Patents

Literature

93results about How to "Uniform spacing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing a chip

InactiveUS20020025432A1Satisfactory uniform chip spacingImprove productivityLamination ancillary operationsSolid-state devicesSemiconductor chipEngineering

A process for producing a chip, comprising the steps of: setting an object to be diced on a pressure sensitive adhesive sheet for producing chip comprising at least one layer of shrinkable film, an expansible film and a pressure sensitive adhesive layer for setting the object; fixing edges of the pressure sensitive adhesive sheet for producing chip; dicing the object into chips, and shrinking the shrinkable film to thereby expand chip spacings. In the process for producing small chips such as semiconductor chips, chip spacings can be expanded without the need to conduct the conventional expansion step.

Owner:LINTEC CORP

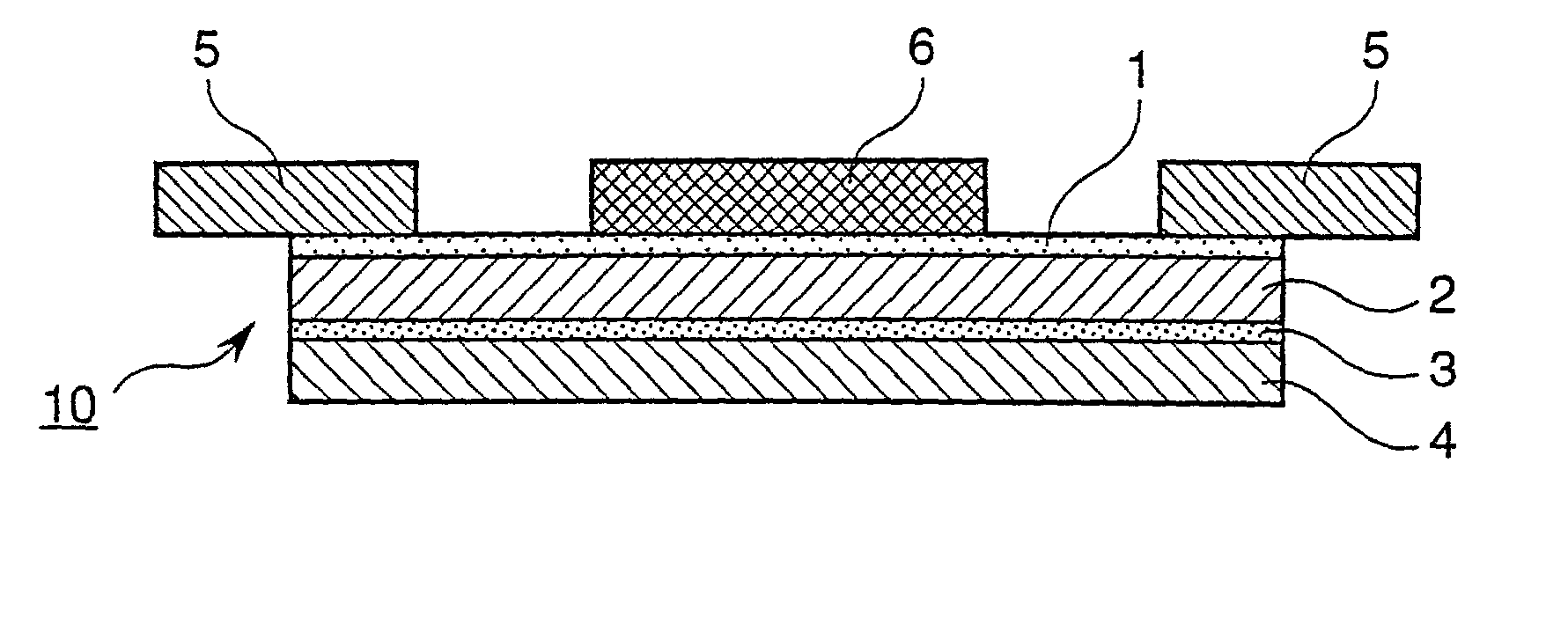

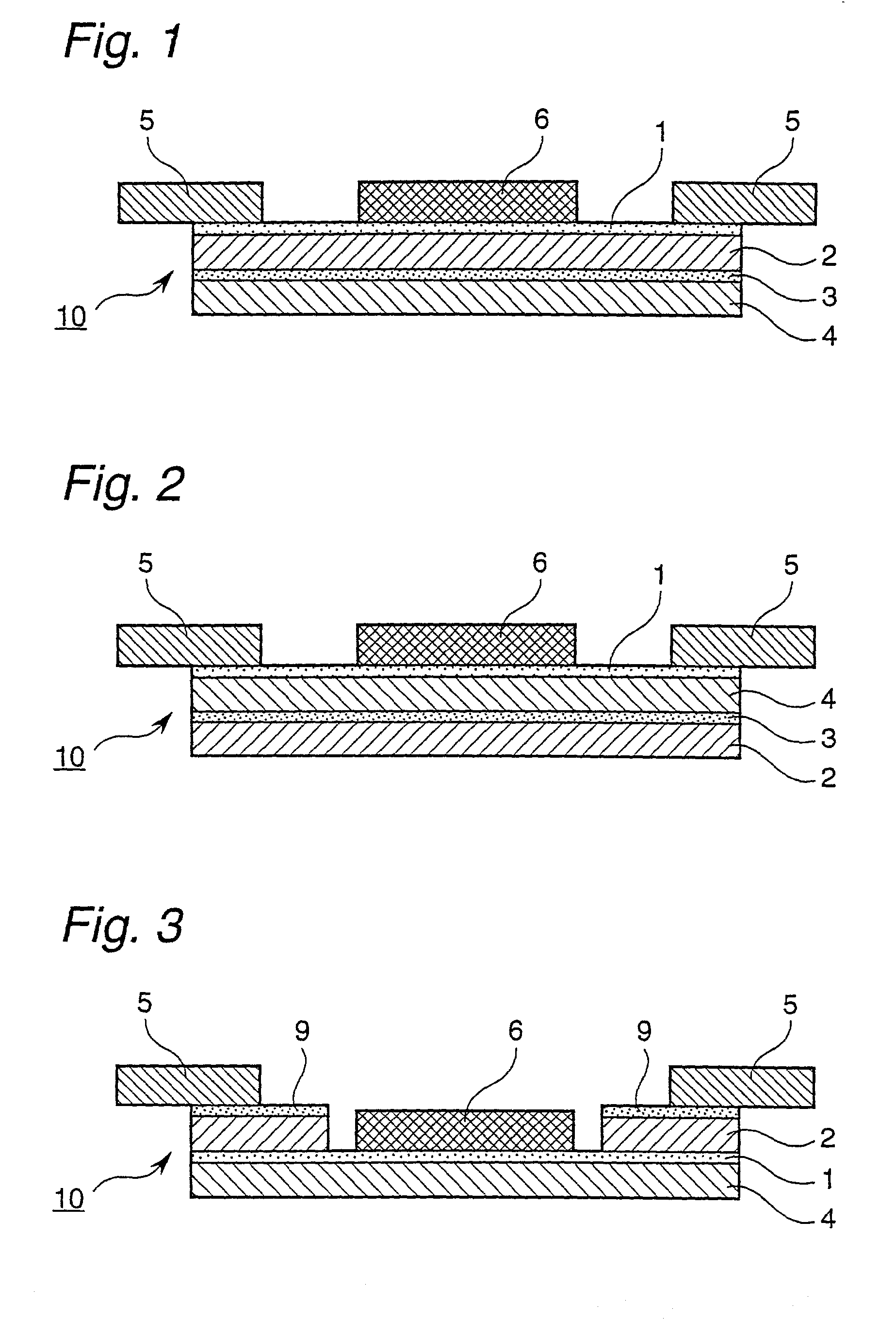

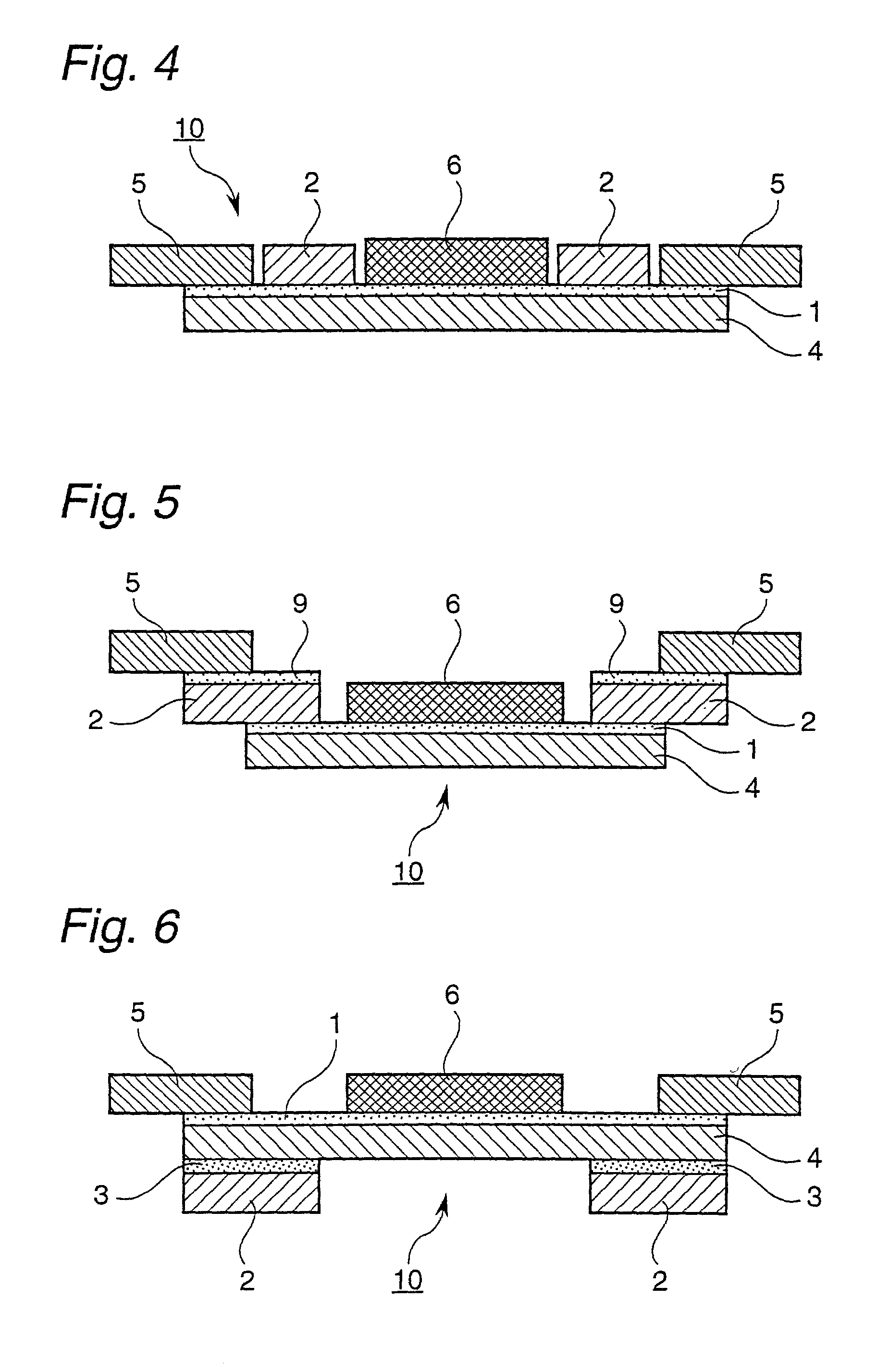

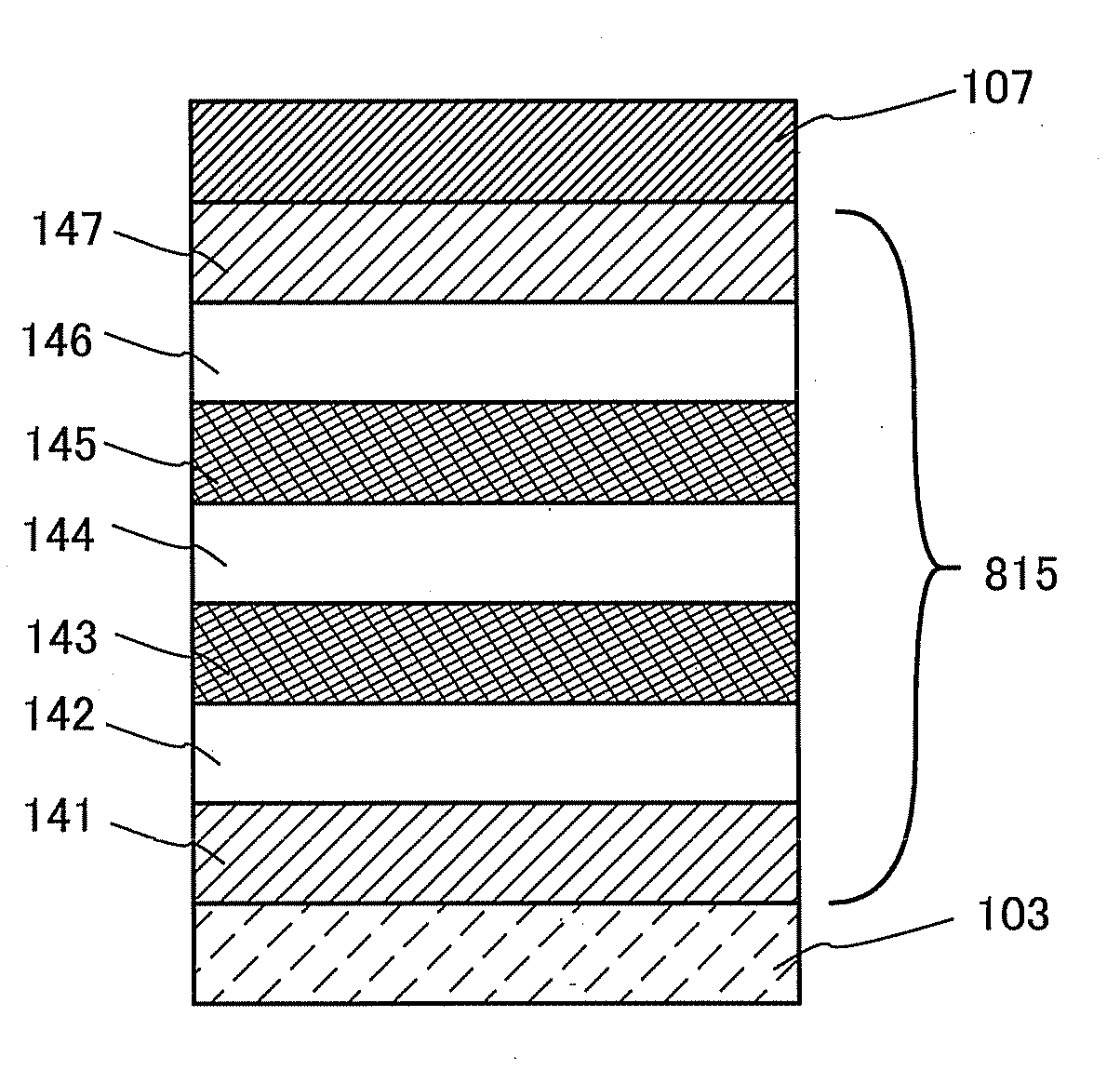

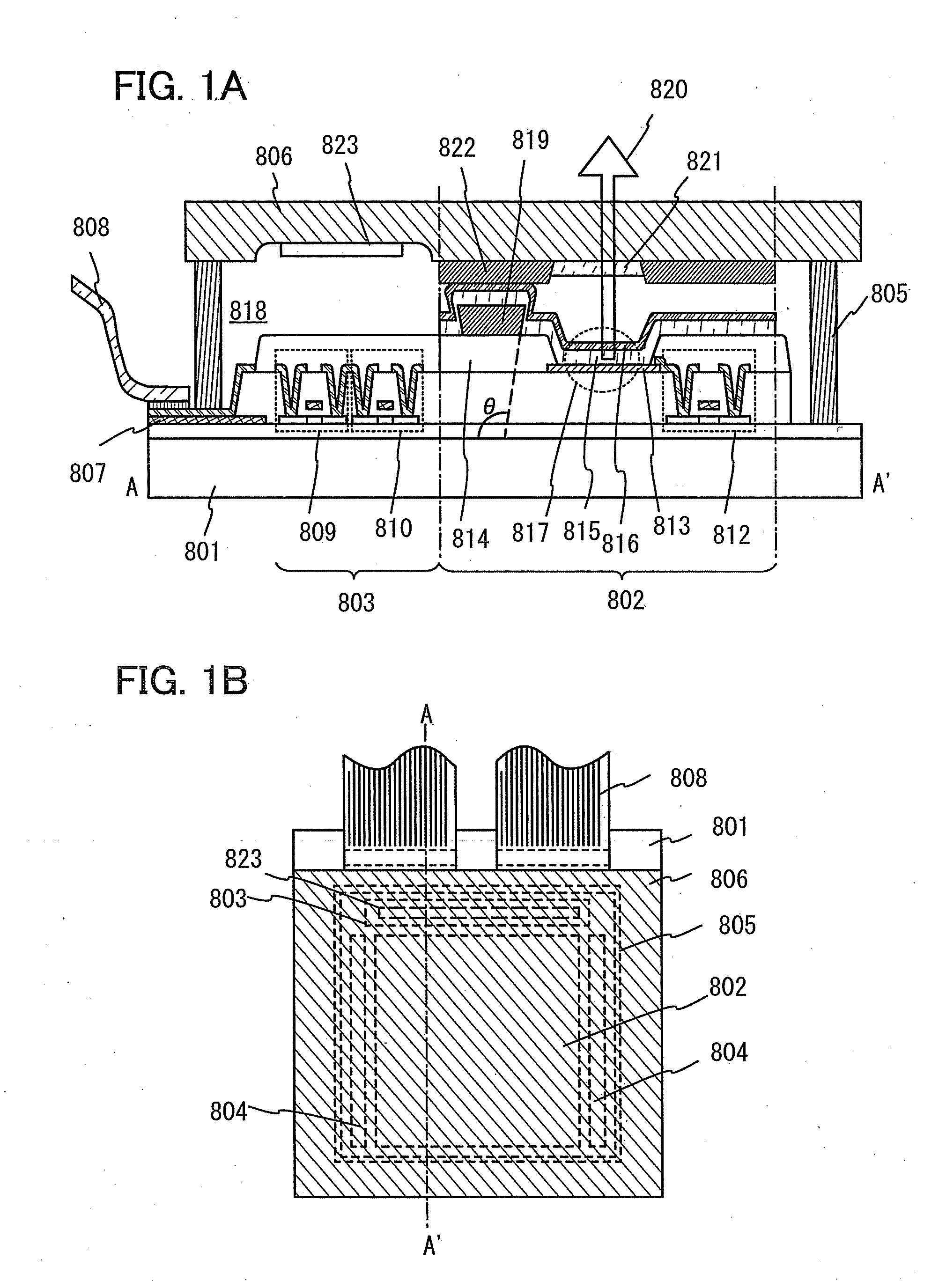

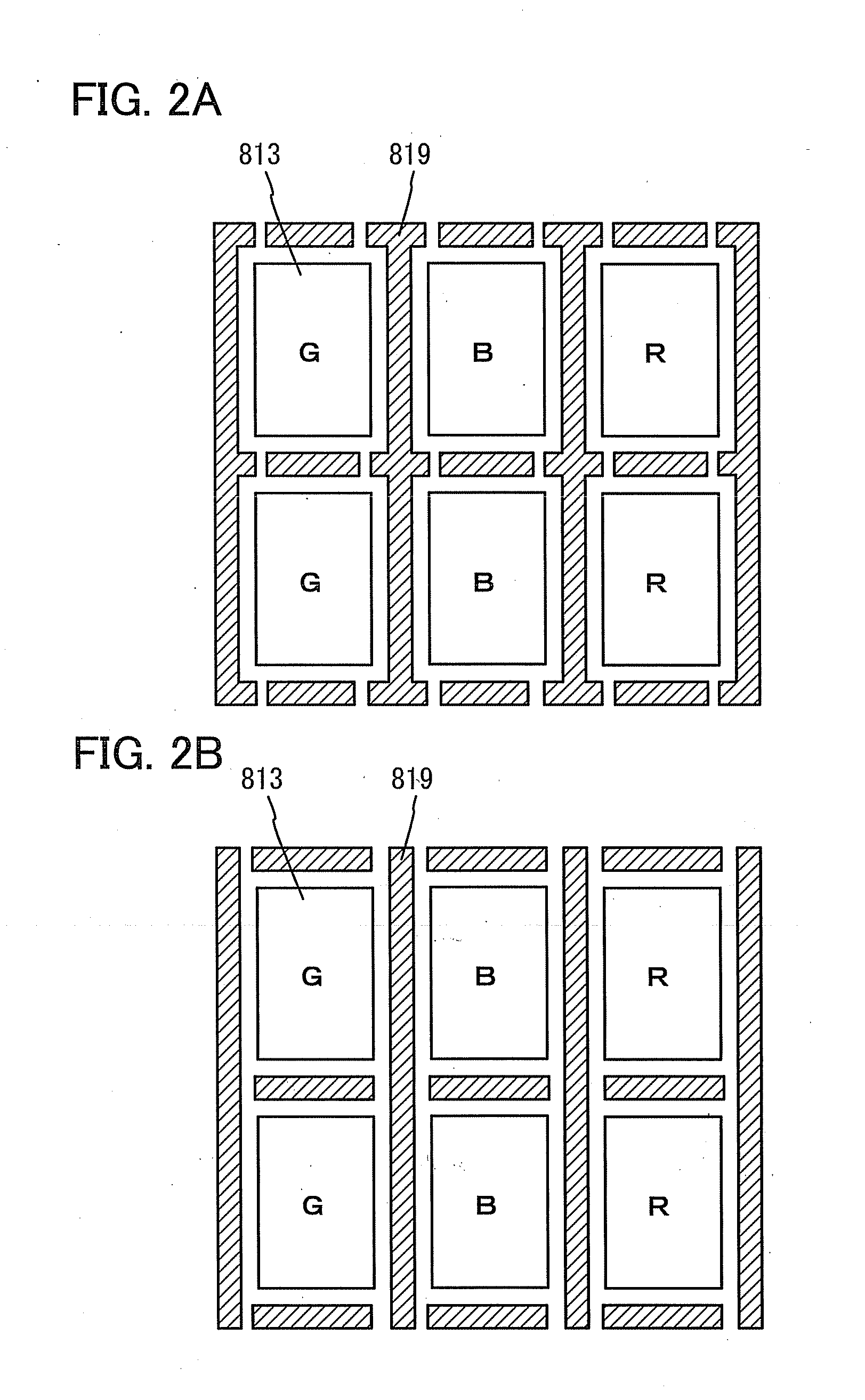

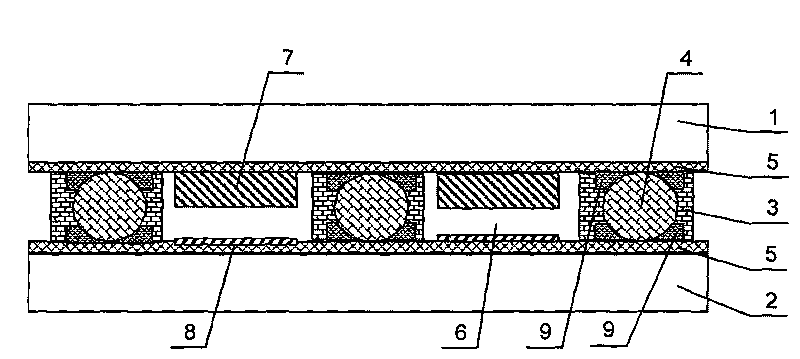

Light-Emitting Device and Manufacturing Method Thereof

ActiveUS20120273804A1Reduce light leakageUniform spacingSolid-state devicesPhotovoltaic energy generationEngineeringAdhesive

When a hollow structure in which a light-emitting element is provided between a pair of substrates is used in order to prevent oxygen or moisture from reaching the light-emitting element, light leakage to an adjacent pixel easily occurs as compared to a structure in which a space between a pair of substrates is filled with a resin such as an adhesive. In order to reduce light leakage to an adjacent pixel in the hollow structure, a light-blocking spacer is formed over a partition to keep the distance between the pair of substrates uniform. The cross-sectional shape of the light-blocking spacer is a trapezoid having a lower side shorter than an upper side.

Owner:SEMICON ENERGY LAB CO LTD

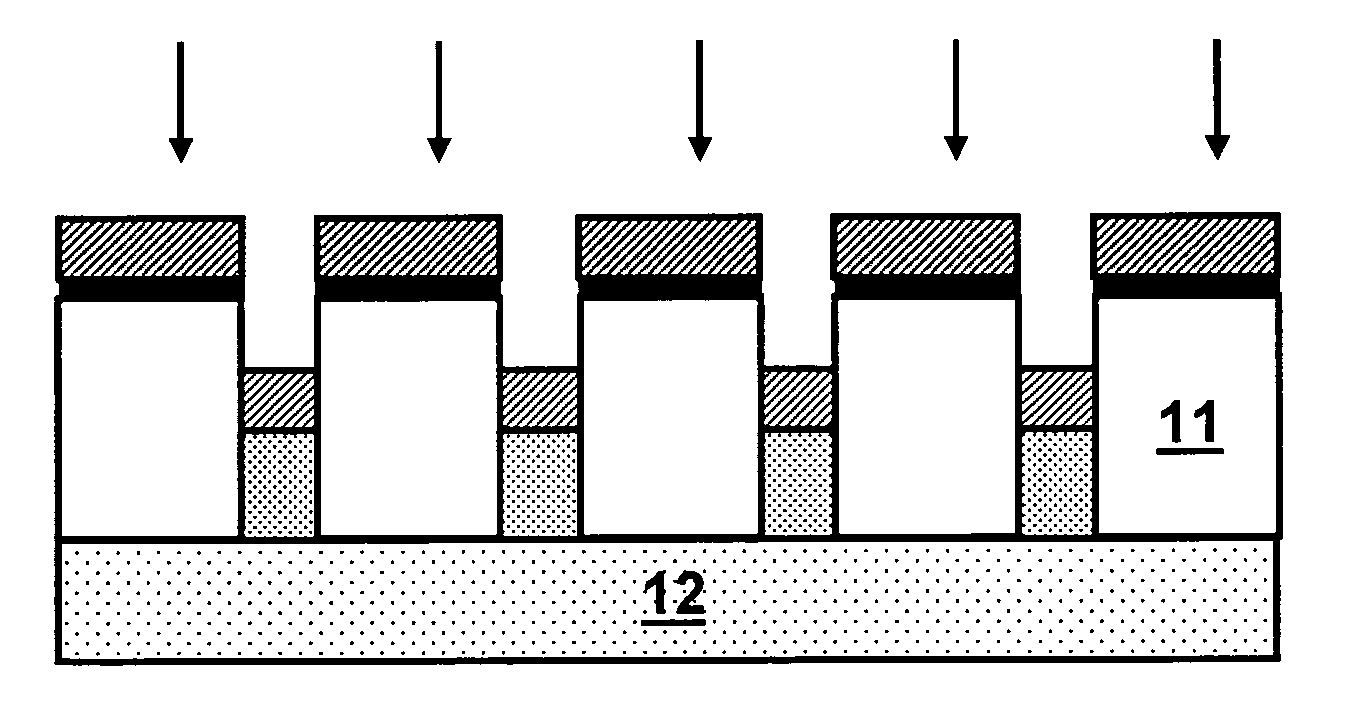

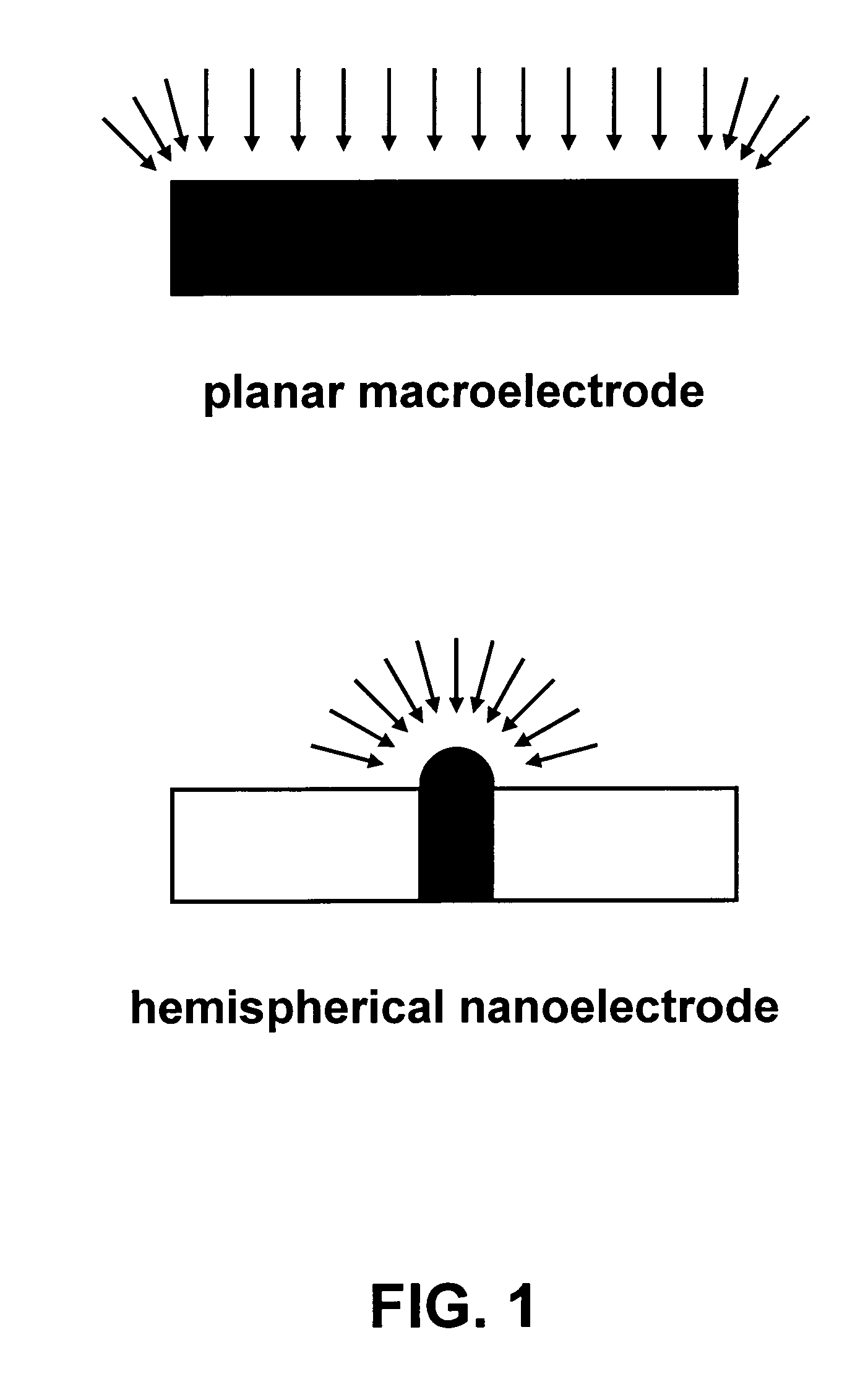

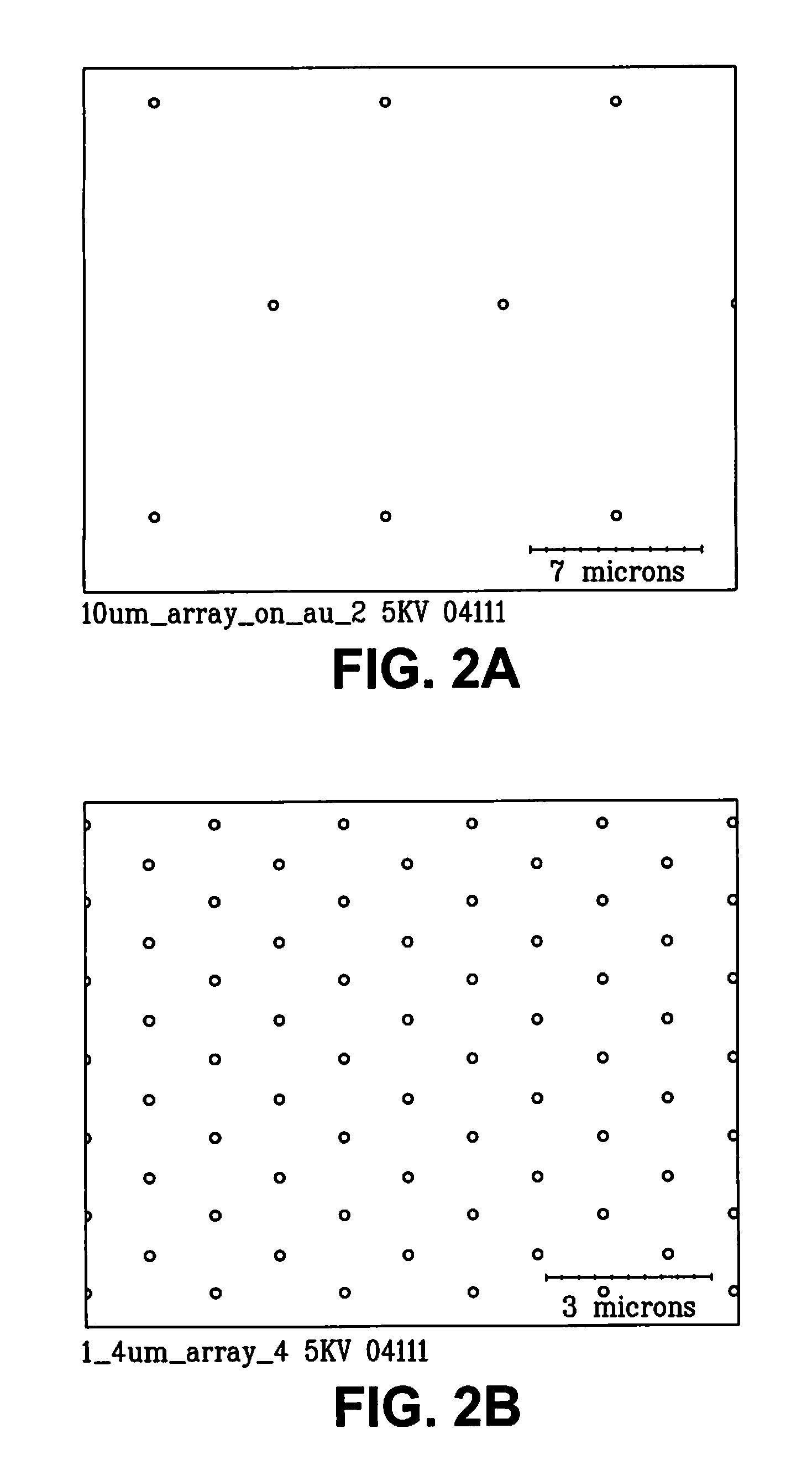

Nanoelectrode array for electrochemical analysis

A nanoelectrode array comprises a plurality of nanoelectrodes wherein the geometric dimensions of the electrode controls the electrochemical response, and the current density is independent of time. By combining a massive array of nanoelectrodes in parallel, the current signal can be amplified while still retaining the beneficial geometric advantages of nanoelectrodes. Such nanoelectrode arrays can be used in a sensor system for rapid, non-contaminating field analysis. For example, an array of suitably functionalized nanoelectrodes can be incorporated into a small, integrated sensor system that can identify many species rapidly and simultaneously under field conditions in high-resistivity water, without the need for chemical addition to increase conductivity.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

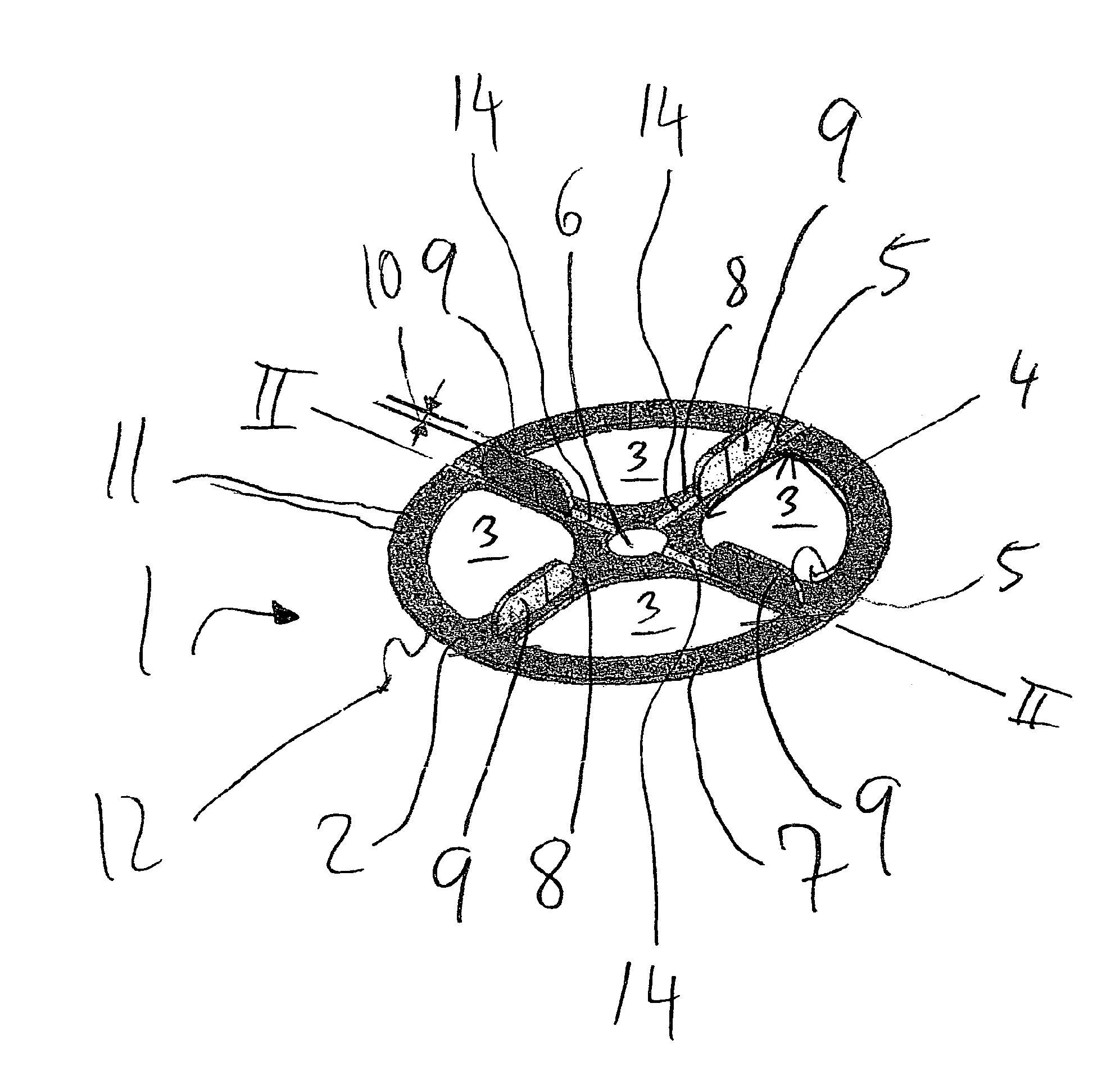

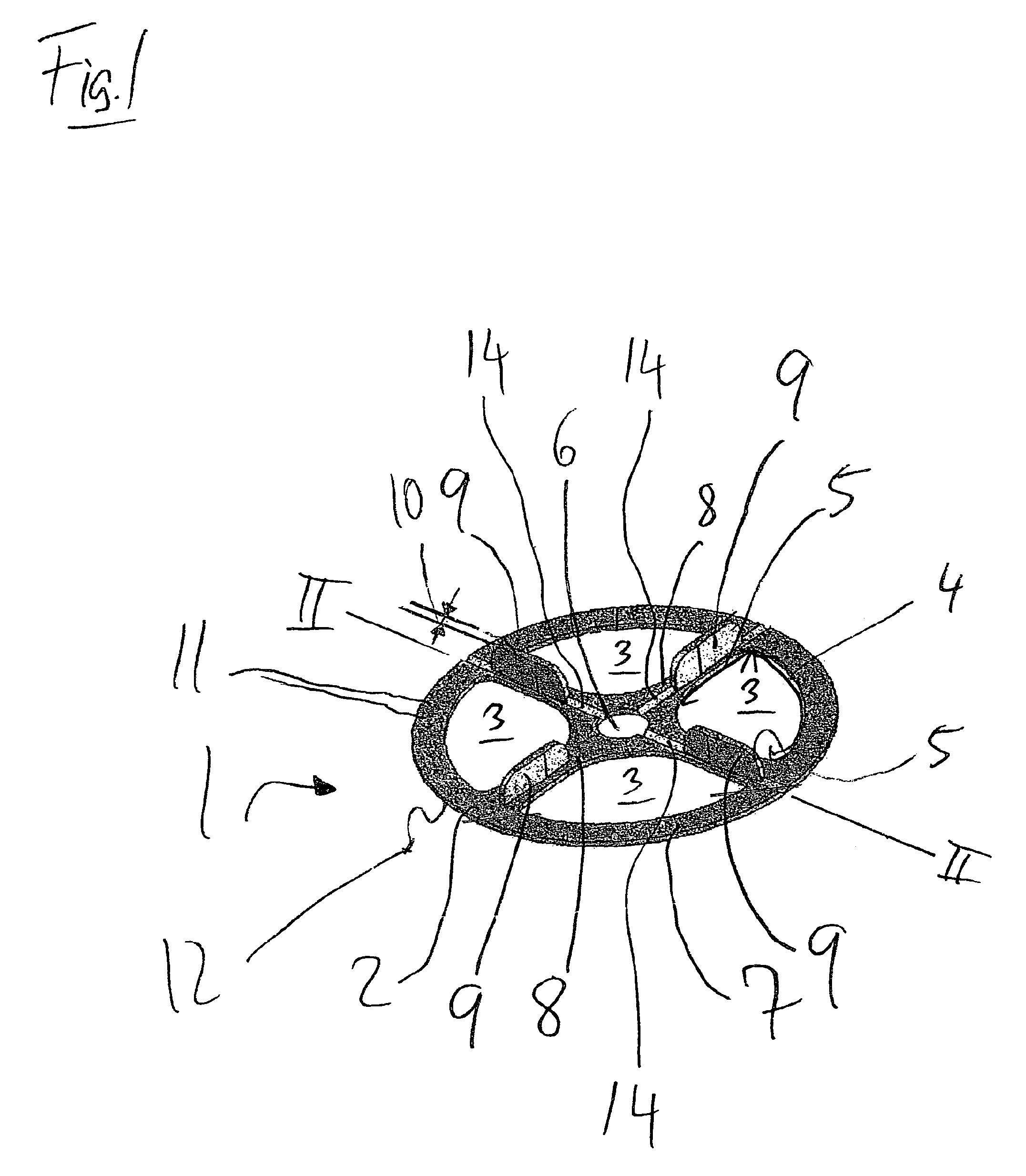

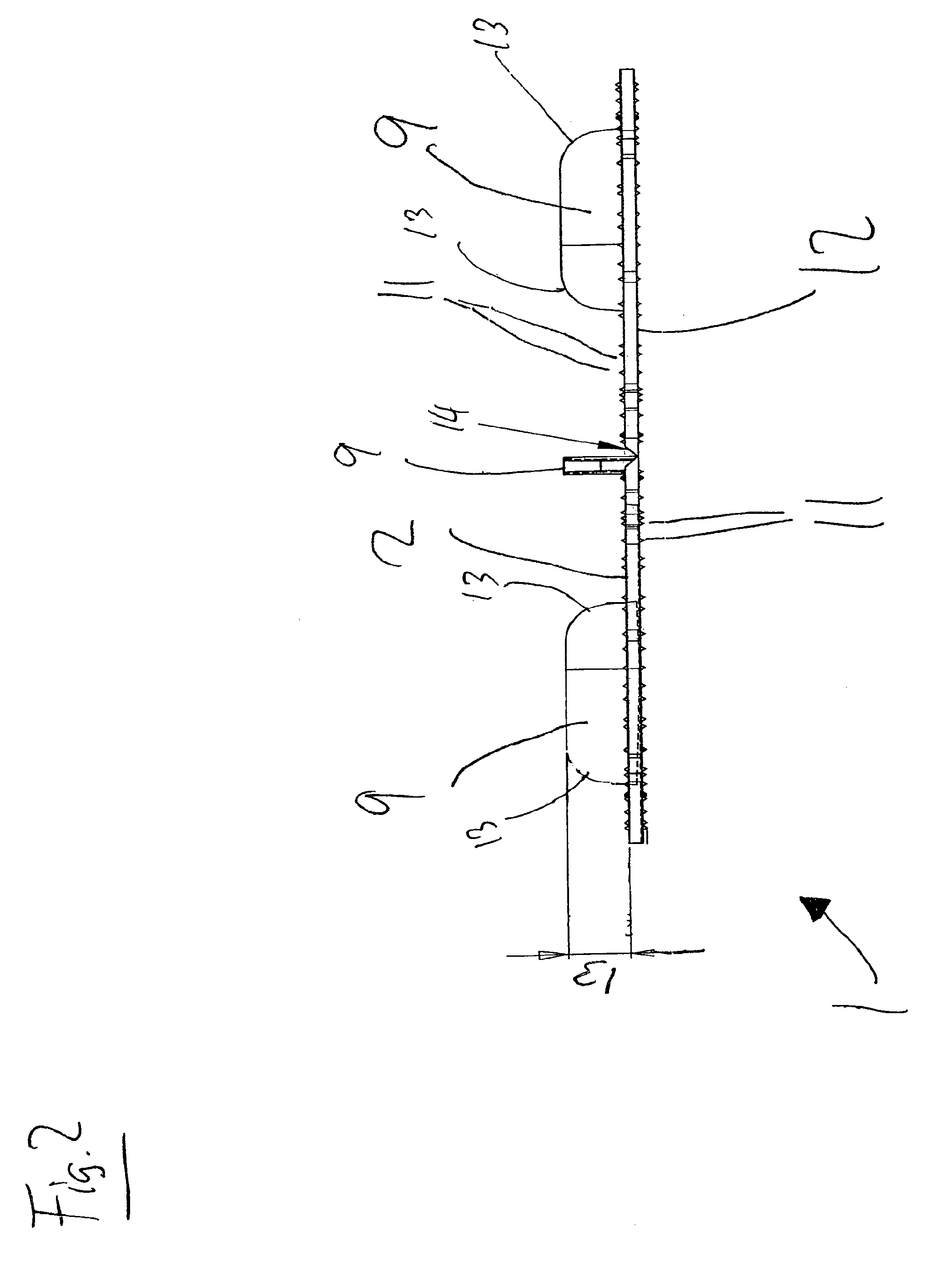

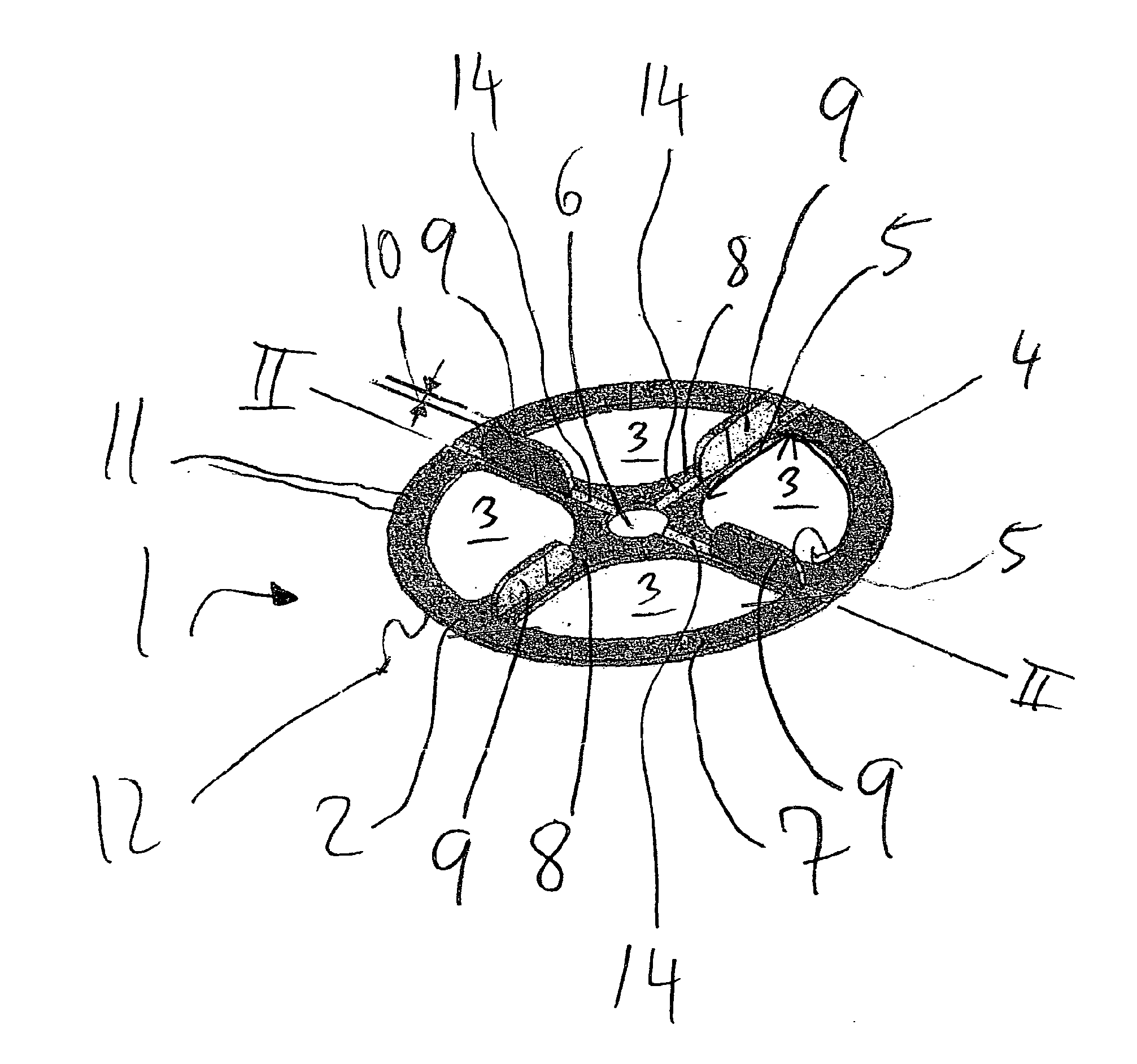

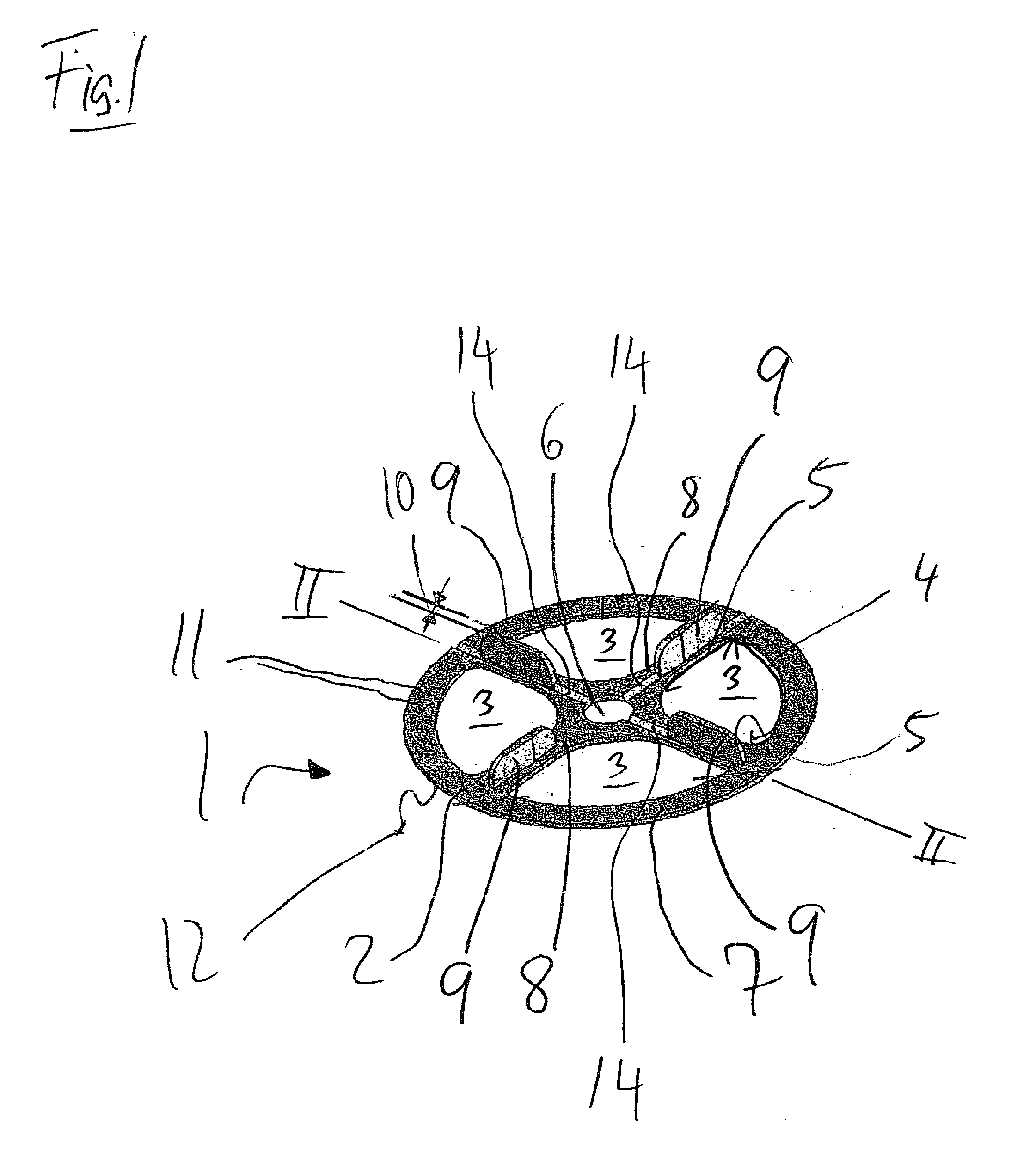

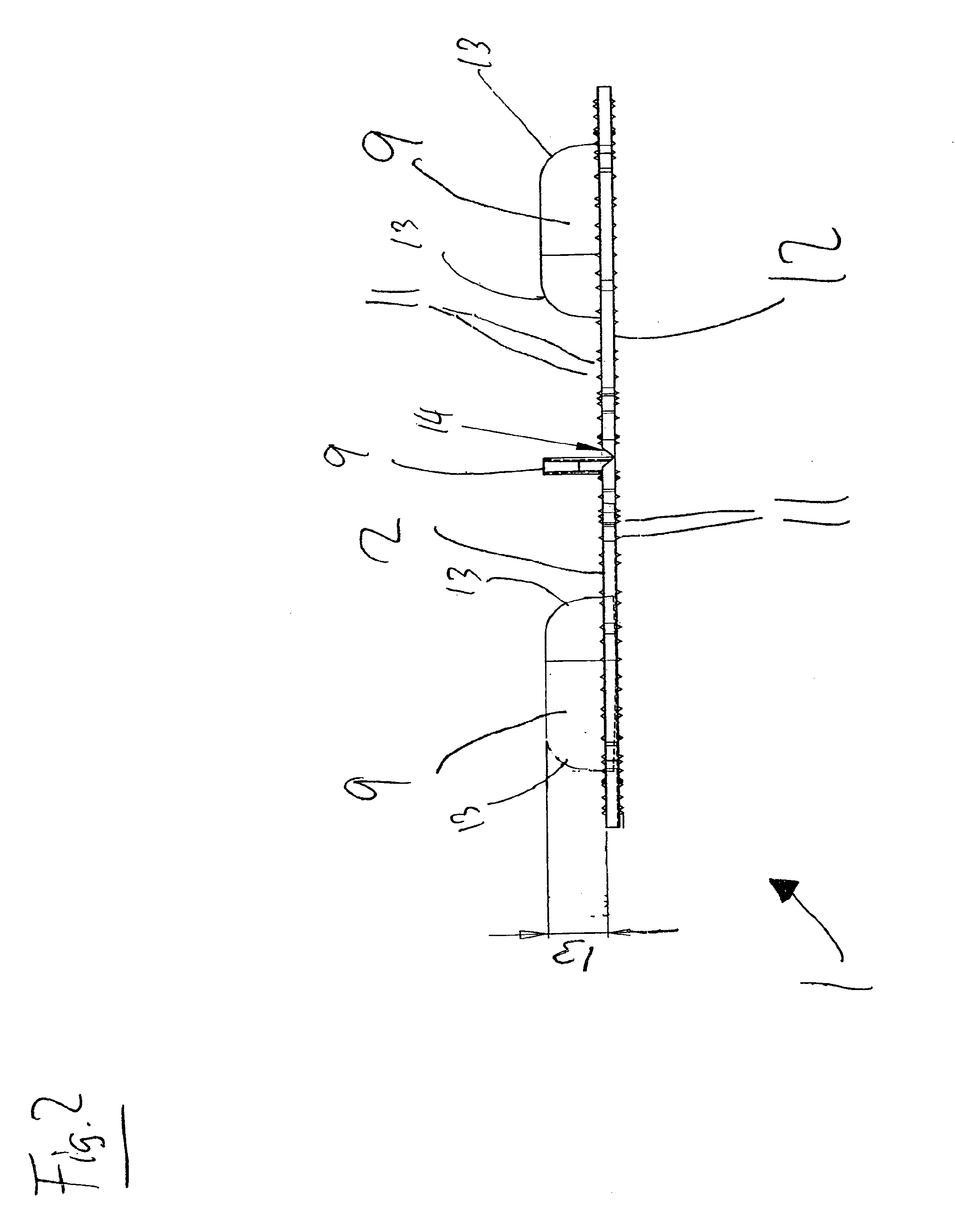

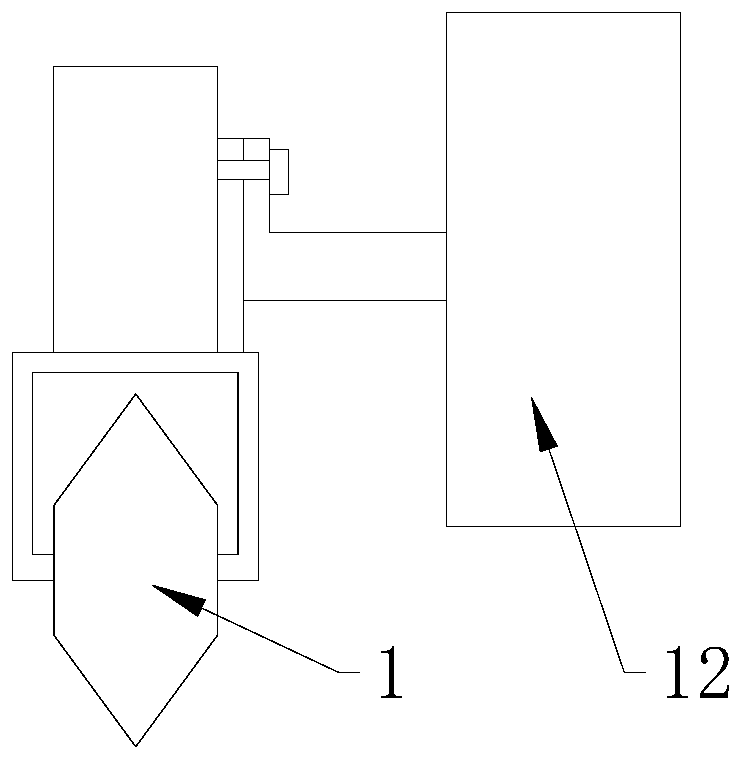

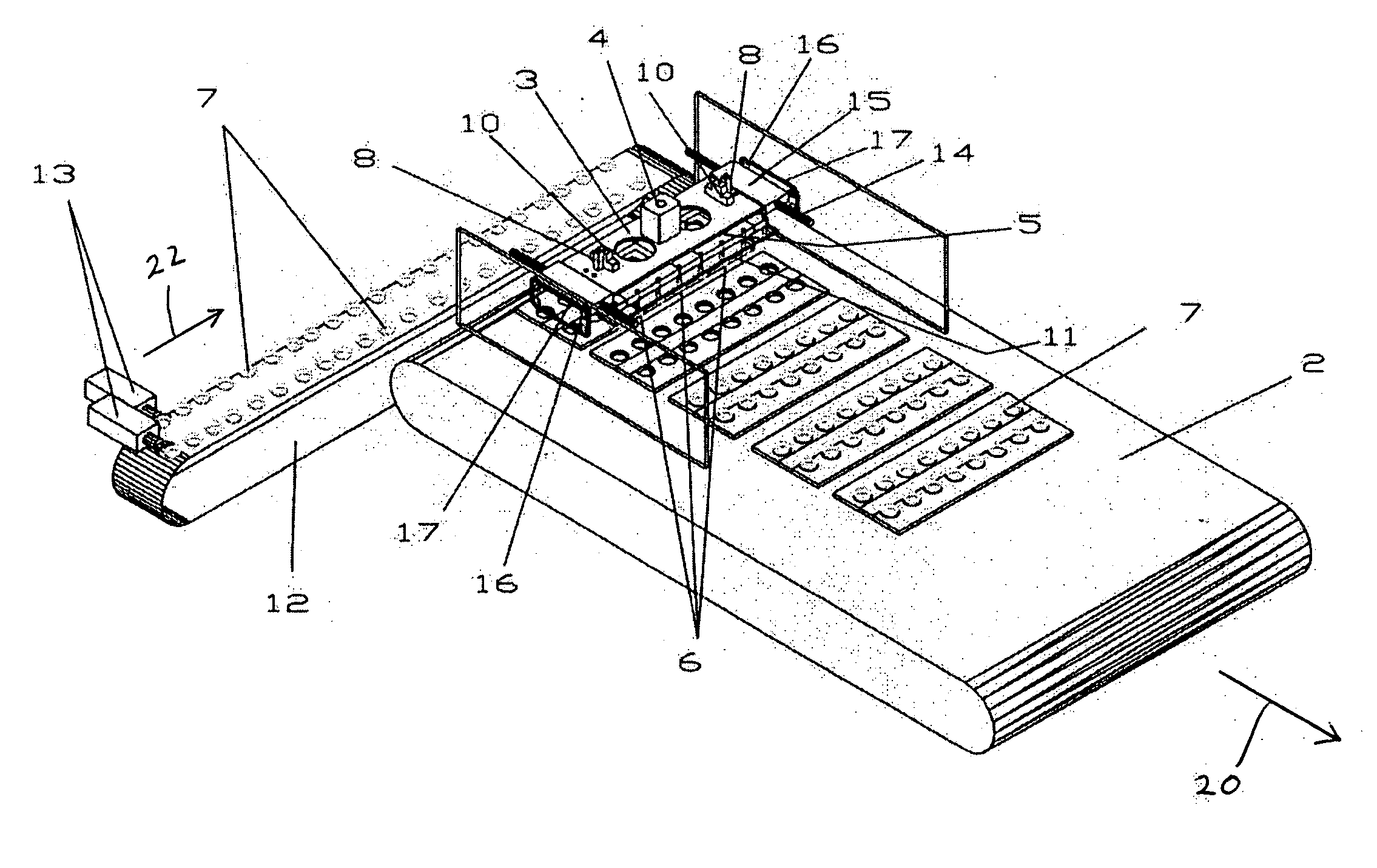

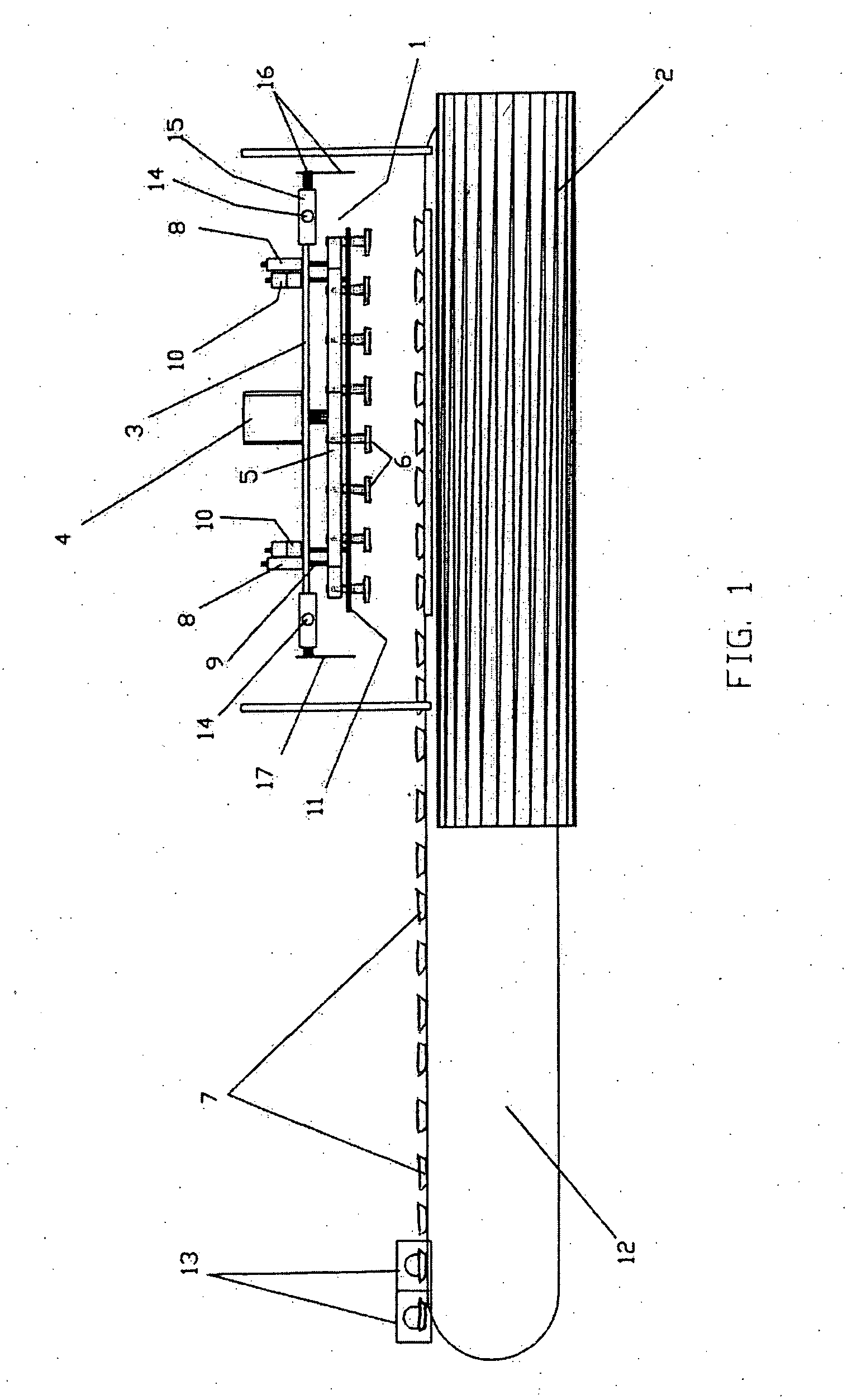

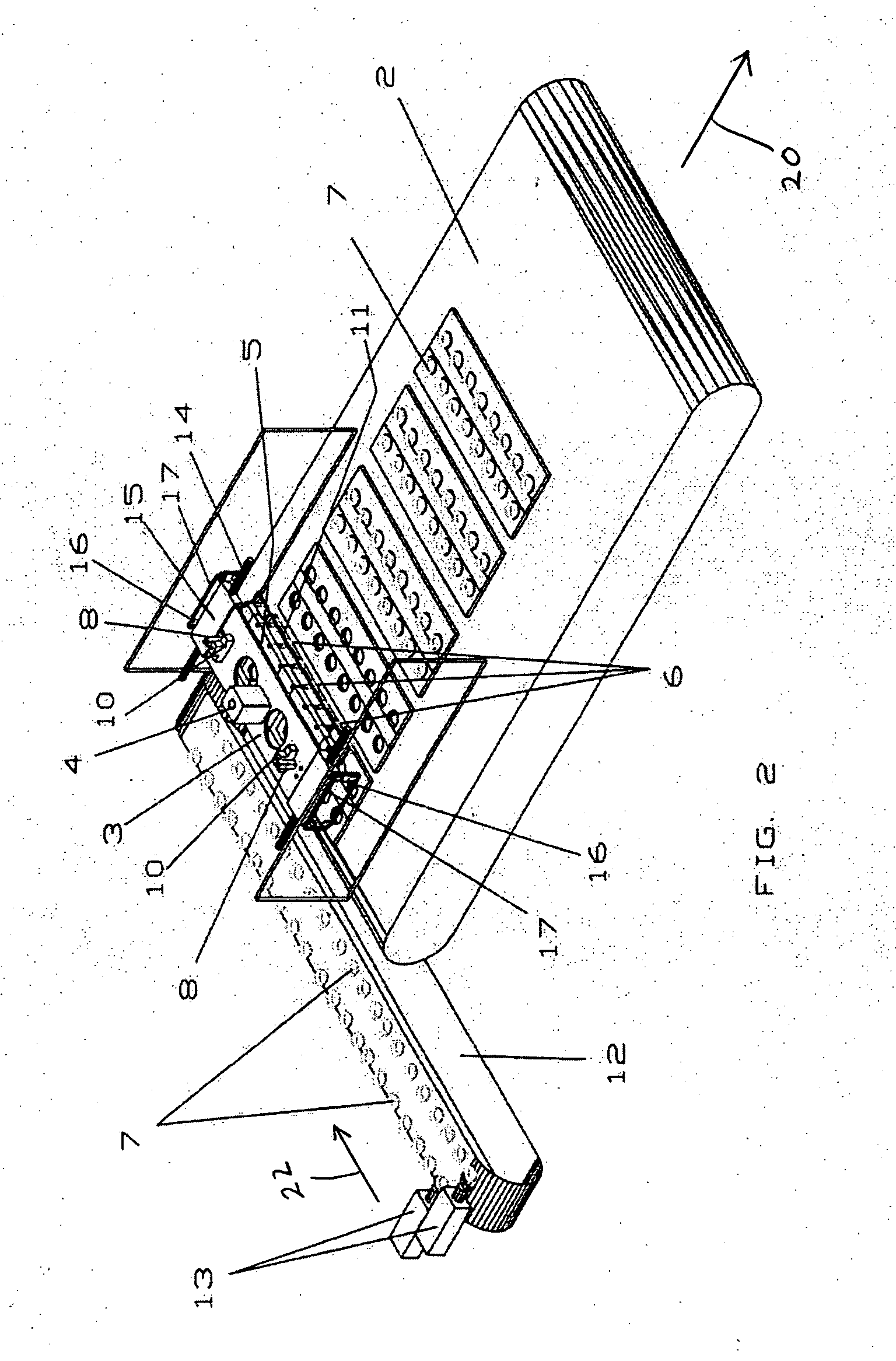

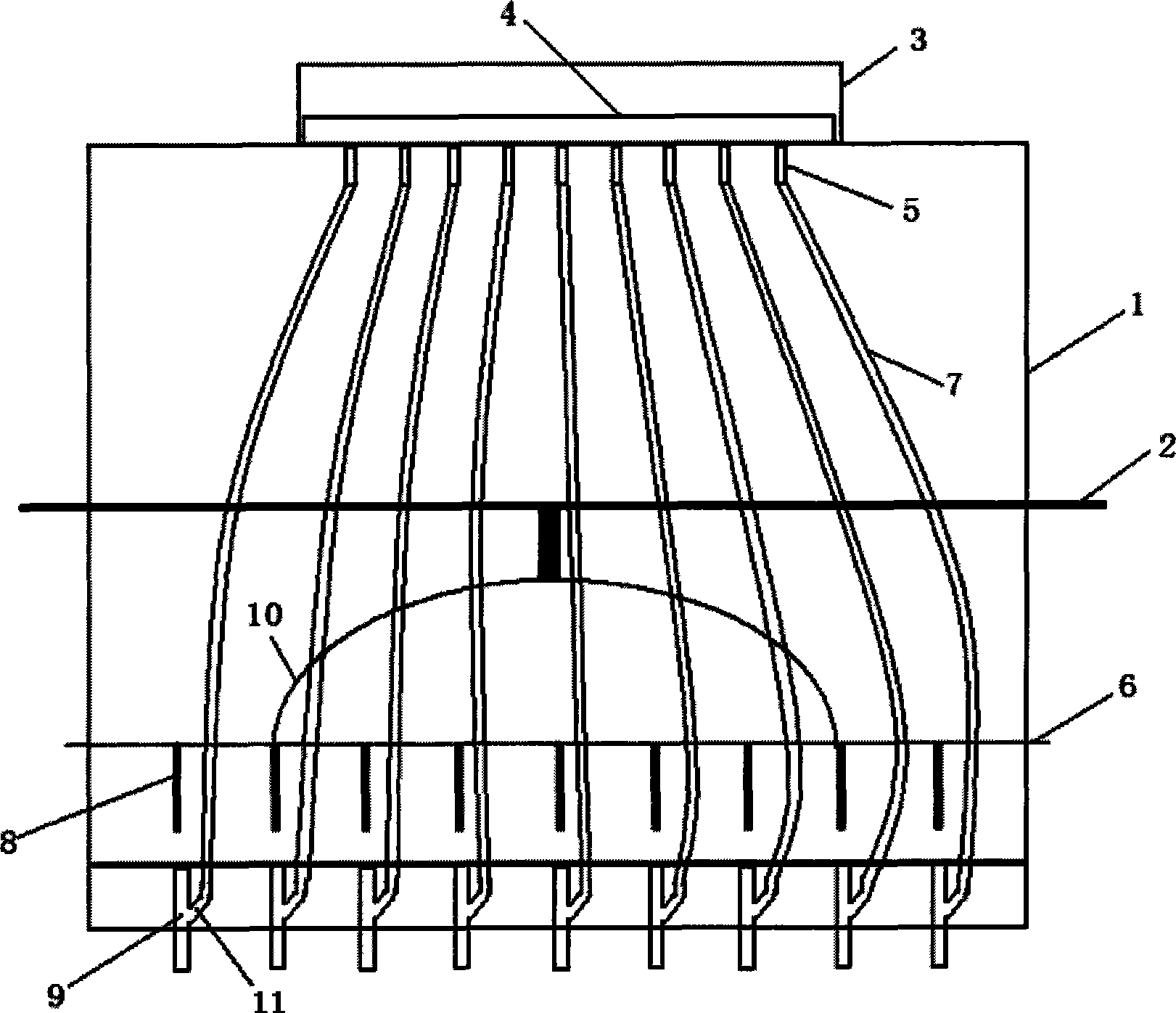

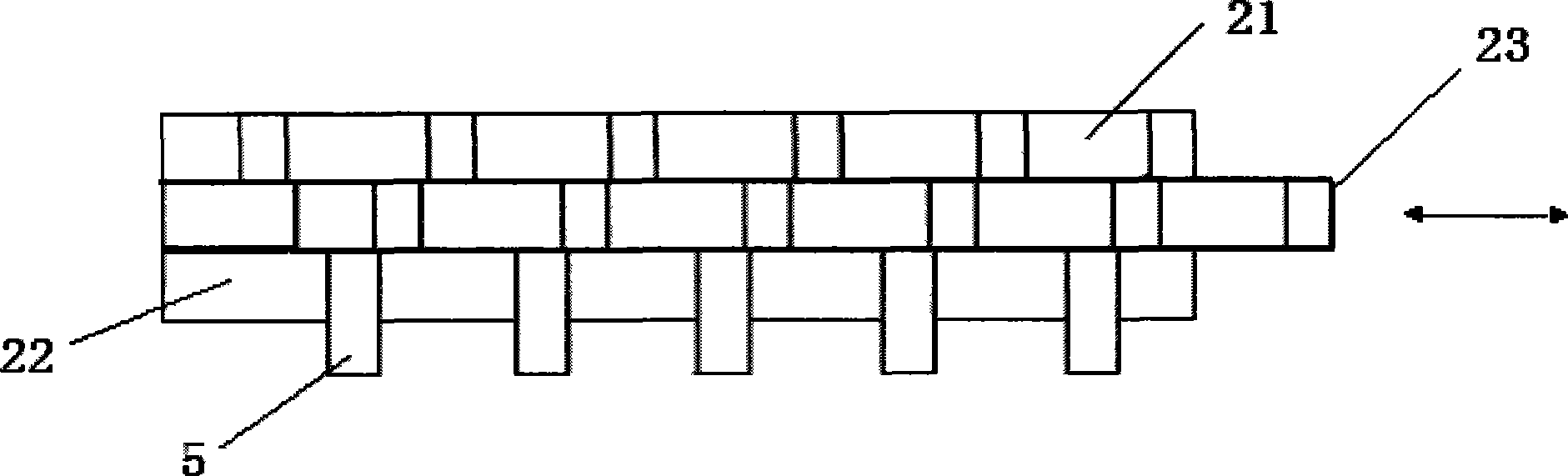

Laying aid for tiles

The invention relates to a device (1) used as a laying aid for tiling work, comprising a base element (7, 8) having a support region (12) for laying flat on a surface to be covered with tiles (16), and a tile-supporting region (2) on which tiles (16) are placed. The tile-supporting region (2) has at least two web-like spacer elements (9) which extend perpendicularly with respect to a plane defined by the tile-supporting region (2) and which are arranged at an angle of an integer multiple of 90° relative to one another in said plane, and which have a thickness (10) corresponding to a desired joint spacing. To avoid the disadvantages of the known laying aids and to achieve uniform joint spacing and an even surface, whereby the laying aid is intended to be especially easy to handle, the base element (7, 8) is designed as a disk-like element having a base area that is smaller than a base area of the tiles (16) to be laid.

Owner:BRINKMAN SILKE +1

Laying Aid for Tiles

The invention relates to a device (1) used as a laying aid for tiling work, comprising a base element (7, 8) having a support region (12) for laying flat on a surface to be covered with tiles (16), and a tile-supporting region (2) on which tiles (16) are placed. The tile-supporting region (2) has at least two web-like spacer elements (9) which extend perpendicularly with respect to a plane defined by the tile-supporting region (2) and which are arranged at an angle of an integer multiple of 90° relative to one another in said plane, and which have a thickness (10) corresponding to a desired joint spacing. To avoid the disadvantages of the known laying aids and to achieve uniform joint spacing and an even surface, whereby the laying aid is intended to be especially easy to handle, the base element (7, 8) is designed as a disk-like element having a base area that is smaller than a base area of the tiles (16) to be laid.

Owner:BRINKMAN SILKE +1

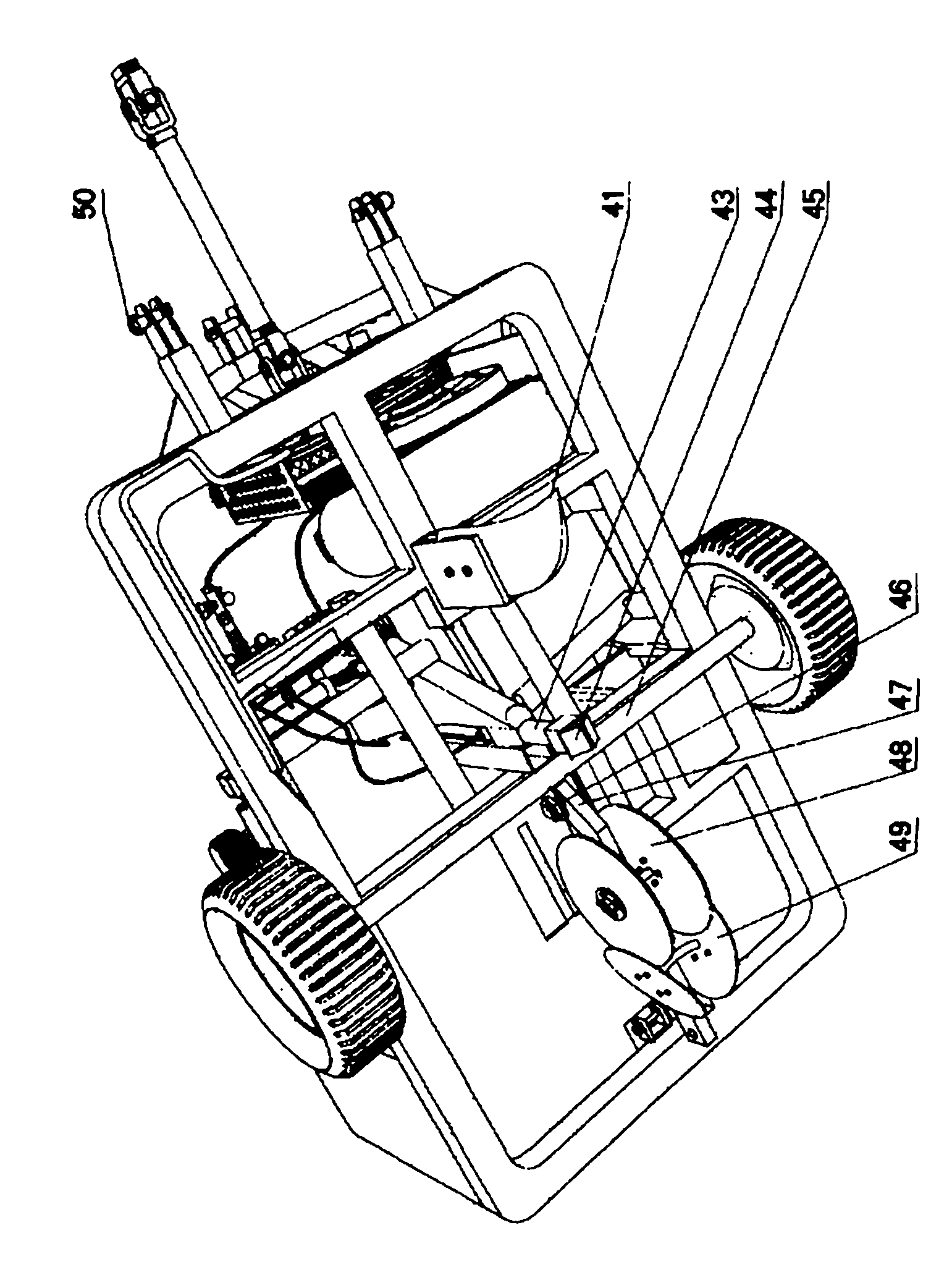

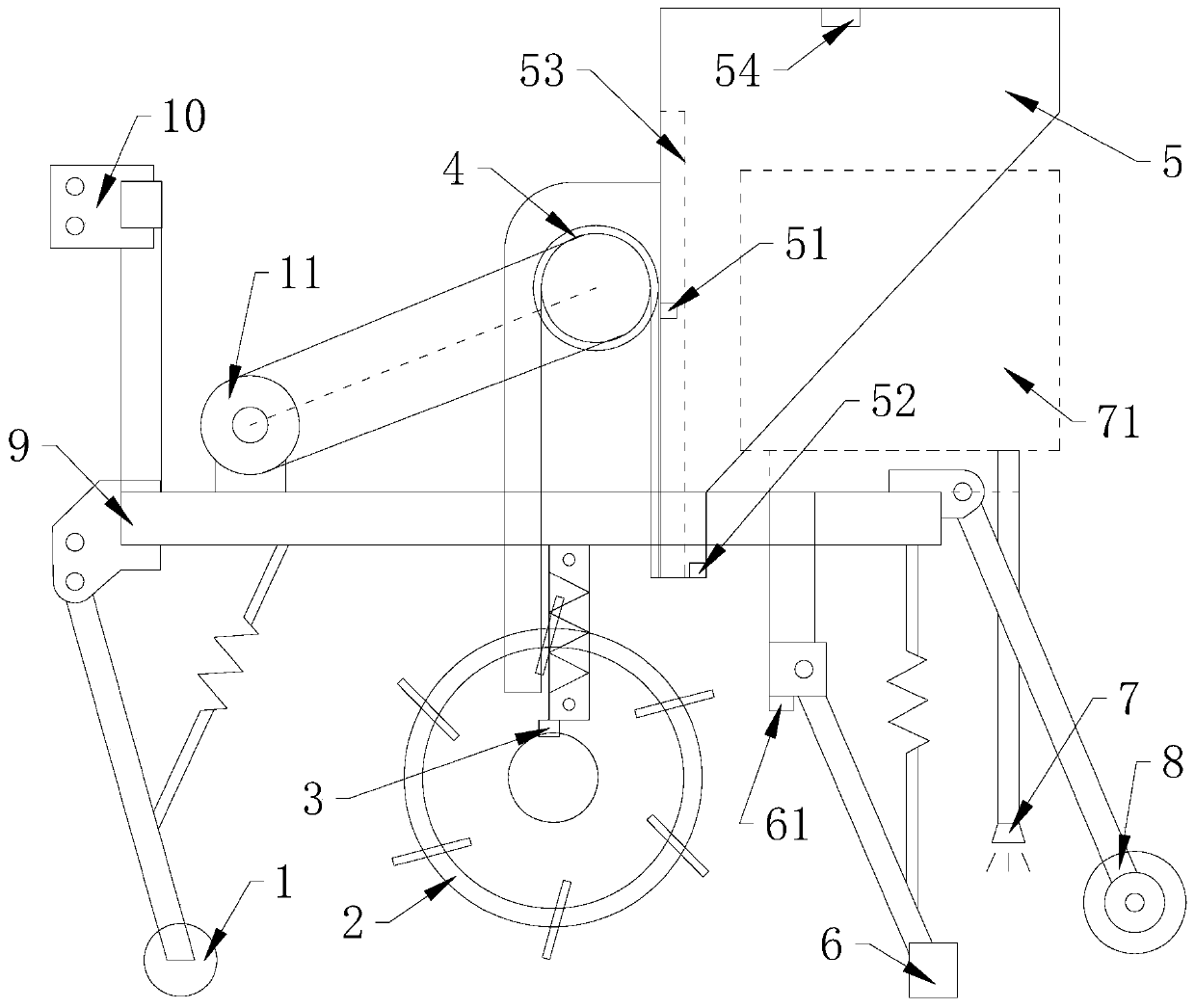

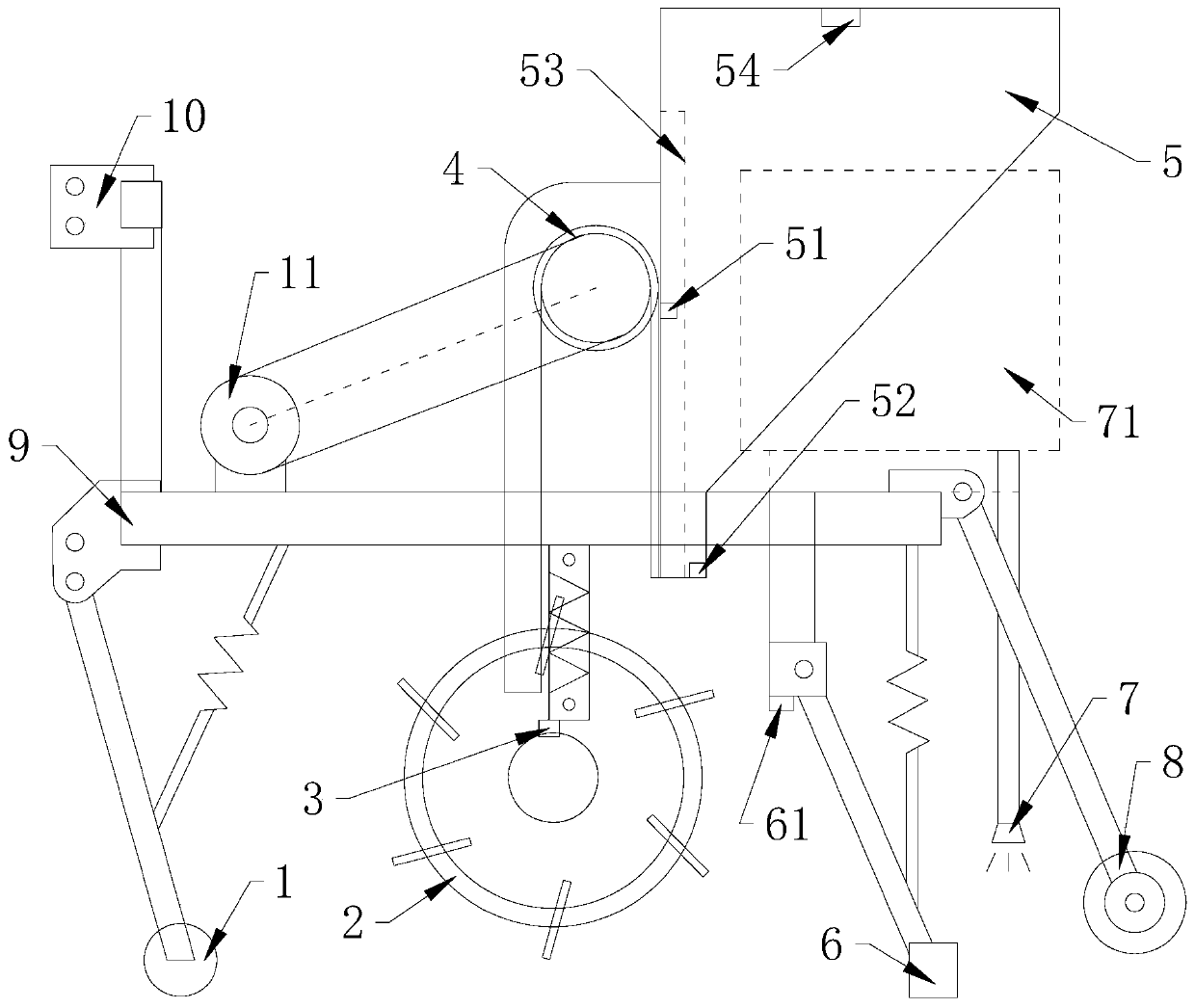

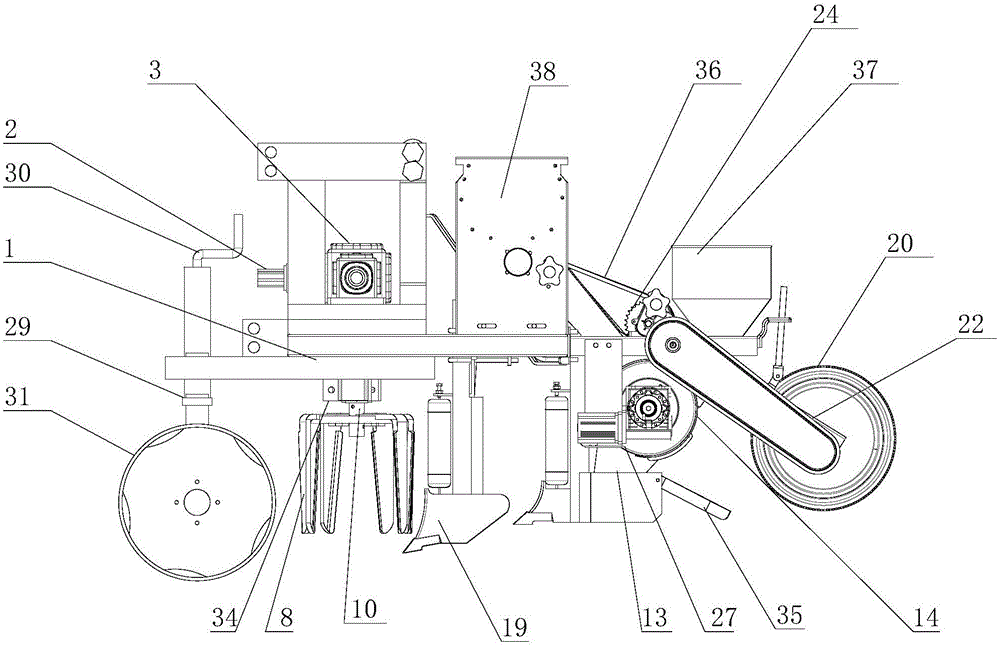

Intelligent air-suction seeder unit

PendingCN109451928AStable jobDoes not affect the depth of sowingPlantingFurrow making/coveringCircular discSeeder

The invention relates to an intelligent air-suction seeder unit, which belongs to the technical field of seeders. By adopting the intelligent air-suction seeder unit, the accurate control of a planting depth and a plant distance can be realized, the seeds can be precisely fed in place, the seeds can be saved, and the crop yield can be increased. A pressure control oil cylinder of a feeler mechanism is fixedly installed on a unit fixing frame and used for controlling a furrowing depth of a furrowing disc of a seeding mechanism, a depth limiting wheel pressure sensor of the feeler mechanism is installed on a tail end of an a depth limiting wheel adjusting handle of a depth limiting mechanism, and the depth limiting wheel pressure sensor is matched with the pressure control oil cylinder and used for transmitting a signal to the pressure control oil cylinder; and a seed metering device of the seeding mechanism is an electric control air-suction seed metering device. By adopting the hydraulic oil cylinder and the depth limiting wheel pressure sensor matched with each other, the hydraulic oil cylinder outputs stable setting pressure according to the signal and the depth limiting wheel pressure sensor, the change of seed quantity and unit weight of a seed box does not influence the seeding depth, the stable work of a furrowing device can be ensured, and the consistency of the furrowing depth and the seeding depth can be ensured.

Owner:黑龙江精播科技开发有限公司

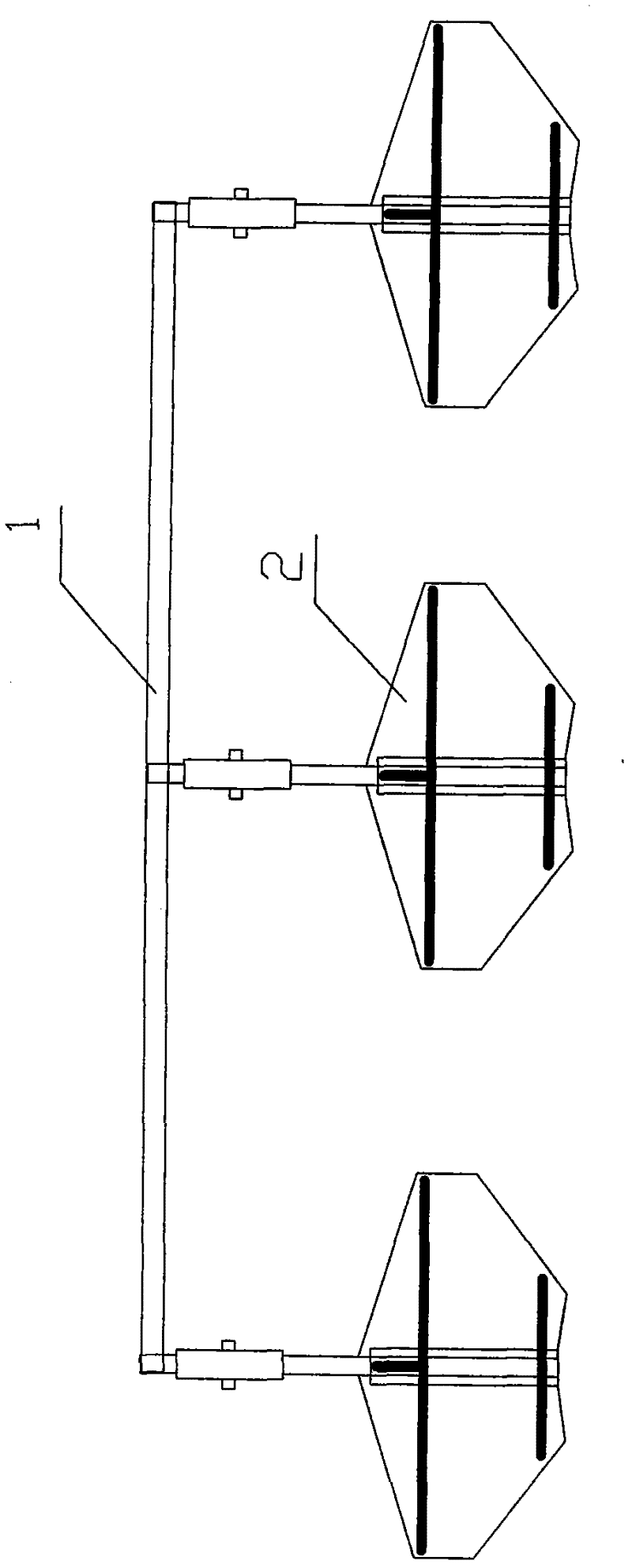

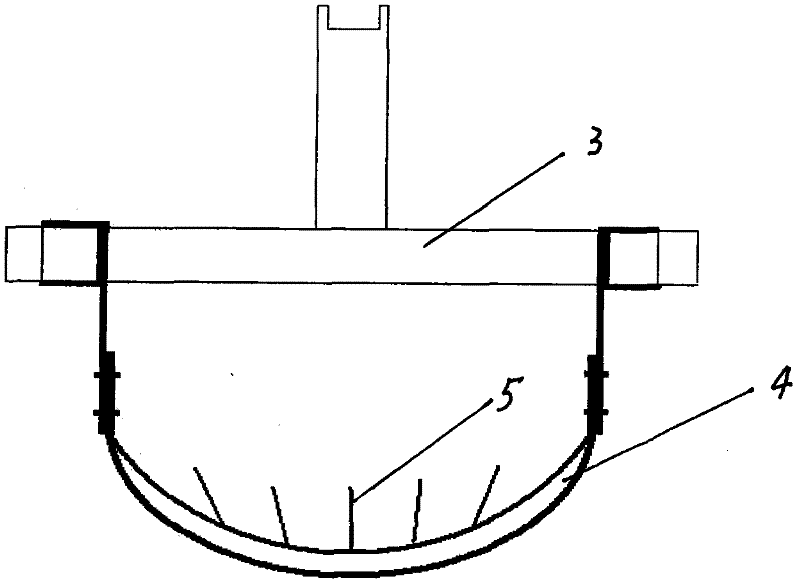

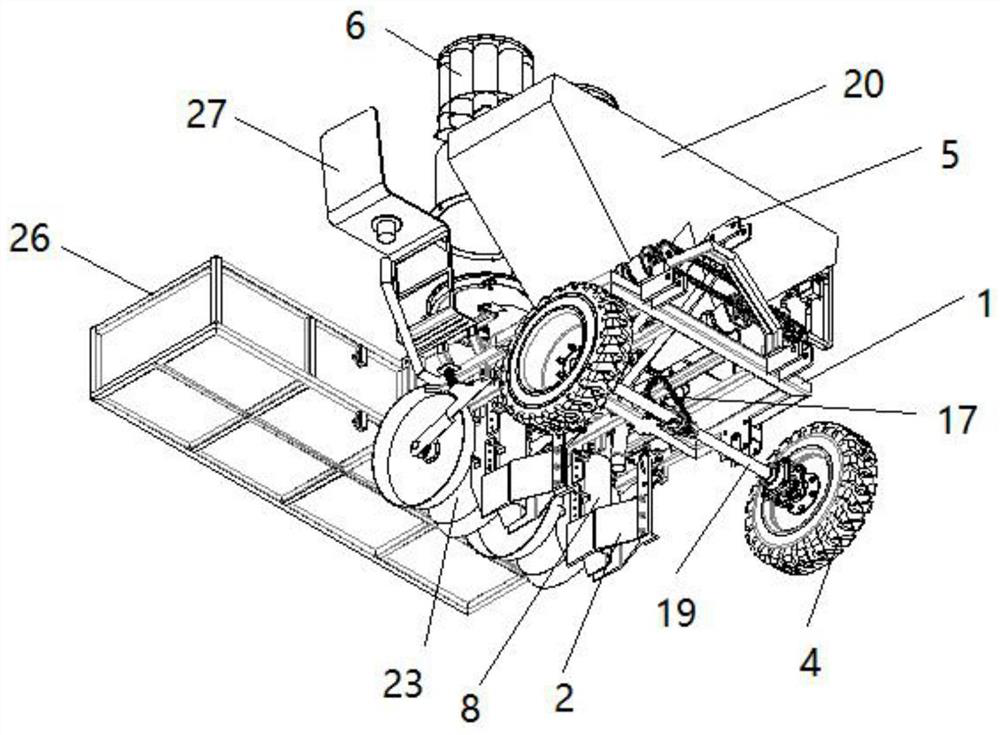

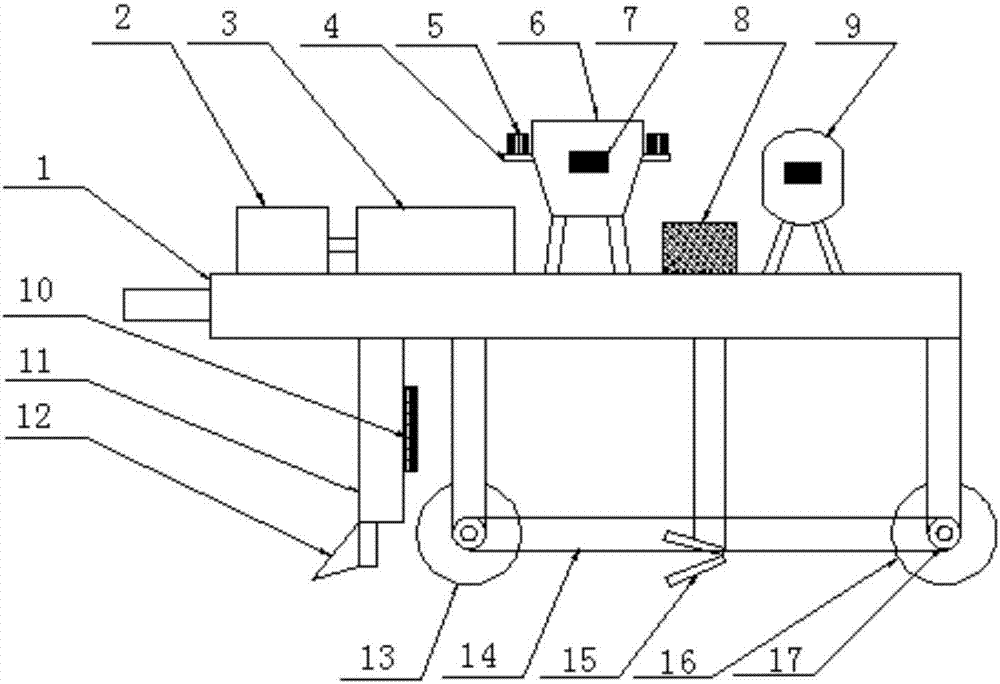

Automatic sand willow planting machine

InactiveCN102318537ACover levelComply with planting process requirementsForestryVegetationDrive wheel

The invention relates to a machine for planting sand willows in farming and stockbreeding areas and desert areas, which comprises a rectangular rack, a three-point suspension traction frame, an air compressor, a wicker inserting cylinder, a wicker gripping cylinder, a continuously variable transmission, a first electromagnetic valve, a second electromagnetic valve, a radiating fan and a walking wheel assembly. The machine is characterized in that the air compressor is driven to work through a universal power input shaft, a walking wheel drives a driven wheel to move to enable the continuouslyvariable transmission to control a multi-tooth cam to work, and the wicker gripping cylinder and the wicker inserting cylinder are driven to work alternately through a bidirectional switch to complete a series of working processes such as wicker gripping and inserting, soil compaction and soil covering. The invention aims at providing an automatic sand willow planting machine which has the advantages that the working efficiency is high, the labor intensity is reduced, the operation quality is ensured and the damage to the original soil vegetation is very small.

Owner:巴图 +2

Method for casing planting of Chinese yam

InactiveCN106386063ATimely and tidy germinationReduce deformityCultivating equipmentsSeed arrangmentsForest yamPlant Tubers

The invention relates to a method for casing planting of Chinese yam. The method comprises the specific steps of preparation of seedlings, land selection and furrow excavation, splicing of a casing device and casing embedding, sowing, excavation of a drainage trench, daily management, and harvesting and storage. The method provided by the invention has the beneficial effects that timely and orderly seedling production after sowing of the Chinese yam can be ensured; growth malformation of the Chinese yam can be avoided; tubers can be formed in an oriented manner; the planting and harvesting become easy and effort-saving; the row spacing and the tuber formation are uniform and consistent, so that the goals of cost-saving, economic and efficient planting of the Chinese yam can be achieved.

Owner:ANHUI HUAFENG AGRI PROD PROFESSIONAL COOP

Mechanical directional half sleeve pipe yam ridge cultivation method

The invention relates to a yam plantation method, in particular to a mechanical directional half sleeve pipe yam ridge cultivation method which comprises the following steps: (1) carrying out deep plowing in winter to improve soil structure and reduce the diseases, pests and of harmful grass in yam land; (2) mechanically ridging in the middle ten days of April in spring by using a yam land ridging machine, wherein the heights of the ridges are 35-40cm; (3) directionally cultivating by using half sleeve pipes; and (4) mechanically harvesting in the middle or last ten days of October by using a yam harvesting plough. The invention has the advantages of saving yam planting and harvesting cost, creating the novel convenient, efficient, directional and labor-cost saving yam cultivating mode, overcoming the defect that the underground water level raises to cause adverse effect to the formation and the yield of the yam which is the tuber crop, solving the problems of mechanical ridge cultivation, high-density planting and mechanical harvesting and promoting the large-scale intensified and industrialized yam production. Due to the adoption of the method, the labor intensity is greatly reduced, the labor efficiency is improved, and the ridges are uniform and have good shapes.

Owner:XUZHOU ACAD OF AGRI SCI

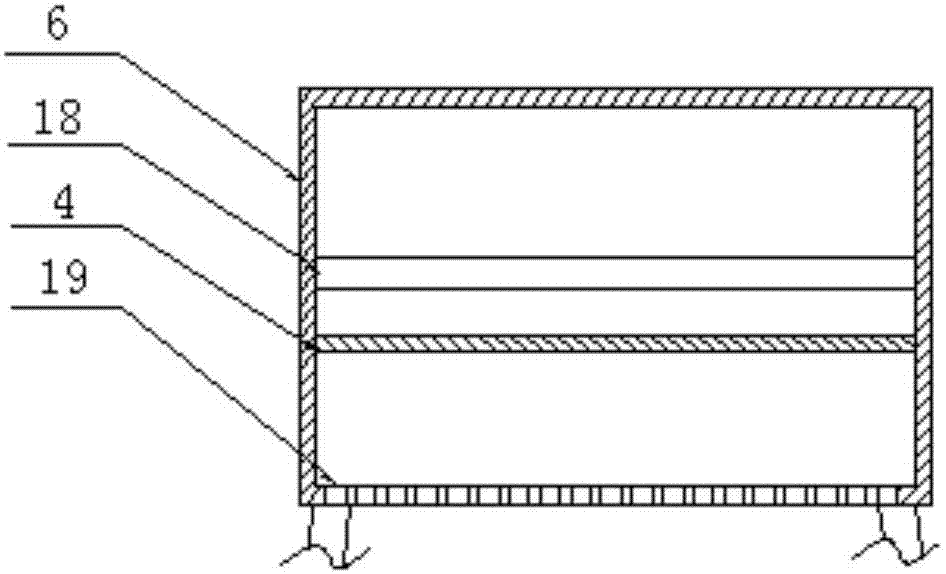

Large-power dye-sensitized solar cell

InactiveCN101694818AImprove performanceImprove reliabilityLight-sensitive devicesSolid-state devicesEpoxyEngineering

The invention discloses a large-power dye-sensitized solar cell. The solar cell comprises a plurality of strip-shaped monomer dye-sensitized solar cells (DSC) that are connected in series or in parallel. The solar cell comprises an upper substrate and a lower substrate, and both of the two substrates face to each other and comprise a plurality of strip-shaped monomer cell areas; a light-anode and a counter electrode are formed on the upper substrate and the lower substrate respectively; and the dye is adsorbed on the photo-anode. The upper substrate and the lower substrate are sealed by glass dust of low melting point or epoxy resin; furthermore, the glass spherules or polymer spherules with the diameter of 20-100 microns are taken as isolation materials; a space with uniform spacing is formed between the upper substrate and the lower substrate with large area; and an electrolyte is filled in the space between the upper substrate and the lower substrate. In the invention, the optical absorption efficiency is improved, the problems of the nano-material dye-sensitized solar cells of TiO2, ZnO and the like, such as bad stability, small area, bad consistency and poor repeatability of the device and the like, are solved, and the solar cell is applicable to the industrial large-scale production.

Owner:EAST CHINA NORMAL UNIV

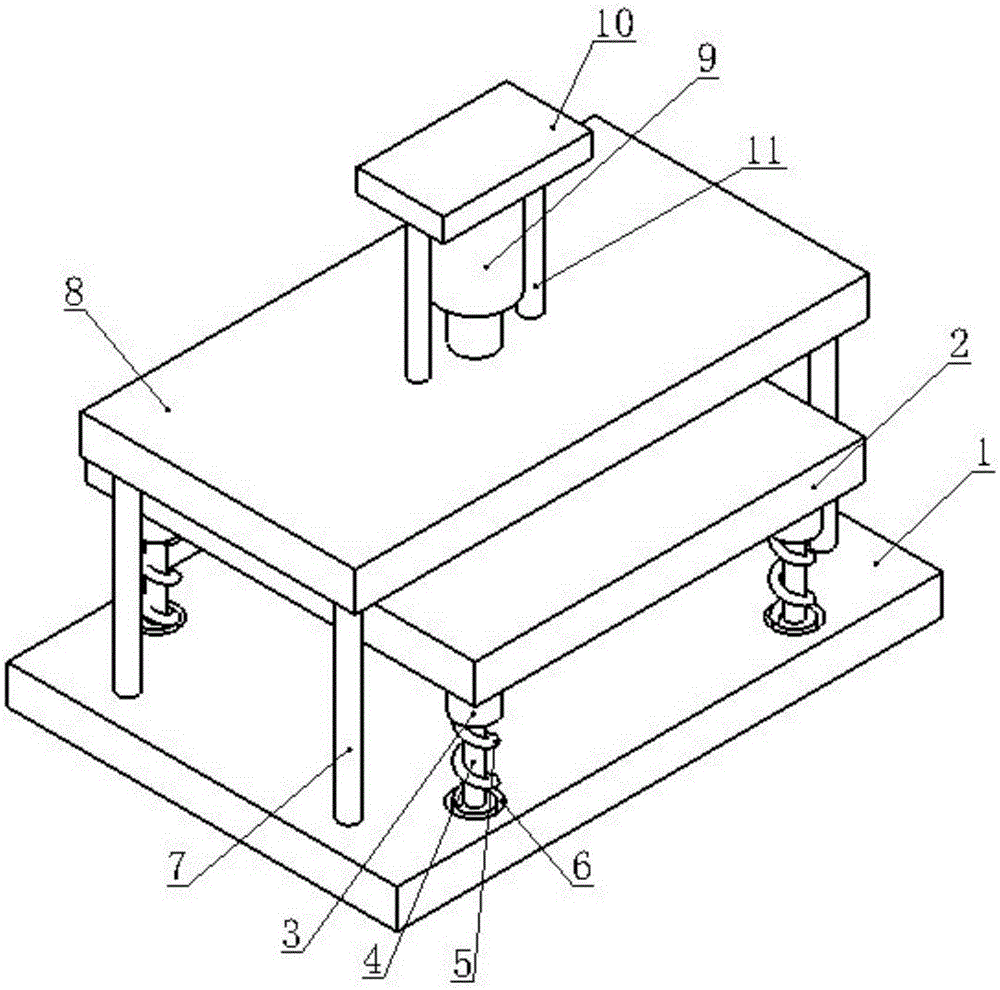

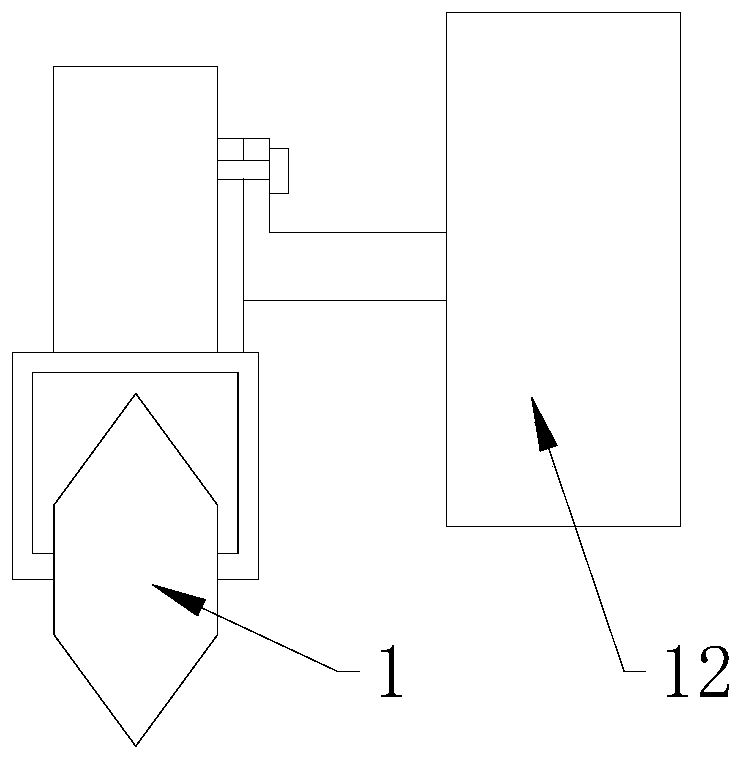

Device for punching traceability steel seal mark

The invention provides a device for punching a traceability steel seal mark. The device comprises a support seat, a mold frame, a plurality of prefix modules, an upper pedestal and a hydraulic cylinder, wherein a plurality of avoidance grooves are formed in the support seat; a plurality of guide sleeves are arranged on the corresponding positions of the mold frame and can partly extend into the corresponding avoidance grooves; the prefix modules are fixed to the bottom of the mold frame; salient mark characters are arranged on the corresponding prefix modules; the top surface of each prefix module is higher than the bottom surface of the mold frame; the upper pedestal is fixedly installed above the mold frame; the hydraulic cylinder is fixedly installed on the upper pedestal; and a piston rod of the hydraulic cylinder is fixedly connected with the mold frame. With the adoption of the device for punching the traceability steel seal mark, the traceability steel seal mark is formed at one time by adopting hydraulic power, fronts are uniform in size, same in depth and unified in interval, the characters are tidy, and meanwhile, the labor intensity is weak.

Owner:TIANJIN XINNUO JINZHI TECH CO LTD

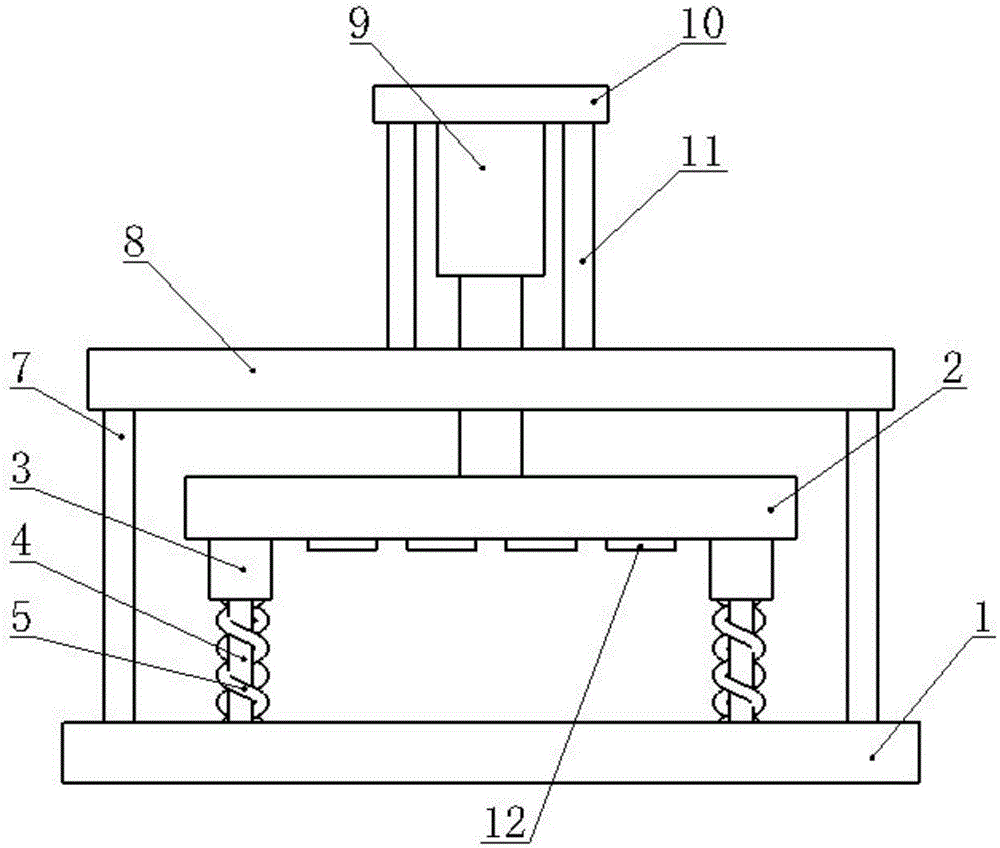

Improved sowing machine

InactiveCN103004337AUniform spacingSimple structureRegular seed deposition machinesAgricultural engineering

The invention relates to an improved sowing machine. The improved sowing machine comprises a rack, a sowing box installed on the rack, and a wheel and a handle respectively arranged at two ends of the rack, wherein a discharging hole is formed on the bottom of the sowing box; the improved sowing machine is characterized in that a sowing mechanism is arranged at the discharging hole, a baffle is arranged between the discharging hole and the sowing mechanism, the sowing mechanism comprises a sowing pipe, a sowing wheel and a sowing storehouse, the sowing wheel is arranged inside the sowing pipe, at least one sowing storehouse is arranged on the sowing wheel, a driving wheel is arranged on a main shaft of the wheel, a driven wheel is arranged outside the sowing mechanism, the driven wheel and the driving wheel are connected by a belt, and the sowing wheel and the driven wheel are linked. The improved sowing machine has the advantages that the structure is simple, the operation is convenient, the sowing mechanism is used for sowing so that distances among seeds are uniform, the manufacturing cost is low, so the improved sowing machine is suitable for fundamental states of vast rural areas in China, the time and labor are saved, and the work efficiency is improved.

Owner:倪卫星

Sugarcane single-bud precision sowing and planting method

ActiveCN109984005AHigh in sugarReduce the amount of plantingBiocideSugarcane cultivationSaccharumSucrose

The invention discloses a sugarcane single-bud precision sowing and planting method and belongs to the technical field of planting. The method comprises the steps of soil preparation, variety selection and sowing time determination, seed stem preparation and treatment, planting by a sugarcane single-bud precision seeder and the like. According to the method, a pretreated sugarcane single bud segment is used as a seed stem for sowing and planting, and the processes of sowing, spraying a bottom fertilizer, covering with soil, spraying a pesticide and covering with a film are completed at one time through the sugarcane single bud precision seeder, so that monitoring and intelligent control of the seeding process of the sugarcane are realized, reasonable close planting is also realized, and the purposes of greatly reducing the seeding quantity, improving the germination rate and increasing the yield are achieved. The seeding quantity per mu of single-bud precision planting is about 0.1 ton, and the seed consumption is saved by 90% or above compared with a traditional seeding method; and the yield per mu of single-bud precision sowing and planting method is increased by 15% or above compared with a traditional planting method, and the sugar content of the sucrose is increased by 0.3% or above.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

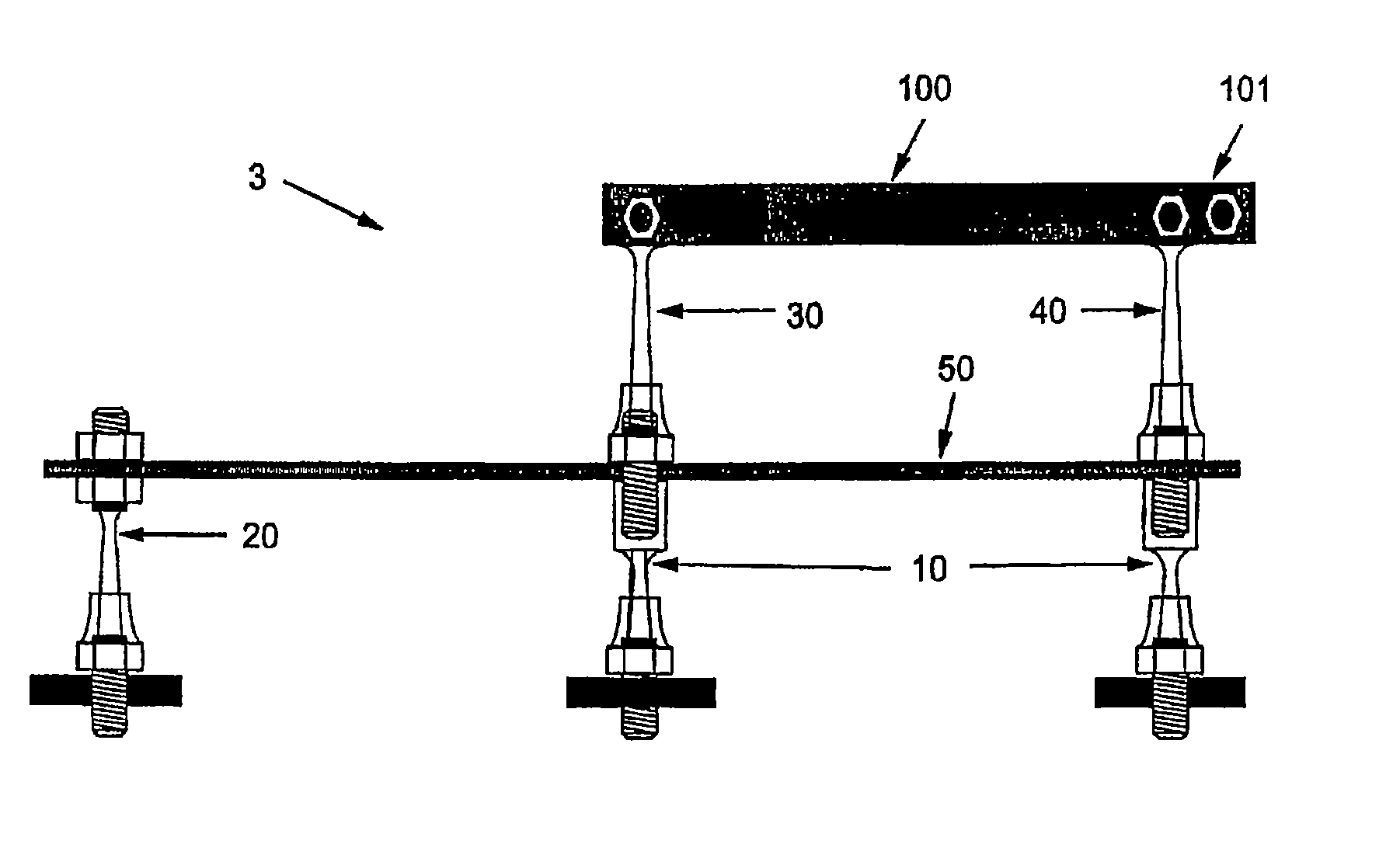

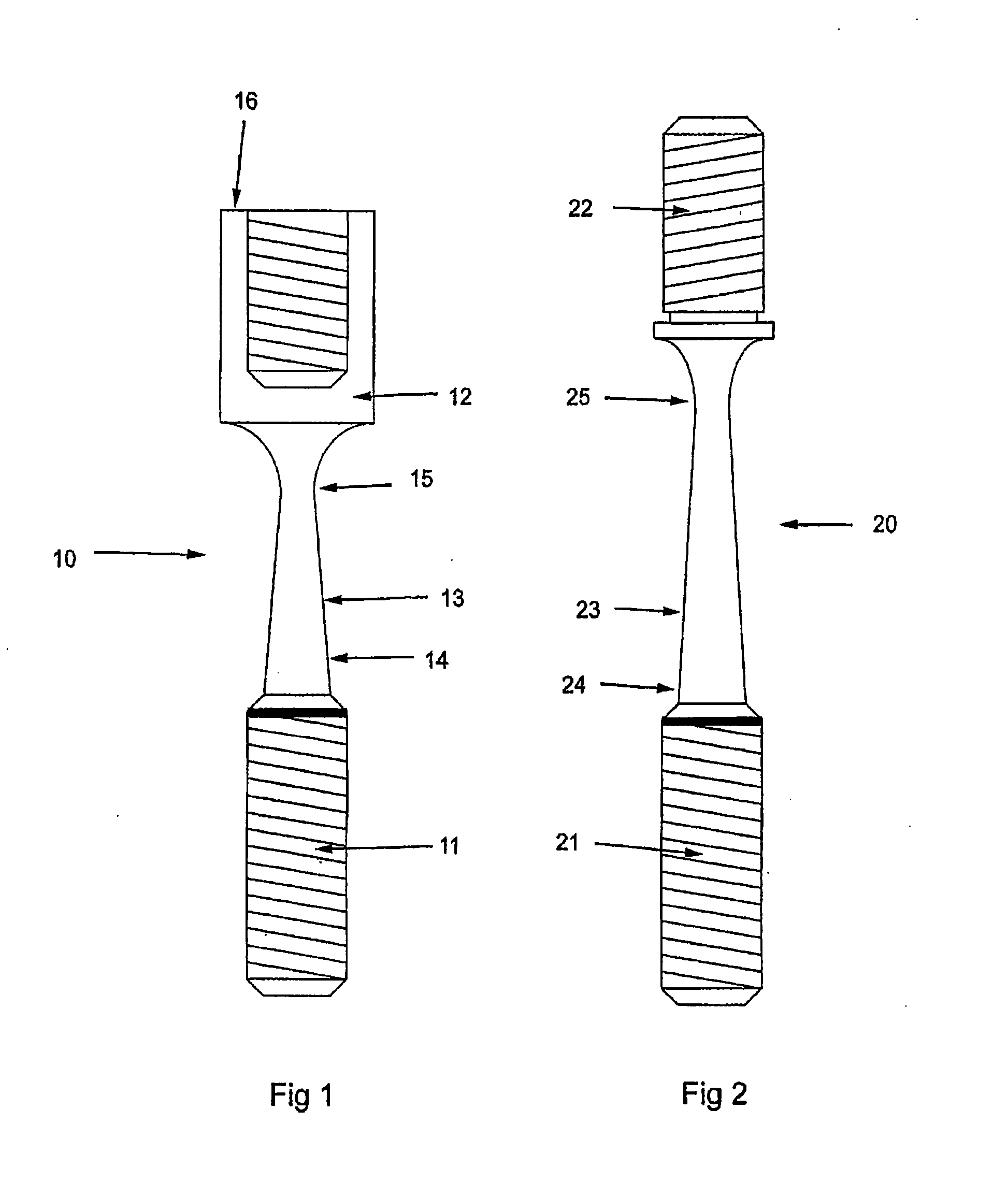

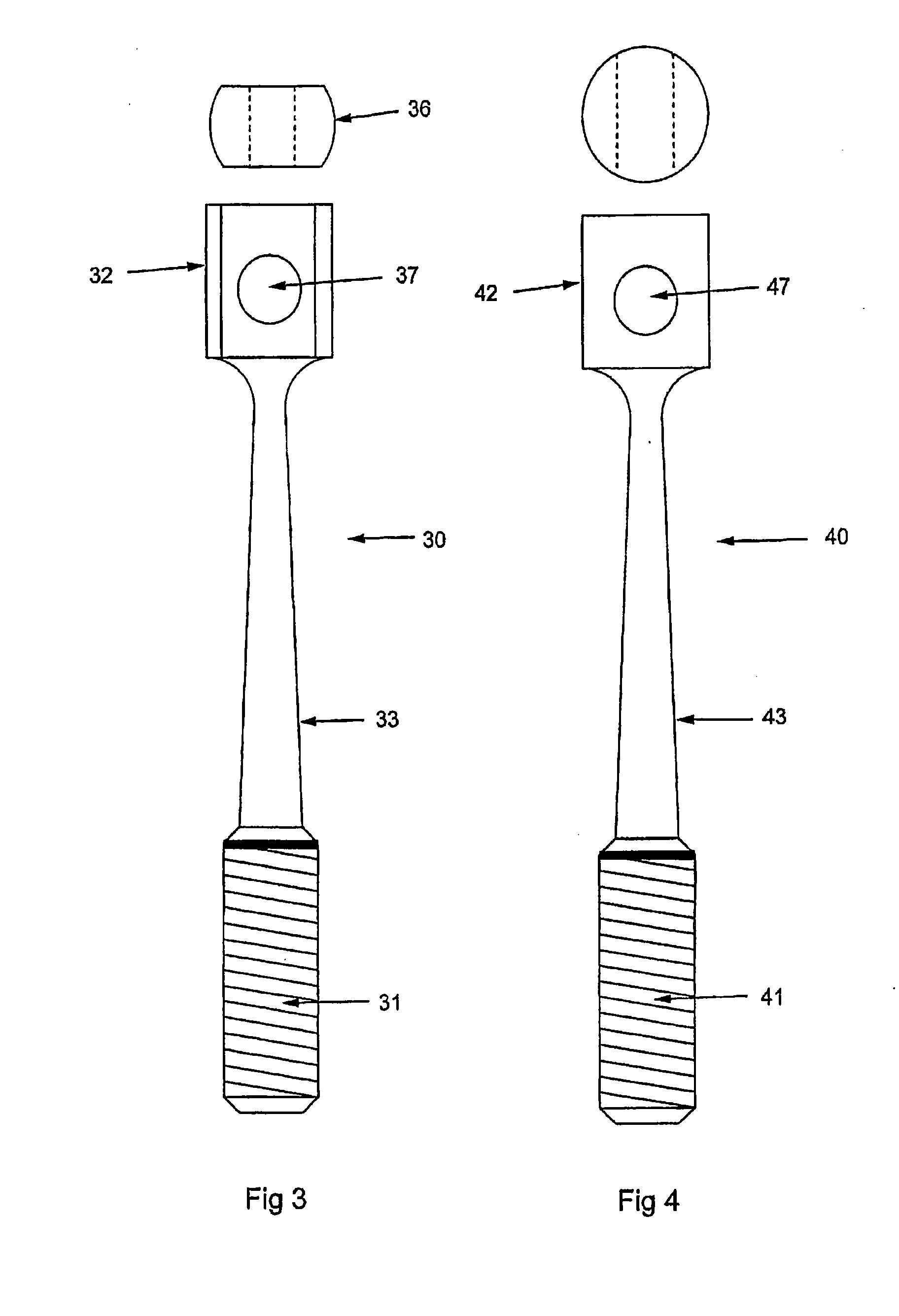

Anchor assembly for safety device

InactiveUS20060272892A1Uniform spacingAdd energy absorption capabilitySafety beltsBuilding rescueEngineeringKinetic energy

An anchor assembly (3) for securing at least one safety device indirectly to a structure is disclosed. The anchor assembly includes at least two spacers (10,20), including a first spacer and a second spacer; at least one bridging member (50) spanning between the spacers; and engagement means (30,40) for securing the safety device to the anchor assembly. Each spacer includes securing means for securing the spacer directly to the structure; a head for fastening the spacer to the bridging member and / or to the engagement means; and a shaft extending between the securing means and the head. The shaft of at least the first spacer is adapted to deform progressively so as to at least partially absorb the kinetic energy applied by a load of a falling object attached to the safety device.

Owner:ARVO POLDMAA KATHLEEN POLDMAA ROBYN POLDMAA & DANIEL POLDMAA

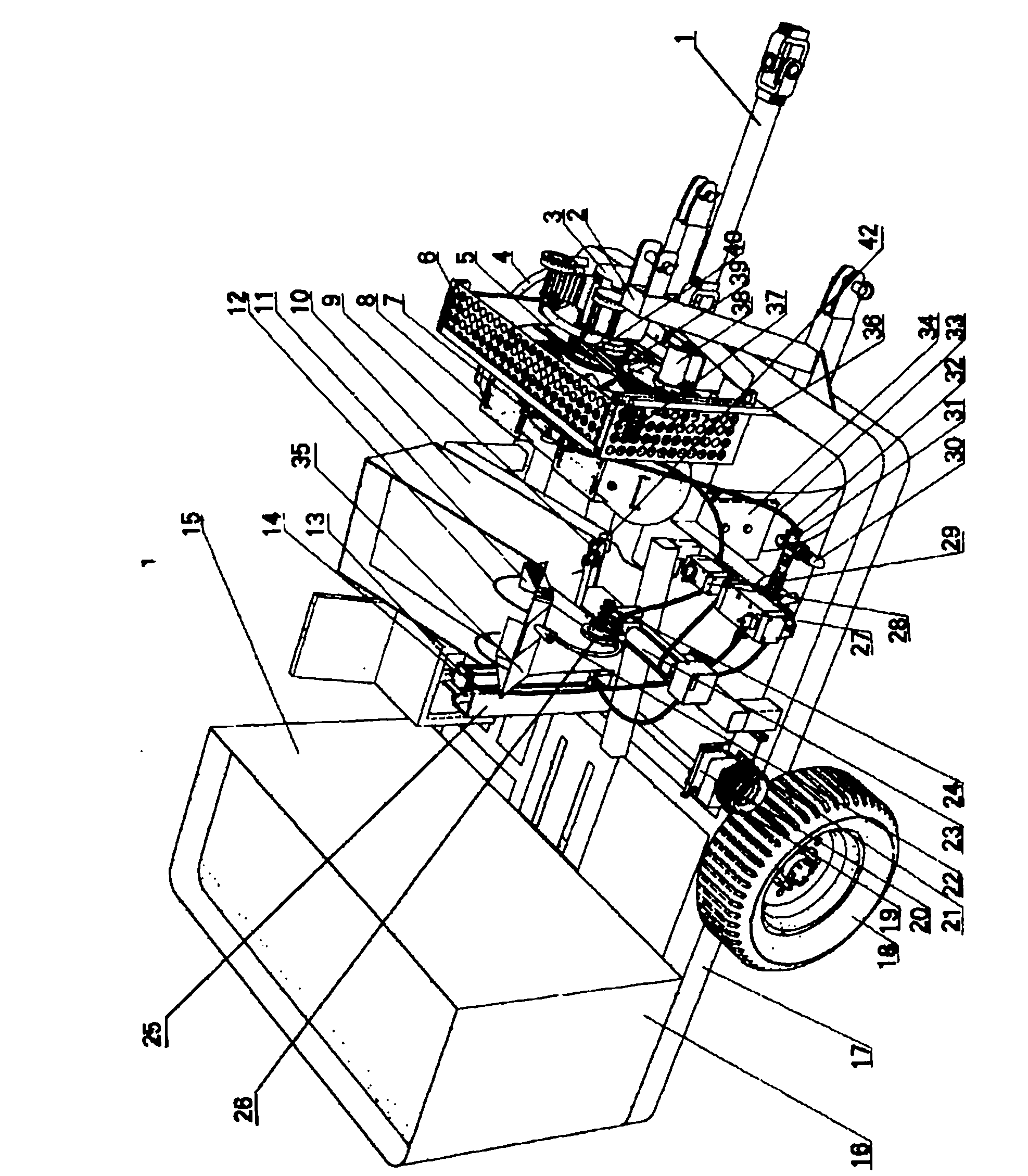

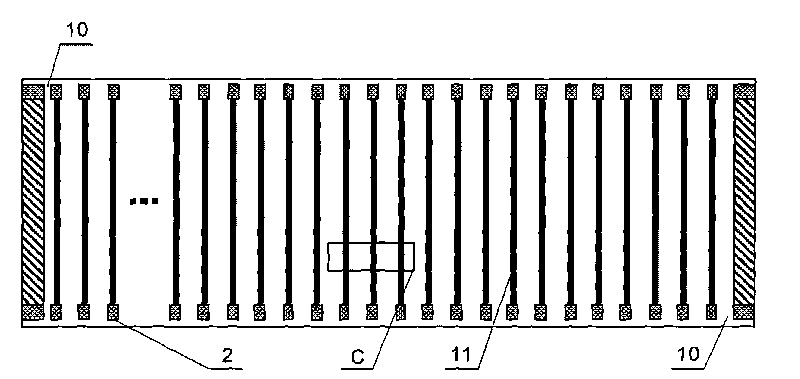

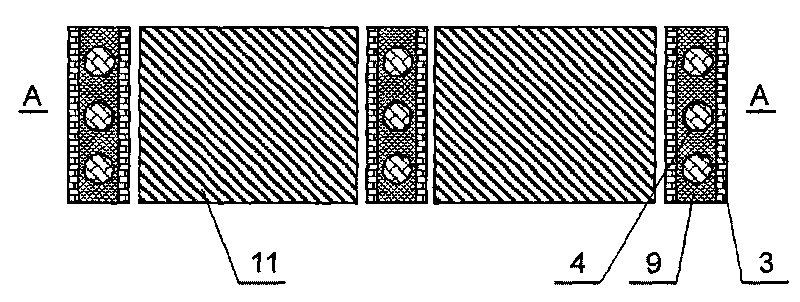

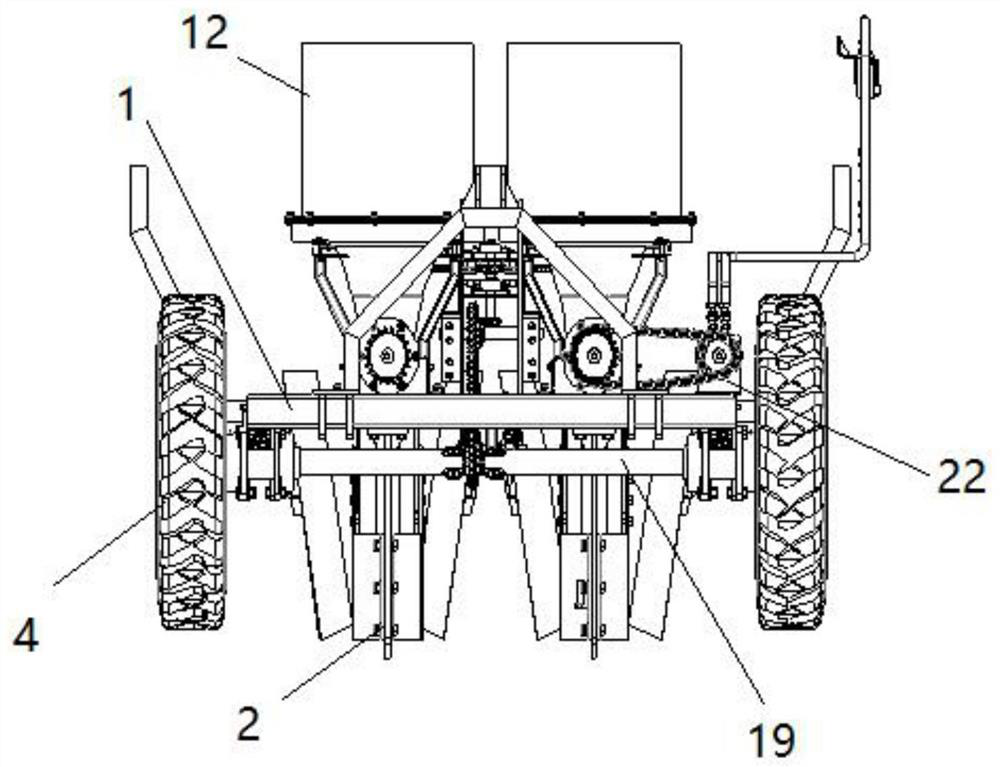

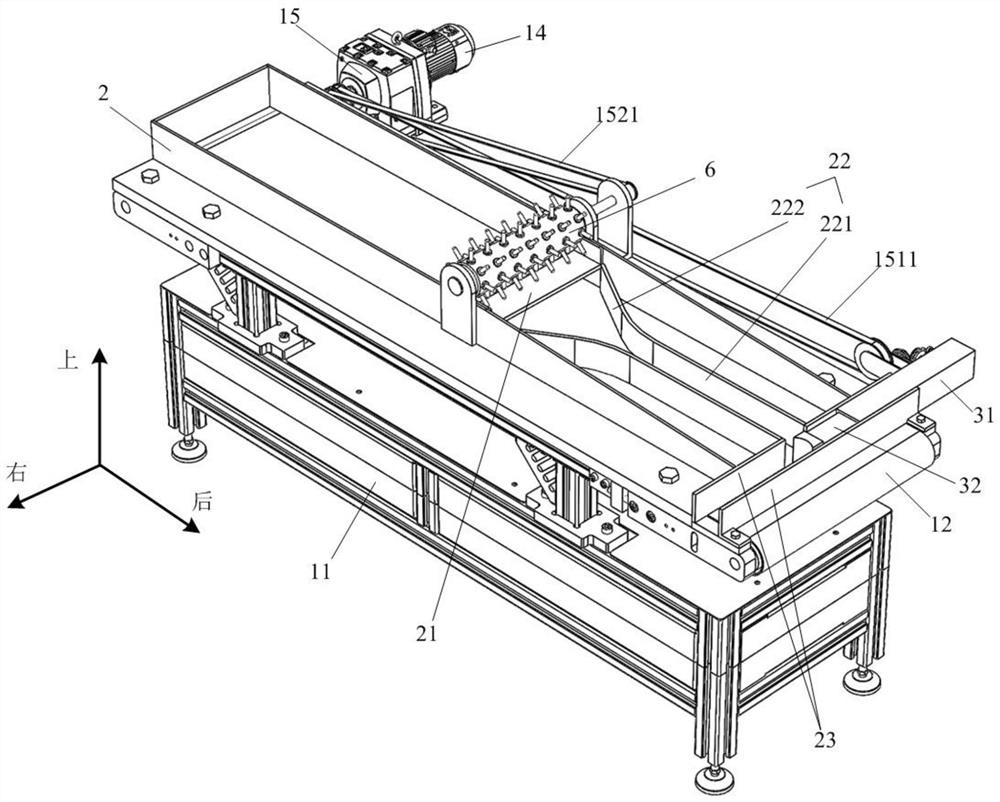

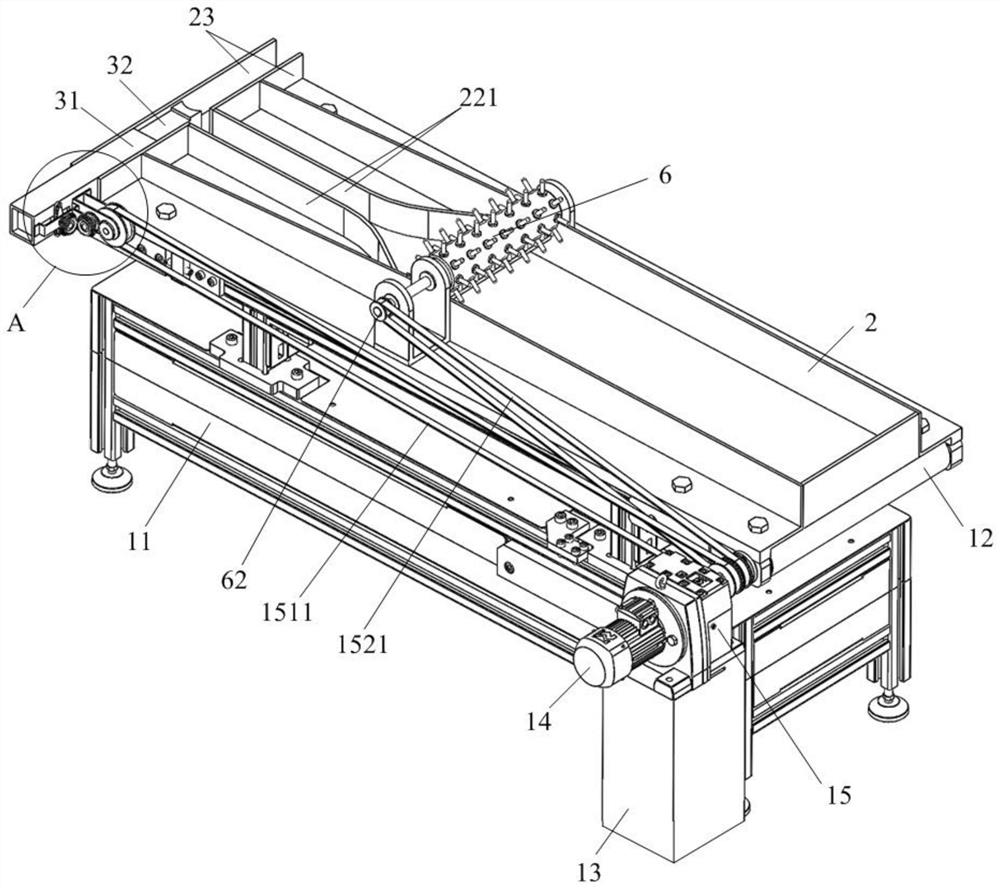

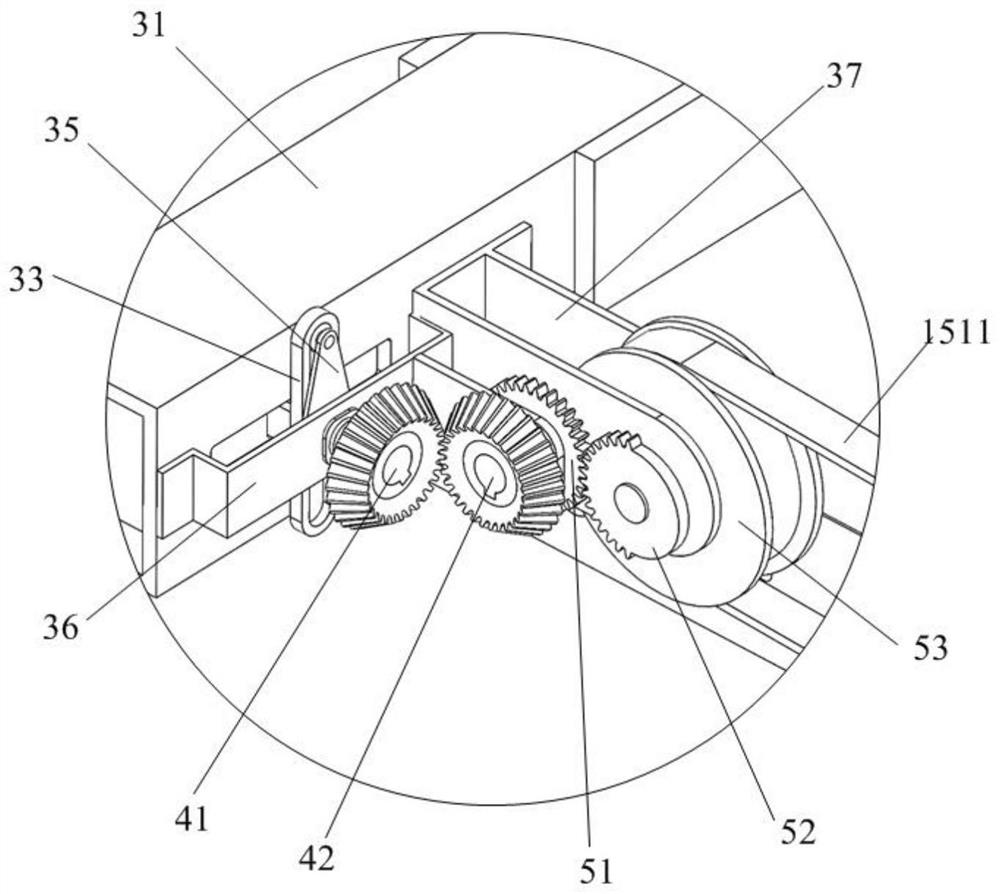

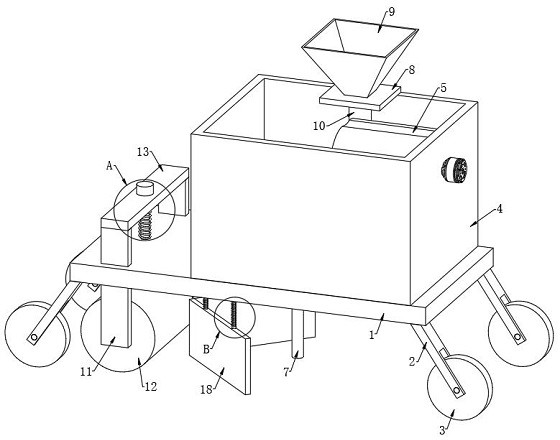

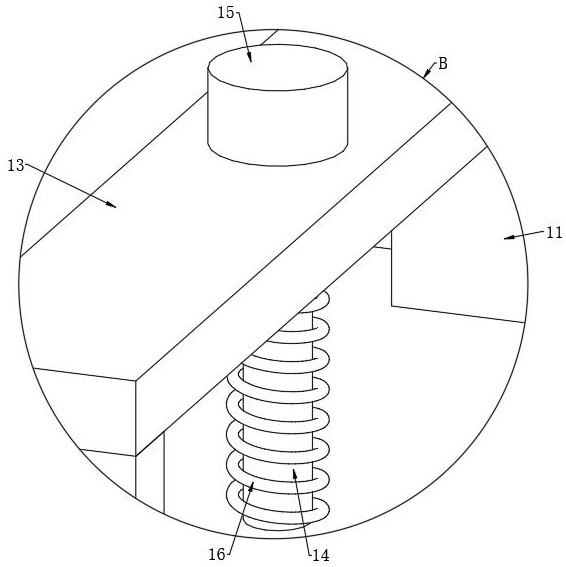

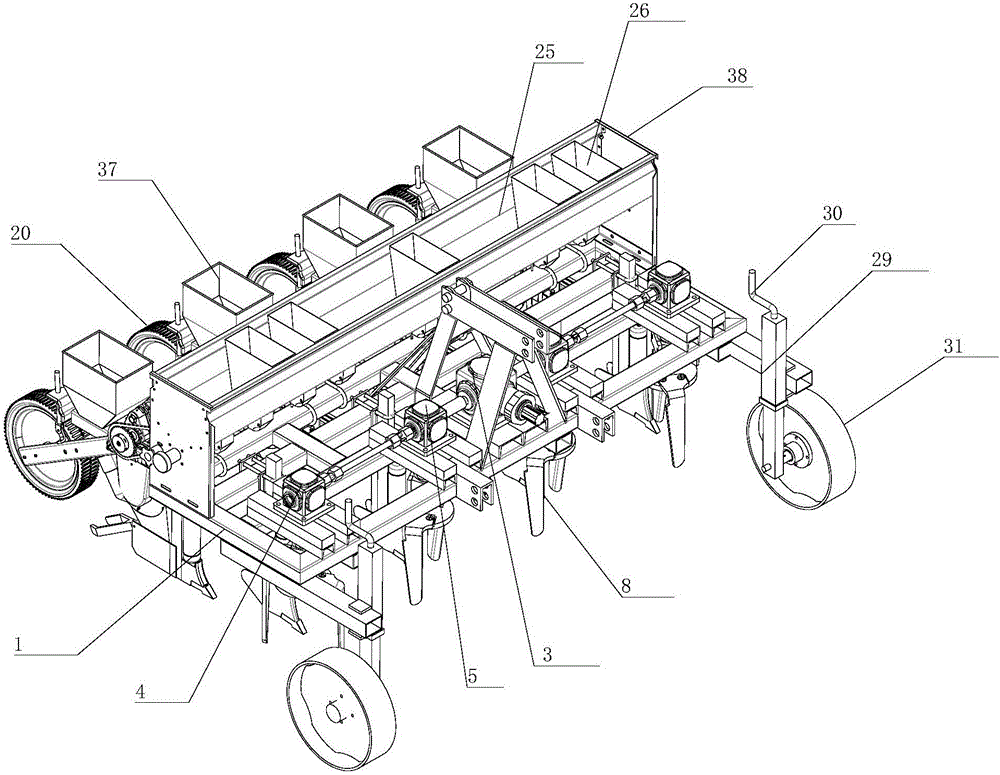

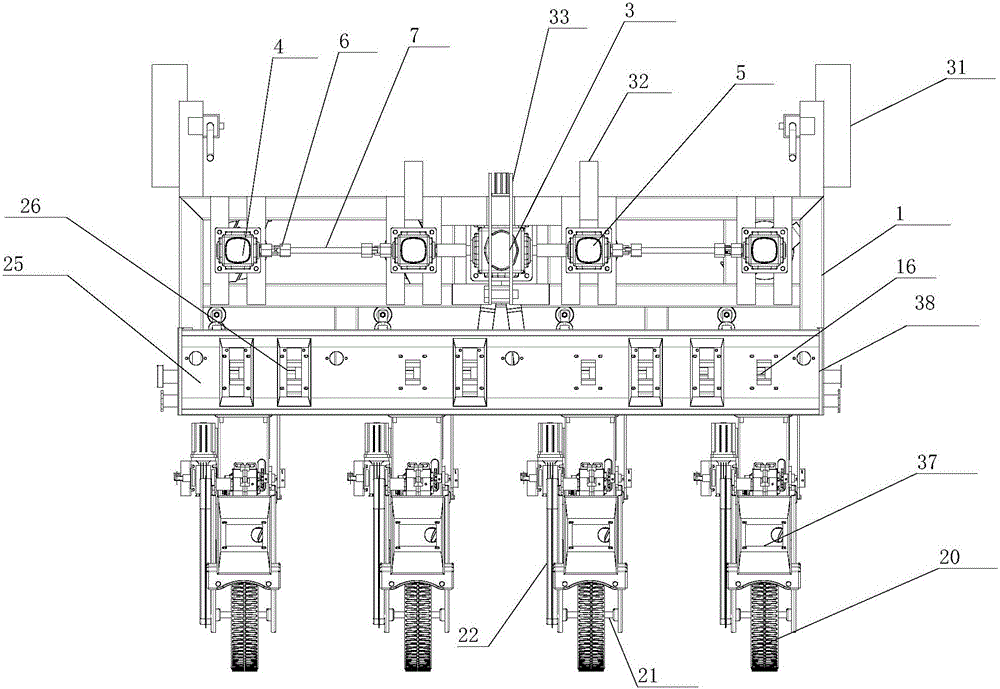

Sugarcane single-bud precise seeder

ActiveCN109964606ARealize monitoringRealize intelligent controlPlantingWatering devicesMonitoring systemAgricultural engineering

The invention discloses a sugarcane single-bud precise seeder, and belongs to the technical field of agricultural machinery. A ditching device, a sowing device, a soil covering device, a watering mechanism and a film covering device are sequentially arranged on a main frame from front to back, wherein the sowing device is used for sowing sugarcane seeds in ditches formed through the ditching device, and then, the soil covering device, the watering mechanism and the film covering device sequentially carry out soil covering, watering and film covering on the ditches. The seeder also comprises aseeding monitoring system, and the seeding monitoring system comprises a central controller, and a walking detection unit and a sowing monitoring unit which are connected with the central controller.The walking detection unit is used for detecting and acquiring the walking speed and travel data, and the sowing monitoring unit is used for detecting and recording sowing information of the sowing device, giving an alarm according to the sowing information when the number of the sugarcane seeds is insufficient, and controlling the rotation speed of a power mechanism according to the speed so as to adjust the sowing speed of the sowing device, so that the plant spacing of the sugarcane seeds in the ditches is uniform, and the sugarcane seeding process is monitored and intelligently controlled.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

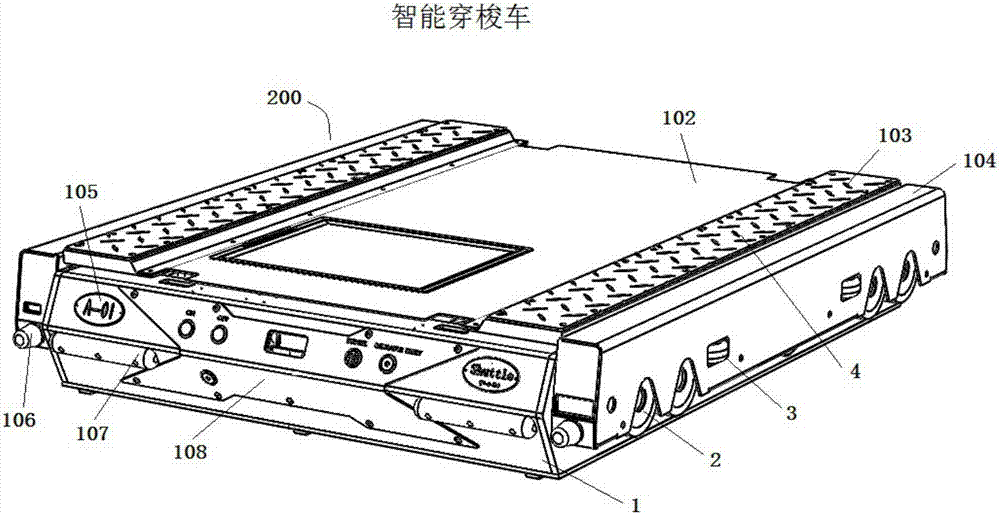

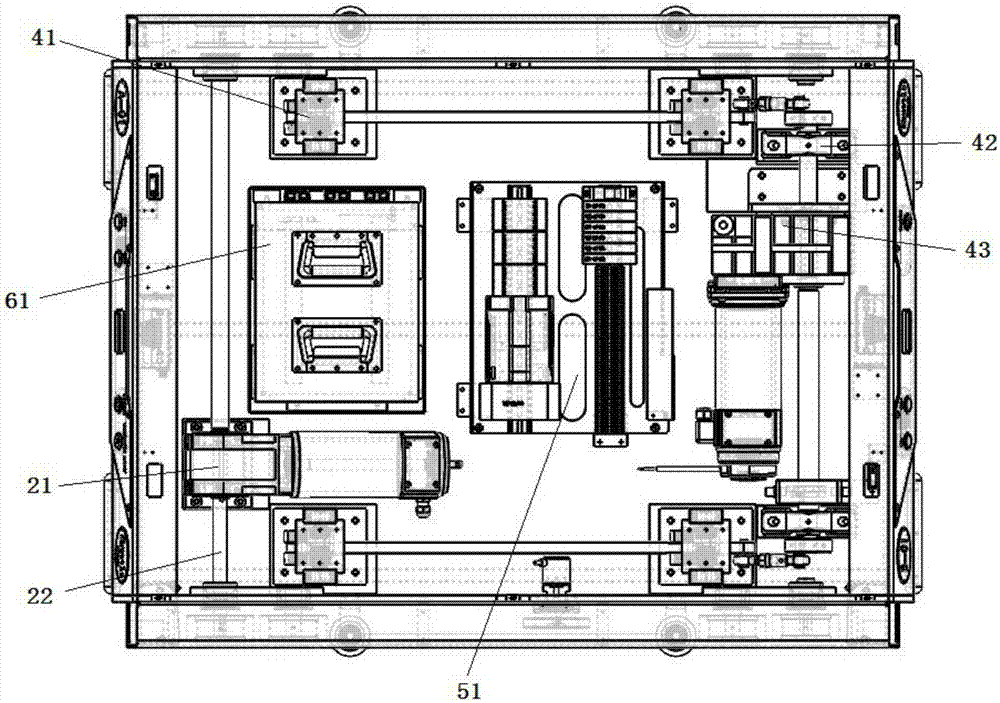

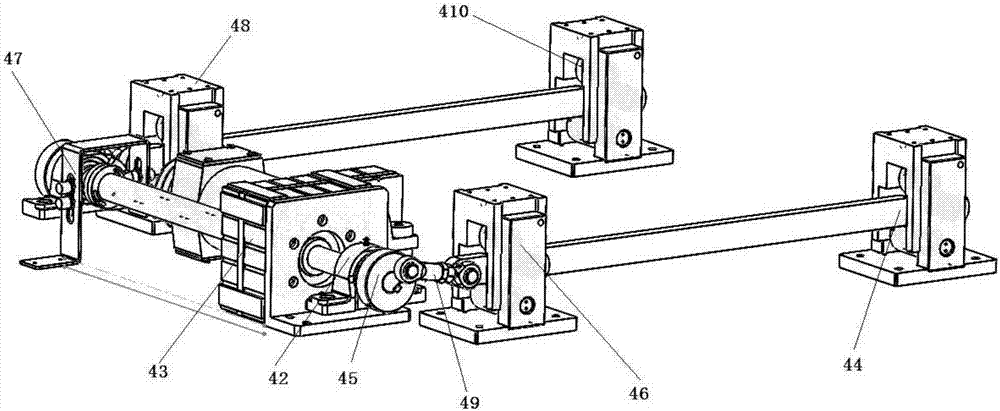

Shuttle vehicle

The invention discloses a shuttle vehicle. The shuttle vehicle comprises a vehicle frame and a travelling mechanism fixed to the vehicle frame and further comprises a lifting mechanism and a detecting device which are fixed to a rack. The travelling mechanism is driven by a motor to move, the lifting mechanism is driven by the motor to drive a connecting rod arranged on the rack to act to complete the lifting action, and after detecting signals of the detecting device fixed to a rack are processed, the travelling and lifting actions are controlled. Products can be stored and output in a semi-automatic mode, the inconvenience when a forklift drives into a passage to store and take goods in traditional storage is avoided, a large amount of site space and production cost are saved, and the production efficiency is improved.

Owner:南京冠帝仓储设备有限公司

Automatic feeder for bakery products

ActiveUS20070166145A1Efficiently and continuously formUniform spacingBaking ovenControl devices for conveyorsLinear actuatorHeadstock

An automated feeder transports pastry product dishes and / or moulds and includes a movable headstock arranged transversely above a first conveyor. The headstock includes an upper plate, a main linear actuator attached thereto, a lower mobile plate extendable by the main linear actuator, and a plurality of magnetic elements attached to the lower mobile plate. The magnetic elements hold a plurality of metallic plates in a predetermined arrangement. The headstock also includes at least two secondary vertical linear actuators disposed on the upper plate for actuating a releasing mechanism to dislodge the dishes from the magnetic elements and a transportation mechanism to provide longitudinal movement along a pair of longitudinal rails. The transportation mechanism permits the headstock to move between a first position over the first conveyor to a second position over a second.

Owner:GRUPO BIMBO B DE C V

Method for planting rivier giantarum rhizome through ditching, film laying and ridging

InactiveCN105493821ADisease resistanceEasy to digPlant cultivationCultivating equipmentsDiseasePlastic mulch

The invention discloses a method for planting rivier giantarum rhizomes through ditching, film laying and ridging. The method achieves fertilizer conservation, heat preservation, disease resistance, high yield and convenient digging. The method comprises the specific steps that 50-300 g of rivier giantarum rhizomes are selected as seed rivier giantarum rhizomes; ditches with the width of 0.8-1.2 m and the depth of 20-30 cm are dug, and black microhole mulching films are laid on the bottoms of the ditches; farmyard manure is laid on the black microhole mulching films and covered with soil with the thickness of 2-5 cm; the seed rivier giantarum rhizomes are placed on the soil layer according to the certain row spacing and line spacing, and then earthing and ridging are carried out, wherein the height of ridges is 20-40 cm; the ridge faces are covered with grass with the thickness of 2-5 cm; 1000-1500 jin of farmyard manure is applied to each mu of land. A row of corn can be planted on the sides of the ridges. The fertilizer efficiency can be sufficiently utilized, the production cost is reduced, it is ensured that the rivier giantarum rhizomes are dug conveniently and rapidly, and the digging cost can be saved by 400-500 yuan for per mu.

Owner:竹溪县泉溪益群魔芋专业合作社

Dibber for crop breeding and exact cultivation test

InactiveCN101480125AUniform spacingSame shadeFertiliser distributersHand sowing implementsEngineeringRebar

The invention discloses a dibbler for crop breeding and exact culture test, which comprises a framework and a vessel used for storing seeds, wherein a plurality of steel pipes are evenly distributed at the bottom of the framework, reinforcing steels capable of being inserted into the steel pipes are arranged on all the steel pipes, the lengths of the reinforcing steels are more than those of the steel pipes, the reinforcing steels penetrate through the steel pipes for motion, all the reinforcing steels are connected together through a transverse pipe which is connected with a rod part through a bent plate, the length of the rod part more than that of the framework, the rod part slides up and down in the center of the framework to drive the reinforcing steels to move up and down in the steel pipes, an inclined pipe is also arranged on the side surface of each steel pipe, a pipeline is connected to the inclined pipe, and the pipeline is connected with a seed outlet opening at the bottom of the vessel; the vessel is arranged above the framework, and a seed metering device is arranged at the bottom of the vessel. The invention can ensure that the interplant spacing, the row pitch and the depth are basically consistent for the crop seed seeding and ensure the single-seed sowing and can especially perform the anti-drought sowing. The dibbler has the advantages of simple structure, convenient operation and higher efficiency.

Owner:NORTHWEST A & F UNIV

Transplanting and fertilizing machine for pineapples

PendingCN111670657AHigh degree of integrationImprove work efficiencyFertiliser distributersTransplantingAgricultural engineeringTransplanting

The present invention discloses a transplanting and fertilizing machine for pineapples. The transplanting and fertilizing machine for pineapples comprises a machine frame, a fertilizing device and a transplanting device at a top side of the machine frame, and furrow openers and soil pressing wheels on a bottom side of the machine frame, the transplanting device is arranged at a rear side of the fertilizing device, the furrow openers are arranged at a bottom side of the fertilizing device, a seed guiding groove is arranged at a rear side of the furrow openers, the soil pressing wheels are arranged at a rear side of the seed guide groove, land wheels are also arranged on a bottom side of the machine frame, and a front side of the machine frame is connected with a tractor through a three-point suspension bracket. The transplanting and fertilizing machine for pineapples can carry out semi-automatic integrated operations of ditching, transplanting, fertilizing, etc., on pineapple seedlings,transplanted plants are consistent in row spacing, fertilizing is uniform, working efficiency is high, and operations are simple, safe and reliable.

Owner:AGRI MACHINERY INST CHINESE TROPICAL ACAD OF SCI

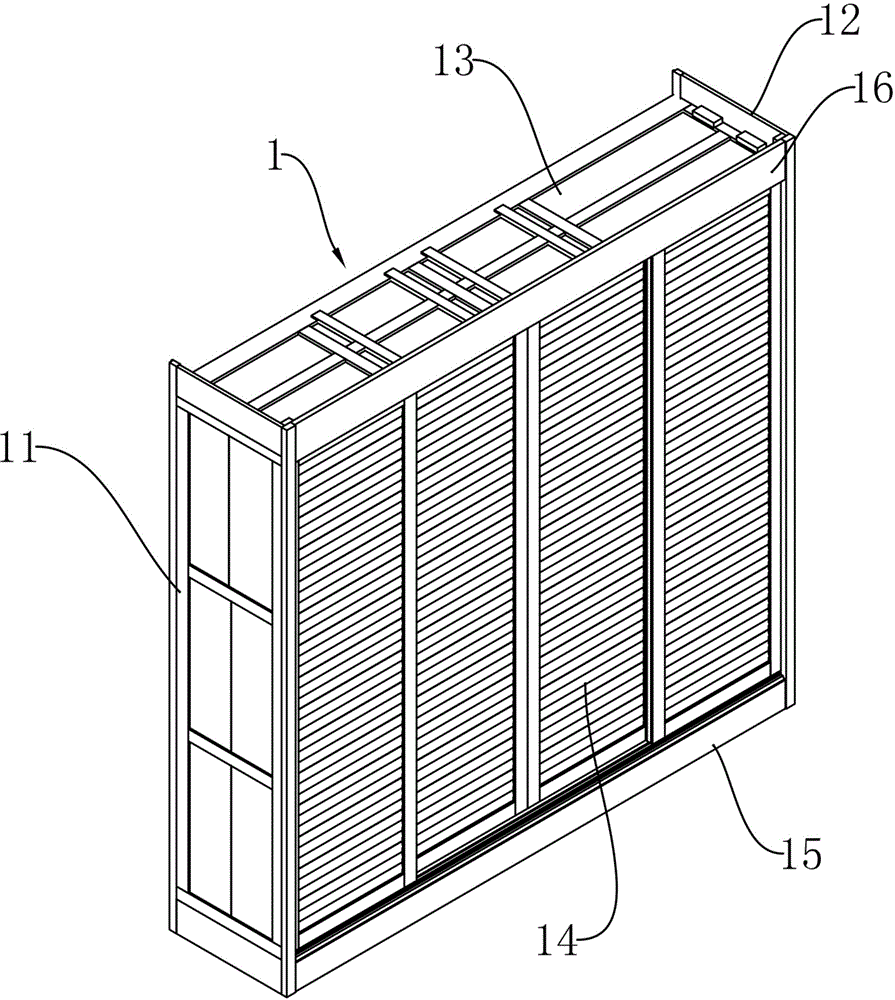

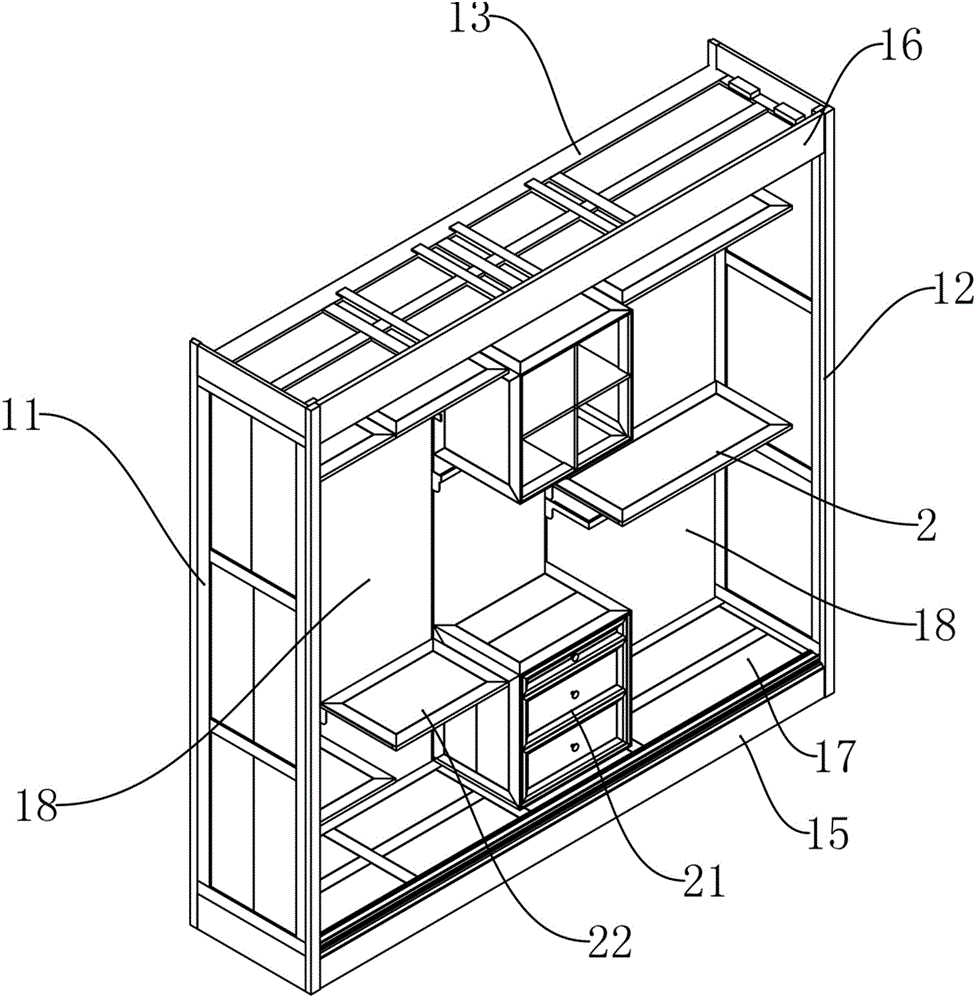

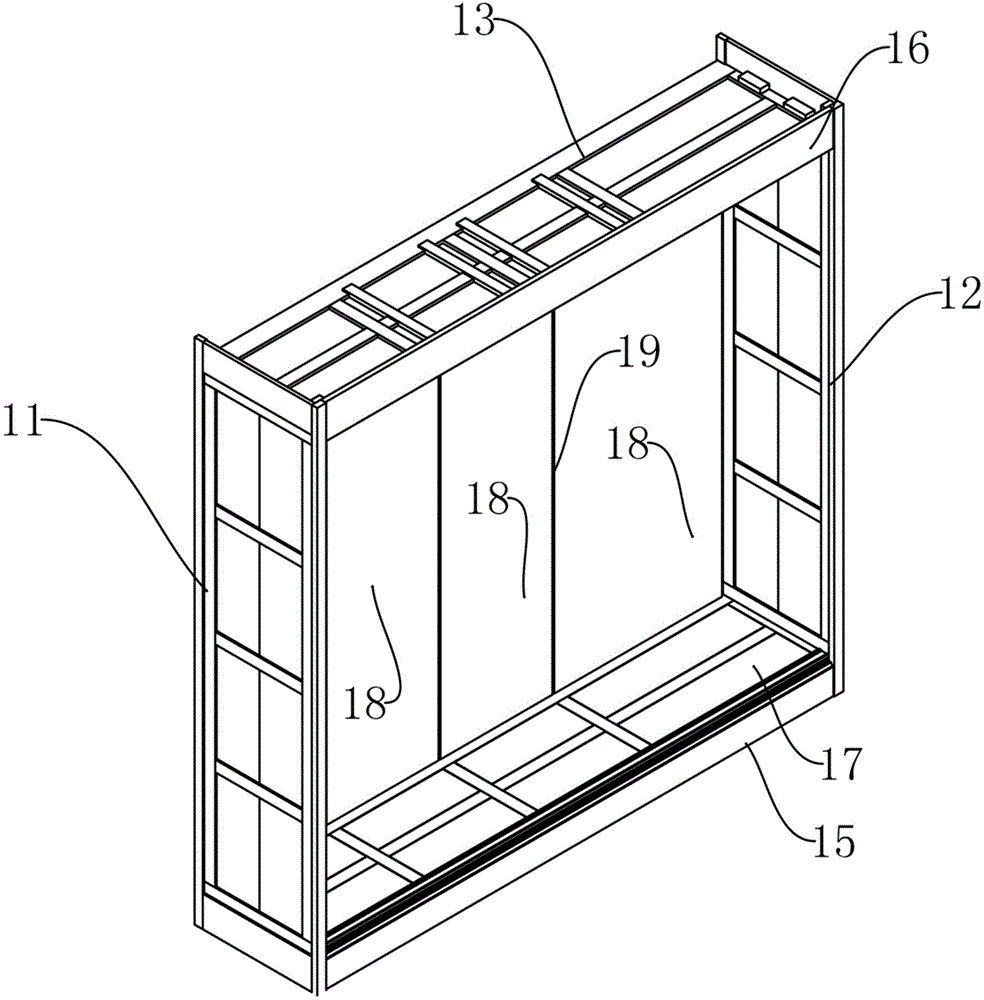

Disassembly and assembly type wardrobe

ActiveCN104814607ADoes not affect connection stabilityEasy to lean onFurniture partsDismountable cabinetsEngineering

The invention relates to a detachable wardrobe which comprises a back plate, a bottom plate and a metal bottom frame system. The metal bottom frame system comprises at least two L-shaped hollow metal bottom frames arranged in a left and right spacing mode and side by side. The metal bottom frames comprise vertical stand columns and horizontal columns, wherein the vertical stand columns and the horizontal columns are connected into one. The inner side walls of the vertical stand columns are provided with first clamping holes arranged at intervals. A plurality of the first clamping holes are formed in the extending direction of the vertical stand columns. The bottom plate is arranged on the horizontal columns, and the back plate is vertically arranged on the vertical stand columns. The first clamping holes are exposed out of the two sides of the back plate. The bottom plate and the horizontal columns are connected through a stud or the left and right metal bottom frames are connected through a transverse connecting rod. Accordingly, the wardrobe can be disassembled and assembled on site, the whole stability of the wardrobe is improved by means of the metal frames, the metal frames bear the main weight of the wardrobe, the number of installation holes in the side wooden plate or the bottom wooden plate or the top wooden plate can be reduced, and the thickness, namely, the adopted amount of the side plate or the bottom plate or the top plate can be reduced.

Owner:佛山市南海树和家具有限公司

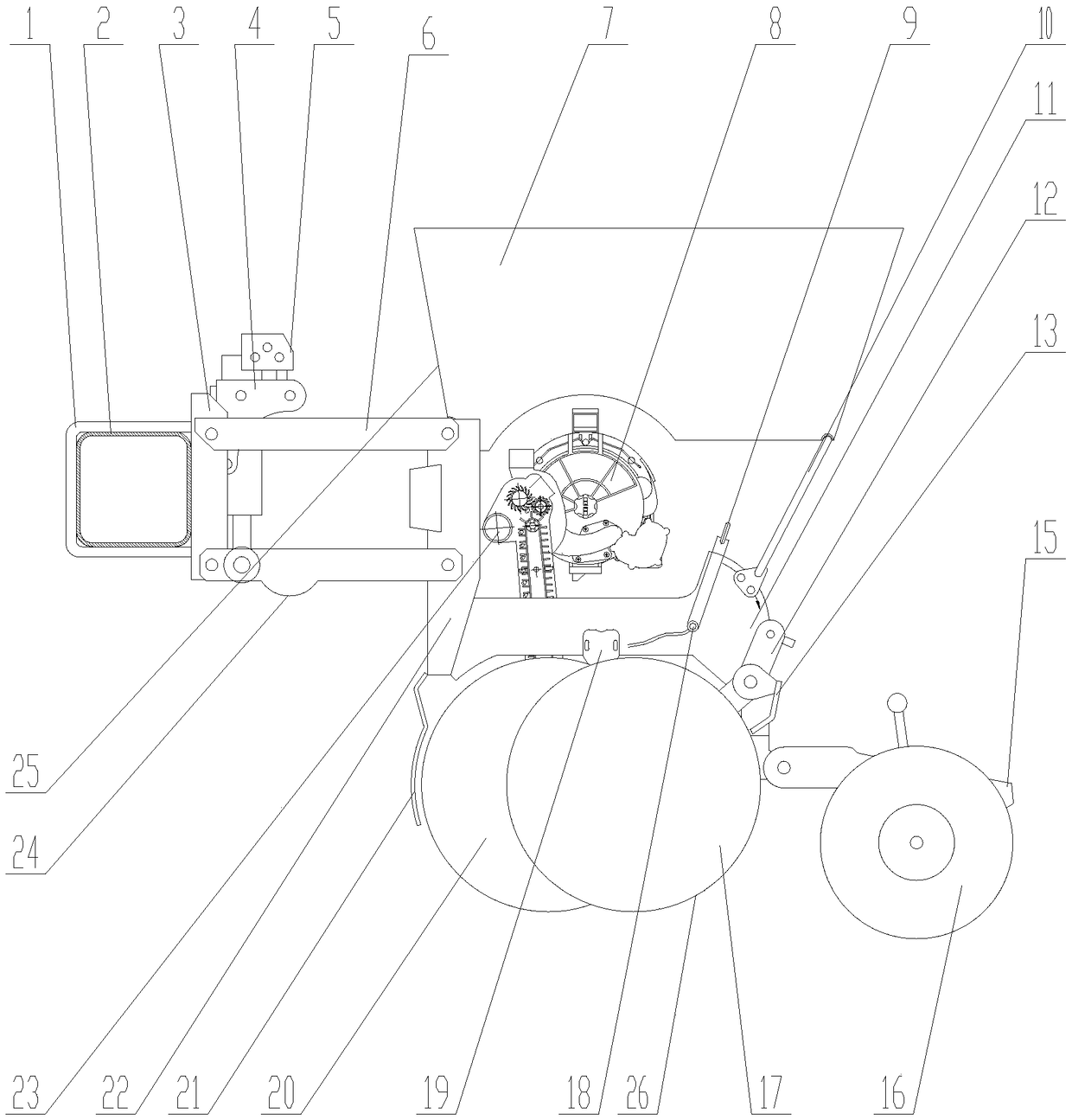

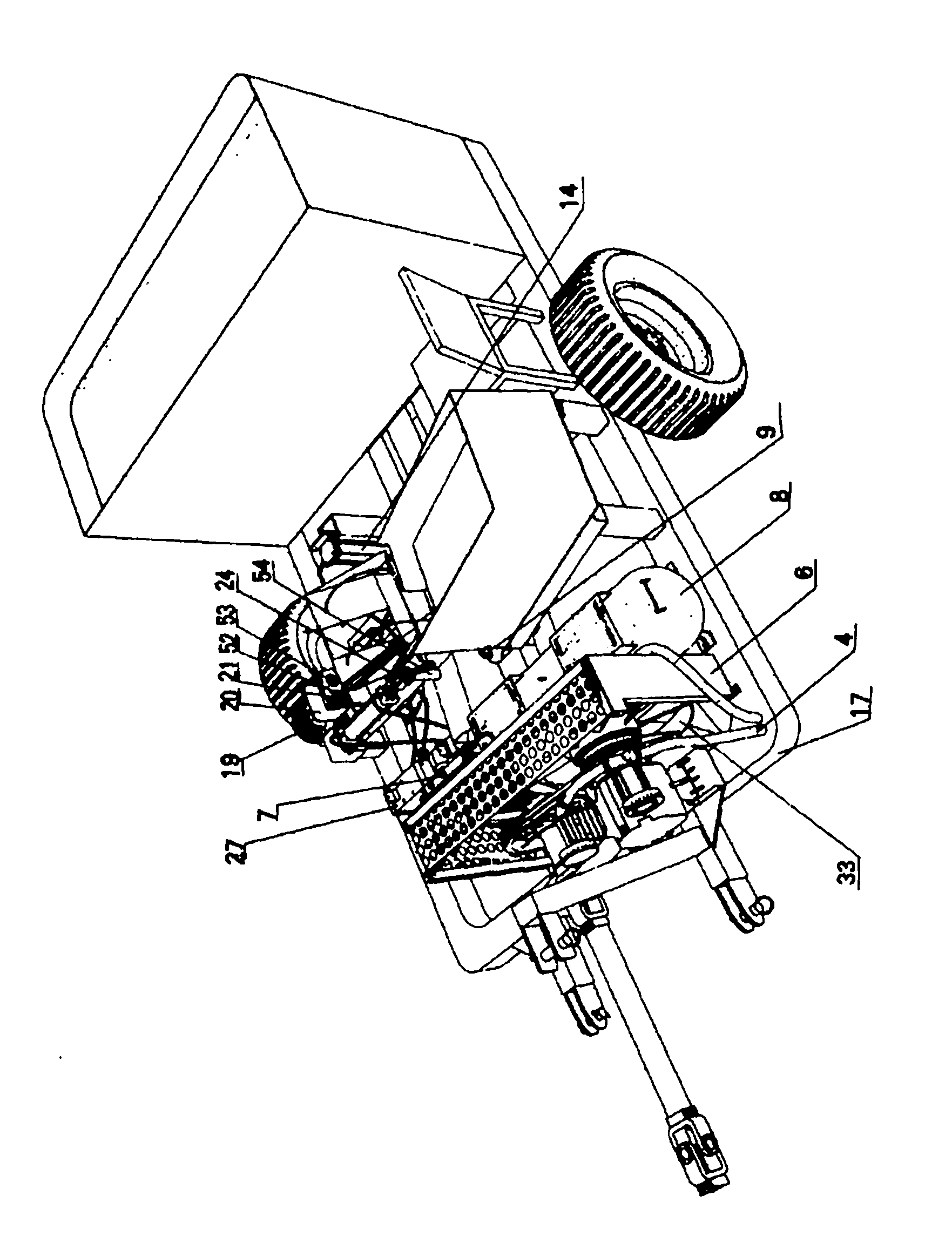

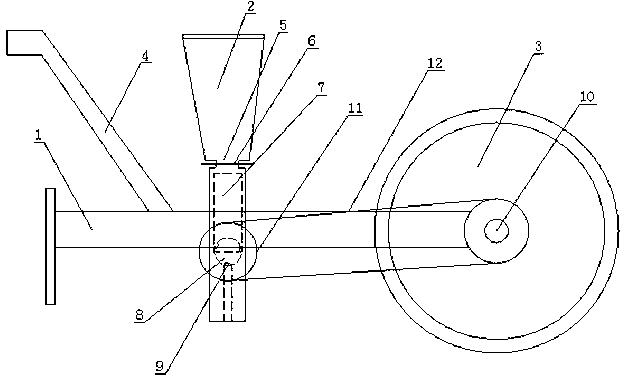

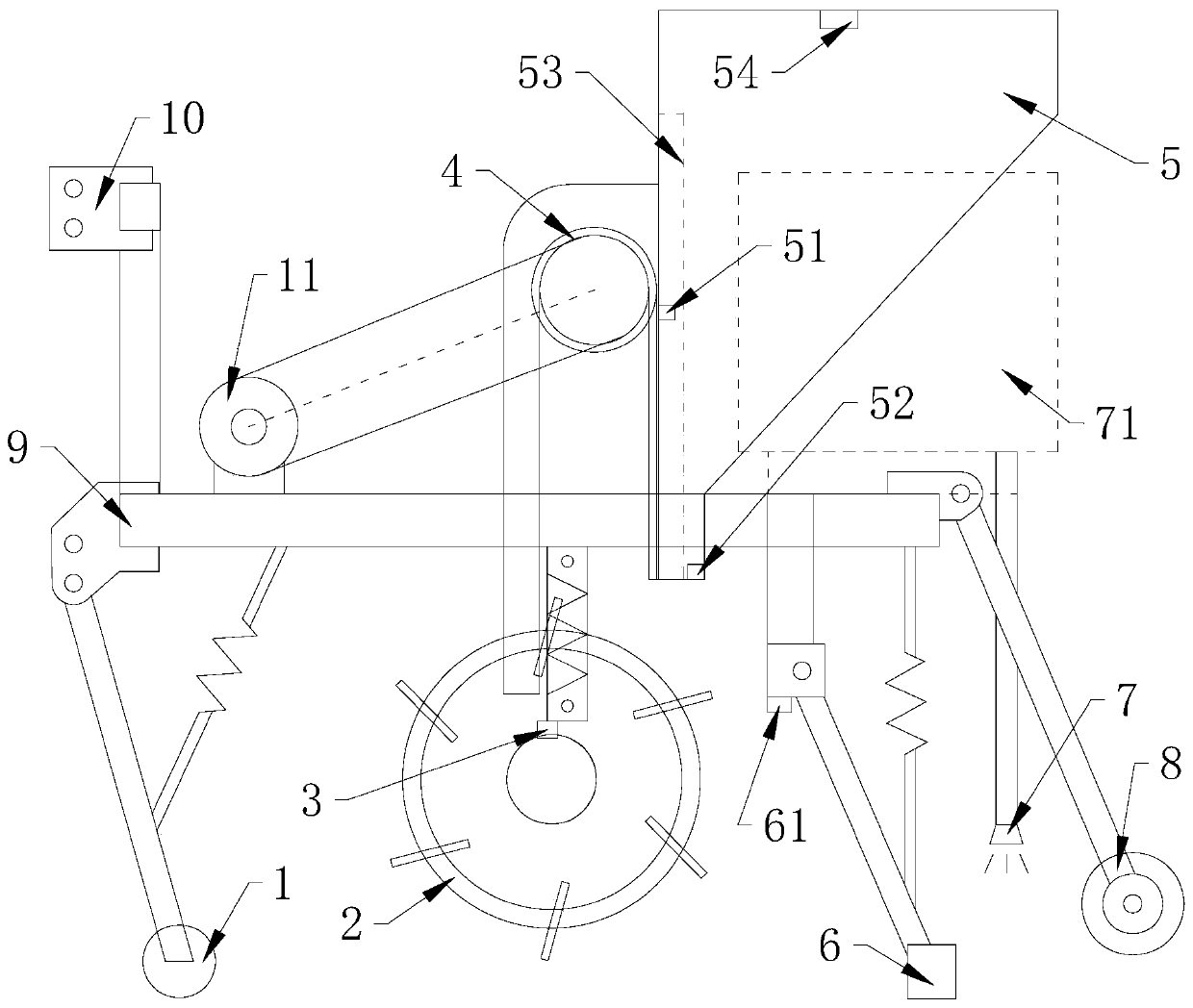

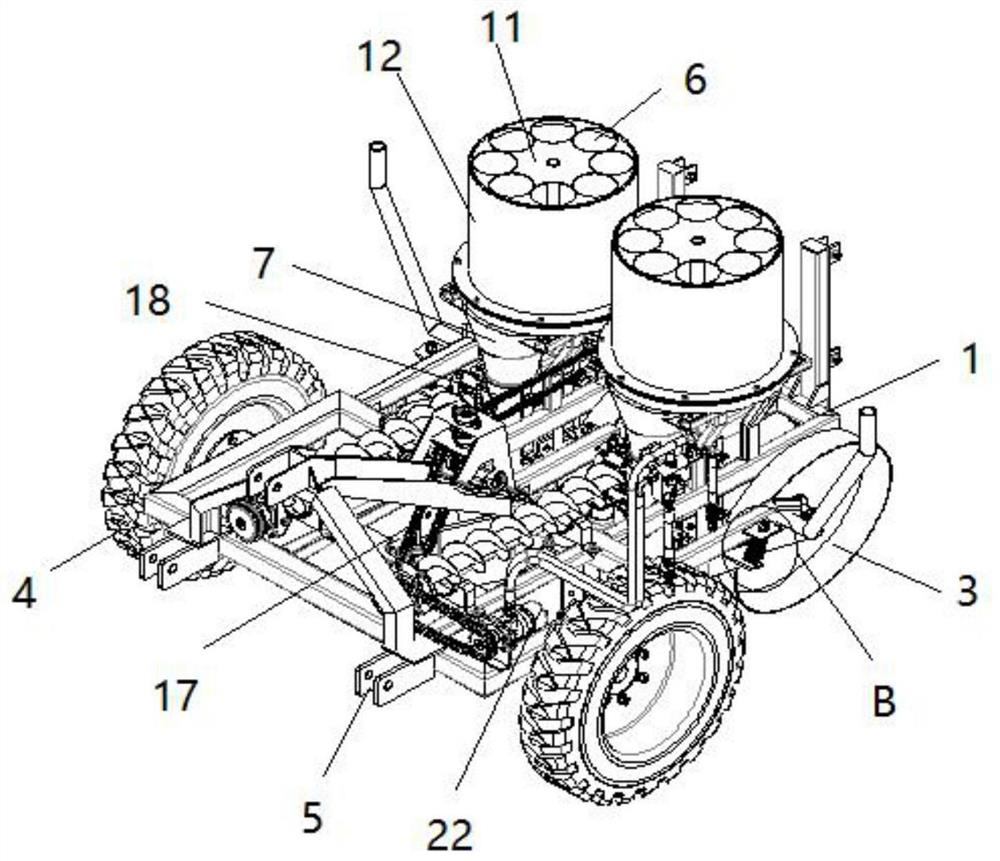

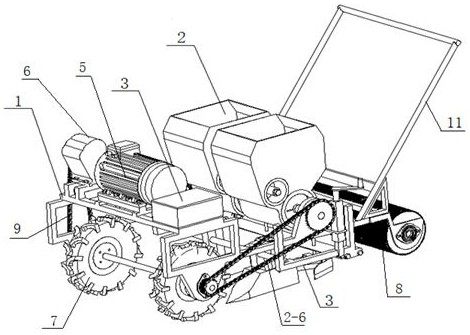

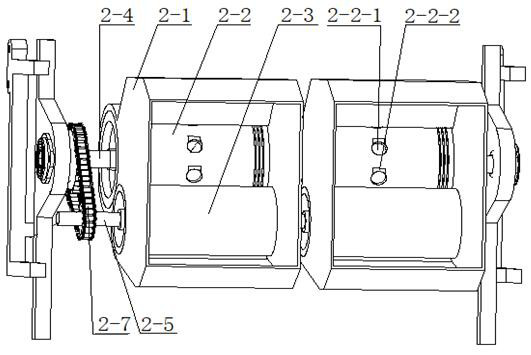

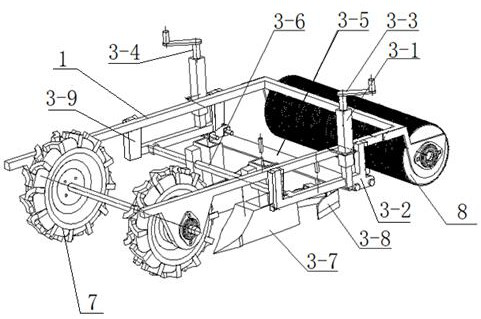

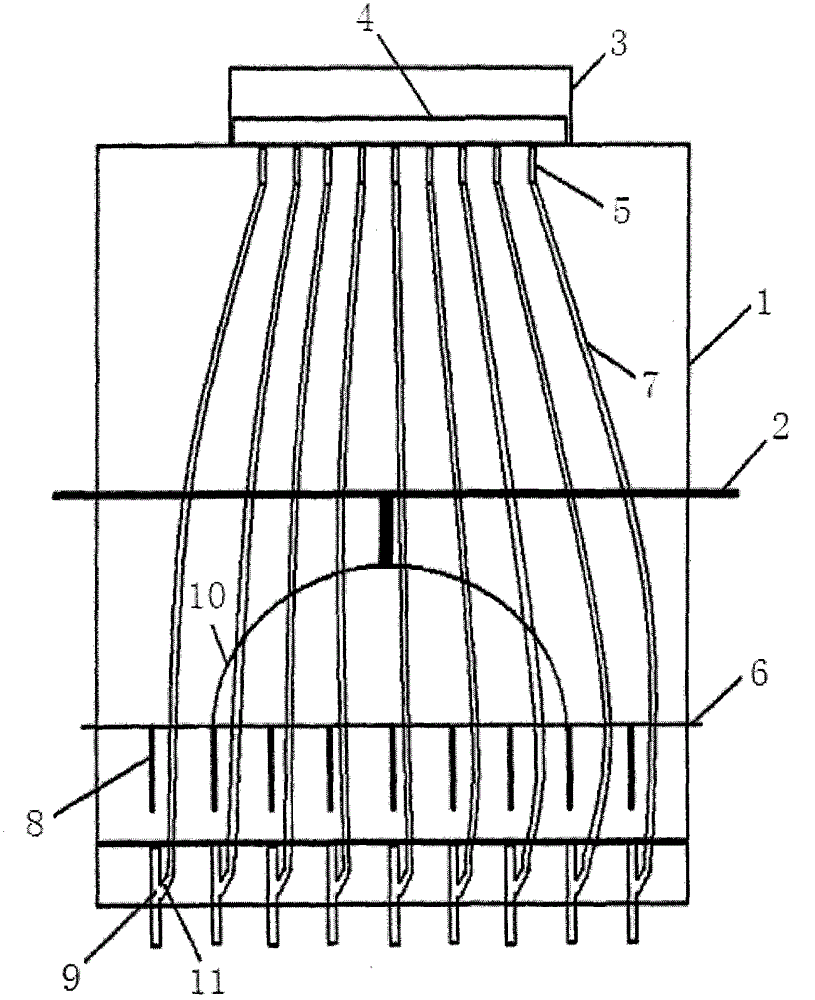

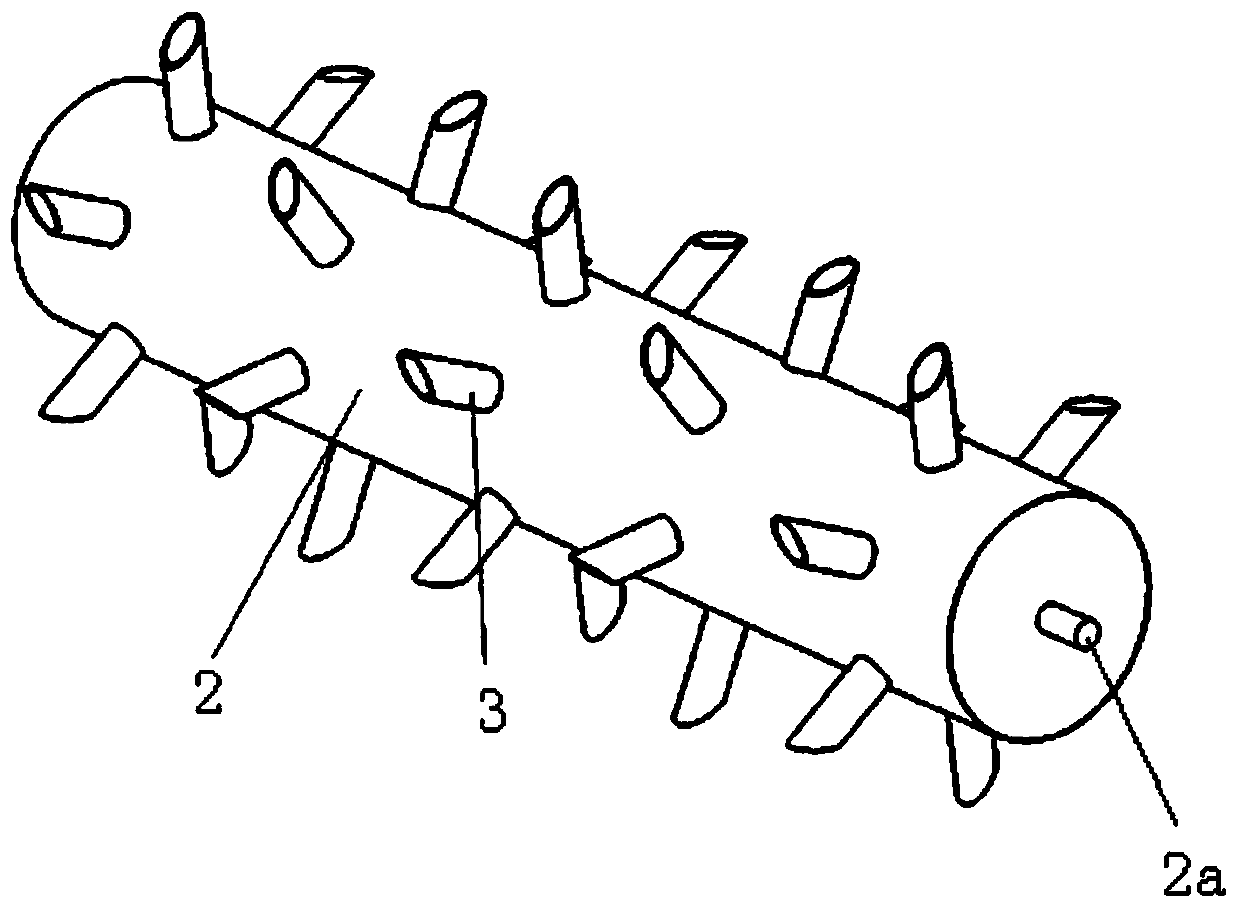

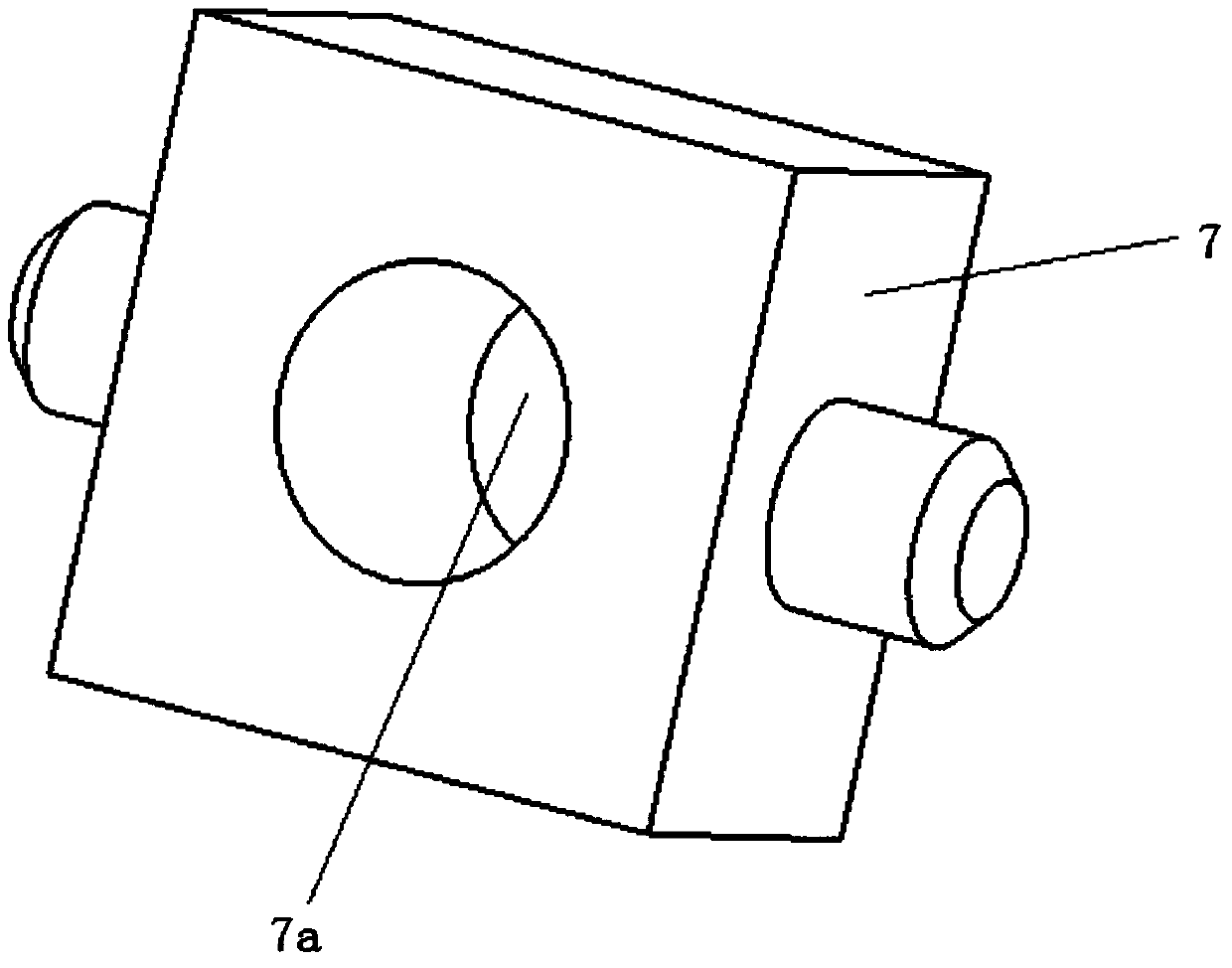

Indented wheel special-shaped hole precision seeding device for broad beans

PendingCN112806129AReduce resistanceReduce breakage ratePlantingFurrow making/coveringBroad beansAgricultural engineering

The invention relates to an indented wheel special-shaped hole precision seeding device for broad beans and belongs to the technical field of agricultural machinery. The indented wheel special-shaped hole precision seeding device for broad beans comprises a frame (1), a seed metering device (2), a ditching and soil covering assembly (3), a motor (5), a speed reducer (6), walking wheels (7), a press wheel (8), and a sprocket drive mechanism I (9). Seeding wheels and seed cleaning wheels cooperate to work, such that a re-seeding condition can be avoided as much as possible, meanwhile, seed cleaning slopes are arranged in seed metering holes of seed metering wheels, such that resistance of the seed cleaning wheels to seeds in a seed cleaning process can be reduced, and a damage rate of the seeds is reduced. The indented wheel special-shaped hole precision seeding device replaces manual broad bean sowing, realizes consistent plant spacing and row spacing and uniform depth during the sowing, reduces labor intensity of farmers and a production cost, and meanwhile improves an operation speed during the broad bean sowing.

Owner:KUNMING UNIV OF SCI & TECH

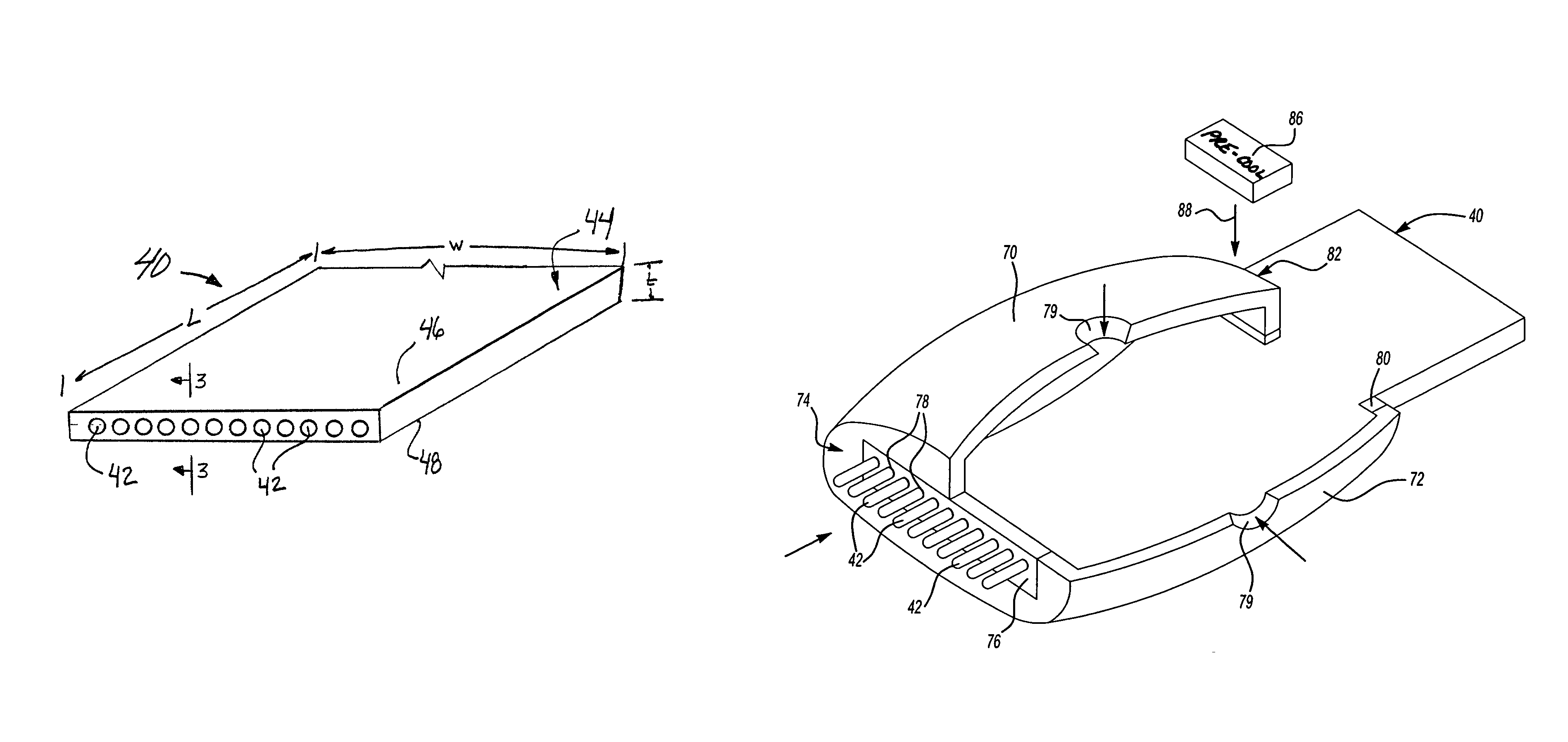

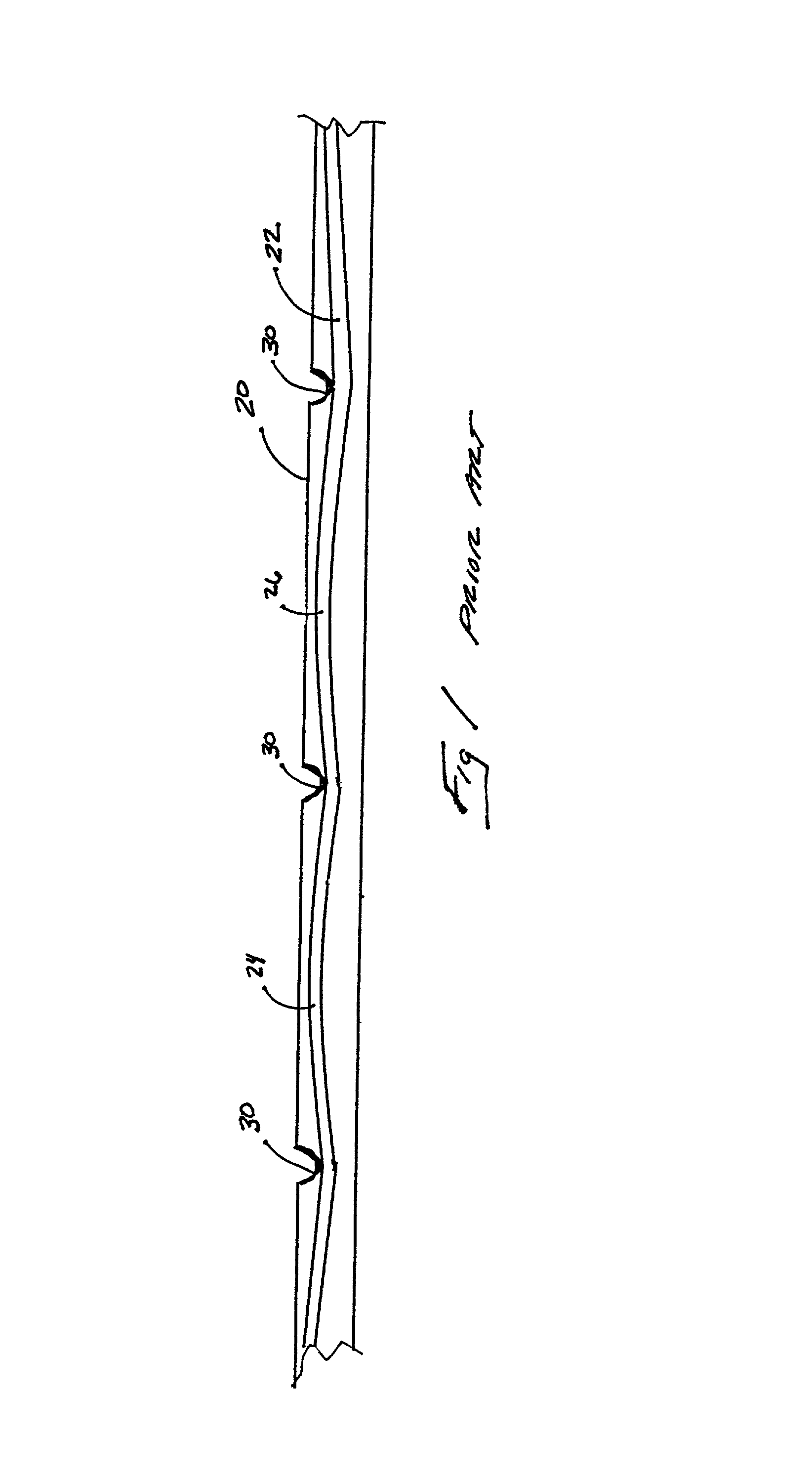

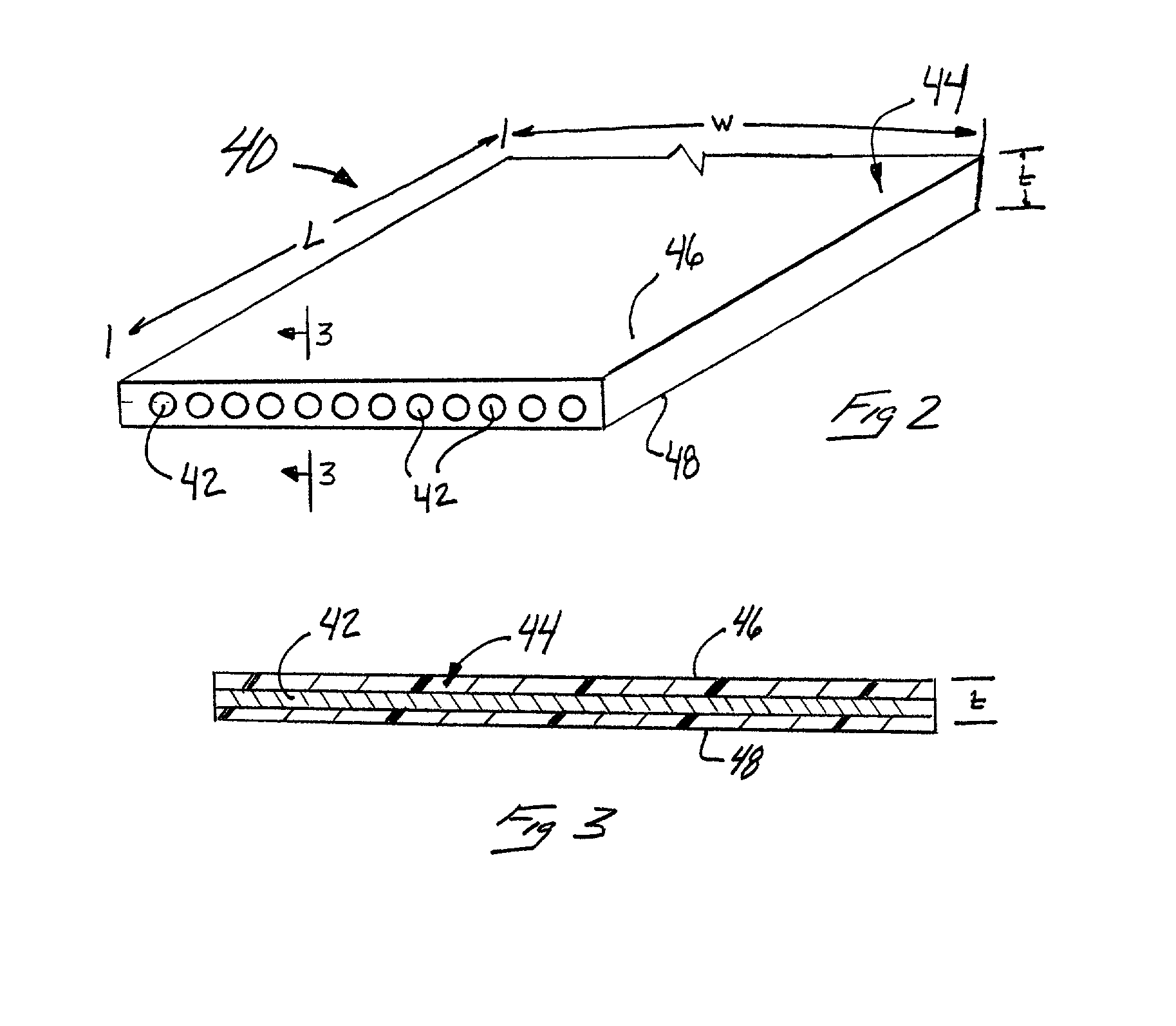

Elevator belt assembly with noise and vibration reducing grooveless jacket arrangement

ActiveUS8444515B2Improve flatnessImprove quietnessV-beltsRopes and cables for vehicles/pulleyElevator systemPulley

An elevator load bearing assembly includes a plurality of cords within a jacket. The cords are spaced from an exterior surface on the jacket such that the spacing remains generally constant along the length of the belt. The jacket has a smooth, uninterrupted exterior surface for contacting sheaves as the belt moves in the elevator system. A method of making the inventive belt assembly is disclosed. The inventive belt assembly minimizes the possibility for generating an annoying, audible sound and vibration during elevator operation.

Owner:OTIS ELEVATOR CO

Sowing and fertilizing integrated machine for peanut cultivation

InactiveCN107409546AUniform spacingPrecise seeding ratePlantingFurrow making/coveringFertilizerDrive motor

The invention discloses an integrated planting and fertilizing machine for peanut planting, which comprises a frame, a gearbox, and a driving motor. A bracket is fixed on the top of the bracket, and a seed storage box is welded on the top of the bracket. An opening and closing plate is arranged in the seed storage box, and a vibrating grating plate is arranged on one side of the opening and closing plate, and vibration motors are installed at both ends of the vibrating grating plate. One side of the frame is provided with an intelligent motor controller; one side of the intelligent motor controller is provided with a fertilizer box; There are several connecting rods, one side of the connecting rod is equipped with an infrared sensor, and the bottom of the connecting rod is fixed with a ditching device and a soil covering board. Through the set vibrating grate and through holes, the peanut grains can be evenly spaced and the sowing amount is accurate. , consistent sowing depth, saving seeds, ensuring stable and high yield of peanuts.

Owner:WUXI SPECIAL EDUCATION SCHOOL

Spot sowing device for crop breeding and cultivation precision tests

InactiveCN105638038AUniform spacingSame shadeSeed depositing seeder partsSingle grain seedersSteel barEngineering

The present invention discloses a spot sowing device for crop breeding and cultivation precision tests. The spot sowing device comprises a frame and a container for placing seeds, wherein a plurality of steel pipes are uniformly distributed on the bottom portion of the frame, each steel pipe is provided with a steel bar capable of inserting into the steel pipe, the steel bar performs penetrating movement in the steel pipe, all steel bars are integrally connected through a horizontal pipe, the horizontal pipe is connected to a rod member with a length of larger than the length of the frame through a bending plate, the rod member slides up and down in the middle of the frame so as to drive the steel bar to move up and down in the steel pipe, the side surface of the steel pipe is provided with an inclined pipe, the inclined pipe is connected to a pipeline, the pipelines are connected to seed outlets on the bottom portion of the container, the container is arranged above the frame, and the bottom portion of the container is provided with a seed discharging device. With the spot sowing device of the present invention, the basic uniformity of the plant spacing, the row spacing and the depth of the crop seed sowing can be ensured, the single seed sowing can be ensured, especially drought-resistant sowing can be ensured, and the spot sowing device has characteristics of simple structure, easy operation, and high efficiency.

Owner:重庆市涪陵区渝杨榨菜(集团)有限公司

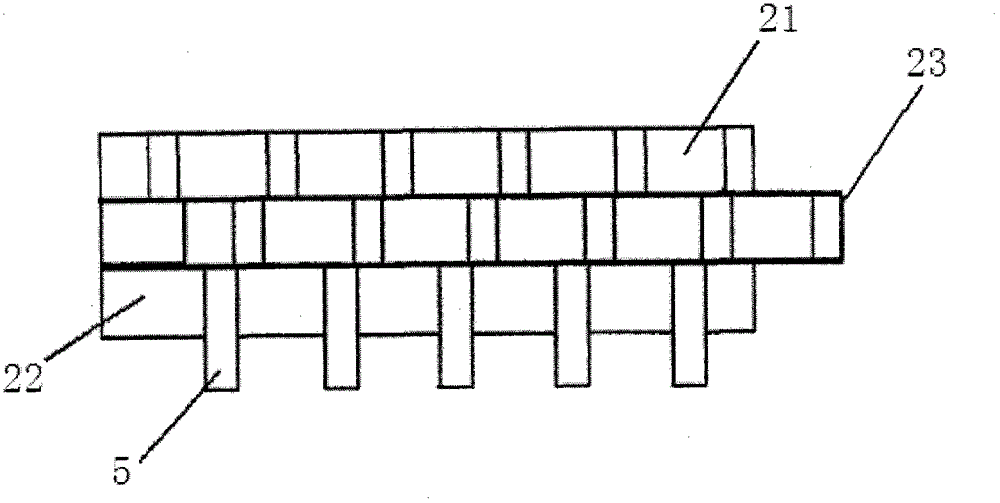

Automatic ranking device for bearing production line

ActiveCN113859926AEvenly spacedUniform spacingGrinding feedersConveyor partsReduction driveReciprocating motion

The invention discloses an automatic ranking device for a bearing production line, and relates to the technical field of bearing machining. The ranking device comprises a tool table, a roller and a driving mechanism used for driving the roller to rotate are arranged on the tool table, and a conveying belt is arranged on the outer side of the roller in a sleeving mode. Baffles are arranged on the tool table and located around the conveying belt. A height limiting plate is further arranged between every two adjacent baffles in the left-right direction. Two first guide plates which longitudinally extend and form a first guide channel are symmetrically arranged on the rear sides of the height limiting plates. Two second guide plates which extend in the transverse direction and form a second guide channel are arranged on the rear sides of the first guide plates. The first guide channel and the second guide channel are communicated with each other. A push arm is slidably arranged in the second guide channel. A transmission mechanism for driving the push arm to do reciprocating motion is arranged between the driving mechanism and the push arm. The driving mechanism comprises a driving motor and a speed reducer matched with the driving motor, and a power output shaft of the speed reducer is matched with the roller.

Owner:SHANDONG BOTE BEARING

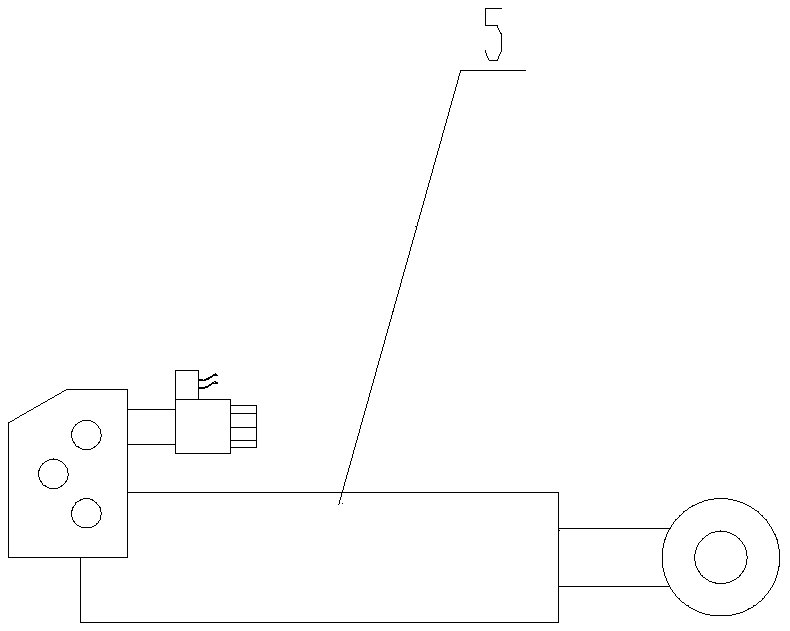

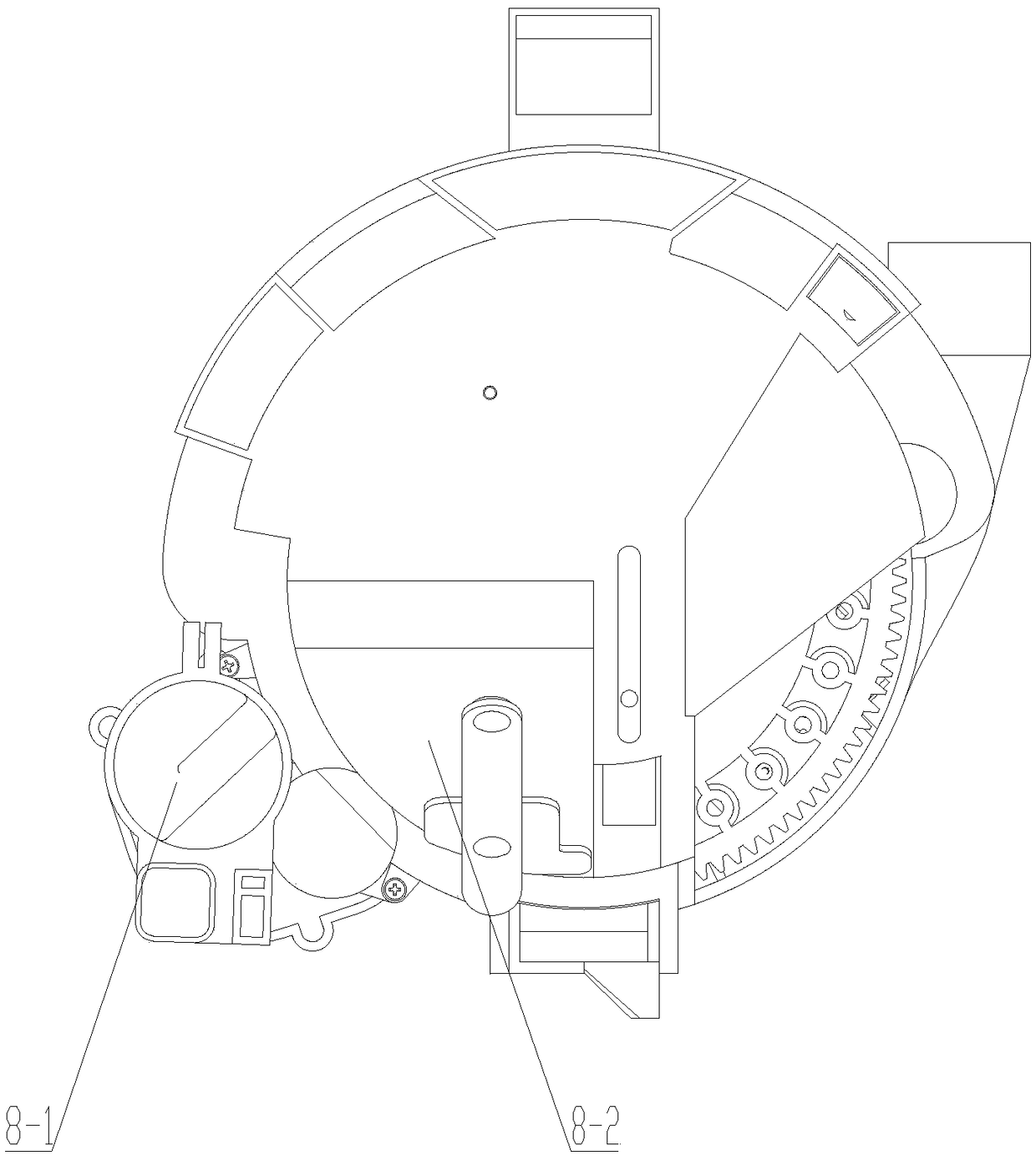

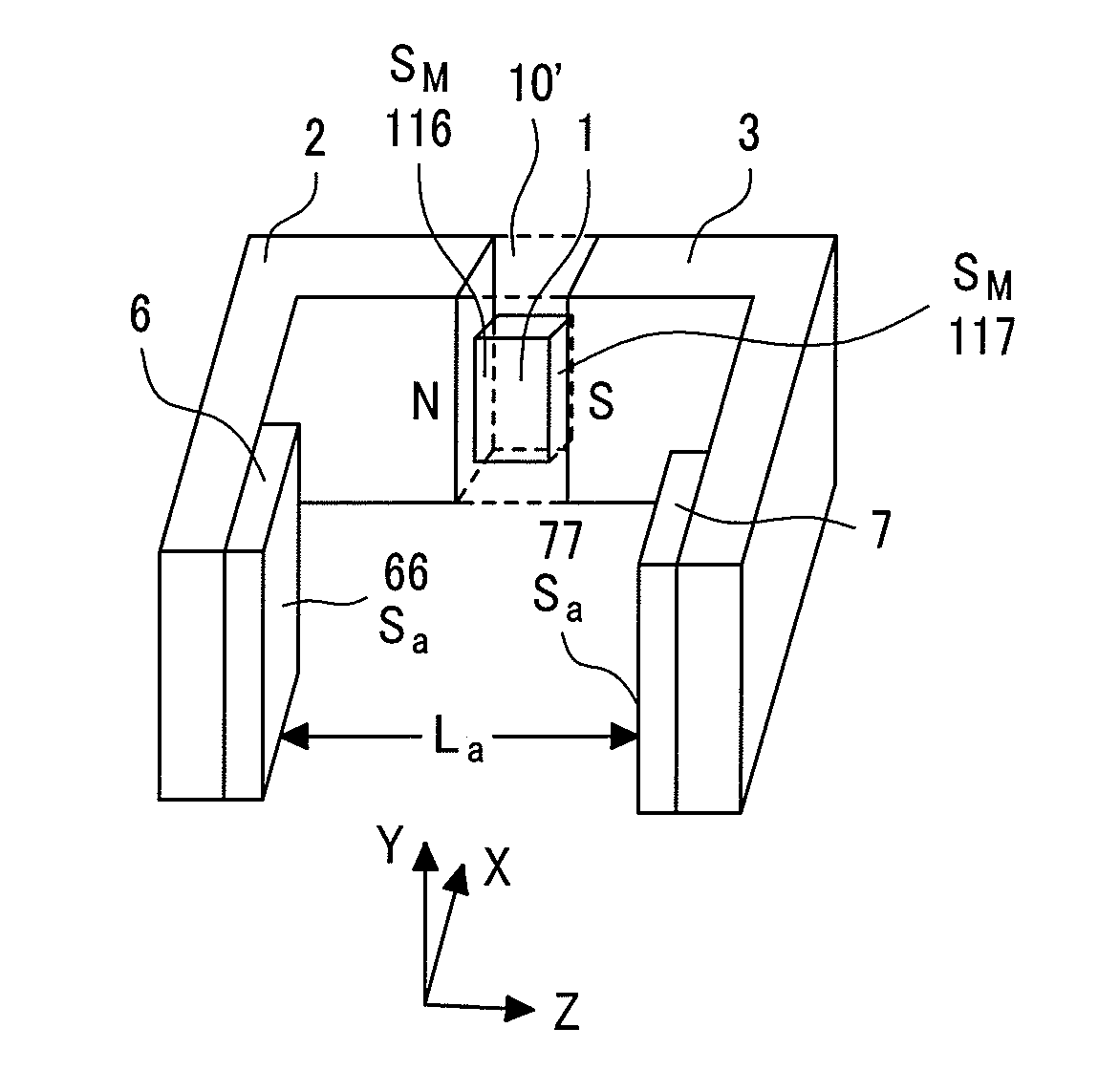

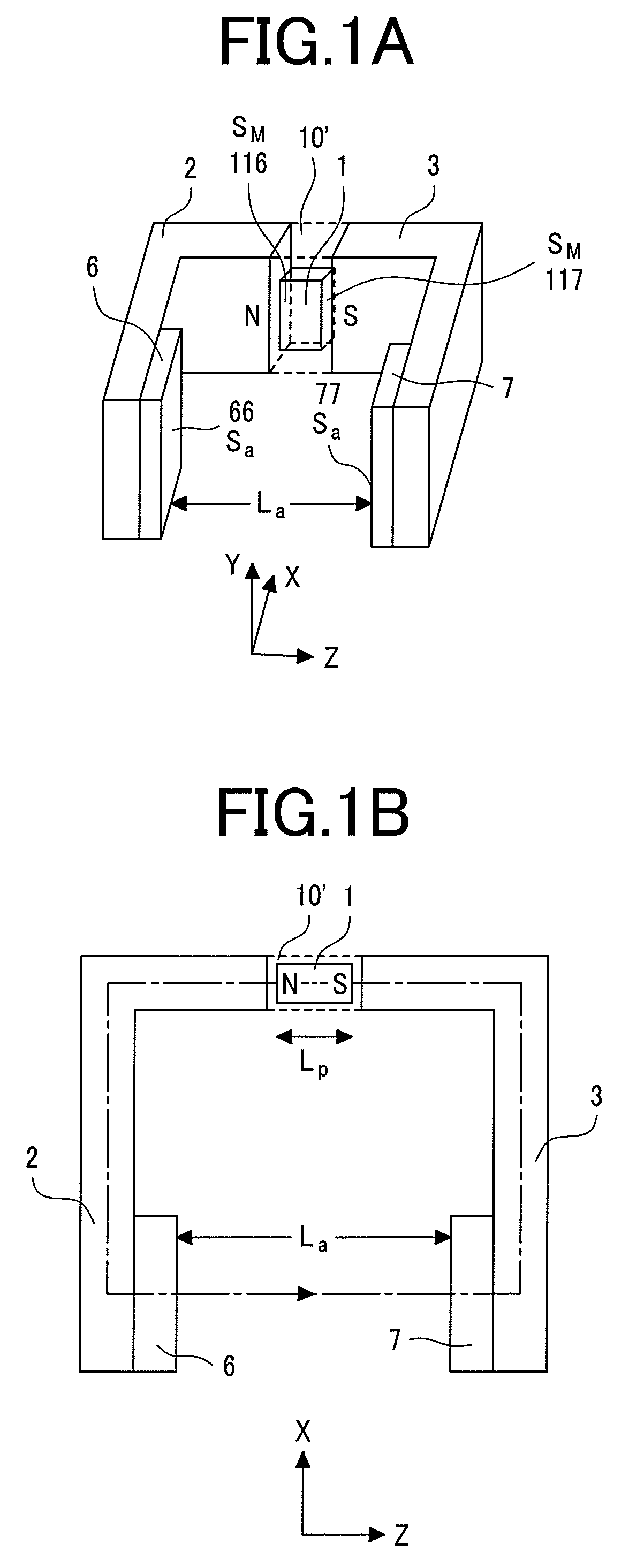

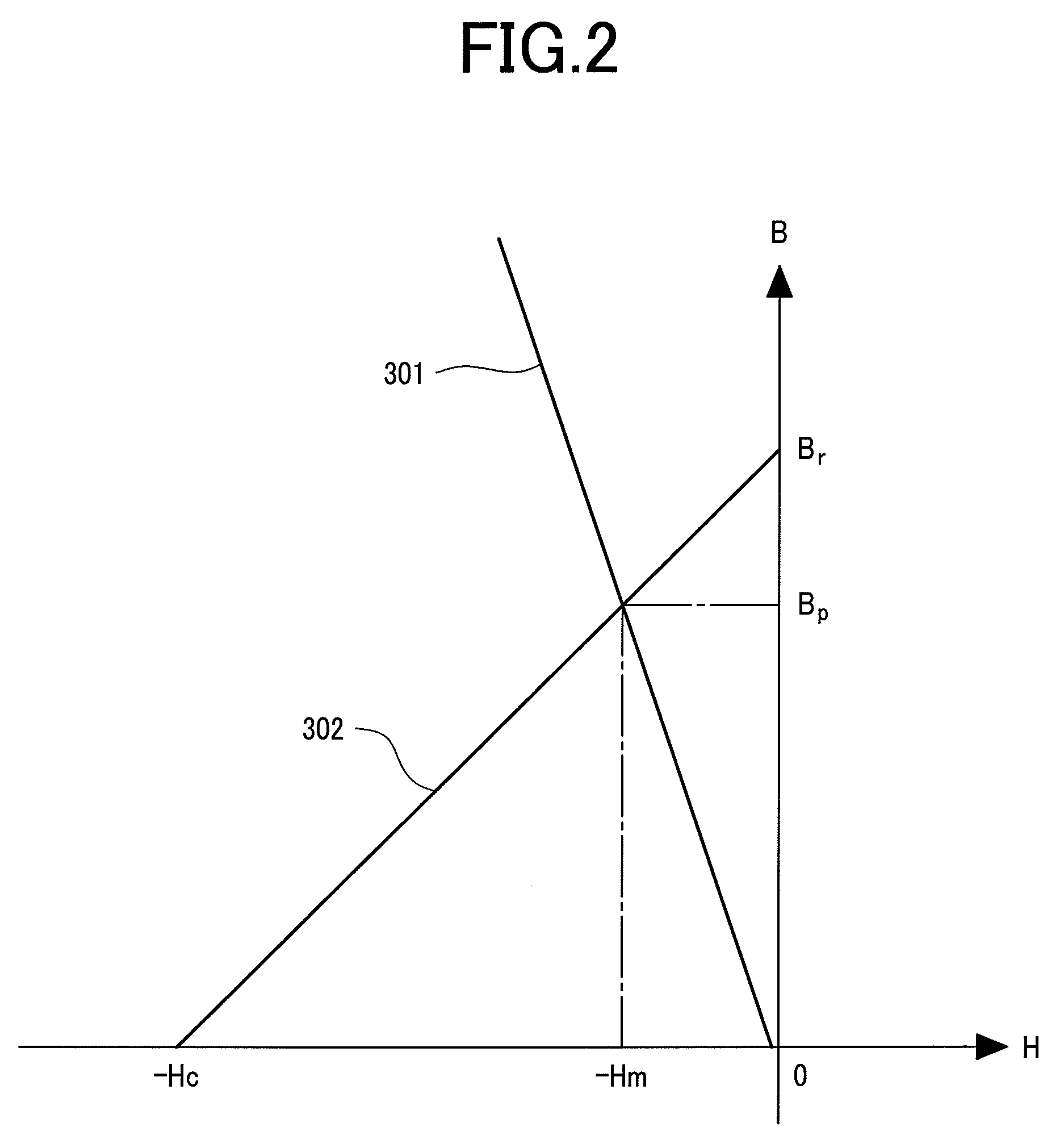

Apparatus for electron spin resonance CT

InactiveUS7541811B2Wide gapHigh Remanent Flux DensityMagnetic measurementsAnalysis using electron paramagnetic resonanaceSmall animalImage resolution

A compact, lightweight, and easy-to-use ESR-CT apparatus including a magnetic field leak line (5-G line) which is capable of imaging a small animal, such as a mouse, within 15 minutes, and of observing a desired region with a spatial resolution of 1 mm or less. A permanent magnet system is introduced of the apparatus includes pole pieces having a predetermined area which are opposed to each other through a measured space, yokes combined with the pole pieces, and a permanent magnet inserted in series so that at least one magnetic pole plane intersects perpendicularly to the closed magnetic circuit for magnetic coupling with the yokes. This makes it possible to locate a gradient coil system and a field scanning coil system sufficiently apart from end faces of the pole pieces, and to downsize the field scanning coil system so that the gradient field system is movable.

Owner:HITACHI LTD

Deep-pit seeding device and seeding method for agricultural production

PendingCN114766146AImprove survival rateImprove skin breaking effectPlantingSeed and root treatmentAgricultural engineeringAgriculture

The invention relates to a deep pit seeding device for agricultural production, the deep pit seeding device comprises a bottom plate, the lower surface of the bottom plate is fixedly connected with supporting legs, the supporting legs are rotatably connected with walking wheels, the upper surface of the bottom plate is fixedly connected with a mounting box, and the inner wall of the right side of the mounting box is fixedly connected with a conveying assembly. The inner walls of the front side and the rear side of the mounting box are fixedly connected with the same seeding assembly, and the lower surface of the bottom plate is fixedly connected with a seeding pipe. According to the seed sowing device, a corrugated hose is lengthened and inserted into an injection hole, seeds are injected into the conveying assembly through an injection hopper and the corrugated hose, the seeds are conveyed into the seed sowing assembly through the conveying assembly, the seeds are quantitatively conveyed into a seed sowing pipe through the seed sowing assembly, and then the seeds are sown; therefore, the deep-pit seeding device for agricultural production solves the problem that a seeding machine in the prior art is large in size and cannot be applied to a field with a small area.

Owner:杨琰晴

No-tillage electronic control corn compound planter

ActiveCN105815010AImprove work efficiencySolve the grass problemAgriculture gas emission reductionPlant protectionUniversal jointControl system

The invention provides a no-tillage electronic control corn compound planter. The planter comprises a rack, a stirring knife cleaning mechanism and a seeding mechanism, wherein the stirring knife cleaning mechanism comprises a spline input shaft, a speed reducer, a single-output commutator, a dual-output commutator, a universal joint, a universal joint connecting shaft, a vertical rotary stirring knife, a cutter head and a cutter shaft; the spline input shaft is in transmission connection with the speed reducer; the speed reducer and the double-output commutator are in transmission connection; one end of the universal joint connecting shaft is connected with the universal joint; the other end of the universal joint connecting shaft is connected with the double-output commutator; the universal joint is connected with the single-output commutator; the speed reducer, the double-output commutator and the single-output commutator are in transmission connection with the cutter shaft; the cutter shaft is connected with the cutter head; the vertical rotary stirring knife is connected with the cutter head; and the seeding mechanism comprises a control system assembly, a seeding apparatus assembly, a seeding apparatus shaft, a seeding pipe and a seeding coulter assembly. The no-tillage electronic control corn compound planter can stably work under the no-tillage operation condition; and accurate seeding and retest operation can also be achieved.

Owner:ANHUI AGRICULTURAL UNIVERSITY

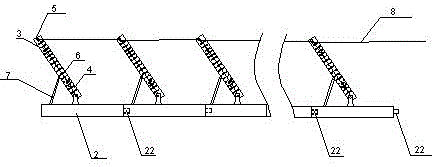

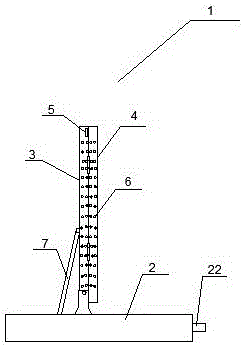

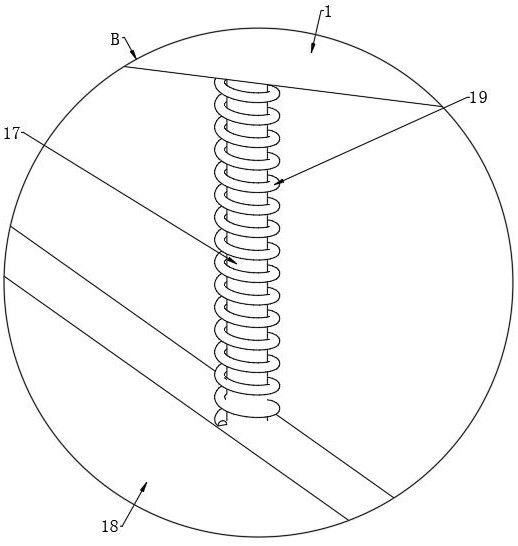

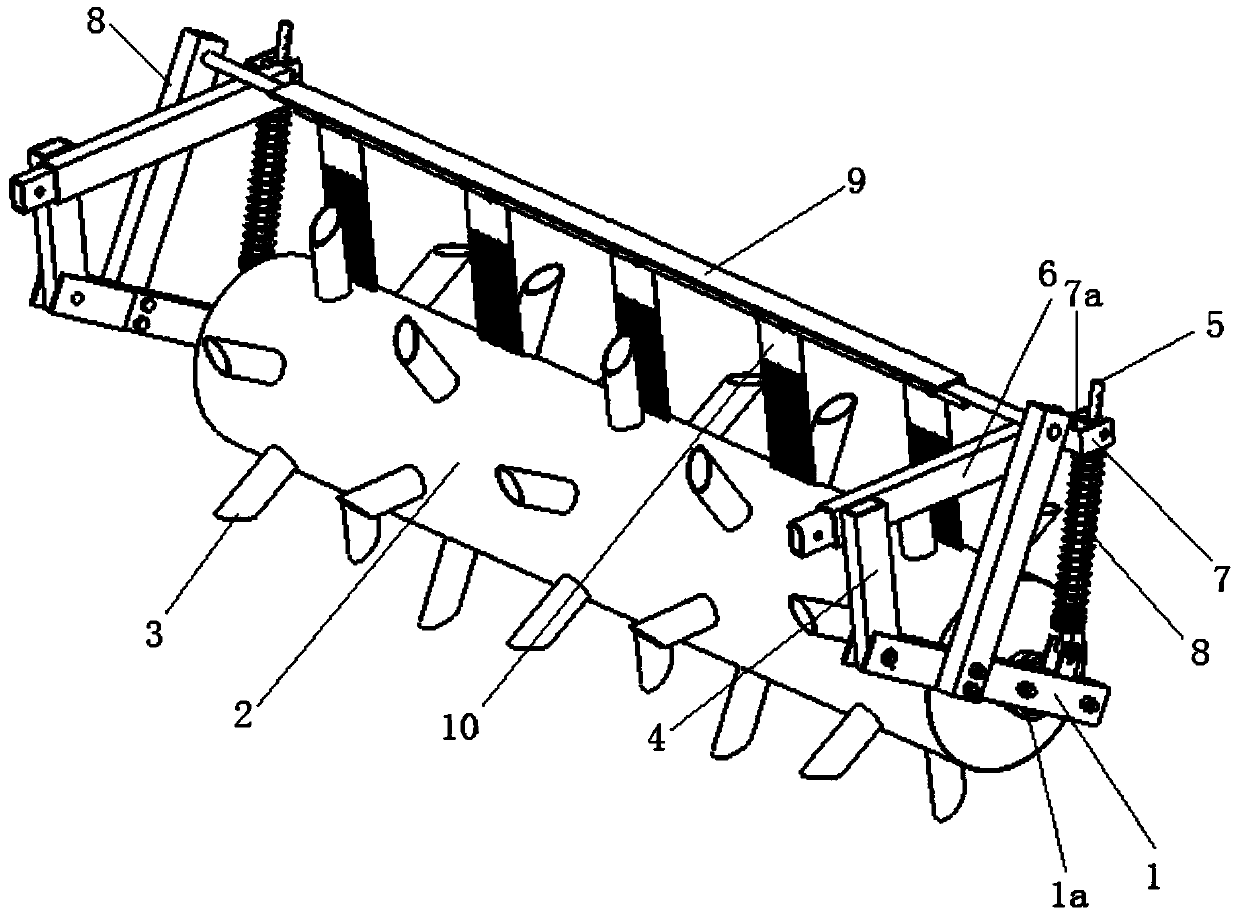

Traction-type continuous punching and surface profiling leveling device for transplanting work

ActiveCN103988624AReduce shock loadReduce vibrationTransplantingFurrow making/coveringPillow block bearingPunching

The invention discloses a traction-type continuous punching and surface profiling leveling device. The device comprises a two roller support frames provided with pillow block bearings, a plurality of punching circular pipes and a leveling roller provided with connection shafts at the two ends; the connection shaft at two ends are respectively arranged in the two pillow block bearings, the plurality of punching circular pipes are arranged in multi-head spiral linear distribution in the leveling roller, wherein a notch of each punching circular pipe is an angular cut, and the angular cut surfaces of the plurality of punching circular pipes are in the same direction. The punching circular pipes in the invention are distributed on the leveling roller according to the multiple spiral patterns; in the punching process, at least two punching circular pipes are inserted into the soil, and the punching circular pipes in left and right symmetrical position penetrate into the soil simultaneously, so as to effectively reduce the shock load and the vibration caused by uneven stress on the punching device from the left and right during the penetration of the punching circular pipes into the soil.

Owner:HUAZHONG AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com