Patents

Literature

54results about How to "High Remanent Flux Density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rare earth - iron - bron based magnet and method for production thereof

InactiveUS20070034299A1High energyImprove resolutionInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementTrace element

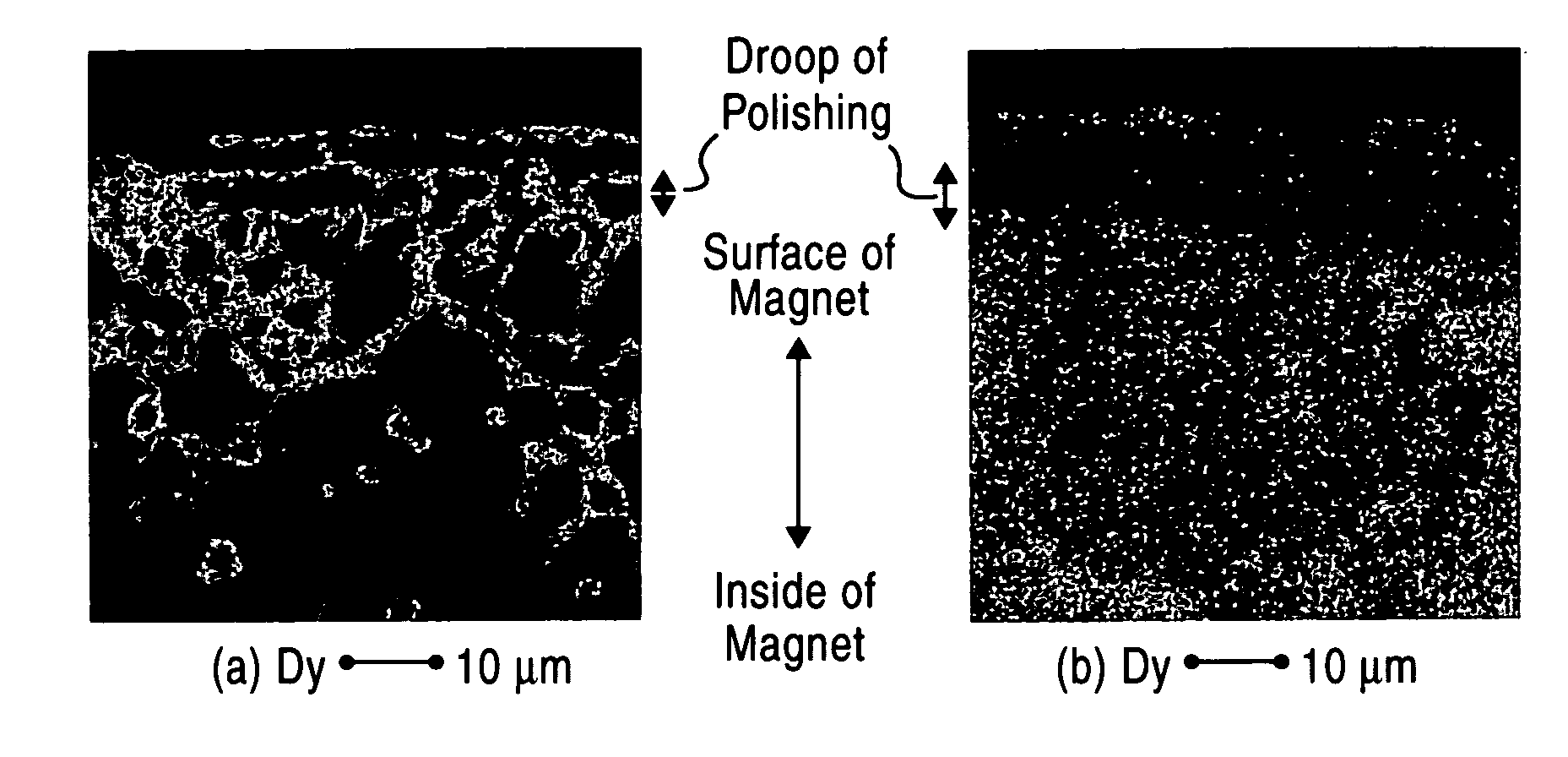

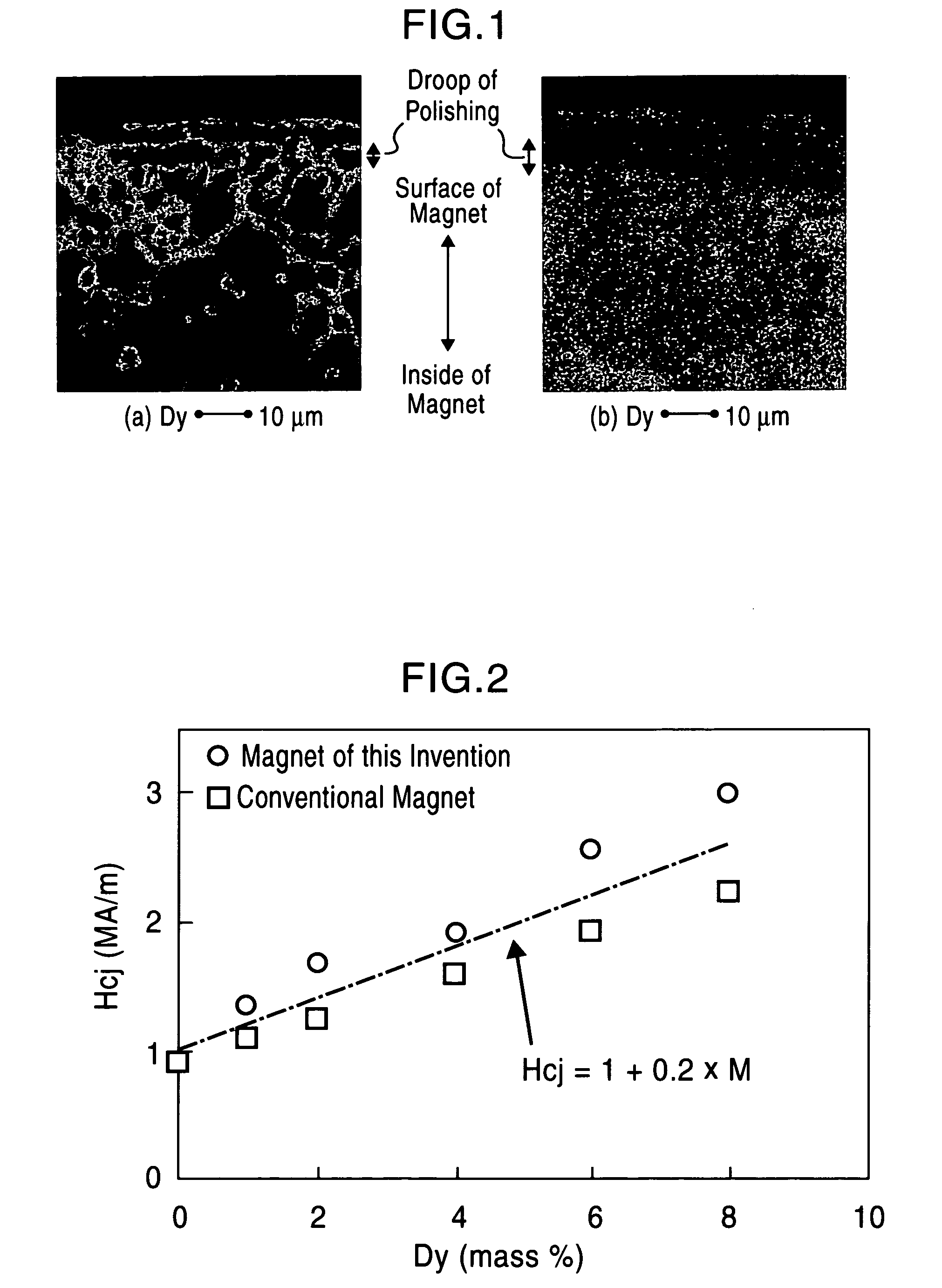

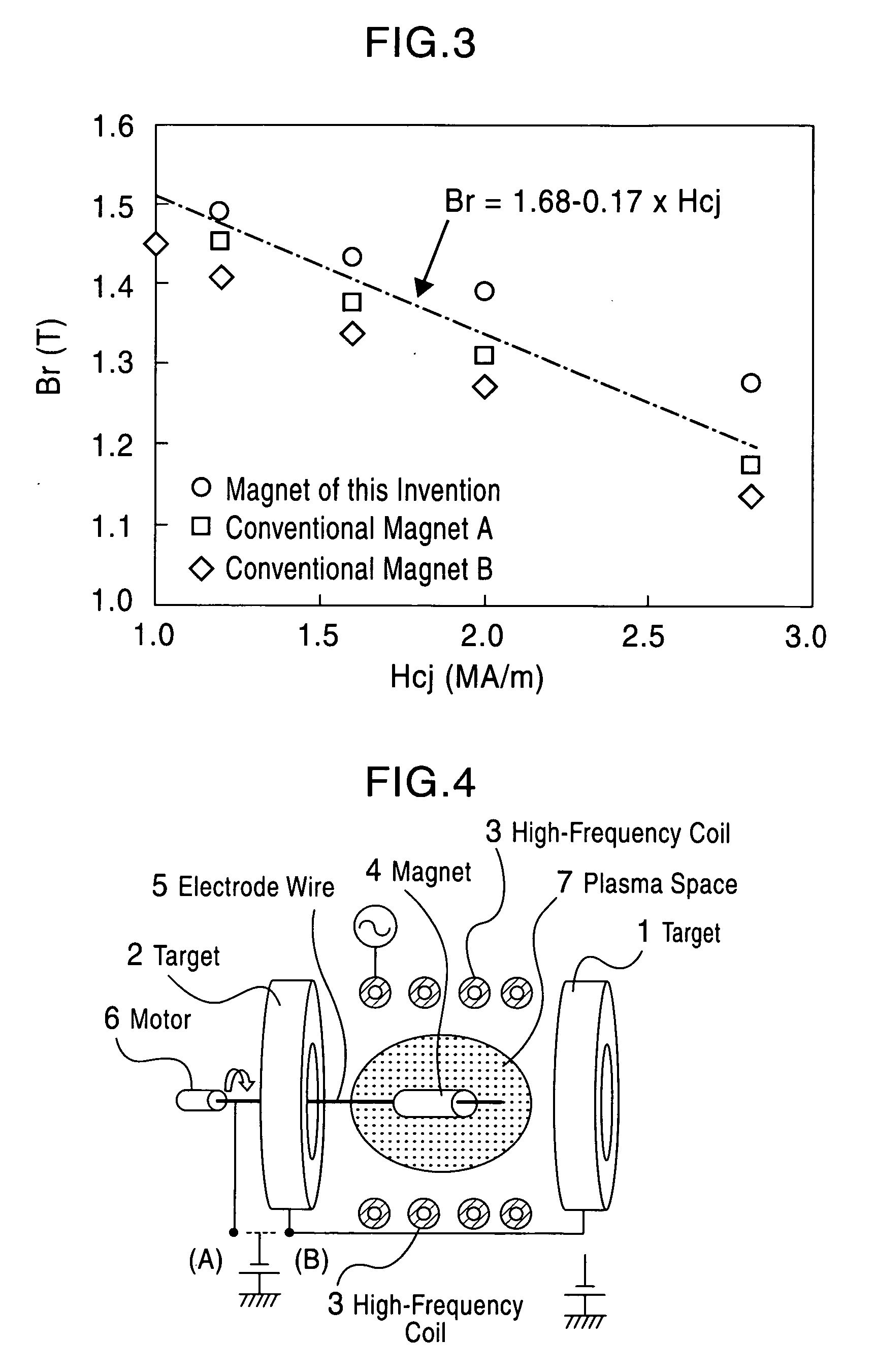

[Object] To provide a high-performance rare earth-based magnet exhibiting a high coercive force or a high residual magnetic flux density even when the content of a rare earth element such as Dy or the like which is scarce is reduced. [Construction] A rare earth-iron-boron based magnet includes a crystal grain boundary layer enriched in element M (M is at least one rare earth element selected from Pr, Dy, Tb, and Ho) by diffusion of the element M from the surface of the magnet, wherein the relation between the coercive force Hcj and the content of the element M in the whole of the magnet is represented by the following expression: Hcj≧1+0.2×M (wherein 0.05≦M≦10) wherein Hcj is the coercive force (unit: MA / m), and M is the content of the element M in the whole of the magnet (% by mass). Furthermore, the magnet satisfies the following expression: Br≧1.68−0.17×Hcj wherein Br is the residual magnetic flux density (unit: T).

Owner:JAPAN SCI & TECH CORP +1

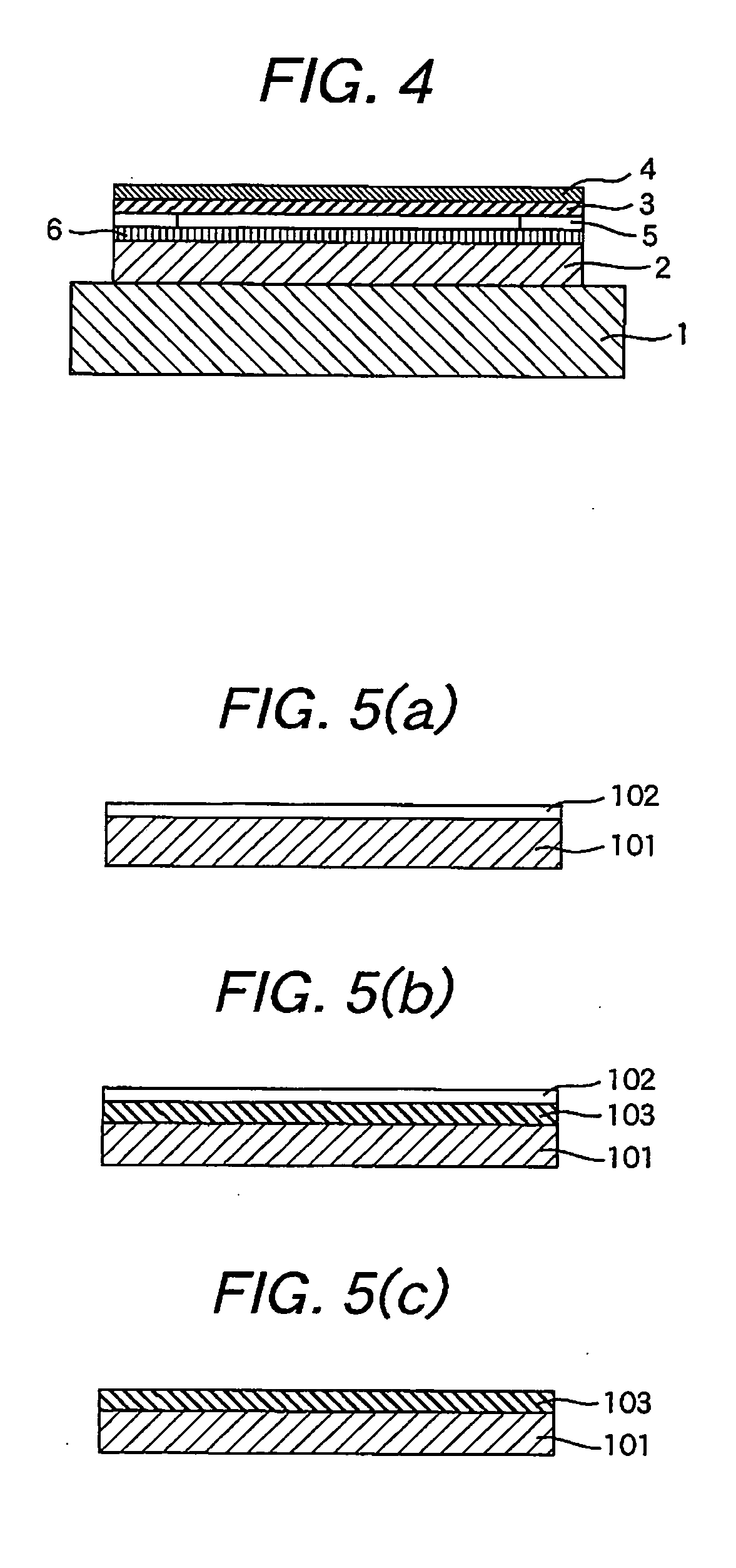

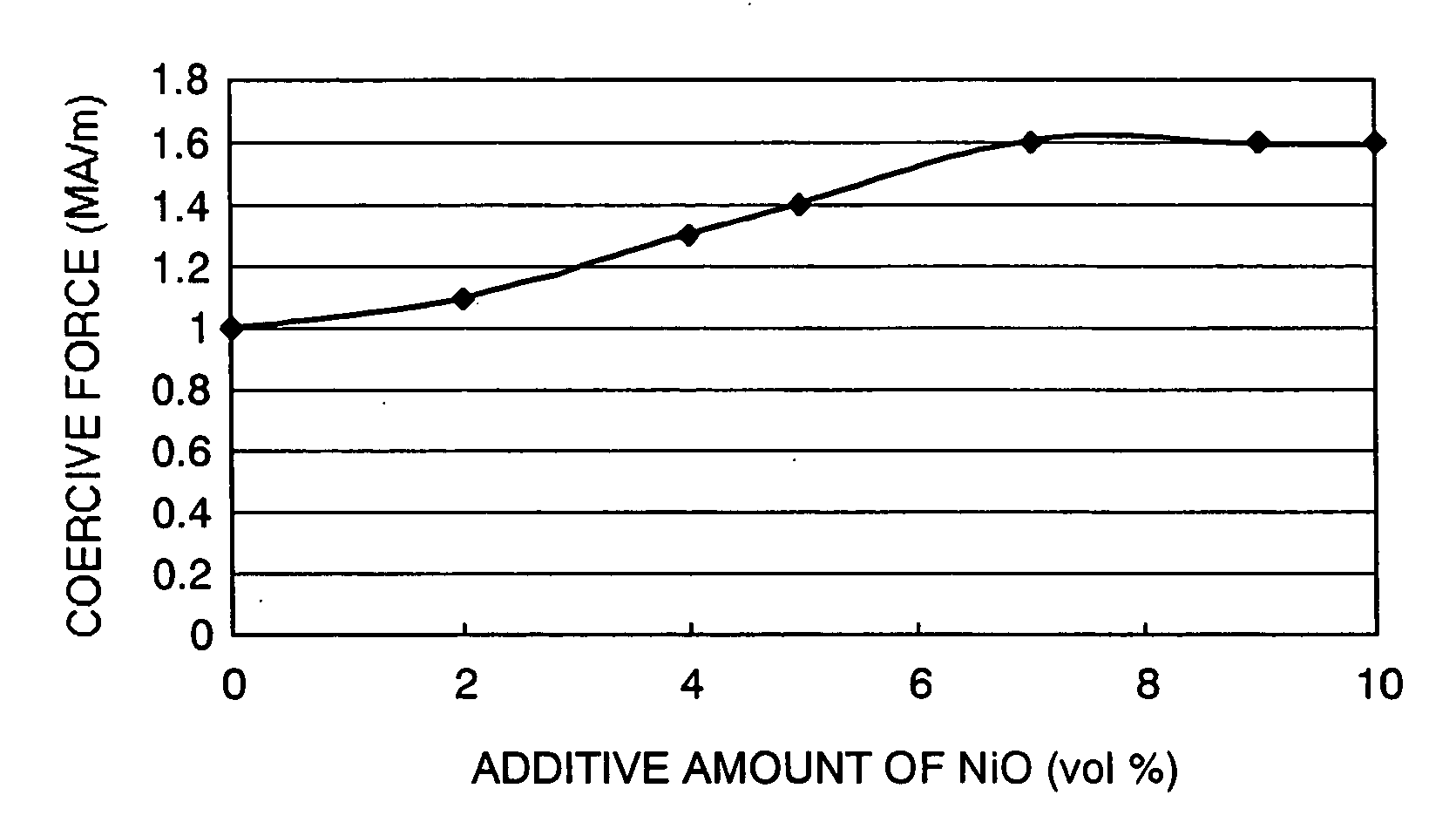

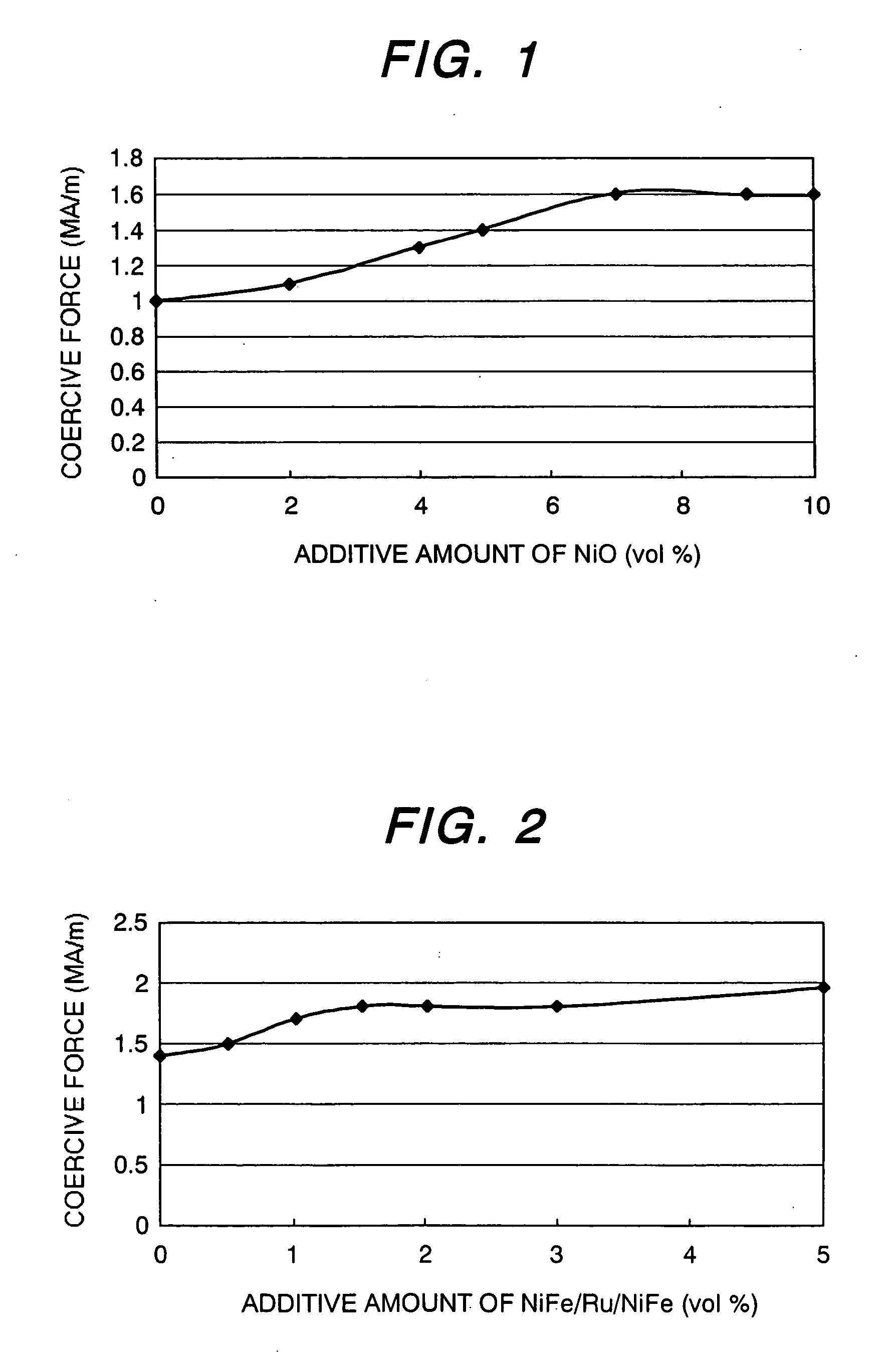

Oxide magnetic material, ferrite particles, bonded magnet, sintered magnet, process for producing the same, and magnetic recording medium

InactiveUS6402980B1Excellent magnetic propertiesIncrease valueMagnetic materials for record carriersInorganic material magnetismRare-earth elementSintered magnets

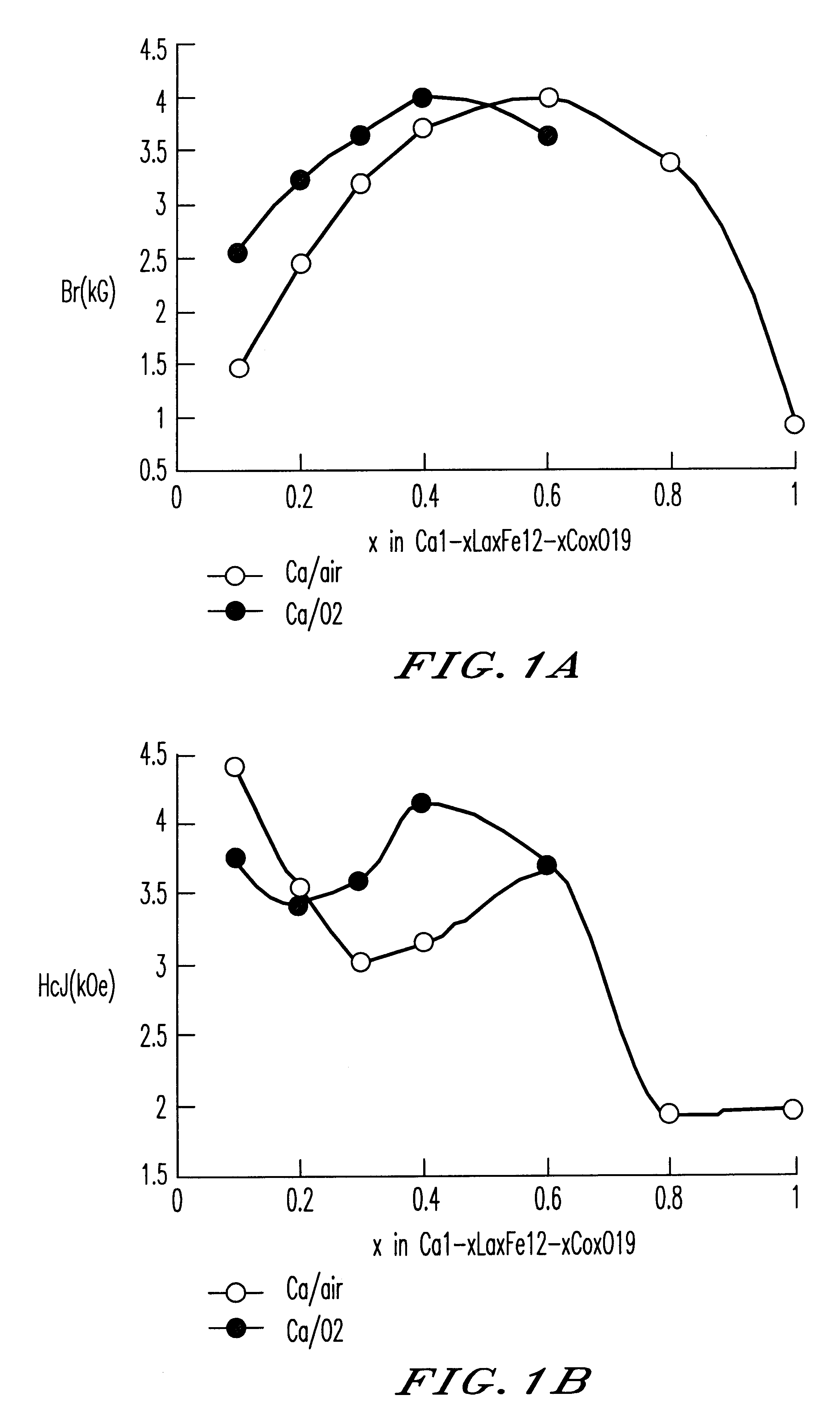

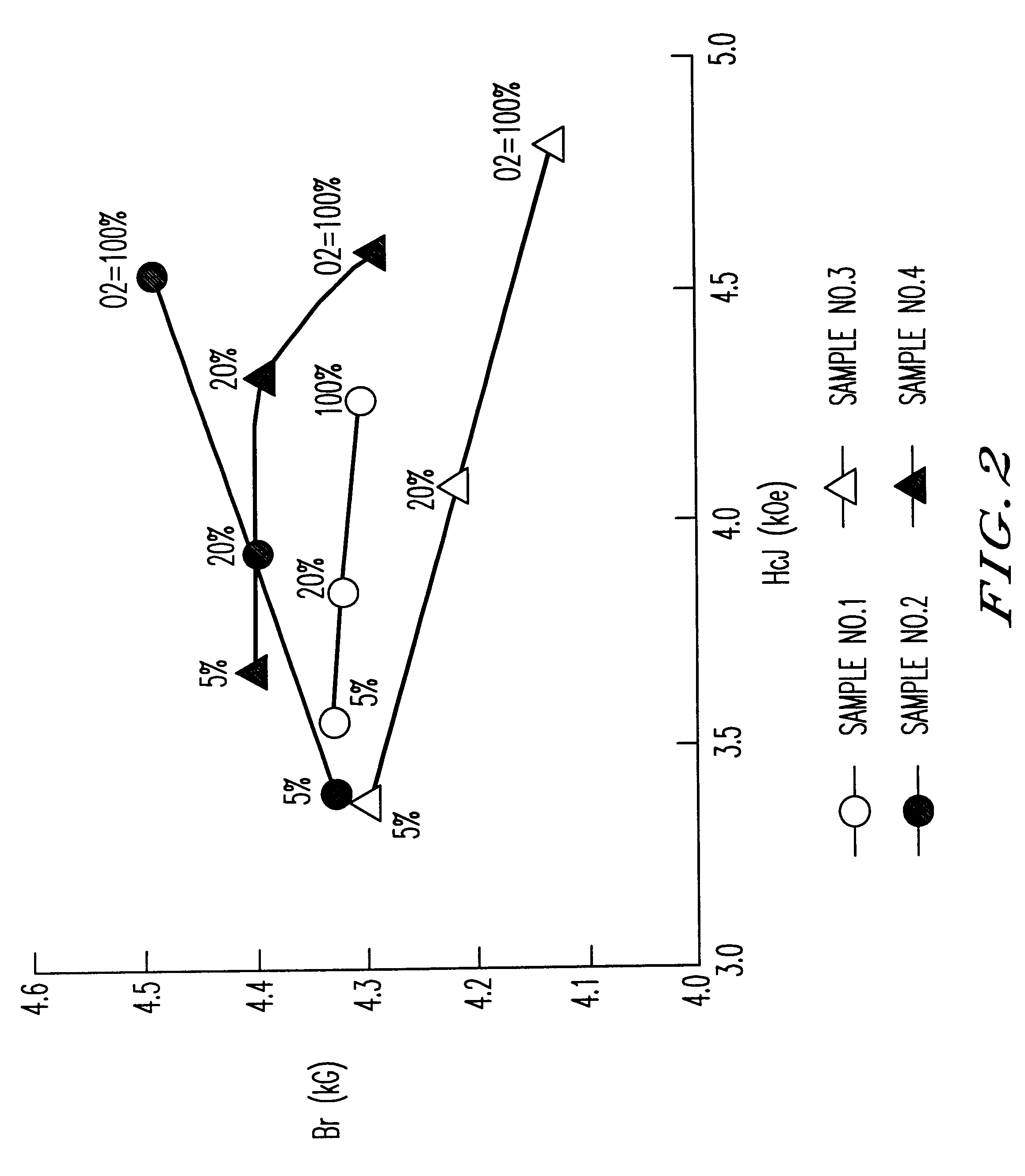

The present invention provides an oxide magnetic material, which includes a primary phase of a hexagonal ferrite containing metallic elements Ca, R, Fe and M, where M represents at least one element selected from the group including Co, Ni and Zn, and R represents at least one element selected from the group including Bi and rare earth elements including Y, with La being essentially included in R; wherein the proportions of the metallic elements Ca, R, Fe and M with respect to the total amount of the metallic elements are from 1 to 13 atomic % for Ca, from 0.05 to 10 atomic % for R, from 80 to 95 atomic % for Fe, and from 1 to 7 atomic % for M. The present invention also provides ferrite particles, a bonded magnet, a sintered magnet, a process for producing them, and a magnetic recording medium, which contain the oxide magnetic material.

Owner:TDK CORPARATION

Rare-earth magnet and manufacturing method thereof and magnet motor

InactiveUS20050284545A1Good balanceHigh coercive forceInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementMagnetic flux

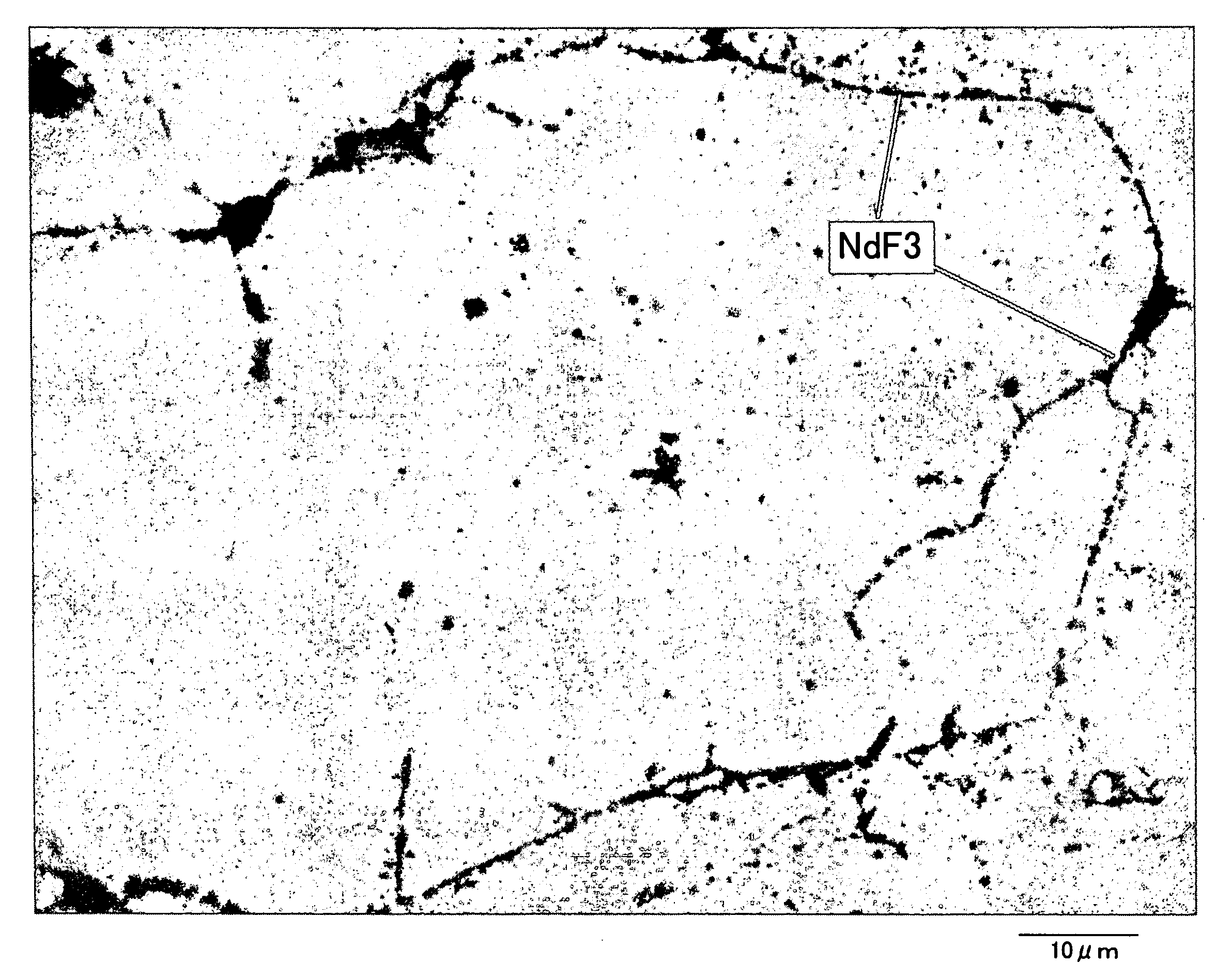

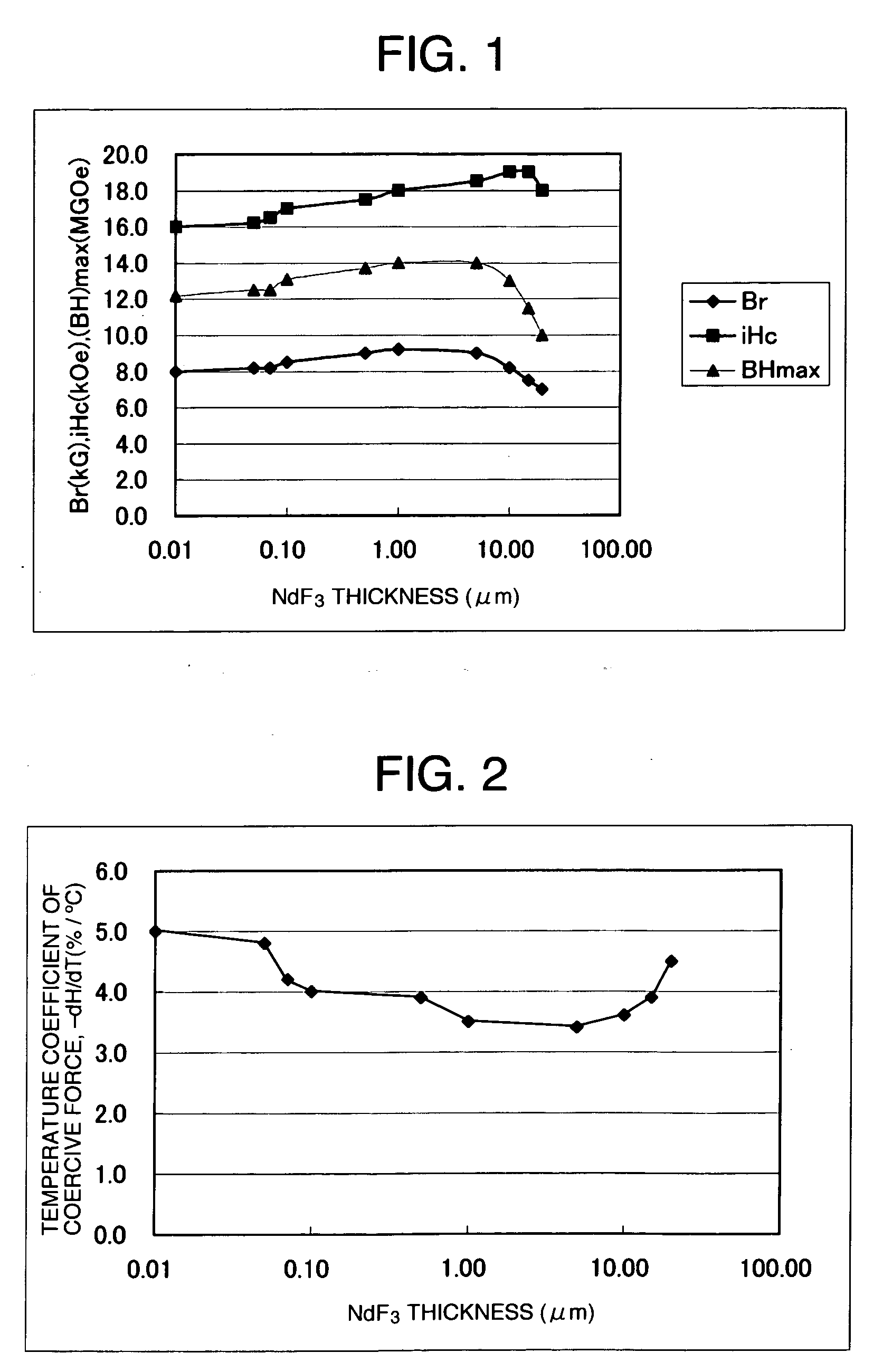

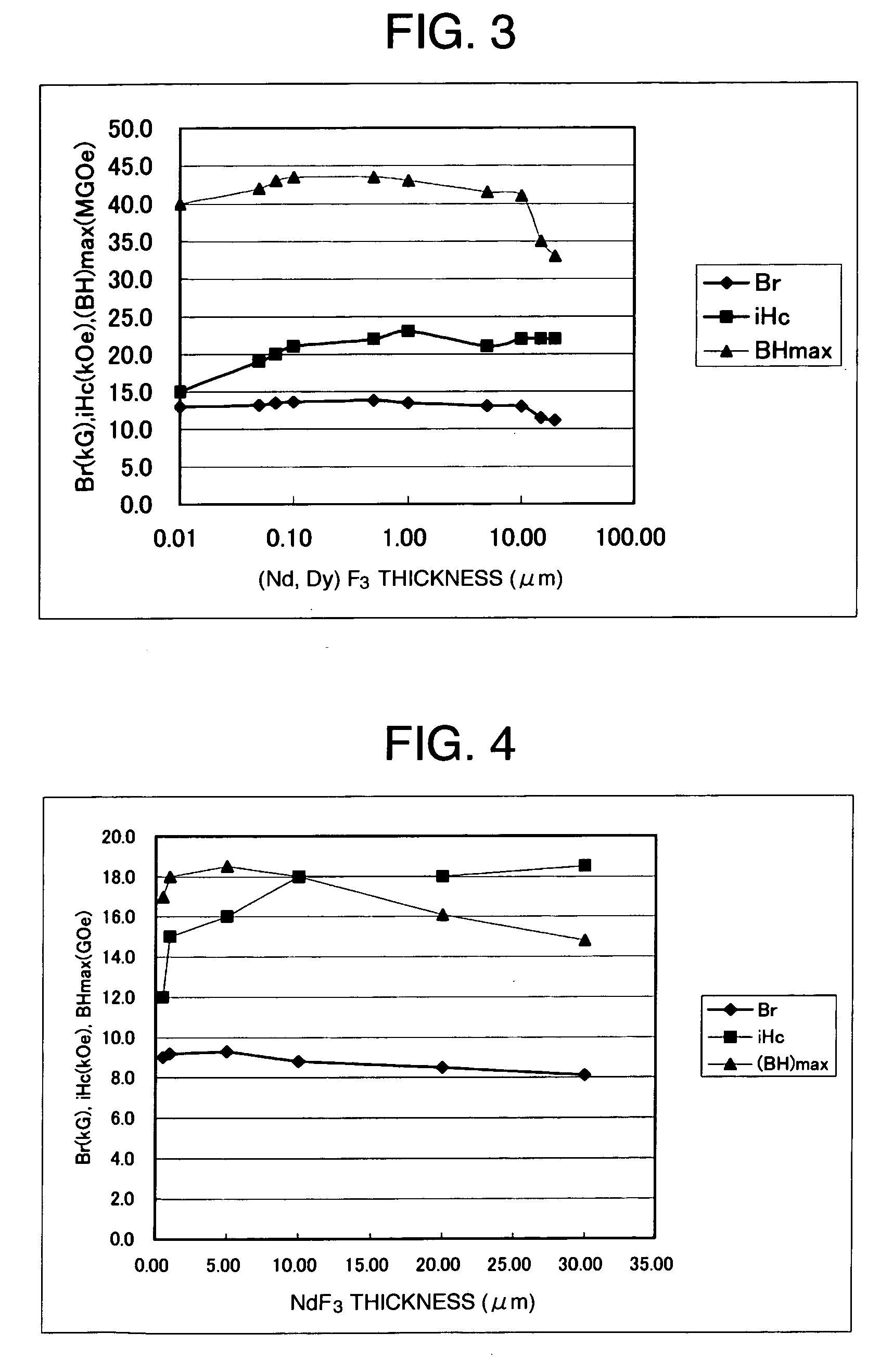

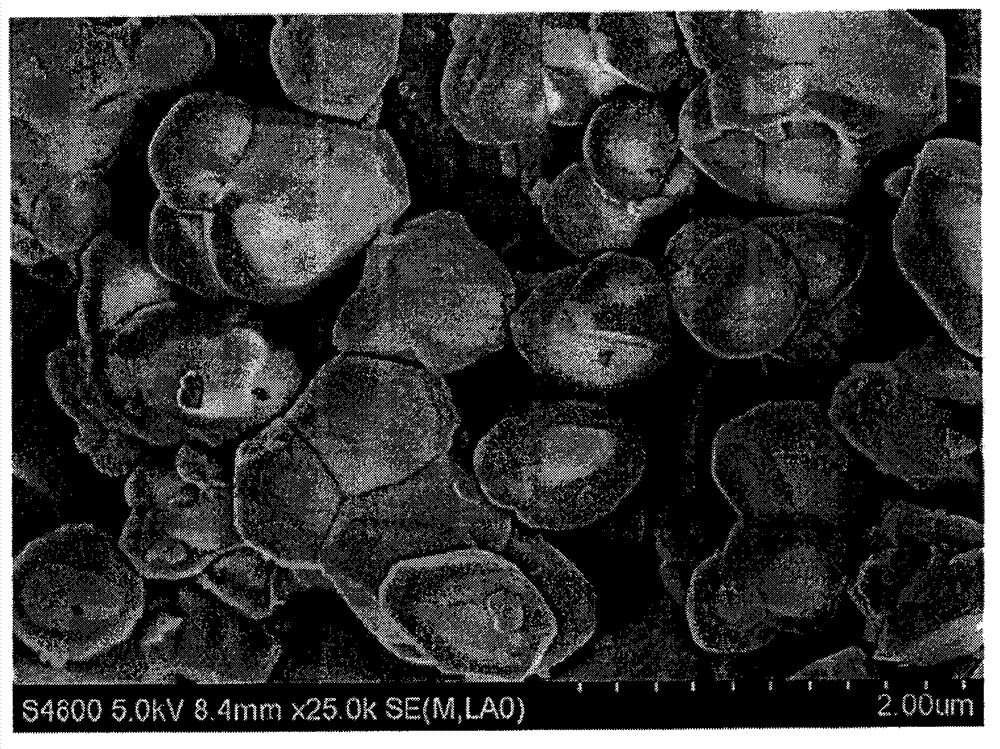

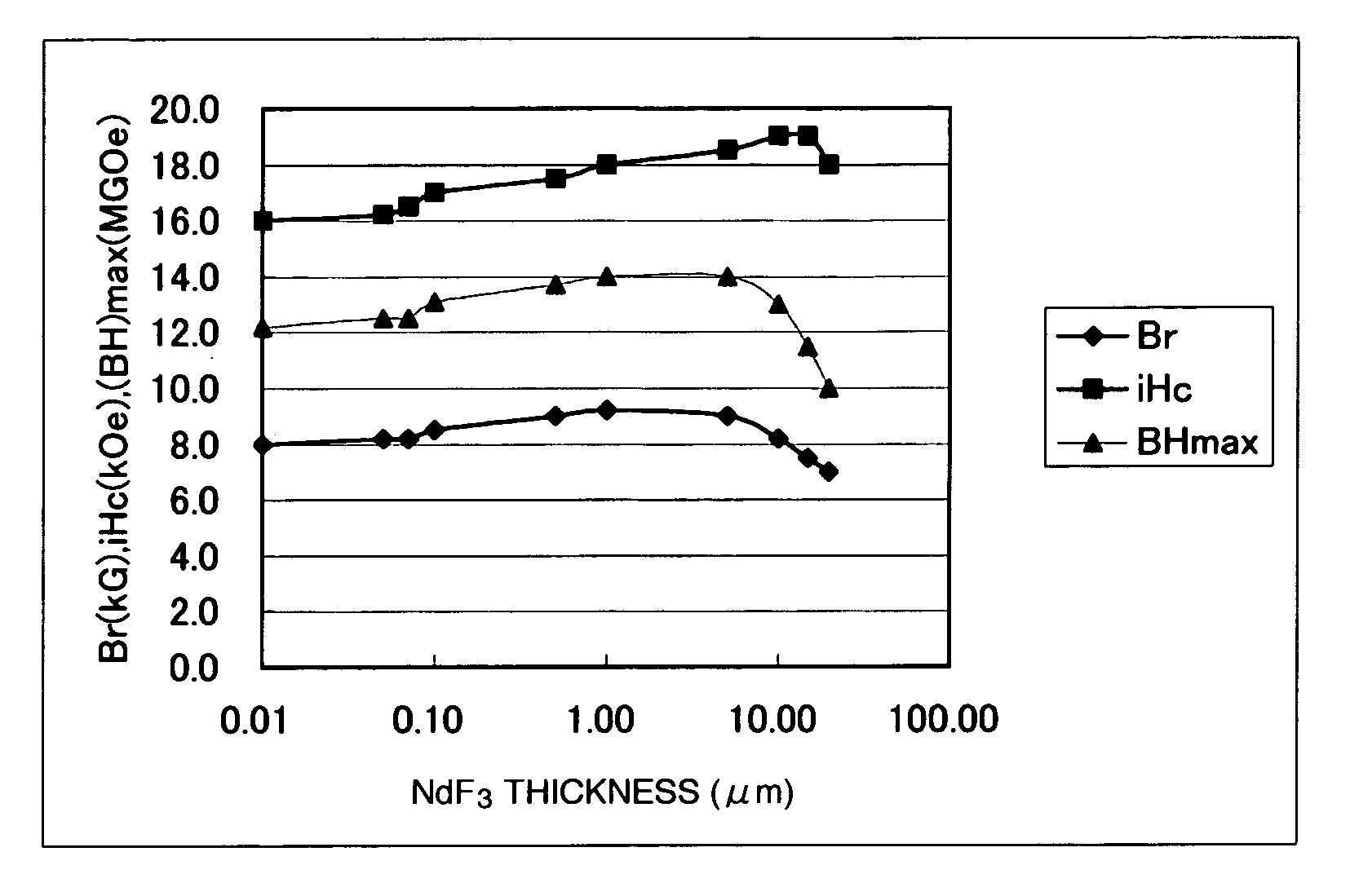

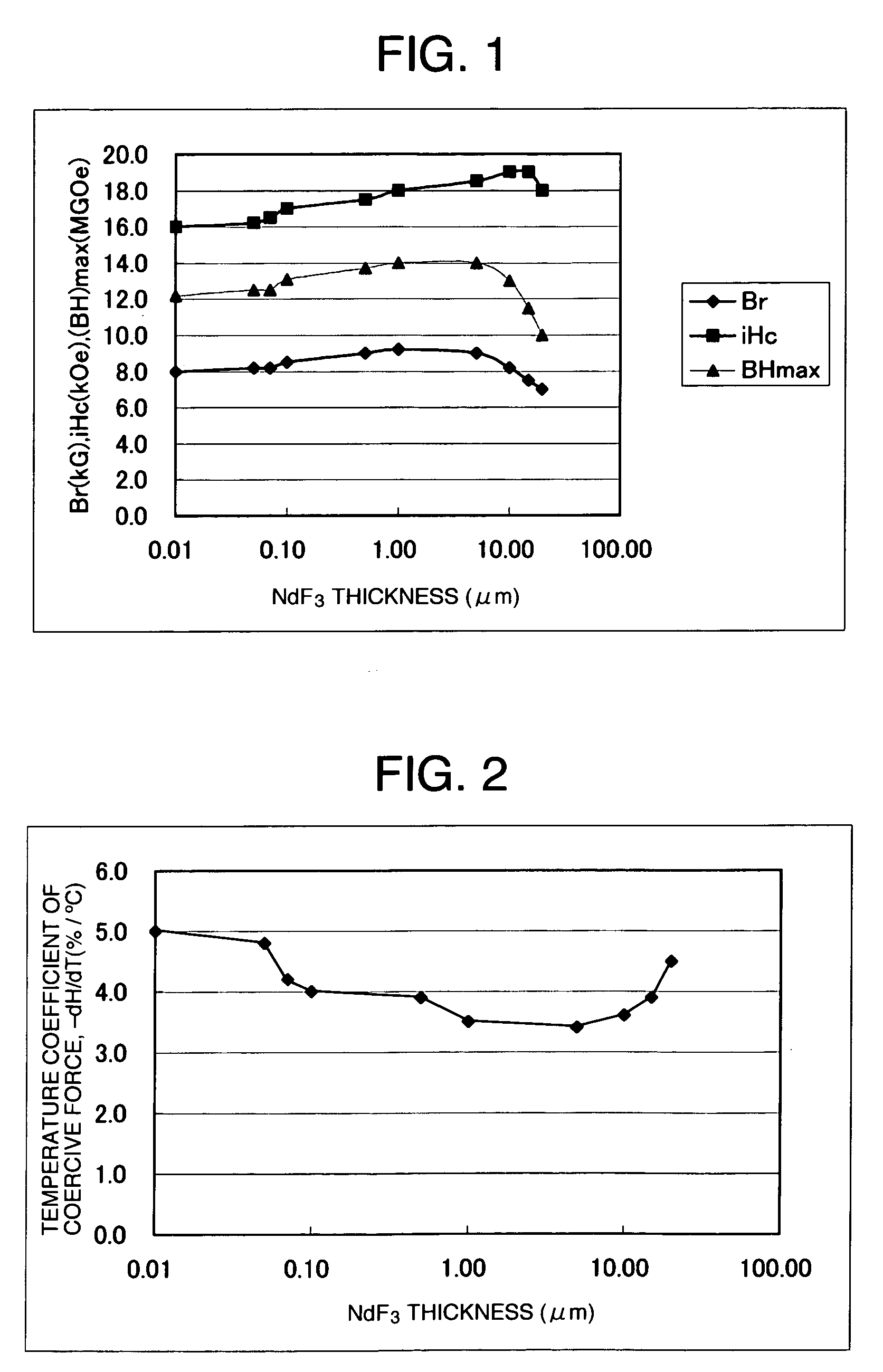

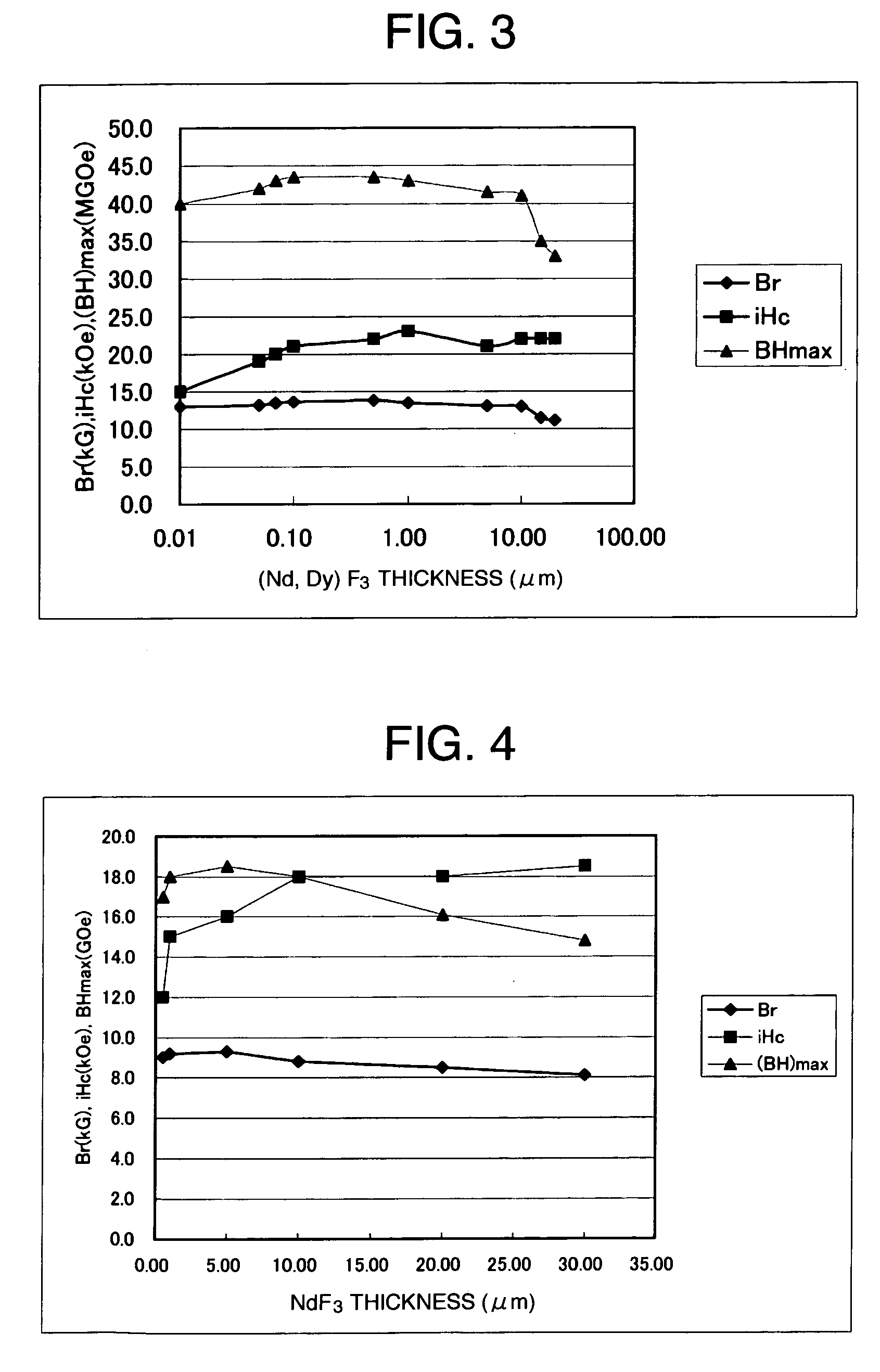

The object of the present invention is to provide a rare earth magnet which enables to achieve a good balance between high coercive force and high residual magnetic flux density, and its manufacturing method. The present invention provides a rare earth magnet in which a layered grain boundary phase is formed on a surface or a potion of a grain boundary of Nd2Fe14B which is a main phase of an R—Fe—B (R is a rare-earth element) based magnet, and wherein the grain boundary phase contains a fluoride compound, and wherein a thickness of the fluoride compound is 10 μm or less, or a thickness of the fluoride compound is from 0.1 μm to 10 μm, and wherein the coverage of the fluoride compound over a main phase particle is 50% or more on average. Moreover, after layering fluoride compound powder, which is formed in plate-like shape, in the grain boundary phase, the rare earth magnet is manufactured by quenching the layered compound after melting it at a vacuum atmosphere at a predetermined temperature, or by heating and pressing the main phase and the fluoride compound to make the fluoride compound into a layered fluoride compound along the grain boundary phase.

Owner:HITACHI LTD

Self starting permanent magnet synchronous motor

InactiveUS20090200885A1Increase resistanceImprove the immunityTransportation and packagingMetal-working apparatusMagnetizationPermanent magnet synchronous motor

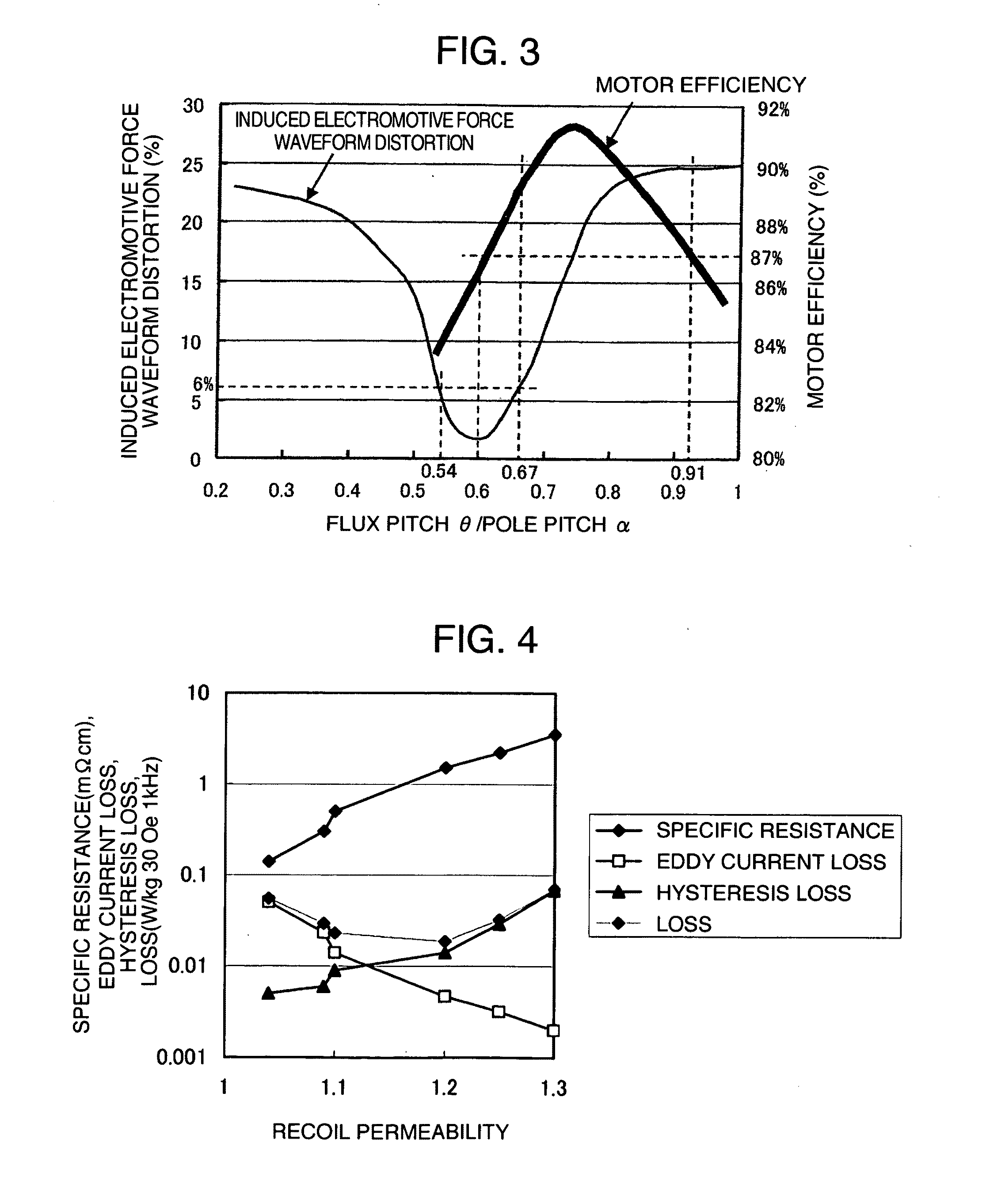

The present invention provides a permanent magnet that a fluorine compound is formed on the surfaces of Fe-based magnetic particles, and a recoil permeability is determined in a range of 1.05 to 1.30 by controlling an iron concentration in the fluorine compound to a range of 1 to 50% to reduce a loss due to magnetization rotation, thereby remedying reduction of a residual magnetic flux density and degradation of steady-state characteristics.

Owner:HITACHI LTD

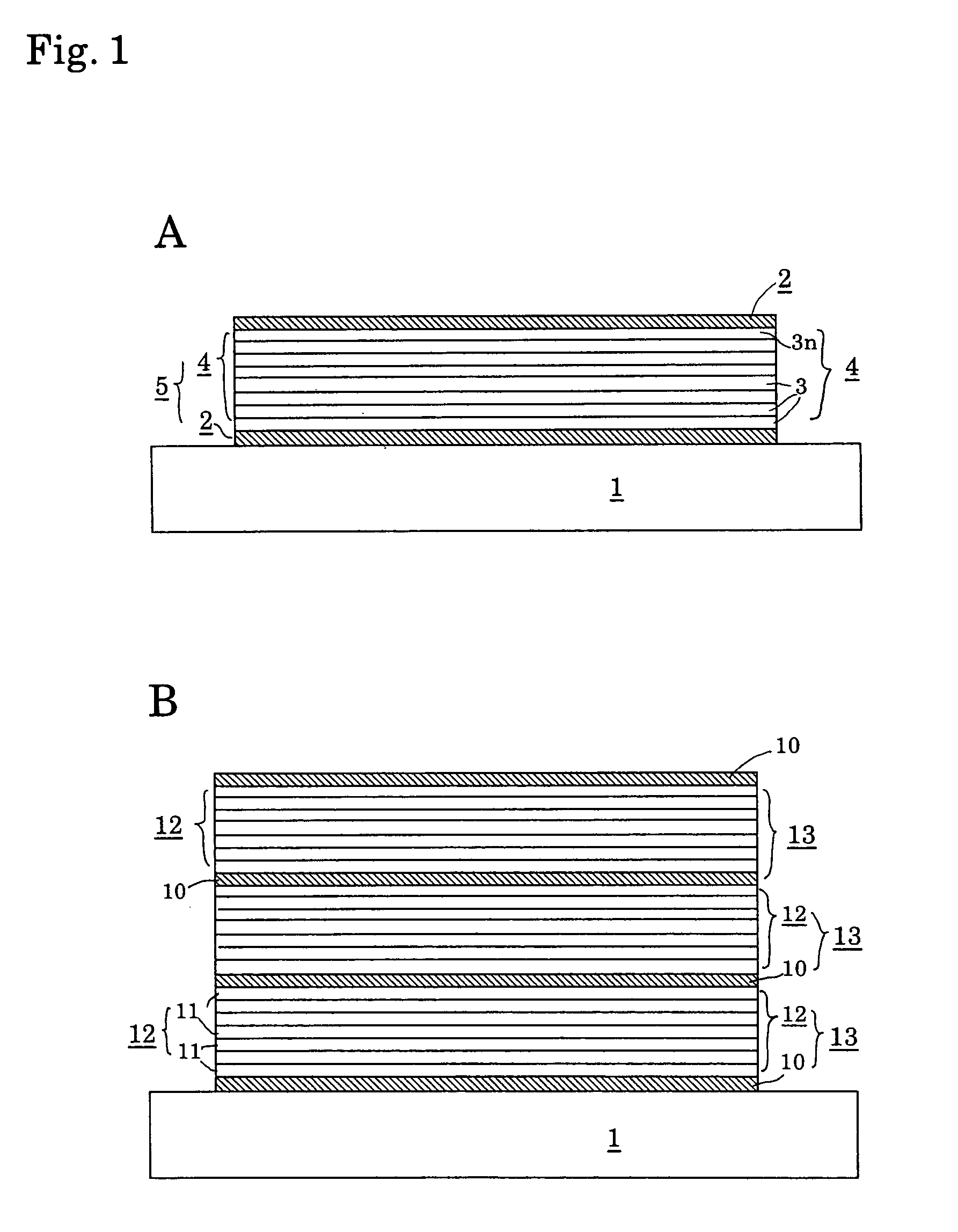

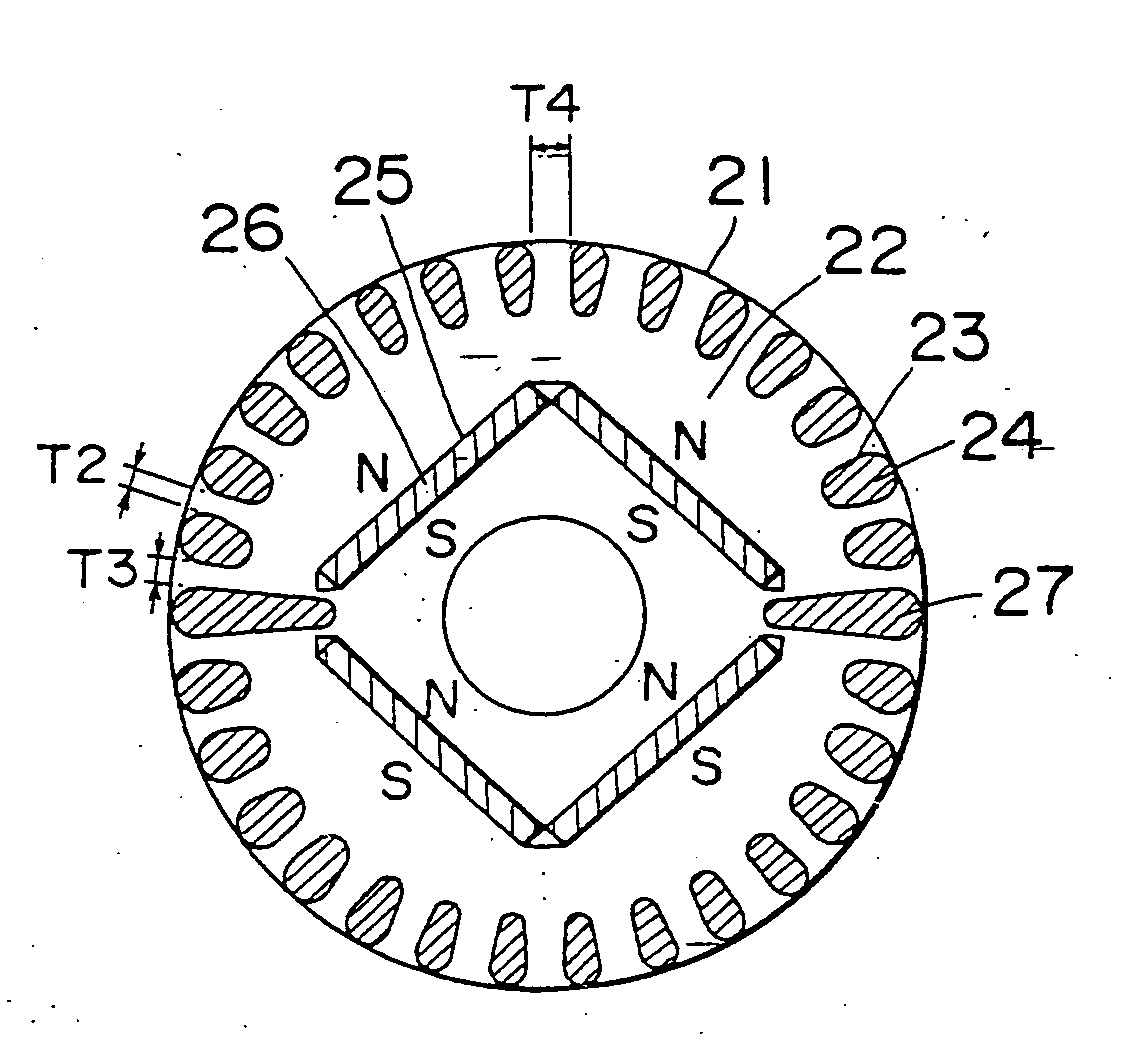

Permanent magnet synchronous motor

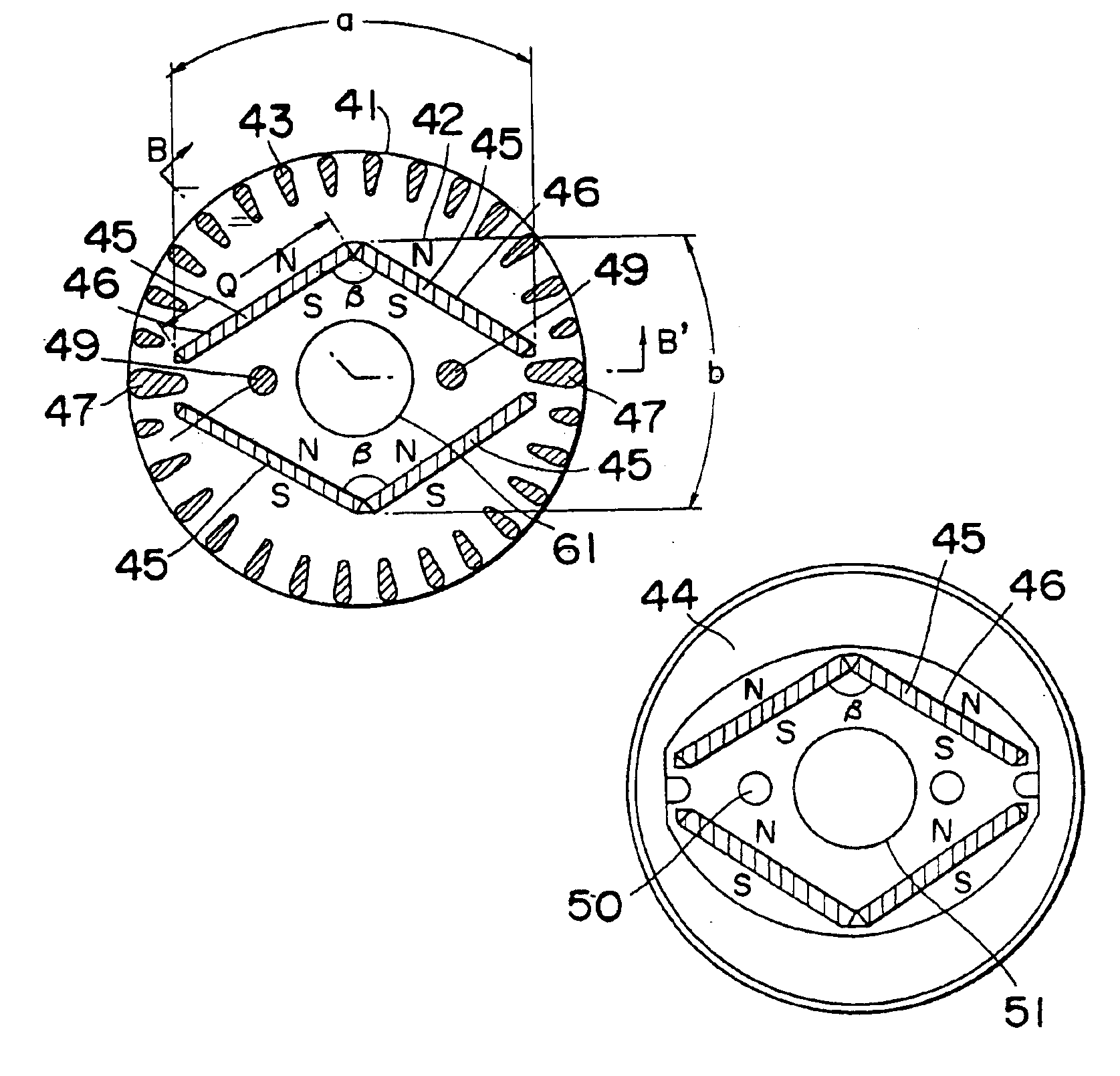

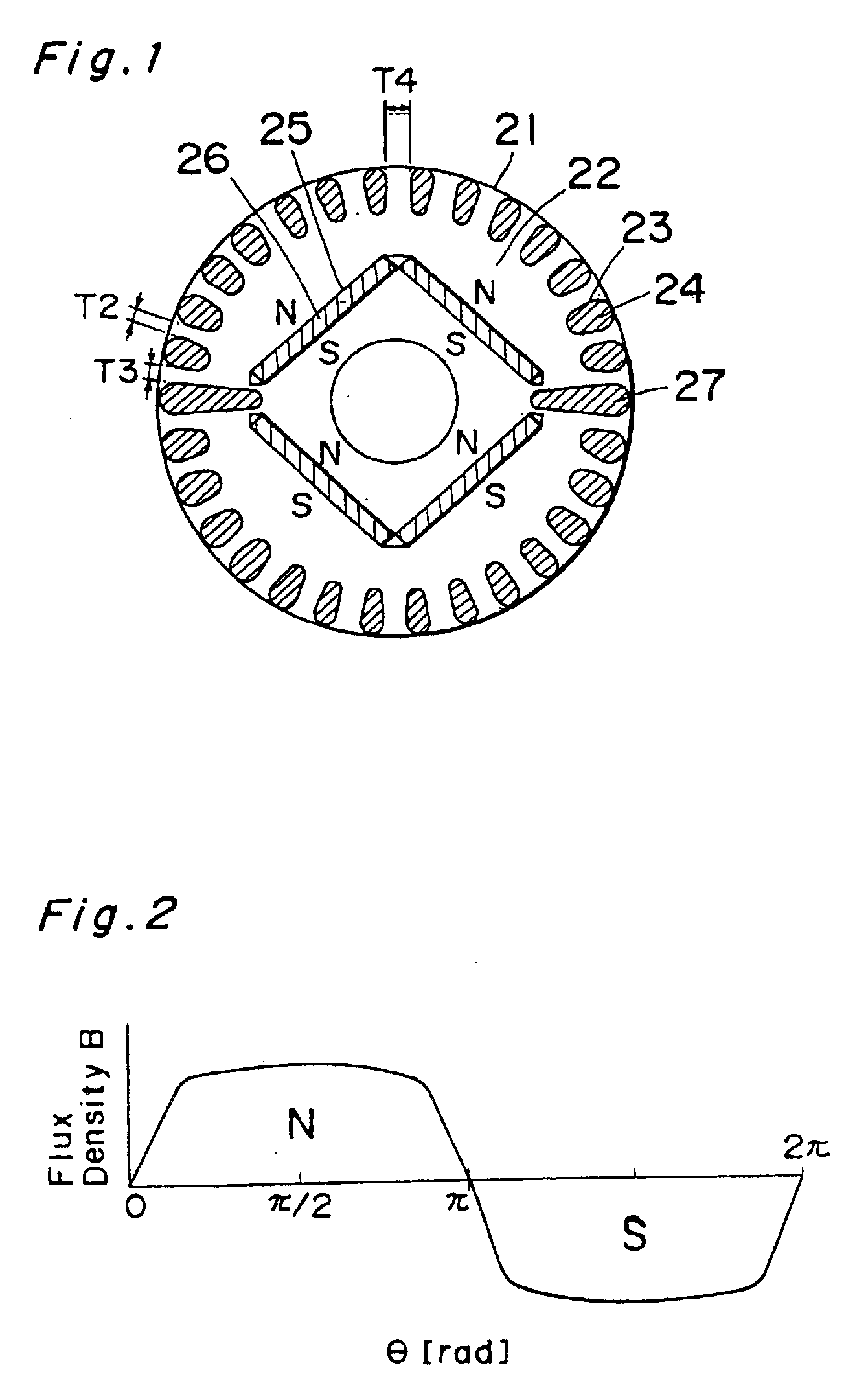

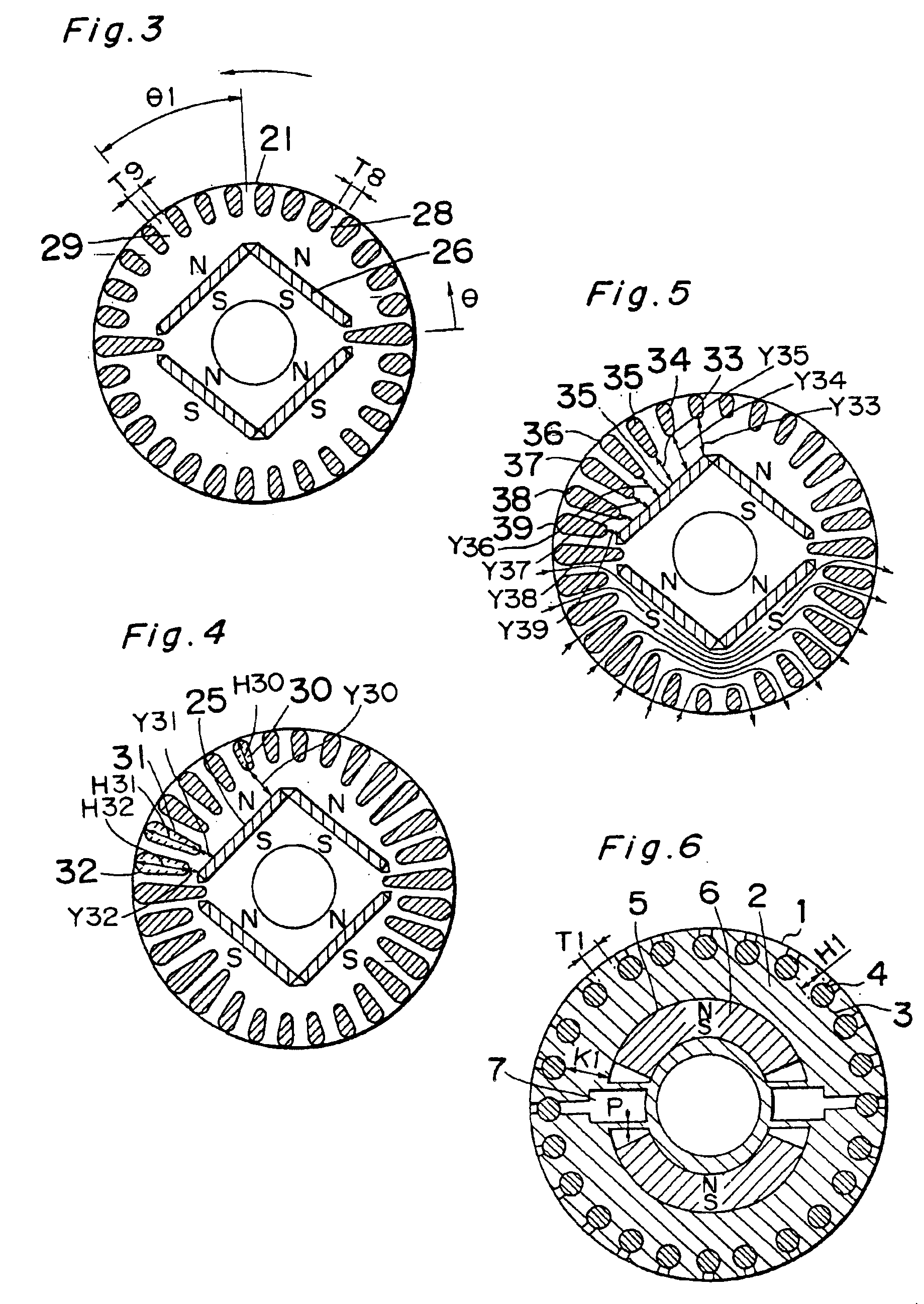

InactiveUS6876119B2Reduce in quantityWork lessMagnetic circuit rotating partsSynchronous motorsElectrical conductorSynchronous motor

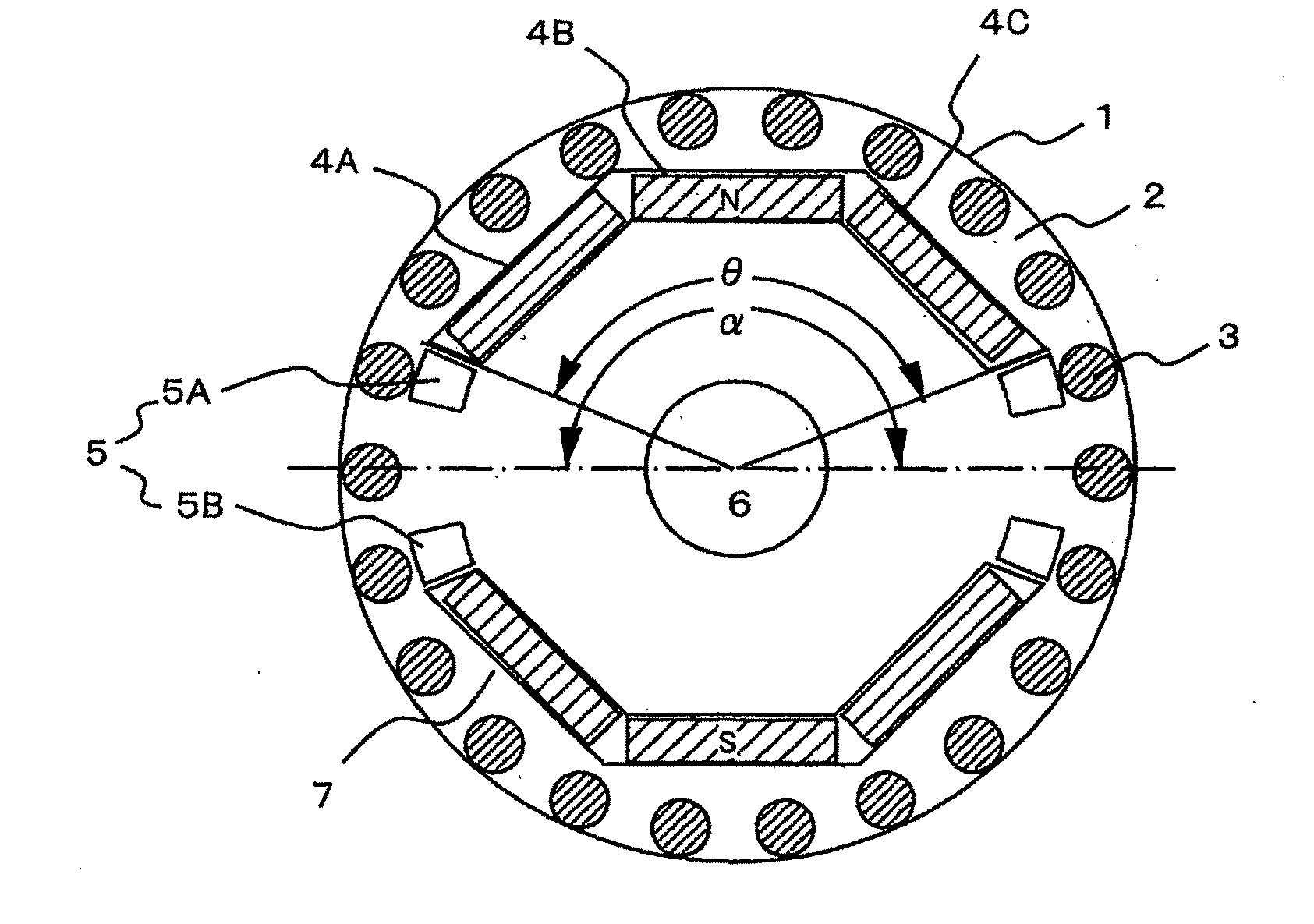

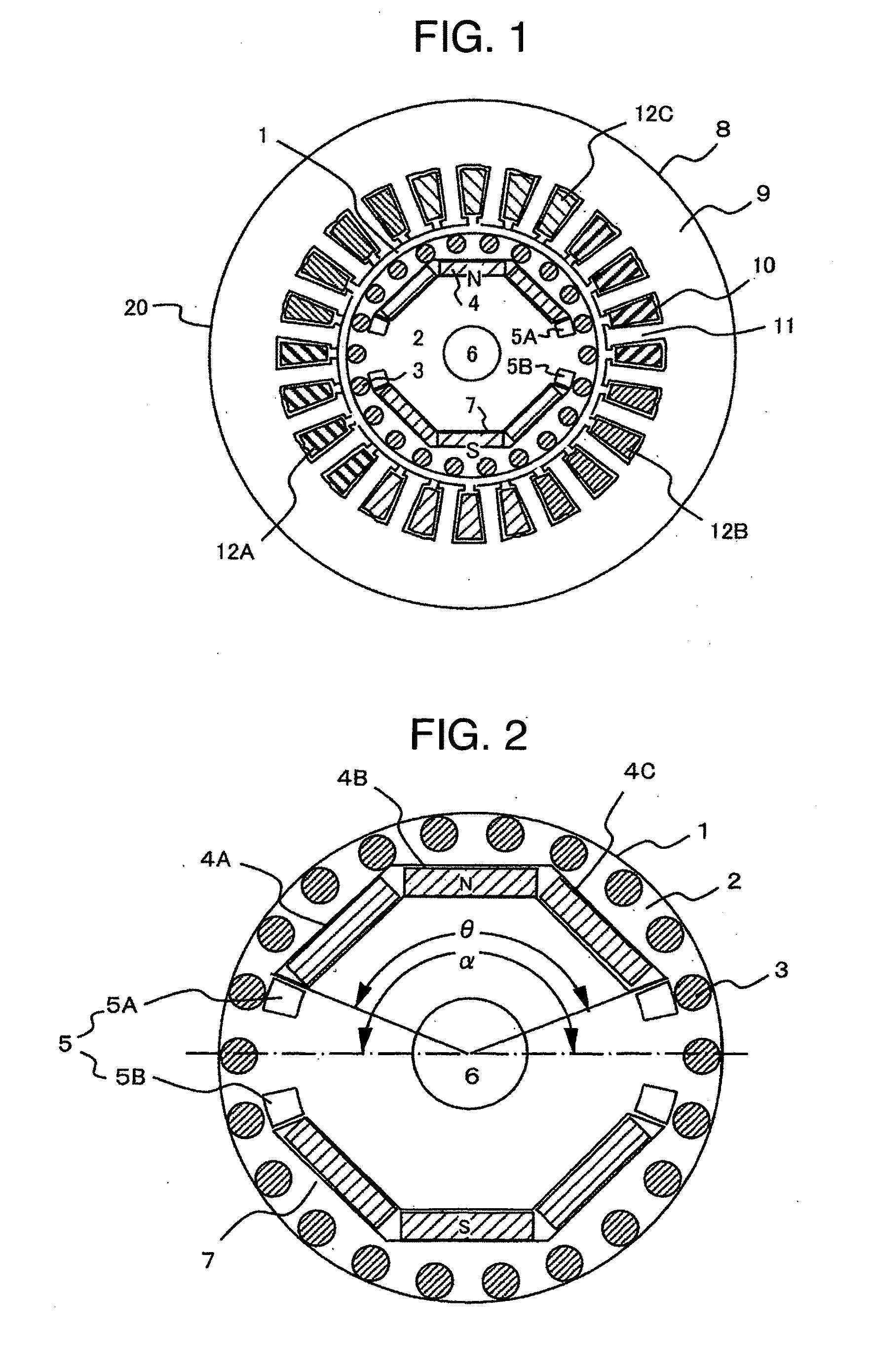

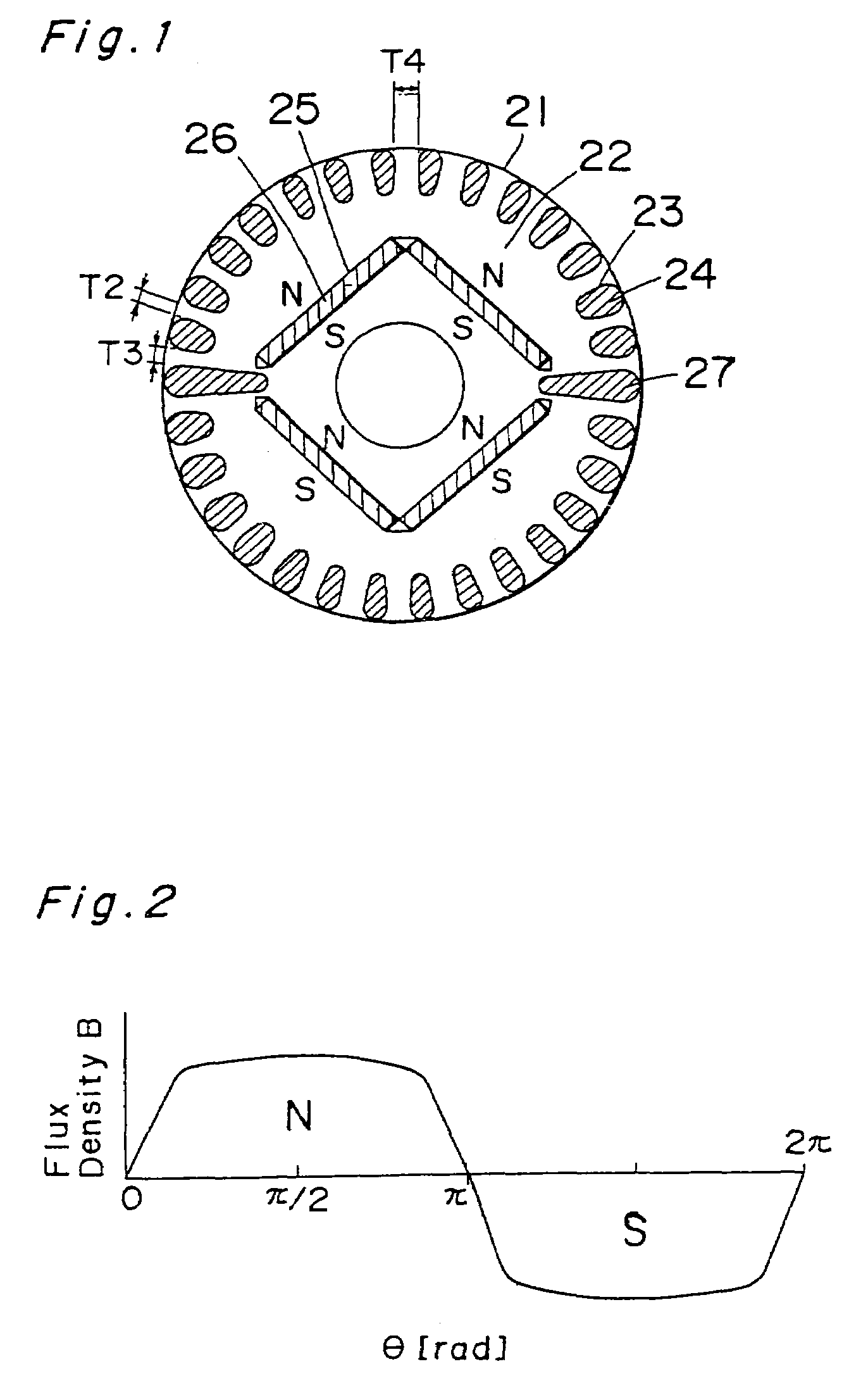

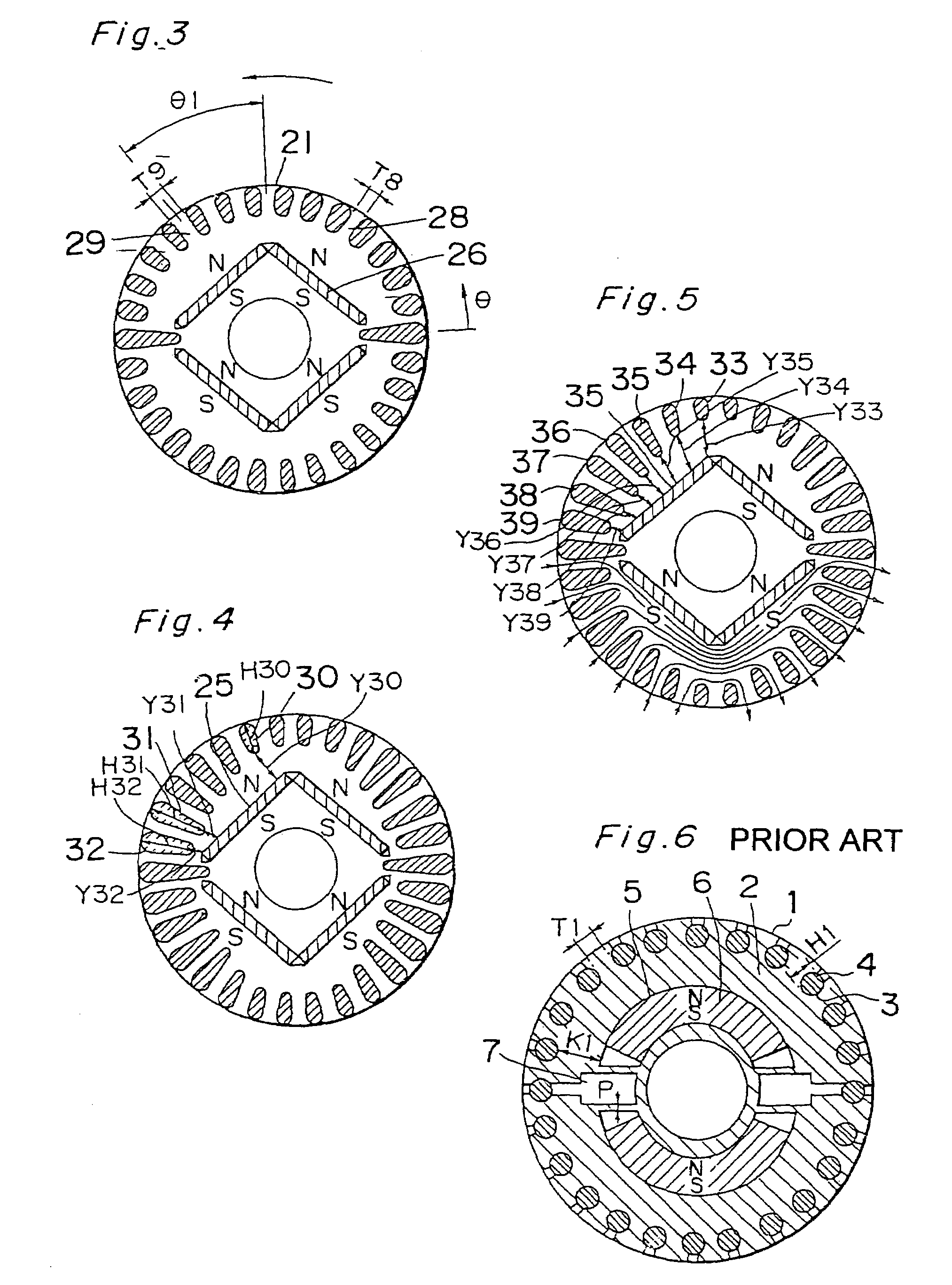

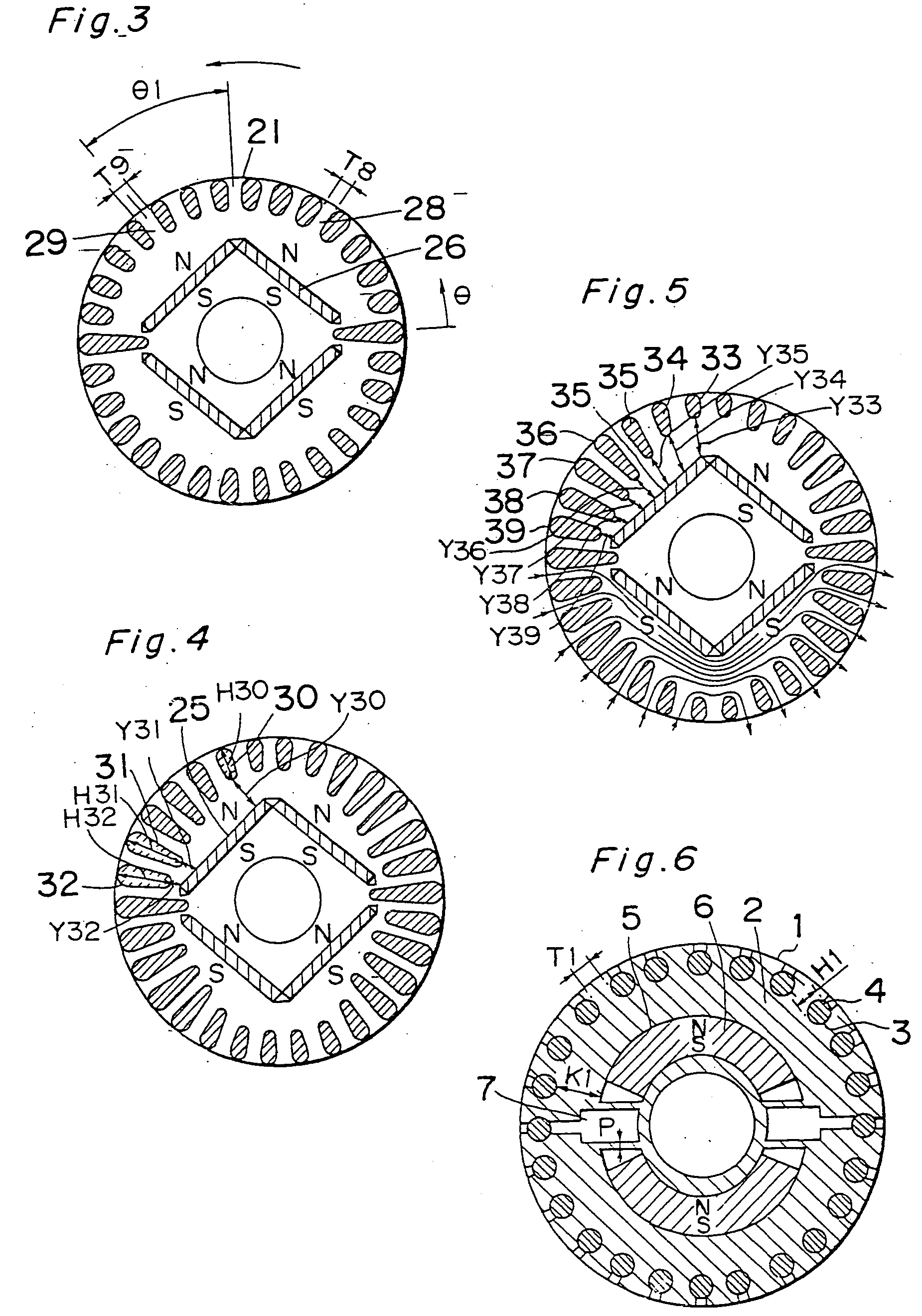

A synchronous motor includes a stator, a rotor and permanent magnets. The rotor includes a rotor iron core and rotatable relative to the stator, a plurality of conductor bars accommodated within corresponding slots in the rotor iron core. The conductor bars have their opposite ends shortcircuited by respective shortcircuit rings to form a starter cage conductor. The rotor also has a plurality of magnet retaining slots defined therein at a location on an inner side of the conductor bars, in which hole permanent magnets are embedded.

Owner:PANASONIC CORP +1

Permanent magnet synchronous motor

InactiveUS7019427B2High Remanent Flux DensityIncrease volumeMagnetic circuit rotating partsSynchronous motorsElectrical conductorSynchronous motor

A synchronous motor includes a stator, a rotor and permanent magnets. The rotor includes a rotor iron core rotatable relative to the stator, and a plurality of conductor bars accommodated within corresponding slots in the rotor iron core. The conductor bars have their opposite ends shortcircuited by respective shortcircuit rings to form a starter cage conductor. The rotor also has a plurality of magnet retaining slots defined therein at a location on an inner side of the conductor bars, in which hole permanent magnets are embedded.

Owner:PANASONIC CORP +1

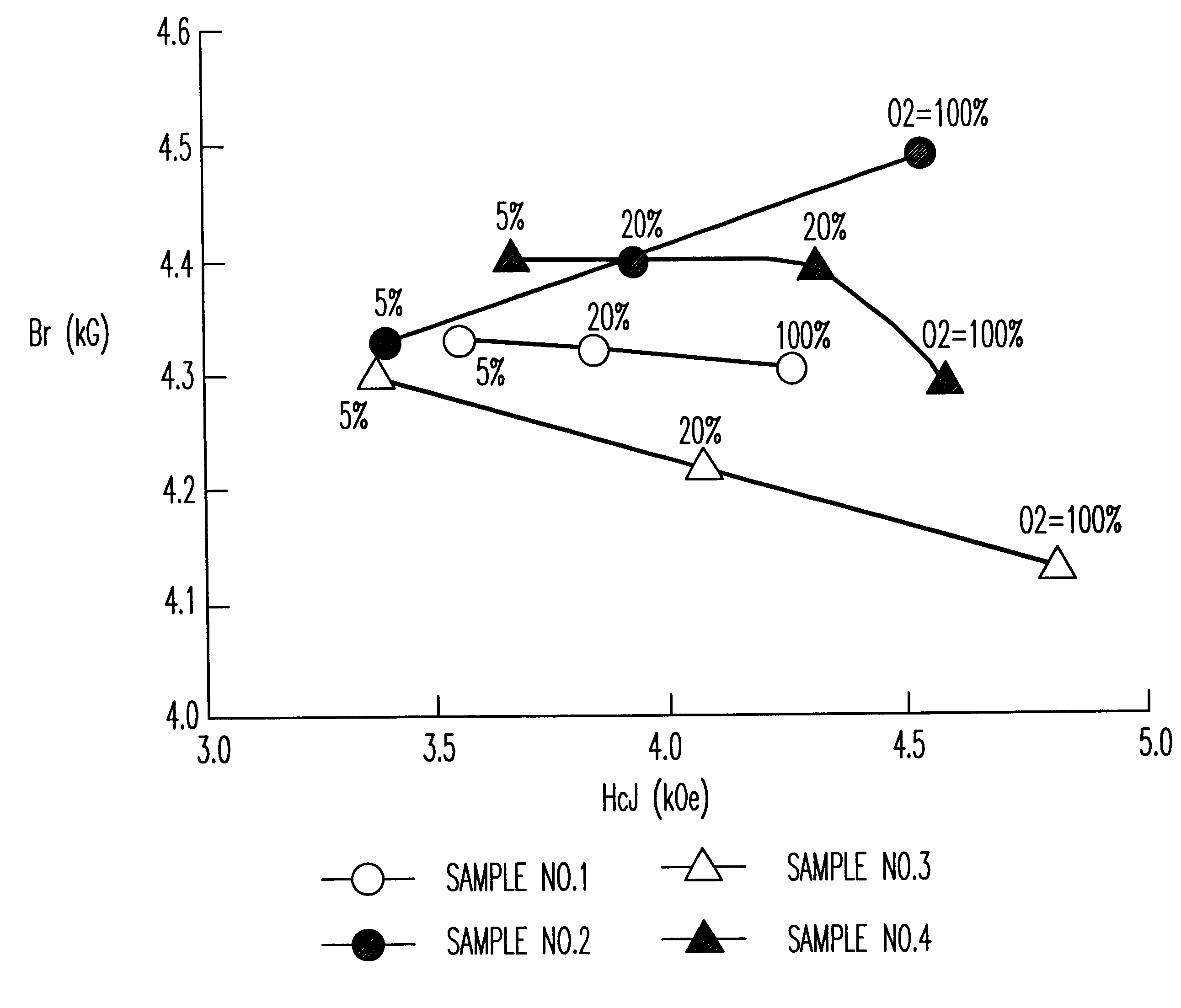

Plumbite type yttrium permanent magnetic ferrite material and preparation method thereof

The invention discloses a plumbite type yttrium permanent magnetic ferrite material and a preparation method thereof. The plumbite type yttrium permanent magnetic ferrite material is a hexagonal system, the chemical structural formula of which is R1-x-yYxLayO.nFe(12-z) / nCoz / nO3, wherein x is less than or equal to 0.5 but greater than or equal to 0.01, y is less than or equal to 0.75 but greater than or equal to 0.1, z is less than or equal to 0.082 but greater than or equal to 0.07, n is less than or equal to 6.5 but greater than or equal to 5.0, and (1-x-y) is less than or equal to 0.5 but greater than or equal to 0. R is Ca, Ba, Sr or one, two and three of Ce, Pr and Nd and Sm in lanthanide series exclusive of La. Compared with the conventional permanent magnetic ferrite, for the plumbite type yttrium permanent magnetic ferrite material, at the sintering temperature of 1150-1300 DEG C, the remanence Br value reaches 4.2-4.8kGs, the magnetic induction coercive force Hcb value reaches 4.2-5.2kOe, the intrinsic coercive force Hcj value reaches 4.5-6.0kOe, and the magnetic energy product value reaches 5.2-5.7MGOe. The plumbite type yttrium permanent magnetic ferrite material provided by the invention is high in remanence and intrinsic coercive force. When the sintered magnet becomes smaller and thinner, the high residual magnetic flux density is still maintained.

Owner:ANHUI UNIVERSITY

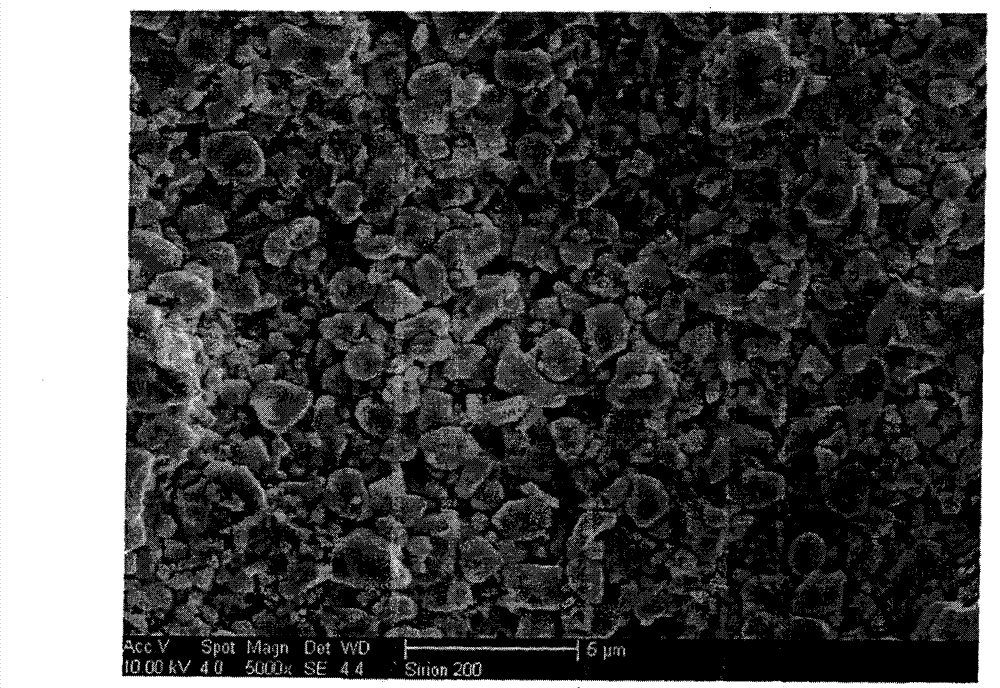

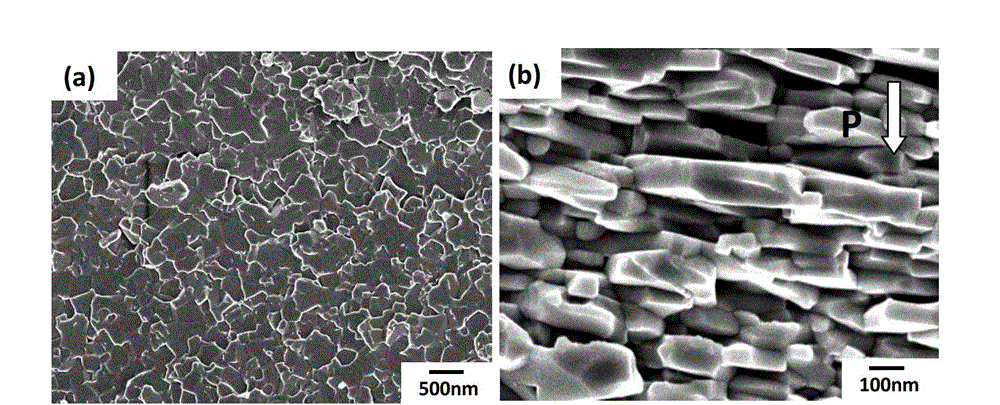

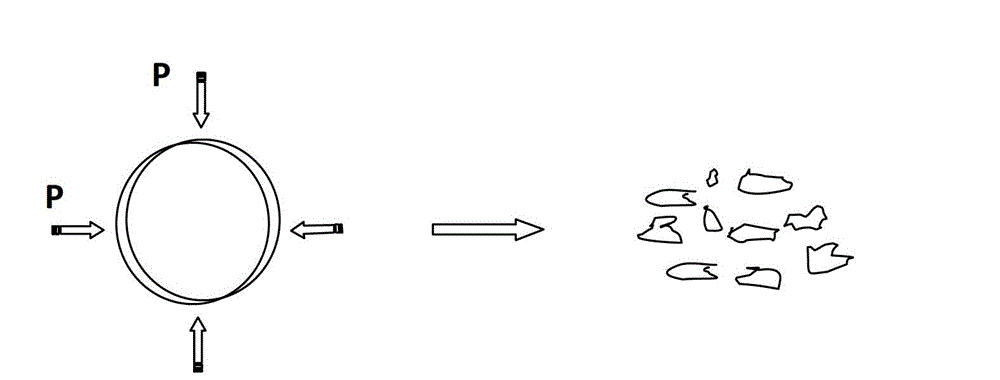

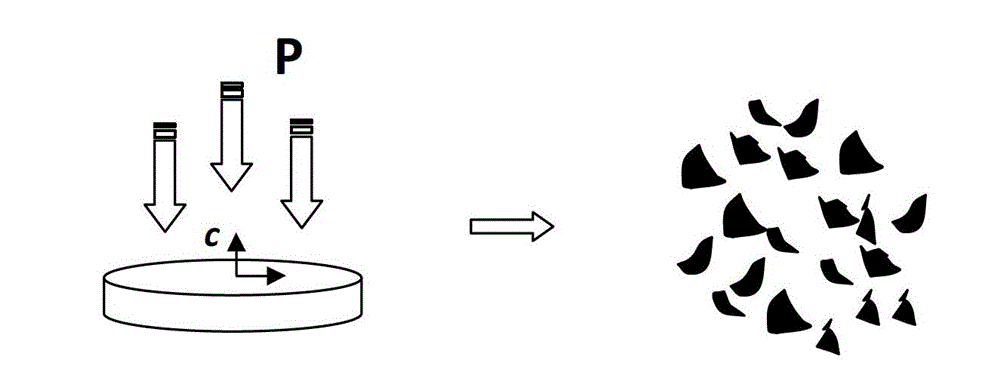

Method for preparing anisotropic neodymium iron boron magnetic powder through directionally breaking thermal deformed magnet

ActiveCN103151161AImprove coercive forceHigh energy productInductances/transformers/magnets manufactureMagnetic materialsThermal deformationRoom temperature

The invention discloses a method for preparing anisotropic neodymium iron boron magnetic powder through directionally breaking a thermal deformed magnet. The method comprises the following steps: (1) preparing a full-densification isotropic neodymium iron boron magnet; (2) preparing a thermal deformation anisotropic neodymium iron boron magnet; (3) directionally breaking the thermal deformation magnet: directionally breaking the round-cake-shaped anisotropic neodymium iron boron magnet, prepared in the step (2), by applying a symmetrical and circulating applied force along a radial direction at room temperature under the protection of argon, wherein the breaking force is 600-700MPa, so as to obtain a lamellar magnetic sheet; and (4) breaking the magnetic sheet in a regularized way: carrying out regularized breaking on the magnetic sheet prepared in the step (3) under the protection of the argon by adopting a rolling minding method, so as to obtain the anisotropic neodymium iron boron magnetic powder.

Owner:SICHUAN UNIV

Rare-earth magnet and manufacturing method thereof and magnet motor

InactiveUS7179340B2Improve balanceImprove coercive forceInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementRare-earth magnet

The object of the present invention is to provide a rare earth magnet which enables to achieve a good balance between high coercive force and high residual magnetic flux density, and its manufacturing method. The present invention provides a rare earth magnet in which a layered grain boundary phase is formed on a surface or a potion of a grain boundary of Nd2Fe14B which is a main phase of an R—Fe—B (R is a rare-earth element) based magnet, and wherein the grain boundary phase contains a fluoride compound, and wherein a thickness of the fluoride compound is 10 μm or less, or a thickness of the fluoride compound is from 0.1 μm to 10 μm, and wherein the coverage of the fluoride compound over a main phase particle is 50% or more on average. Moreover, after layering fluoride compound powder, which is formed in plate-like shape, in the grain boundary phase, the rare earth magnet is manufactured by quenching the layered compound after melting it at a vacuum atmosphere at a predetermined temperature, or by heating and pressing the main phase and the fluoride compound to make the fluoride compound into a layered fluoride compound along the grain boundary phase.

Owner:HITACHI LTD

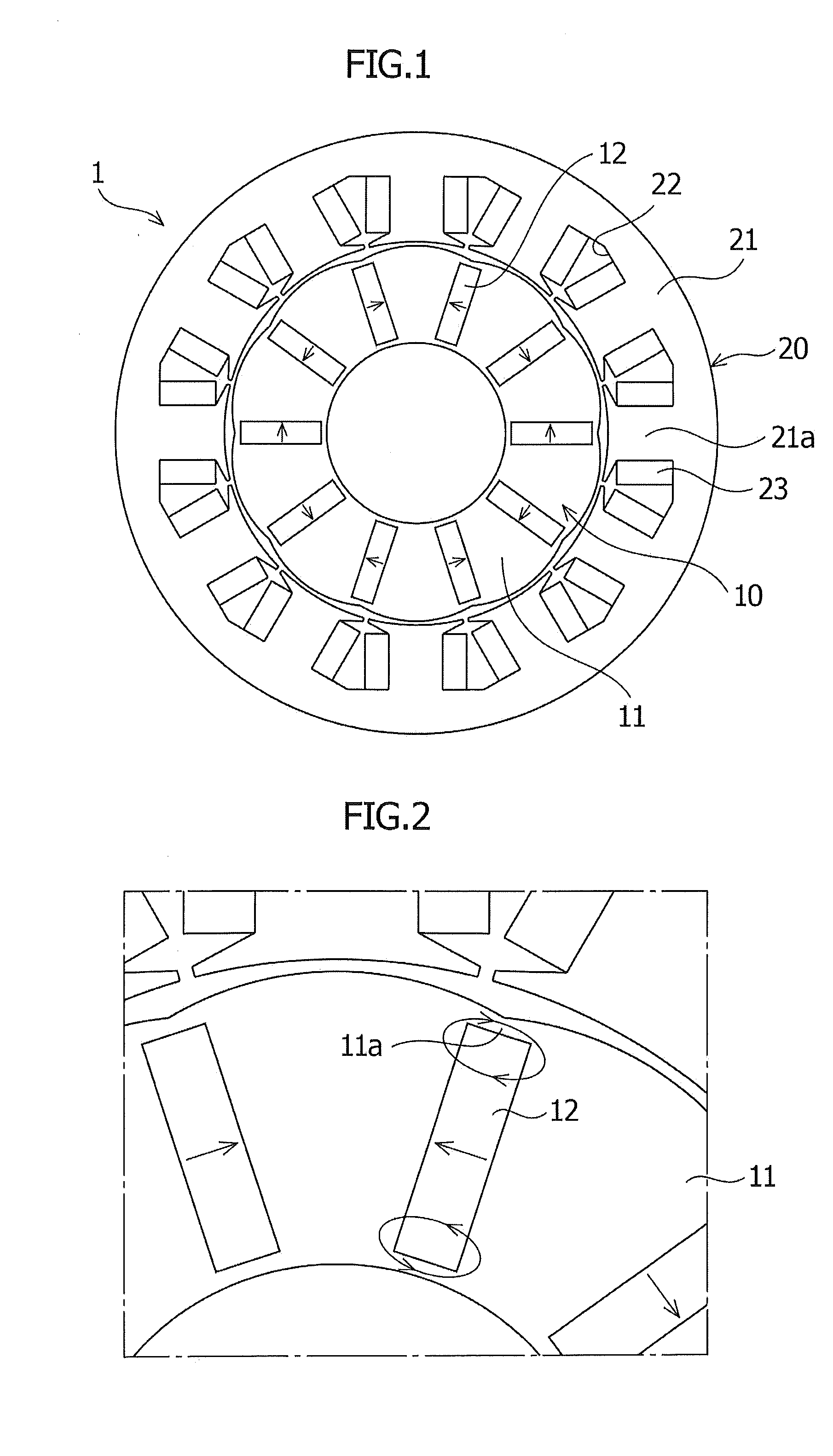

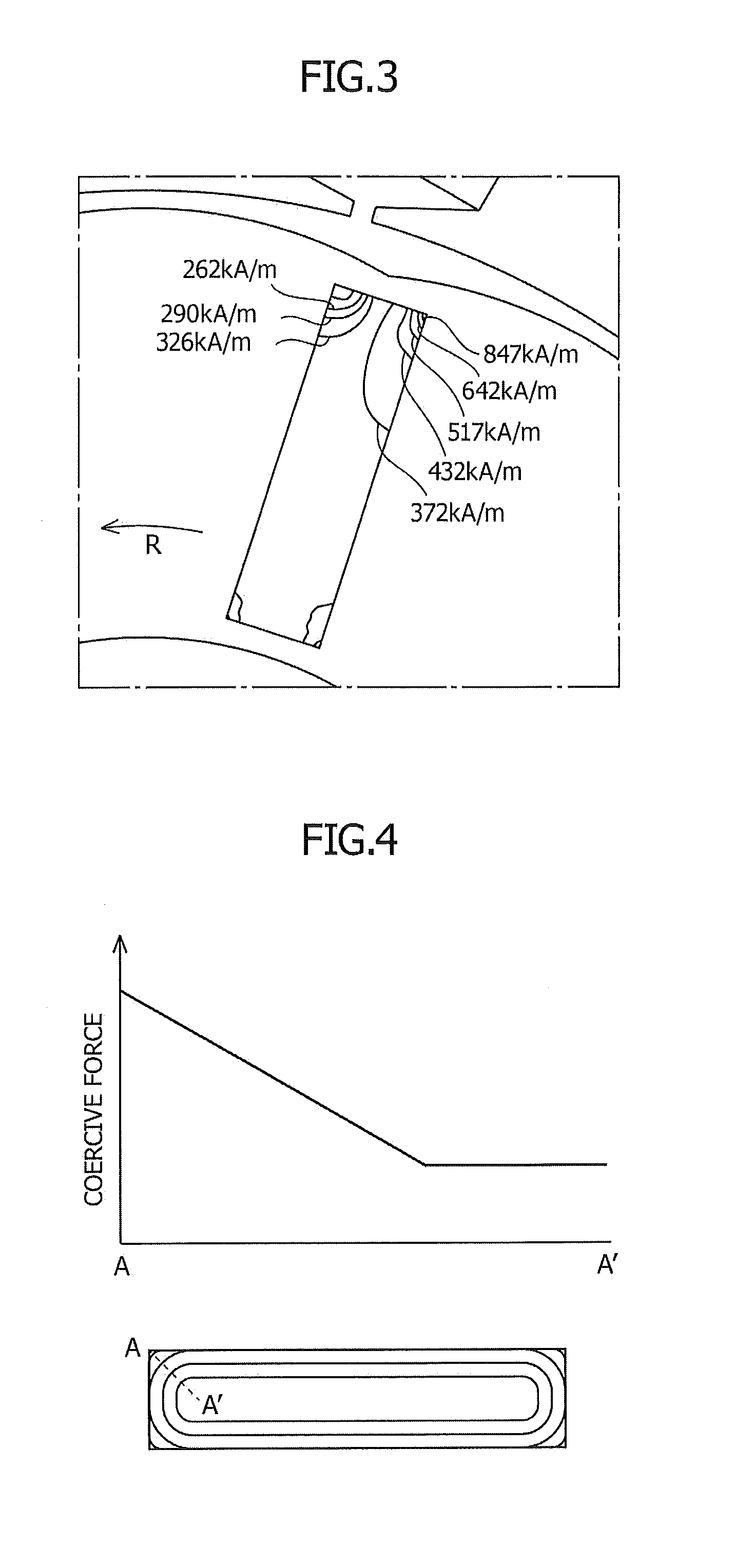

Rotor and permanent magnetic rotating machine

InactiveUS20130119811A1Improve resistance to demagnetizationHigh Remanent Flux DensityMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsMagnetPhysics

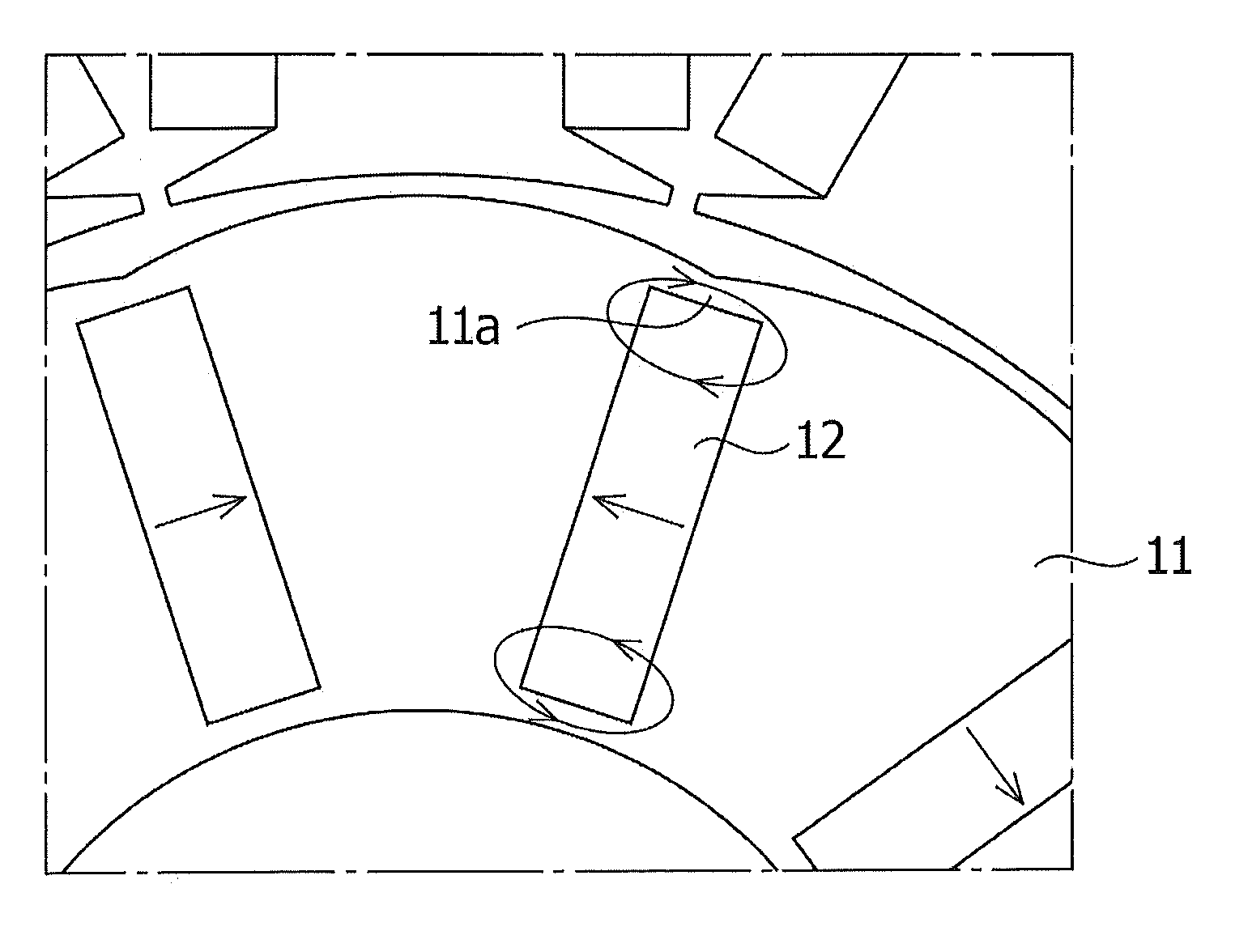

Provided are a rotor adapted for a permanent magnetic rotating machine, the machine includes a rotor and a stator comprising a stator core having two or more slots, and winding wires wound through the stator core. The rotor includes a rotor core having two or more insertion holes formed in the rotor core; and two or more permanent magnets in the two or more insertion holes; and each of the permanent magnets is in form of rectangle with two opposite sides substantially parallel to a radial direction of the rotor on a surface vertical to a rotation axis of the rotor, and is in form of rectangular parallelepiped with four longitudinal edges parallel to the rotation axis, and the permanent magnet has at least one angular portion of four angular portions containing the four longitudinal edges.

Owner:SHIN ETSU CHEM IND CO LTD

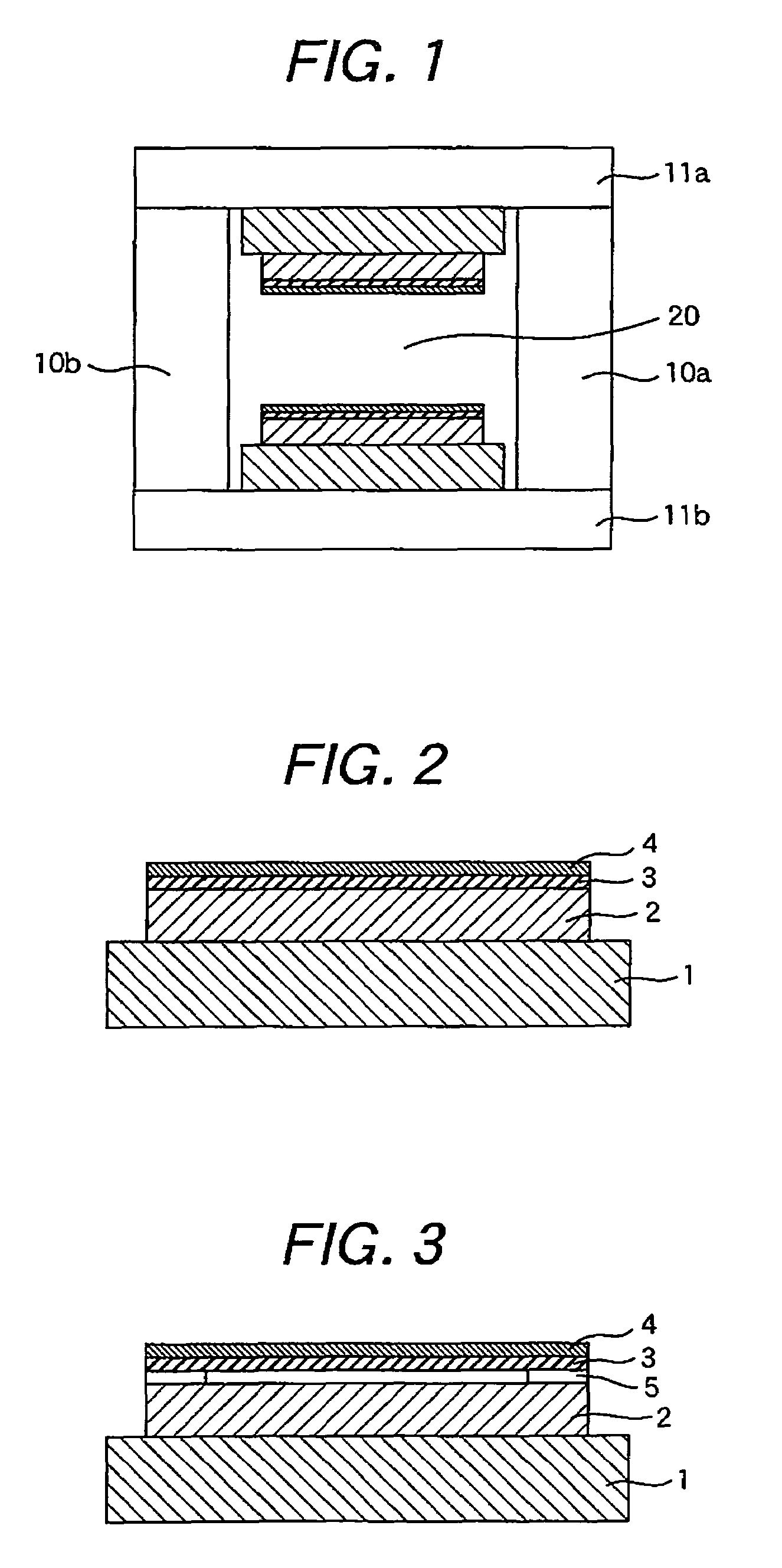

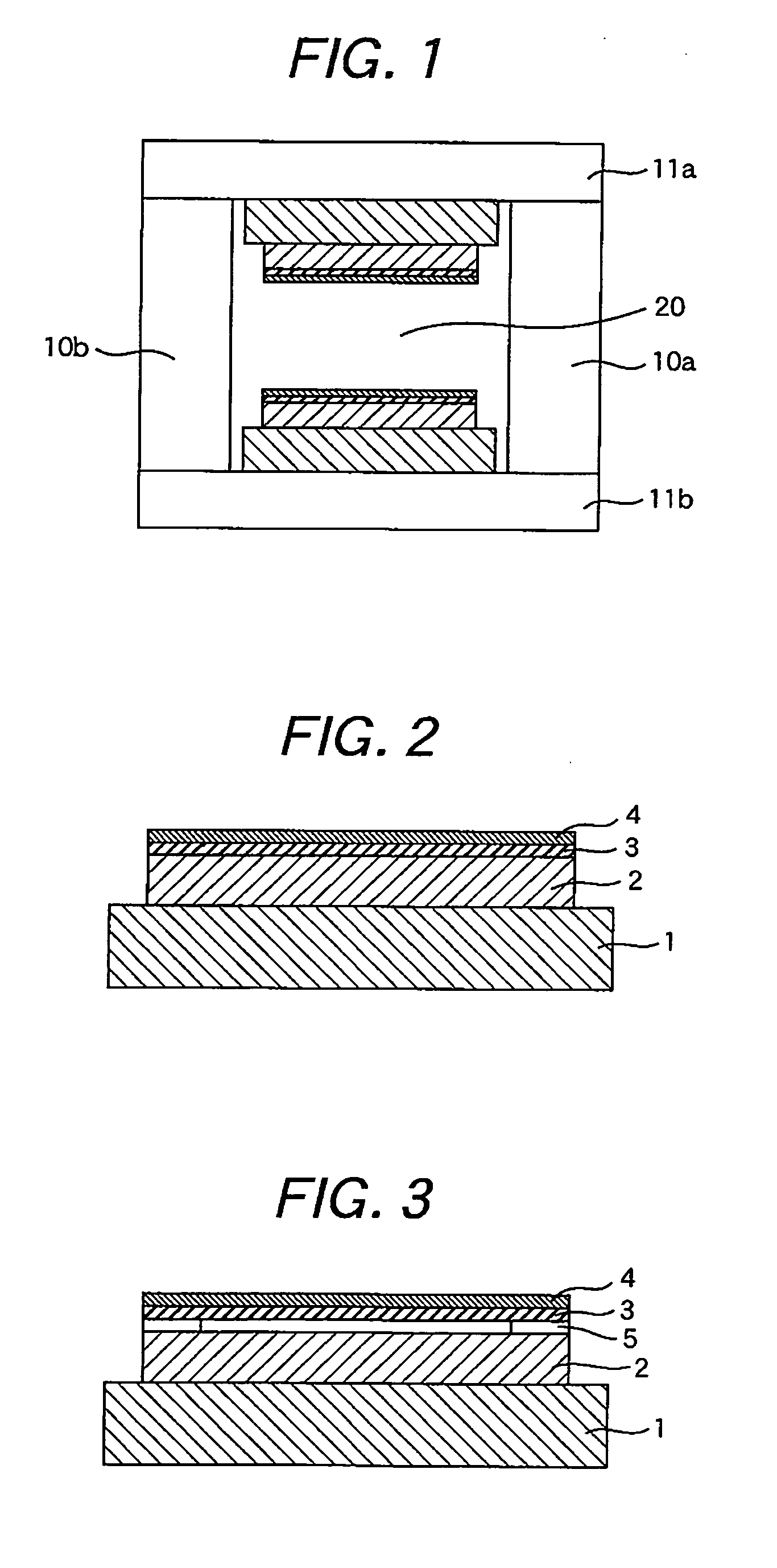

MRI apparatus with high-resistance magnet

InactiveUS7352184B2Quality improvementHigh magnetic coercive forceMagnetic measurementsThin material handlingElectrical resistance and conductanceHigh resistance

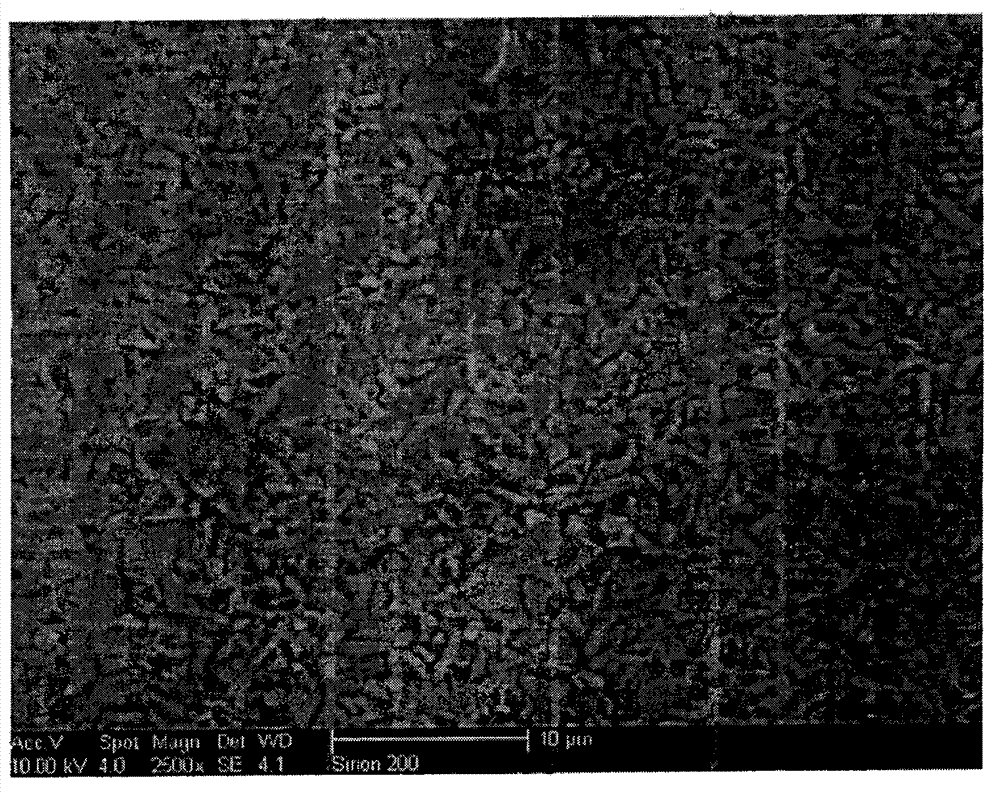

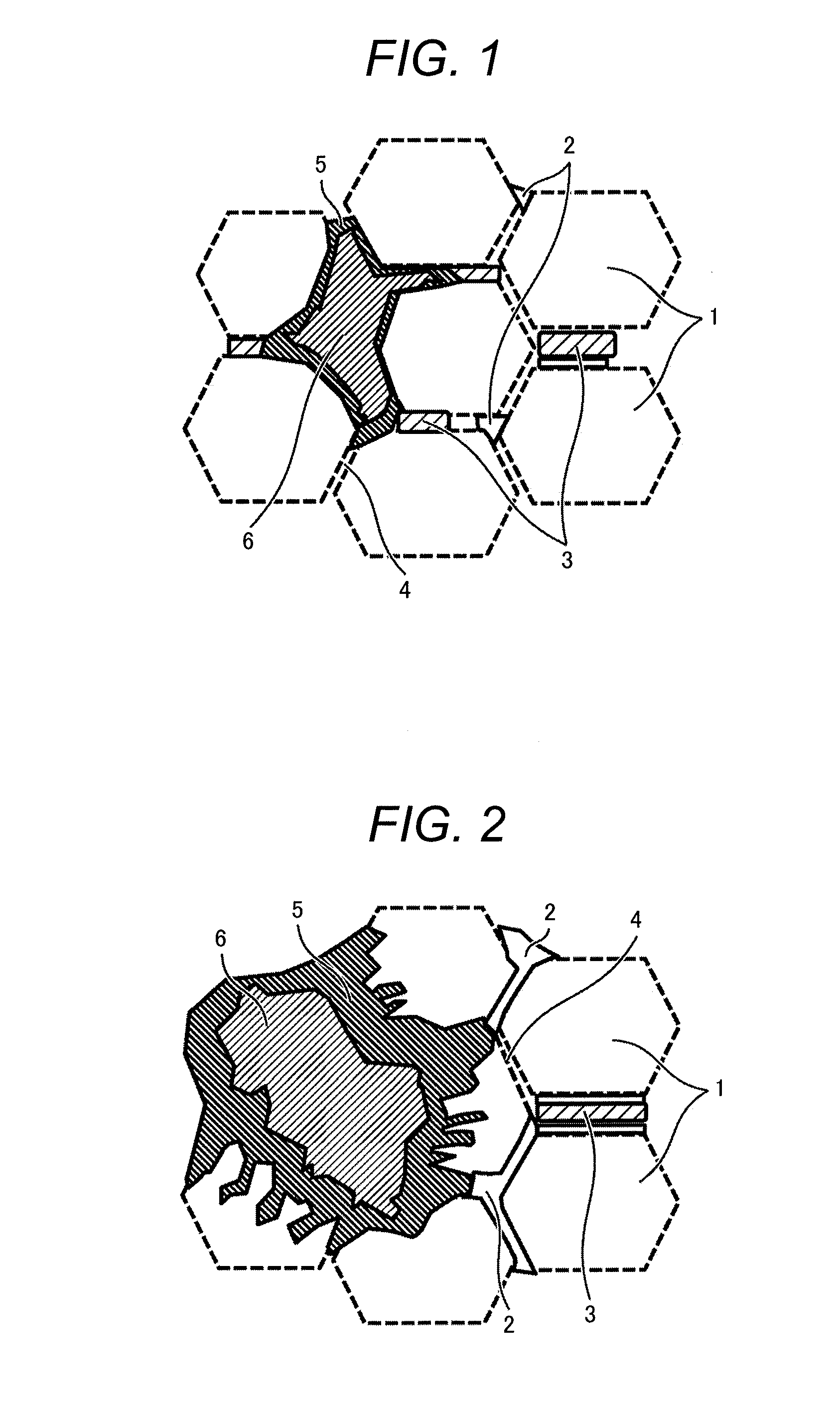

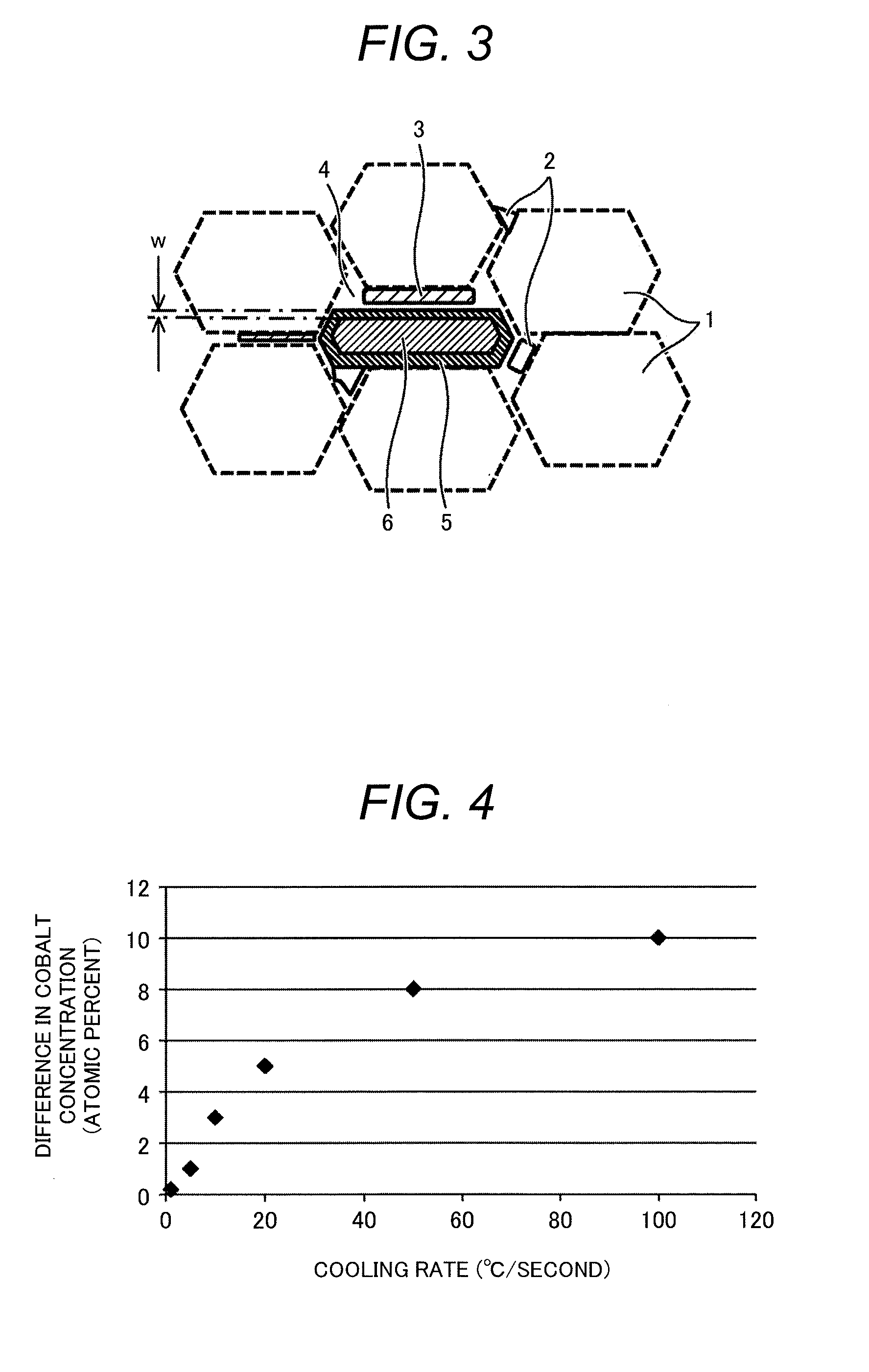

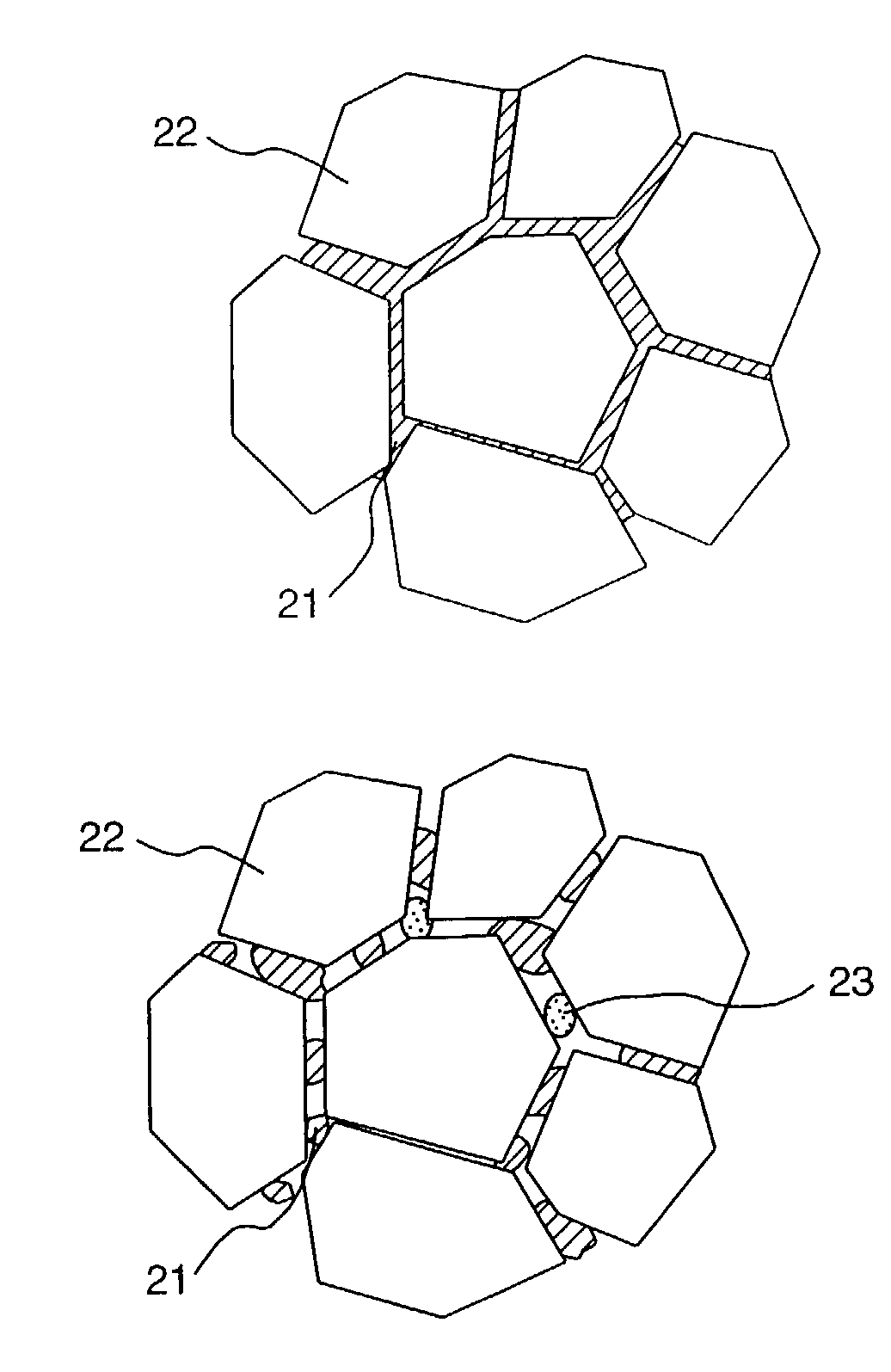

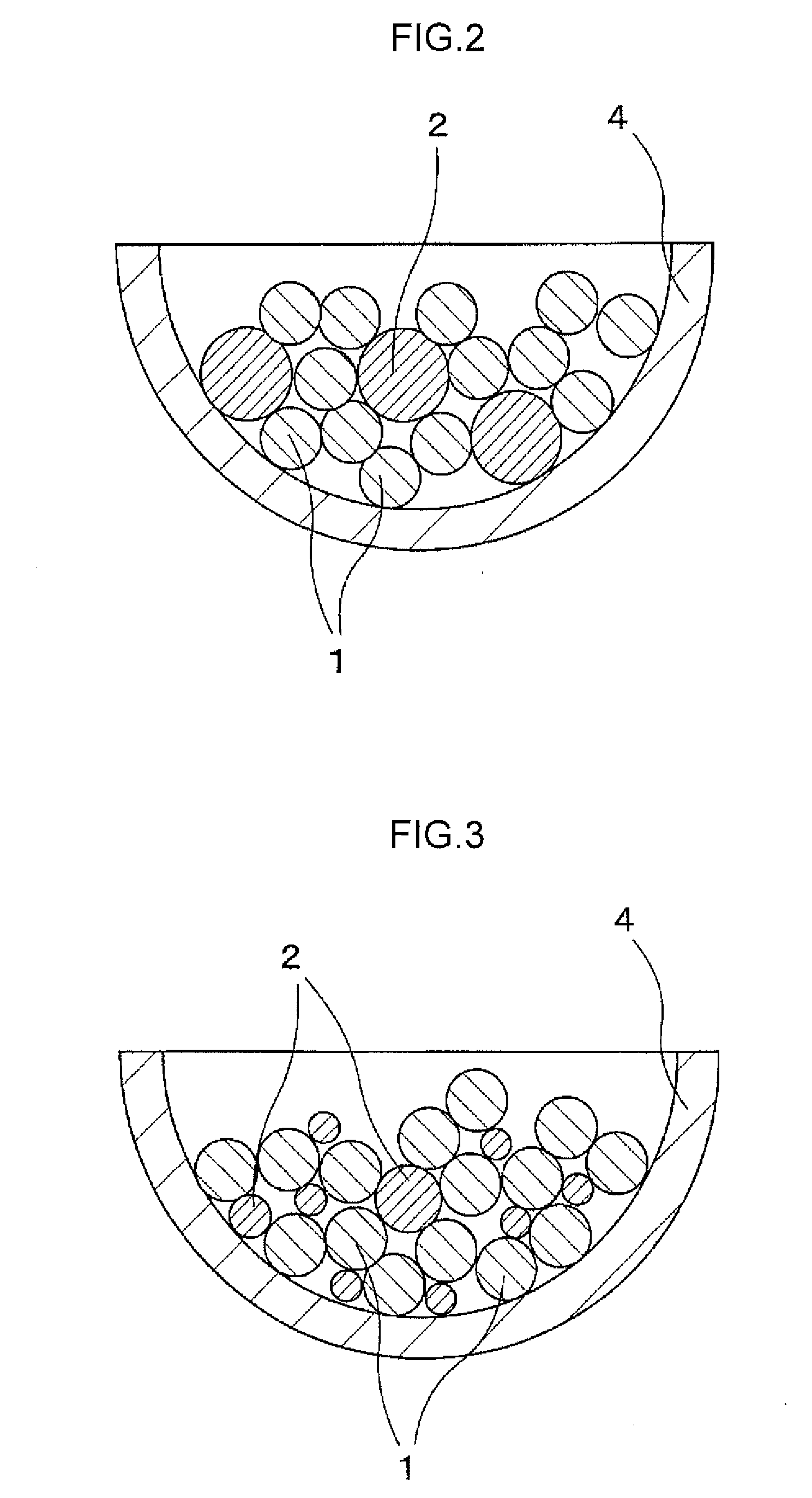

Eddy current generated around a magnetic circuit in an MRI apparatus is one of the causes of deviation from an ideal magnetic field gradient waveform and causes image distortion, loss of strength, ghost generation, loss of signal, and spectral distortion. An object of the present invention is to suppress the generation of the eddy current. In an MRI apparatus, a ferromagnetic material formed from powder is used in a part of a magnetic circuit: the powder mainly comprising a mother phase containing iron or cobalt and showing ferromagnetism; and a high-resistance layer having a resistance not less than ten times as high as the mother phase and a Vickers hardness lower than that of the mother phase being formed in layers along parts of the surface of the powder on parts or the entire of the surface.

Owner:HITACHI LTD

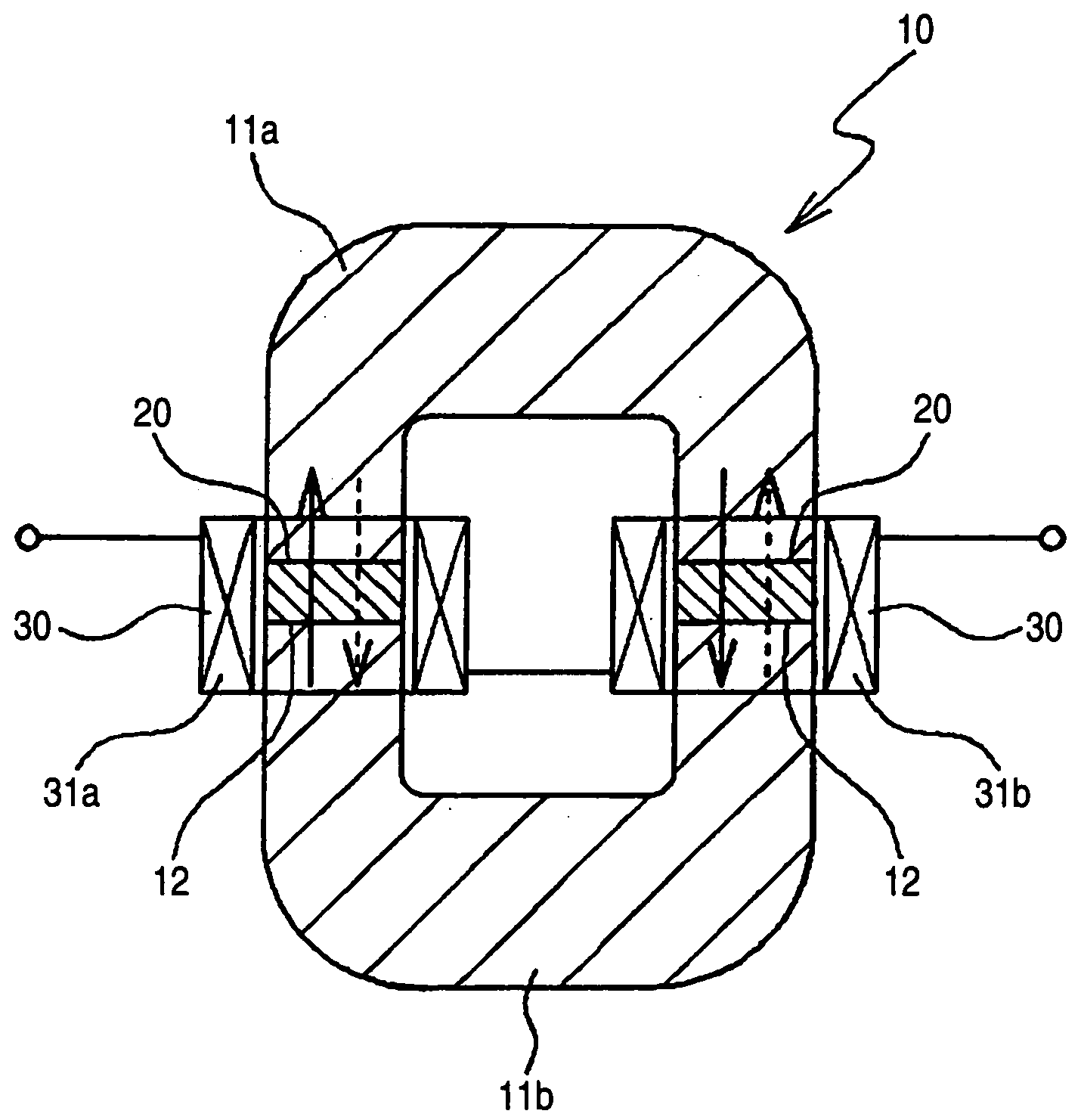

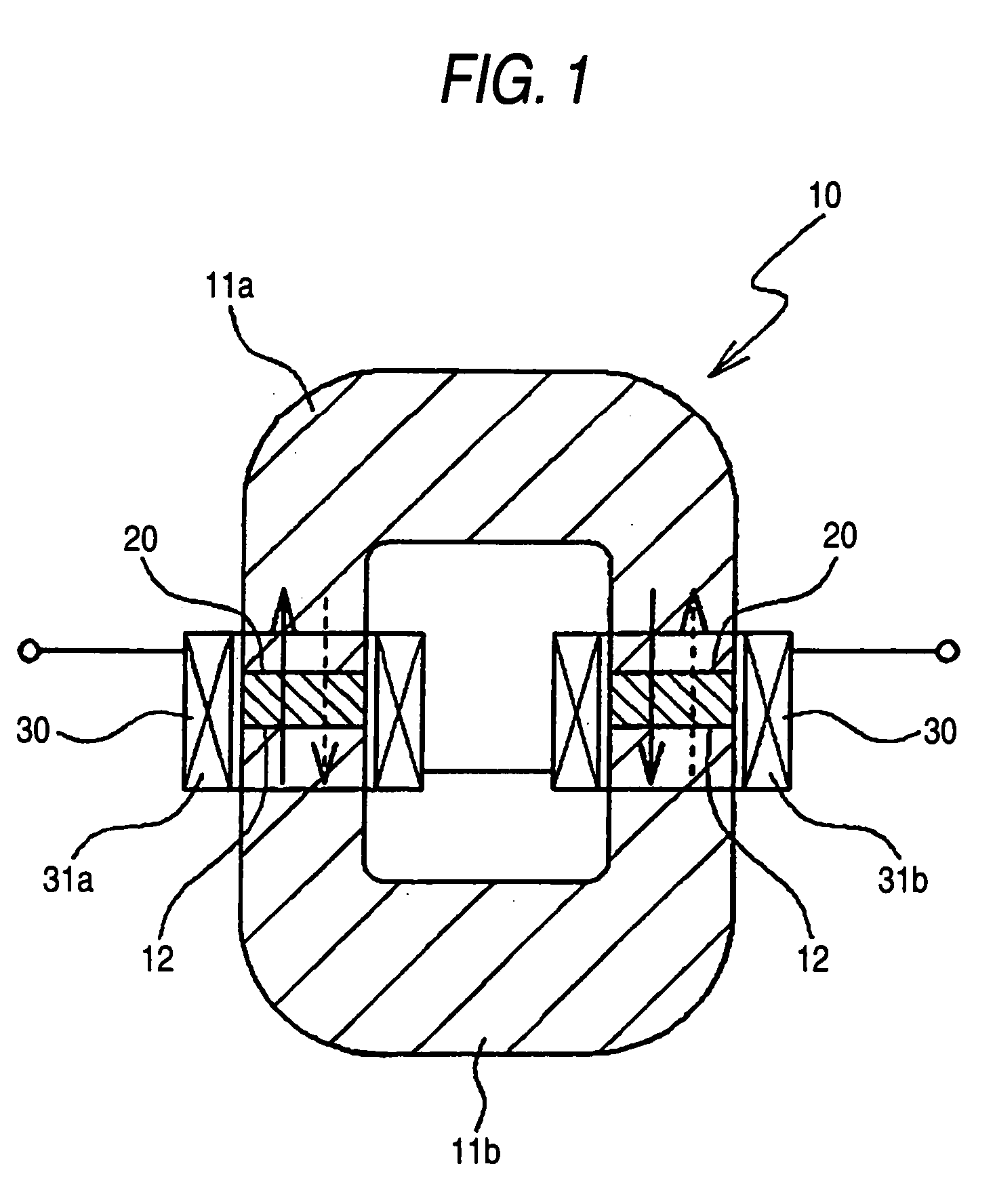

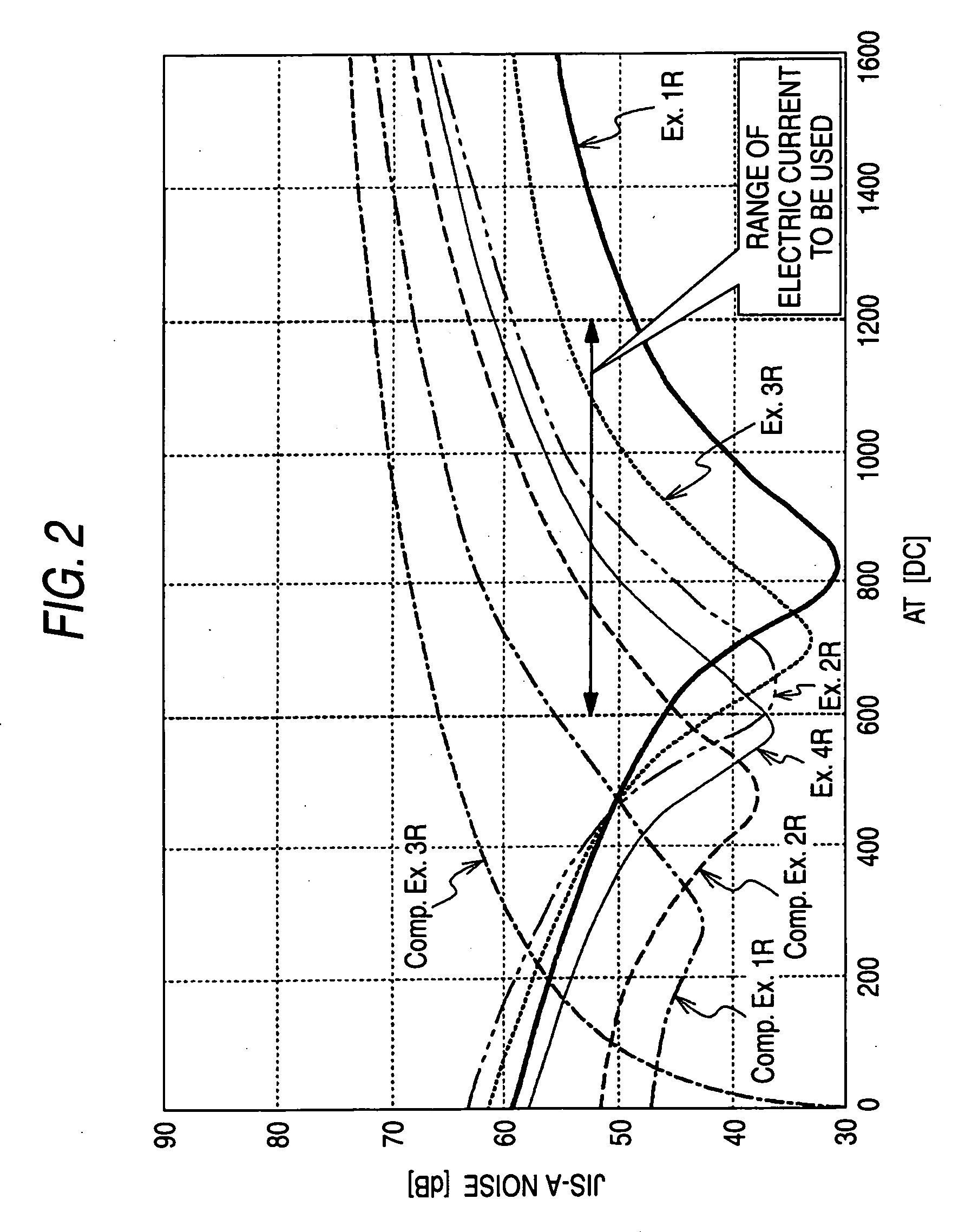

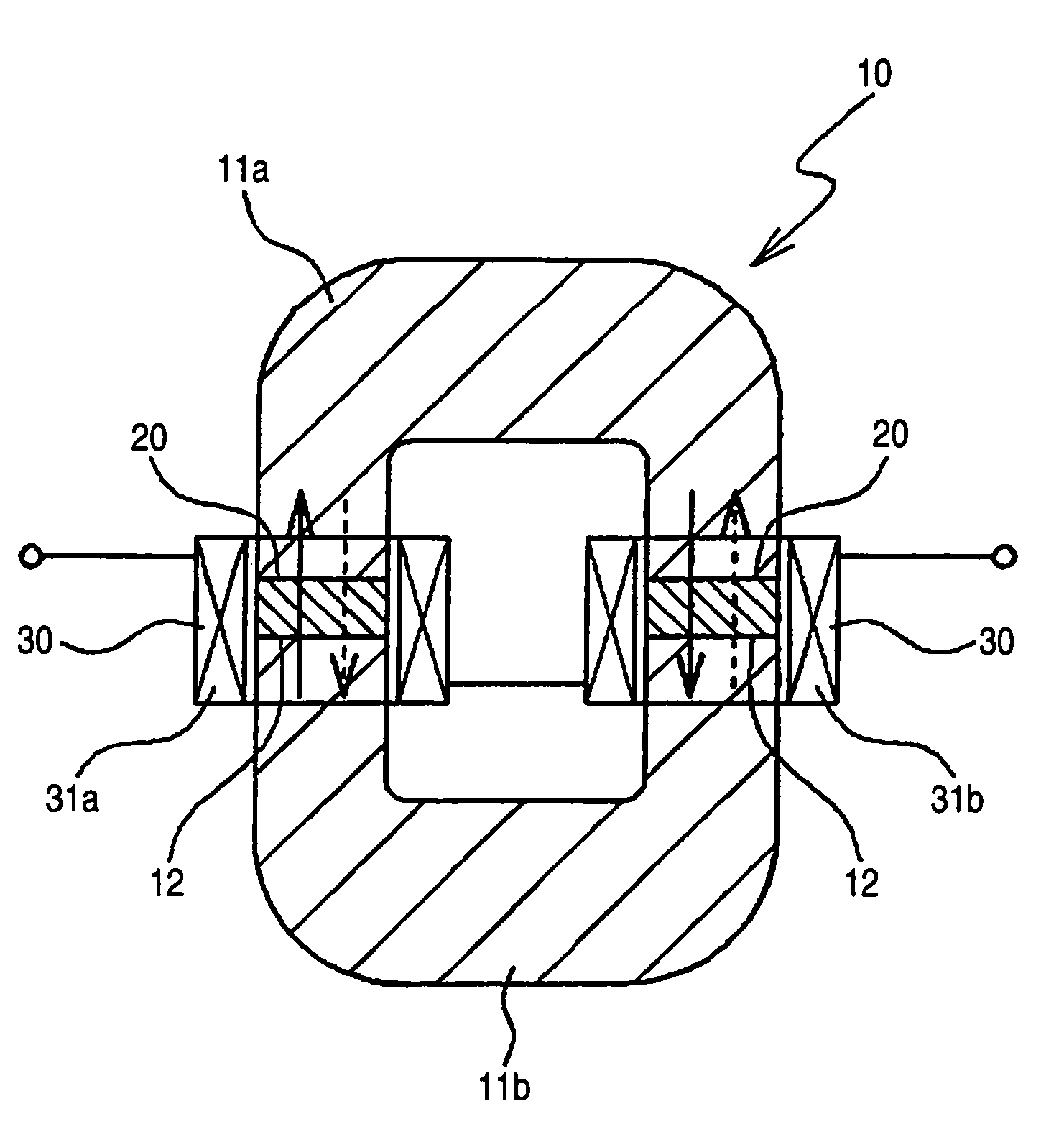

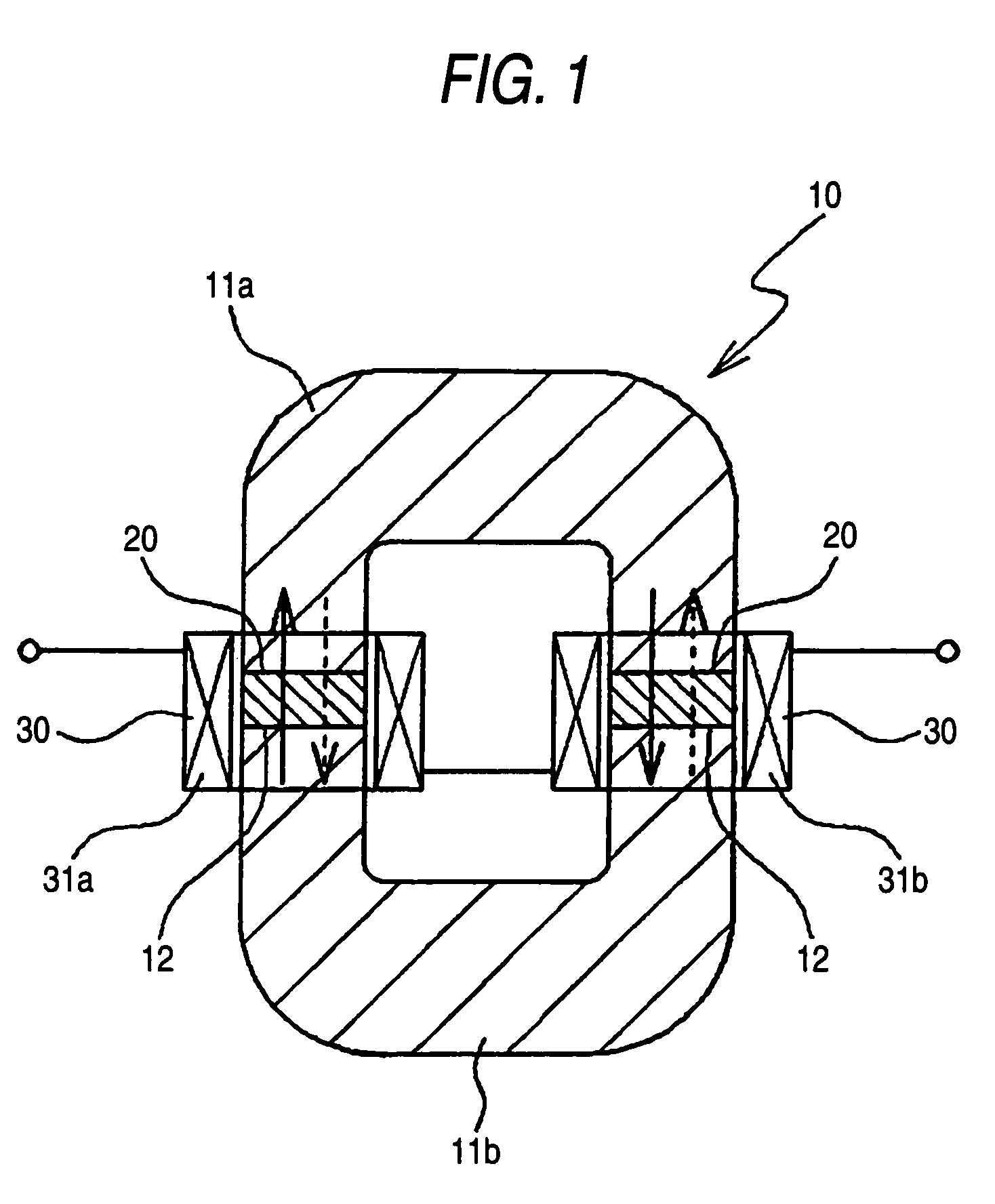

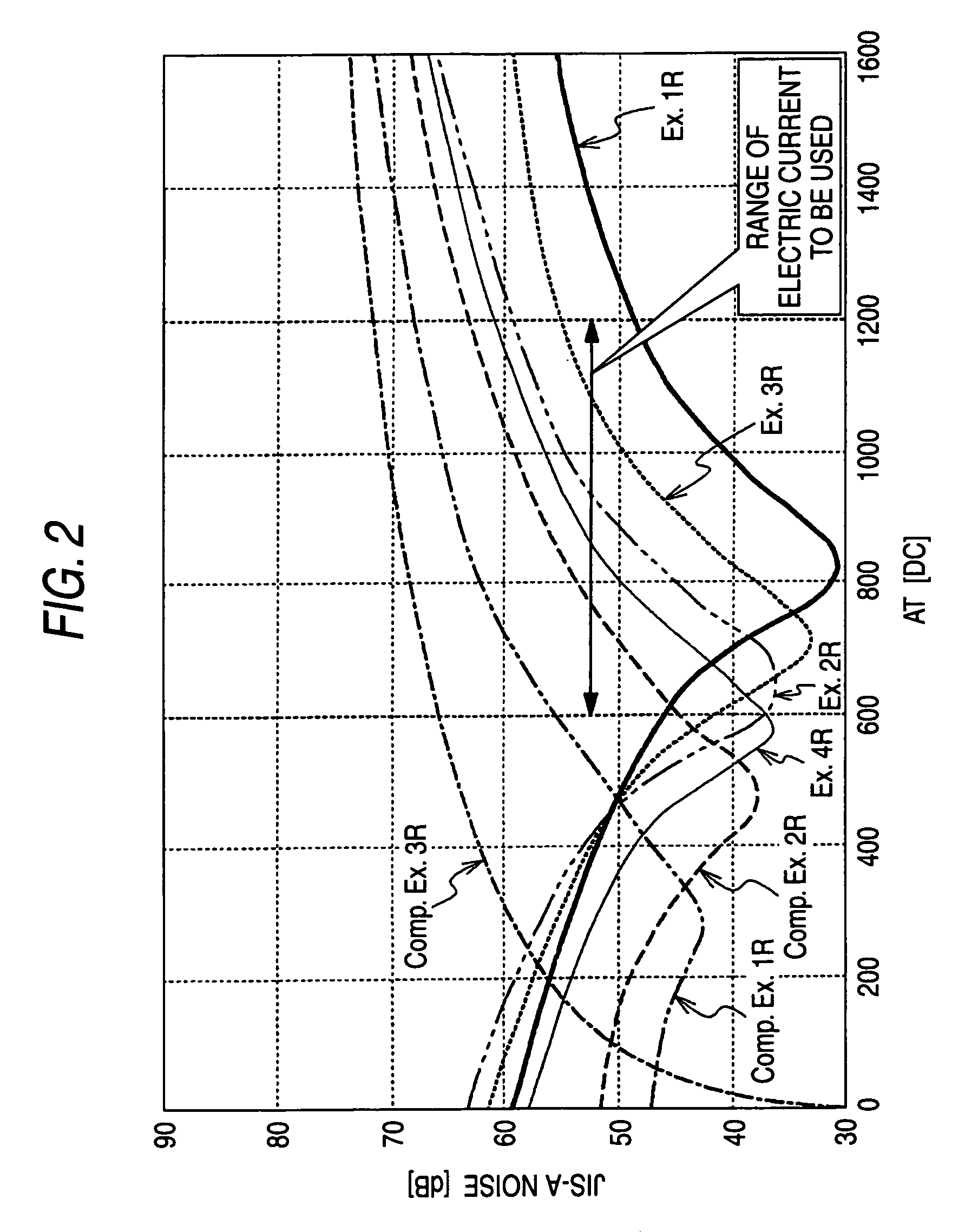

Bond magnet for direct current reactor and direct current reactor

InactiveUS20090206973A1Reduce vibrationReduce noisePermanent magnetsVariable inductances/transformersRare-earth magnetDirect current

The present invention provides a bond magnet for direct current reactor which is to be disposed in a gap formed in a magnetic core of a direct current rector, the bond magnet containing a magnet powder containing a rapidly quenched powder of a rare earth magnet alloy. The present invention also provides a direct current reactor including a magnetic core having a gap and a winding area wound around the magnetic core, in which the bond magnet is disposed in the gap of the magnetic core.

Owner:DAIDO STEEL CO LTD +1

Anisotropic thin-film rare-earth permanent magnet

InactiveUS7285338B2Improve featuresHigh Remanent Flux DensityNanostructure applicationNanomagnetismRare-earth elementMagnetic flux

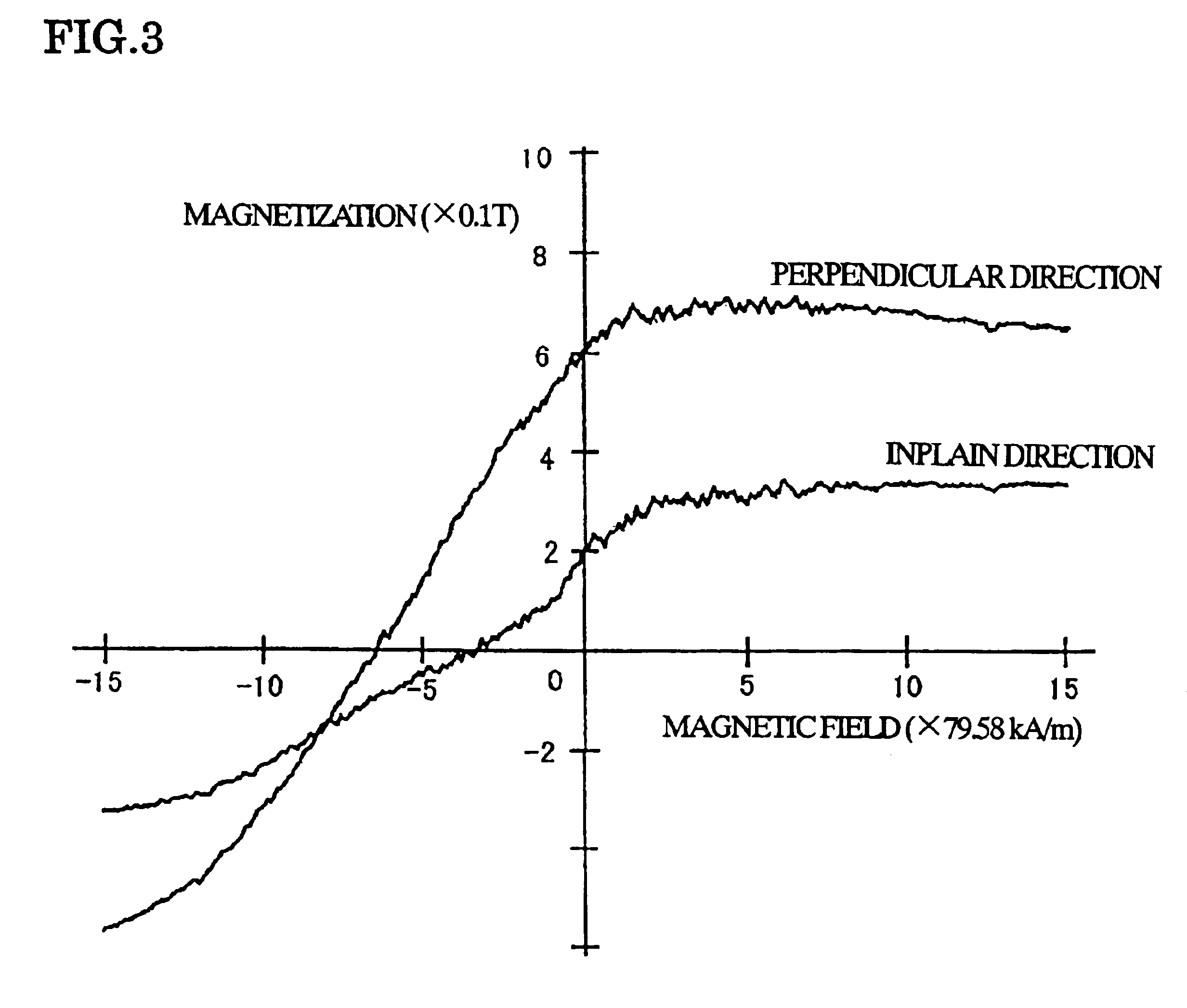

An anisotropic thin-film rare-earth permanent magnet endowed with high magnetic characteristics by rendering a vapor-phase-grown thin film anisotropic in the layering direction. The atomic laminate units are formed by laminating a monoatomic layer of a rare earth element on a substrate of a non-magnetic material having, a flat smoothness and then by laminating an atomic laminate of a transition metal element having a plurality of monoatomic layers of a transition metal element, so that the atomic laminate units of a characteristic construction are laminated in a plurality of layers. As a result, each atomic laminate of the transition metal element has an easy magnetizable axis in the laminate direction of the monoatomic layers and which are sandwiched between a monoatomic layer of a rare-earth element so that an inverse magnetic domain is suppressed to establish a strong coercive force. Moreover, the content of the transition metal element to the rare-earth metal is raised to improve the residual magnetic flux density drastically.

Owner:SUMITOMO SPECIAL METAL CO LTD

Permanent magnet synchronous motor

InactiveUS20050121991A1High Remanent Flux DensityIncrease volumeMagnetic circuit rotating partsSynchronous motorsSynchronous motorElectrical conductor

A synchronous motor includes a stator, a rotor and permanent magnets. The rotor includes a rotor iron core rotatable relative to the stator, and a plurality of conductor bars accommodated within corresponding slots in the rotor iron core. The conductor bars have their opposite ends shortcircuited by respective shortcircuit rings to form a starter cage conductor. The rotor also has a plurality of magnet retaining slots defined therein at a location on an inner side of the conductor bars, in which hole permanent magnets are embedded.

Owner:PANASONIC CORP +1

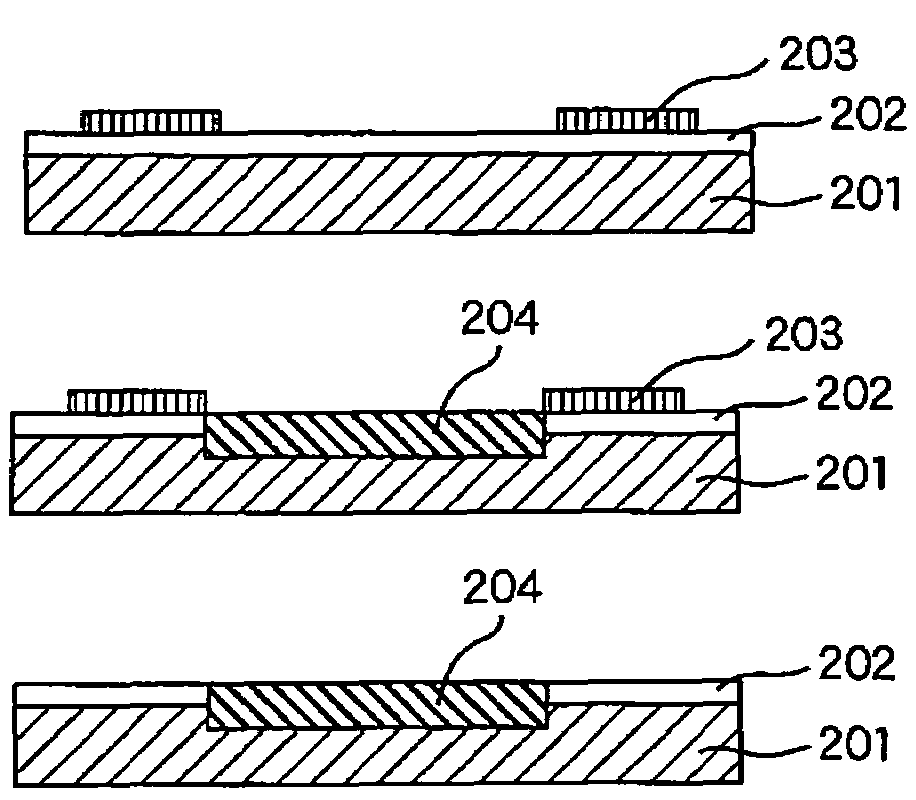

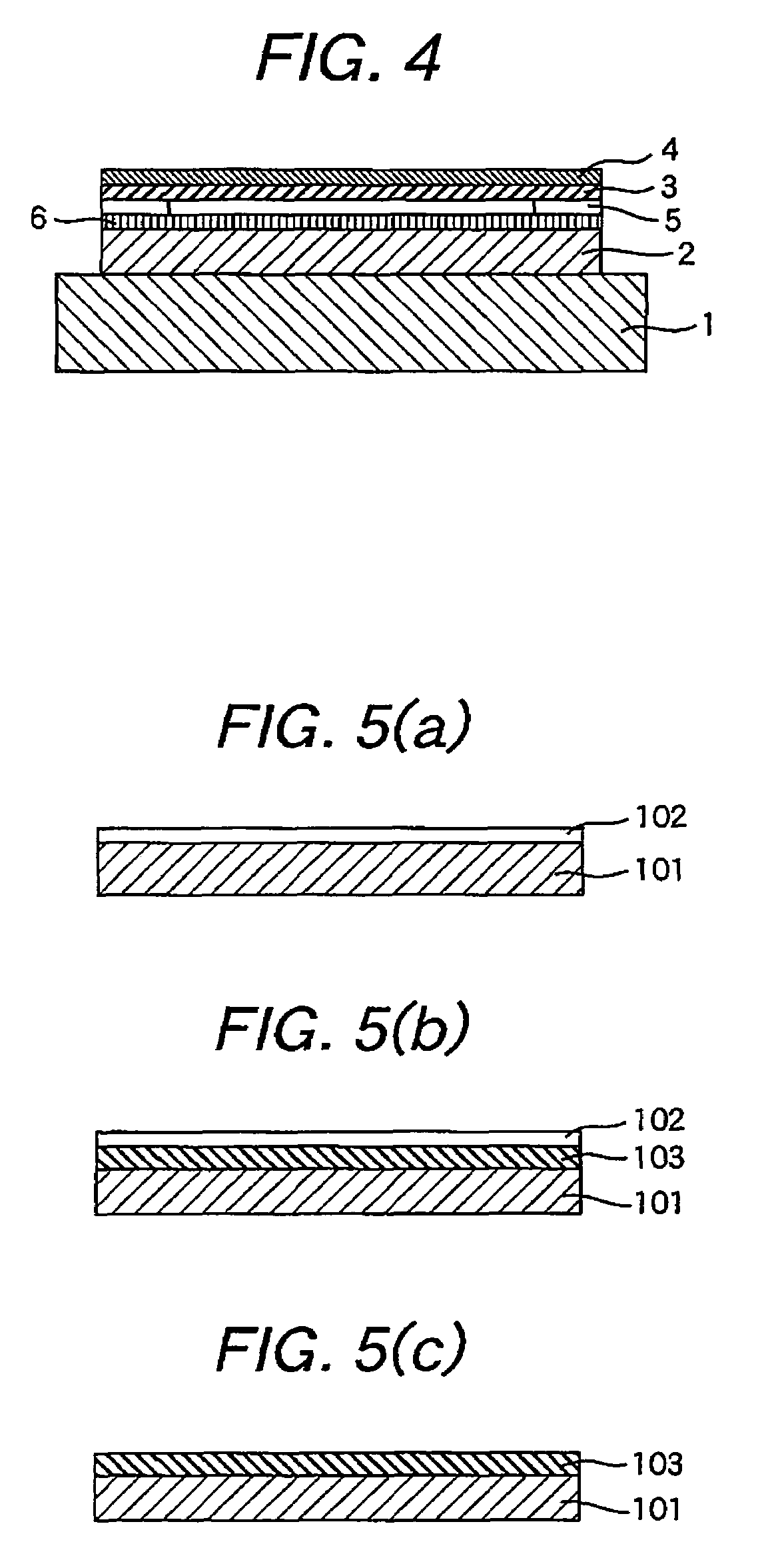

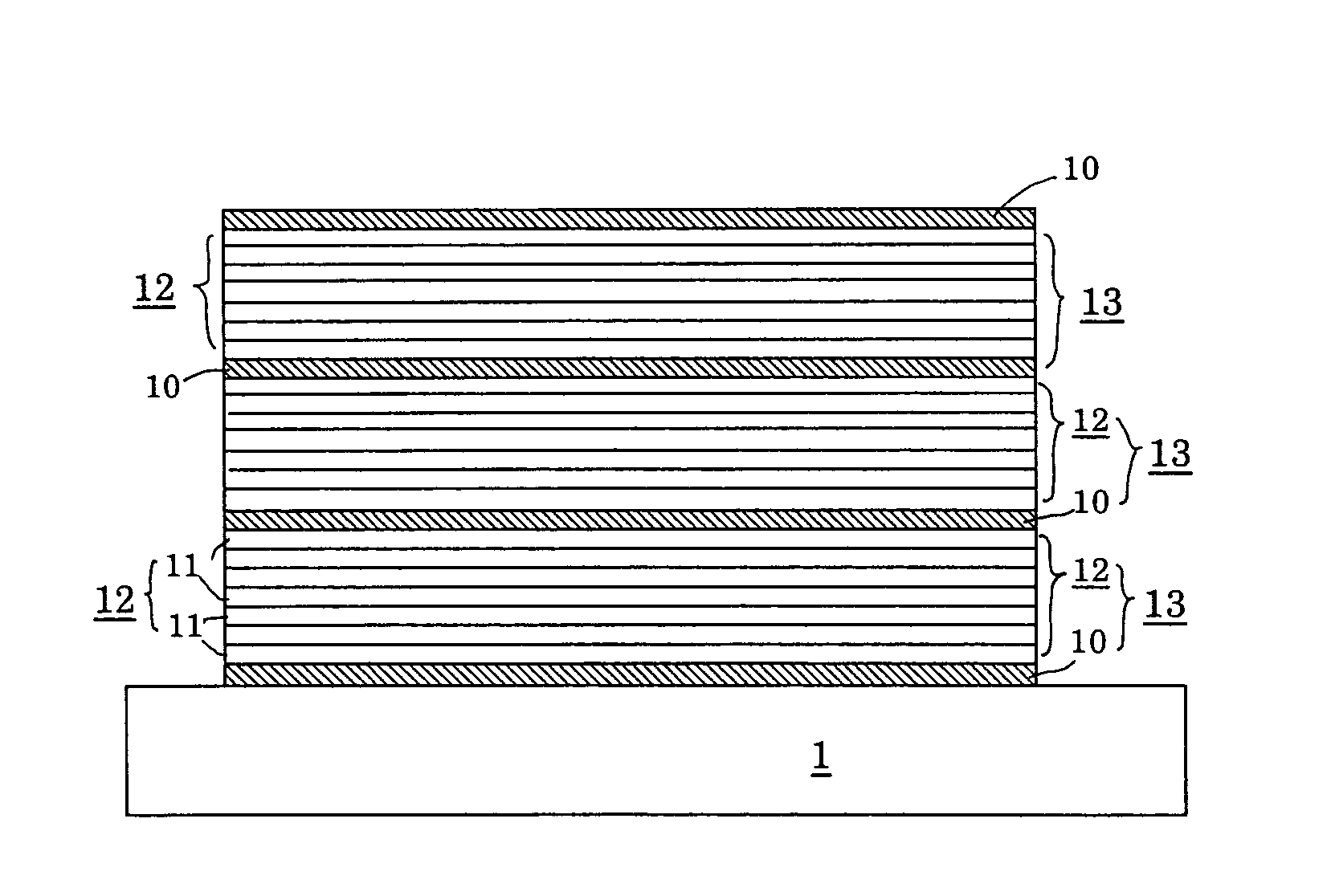

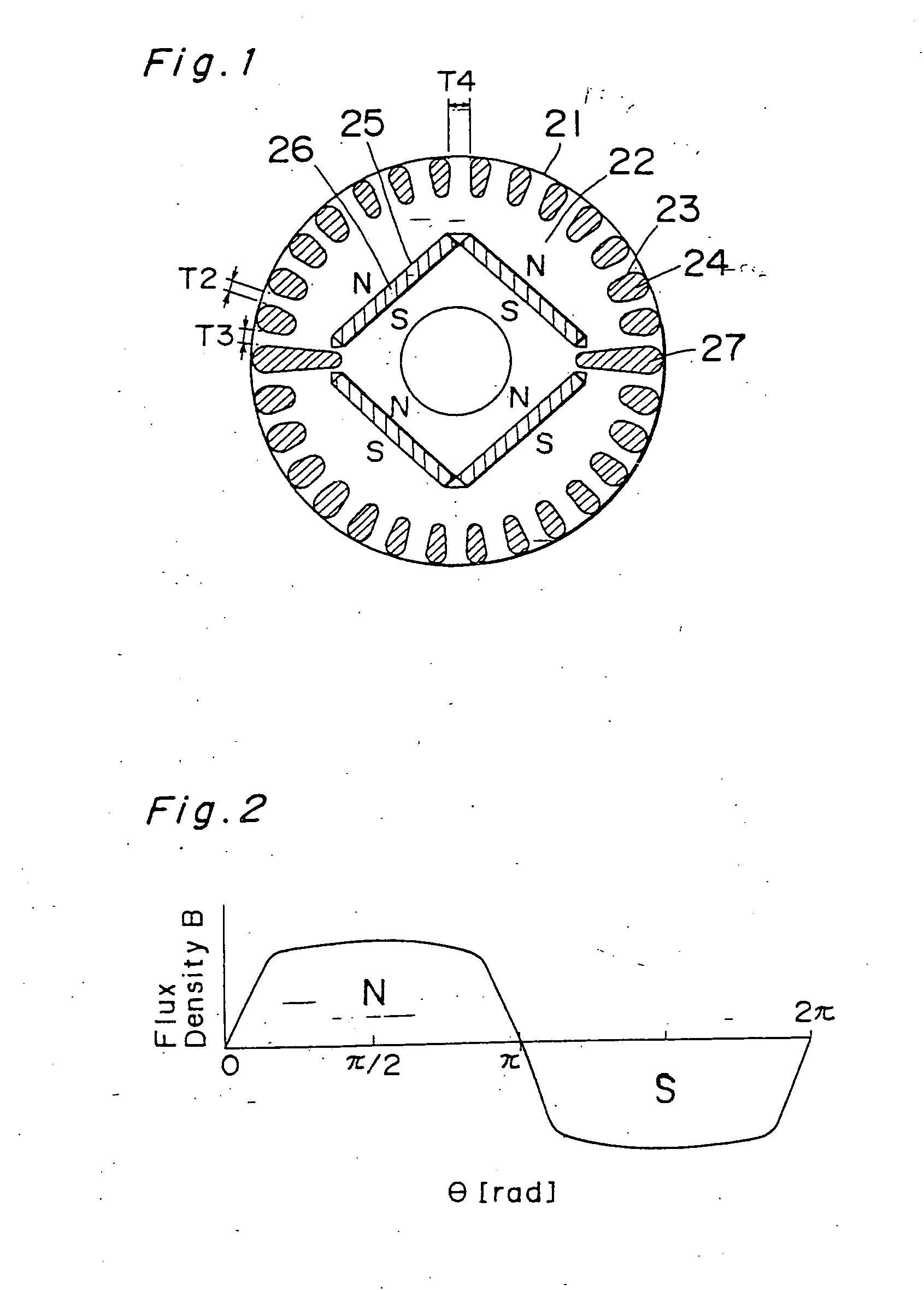

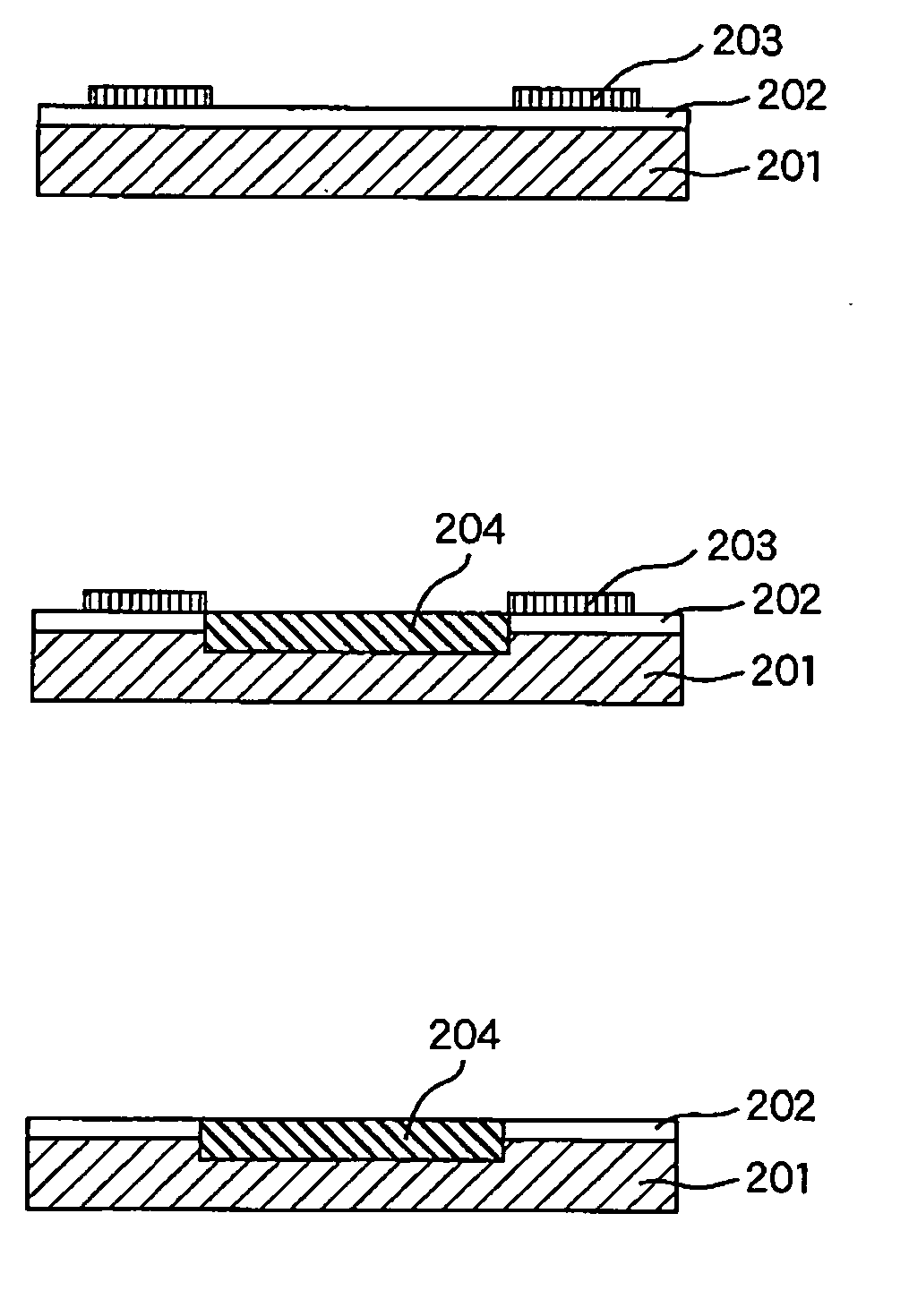

Thin permanent-magnet film and process for producing the same

InactiveUS6805980B2Increasing magnetic anisotropyHigh Remanent Flux DensityNanomagnetismVacuum evaporation coatingCrystal systemThin membrane

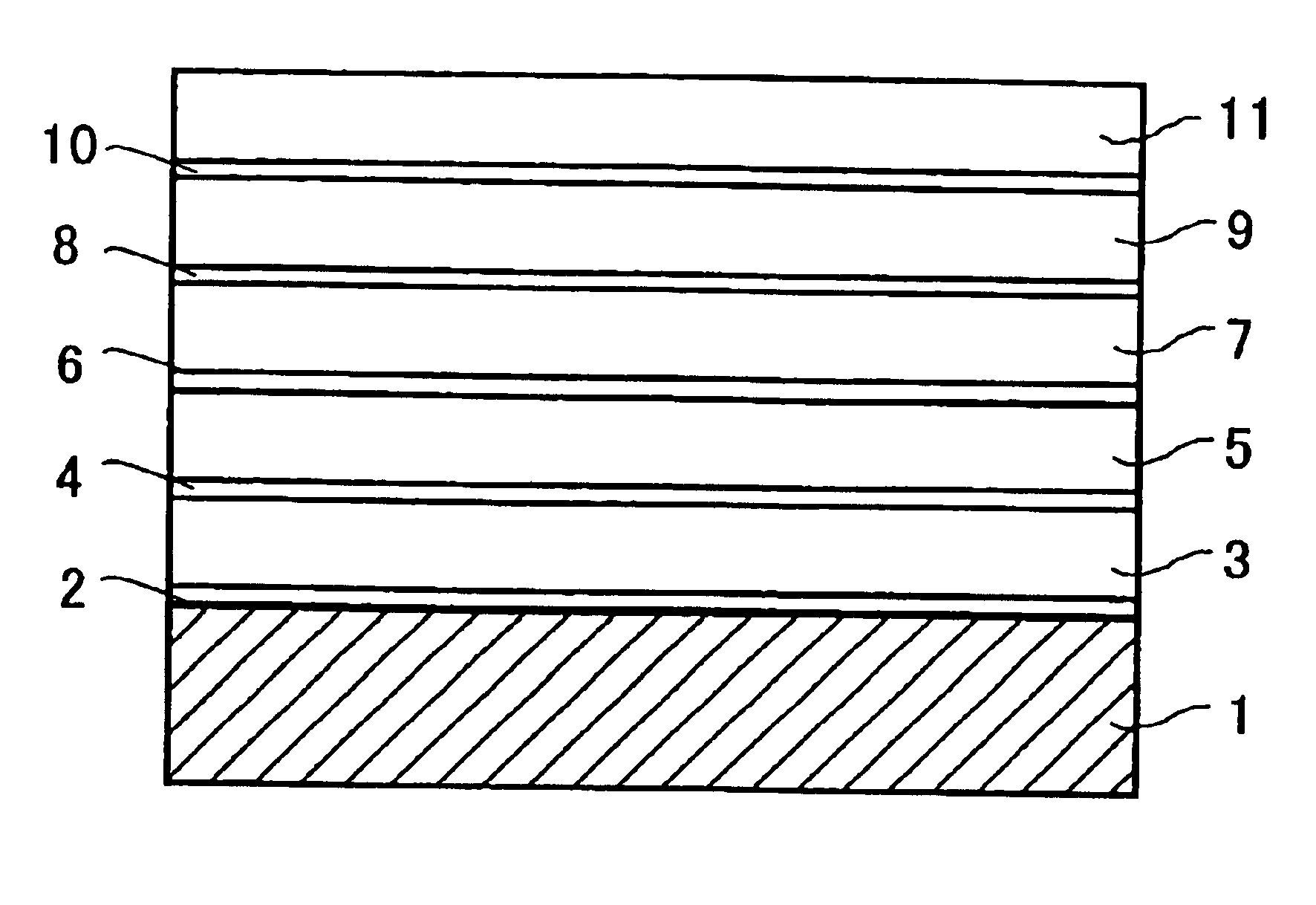

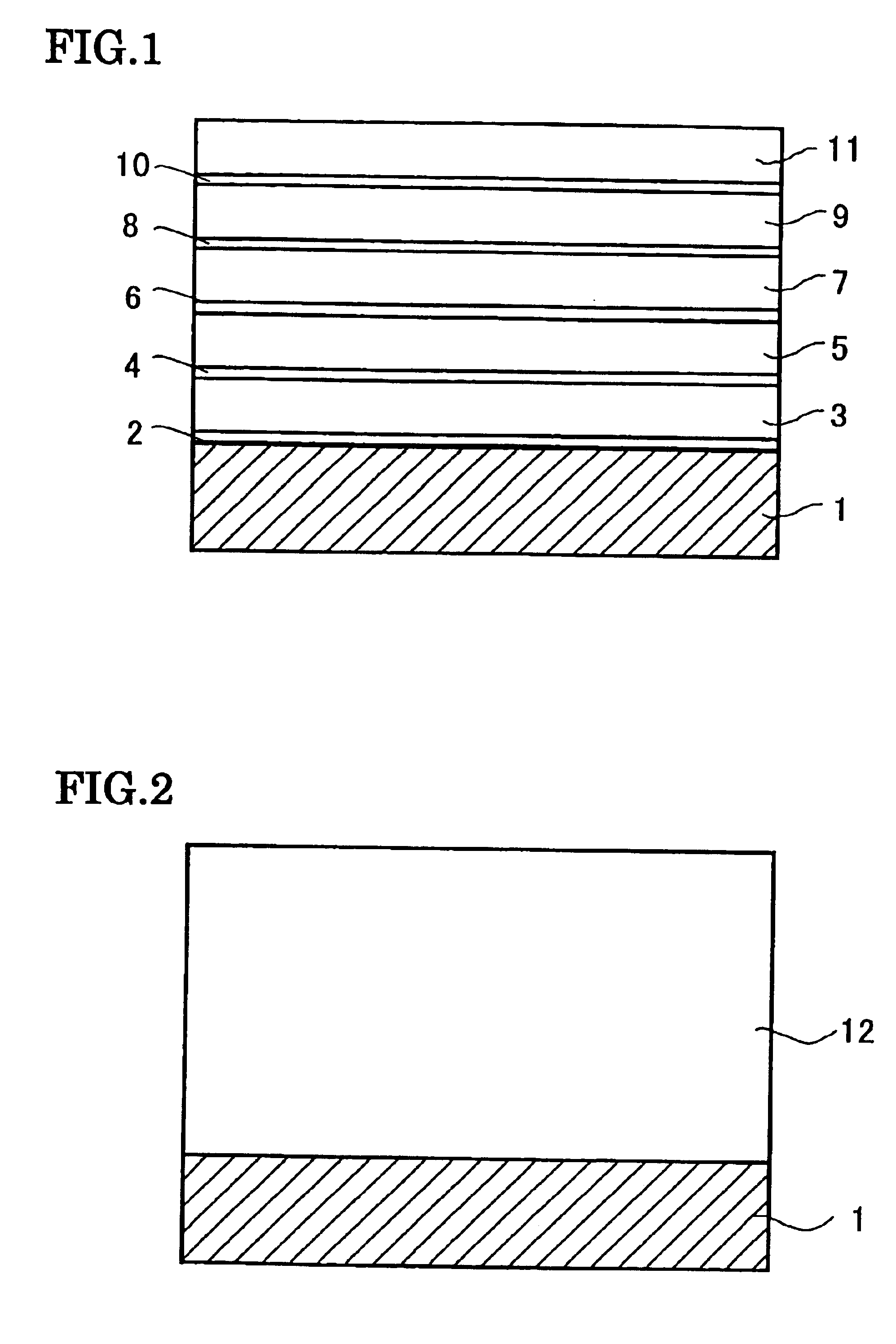

Refractory metal layers 2, 4, 6, 8, and 10, and rare earth alloy magnetic layers 3, 5, 7, 9, 11, and 12 are alternately deposited, so as to form a multilayer structure including four or more layers on a substrate. The refractory metal layers 2, 4, 6, 8, and 10 are formed from at least one kind of material selected from a group consisting of Ti, V, Cr, Zr, Nb, Mo, Hf, Ta, and W, and each has a thickness of not less than 5 nm nor more than 50 nm. The rare earth alloy magnetic layers 3, 5, 7, 9, 11, and 12 have tetragonal R2Fe14B (R is Nd and / or Pr) as a primary constituent phase, and each has a thickness of not less than 50 nm nor more than 500 nm.

Owner:SUMITOMO SPECIAL METAL CO LTD

R-T-B based rare earth permanent magnet and method for production thereof

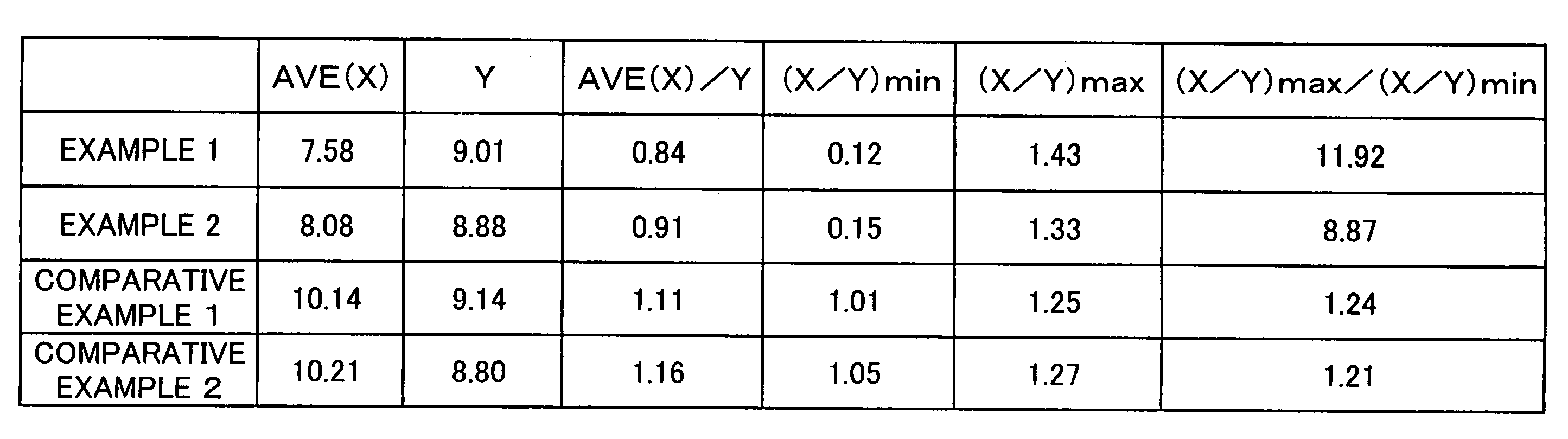

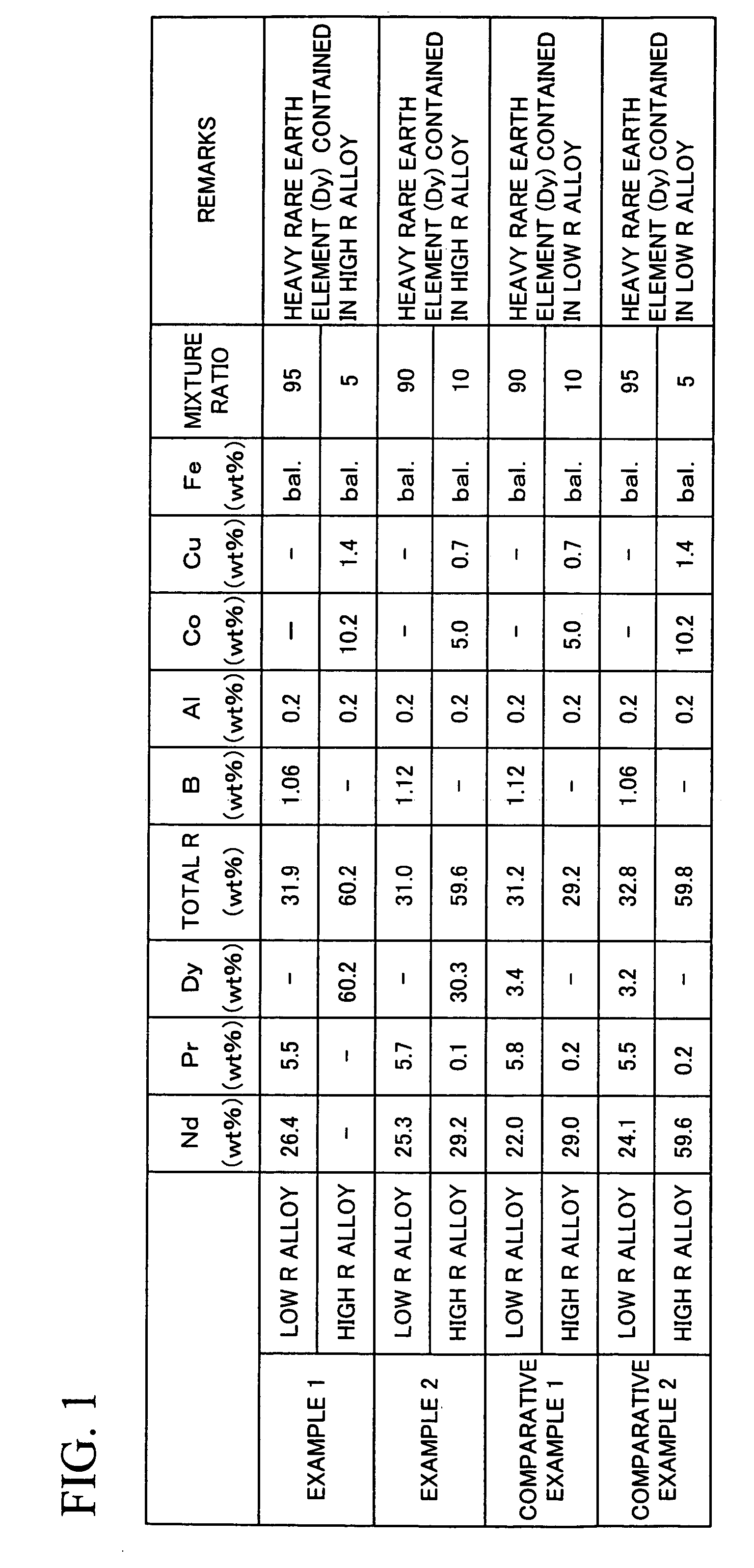

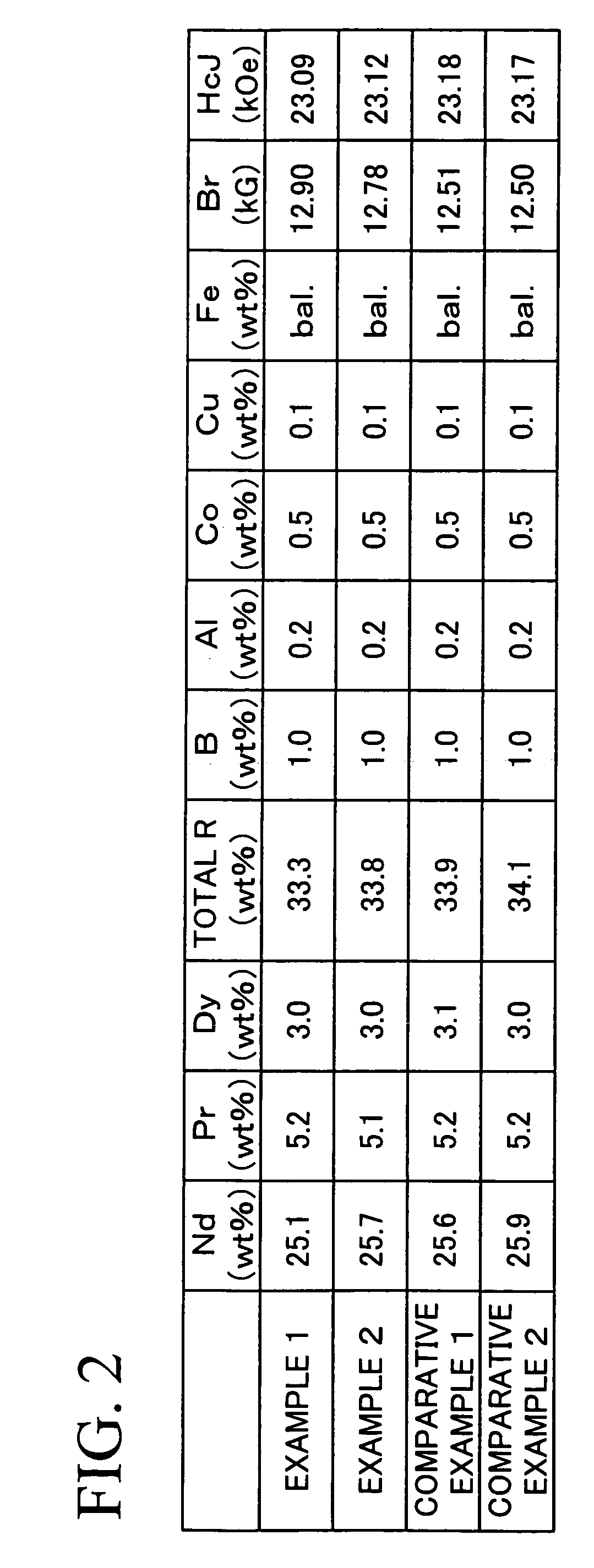

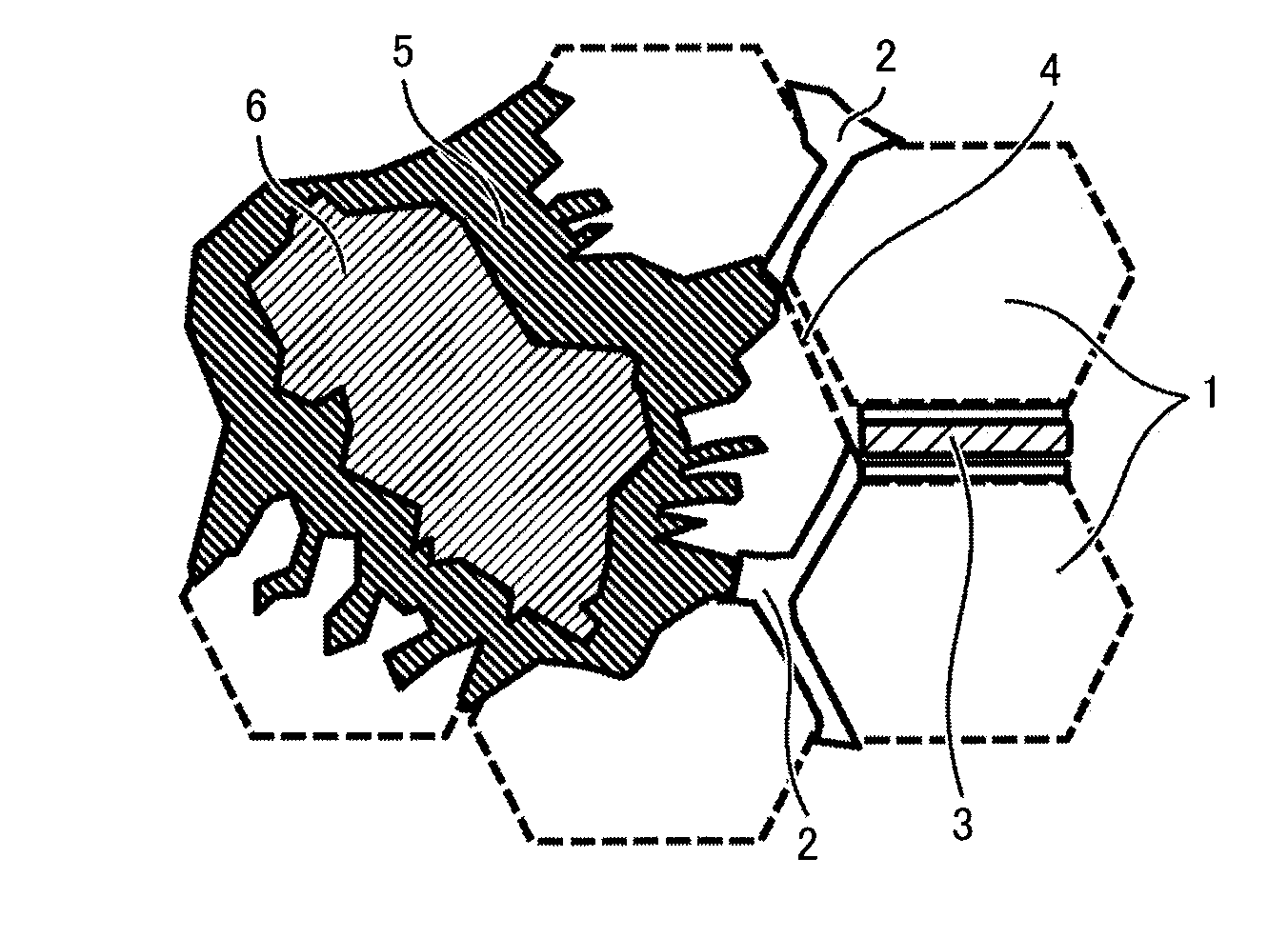

ActiveUS7618497B2High Remanent Flux DensityImprove coercive forceInorganic material magnetismRare-earth elementGrain boundary

An R-T-B system rare earth permanent magnet, which comprises main phase grains consisting of R2T14B compounds and a grain boundary phase having a higher amount of R than the above described main phase grains, and which satisfies AVE(X) / Y=0.8 to 1.0; and (X / Y)max / (X / Y)min=2.0 to 13.0, wherein X represents (weight ratio of heavy rare earth elements) / (the weight ratio of all rare earth elements) for a given number of the above described main phase grains Y represents (weight ratio of heavy rare earth elements) / (weight ratio of all rare earth elements) for the sintered body as a whole; AVE(X) represents the mean value of X obtained for the given number of main phase grains; (X / Y)min represents the minimum value of (X / Y) obtained for the given number of main phase grains; and (X / Y)max represents the maximum value of (X / Y) obtained for the given number of main phase grains.

Owner:TDK CORPARATION

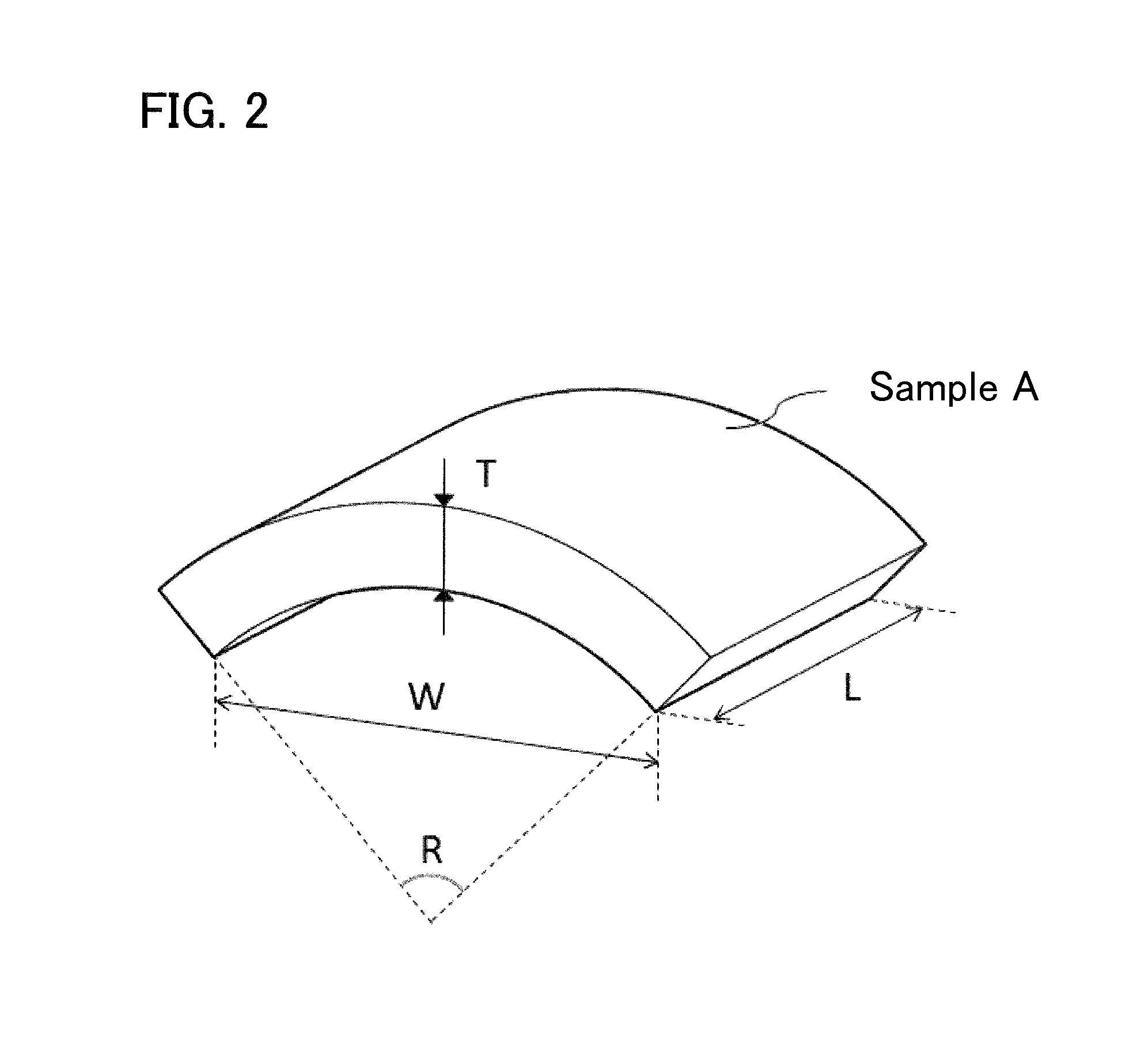

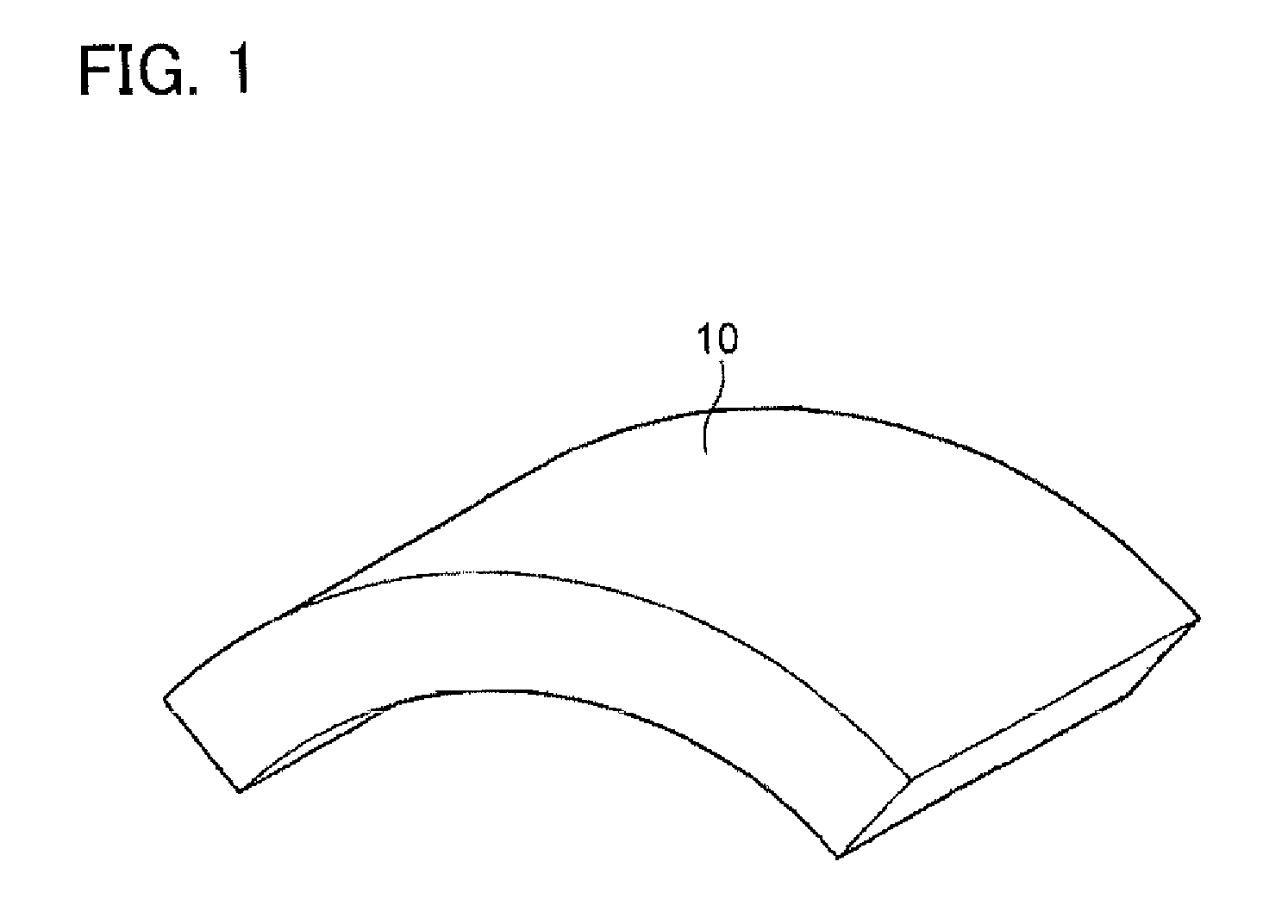

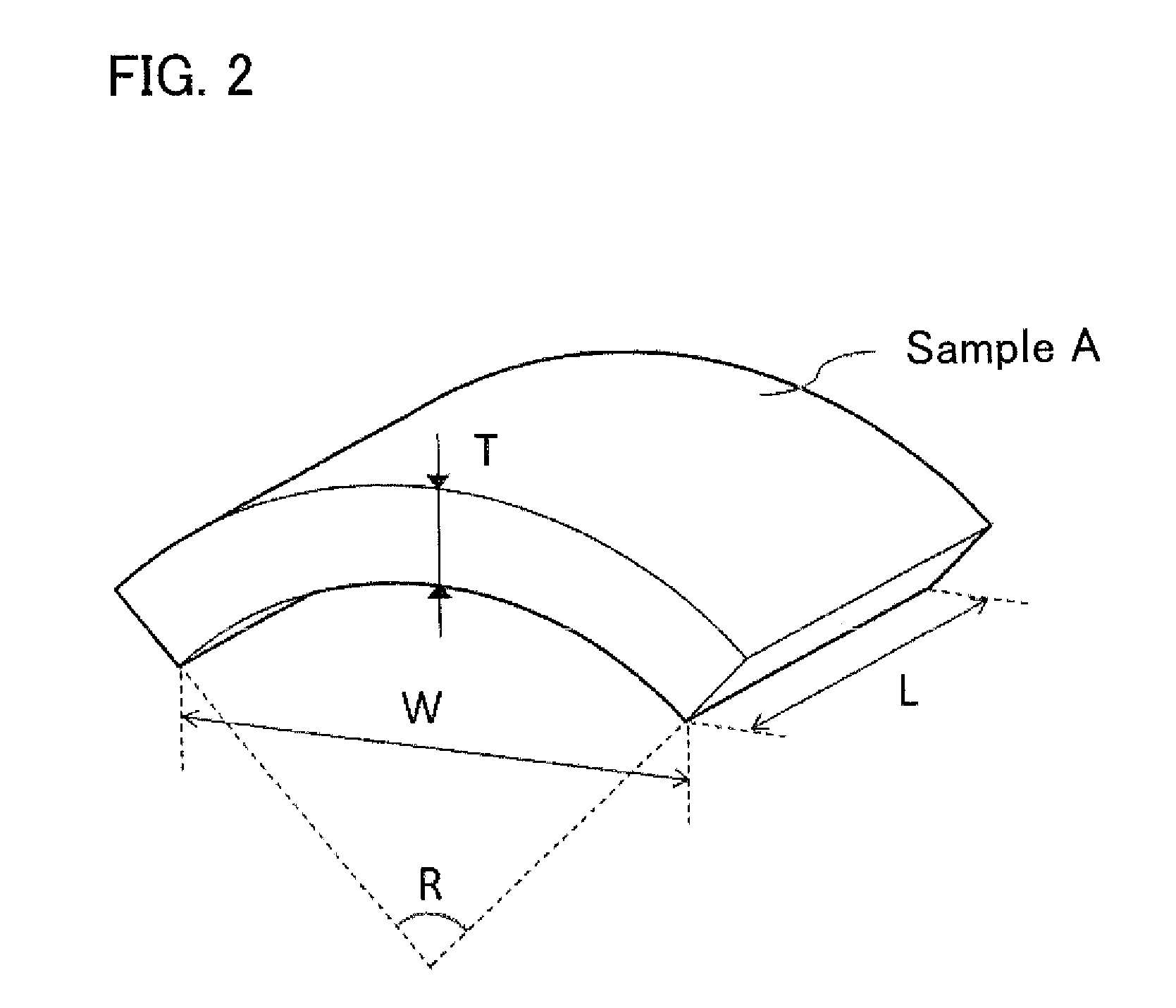

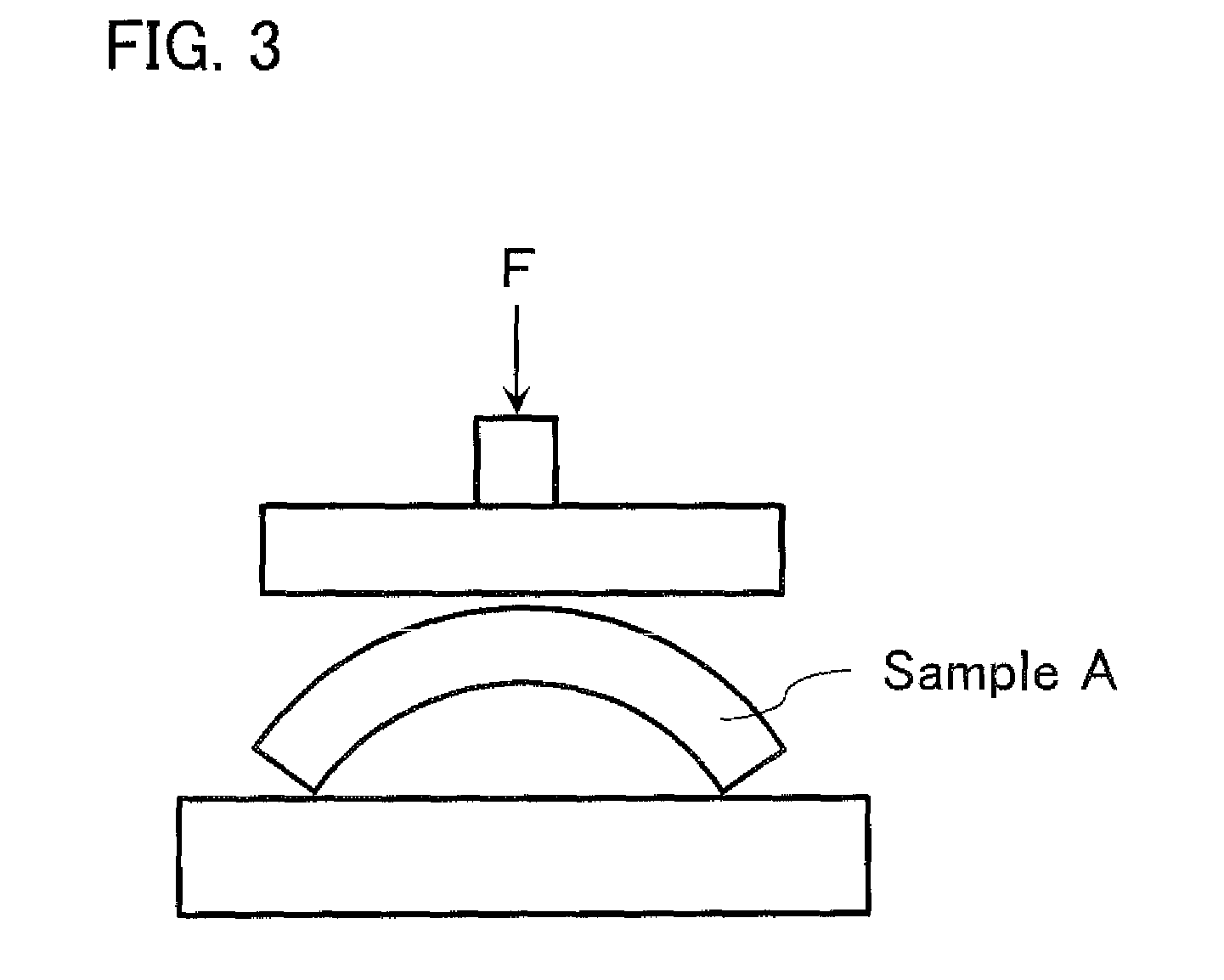

Sintered Magnet

InactiveUS20130069746A1High Remanent Flux DensityHigh energyPermanent magnetsInorganic material magnetismRare-earth elementSintered magnets

Disclosed is a sintered magnet which is a rare-earth magnet using a less amount of a rare-earth element but having a higher maximum energy product and a higher coercivity. The sintered magnet includes a NdFeB crystal; and an FeCo crystal adjacent to the NdFeB crystal through the medium of a grain boundary. The FeCo crystal includes a core and a periphery and has a cobalt concentration decreasing from the core to the periphery. The FeCo crystal has a difference in cobalt concentration of 2 atomic percent or more between the core and the periphery. In the NdFeB crystal, cobalt and a heavy rare-earth element are unevenly distributed and enriched in the vicinity of the grain boundary.

Owner:HITACHI LTD

Sintered ferrite magnet and motor provided therewith

ActiveUS20150255198A1High Remanent Flux DensityPermanent magnetsInorganic material magnetismRare-earth elementMetallurgy

A sintered ferrite magnet comprises a main phase of an M type Sr ferrite having a hexagonal crystal structure. An amount of Zn is 0.05 to 1.35 mass % in terms of ZnO and M1 / M2 is 0.43 or less when an amount of a rare-earth element (R) is M1 in terms of mol and the amount of Zn is M2 in terms of mol.

Owner:COLEMAN CABLE INC +1

Sintered ferrite magnet and motor provided therewith

ActiveUS9589713B2High Remanent Flux DensityInorganic material magnetismIron compoundsRare-earth elementMetallurgy

Owner:TDK CORPARATION

Method for manufacturing magnetic encoder

ActiveUS20170082456A1Improve coercive forceGood molding effectMagnetsInductances/transformers/magnets manufactureNitrile rubberMagnetic flux

Provided is a method for a magnetic encoder having a magnetic body comprised of a magnetic rubber molded article, comprising a mixing step of mixing and then kneading a nitrile rubber (A), a ferrite magnetic powder (B) and a vulcanizing agent (C) to provide a magnetic rubber composition; and a molding step of molding and vulcanizing the magnetic rubber composition in a mold to which a magnetic field is applied to provide the magnetic rubber molded article, wherein a content of the ferrite magnetic powder (B) is 700 to 1500 parts by mass based on 100 parts by mass of the nitrile rubber (A); and a compressed density of the ferrite magnetic powder (B) is 3.5 g / cm3 or more. According to this method, a magnetic encoder having a magnetic body with high coercivity and residual magnetic flux density can be produced by vulcanizing a magnetic rubber composition having favorable moldability.

Owner:UCHIYAMA MFG

Motor using magnet

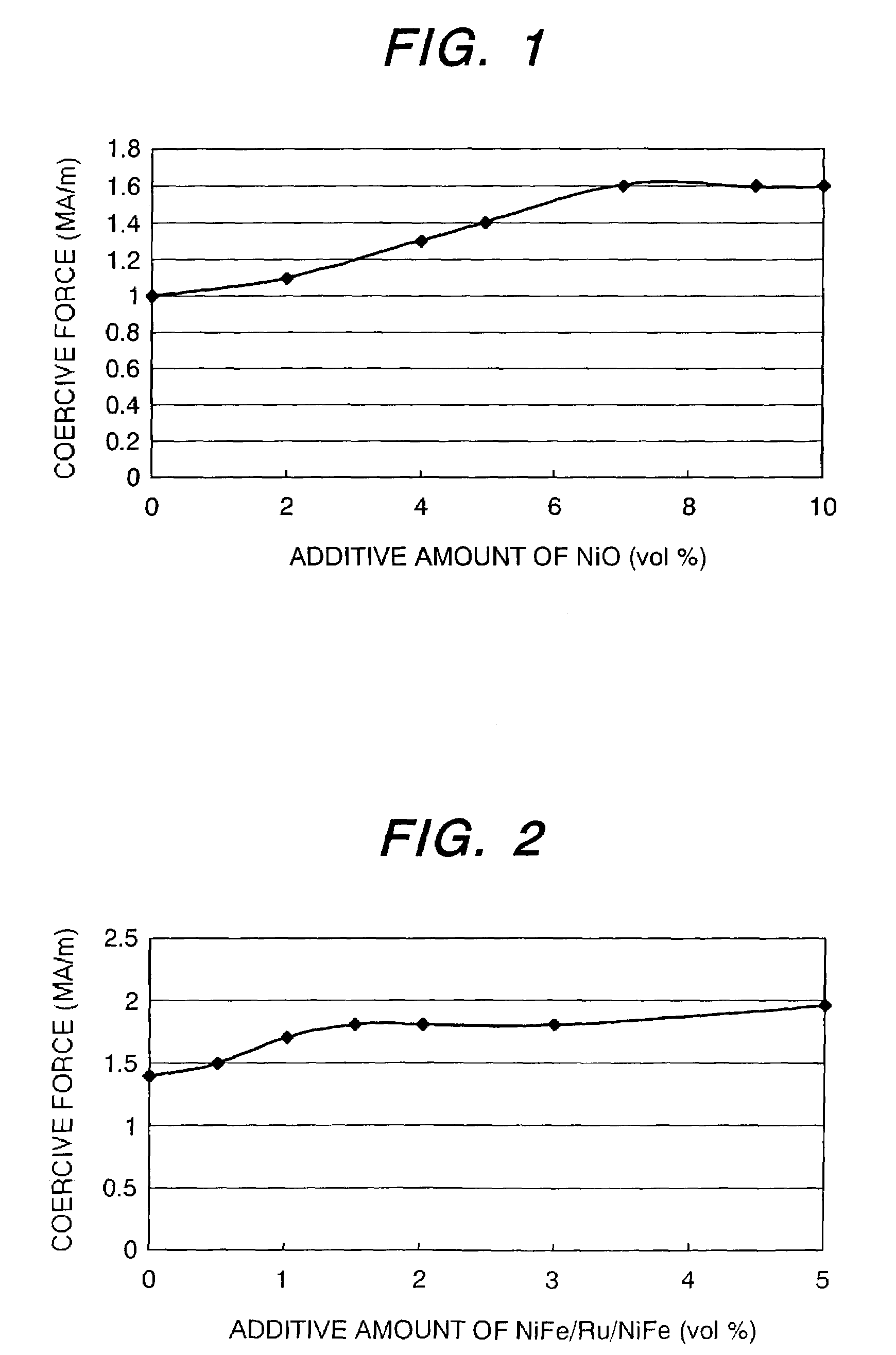

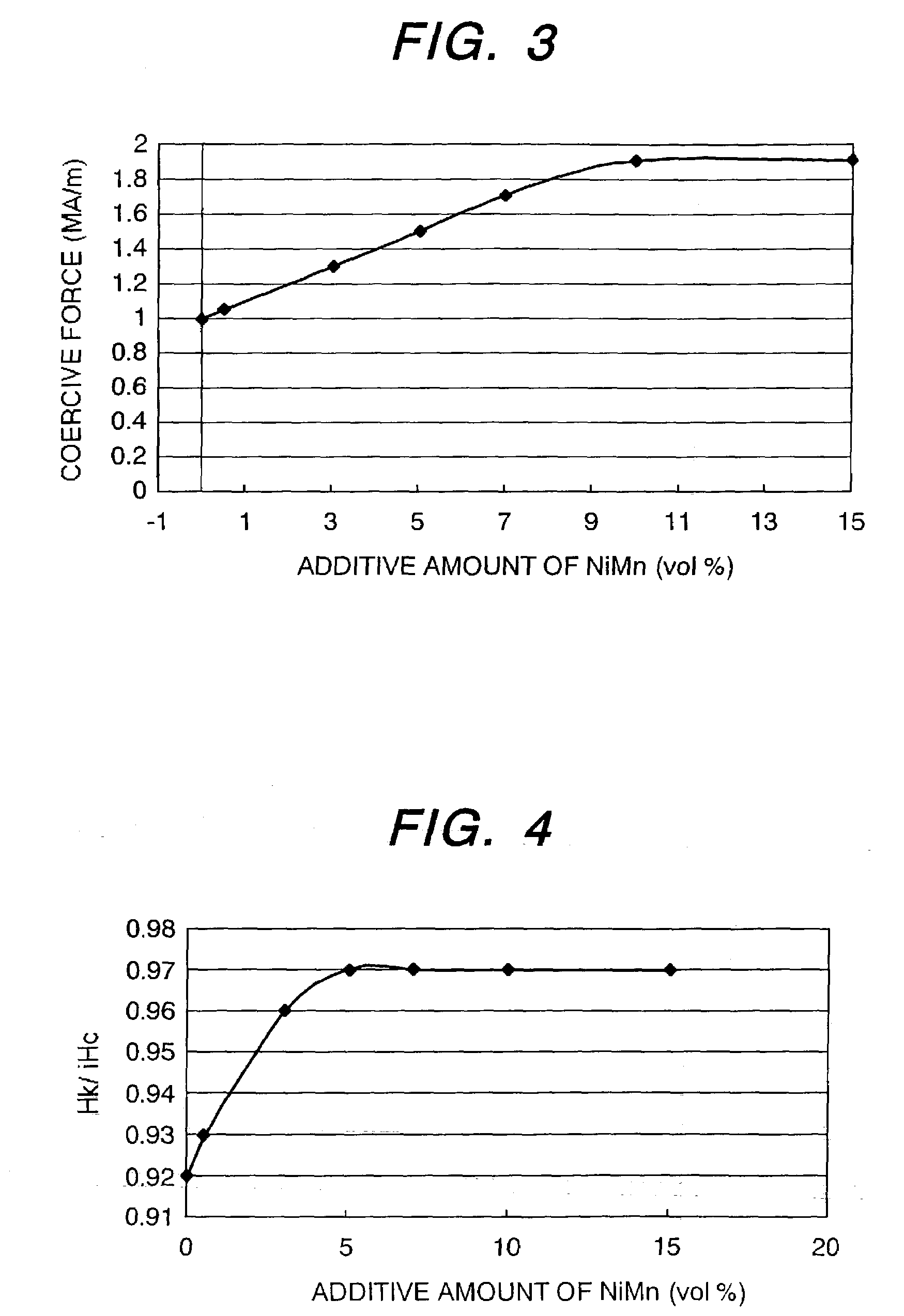

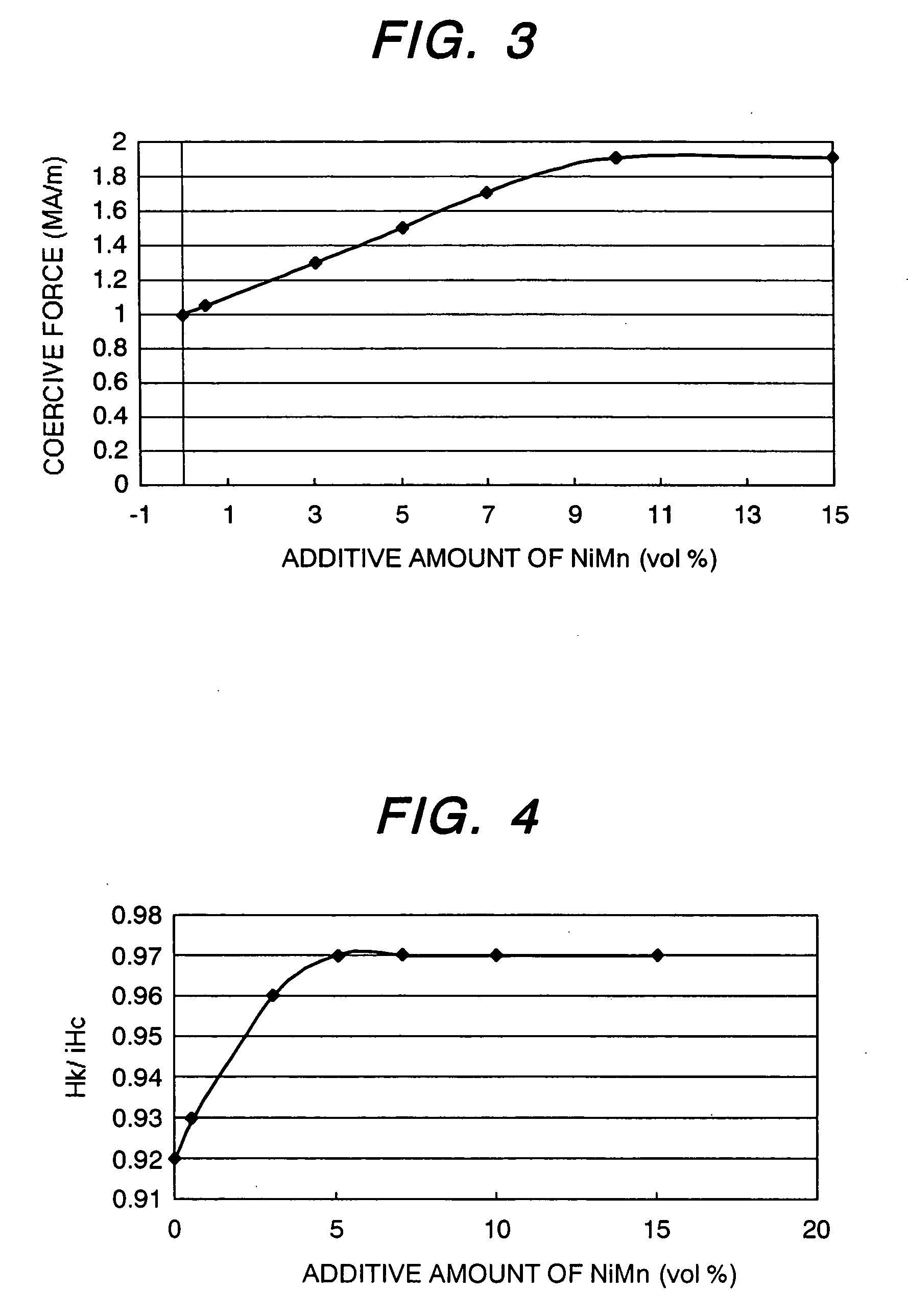

InactiveUS7064642B2Improve coercive forceHigh Remanent Flux DensityMagnetic circuit rotating partsMagnetic paintsRare-earth elementMaterials science

A permanent magnet comprises a hard magnetic material that contains at least a rare earth element and an anti-ferromagnetic material, wherein the hard magnetic material and the anti-ferromagnetic material are magnetically coupled. A volume ratio of the anti-ferromagnetic material is 20% or less, based on the permanent magnet.

Owner:HITACHI LTD

R-T-B based permanent magnet

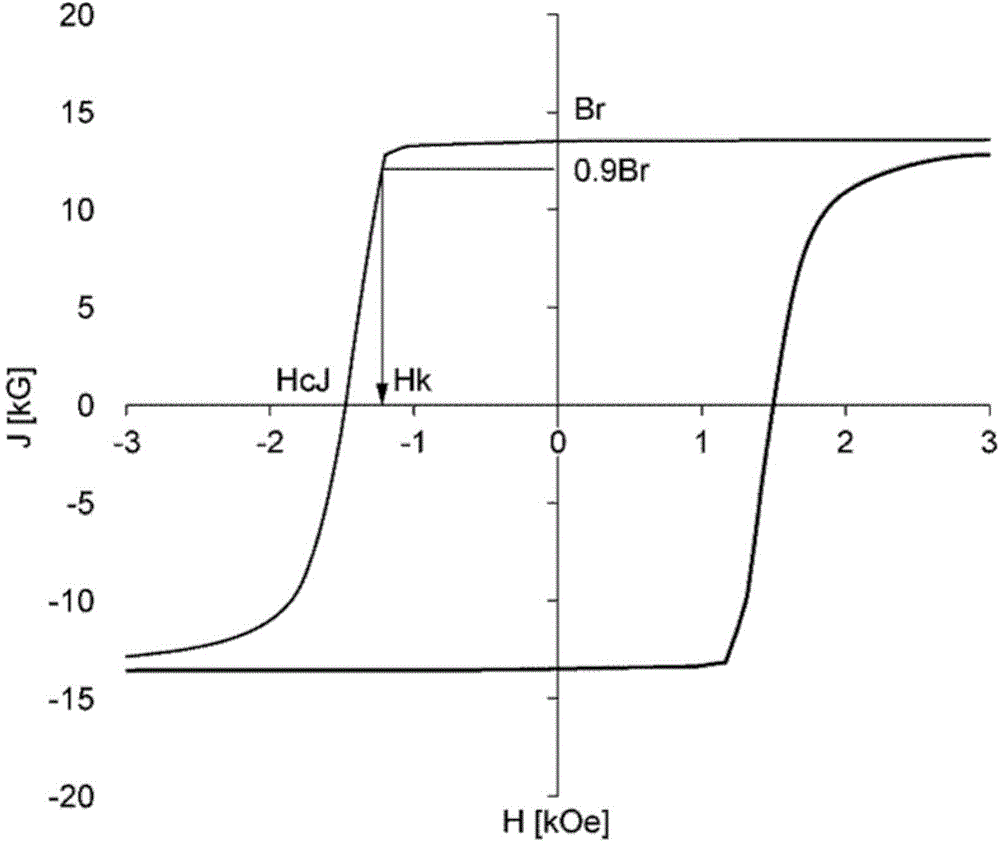

ActiveCN104952575AImprove controllabilityHigh Remanent Flux DensityInorganic material magnetismMagnetic circuit characterised by magnetic materialsRare-earth elementMetallurgy

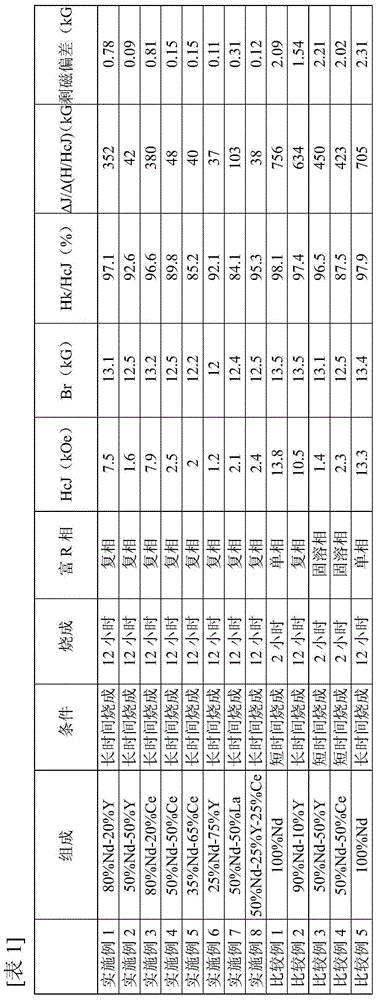

The present invention provides a R-T-B based permanent magnet, comprising a demagnetization curve having a slope ΔJ / Δ(H / HcJ) of less than 400 kG at a region where the value of magnetic field is Hk or less, wherein it is preferable that R in the composition of R-T-B is represented by (R11-xR2x), and T represents one or more transition metal elements containing Fe or a combination of Fe and Co as necessary, where: R1 represents the rare earth element(s) composed of one or more elements selected from the group consisting of Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu, and R2 contains at least one element selected from the group consisting of Y, Ce and La, and 0.2≰x≰0.7.

Owner:TDK CORPARATION

Bond magnet for direct current reactor and direct current reactor

InactiveUS7800474B2Reduce noiseImprove coercive forcePermanent magnetsVariable inductances/transformersRare-earth magnetDirect current

The present invention provides a bond magnet for direct current reactor which is to be disposed in a gap formed in a magnetic core of a direct current rector, the bond magnet containing a magnet powder containing a rapidly quenched powder of a rare earth magnet alloy. The present invention also provides a direct current reactor including a magnetic core having a gap and a winding area wound around the magnetic core, in which the bond magnet is disposed in the gap of the magnetic core.

Owner:DAIDO STEEL CO LTD +1

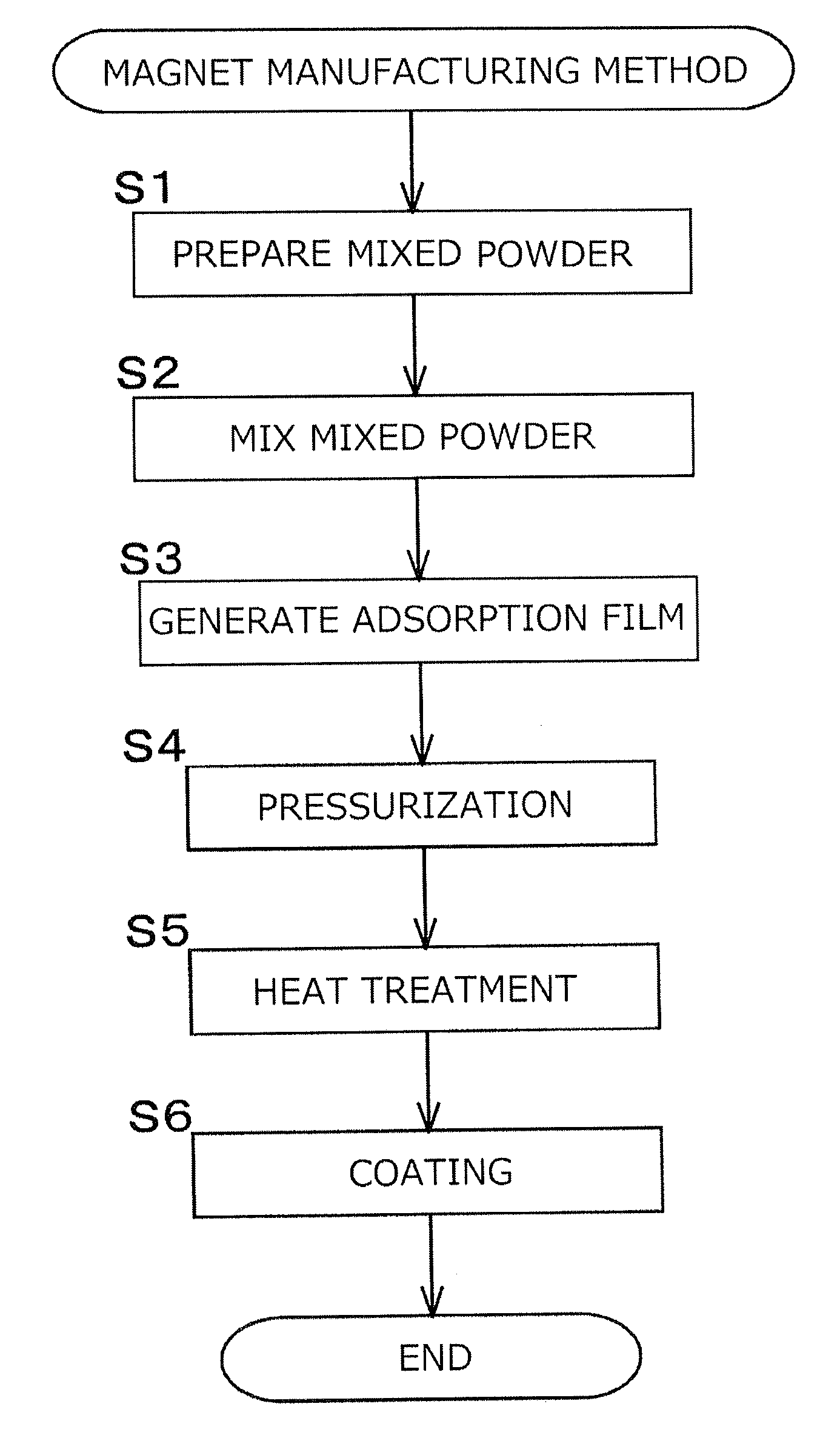

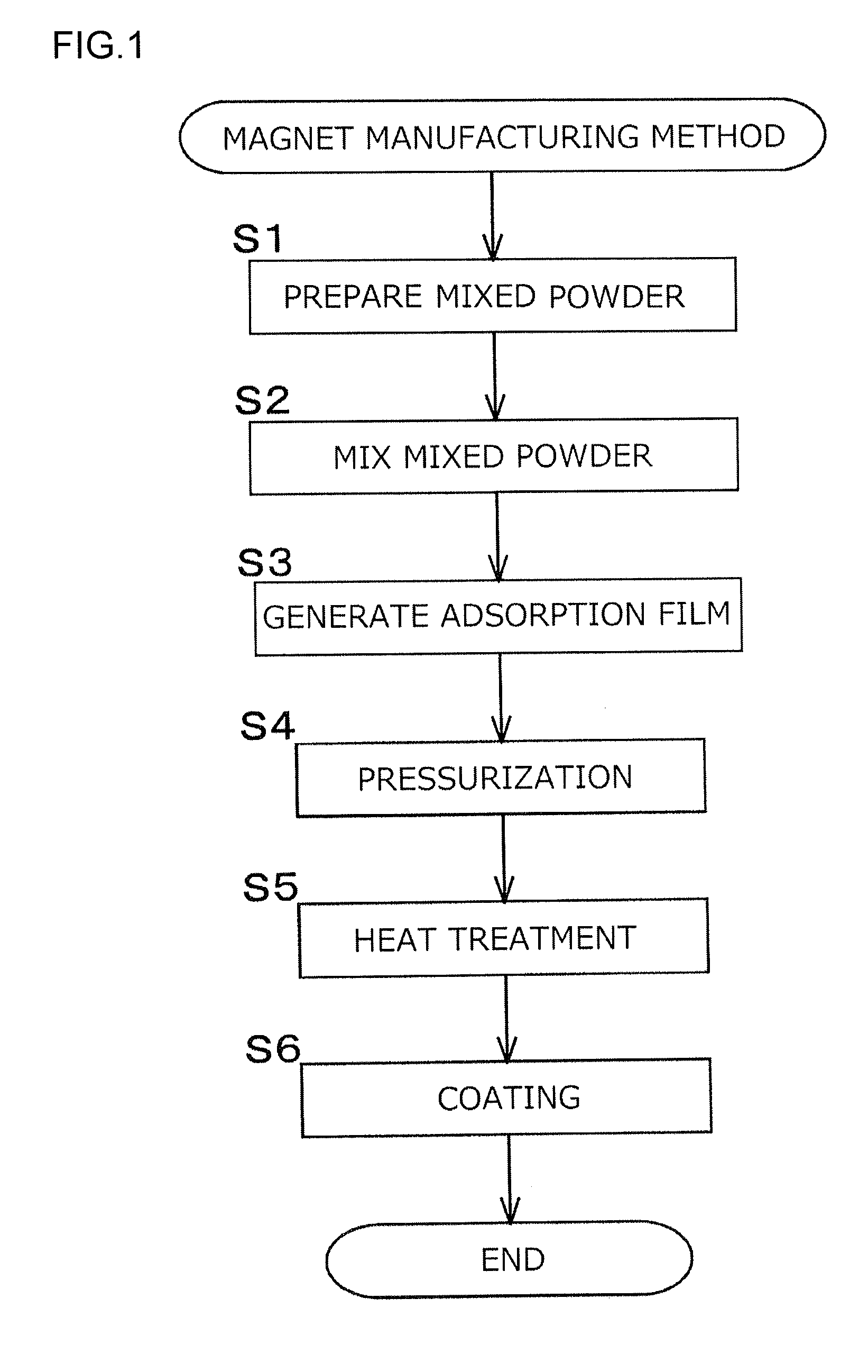

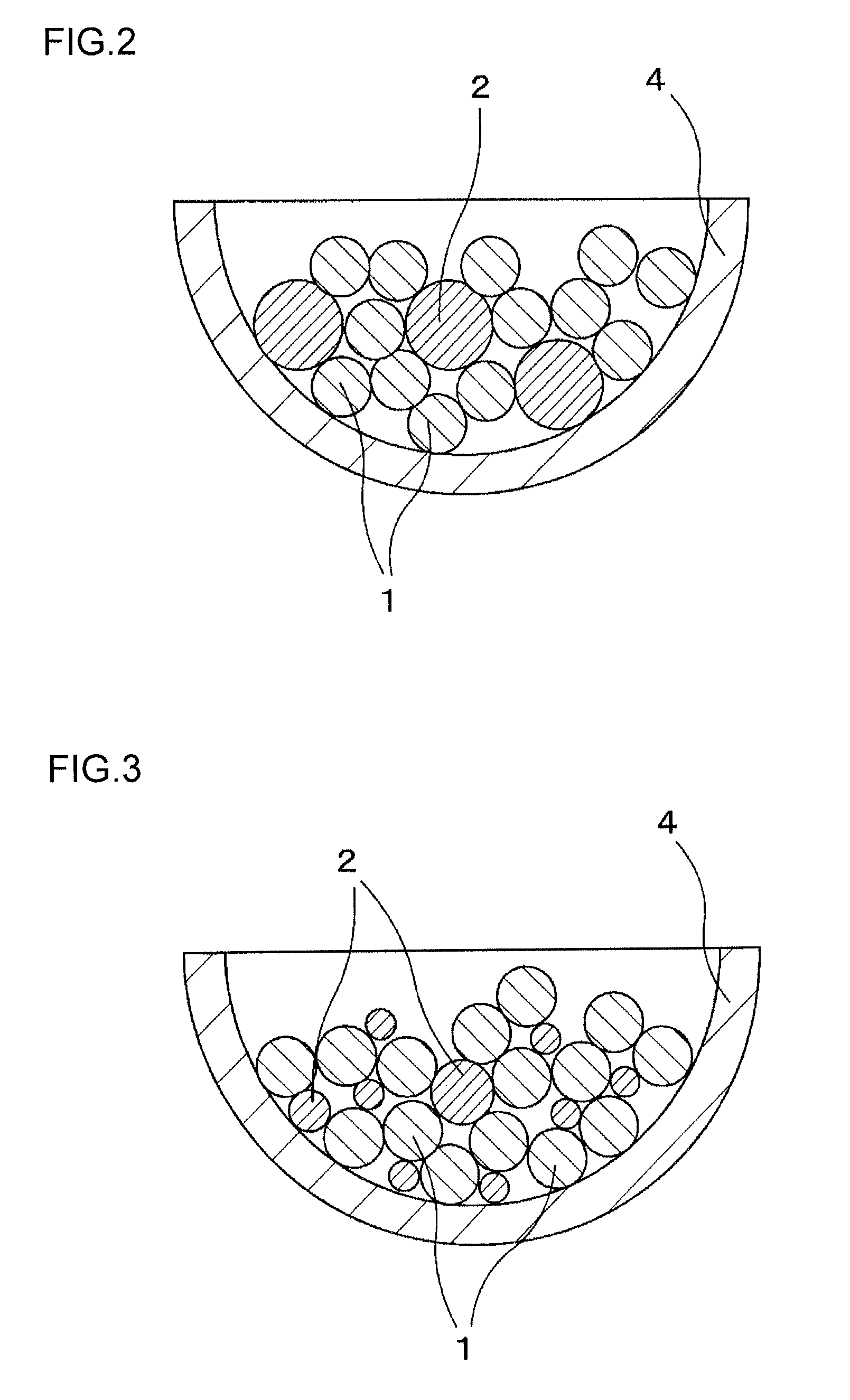

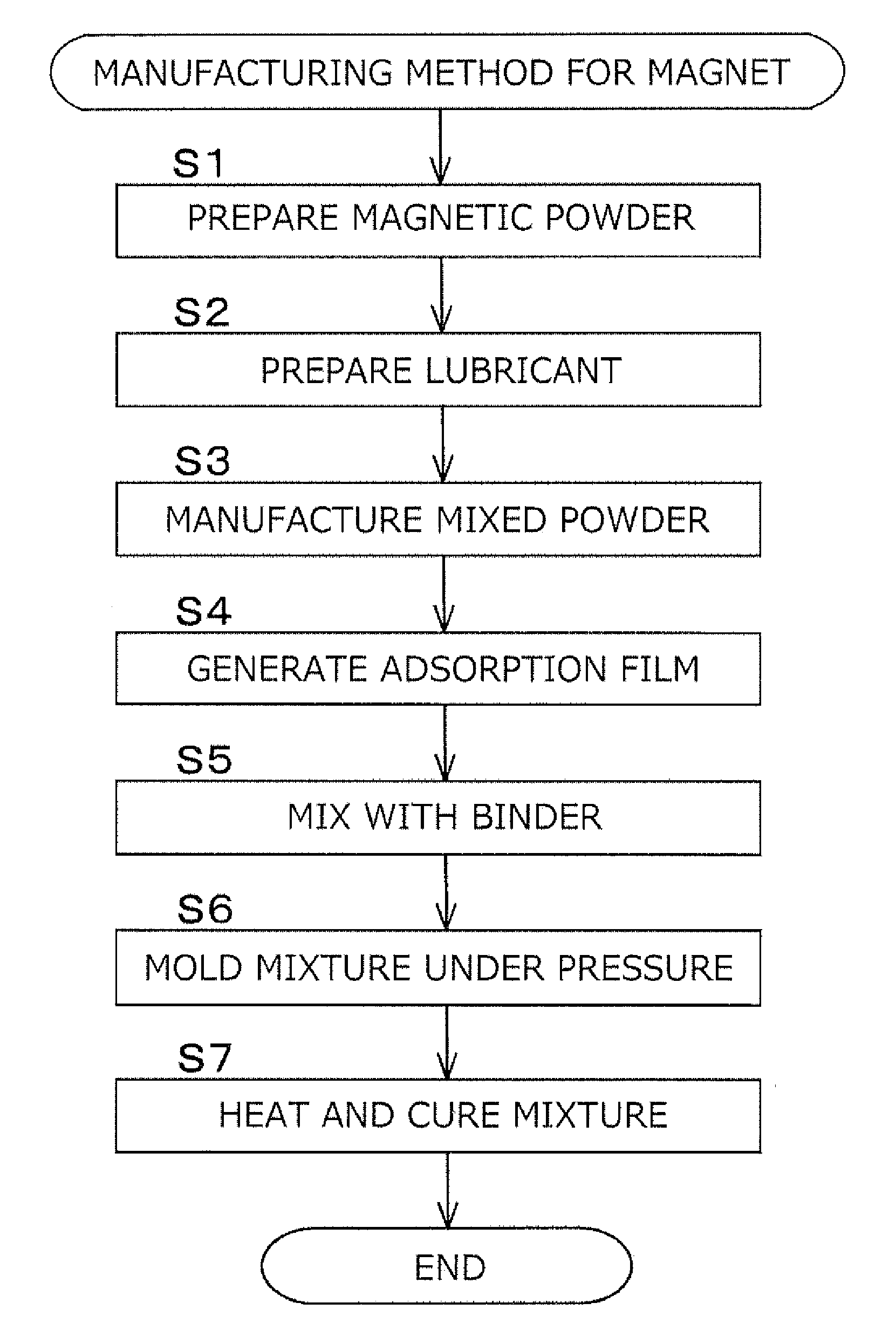

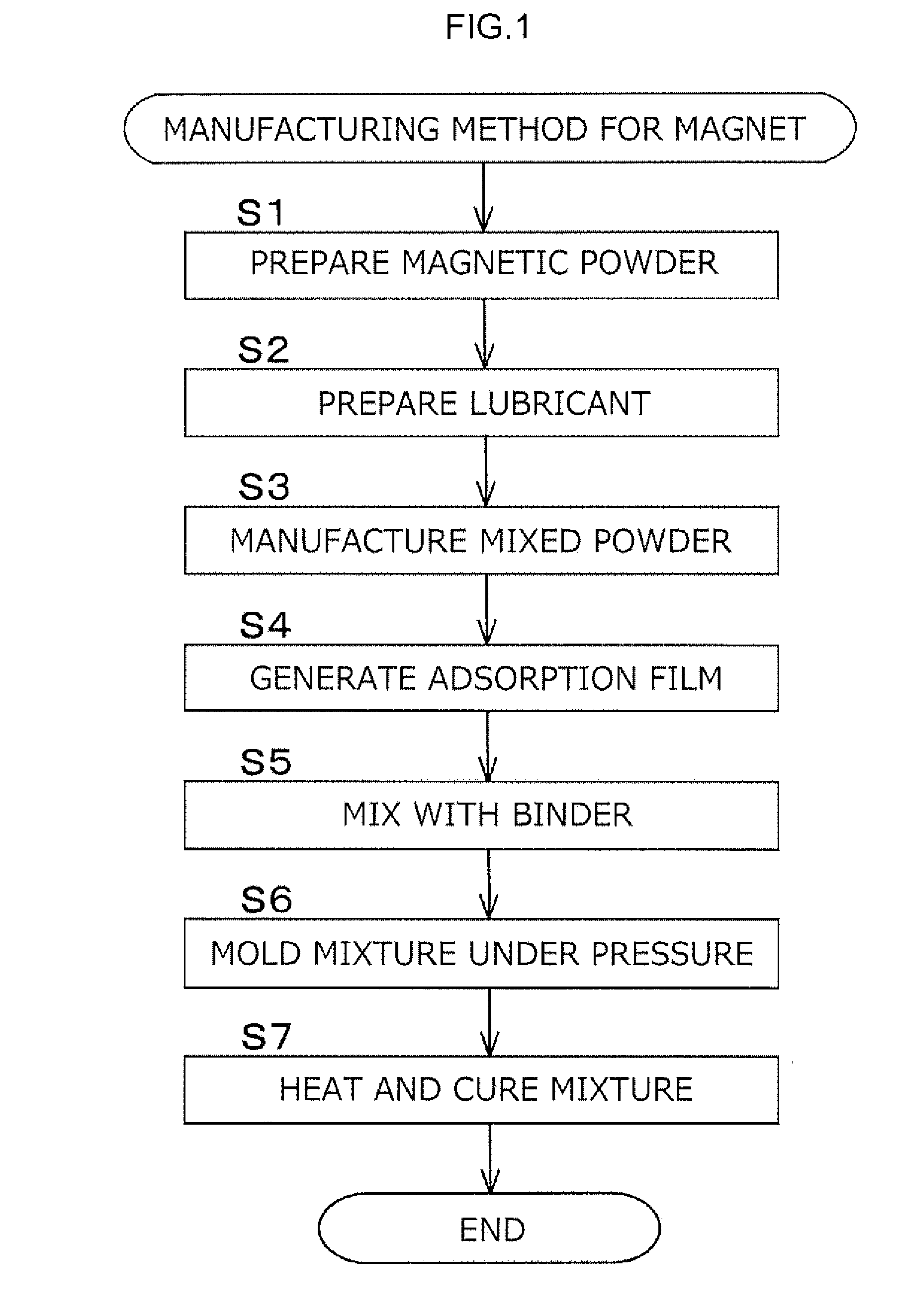

Magnet Manufacturing Method And Magnet

InactiveUS20160307697A1High Remanent Flux DensityReduce manufacturing costTransportation and packagingMetal-working apparatusDecompositionLubricant

A magnet manufacturing method has a step of preparing mixed powder of magnetic powder of a hard magnetic material, which includes one or more of an Fe—N-based compound and an R—Fe—N-based compound and a lubricant that allows formation of an adsorption film on a surface of the magnetic powder, a step of heating the mixed powder at a temperature that is equal to or higher than a melting point of the lubricant and that is lower than a decomposition temperature of the magnetic powder to form the adsorption film of the lubricant on the surface of the magnetic powder, a step of pressurizing and molding the magnetic powder in order to obtain a primary molding, and a step of heating the primary molding at a temperature that is lower than the decomposition temperature of the magnetic powder.

Owner:JTEKT CORP

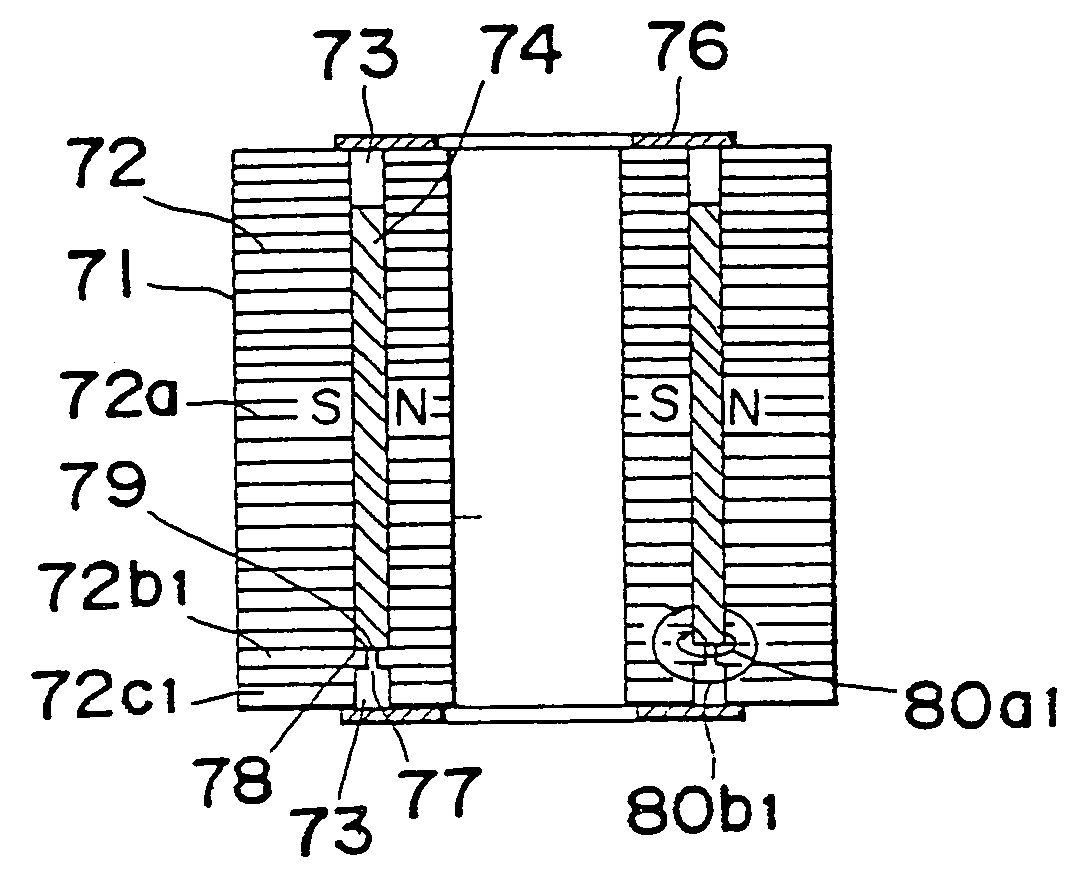

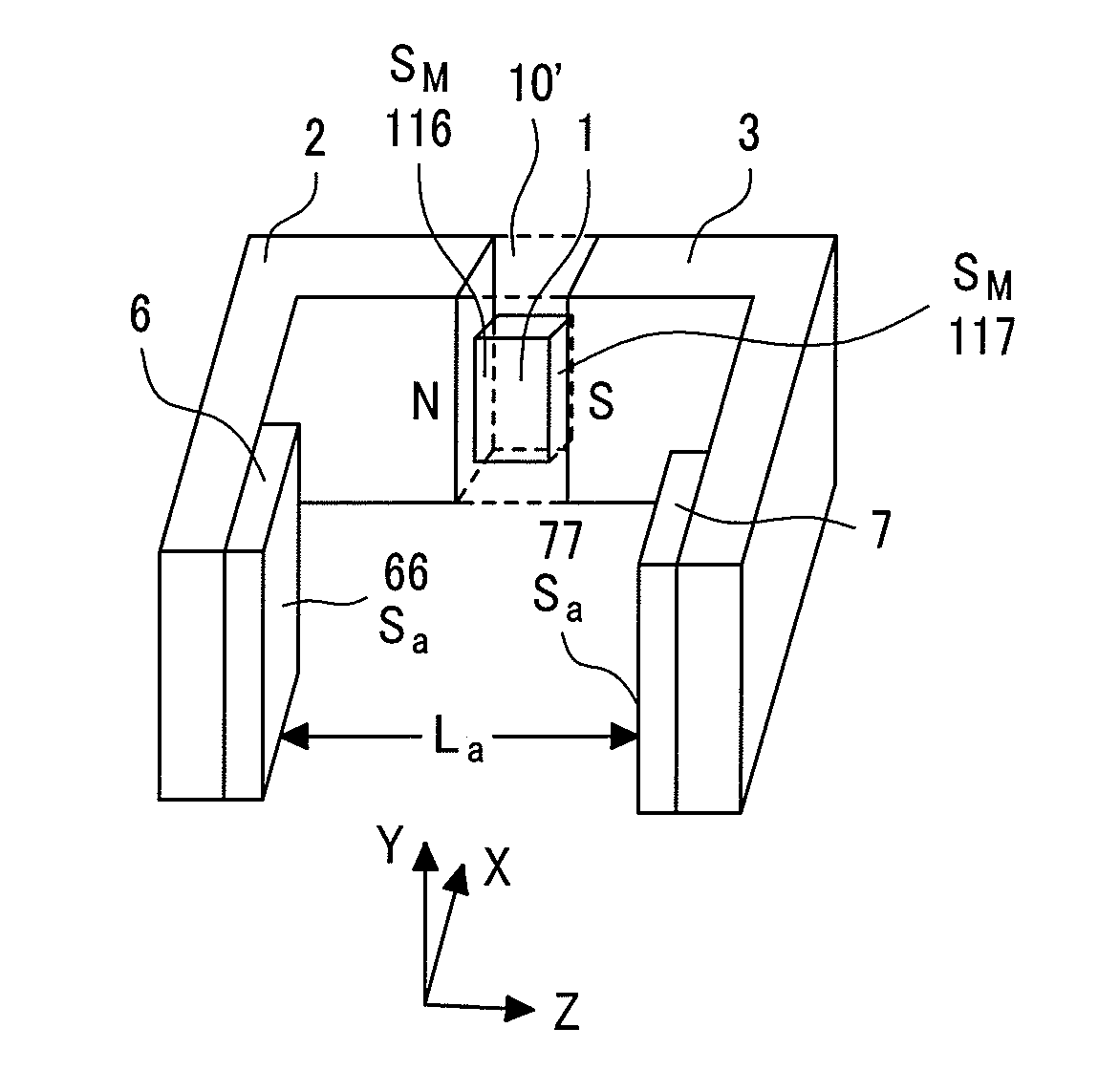

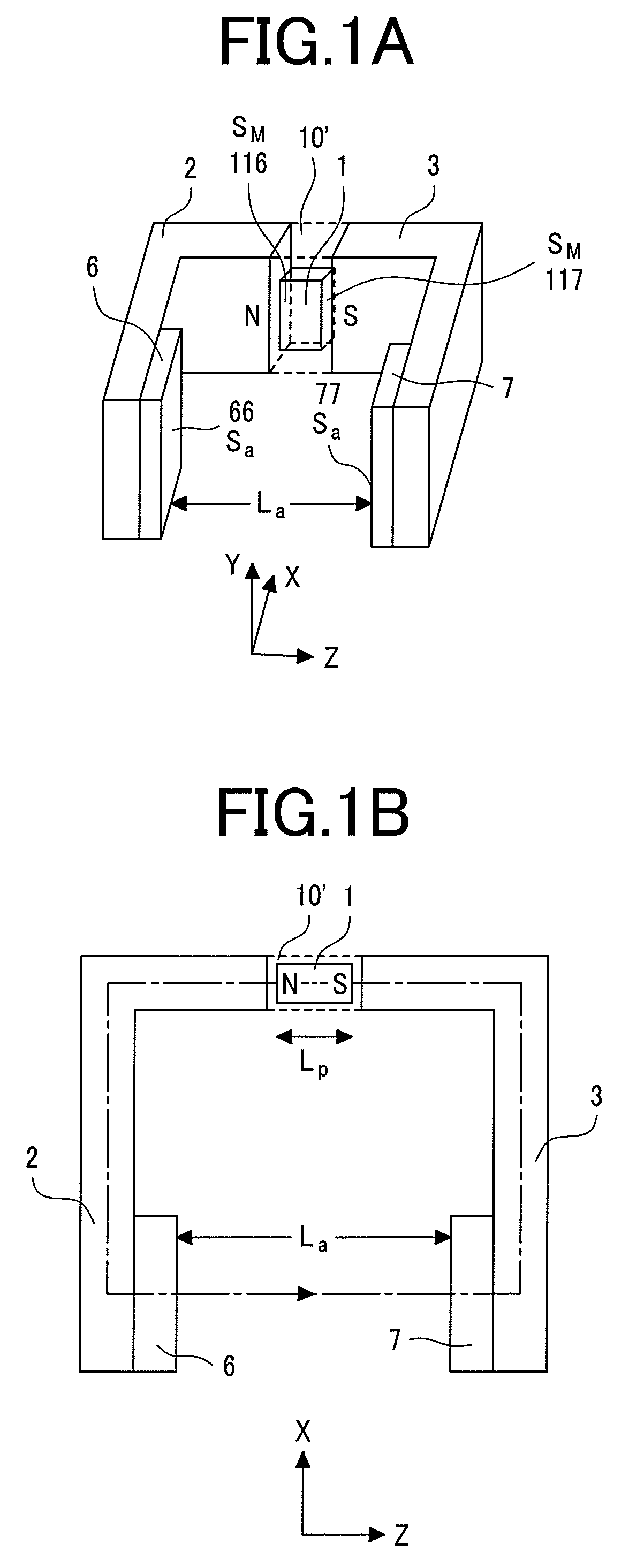

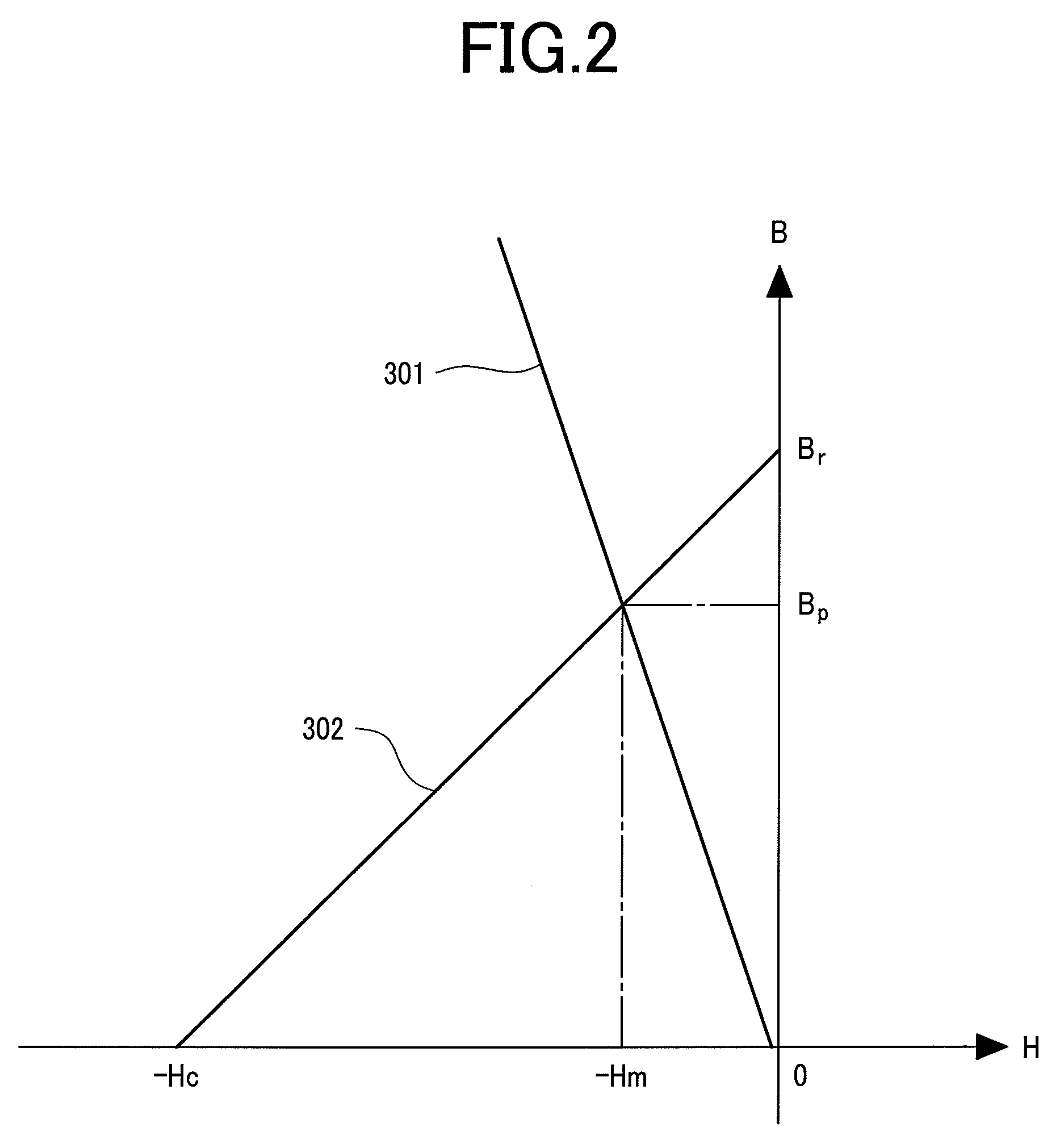

Apparatus for electron spin resonance CT

InactiveUS7541811B2Wide gapHigh Remanent Flux DensityMagnetic measurementsAnalysis using electron paramagnetic resonanaceSmall animalImage resolution

A compact, lightweight, and easy-to-use ESR-CT apparatus including a magnetic field leak line (5-G line) which is capable of imaging a small animal, such as a mouse, within 15 minutes, and of observing a desired region with a spatial resolution of 1 mm or less. A permanent magnet system is introduced of the apparatus includes pole pieces having a predetermined area which are opposed to each other through a measured space, yokes combined with the pole pieces, and a permanent magnet inserted in series so that at least one magnetic pole plane intersects perpendicularly to the closed magnetic circuit for magnetic coupling with the yokes. This makes it possible to locate a gradient coil system and a field scanning coil system sufficiently apart from end faces of the pole pieces, and to downsize the field scanning coil system so that the gradient field system is movable.

Owner:HITACHI LTD

Manufacturing method for magnet and magnet

InactiveUS20160379755A1High Remanent Flux DensityGood molding effectTransportation and packagingMetal-working apparatusLubricantSilicone

A manufacturing method for a magnet includes: a step of obtaining mixed powder of magnetic powder and a lubricant; a step of mixing the mixed powder with an uncured binder that is a silicone composition to attach the binder to a surface of the mixed powder; a step of molding the mixed powder under pressure to obtain a molding, and a step of curing the silicone composition to bind particles of the magnetic powder together,

Owner:JTEKT CORP

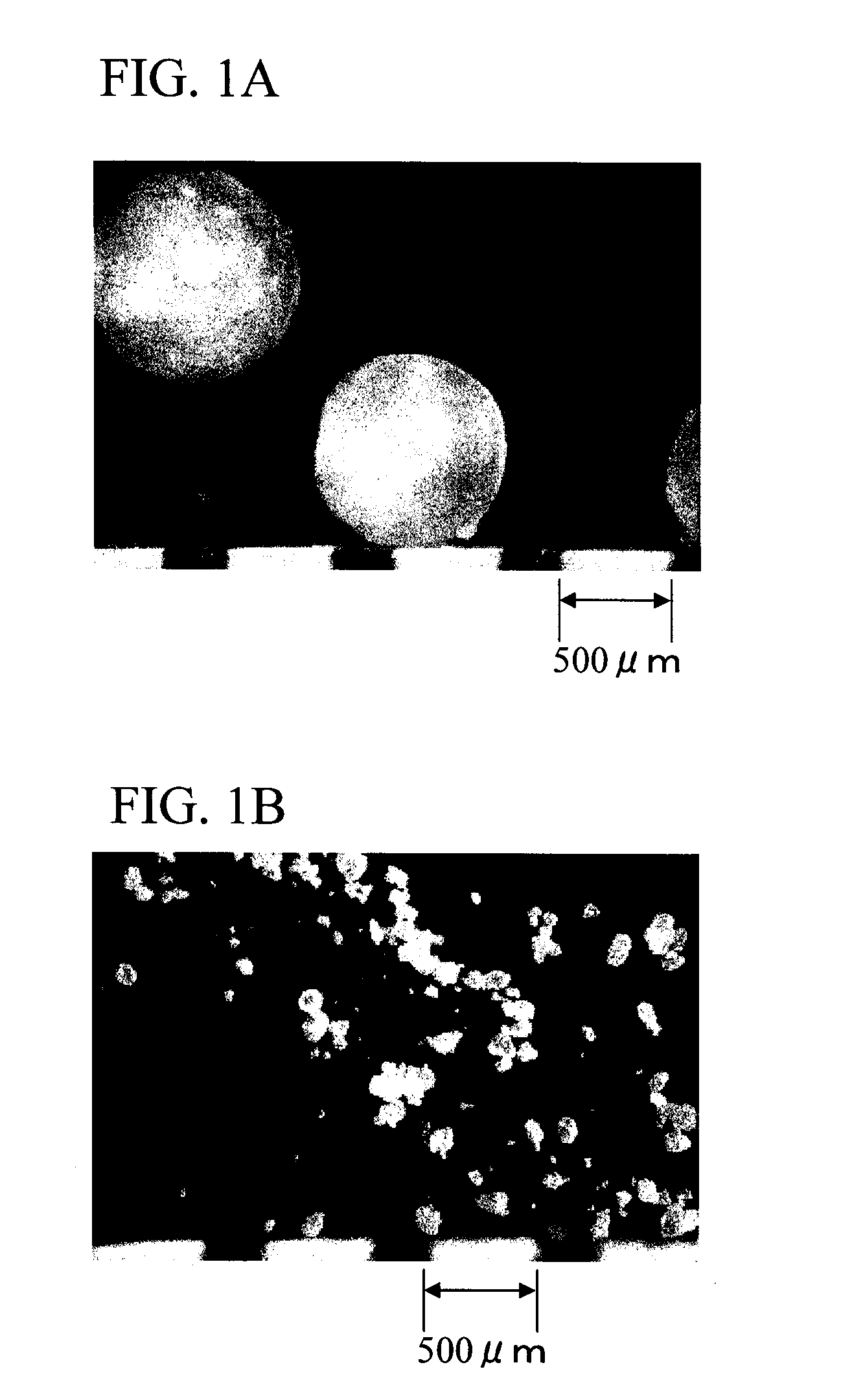

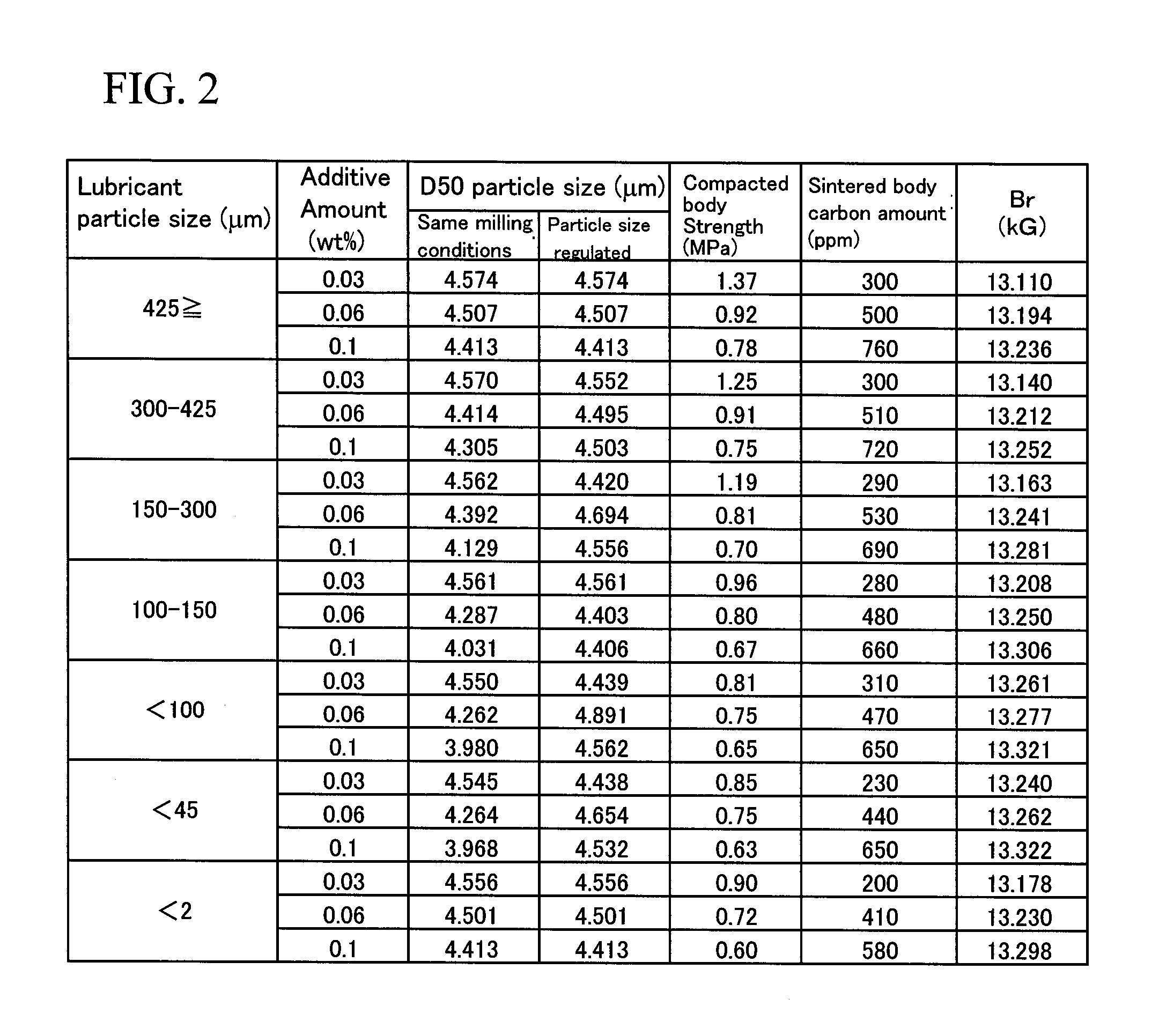

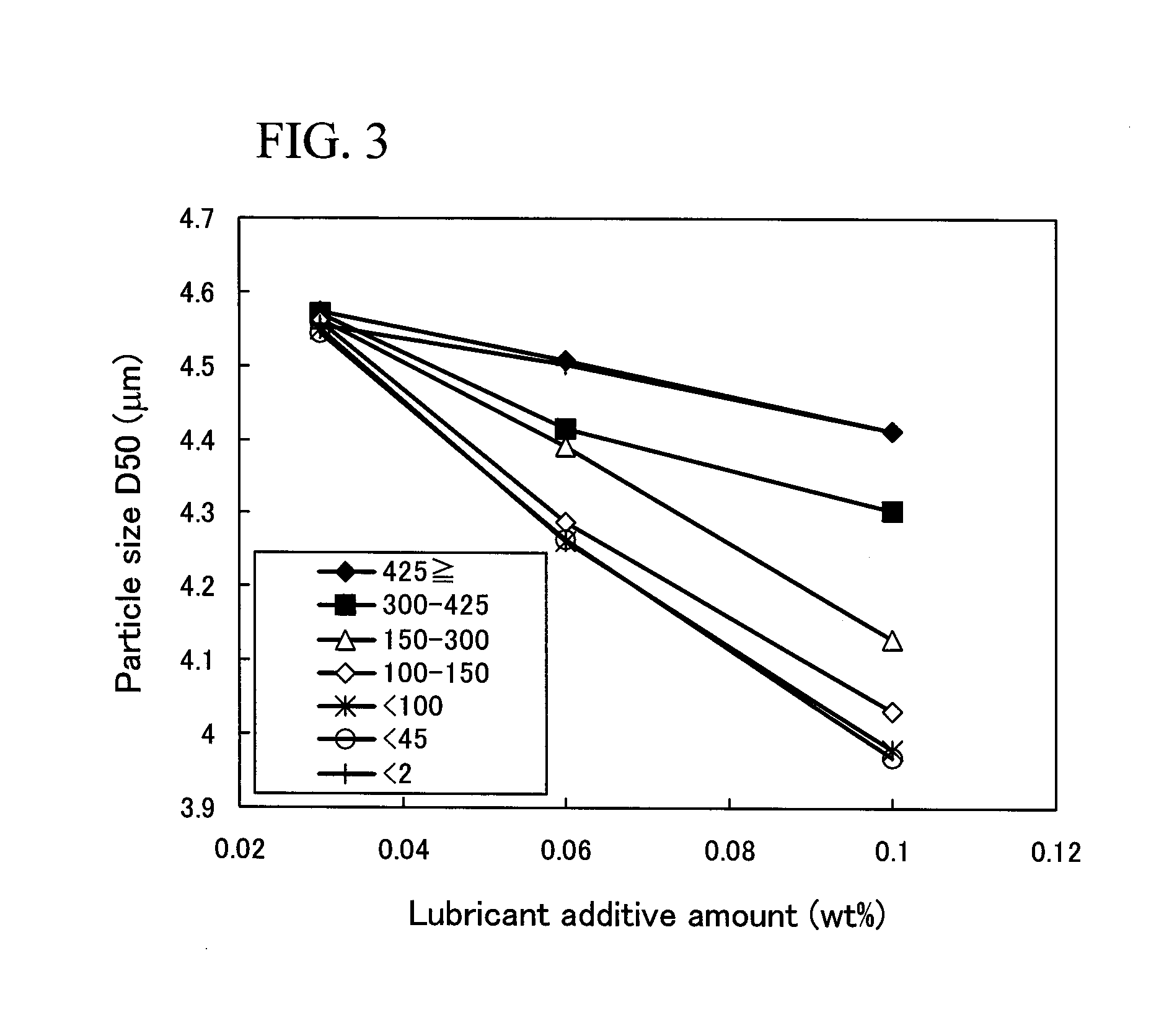

Rare Earth Sintered Magnet, Raw Material Alloy Powder For Rare Earth Sintered Magnet, And Process For Producing Rare Earth Sintered Magnet

InactiveUS20070221296A1High dispersion stateHigh Remanent Flux DensityTransportation and packagingMetal-working apparatusElectron probe microanalysisRare earth

Provided is a rare earth sintered magnet which can attain a high residual magnetic flux density without causing a drop in coercive force or mechanical strength. The above-described problems are resolved by a rare earth sintered magnet which includes a sintered body whose carbon amount as determined by mass spectrometry is between 500 and 1,500 ppm, wherein a cv-value of the carbon amount on a rupture plane thereof is no greater than 200. The production method for this rare earth sintered magnet includes the steps of: preparing a compacted body by compressing in a magnetic field a raw material alloy powder has a carbon amount of no greater than 1,200 ppm as determined by mass spectrometry, and a Cmax / Cmin value of 15 or less wherein Cmax and Cmin respectively represent a maximum value and a minimum value of X-ray intensity of characteristic X-rays of carbon as determined by EPMA (Electron Probe Micro Analyzer); and sintering the compacted body.

Owner:TDK CORPARATION

MRI apparatus with high-resistance magnet

InactiveUS20070159171A1Improve the immunityEasy to demagnetizeMagnetic measurementsThin material handlingHigh resistanceMagnetic field gradient

Eddy current generated around a magnetic circuit in an MRI apparatus is one of the causes of deviation from an ideal magnetic field gradient waveform and causes image distortion, loss of strength, ghost generation, loss of signal, and spectral distortion. An object of the present invention is to suppress the generation of the eddy current. In an MRI apparatus, a ferromagnetic material formed from powder is used in a part of a magnetic circuit: the powder mainly comprising a mother phase containing iron or cobalt and showing ferromagnetism; and a high-resistance layer having a resistance not less than ten times as high as the mother phase and a Vickers hardness lower than that of the mother phase being formed in layers along parts of the surface of the powder on parts or the entire of the surface.

Owner:HITACHI LTD

Motor using magnet

InactiveUS20060238282A1High Remanent Flux DensityHigh energyMagnetic circuit rotating partsMagnetsRare-earth elementMaterials science

A permanent magnet comprises a hard magnetic material that contains at least a rare earth element and an anti-ferromagnetic material, wherein the hard magnetic material and the anti-ferromagnetic material are magnetically coupled. A volume ratio of the anti-ferromagnetic material is 20% or less, based on the permanent magnet.

Owner:HITACHI LTD

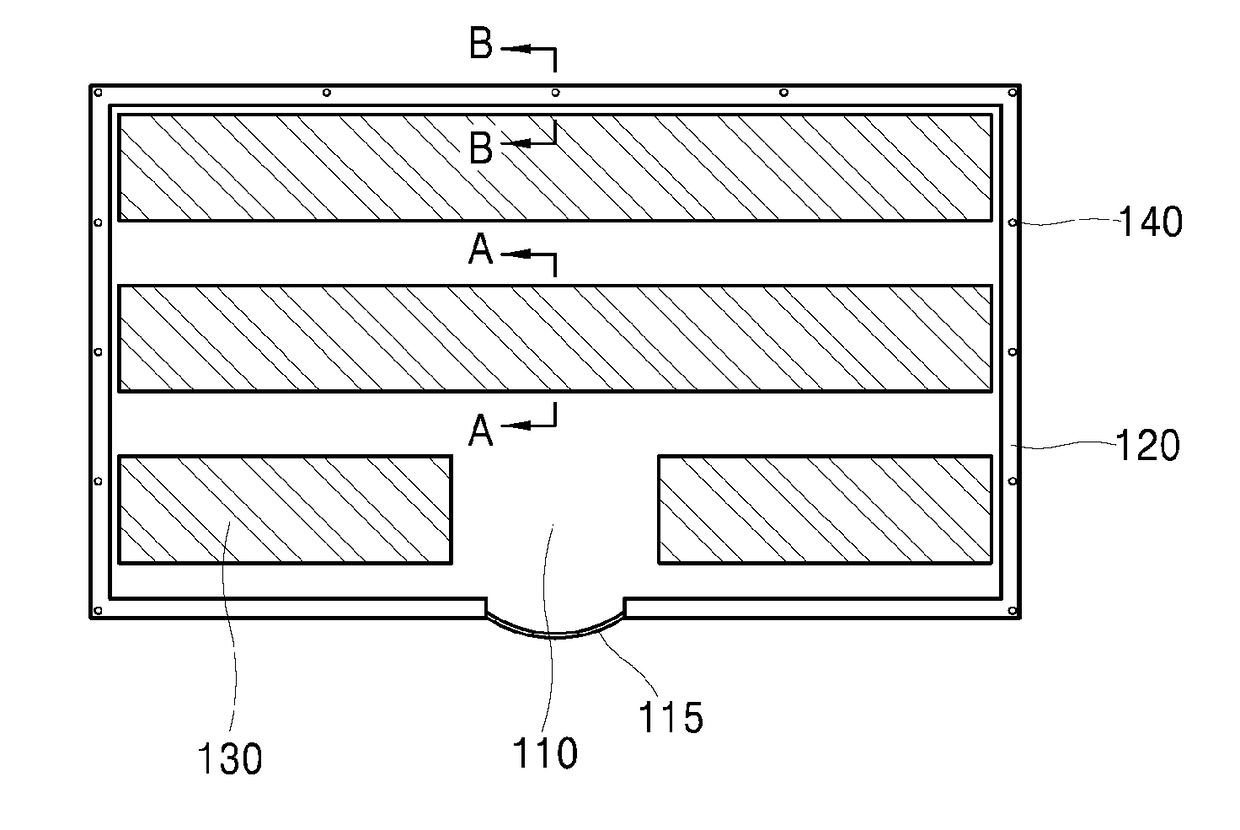

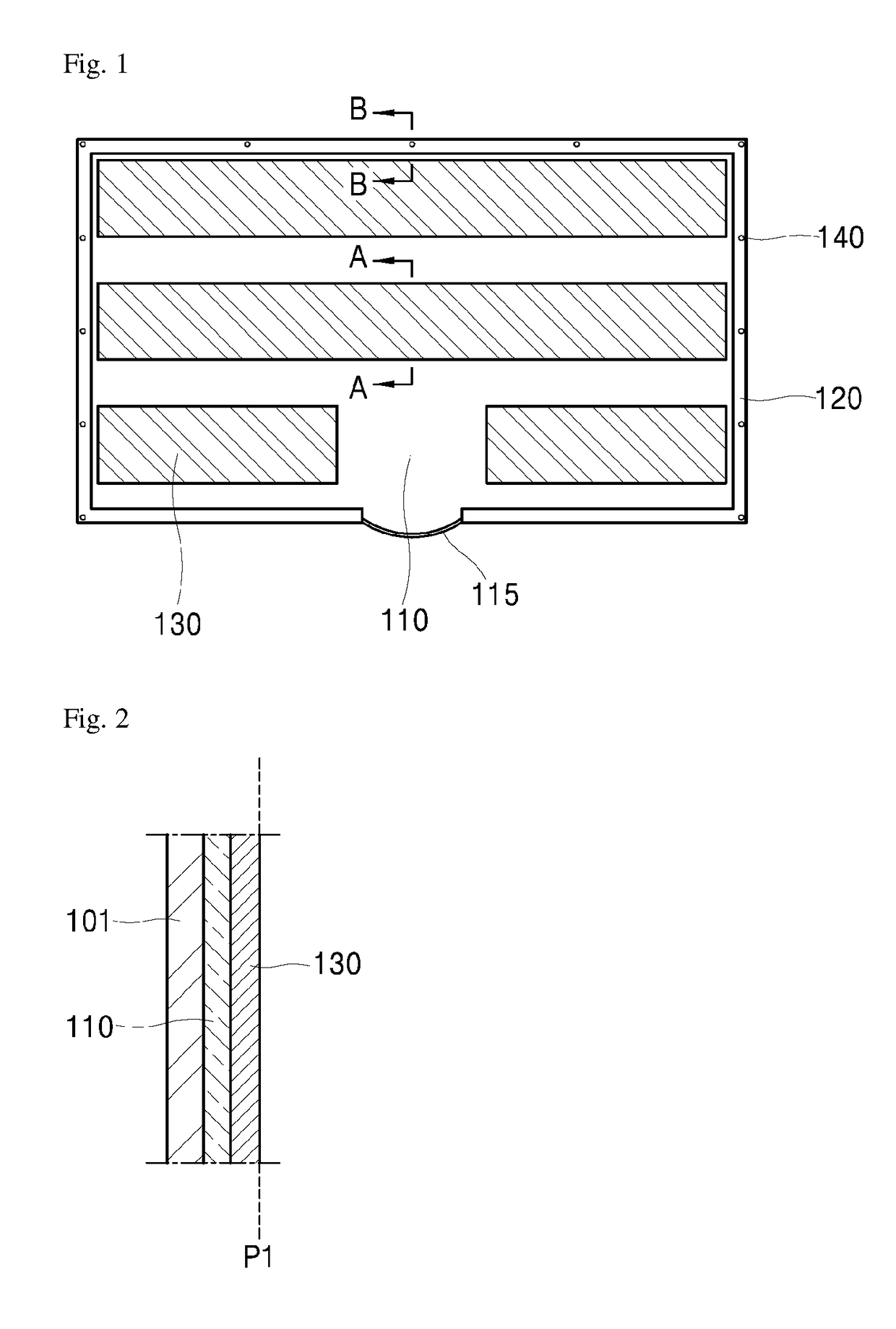

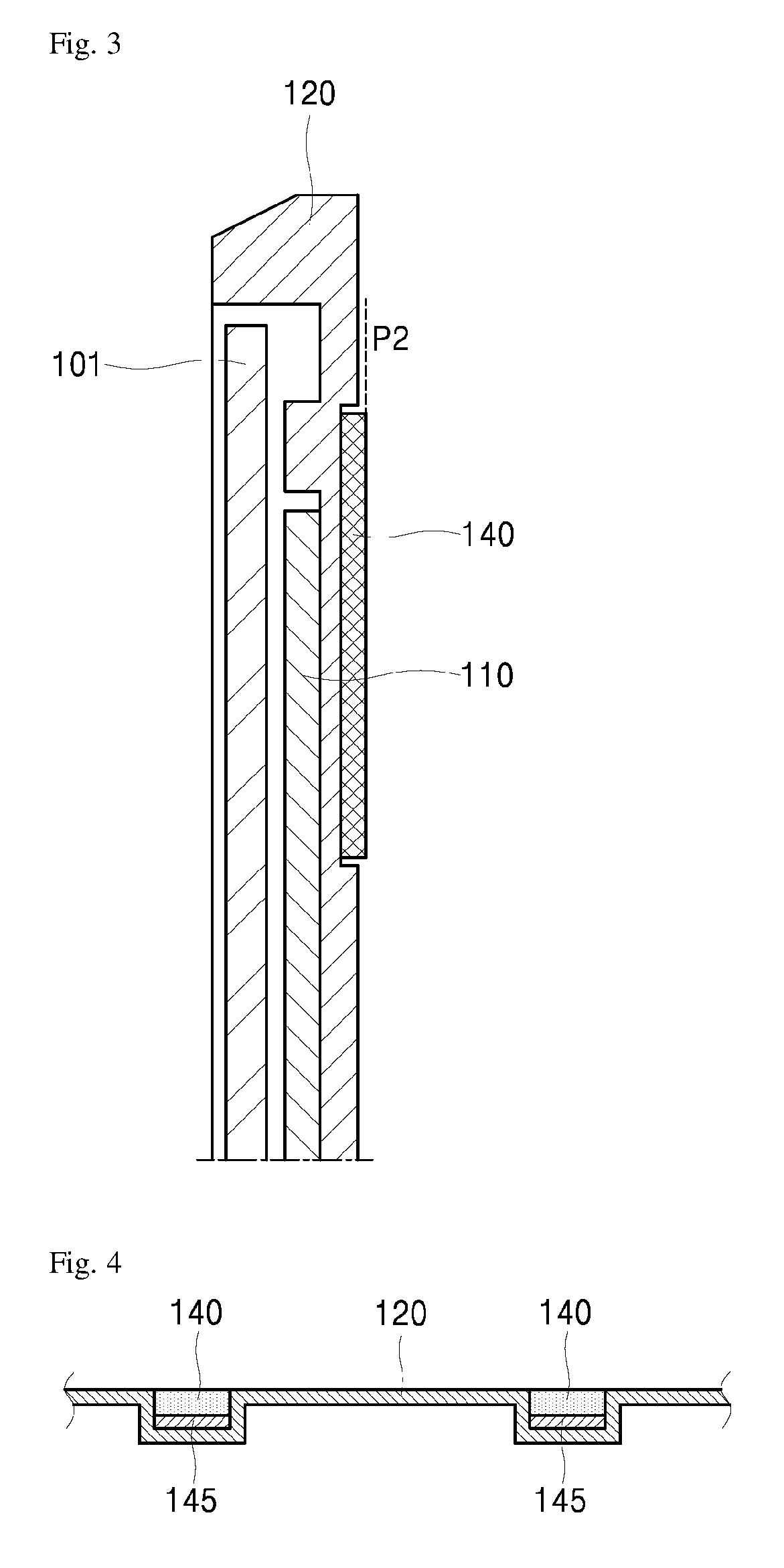

Display panel supporting unit and display device using the same

ActiveUS20170202097A1Close contactGood adhesionMachine supportsDigital data processing detailsDisplay deviceEngineering

A display panel supporting unit according to an embodiment of the present disclosure includes a first magnet provided on a first support member and a second magnet provided on a second support member and having a residual magnetic flux density that is equal to or greater than a residual magnetic flux density of the first magnet. Accordingly, a display device is provided such that even an edge portion of the display panel can closely contact a wall. A first magnet may be a rubber magnet, and a second magnet may be either a rubber magnet or a rare-earth magnet.

Owner:LG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com