Anchor assembly for safety device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0059]FIG. 9 shows an anchor assembly (2) again utilising two anchor points including a pair of first spacers (10). Each of the spacers (10) are connected by a bridging plate (50) having spaced apertures as previously described in FIG. 5. As can be seen in FIG. 9, the spacers (10, 10′) may be anchored to discreet structural members (90) rather than a single structural member.

third embodiment

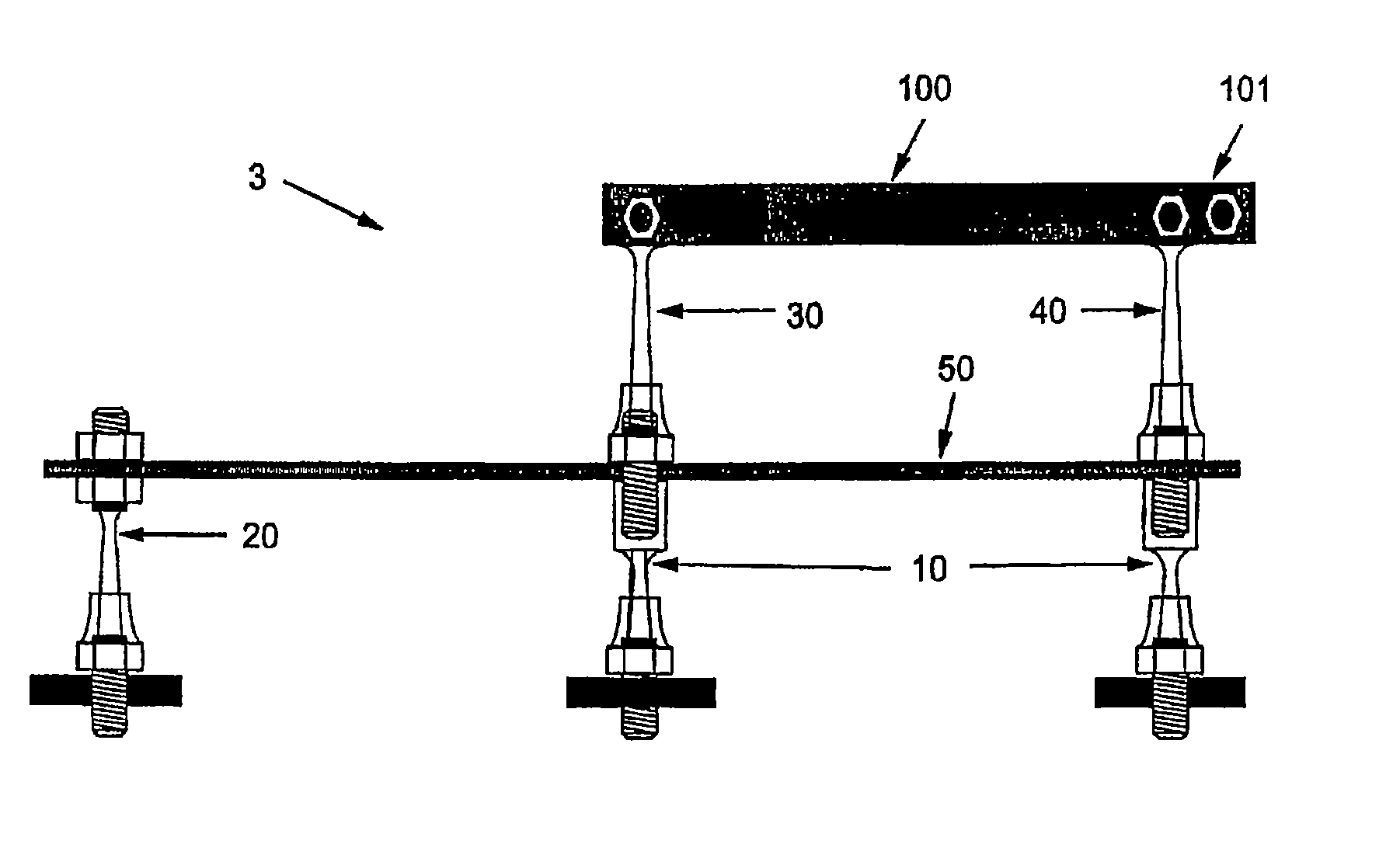

[0060] In FIG. 10 there is shown an anchor assembly (3) in which a pair of eyebolts, for example eyebolts (30, 40), are utilised and secured to the remainder of the third anchor assembly (3) by engagement to a pair of first spacers (10). A bridging plate (50) connects the three spacers (10,20) as previously described in relation to FIG. 8 or 9. The eyebolts (30, 40) are connected at their respective heads (not shown) by a bridging bracket (100) whereby the eyebolt (30) will deform in preference to the spacers (10). The safety device is attached to the third anchor assembly (3) by attachment to the eyelet (101) extending from the end of the bridging bracket (100). In place of solid bridging bracket (100), a turnbuckle may be utilised to provide tension to the assembly (3).

[0061]FIG. 11 shows yet another embodiment (4) utilising three spacers (10, 20) and a pair of eyebolts (30 or 40) in similar arrangement to FIG. 10, except that the assembly (4) has the safety device (eg cable not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com