Stacked battery and production method of stacked battery

A production method and stacking technology, which is applied in the direction of large flat batteries/batteries, secondary battery manufacturing, battery pack components, etc., can solve the problems of lack of stacked batteries, affecting battery life, and affecting the utilization rate of battery active materials, etc., to achieve The effect of reducing gas cycle performance, ensuring effective utilization rate, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

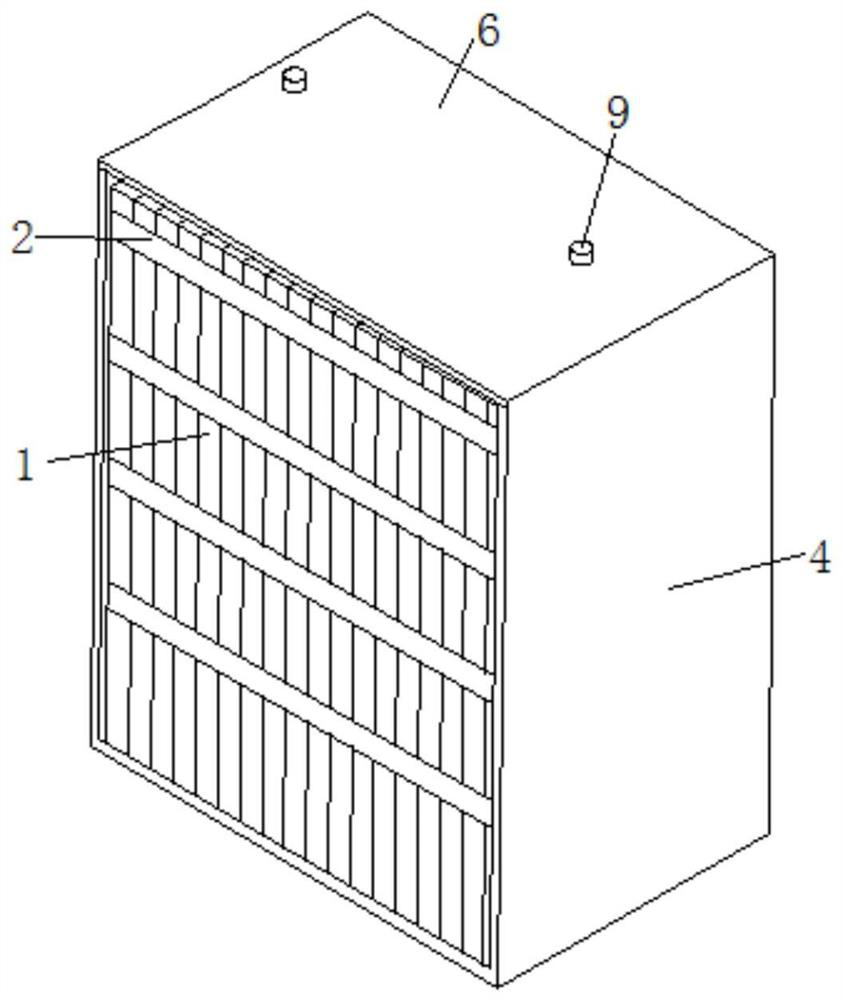

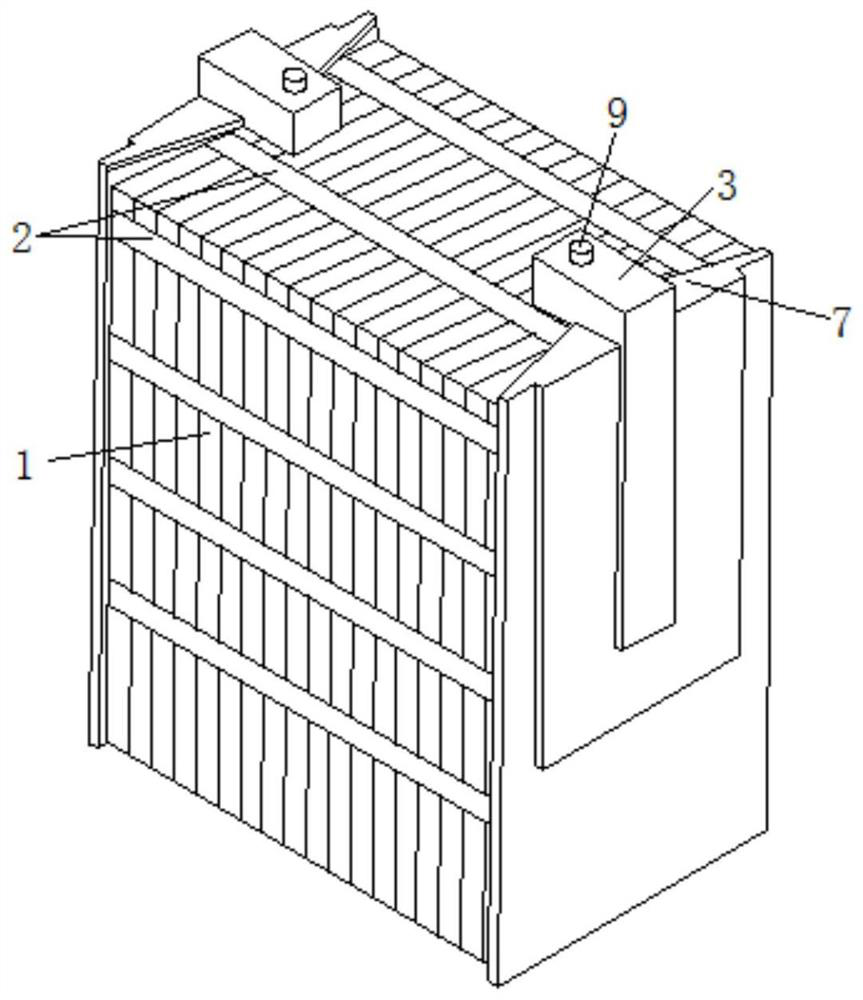

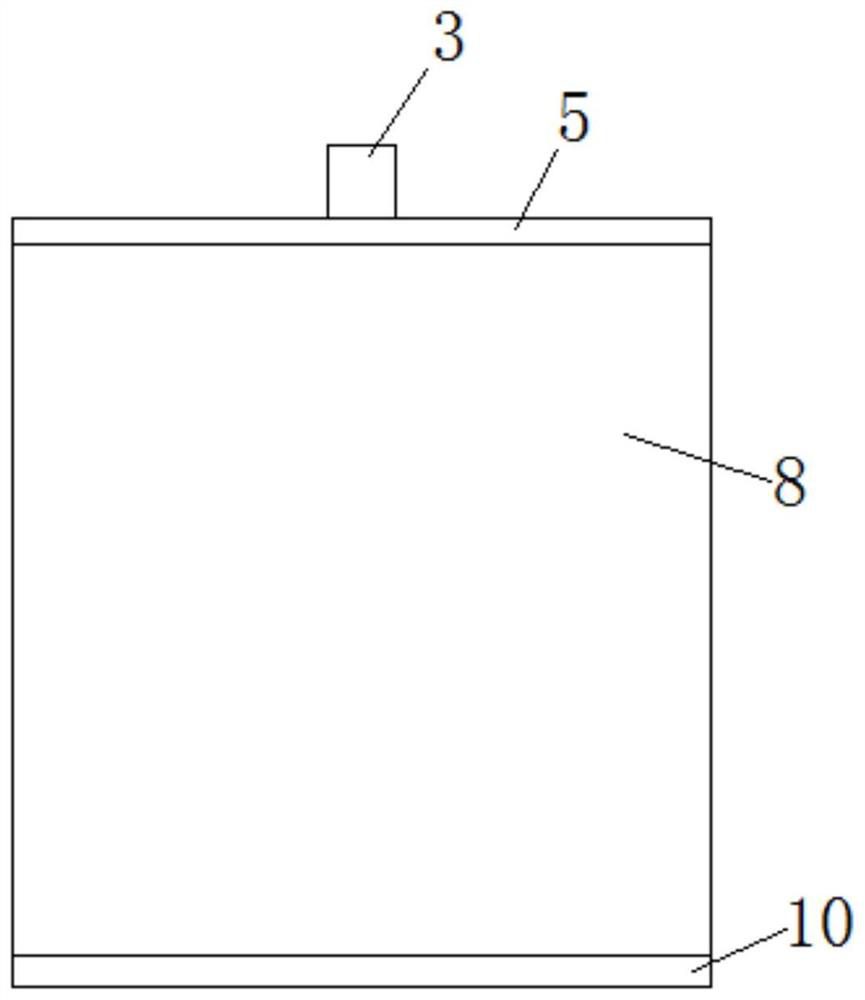

[0043] according to Figure 1-3 As shown, a stacked battery includes an electrode plate group 1, a pressure frame 2, a tab 3 and a casing 4. The electrode plate group 1 includes a positive electrode plate and a negative electrode plate, and the positive electrode plate and the negative electrode plate are stacked alternately to form Both the positive plate and the negative plate have tab groups 5, and the tab groups 5 of two adjacent positive plates or the tab groups 5 of two adjacent negative plates are connected in parallel and cast-welded to form a positive strip or Negative electrode belt; the circumferential outer wall of the pole plate group 1 is provided with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com