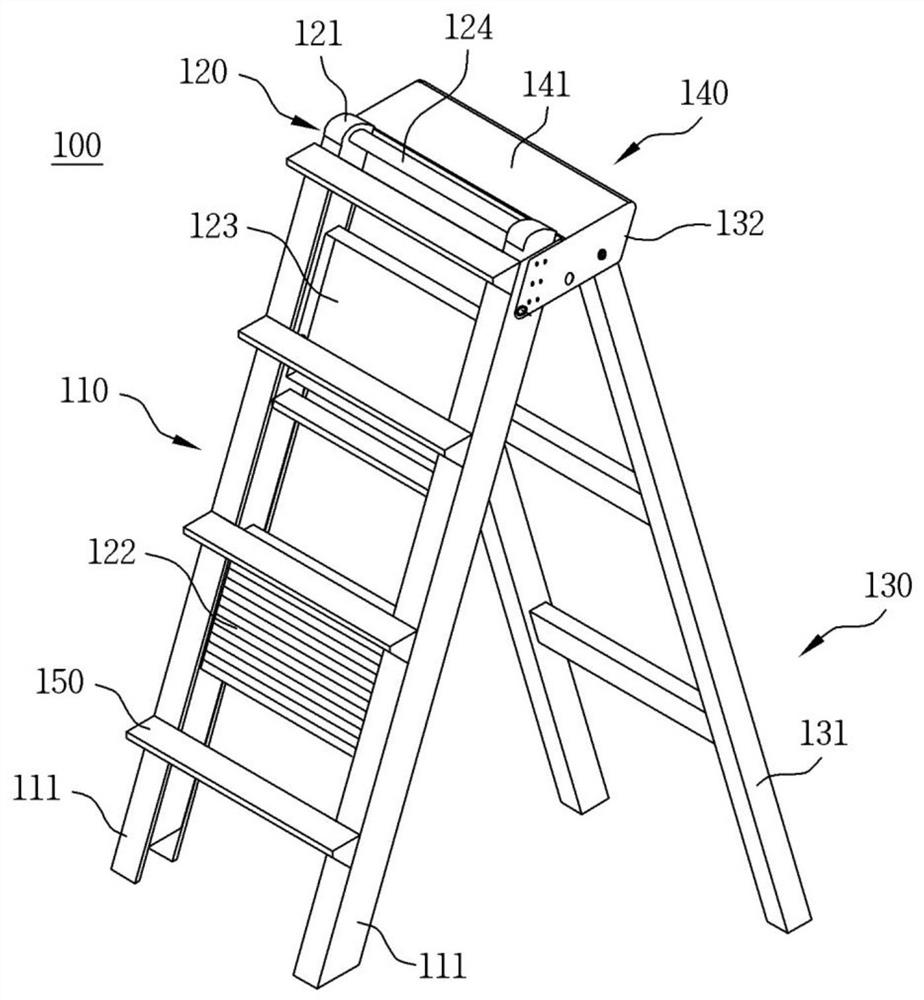

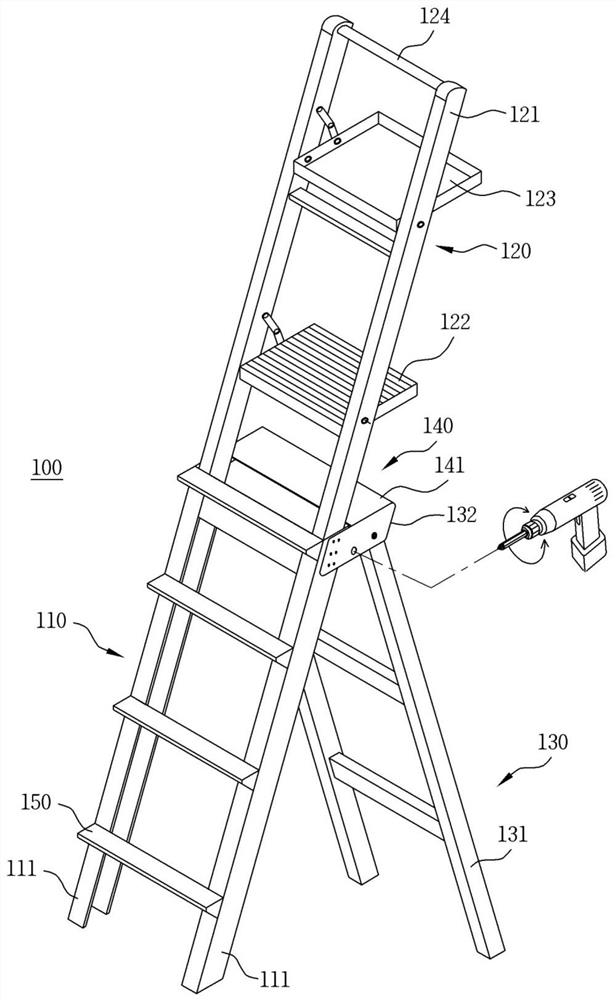

Ladder with adjustable tray height

ActiveCN112412323ATherefore convenienceSo securityWork tools storageLaddersStructural engineeringMechanical engineering

Owner:张永均

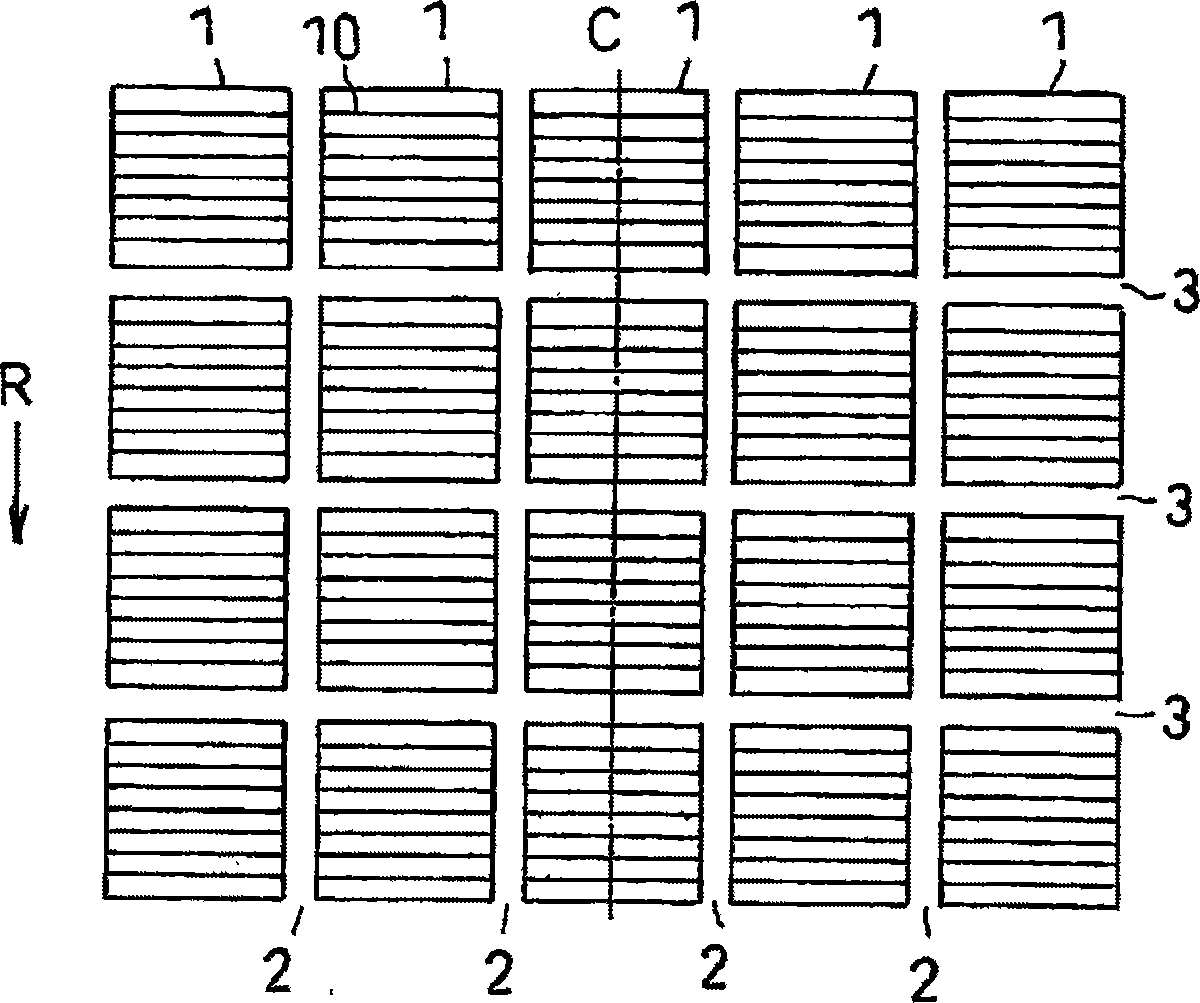

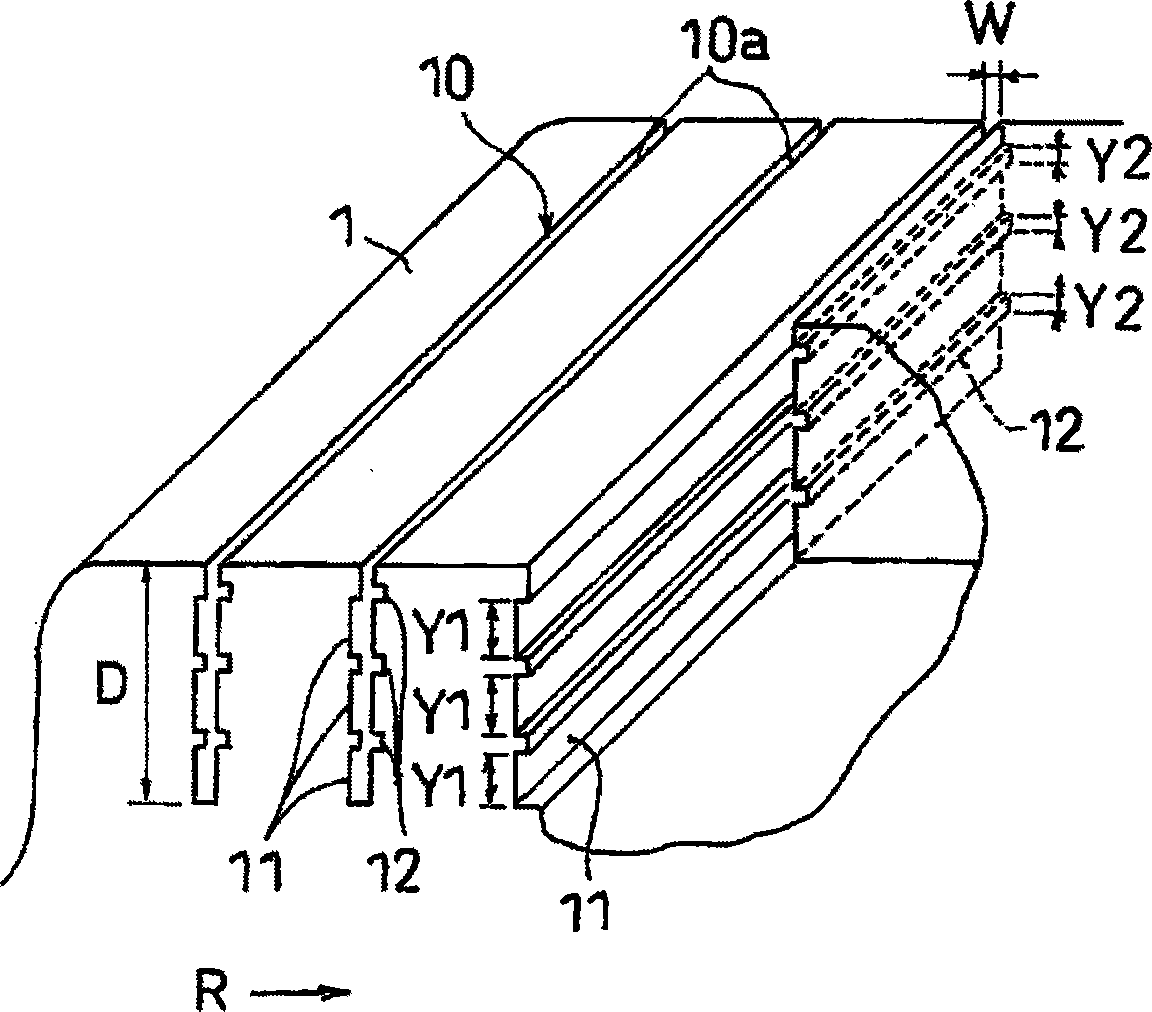

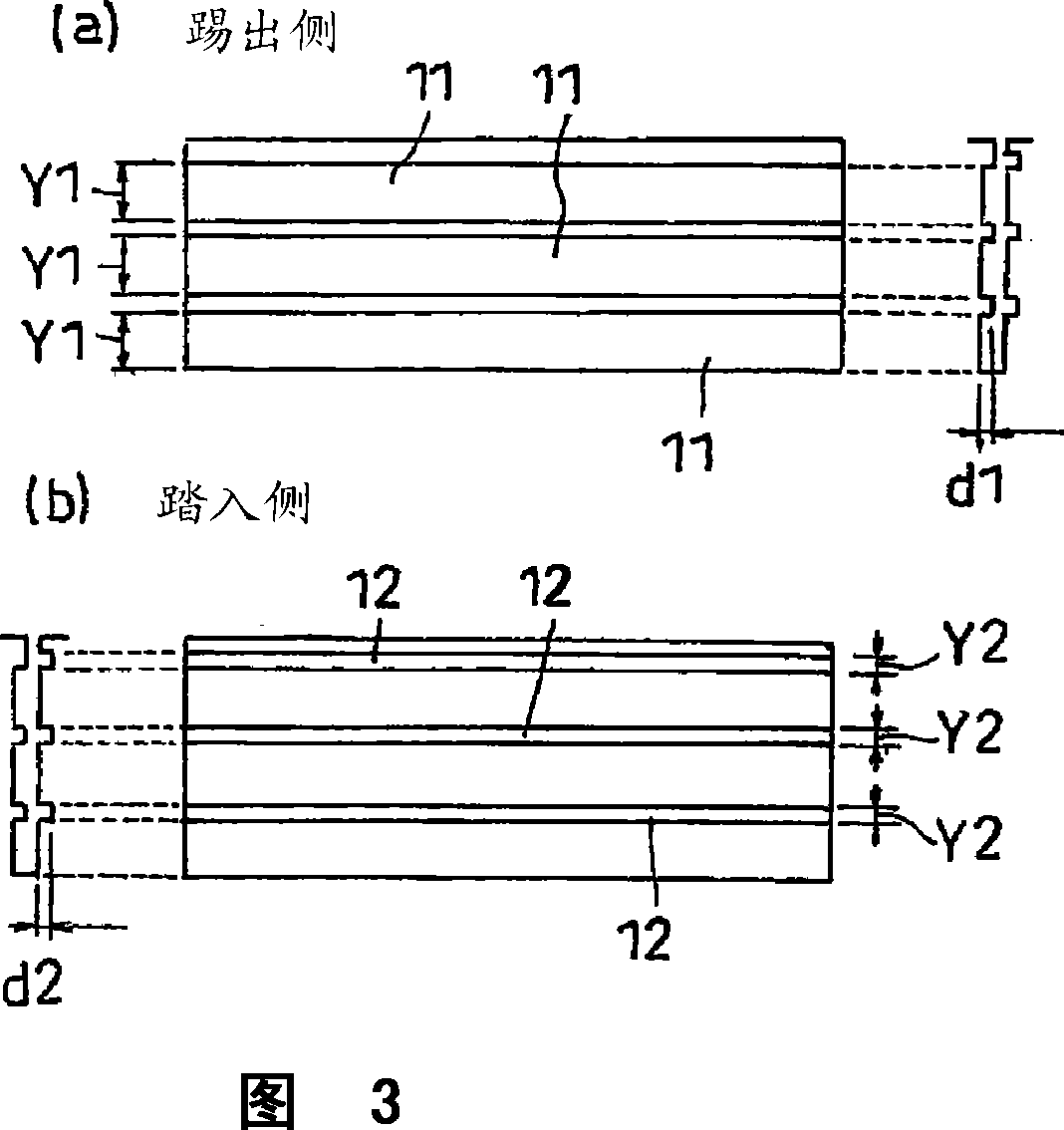

Pneumatic tire

A sipe is formed in a block provided in a tread surface, wide portions extending in a sipe length direction are formed in each of a kick-out side and a step-in side of the sipe, and a total of heights of the wide portions in the kick-out side of the sipe is made larger than a total of heights of the wide portions in the step-in side of the sipe.

Owner:TOYO TIRE & RUBBER CO LTD

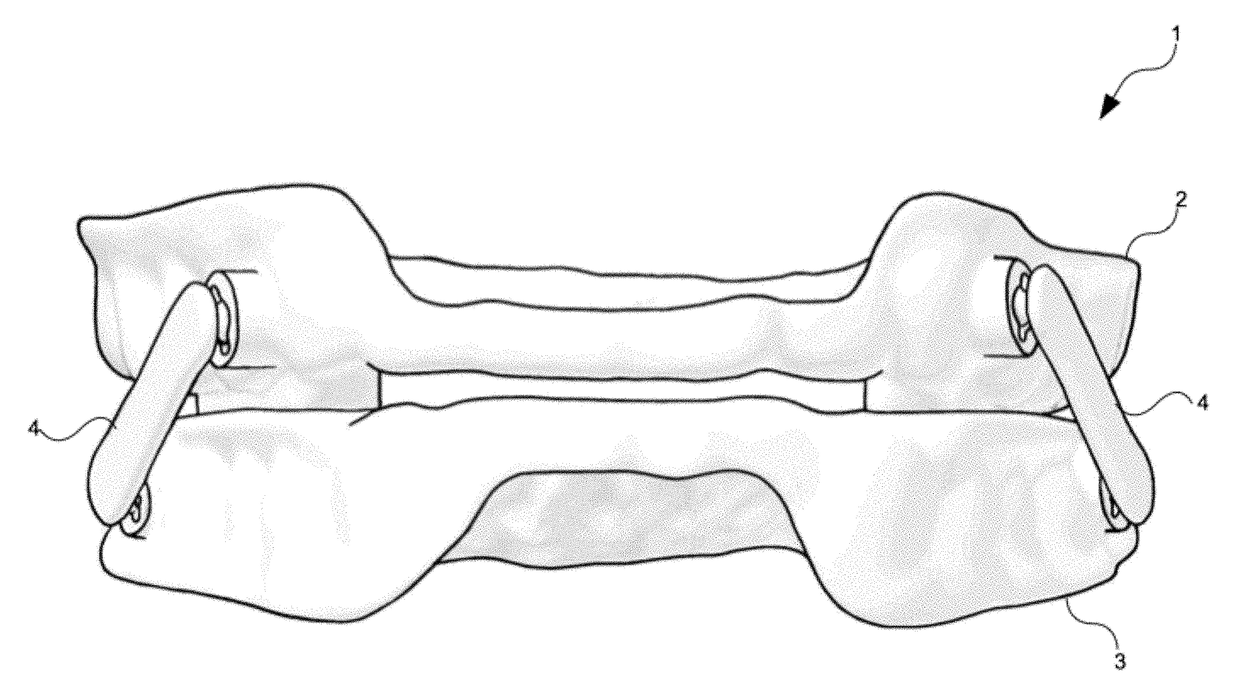

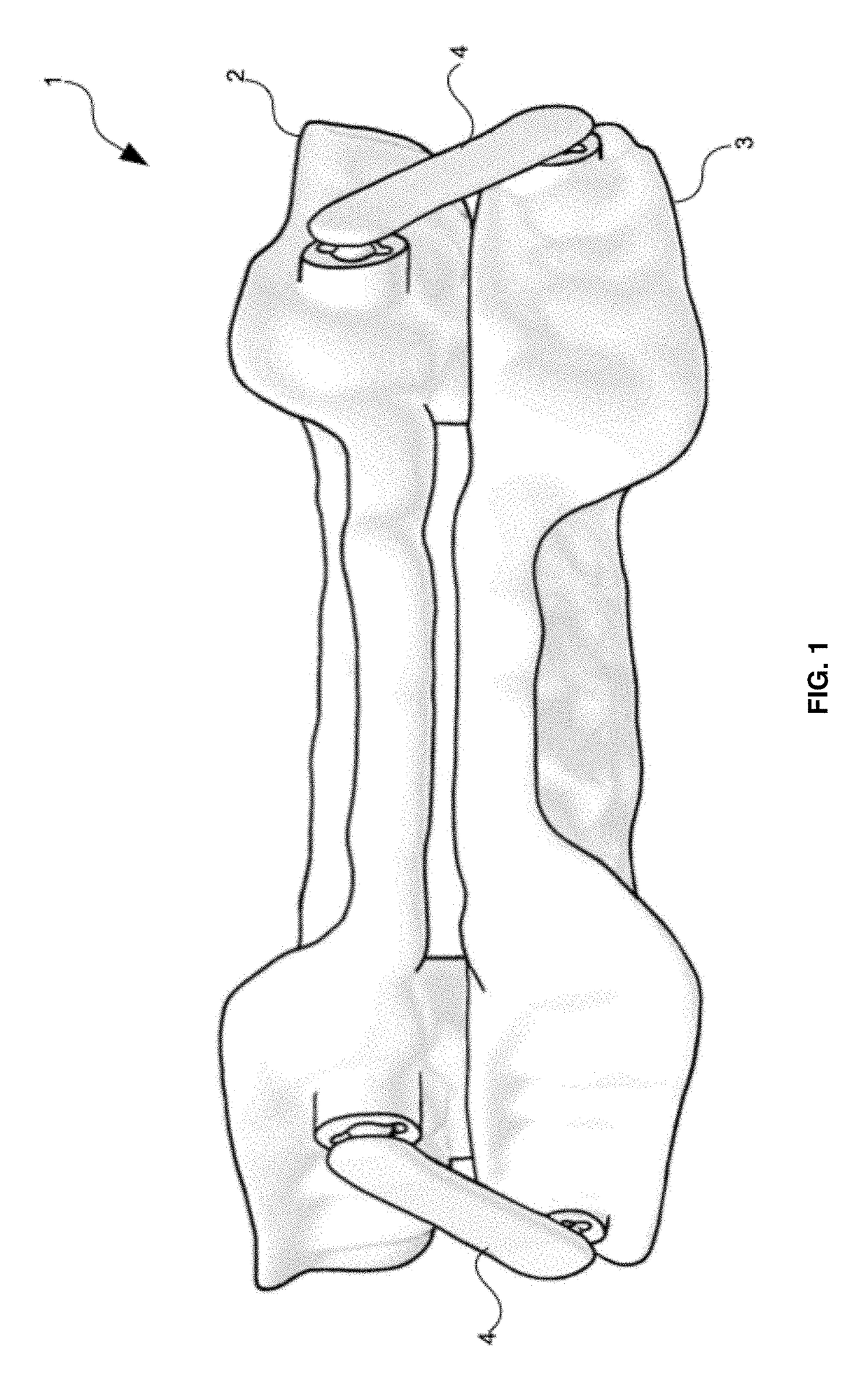

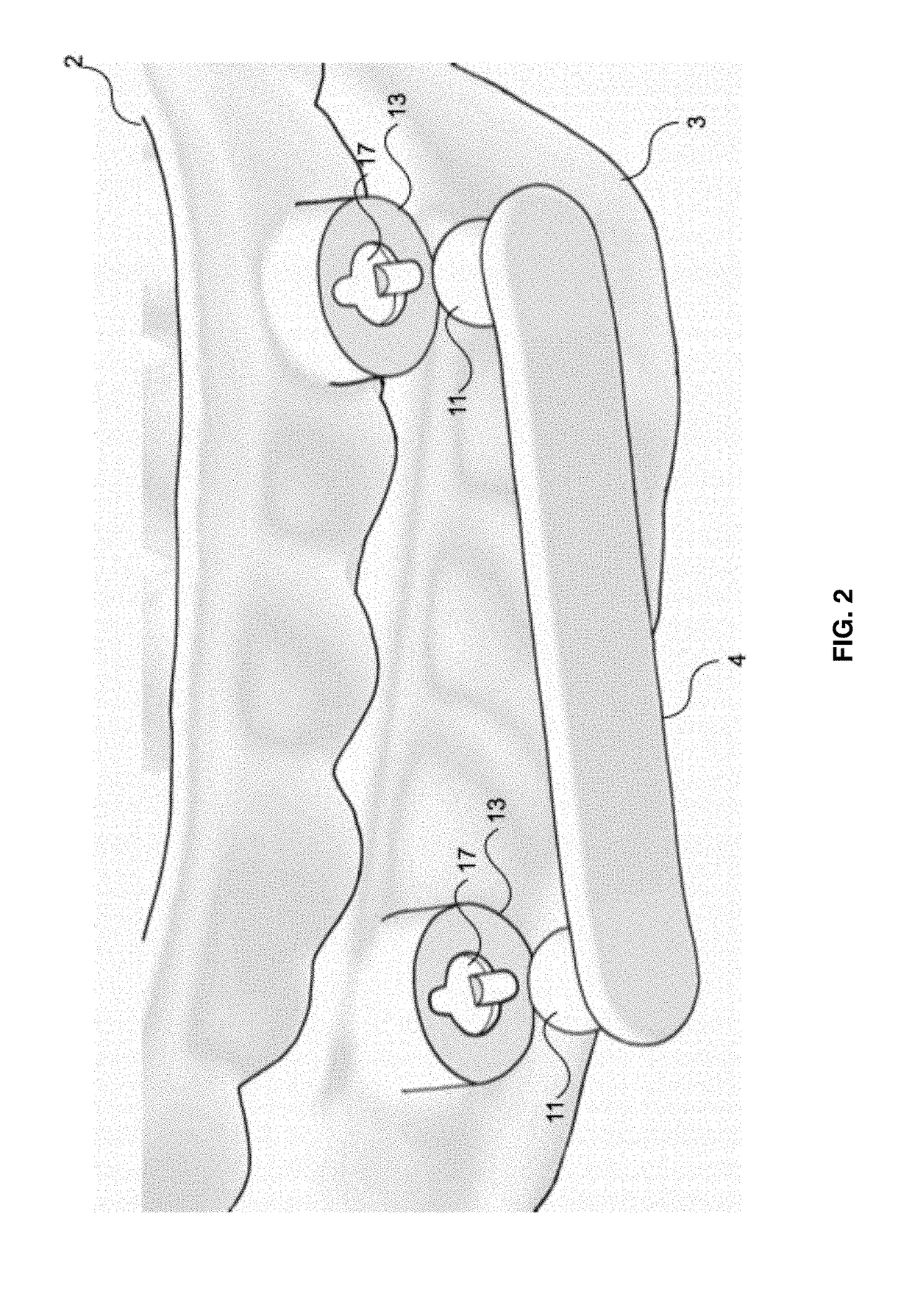

Intraoral Orthosis for Mandibular Advancement for Snoring and Obstructive Sleep Apnea

InactiveUS20170360595A1Prevent narrowingAvoid attenuationSnoring preventionPharynxObstructive sleep apnea

Provided herein is an intraoral orthosis to remedy snoring and / or sleep apnoea via a mandibular advancing action during sleep. Maxilla and mandibular retainers fit the teeth and are coupled with a pair of side retention straps to advance the lower jaw to prevent narrowing of the pharynx. Abutting pairs of planar occlusal faces on the maxilla and mandibular retainers allow lateral and anterioral sliding against each other. A ball engagement couples the retainers to the retention straps at opposing distal ends.

Owner:SMITH JACOB

A kind of production method of stacked battery and stacked battery

ActiveCN111740144BReduce shakingReduce softening and flakingLarge-sized flat cells/batteriesFinal product manufactureStructural engineeringMechanical engineering

The present invention provides a stacked battery, which includes a pole plate group, a pressure frame, a tab and a casing. By wrapping the pressure frame outside the pole plate group, the pressure frame is connected as a whole through buckles, so that the use of the pressure frame to The pole plate group is installed as a whole to reduce the softening and peeling of the active material caused by shaking between the pole plates during the use of the pole plate group. The shell is installed outside the pressure frame to further realize that the battery can pass through the shell during the use of the battery. Insulate and block the outside world from causing damage to the pressure frame or the plate group; the plate group can be fixed through the pressure frame, so that the distance between the positive plate and the negative plate can be unified, and the positive plate and the negative plate can be avoided due to overheating. It often causes the conductive channel narrowing caused by the thickening of the electrode plate group, thereby realizing that each conductive channel in the electrode plate can ensure the effective utilization rate of the active material of the battery; and the service life of the battery can be improved.

Owner:肇庆中特能科技投资有限公司

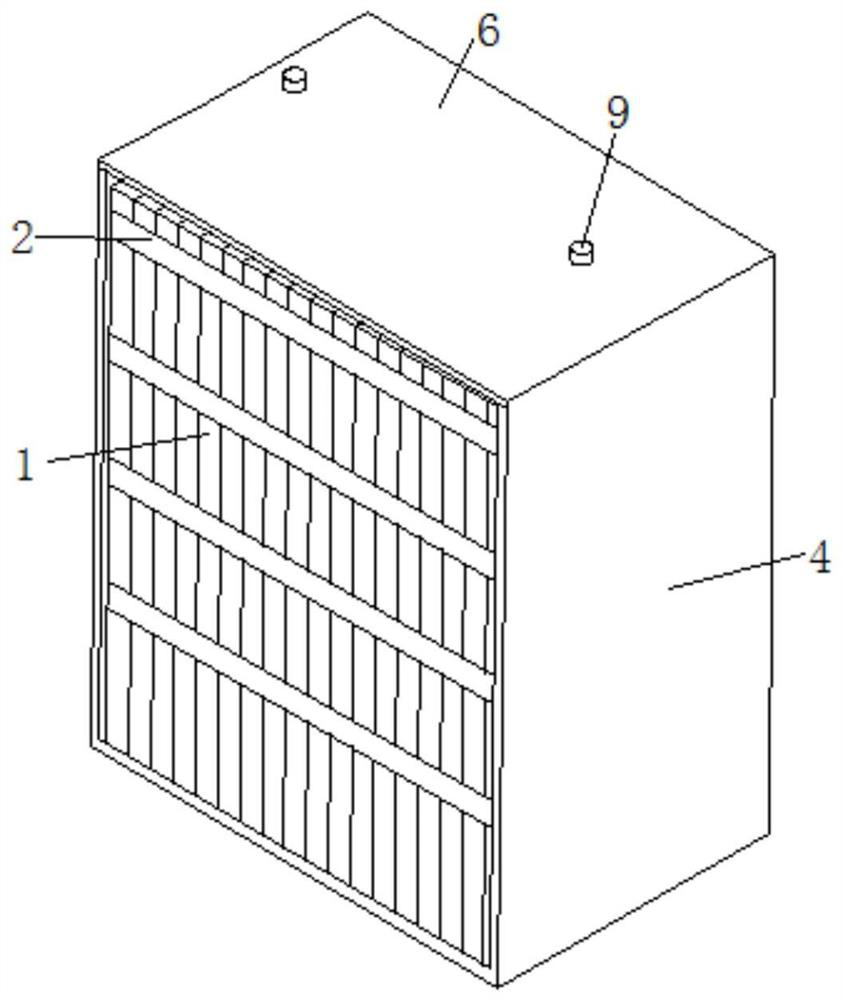

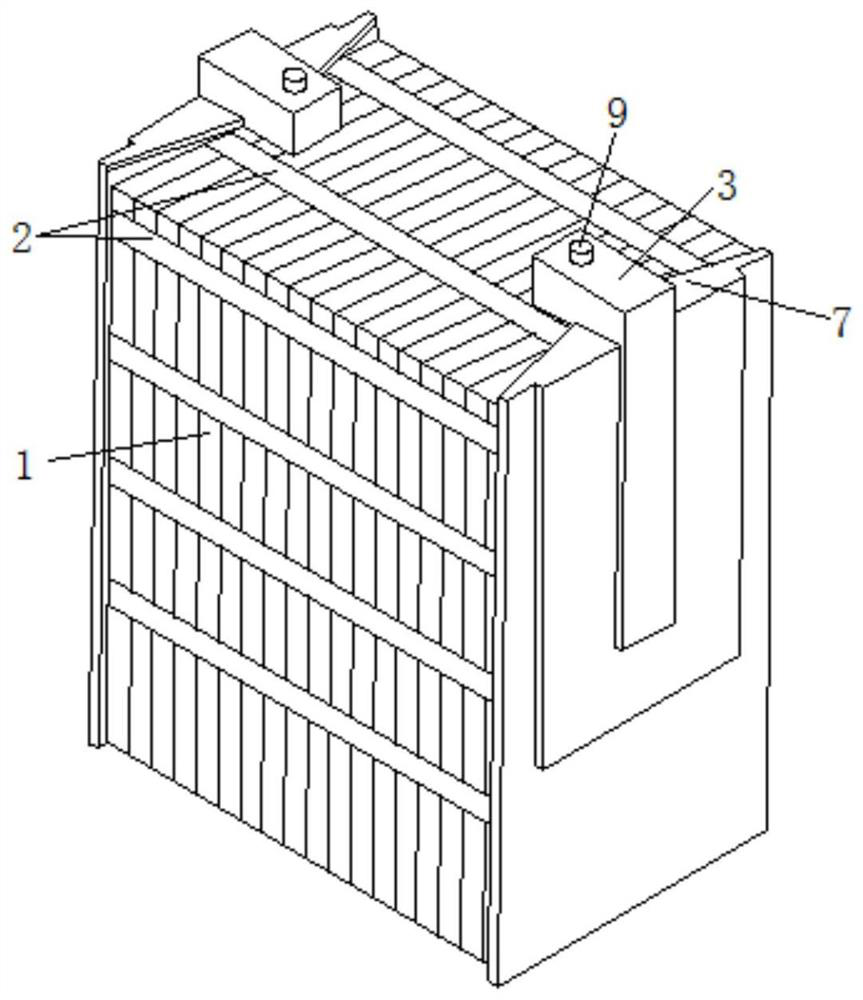

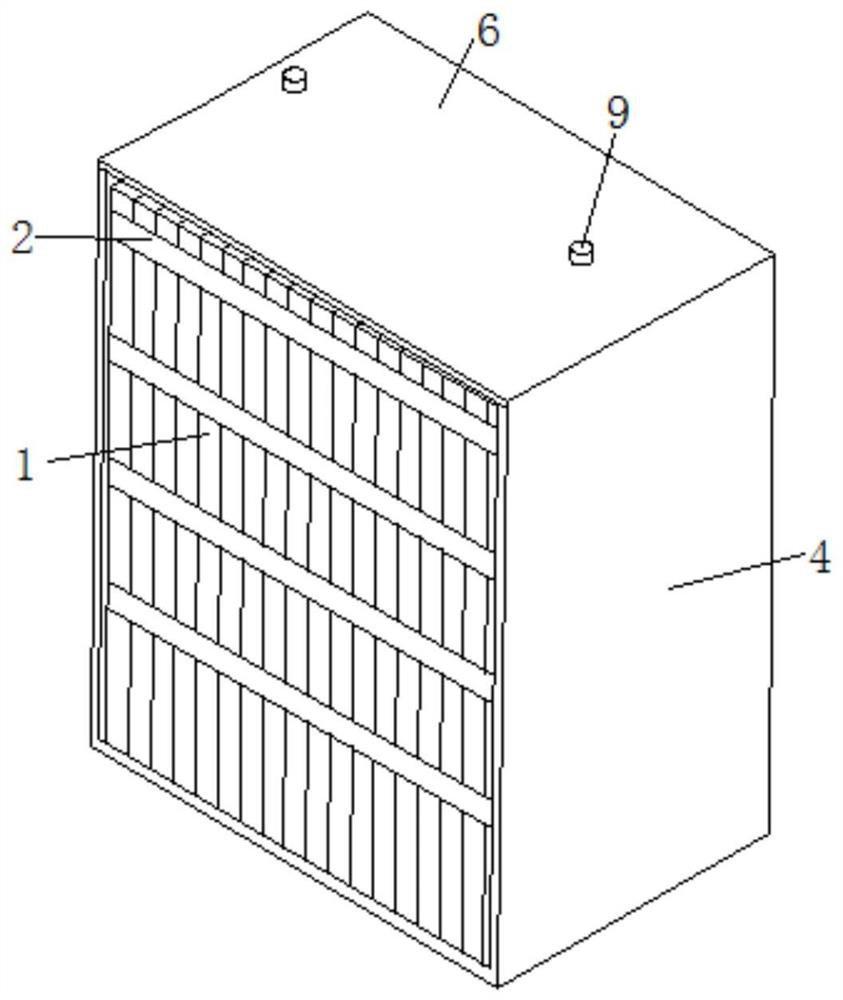

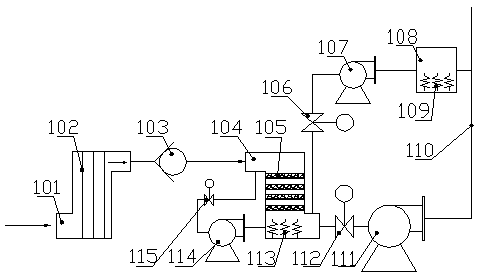

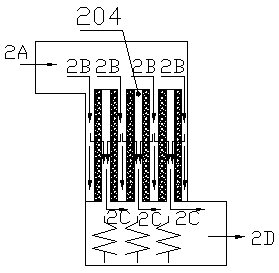

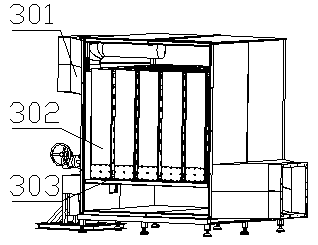

Organic waste gas adsorption and desorption box body

InactiveCN109107340AAvoid deformationPrevent narrowingGas treatmentDispersed particle separationDesorptionRivet

The invention discloses an organic waste gas adsorption and desorption box body. The organic waste gas adsorption and desorption box body is composed of a shell, an adsorption material container and an adsorption material container bracket, wherein the adsorption material container bracket is connected with the shell through welding; the adsorption material container is flatly placed on the adsorption material container bracket; the adsorption material container is mainly composed of an anti-deformation plate, a periphery pressing strip, a net plate, a discharging plate, a connection bolt, a framework and a rivet; the net plate is connected and fixed with the framework through a periphery pressing plate via the rivet; the anti-deformation plate is connected with the periphery pressing strip through welding; the discharging plate is connected with the framework through the connection bolt; the adsorption material container is composed of upper and lower sub-containers; the upper and lower sub-containers are separated through the net plate via an angle steel support; the net plate is connected with the angle steel support through the periphery pressing plate via the rivet; the anglesteel support is welded with the framework; a structure is improved so that a ventilation area is enlarged, an air speed is reduced, the air resistance is reduced, operation noises of equipment are reduced and the installing power of the equipment is reduced.

Owner:邓韶光

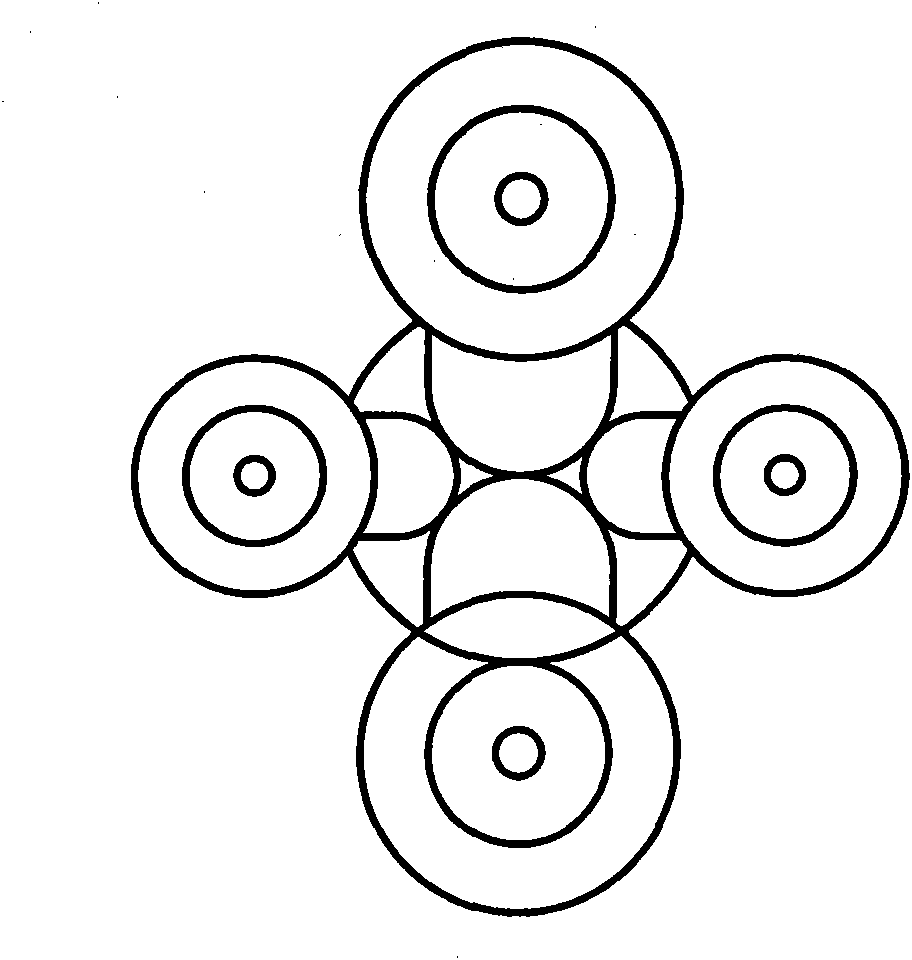

Multidirectional special-shaped feed structure and processing technology thereof

PendingCN114221126AGuaranteed high demands on dimensional accuracyPrevent narrowingLine/current collector detailsSoldered/welded conductive connectionsElectrical conductorElectrical connection

The invention discloses a multidirectional special-shaped feed structure and a processing technology thereof, and belongs to the technical field of feed structure design, and the multidirectional special-shaped feed structure comprises a feed main body in a closed cavity form and at least two feed interfaces. According to the radio frequency connector, the radio frequency connector inner conductor groove and the vertical threaded hole are ingeniously designed, the inner conductor, the positioning pin and the multidirectional special-shaped feature structure are welded into a whole, and the electric connection strength is guaranteed while the radio frequency connector is positioned; through a multi-dimensional integrated welding method of one or more feed interfaces, a cover plate and a shell main body, a forming process of a feed structure comprising a multi-directional special-shaped structure and an interconnection process of the feed interfaces are effectively combined, so that the problems of narrowing of a process window and low yield caused by multiple welding are avoided; feed interconnection and structural mechanical connection are achieved at a time, and a continuous interface is formed through welding, so that the problem of contact nonlinear passive intermodulation caused by a metal contact surface is solved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

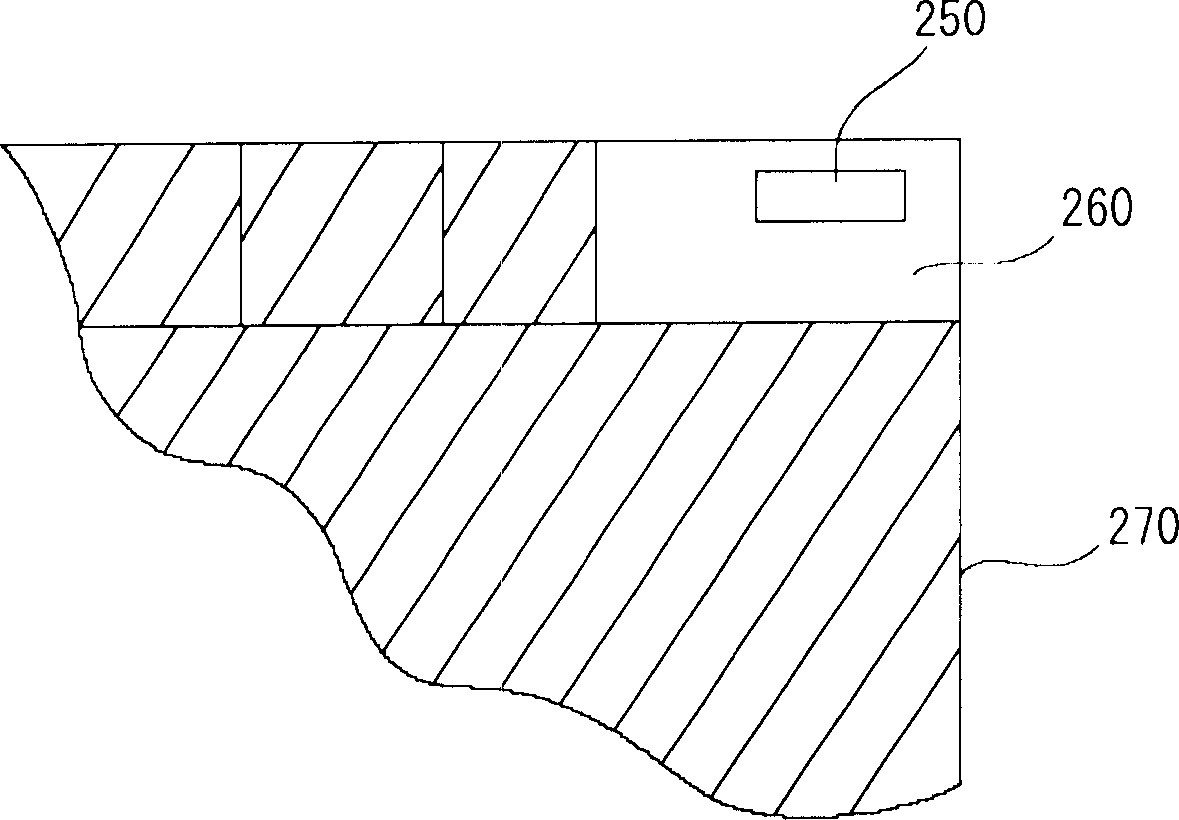

Antenna mounting printed-circuit board

InactiveCN1706072APrevent narrowingAchieving drastic miniaturizationPrinted circuit detailsPrinted electric component incorporationElectrical conductorComputer module

A printed circuit board (50) includes a chip-shaped printed antenna (10) having an open end formed by at least two antenna conductors arranged separately from each other. As shown by a hatched portion, on the printed circuit board (50), a ground required by one or more other modules is arranged so as to surround a region around the printed antenna (10) excluding a certain region. Thus, on the printed circuit board (50), the radiation electric field does not become a dipole mode but is formed to discharge in one direction in a balloon shape as shown by a broken line.

Owner:DEXERIALS CORP

Independent plate coating drying box device

InactiveCN109433558ATake advantage ofPrevent narrowingDispersed particle filtrationTransportation and packagingCold airPulp and paper industry

The invention relates to the technical field of artificial leather production, in particular to an independent plate coating drying box device. The independent plate coating drying box device comprises a drying box structure. A cold air box and the drying box body are of an integrally-formed structure. Air blowers are mounted on the two sides of the cold air box. An air collection hood is mountedbetween the two air blowers. A heat exchanger is mounted on one side of the air collection hood. The bottom of the air collection hood is connected with an air supply pipe. The end, away from the aircollection hood, of the air supply pipe is connected with an air supply row. Multiple hot air spray heads evenly arranged at equal distances are mounted on the bottom face of the air supply row. Conveying guide wheels are symmetrically mounted on the upper side and the lower side in the drying box body. According to the device, the two air blowers are arranged so that the air blowing efficiency can be improved; meanwhile, through the arranged air collection hood and heat exchanger, blown air can be heated and is conveyed into the air supply row through the air supply pipe, and consumption is reduced; and through a corner guide wheel mounted in the drying box body, power is provided through a motor, traction force is provided for operating of artificial leather, and it is guaranteed that artificial leather drying can be carried out constantly.

Owner:QINGYUAN QILI SYNTHETIC LEATHER

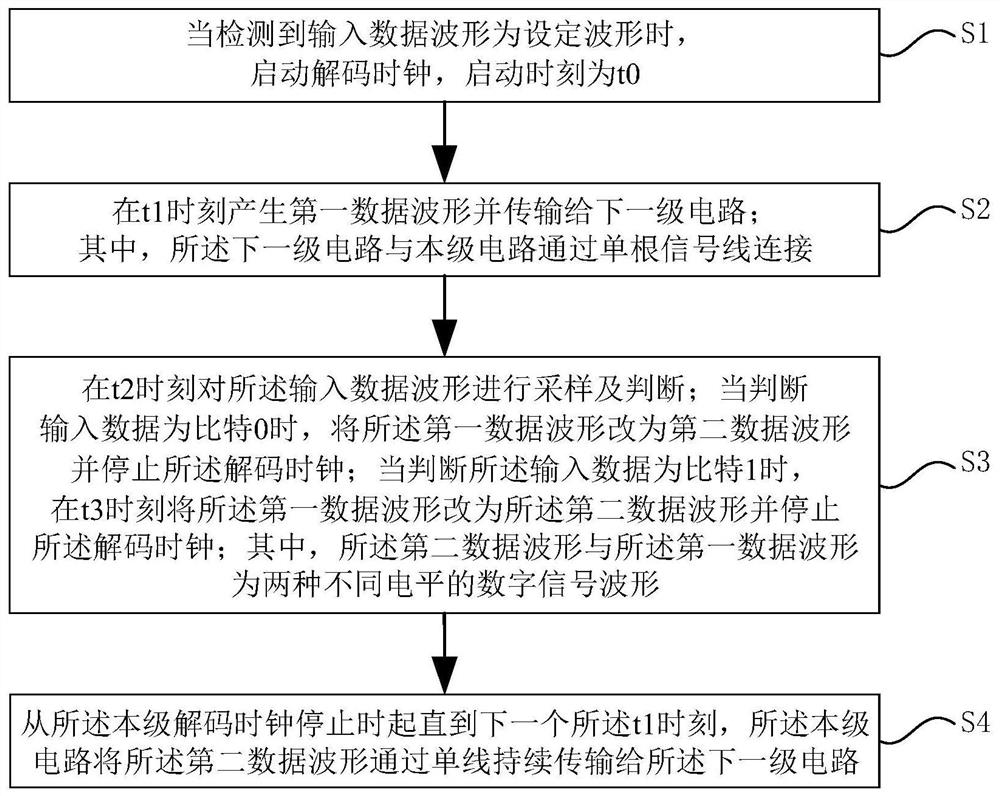

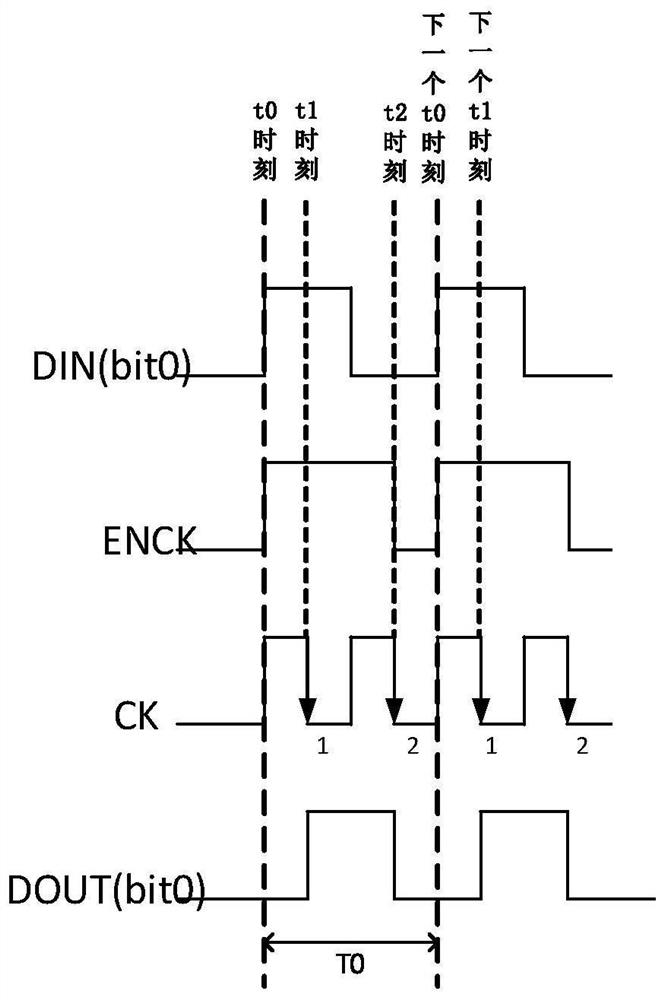

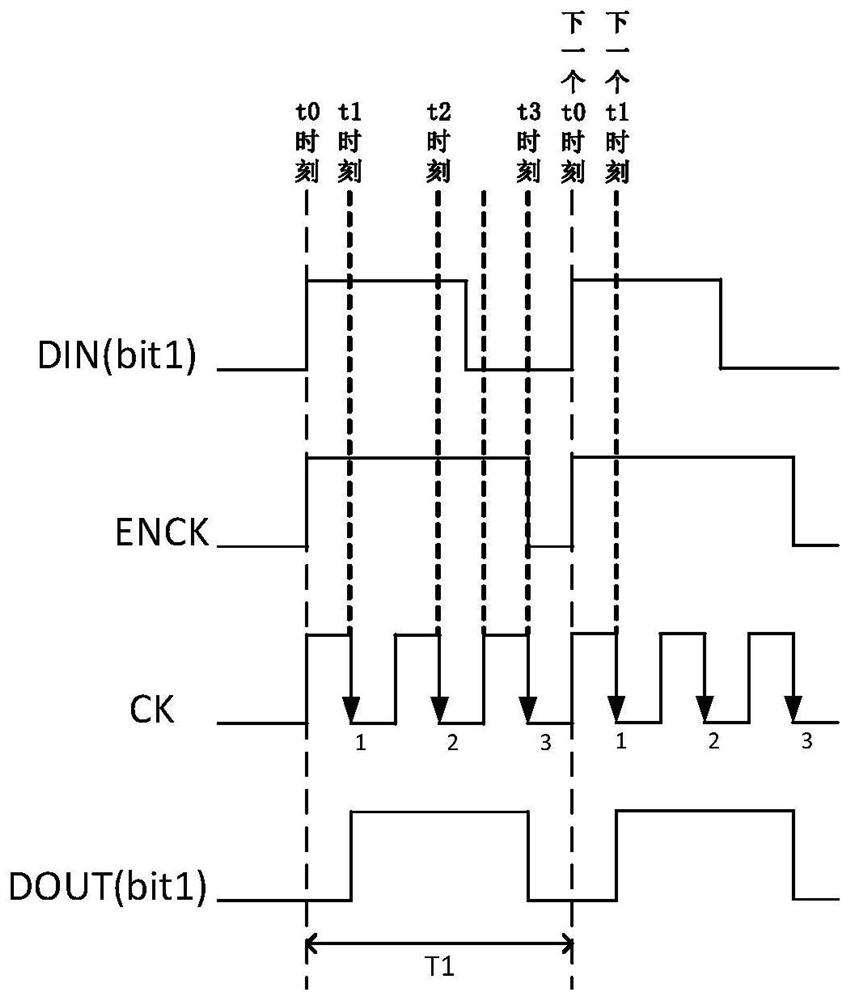

Data transmission method of single-line cascade circuit and LED chip cascade system

ActiveCN113207209ASolve bit errorsReduce transfer timeElectrical apparatusStatic indicating devicesData transmissionHemt circuits

The invention provides a data transmission method of a single-line cascade circuit and an LED chip cascade system, and the method comprises the steps: starting a decoding clock when the input data is detected to be a set waveform; generating a first data waveform at t1, and transmitting the first data waveform to a next-stage circuit; sampling and judging the waveform of the input data at t2; when it is judged that the bit is 0, changing the first data waveform into a second data waveform and stopping decoding the clock; when it is judged that the bit is 1, changing the first data waveform into a second data waveform at t3, and stopping clock decoding; and from the stop of the decoding clock to the next t1, transmitting the second data waveform in a single line to the next stage of circuit. When the output data is at a high level, the length of the output data is integral multiples of a decoding clock period, the problem that the high level is gradually widened or narrowed due to cascade circuit transmission is avoided, and the error code problem of data transmission is solved. Moreover, the transmission duration of bit 0 is shortened, so that the overall data transmission speed of the LED chip cascade system is improved.

Owner:深圳市美矽微半导体有限公司

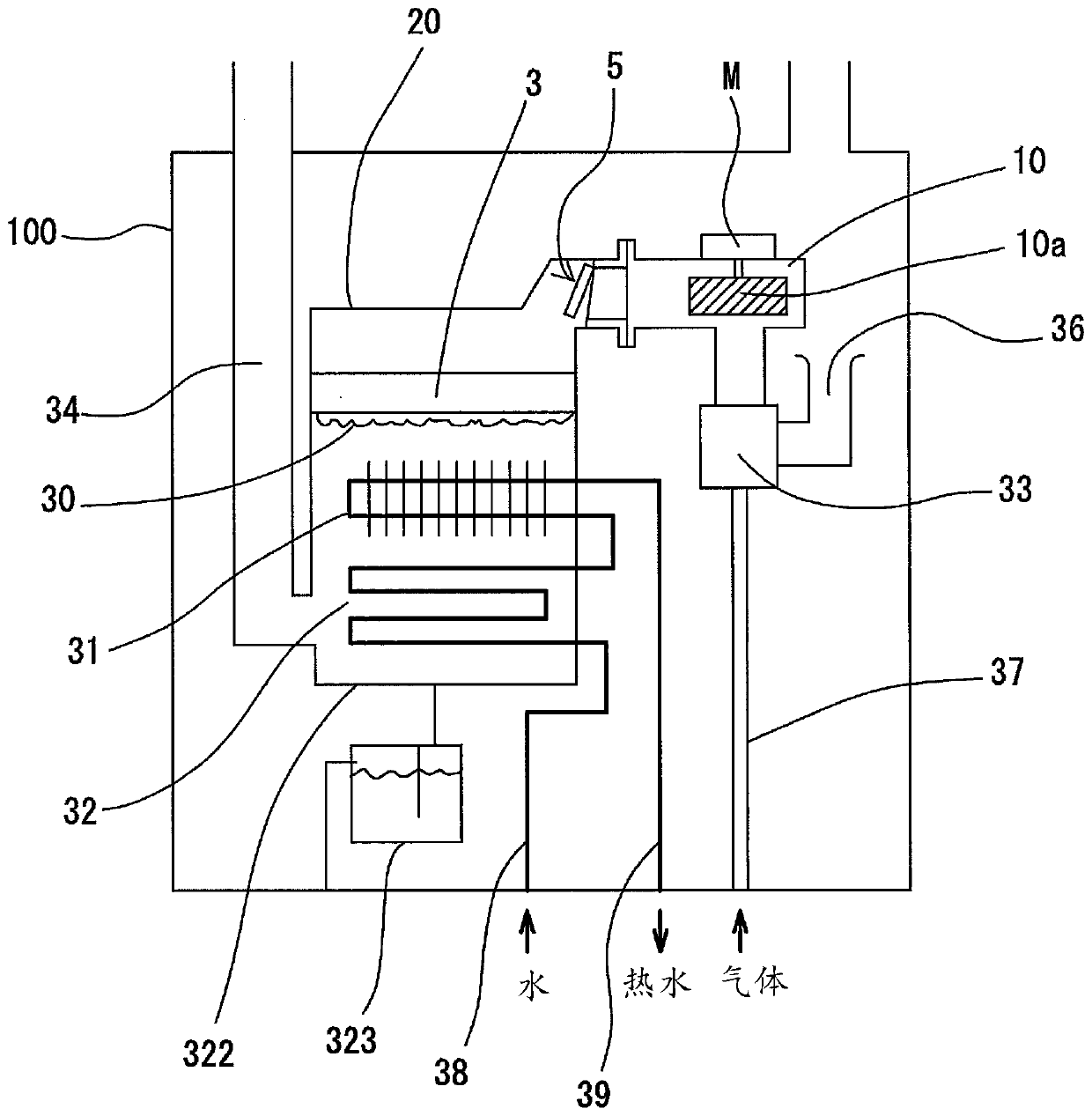

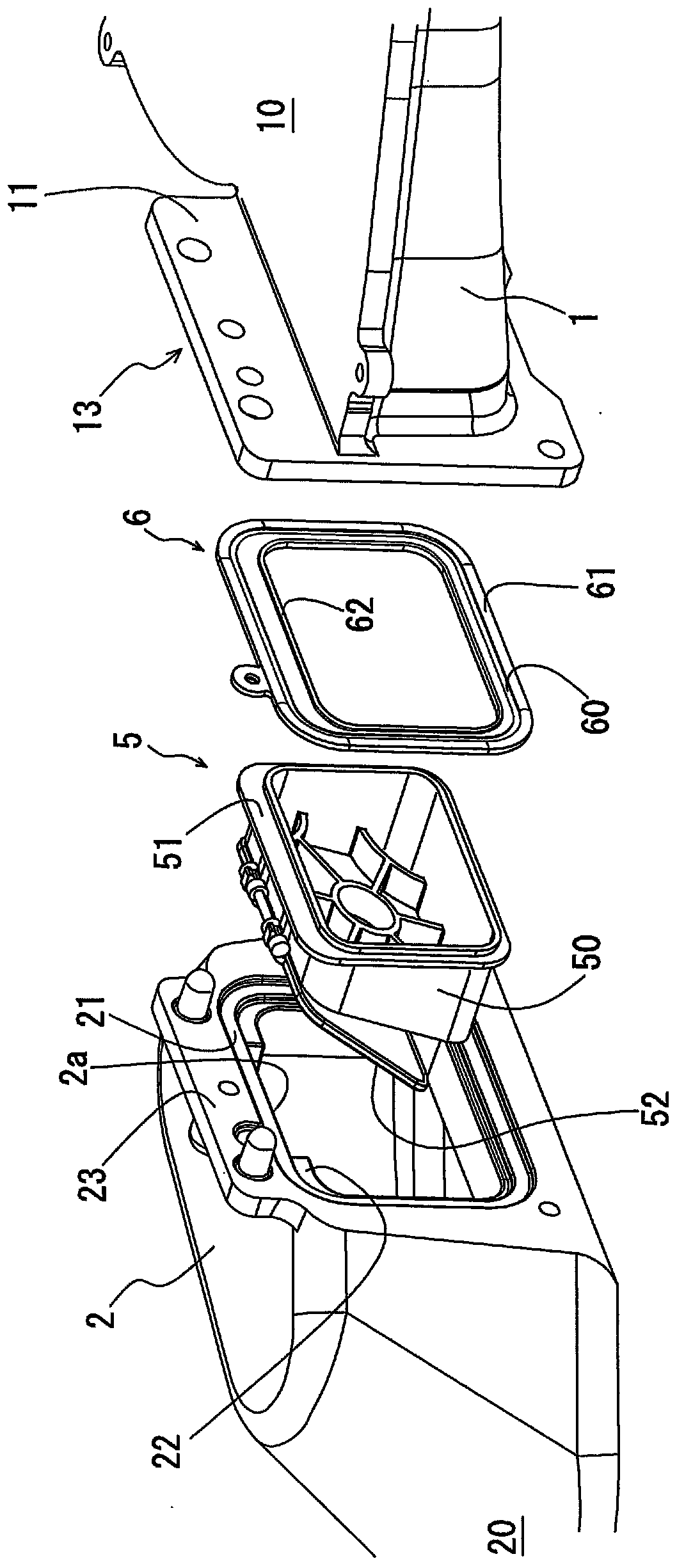

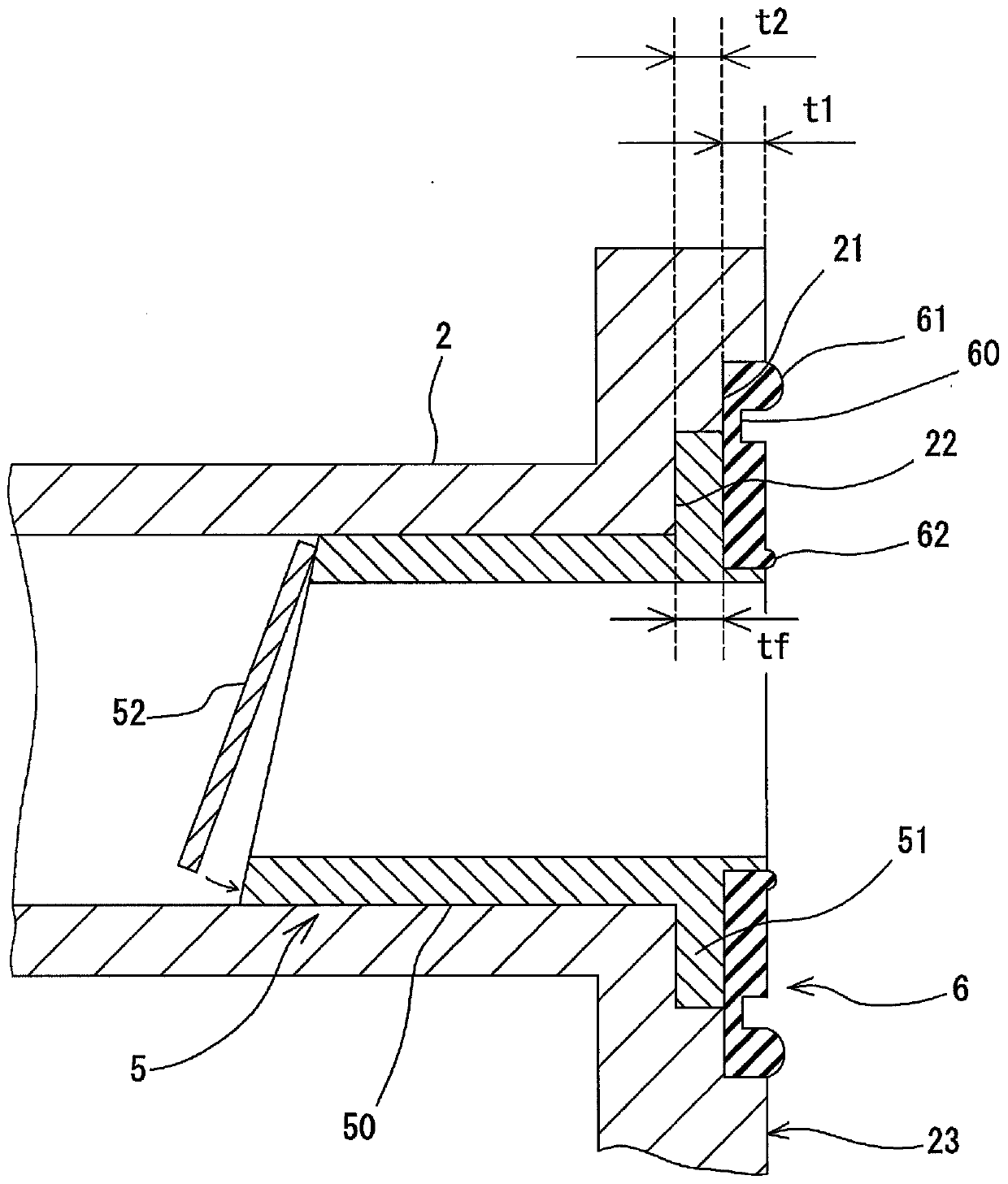

water heater

ActiveCN107709883BPrevent leakageReduce the numberBurner safety arrangementsGaseous fuel feeder/distributionCombustorEngineering

The invention provides a water heater comprising: a container (20) equipped with a burner (3) with a downwardly facing combustion surface; a fan housing (10) containing primary air for combustion and fuel gas The fan (10a) that supplies the mixed gas to the burner; the annular gasket (6), which connects the first connection on the downstream end side of the first flow path (1) that forms the downstream side flow path of the fan casing (10) The end face (13) is connected in an airtight state with the second connecting end face (23) on the upstream end side of the second flow path (2) forming the upstream side flow path of the container (20); and the one-way valve (5), which It is installed near the upstream end in the second flow path (2).

Owner:RINNAI CORP

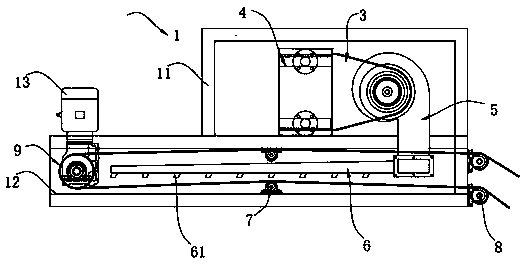

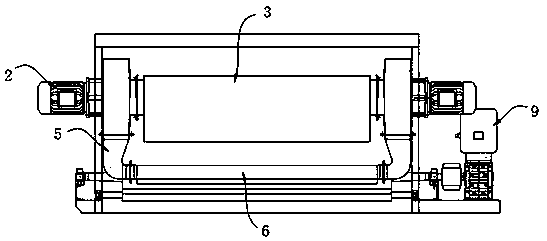

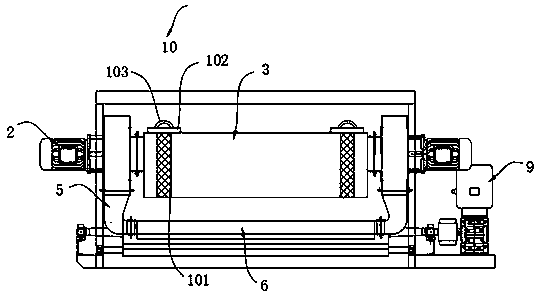

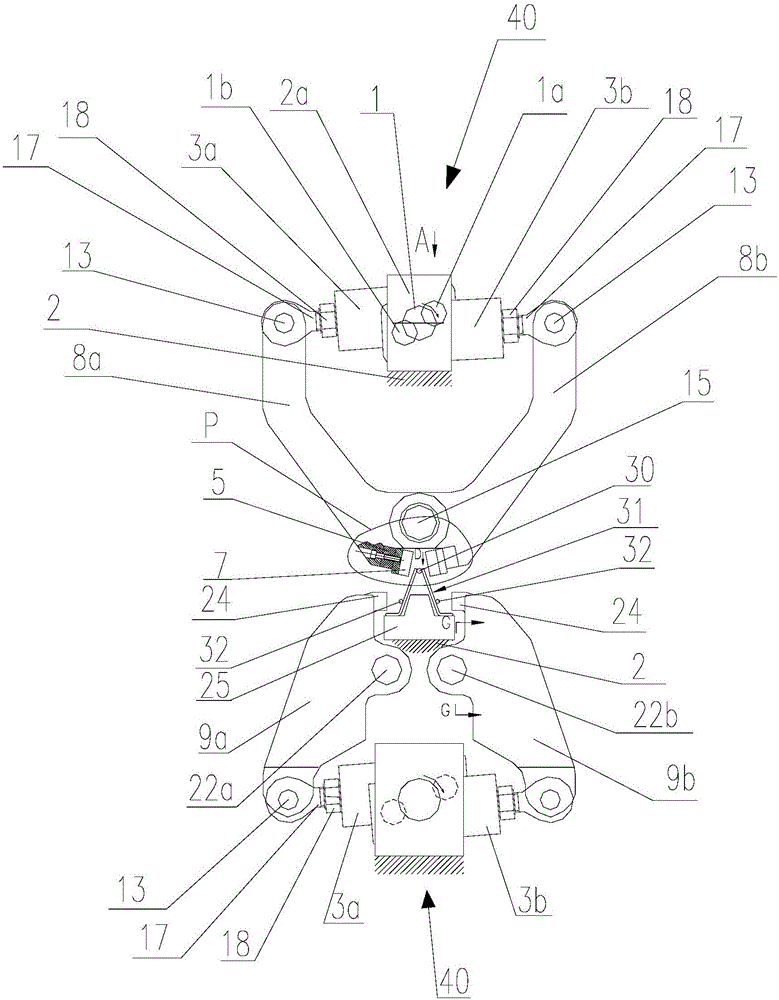

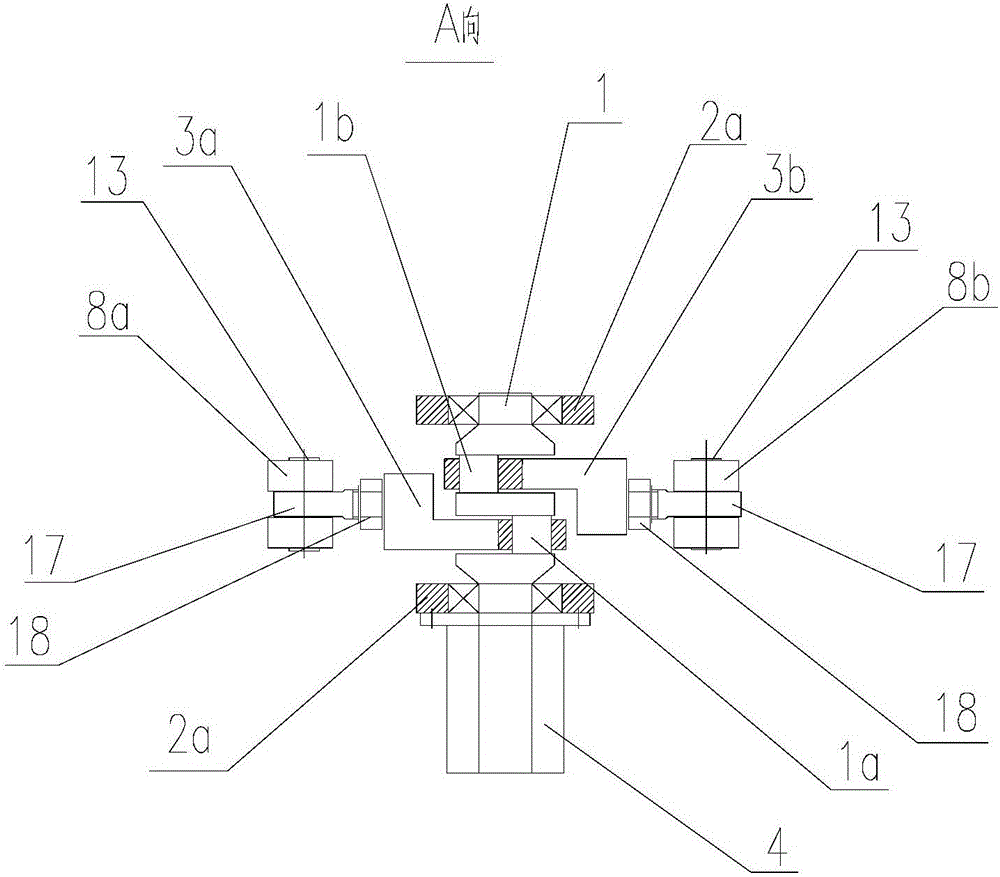

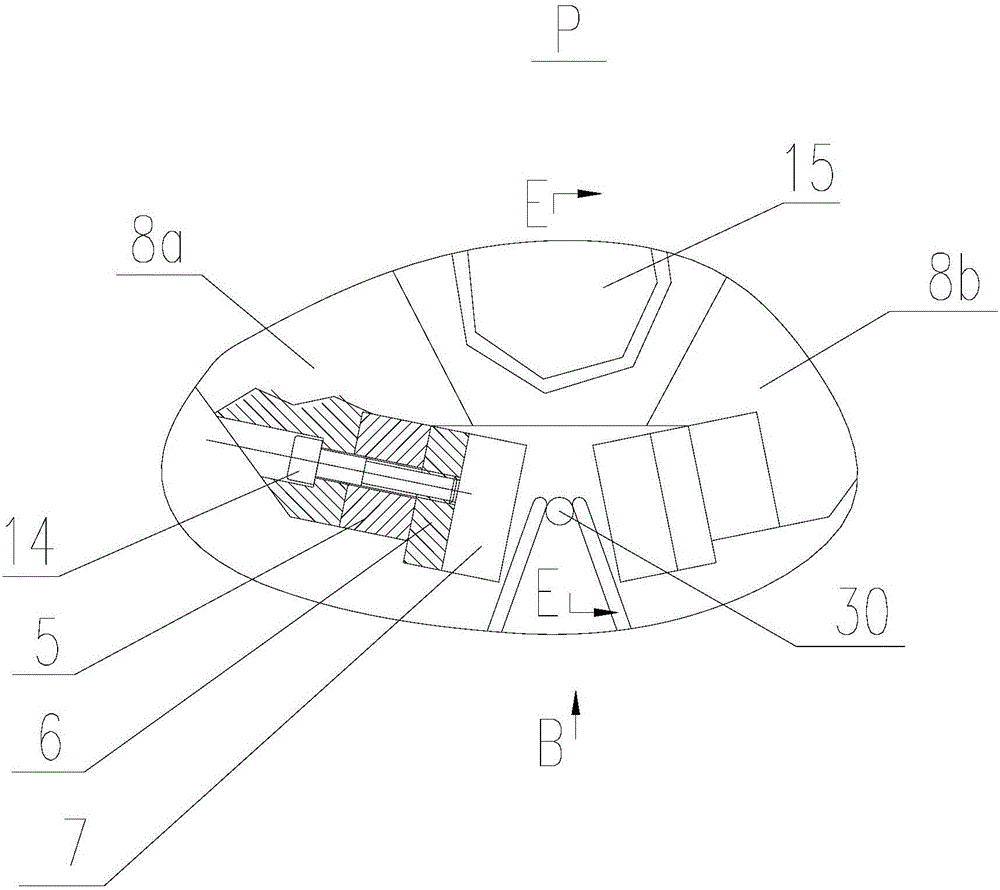

Truss Shearing Mechanism of Triangular Truss Production Line

The invention discloses a truss shearing mechanism of a triangular truss production line. The truss shearing mechanism of the triangular truss production line structurally comprises an upper shearing device and a lower shearing device. According to the upper shearing device, two upper shearing arms are hinged to an upper hinged shaft, upper scissors are installed at the corresponding ends of the upper shearing arms, the other end of each upper shearing arm is hinged to a crankshaft driving mechanism, and the crankshaft driving mechanism drives the two upper shearing arms to shear an upper spiral rib. The lower shearing device comprises two lower shearing arms, wherein the lower shearing arms are hinged to a first lower hinged shaft and a second lower hinged shaft respectively, lower scissors are installed at the corresponding ends of the lower shearing arms, the other ends of the lower shearing arms are hinged to the two sides of the crankshaft driving mechanism, and the crankshaft driving mechanism drives the two lower shearing arms to shear a lower spiral rib. The truss shearing mechanism of the triangular truss production line has the advantages that power is low, impact on a power grid is low, the structure is simple, and the cost is low; the phenomenon that the two pairs of scissors collide with each other is avoided, the service life is long, and the quality of a sheared truss is improved; a cut of the lower spiral rib is flat after the lower spiral rib is sheared, and the phenomenon that due to the fact that the width of the inner side of the triangular truss becomes narrower, the defect of deformation of the triangular truss is avoided.

Owner:TJK MACHINERY TIANJIN

Gate scan drive circuit

ActiveCN108242228BImprove reliabilityPrevent narrowingStatic indicating devicesDriver circuitLiquid-crystal display

Owner:NANJING CEC PANDA LCD TECH

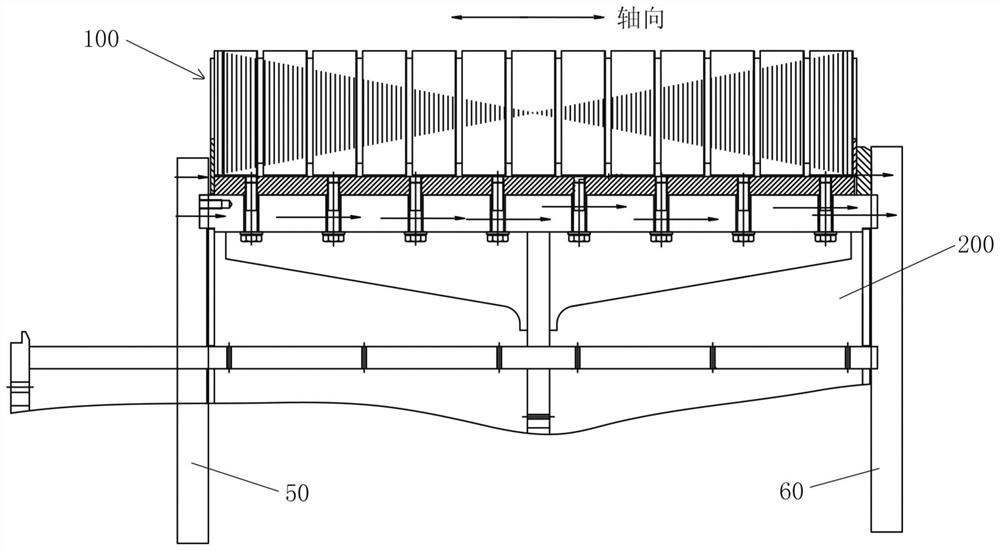

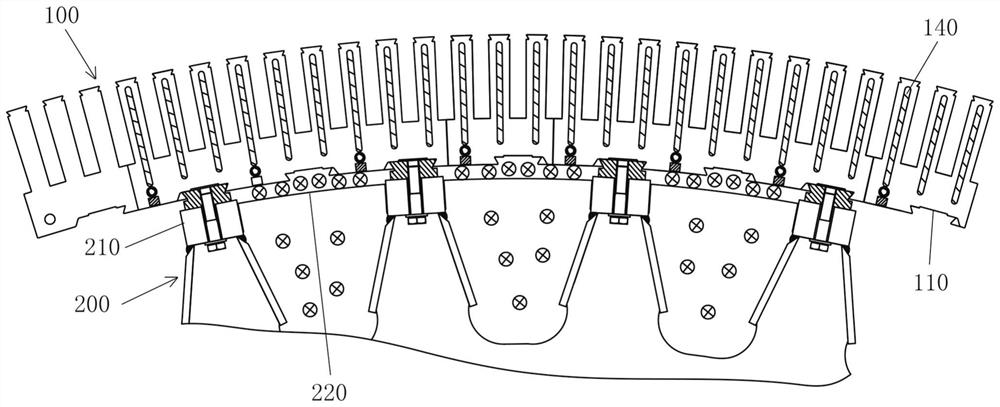

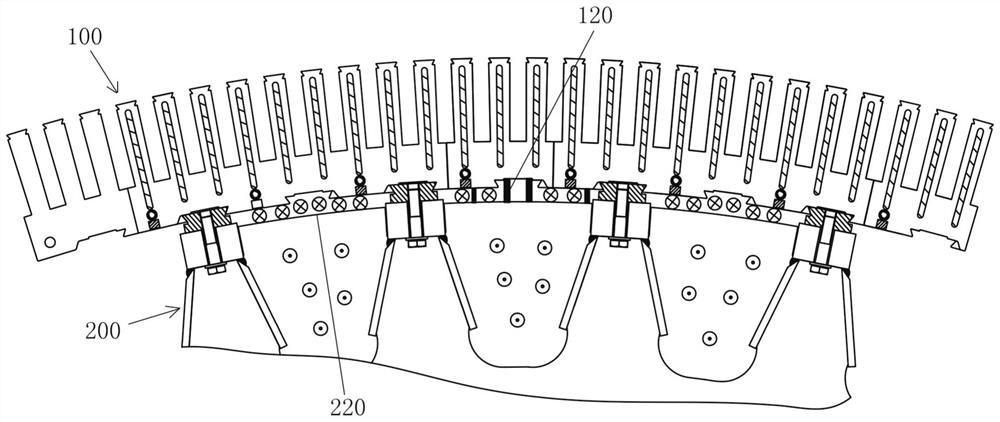

Stator assembly and motor with the stator assembly

ActiveCN110635587BExtended service lifePrevent narrowingMagnetic circuit stationary partsWind energy generationCold airElectric machine

The invention provides a stator assembly and a motor with the stator assembly. The stator assembly includes a stator bracket and a stator core installed on the stator bracket, and the stator bracket includes a support shroud, formed between the support shroud of the stator bracket and the radial side surface of the stator core. There is a first axial airflow passage, and the stator assembly further includes an airflow conveying unit for supplying the first cold airflow to the first axial airflow passage, so that the cold airflow flows in the axial direction. According to the embodiment of the present invention, during the operation of the motor, a cold airflow can be introduced to the other side of the stator opposite to the air gap, so that both radial sides of the stator can be cooled at the same time, reducing the expansion and deformation of the stator core and preventing The air gap is narrowed, and at the same time, it prevents the stator from high-temperature baking of the magnetic poles, protects the magnetic poles, and prolongs the service life of the motor.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Backlight module and display device

ActiveCN104763944BAvoid badPrevent narrowingPlanar light sourcesLight fasteningsDisplay deviceBright line

The invention discloses a backlight module and a display device. The backlight module comprises a back plate and a rubber frame. The back plate comprises a bottom plate and side walls located on the edge of the bottom plate. The rubber frame is arranged on the side walls and provided with a first supporting part for arranging a display panel. A second supporting part is arranged on the side walls. A groove for arranging an optical film is formed between the first supporting part and the second supporting part. The set distance between the bottom of the groove and the valid display area of the display panel is larger than the set distance between the bottom of the display panel and the bottom of the optical film. By means of the backlight module and the display device, the problem that in a narrow frame display device, edge bright lines are not good can be solved.

Owner:BOE TECH GRP CO LTD +1

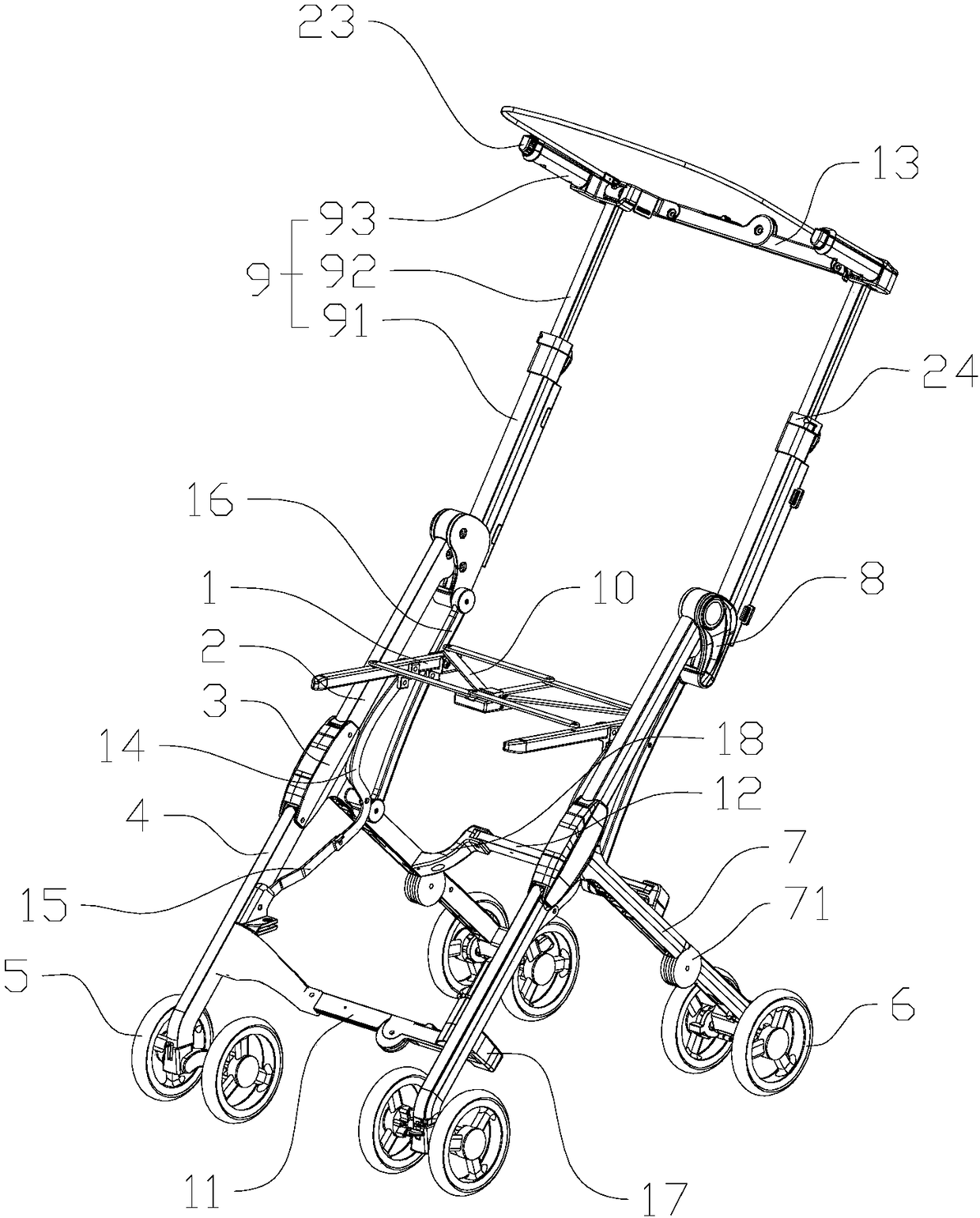

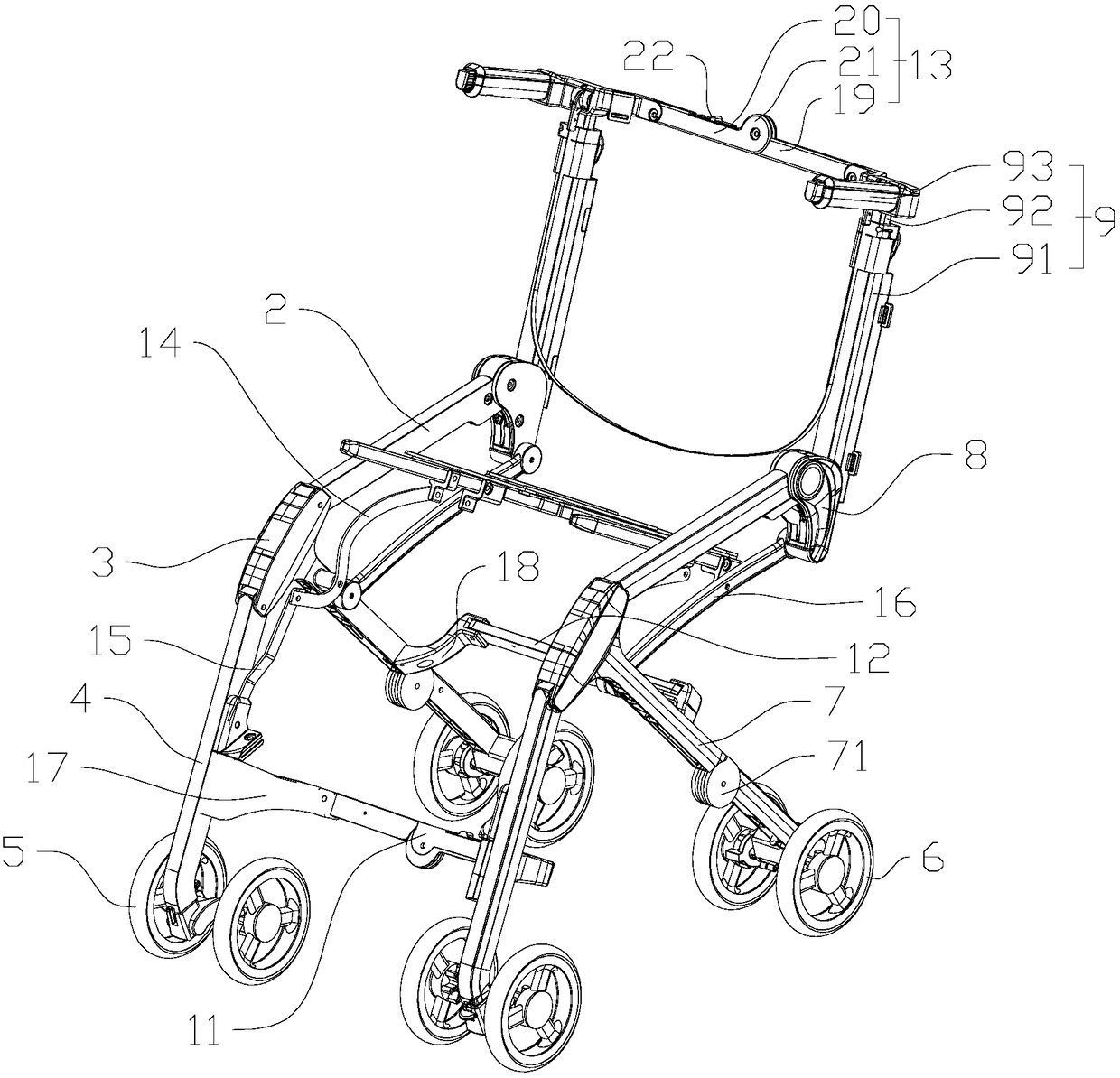

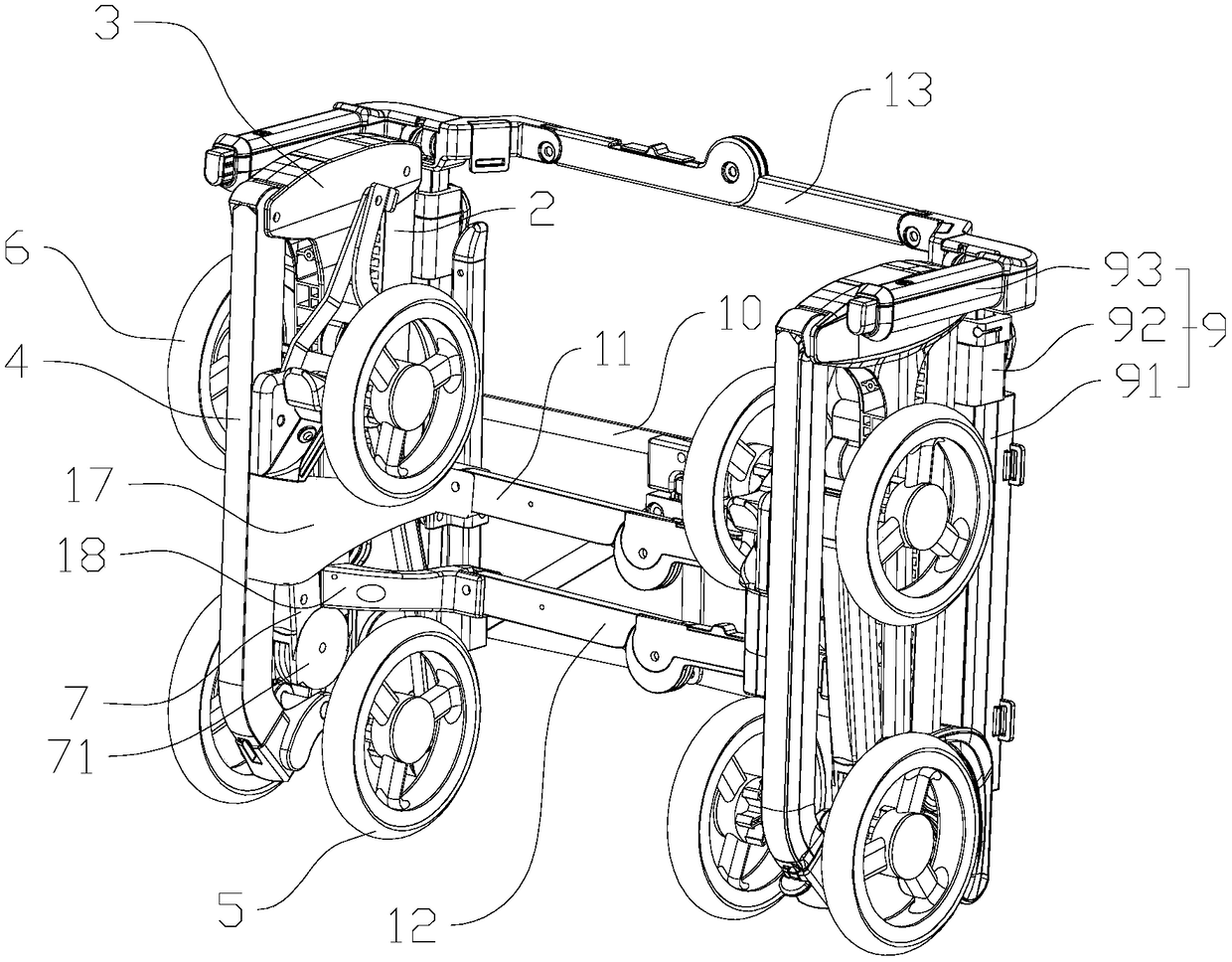

Baby carriage available for secondary folding for collection

PendingCN108313113APrevent narrowingImprove stabilityCarriage/perambulator with multiple axesHand cartsEngineeringMechanical engineering

The invention discloses a baby carriage available for secondary folding for collection. A supporting frame for supporting a baby is arranged on a frame body which comprises supporting rods, one end ofeach supporting rod is rotationally provided with a connection seat, a front wheel supporting leg connected with a front wheel and a rear wheel supporting leg connected with a rear wheel are arrangedon each connection seat, and each front wheel supporting leg is in rotational connection with the corresponding connection seat. One end, away from the corresponding connection seat, of each supporting rod is rotationally provided with a collection seat in rotational connection with a handle component. The supporting frame is provided with a folding frame along the length direction of the supporting frame, and two supporting rods approach to each other after folding of the folding frame. A first folding rod is rotationally connected between the two front wheel supporting legs, and a second folding rod is rotationally connected between the two rear wheel supporting legs. After primary folding is completed, the two supporting rods approach to each other after deformation of the folding frame, the two front wheel supporting legs get close under the action of the first folding rod, the two rear wheel supporting legs get close under the action of the second folding rod, and accordingly anoccupied space of the frame body is reduced, and the baby carriage is convenient for a user to carry and store.

Owner:深圳市秀宝机器人科技有限公司

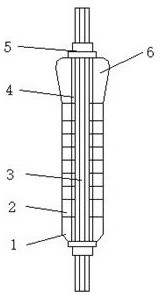

Hemangioma stent weaving process

The invention discloses a hemangioma stent weaving process, and relates to the technical field of medical instrument production. The hemangioma stent weaving process specifically comprises a shaping assembly matched with a stent; the shaping assembly is composed of a first shaping section, a plurality of transition shaping sections and a second shaping section; the transition shaping sections are distributed between the first shaping section and the second shaping section; and circular holes are formed in the first shaping section, the transition shaping sections and the second shaping section, and a shaping tightening latch is inserted into the circular holes. When the stent is unfolded in a blood vessel, the extrusion effect on the protruding portion of a focus is reduced, damage to vascular wall tissue can be reduced, the stent and the blood vessel can be kept fixed, the front-end blood vessel and the rear-end blood vessel far away from the focus are slightly expanded, and the narrowing phenomenon is effectively avoided; and the middle-layer portion of the stent is coated with an inert film, protrusions at lesion positions are prevented from penetrating through net gaps, and the stenosis phenomenon caused by regrowth of lesions is avoided.

Owner:萃杰医疗科技(南京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com