Independent plate coating drying box device

A self-contained, oven-based technology, applied to the surface coating liquid device, coating, transportation and packaging, etc., can solve the problems of wasting resources, the oven guide wheel does not rotate, etc., to improve efficiency and avoid width narrowing , the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

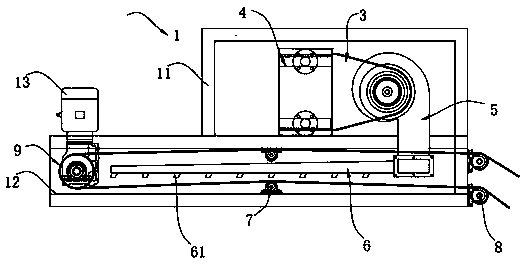

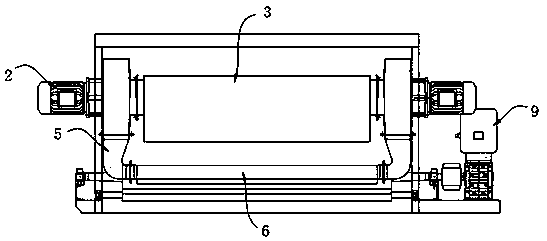

[0022] A free-standing version coating oven device, such as figure 1 and figure 2 As shown, an oven structure 1 is included, and the oven structure 1 includes a cold air box 11 and an oven body 12 installed at the bottom of the cold air box 11, and the cold air box 11 and the oven body 12 are integrally formed, and blowers 2 are installed on both sides of the cold air box 11 , An air collecting hood 3 is installed between the two blowers 2, a heat exchanger 4 is installed on one side of the air collecting hood 3, an air supply pipe 5 is connected to the bottom of the air collecting hood 3, and the air supply pipe 5 is far away from the air collecting hood 3 One end of the air supply row 6 is connected to the bottom surface of the air supply row 6, and a number of uniformly equidistant hot air nozzles 61 are installed on the bottom surface of the air supply row 6. The upper and lower sides of the oven body 12 are symmetrically equipped with conveying guide wheels 7, and one en...

Embodiment 2

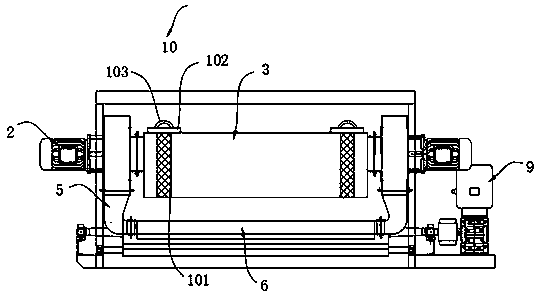

[0028] In order to solve the problem that the impurities in the air are blown into the wind collecting hood 3 during the blowing process and will be adsorbed on the artificial leather during drying, which will affect the quality of the product, the inventor made a design for the wind collecting hood 3 in Example 1. Improvement, as a kind of preferred technical scheme of embodiment 1, such as image 3 As shown, the two ends of the wind collecting hood 3 are symmetrically equipped with filter devices 10, the filter device 10 includes a filter screen plate 101, a limit block 102 is installed on the top of the filter screen plate 101, and a pull ring 103 is installed on the top of the limit block 102 .

[0029] Further, the filter screen plate 101 is plugged on the wind collecting hood 3, and the filter screen plate 101 is plugged and matched with the wind collecting hood 3. When the dust is absorbed too much, the filter screen plate 101 can be extracted, and the filter screen pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com