Patents

Literature

56results about How to "Easy to demagnetize" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

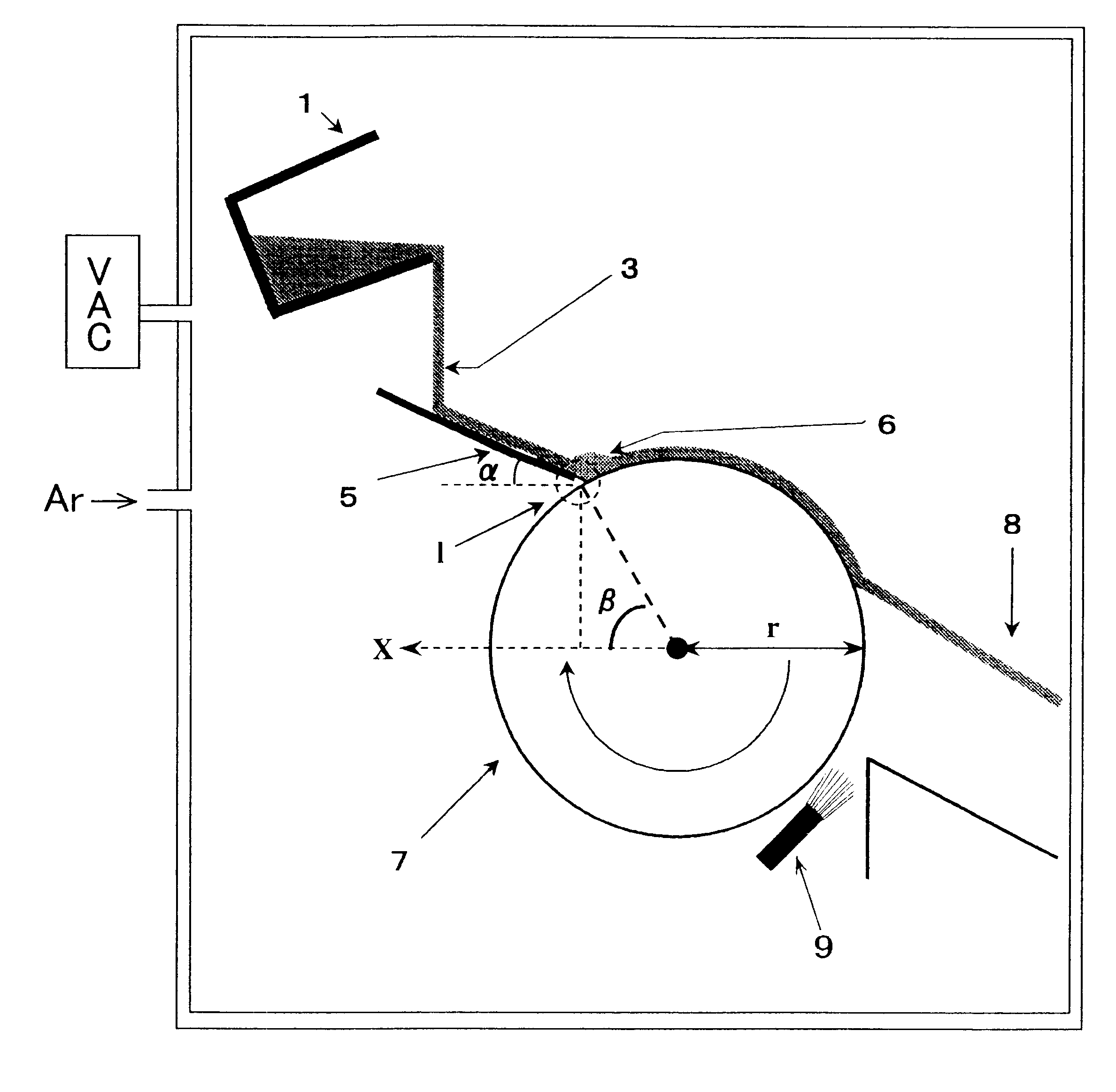

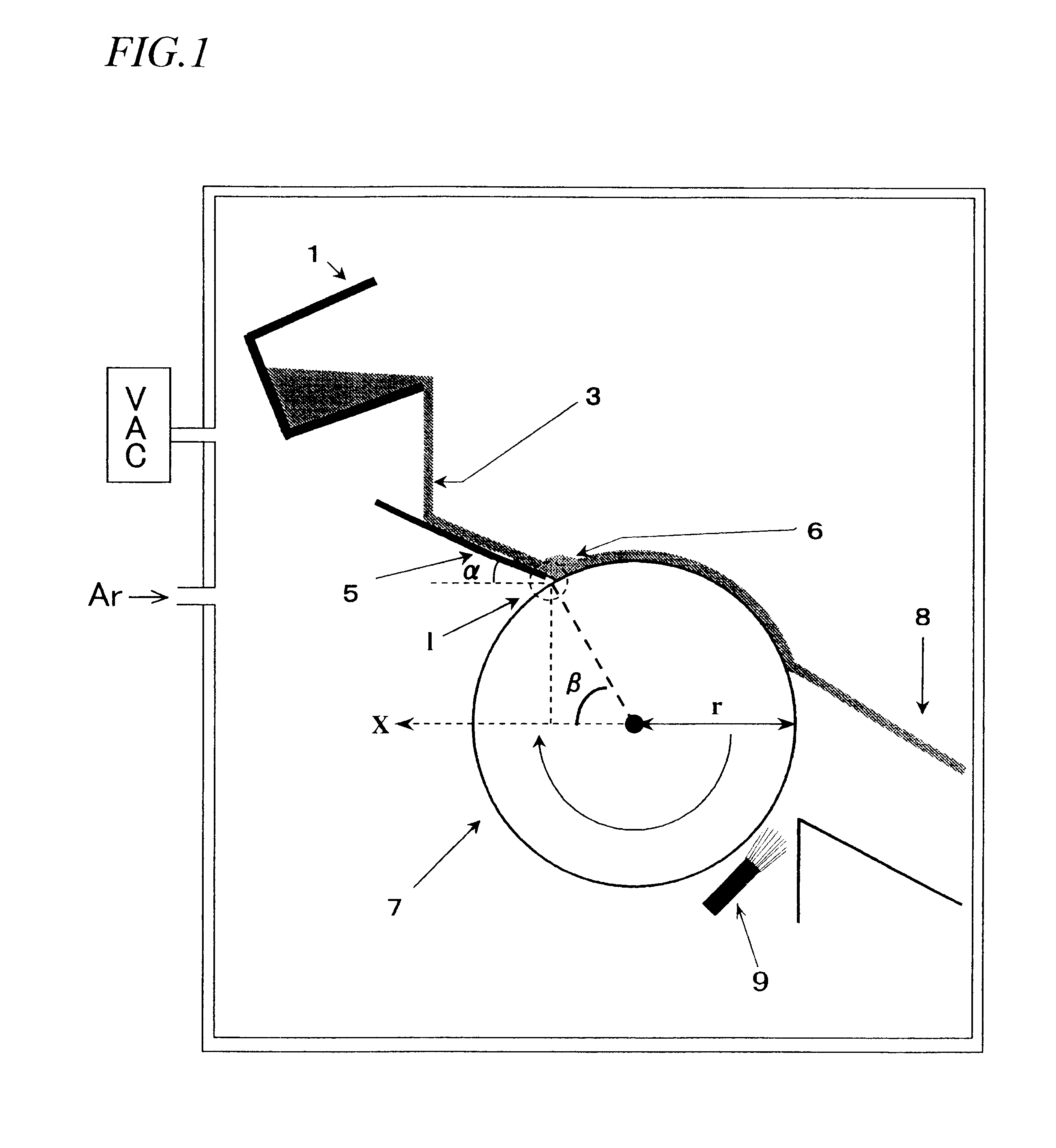

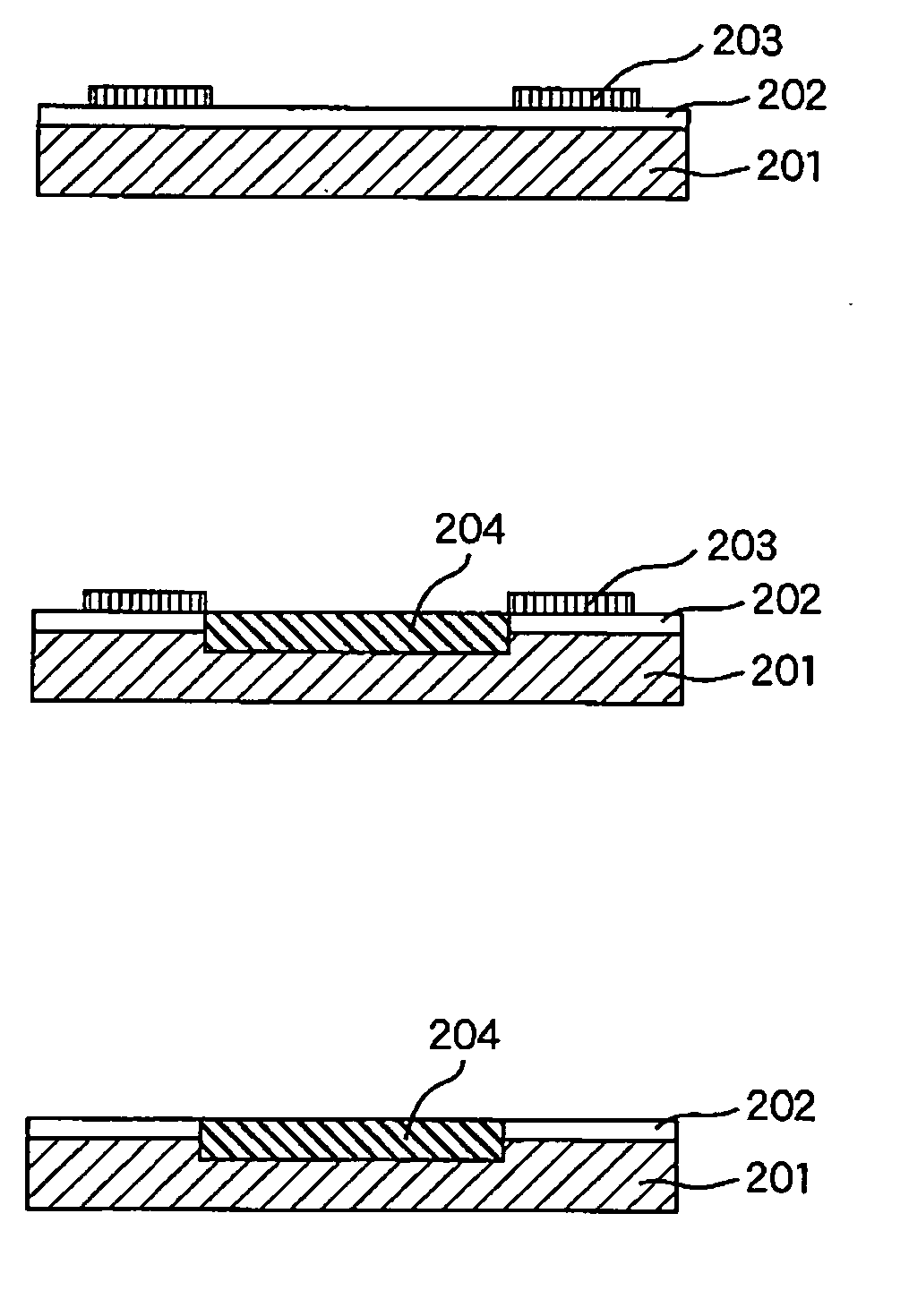

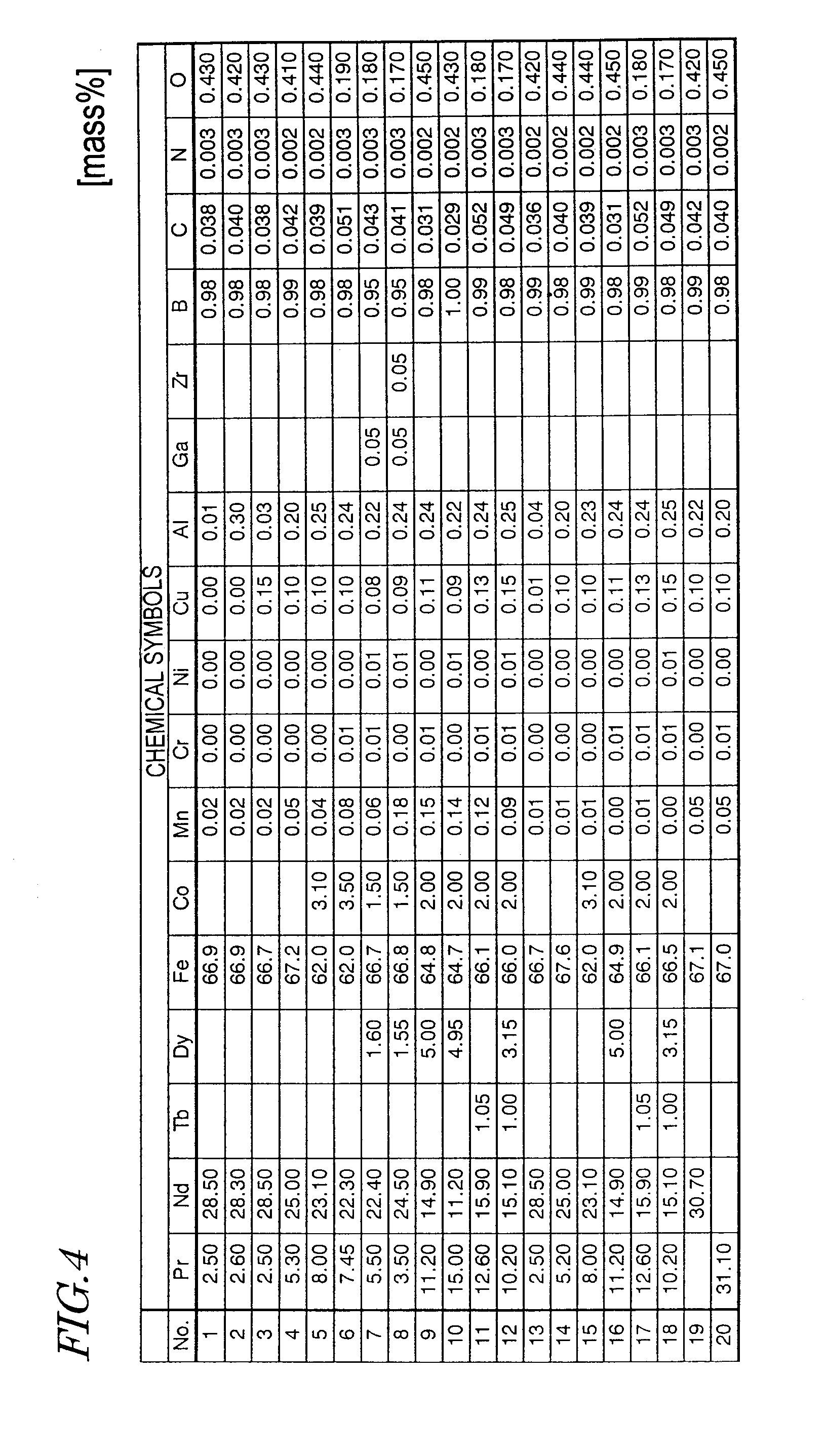

Method of making material alloy for iron-based rare earth magnet

InactiveUS6695929B2Good reproducibilityUniform structureNanomagnetismInorganic material magnetismRare-earth elementRare-earth magnet

A melt of an iron-based rare earth material alloy, represented by (Fe1-mTm)100-x-y-zQxRyMz, is prepared, wherein T is Co and / or Ni; Q is B and / or C; R is selected from Y (yttrium) and the rare earth elements; M is selected from Al, Si, Ti, V, Cr, Mn, Cu, Zn, Ga, Zr, Nb, Mo, Ag, Hf, Ta, W, Pt, Au and Pb; 10<=x<=30 at %; 2%<=y<10 at %; 0<=z<=10 at % and 0<=m<=0.5. The melt is fed onto a guide to form a flow of the melt thereon and move the melt onto a melt / chill roller contact region, where the melt is rapidly cooled by the chill roller to make a rapidly solidified alloy. An oxygen concentration of the melt yet to be fed onto the guide is controlled at about 3,000 ppm or less in mass percentage.

Owner:SUMITOMO SPECIAL METAL CO LTD

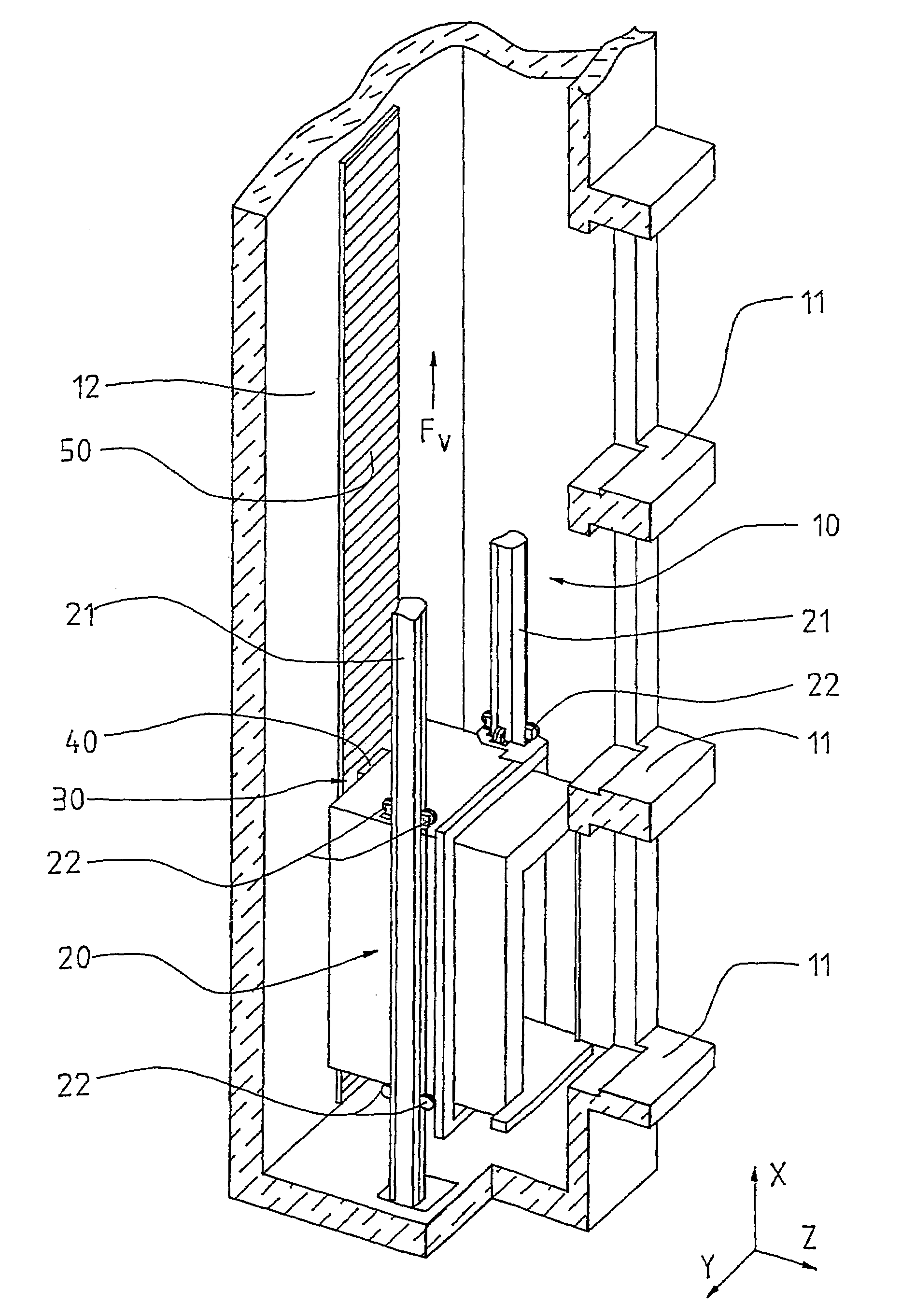

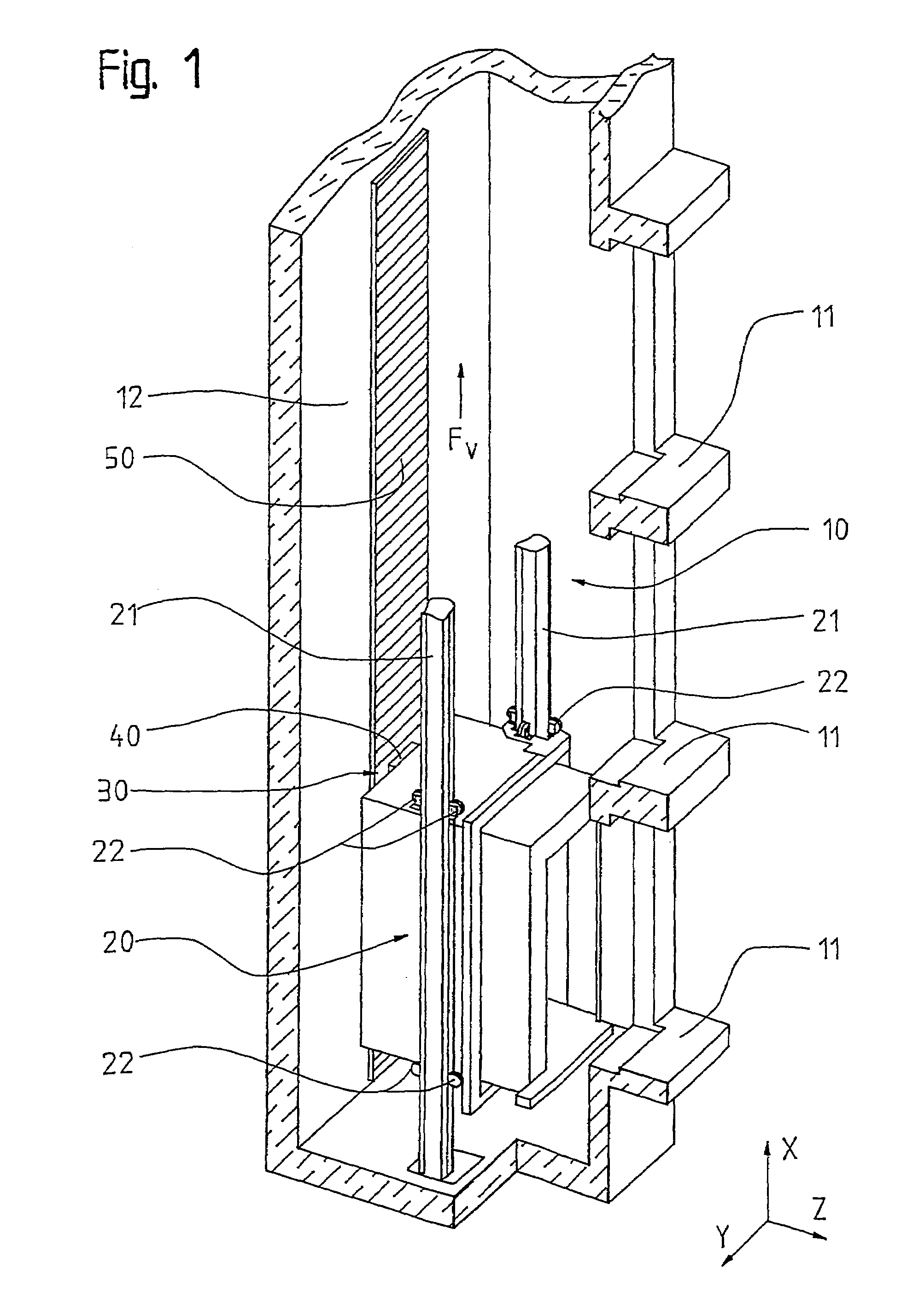

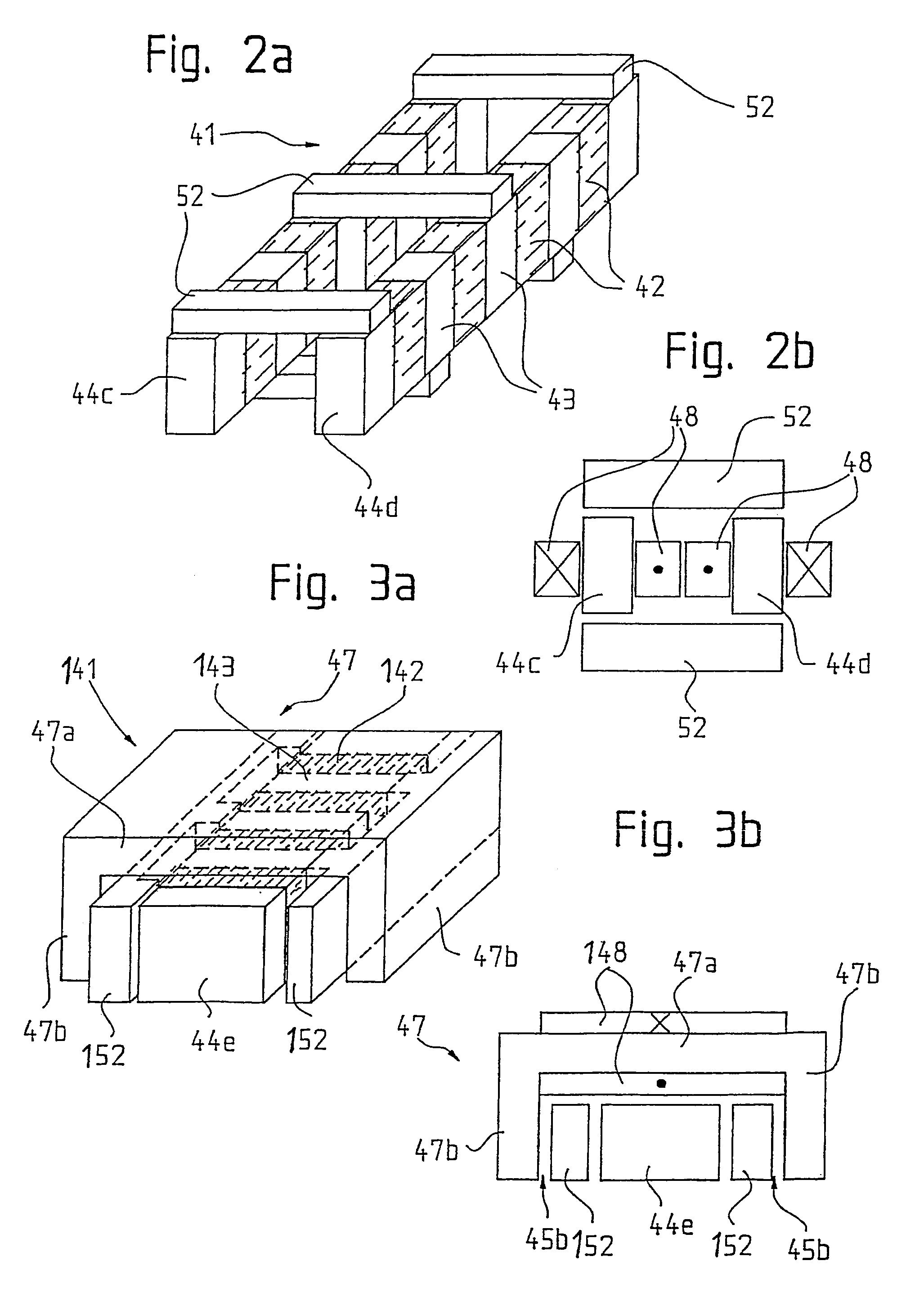

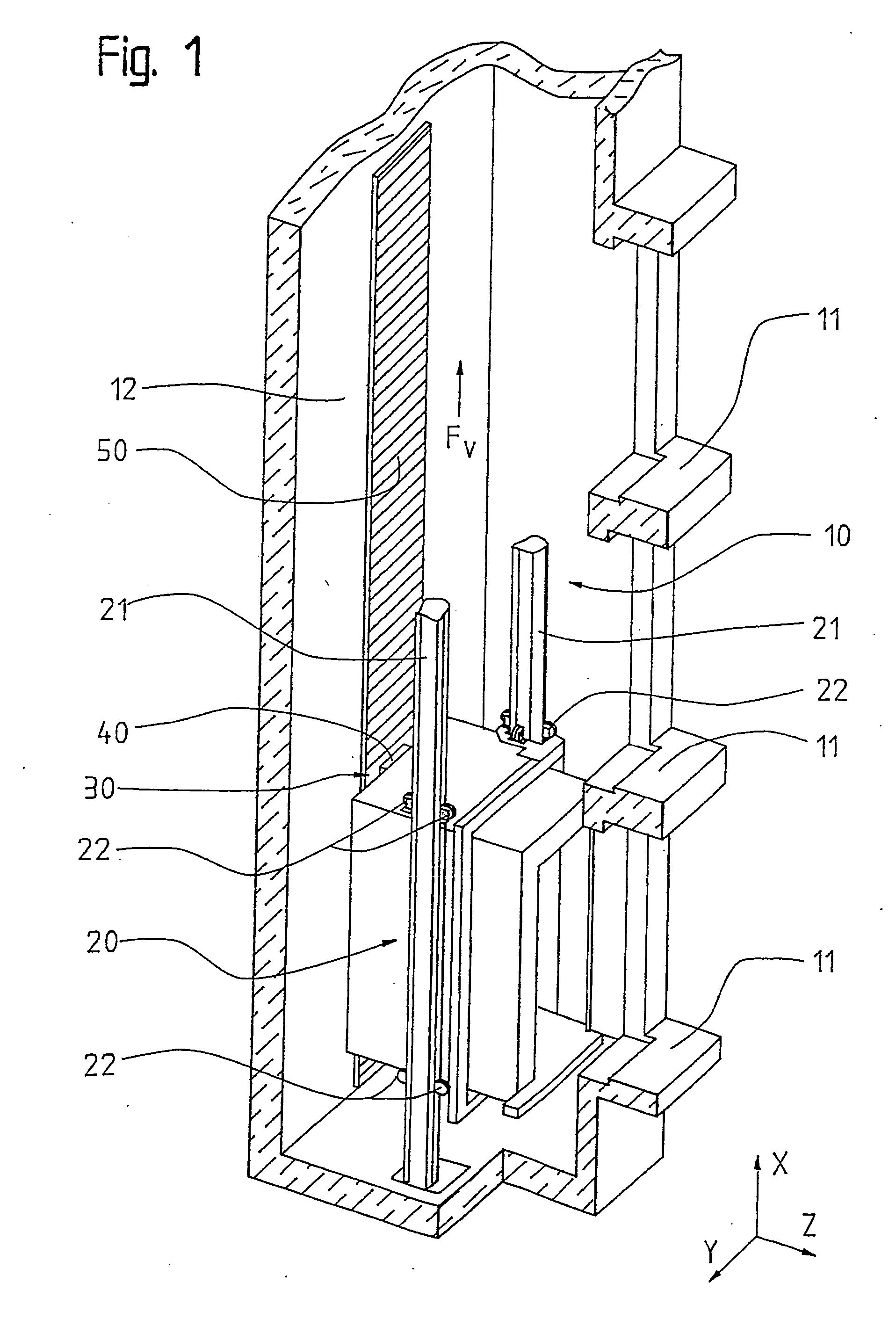

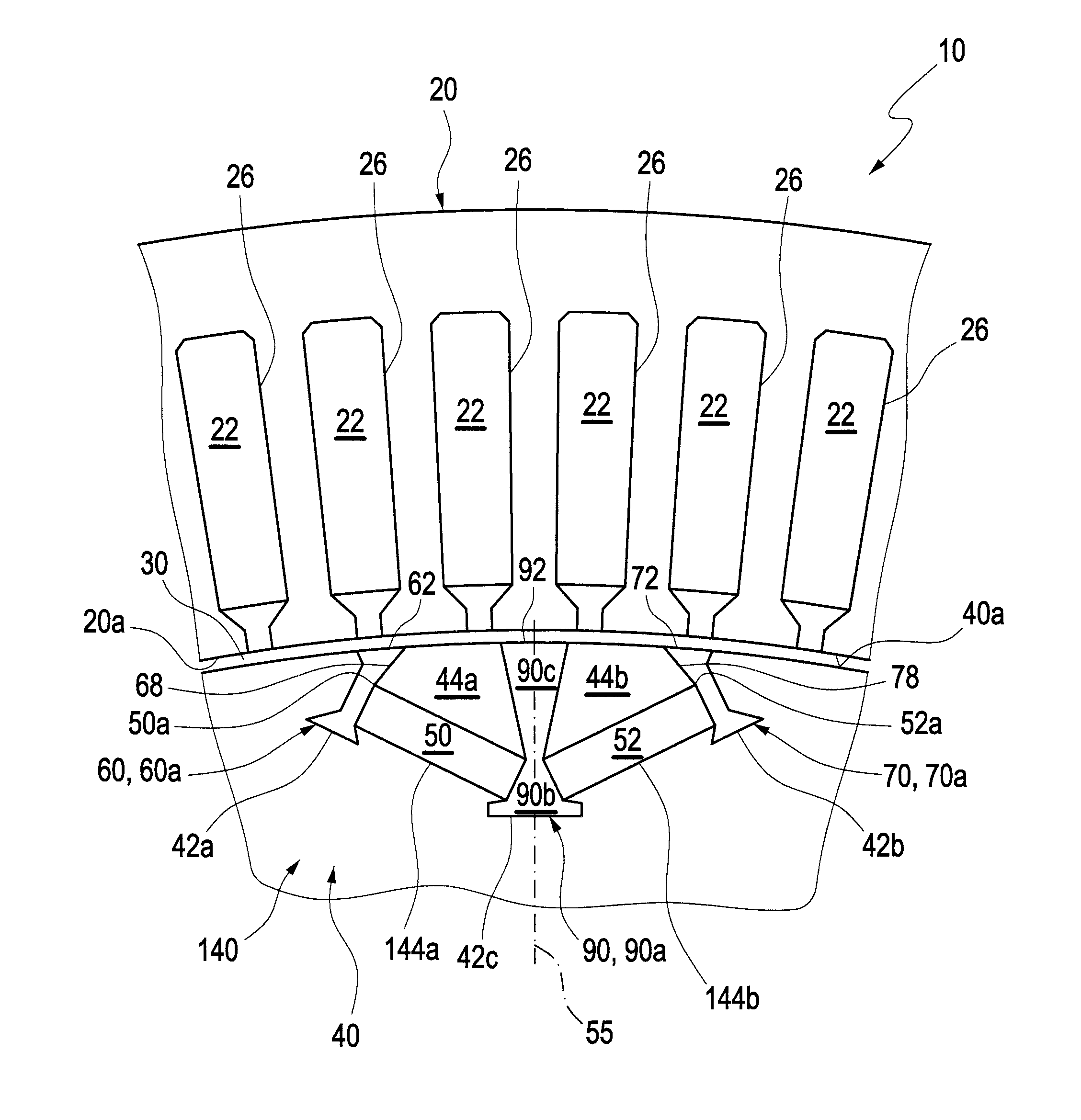

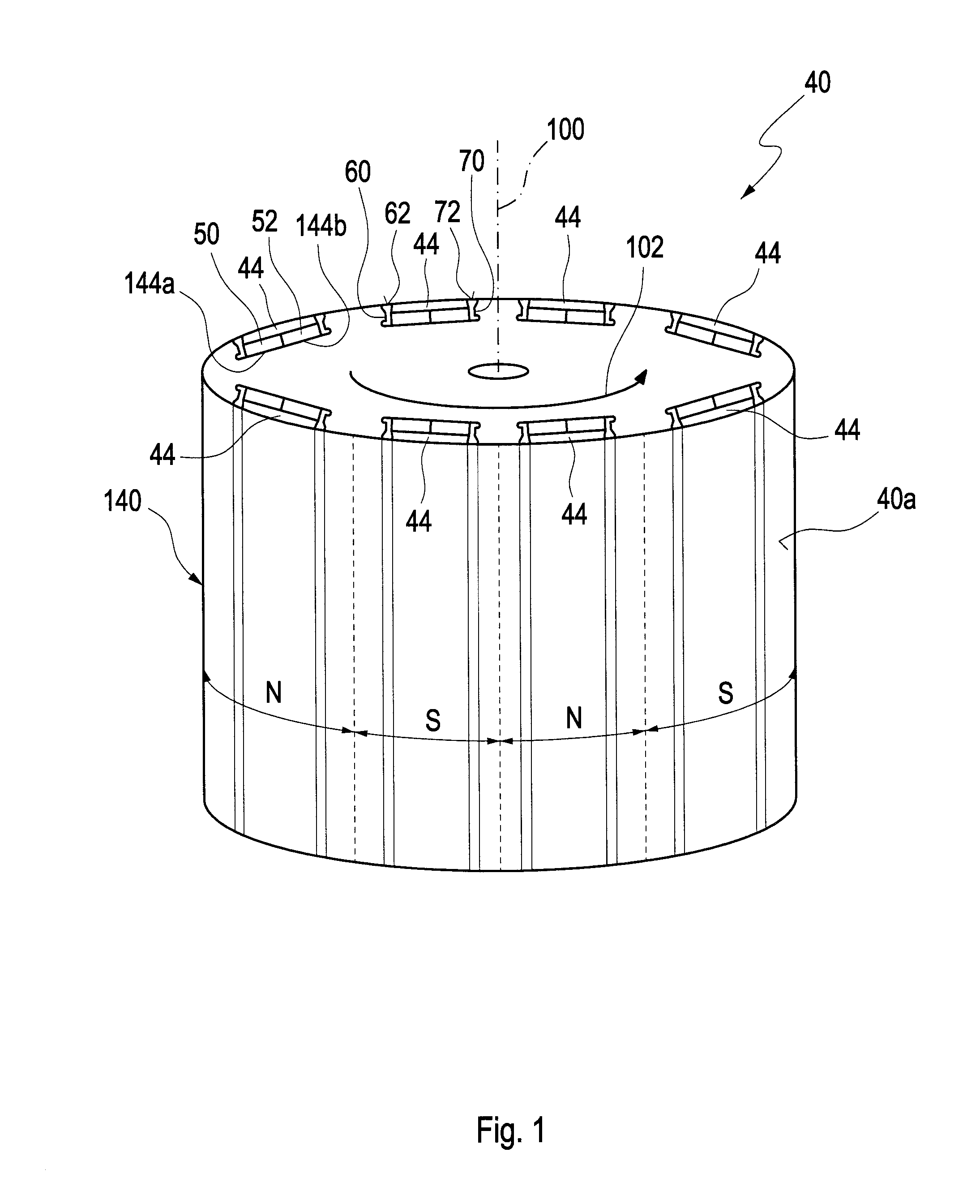

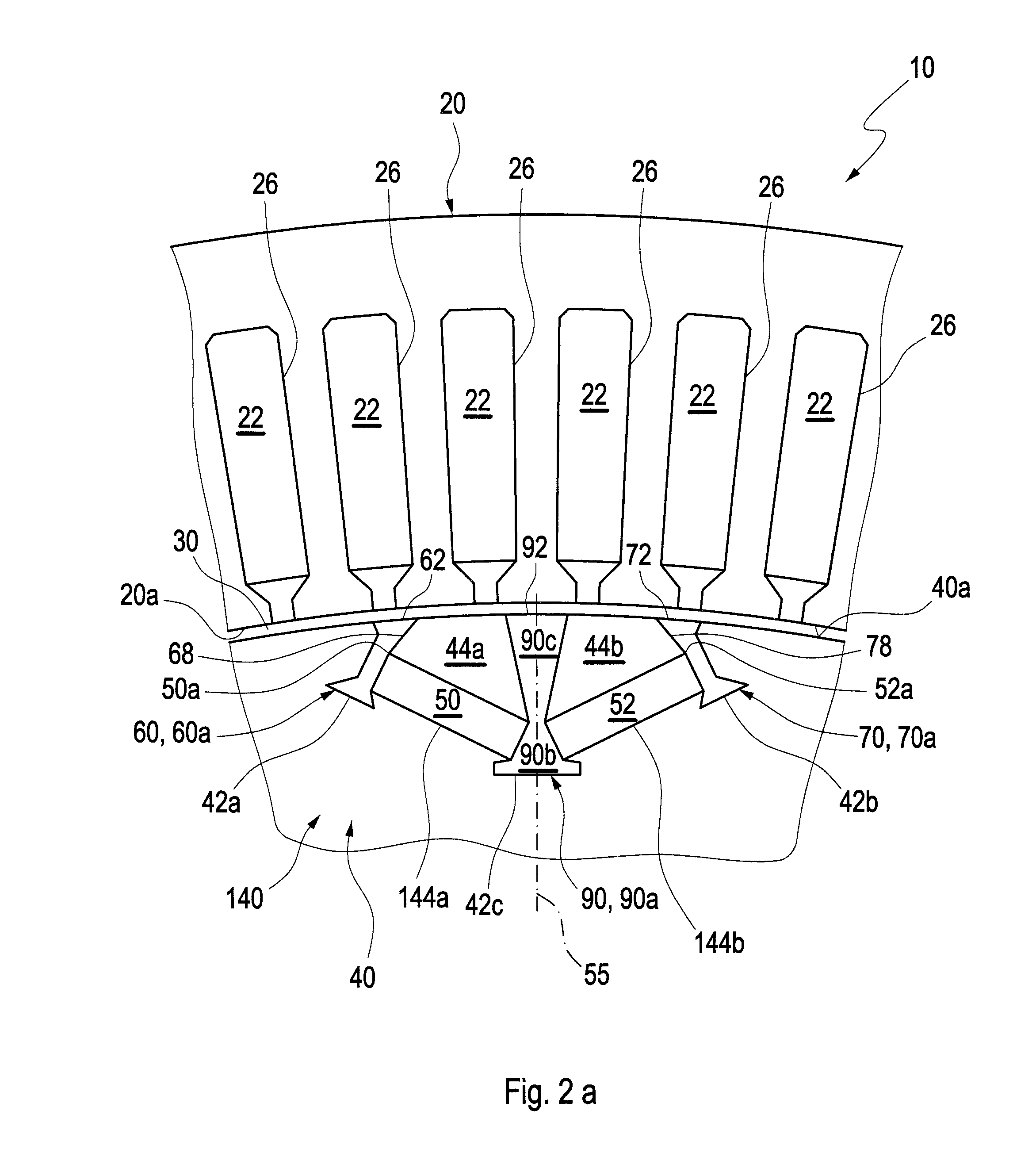

Elevator with transverse flux drive

InactiveUS7261186B2Improve power performanceLow production costMotor/generator/converter stoppersDC motor speed/torque controlTransverse fluxDrive motor

An elevator, particularly for transporting passengers, has an elevator car guided in an elevator shaft a direct drive motor. The drive motor includes an active primary part at the elevator car and a passive secondary part that is fixed in the elevator shaft and is spaced from the primary part by an air gap. In order to achieve a high power capability, the drive motor is configured as a transverse flux motor that moves the primary part linearly relative to the secondary part under the influence of an electromagnetic propulsive force. The secondary part has at least one rail made of a soft magnetic material and subdivided into a plurality of segments having a predetermined length. The segments are fixed to a wall of the elevator shaft by intermediate elements.

Owner:INVENTIO AG

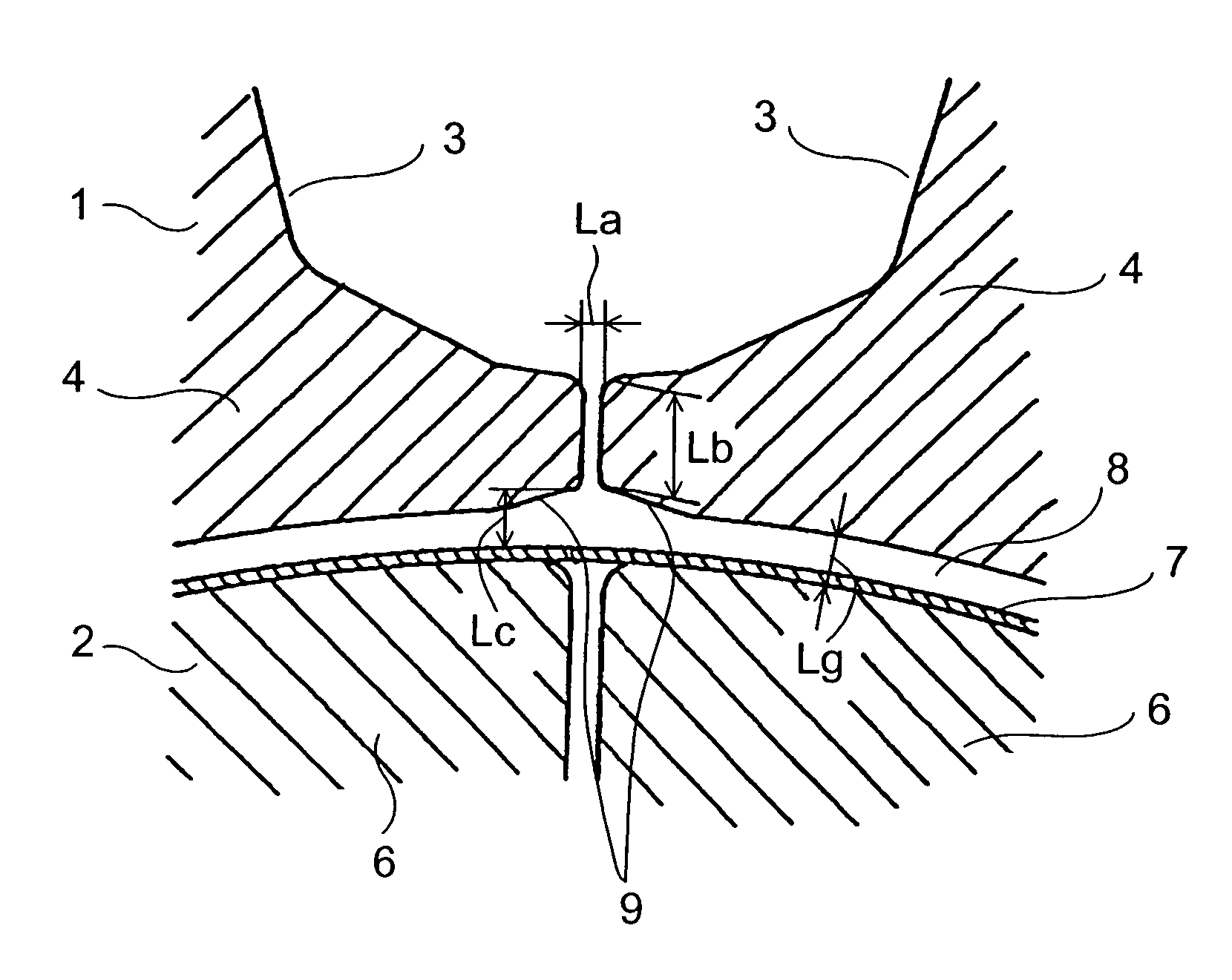

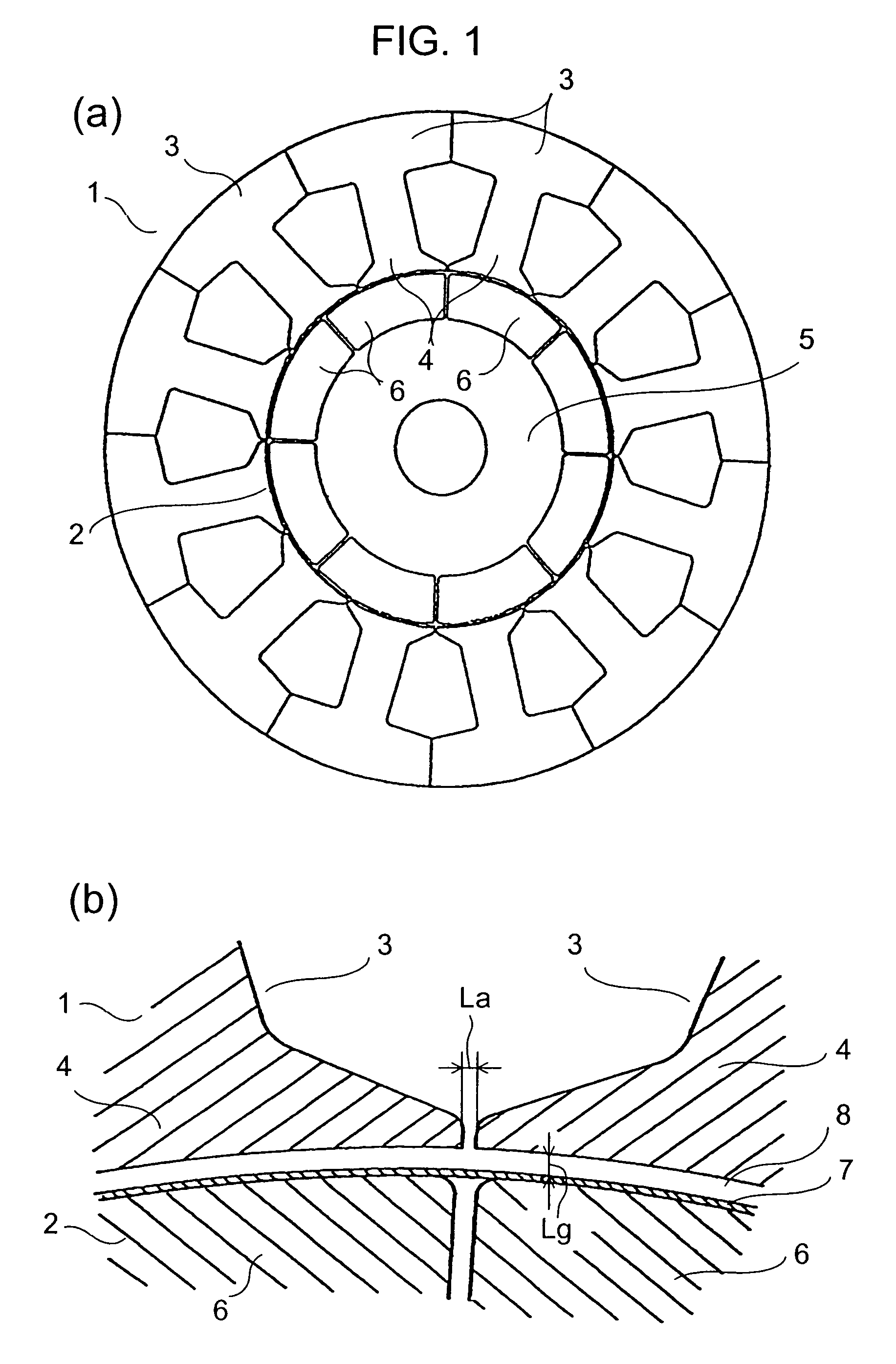

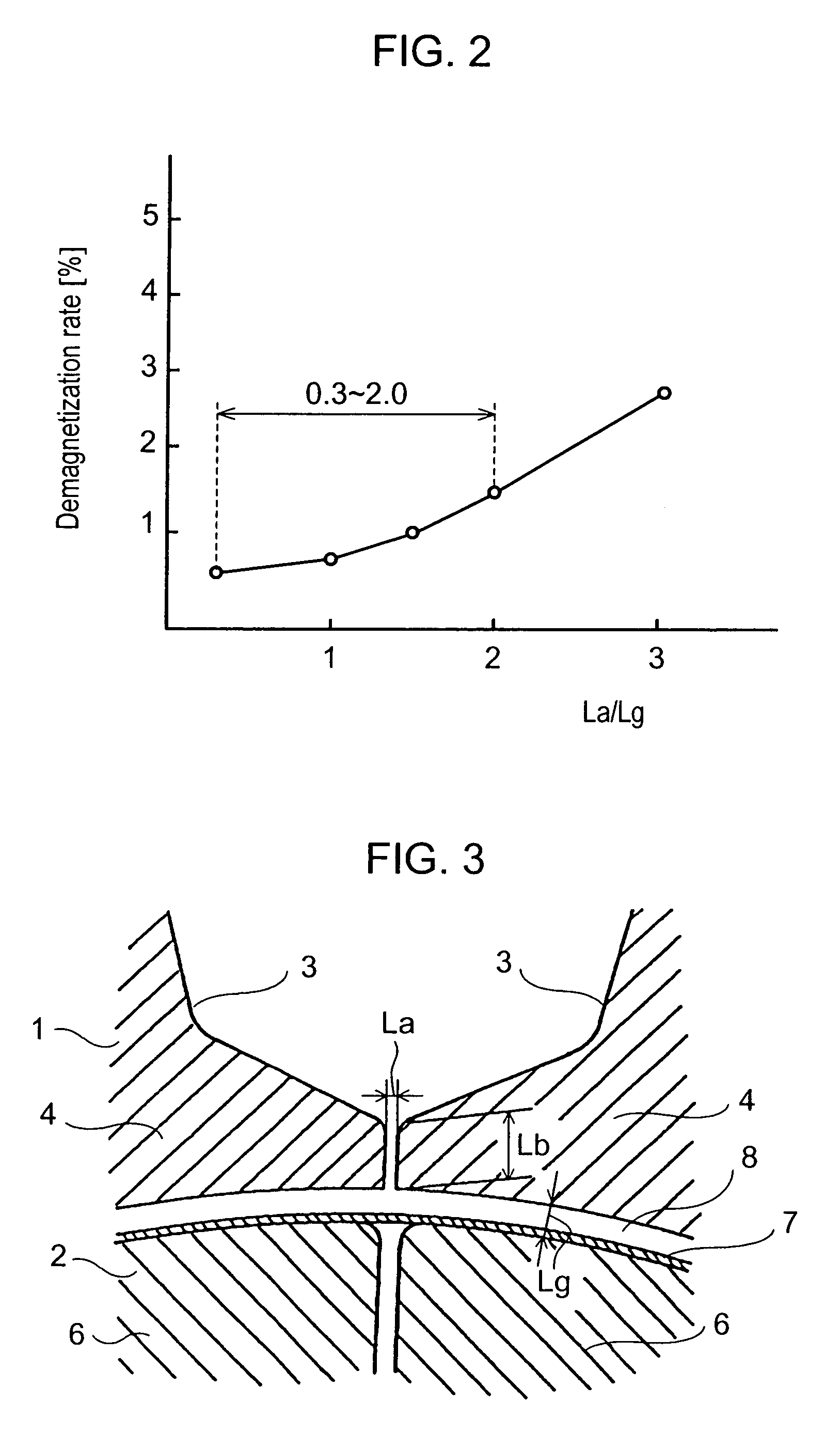

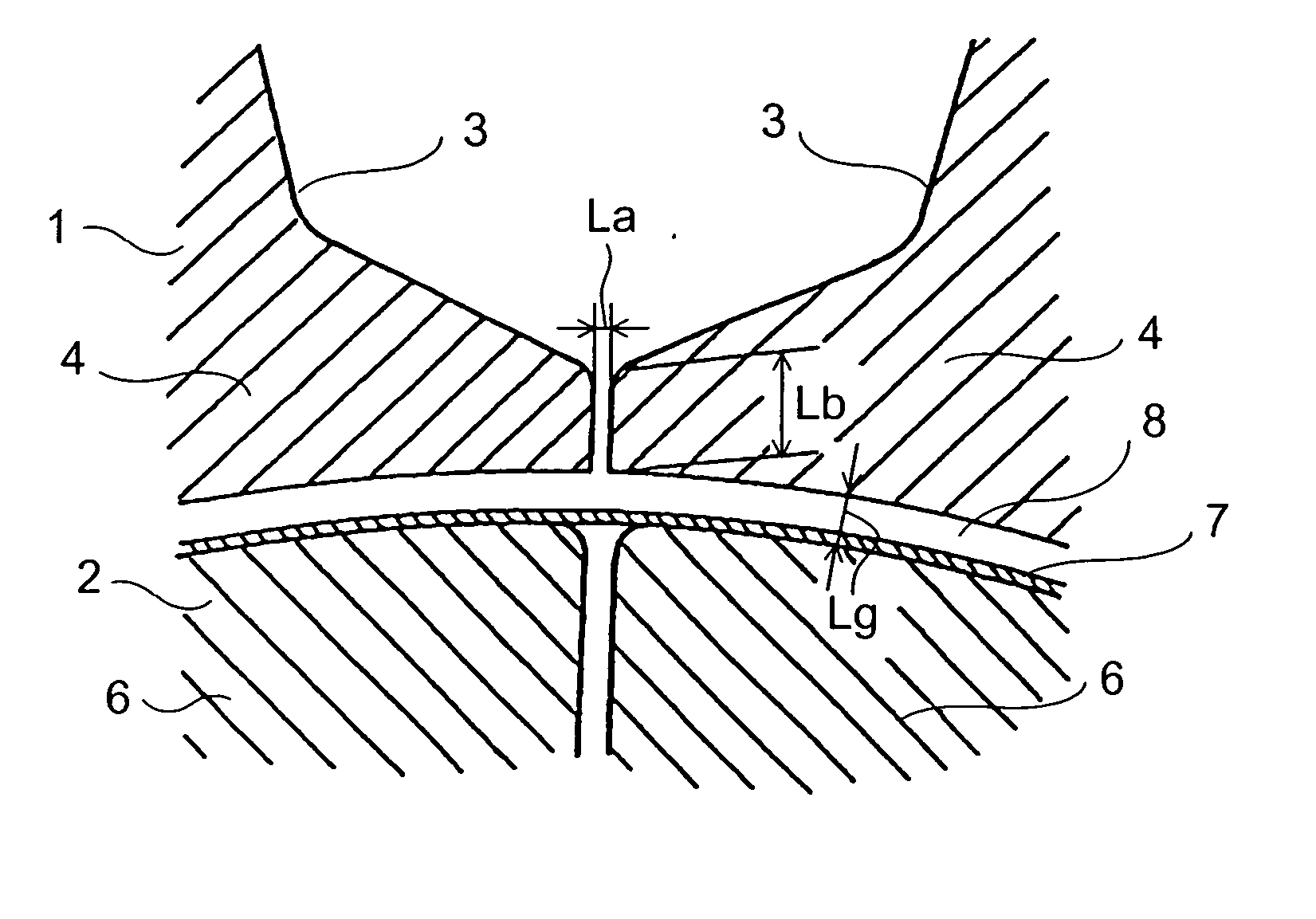

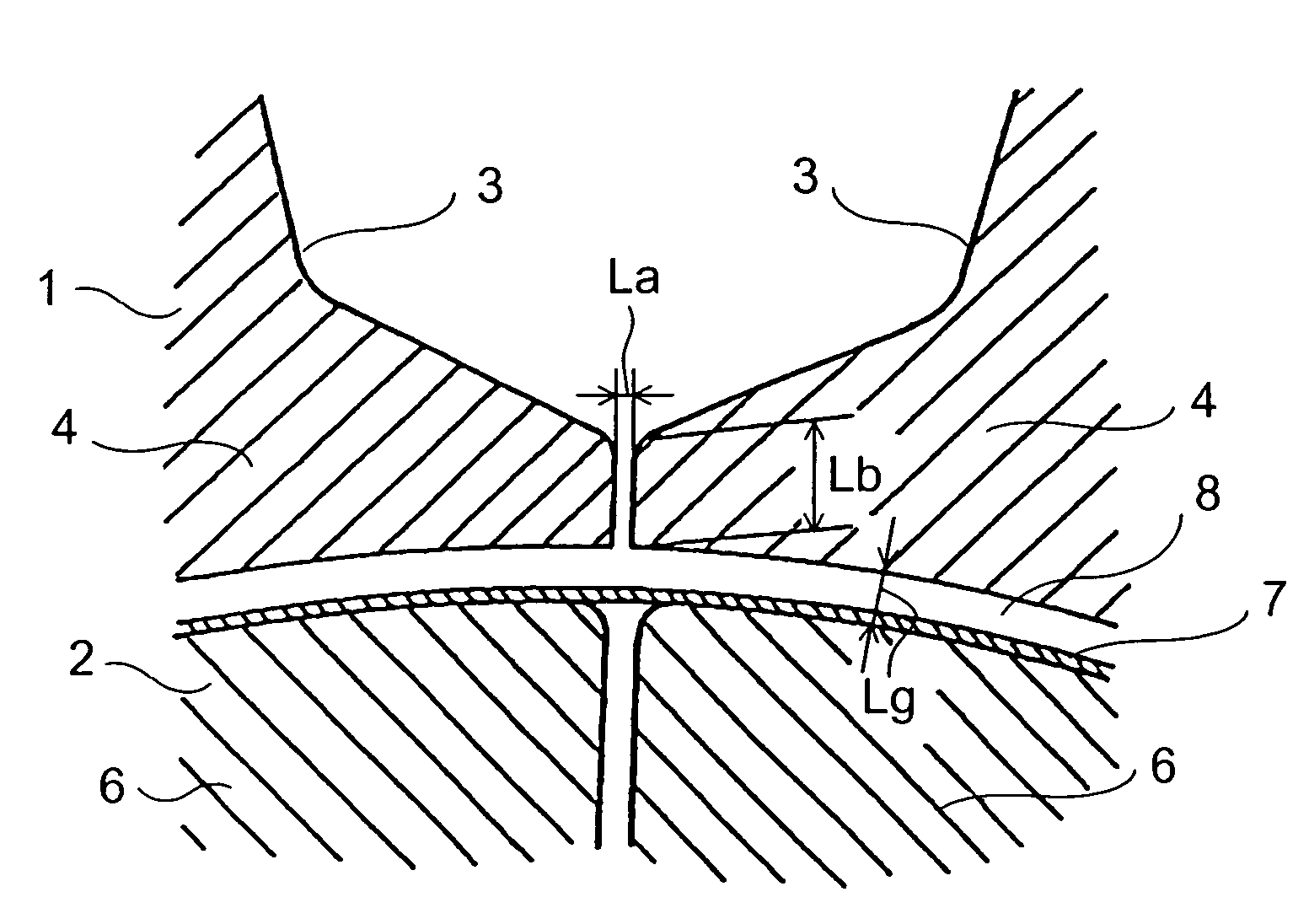

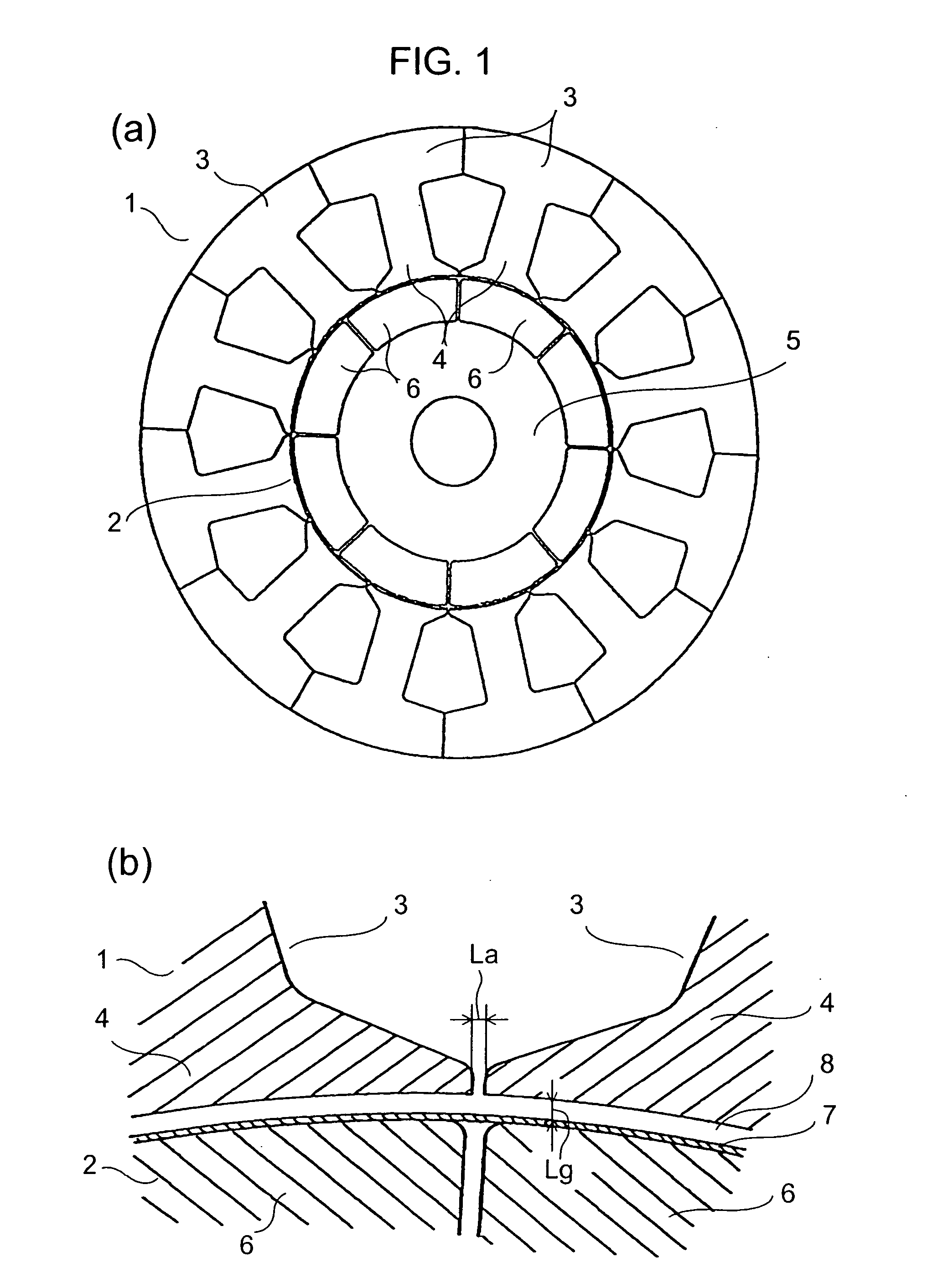

Permanent magnet synchronous motor

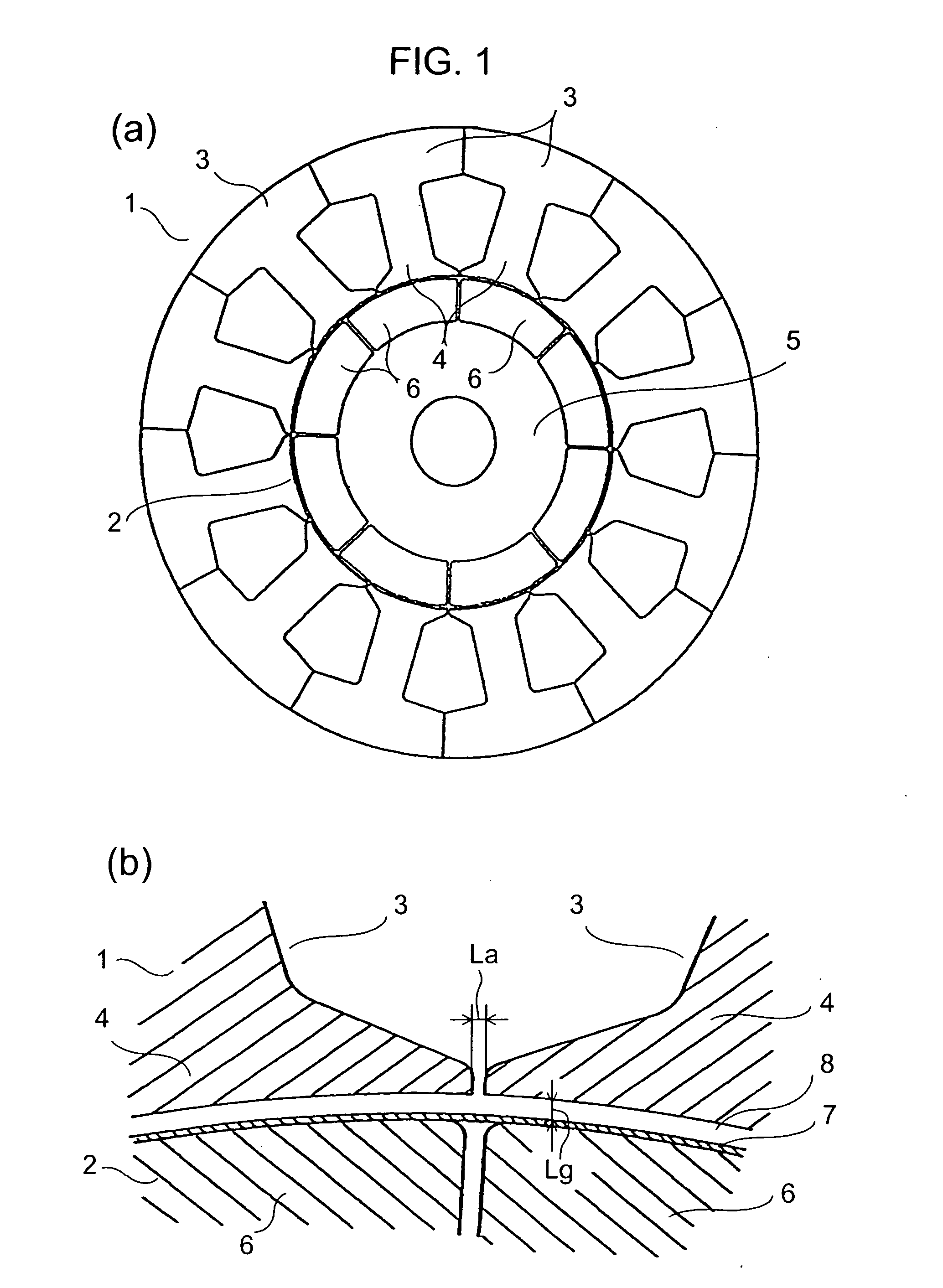

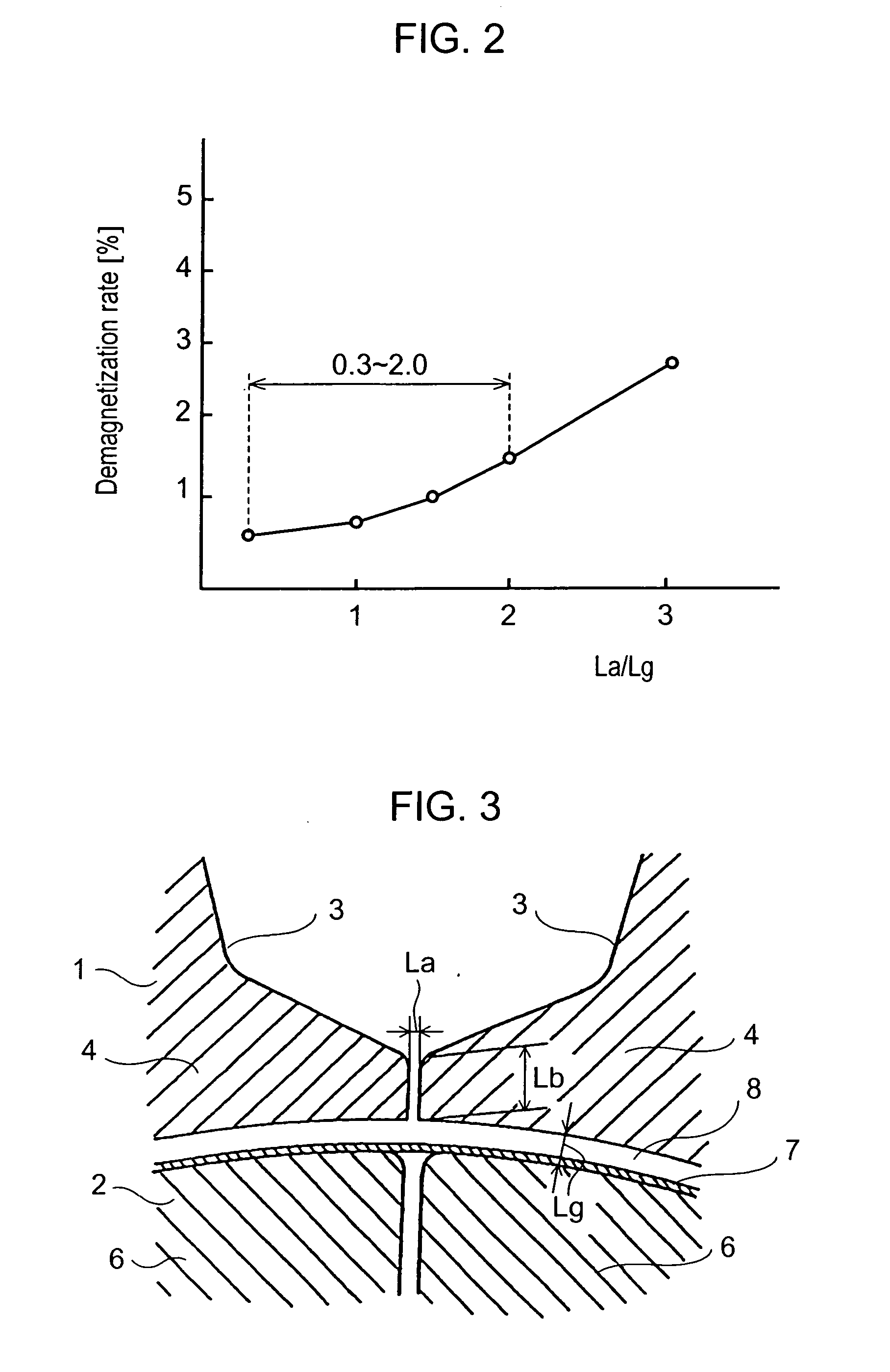

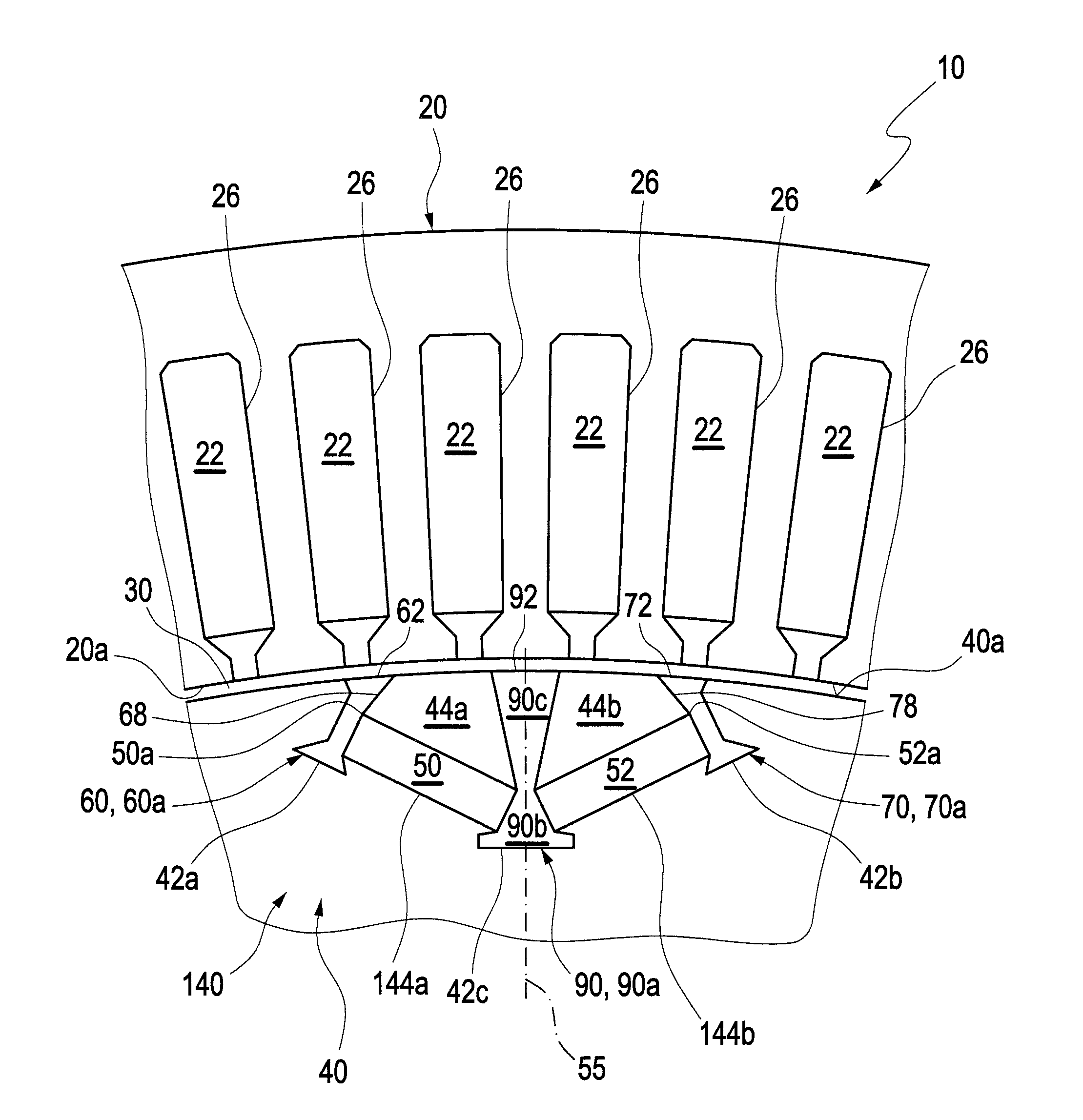

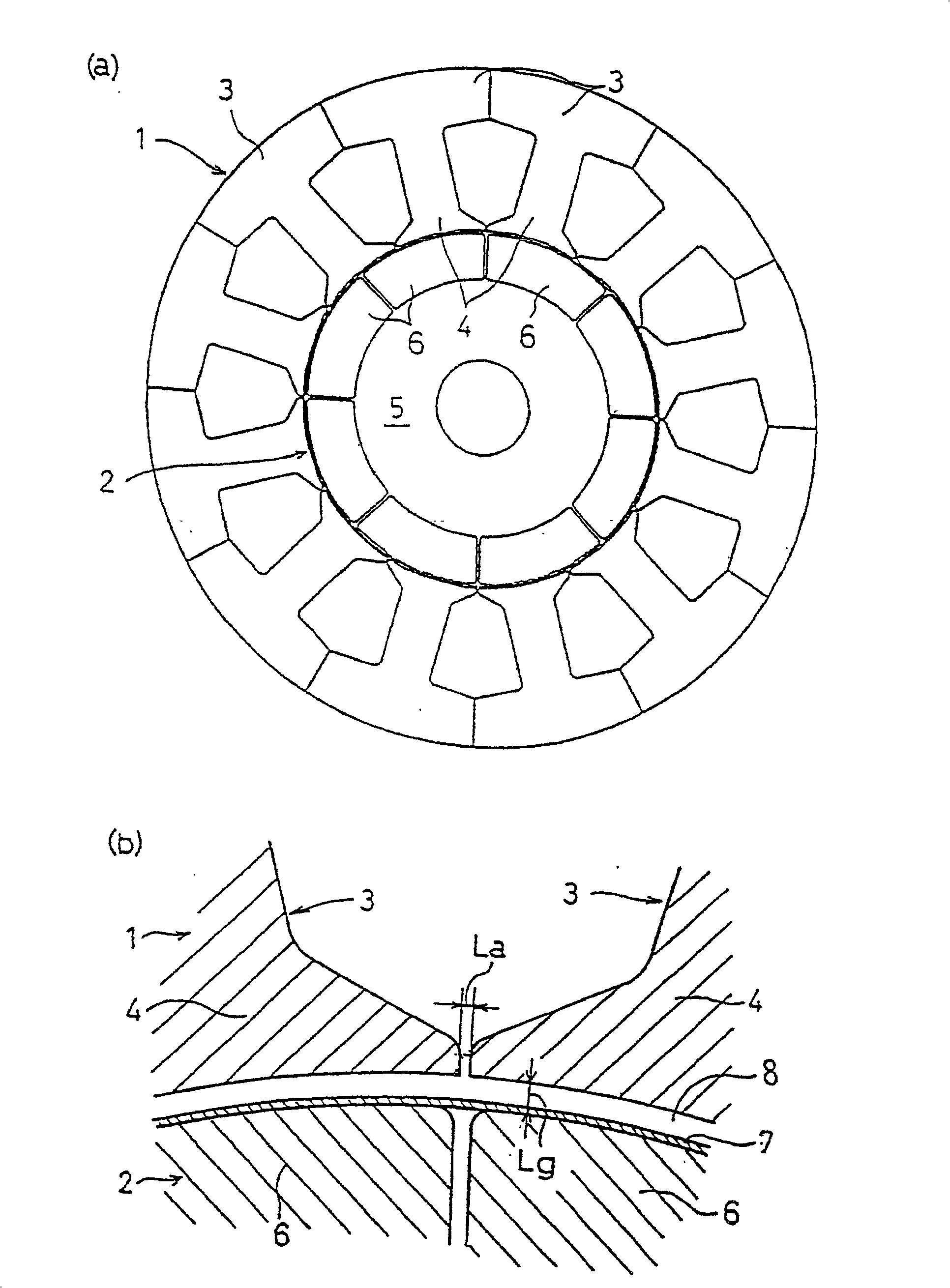

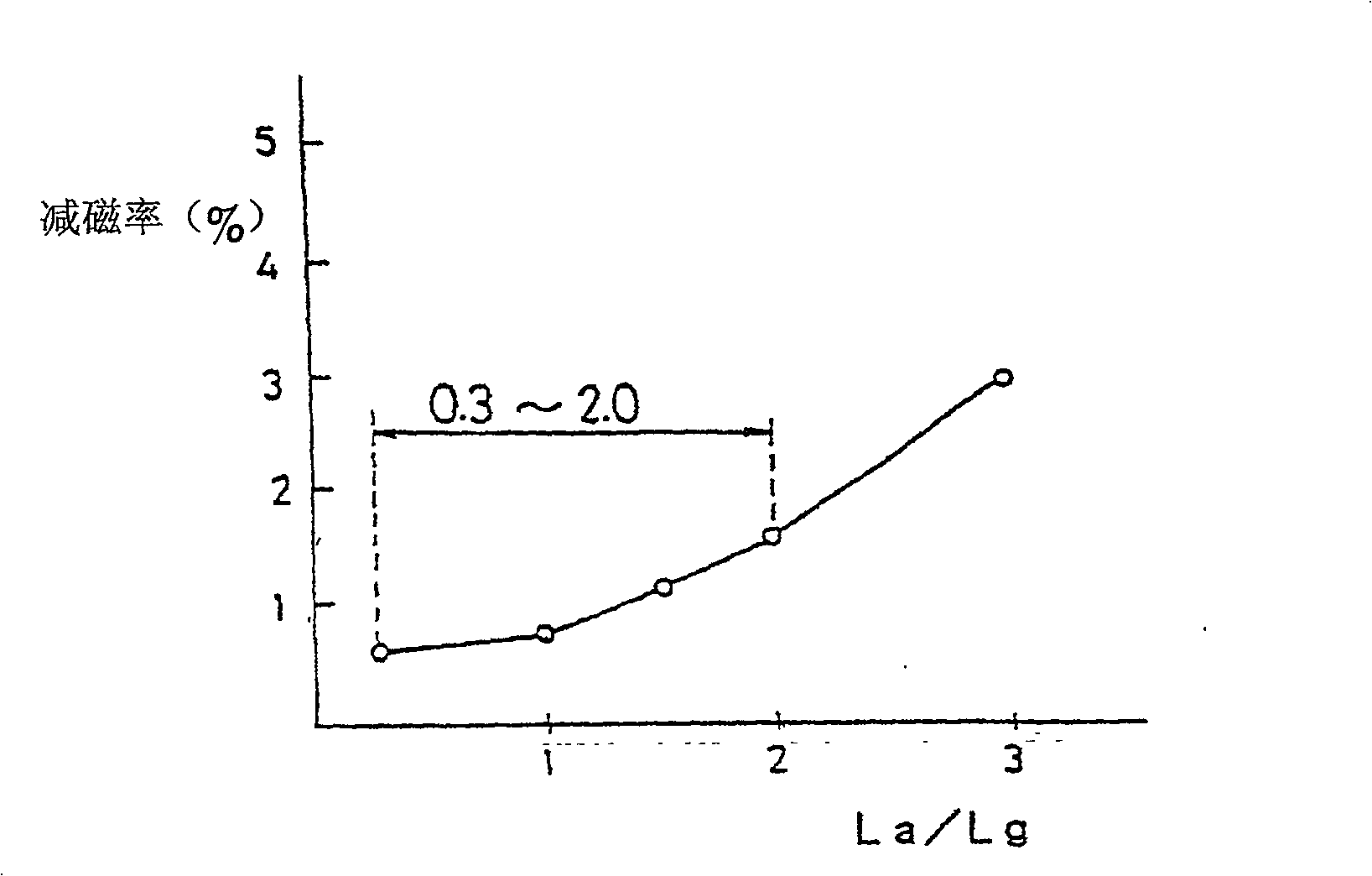

InactiveUS6940205B1Reduce outputGreater withstanding force against demagnetizationMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet synchronous motorConductor Coil

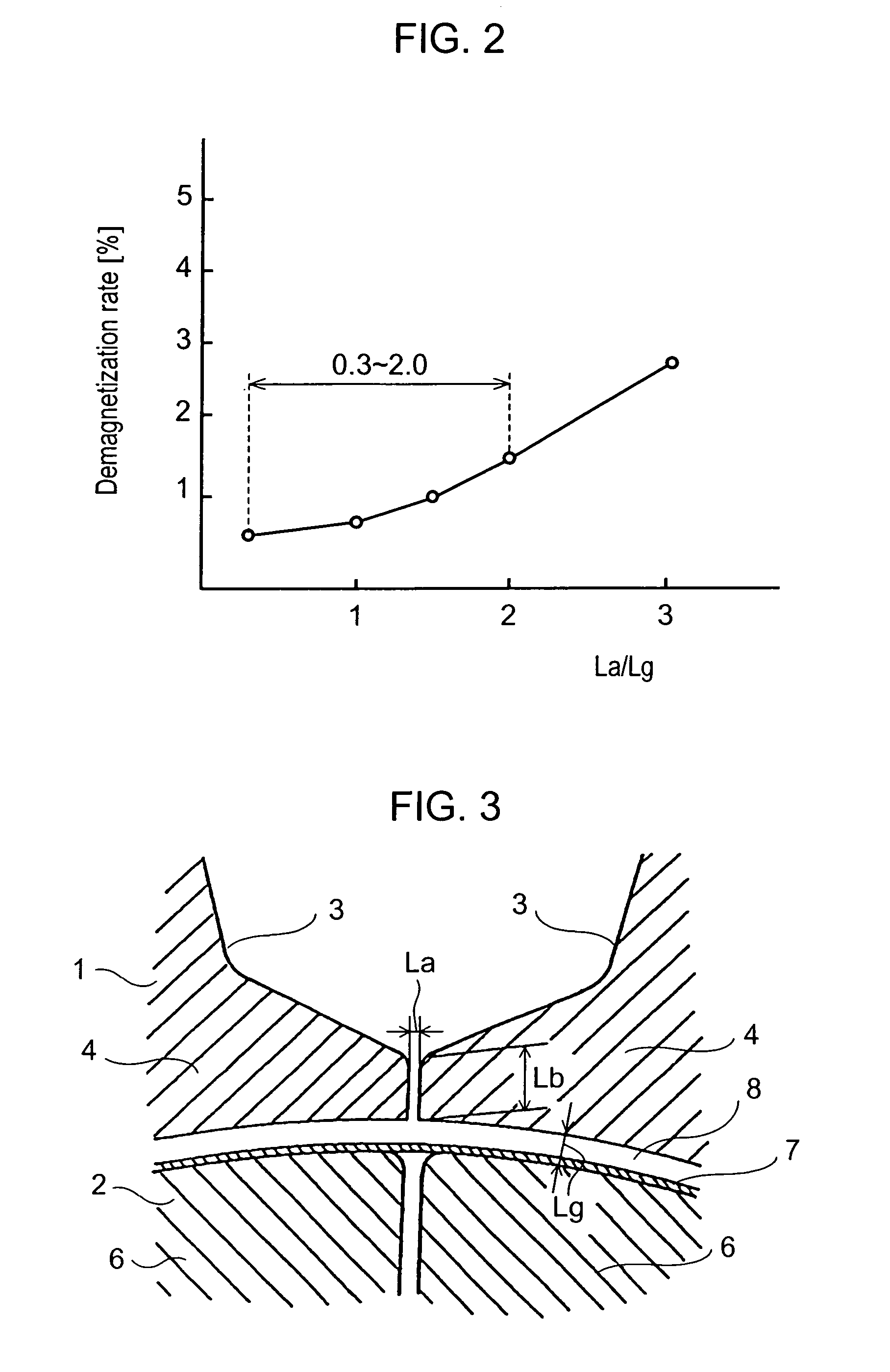

The present invention provides a permanent-magnet-synchronous-motor having a stator with concentrating windings with the following structure so that permanent magnet (6) is hard to subjected to demagnetization magnetic field: 0.3 Lg<La≦2.0 Lg, where La is a clearance between teeth of stator (1), and Lg is an air-gap between stator (1) and rotor (2), and yet outer walls of both ends of the permanent magnet (6) disposed within rotor (2) in a rim direction are tapered toward inside from a rotor rim in a radial direction and thus form recessed section on the outer walls of the magnets. As a result, withstanding force against demagnetization is expected to increase.

Owner:PANASONIC CORP

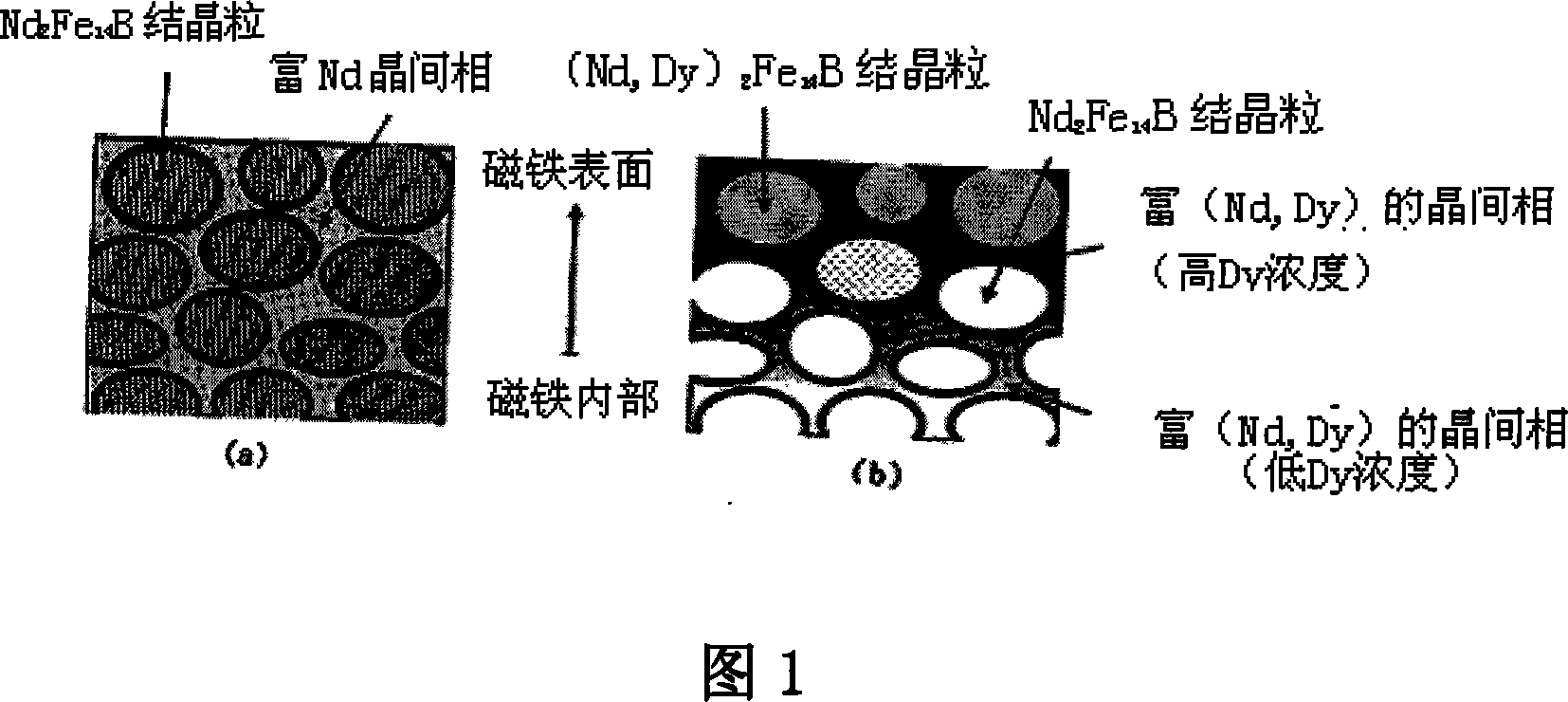

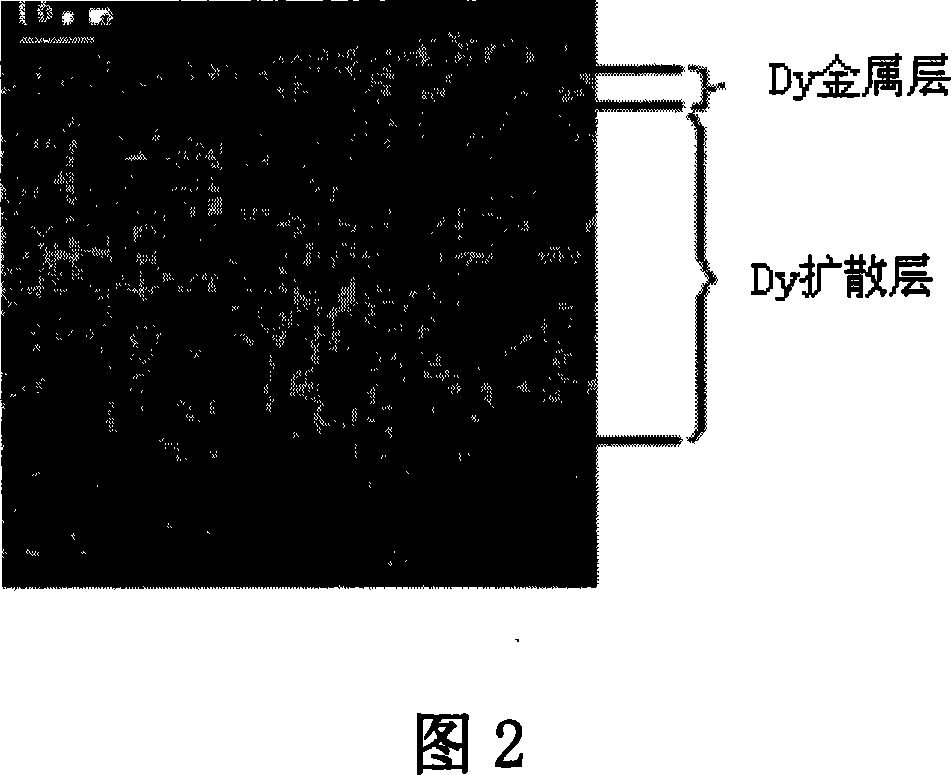

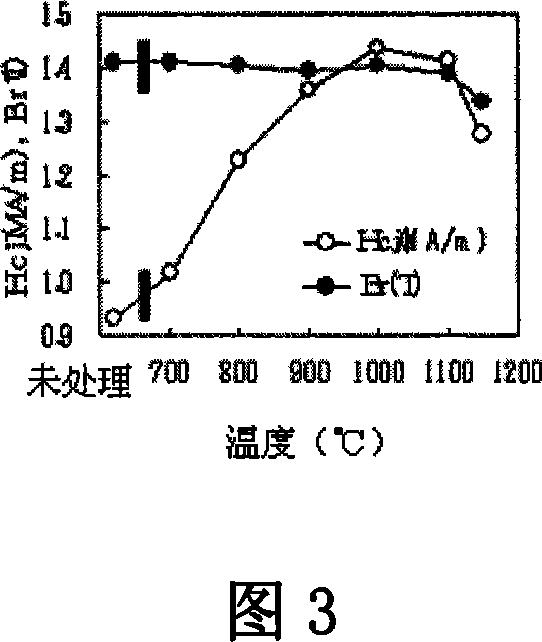

Nd-fe-b magnet with modified grain boundary and process for producing the same

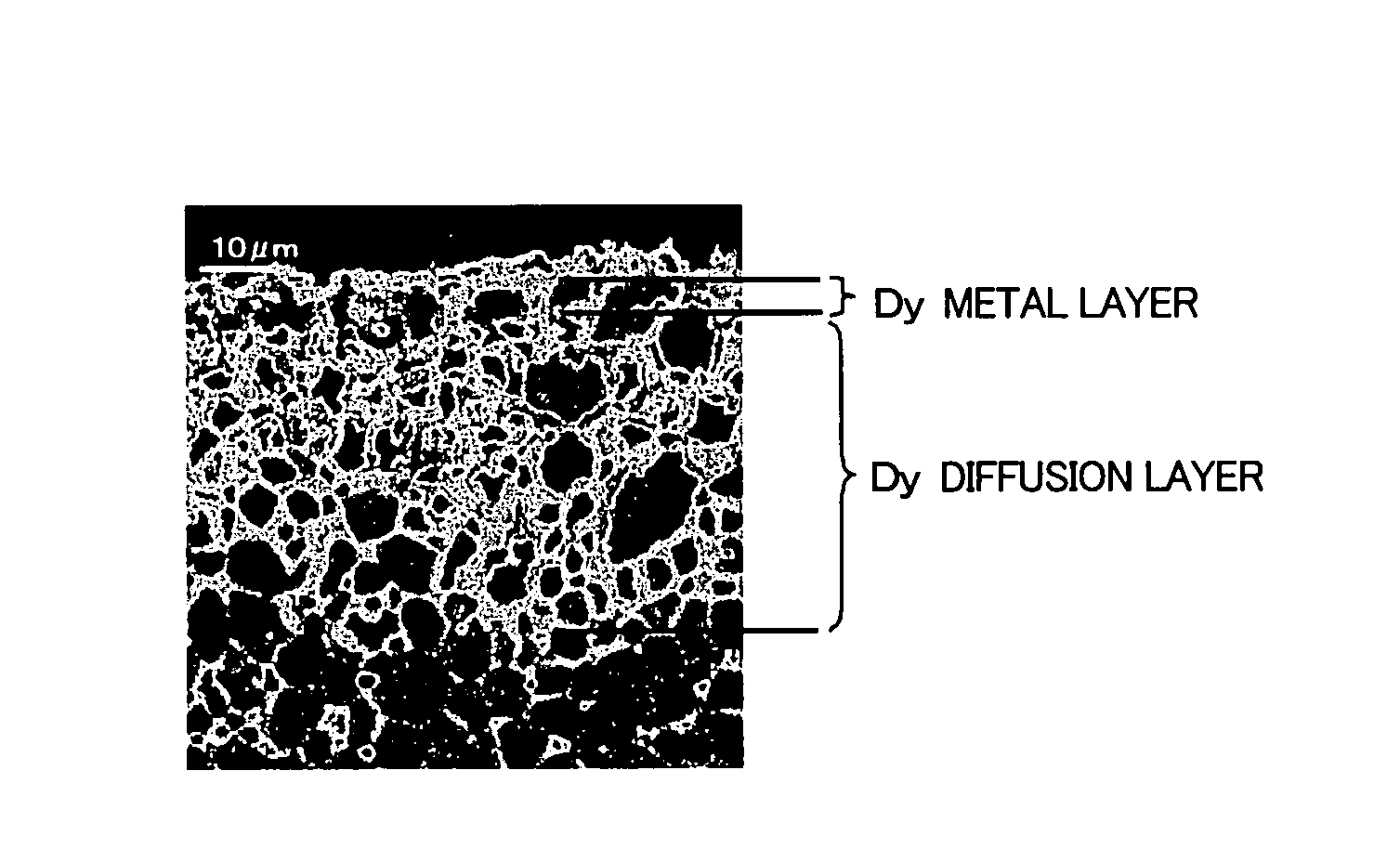

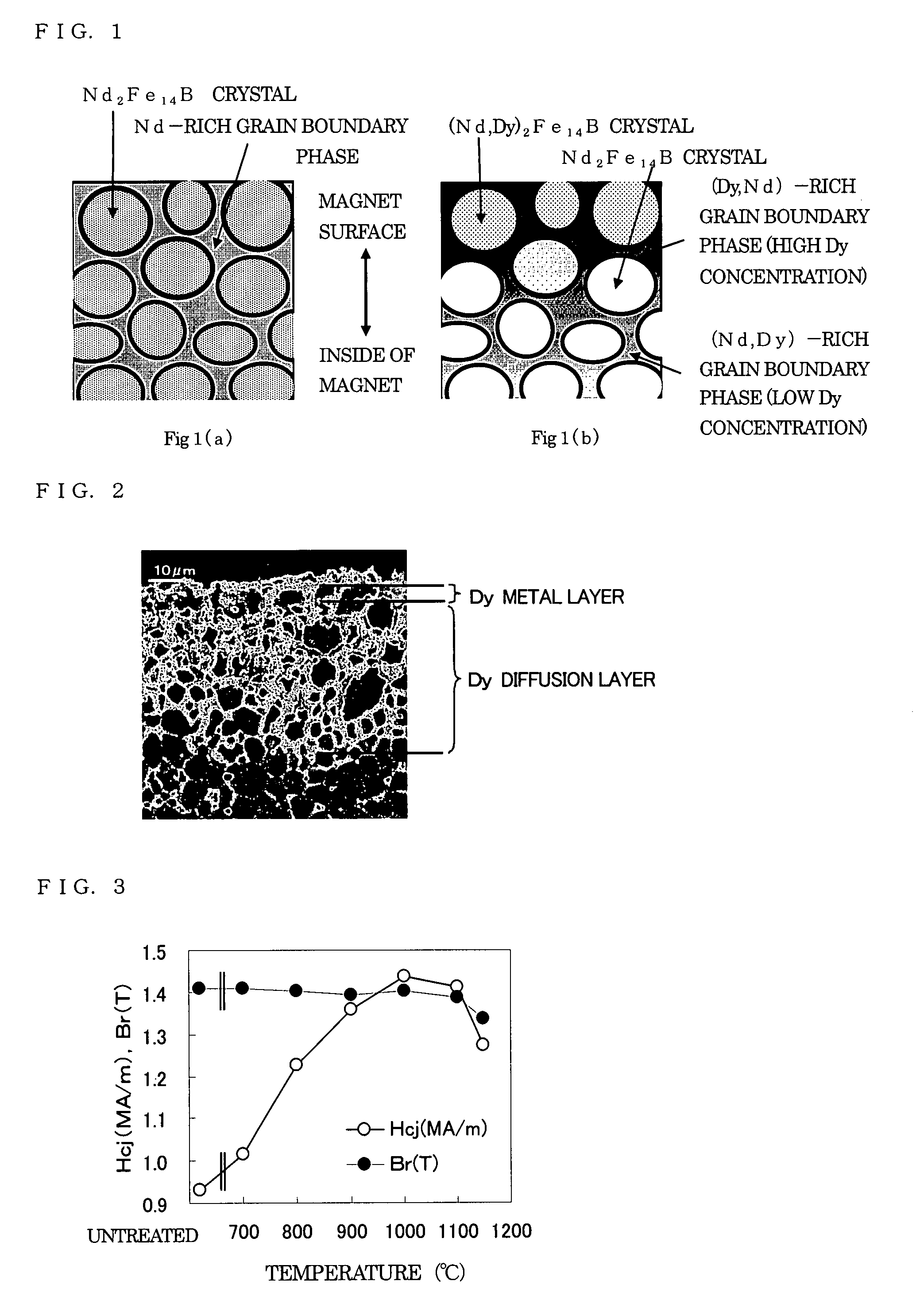

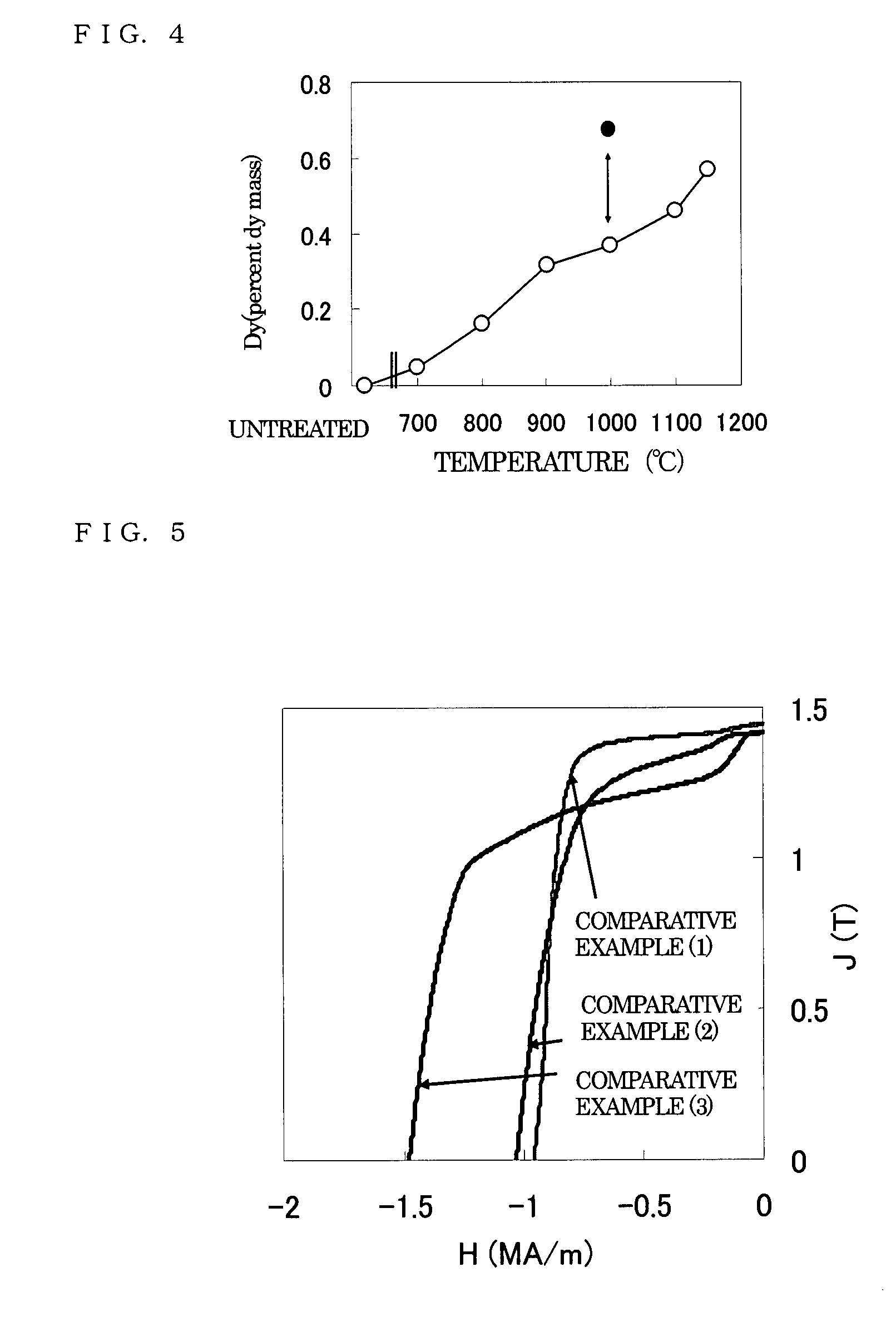

InactiveCN101076870AIncrease the coercive forceEasy to demagnetizeInorganic material magnetismInductances/transformers/magnets manufactureReduction treatmentSintered magnets

In the conventional process, a coercitivity increase is realized by effecting selective presence of, for example, Dy metal in crystal grain boundary zones of sintered magnet. However, as this process employs a physical film forming technique using a vacuum vessel, such as sputtering, there has been a difficulty in mass productivity in the performing of vast quantities of magnet treatment. Further, from the viewpoint, for example, that an expensive high-purity Dy metal or the like must be employed as a film forming material, there has been a drawback in magnet cost. There is provided a method of modifying the grain boundary of Nd-Fe-B magnet, characterized in that a fluoride, oxide or chloride of metal element M (M: Pr, DY, Tb or Ho) is subjected to reduction treatment so that there is effected diffusion infiltration of the metal element M from the surface of Nd-Fe-B sintered magnet having an Nd rich crystal grain boundary phase surrounding the circumferential part of Nd2Fe14B main crystal into the grain boundary phase.

Owner:JAPAN SCI & TECH CORP +1

Permanent magnet synchronous motor

InactiveUS20050225194A1Reduce outputGreater withstanding force against demagnetizationMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet synchronous motorConductor Coil

The present invention provides a permanent-magnet-synchronous-motor having a stator with concentrated windings with the following structure so that permanent magnet (6) is hard to subjected to demagnetization magnetic field: 0.3 Lg<La≦2.0 Lg, where La is a clearance between teeth of stator (1), and Lg is an air-gap between stator (1) and rotor (2). Outer walls of both ends of the permanent magnet (6) disposed within rotor (2) in a rim direction may be tapered toward inside from a rotor rim in a radial direction and to form a recessed section on the outer walls of the magnets. As a result, withstanding force against demagnetization is expected to increase.

Owner:PANASONIC CORP

Rotor of an electric machine with embedded permanent magnets and electric machine

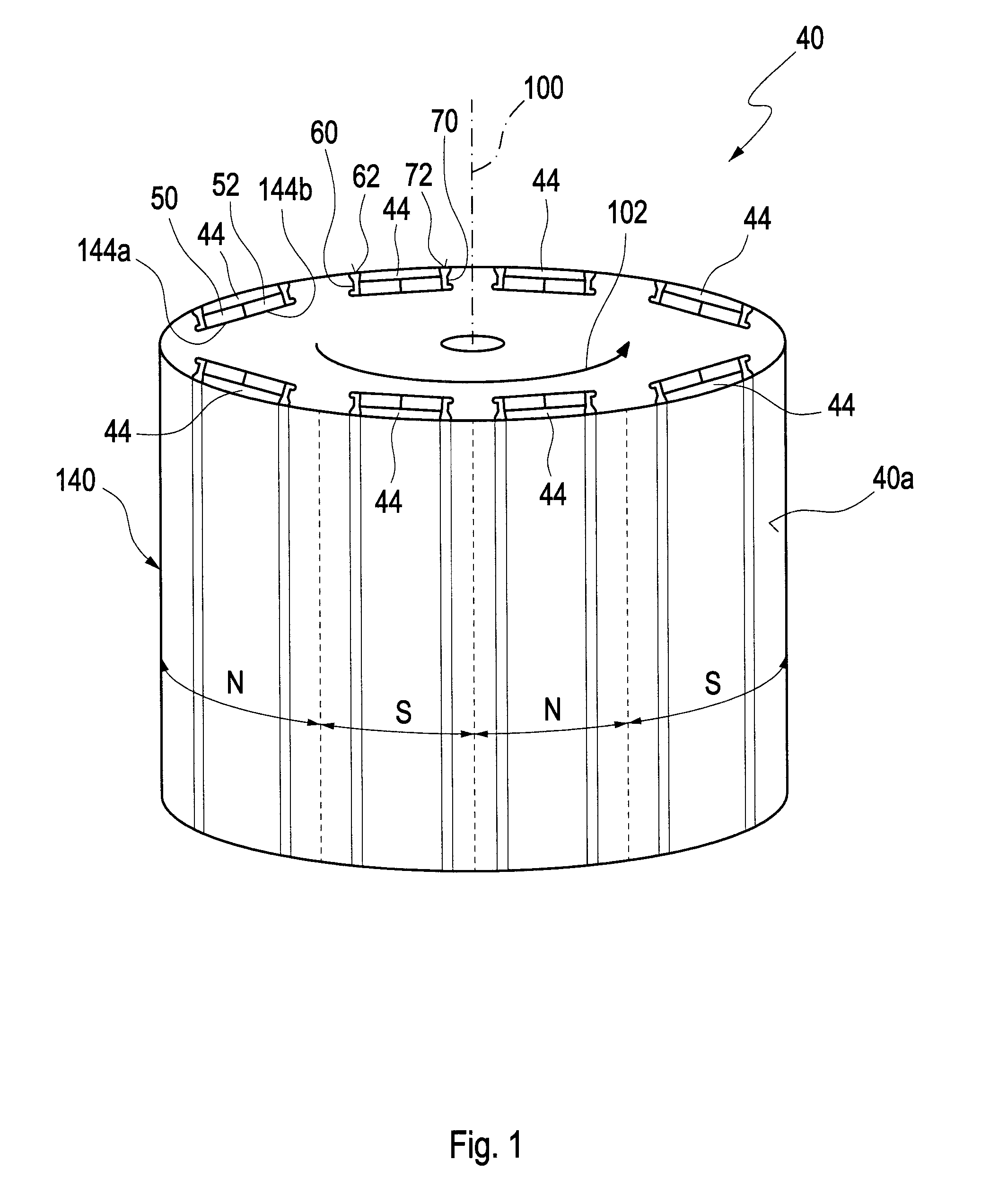

ActiveUS20130026872A1Easily arrange and shapeHigh torque densityMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPhysicsElectric machine

A rotor for an electric machine excited by magnetic poles formed by one or more embedded permanent magnets includes a magnetic body and the one or more embedded permanent magnets associated with the magnetic body defining first magnetic poles and second magnetic poles of alternating magnetic polarity along a rotor direction. For at least one of the one or more embedded permanent magnets a rotor segment is arranged between the one or more embedded permanent magnets and a first surface of the magnetic body. At least one retainer element connects the rotor segment to a portion of the magnetic body.

Owner:VOLVO LASTVAGNAR AB

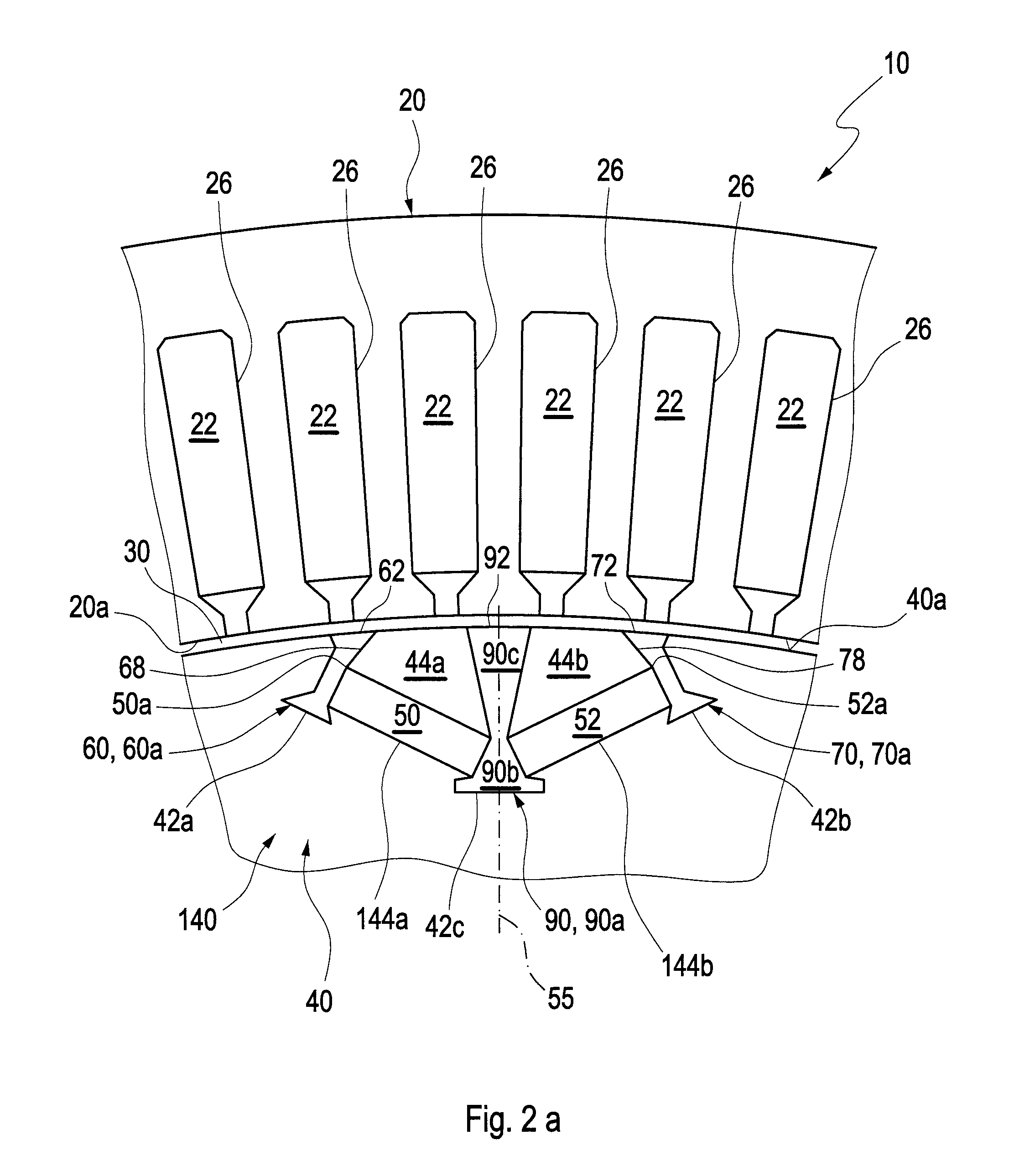

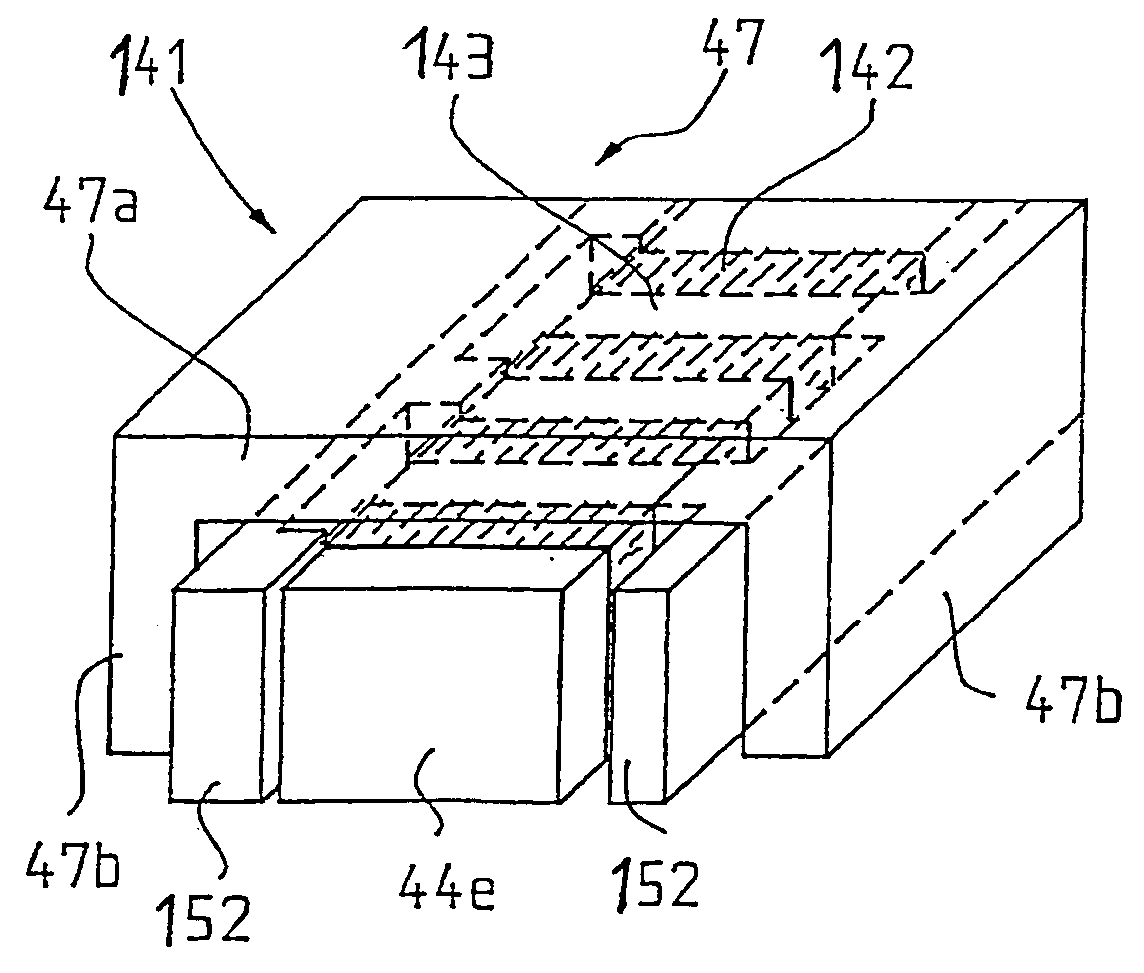

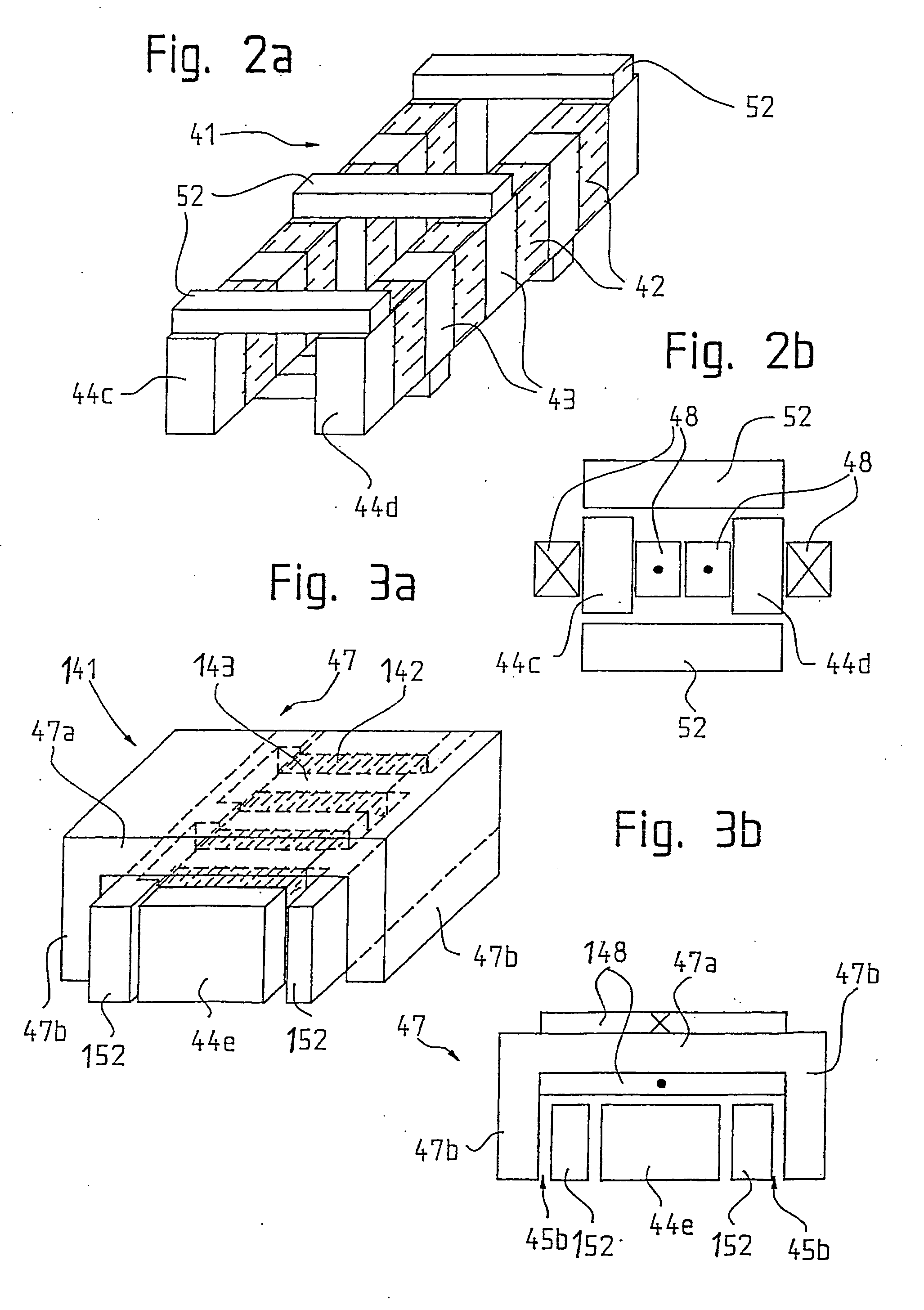

Elevator, particularly for transporting persons

InactiveUS20050077113A1Improve power performanceLow production costMotor/generator/converter stoppersDC motor speed/torque controlTransverse fluxDrive motor

An elevator, particularly for transporting passengers, has an elevator car guided in an elevator shaft a direct drive motor. The drive motor includes an active primary part at the elevator car and a passive secondary part that is fixed in the elevator shaft and is spaced from the primary part by an air gap. In order to achieve a high power capability, the drive motor is configured as a transverse flux motor that moves the primary part linearly relative to the secondary part under the influence of an electromagnetic propulsive force. The secondary part has at least one rail made of a soft magnetic material and subdivided into a plurality of segments having a predetermined length. The segments are fixed to a wall of the elevator shaft by intermediate elements.

Owner:INVENTIO AG

Nd-Fe-B magnet with modified grain boundary and process for producing the same

InactiveUS7824506B2Improve coercive forceEasy to demagnetizeInorganic material magnetismInductances/transformers/magnets manufactureReduction treatmentSintered magnets

In known methods, an improvement of the coercive force is realized by allowing the Dy metal or the like to present selectively in crystal grain boundary portions of a sintered magnet. However, since these are based on a physical film formation method, e.g., sputtering, through the use of a vacuum vessel, there is a mass productivity problem when a large number of magnets are treated. Furthermore, there is a magnet cost problem from the viewpoint that, for example, an expensive, high-purity Dy metal or the like must be used as a raw material for film formation. The method for modifying grain boundaries of a Nd—Fe—B base magnet includes the step of allowing an M metal component to diffuse and penetrate from a surface of a Nd—Fe—B base sintered magnet body having a Nd-rich crystal grain boundary phase surrounding principal Nd2Fe14B crystals to the grain boundary phase through a reduction treatment of a fluoride, an oxide, or a chloride of an M metal element (where M is Pr, Dy, Tb, or Ho).

Owner:JAPAN SCI & TECH CORP +1

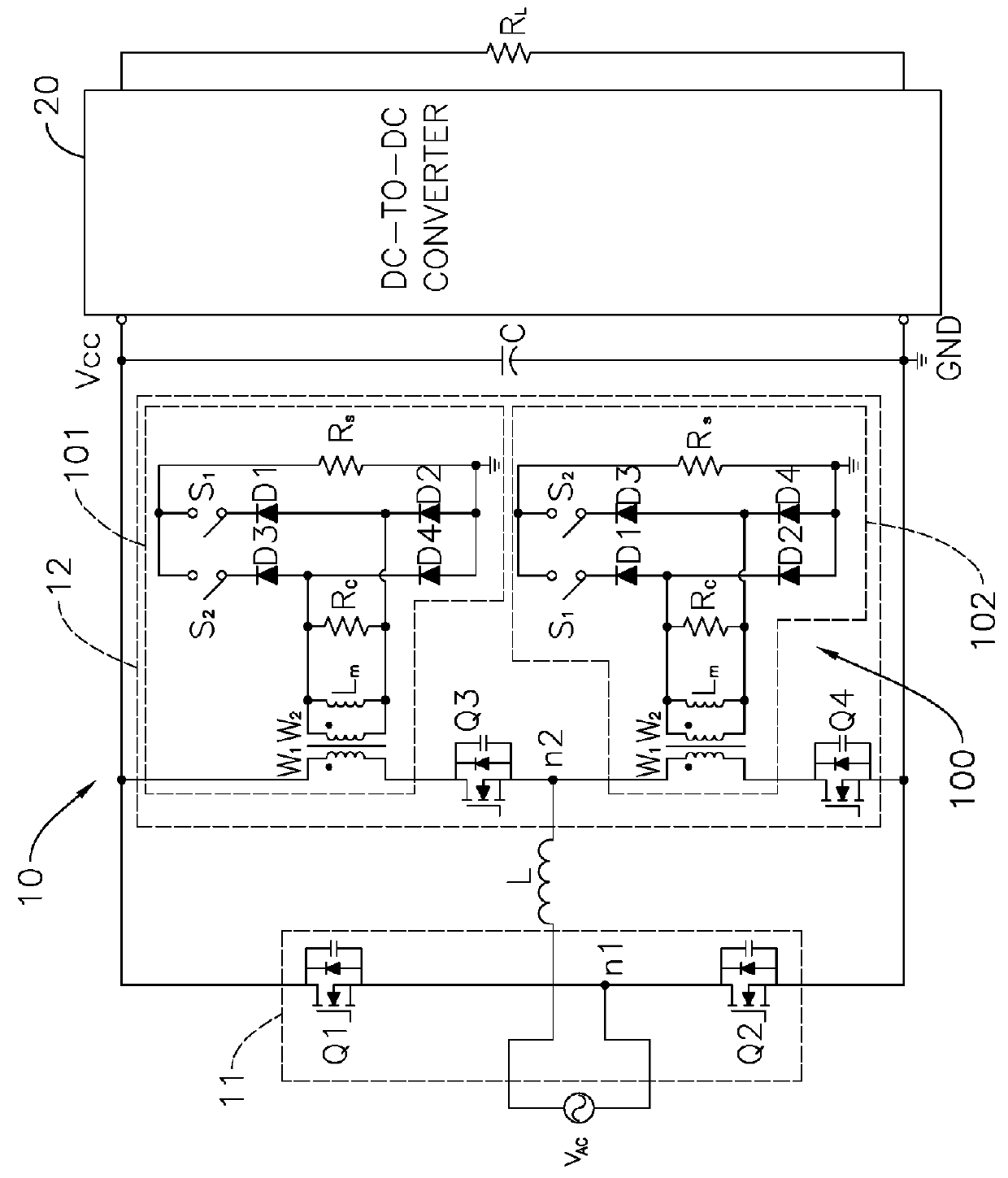

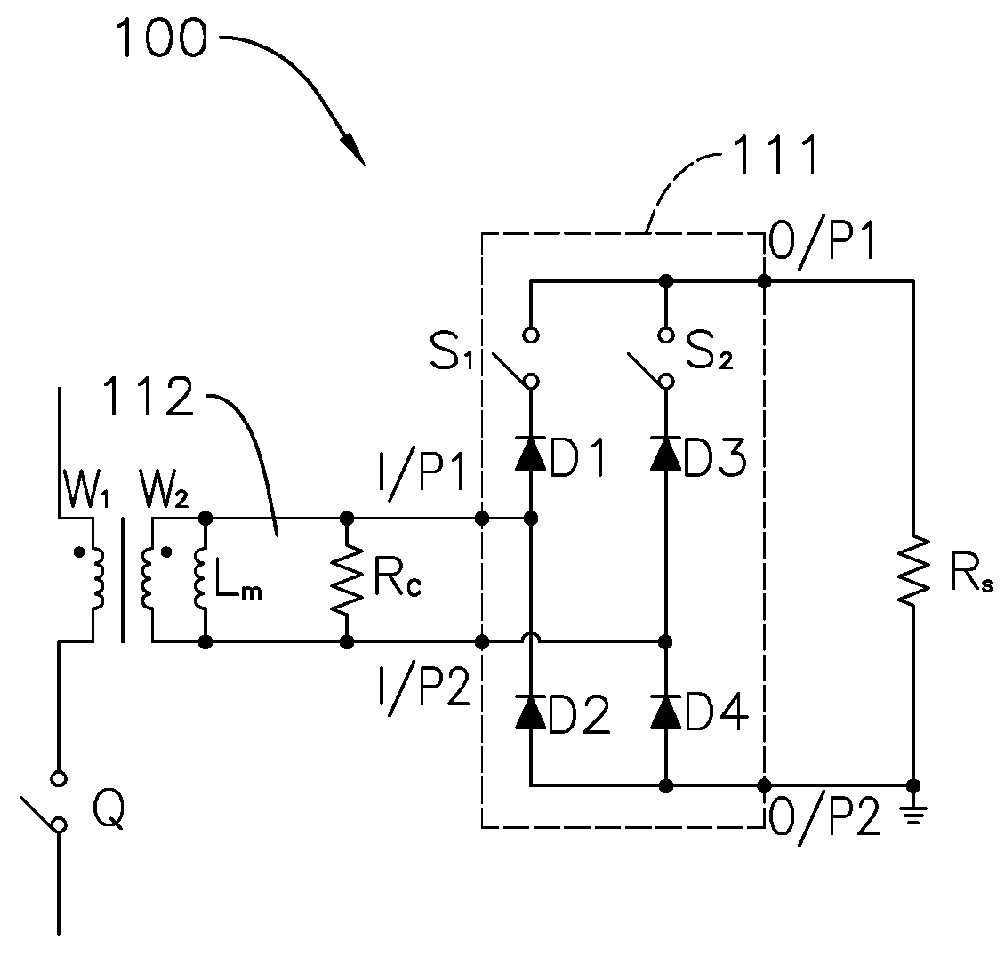

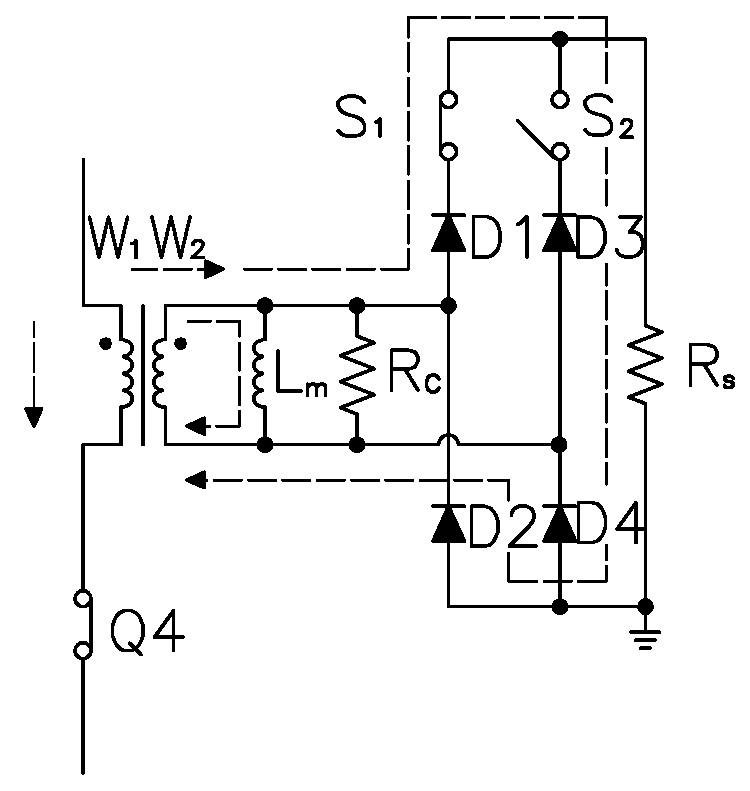

Totem-pole power factor corrector and current-sampling unit thereof

ActiveUS9997994B1Low conversion efficiencyConvenient current detectionAc-dc conversion without reversalEfficient power electronics conversionInductorAC power

A totem-pole PFC and a current-sampling unit of the totem-pole PFC are provided. The totem-pole PFC is electrically connected to an AC power source and a DC-to-DC converter, and is electrically connected to a load through the DC-to-DC converter. The current-sampling unit has a first sampling switch and a second sampling switch. The first sampling switch and the second sampling switch are controlled to be turned on and turned off so that a magnetizing current flows through the magnetizing inductor when a magnetizing inductor is magnetized and a demagnetizing current does not flow through the sampling resistor when the magnetizing inductor is demagnetized, thereby increasing the demagnetization efficiency and overcoming superimposed operations to improve current detection and increase conversion efficiency of the power conversion.

Owner:ACBEL POLYTECH INC

Permanent magnet synchronous motor

InactiveUS7233092B2Reduce outputGreater withstanding force against demagnetizationMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet synchronous motorConductor Coil

The present invention provides a permanent-magnet-synchronous-motor having a stator with concentrated windings with the following structure so that permanent magnet (6) is hard to subjected to demagnetization magnetic field: 0.3 Lg<La≦2.0 Lg, where La is a clearance between teeth of stator (1), and Lg is an air-gap between stator (1) and rotor (2). Outer walls of both ends of the permanent magnet (6) disposed within rotor (2) in a rim direction may be tapered toward inside from a rotor rim in a radial direction and to form a recessed section on the outer walls of the magnets. As a result, withstanding force against demagnetization is expected to increase.

Owner:PANASONIC CORP

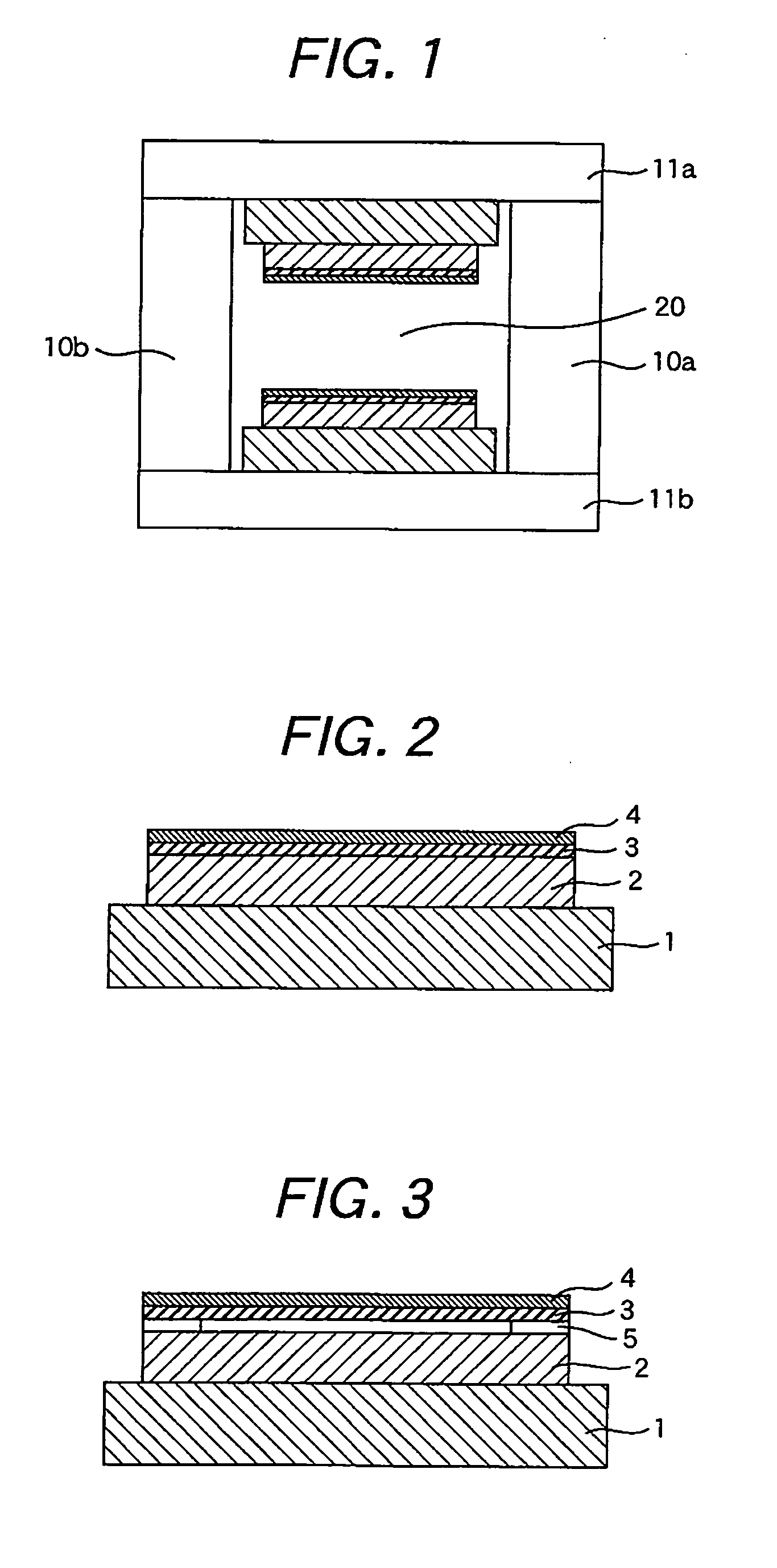

Magnetic recording medium comprising a backcoat layer having specific protrusions

InactiveUS6645648B2Improve featuresIncreased durabilityMagnetic materials for record carriersBase layers for recording layersHigh densityMetallurgy

Provided is a magnetic recording medium having good electromagnetic characteristics, particularly both improved high-density recording characteristics and good durability, and particularly a C / N ratio that is markedly improved in the high-density recording region. A magnetic recording medium comprising a nonmagnetic lower layer and a magnetic layer provided in this order on a support wherein said magnetic layer comprises a ferromagnetic metal powder or a ferromagnetic hexagonal ferrite powder and a binder and has a coercive force equal to or higher than 143 kA / m. Said magnetic recording medium is a medium for recording signals having a surface recording density ranging from 0.2 to 2 Gbit / inch<2>; said support has a thickness equal to or less than 5.5 mum and a Young's modulus in the MD direction equal to or higher than 11,000 Mpa; and said support has on the reverse surface from said magnetic layer a backcoat layer, said backcoat layer having not fewer than 200 and not more than 1,000 protrusions having a height equal to or higher than 50 nm per 10,000 mum<2>.

Owner:FUJIFILM CORP

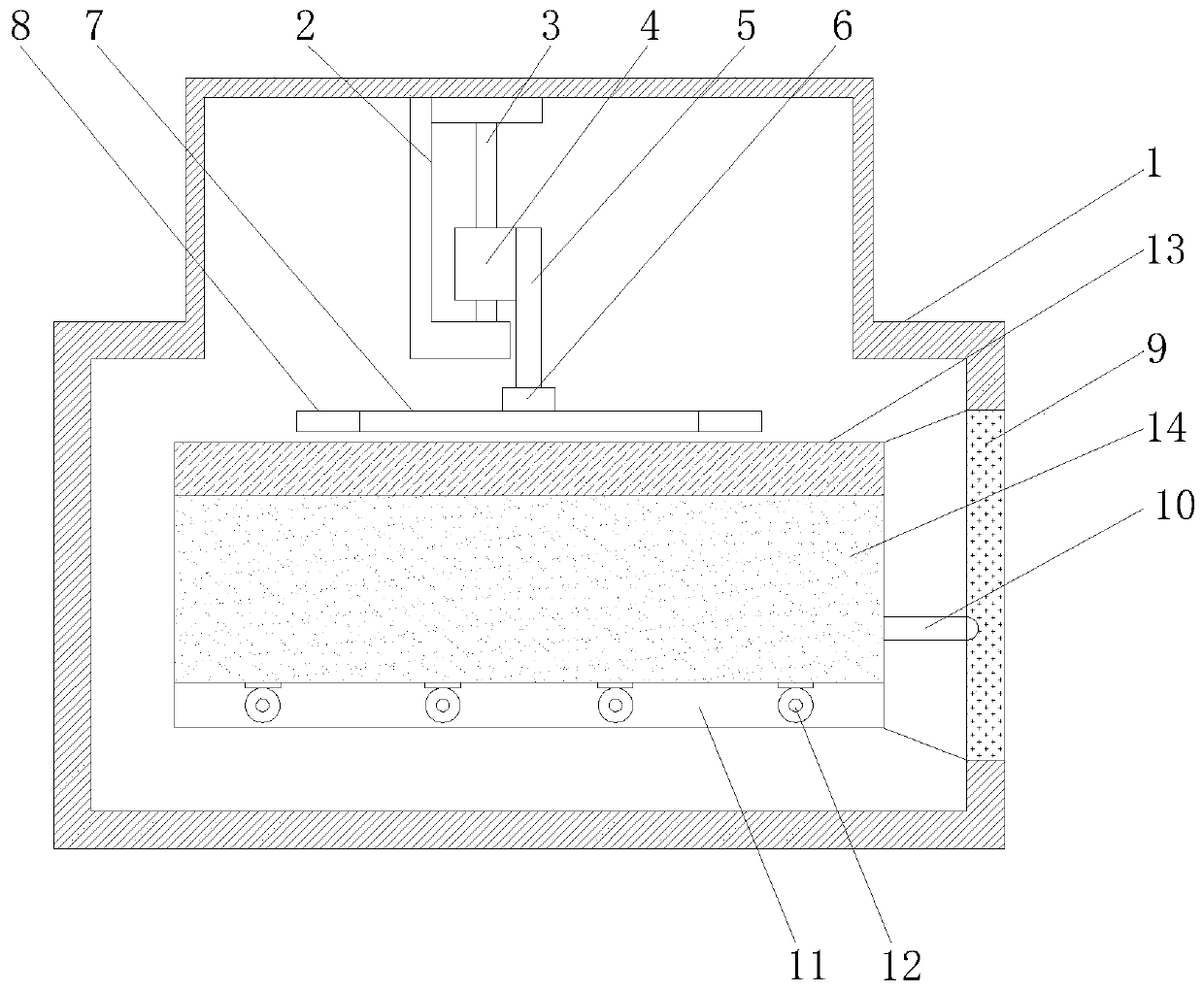

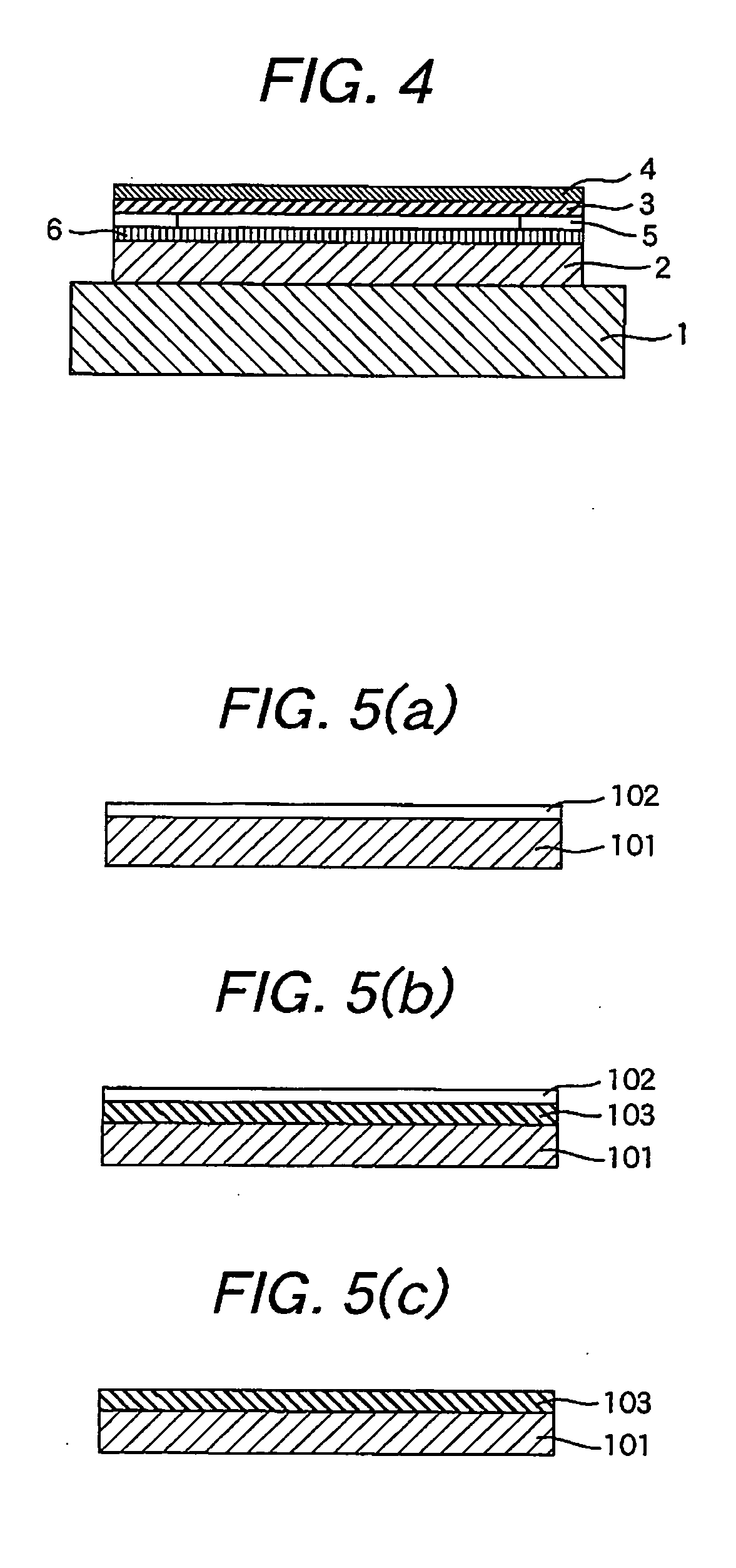

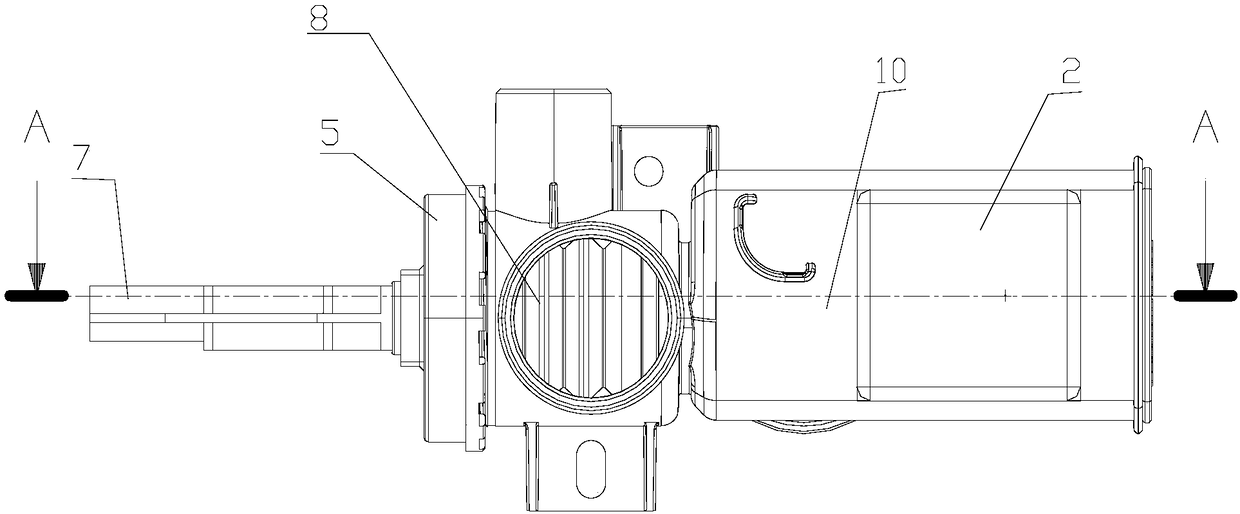

Efficient demagnetization device for computer software storage device

The invention belongs to the technical field of demagnetization equipment, in particular to an efficient demagnetization device for a computer software storage device. The device comprises a shell, amounting frame, a lead screw, a lead screw sliding table, a connecting plate, a micro motor, a demagnetizing coil, a bracket, a side door, a handle, a guide rail, rollers, a fixed frame, a pull plate,a rectangular plate, a transmission rod, a stepping motor, a movable frame, a spring, a limiting column, a through hole, an L-shaped plate, a cam, a fixed frame, a cam motor, an electric push rod anda push plate. According to the invention, the storage device needing demagnetization is placed between the two L-shaped plates and the rectangular plate; the cam motor is started through the externalswitch; the cam motor drives cam to rotate, and the cam rotates to drive the movable frame and the L-shaped plates at the two ends of the movable frame to slide in the two through holes in one end ofthe fixed frame, so that the two ends of the L-shaped plates fix the storage equipment between the rectangular plate, the L-shaped plates and the fixed frame, the storage equipment of different sizescan be fixed conveniently, the demagnetization of the storage equipment is facilitated, and the demagnetization efficiency is improved.

Owner:深圳玖合精工科技有限公司

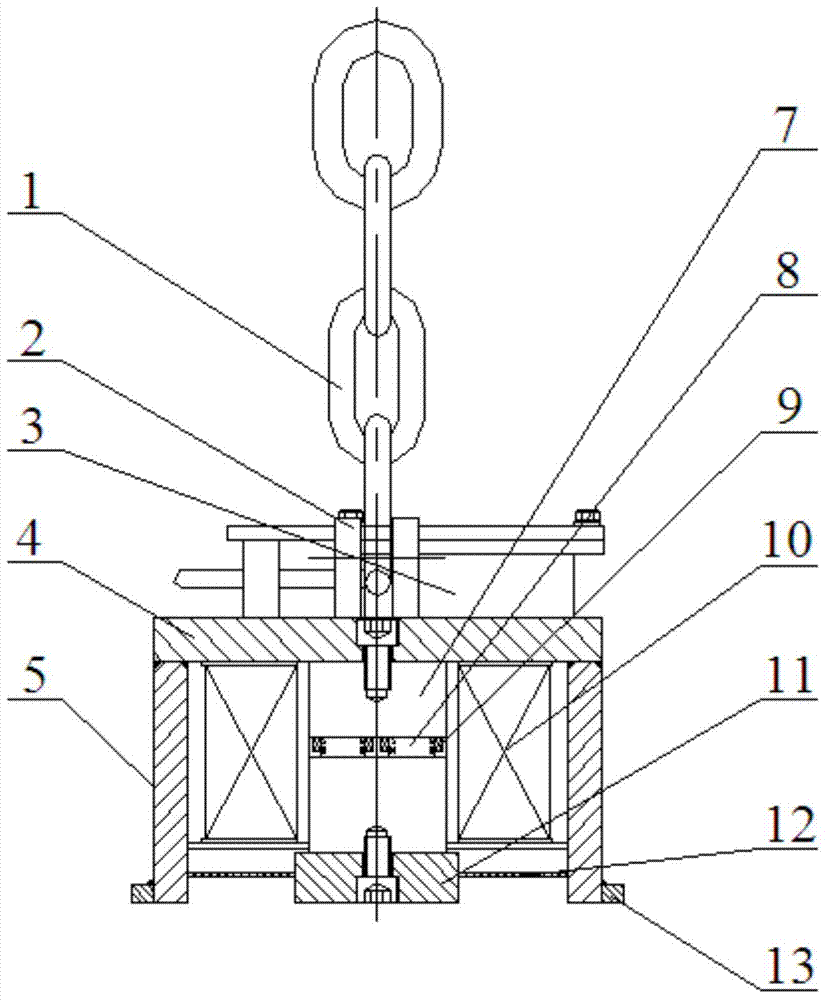

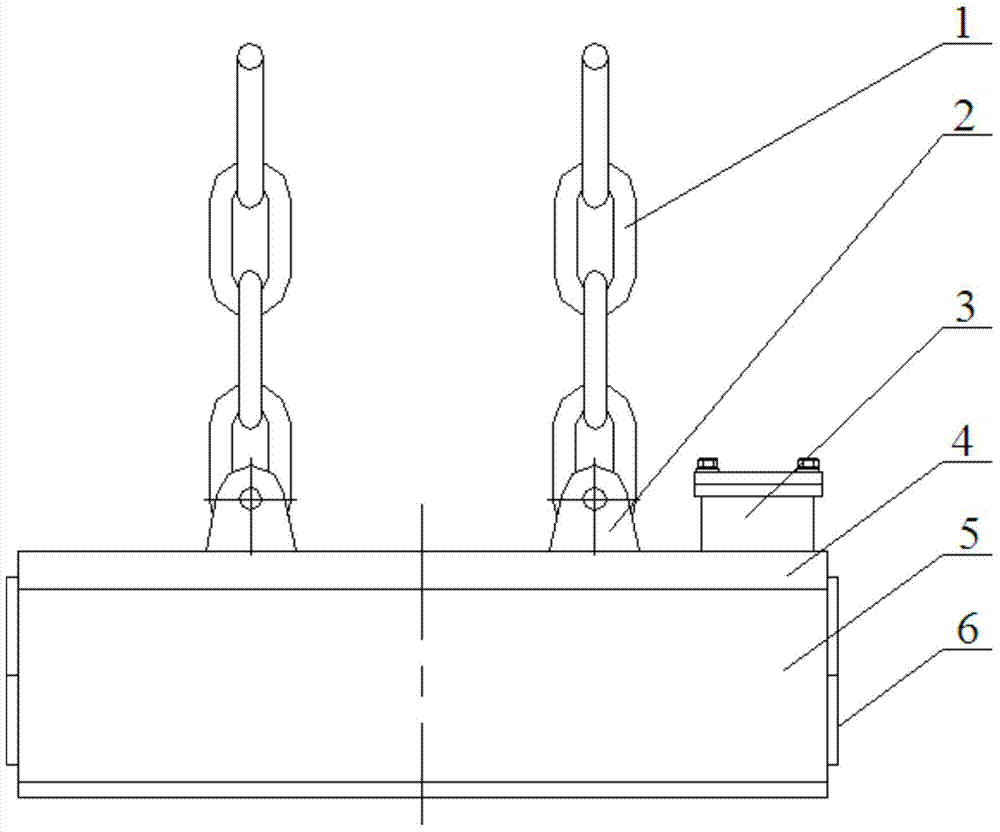

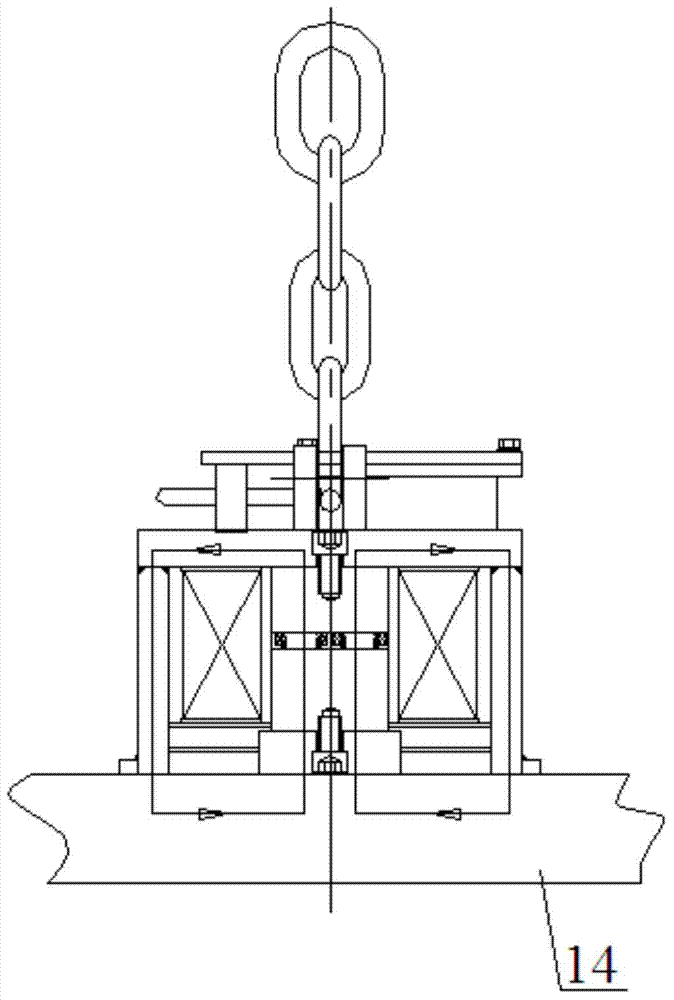

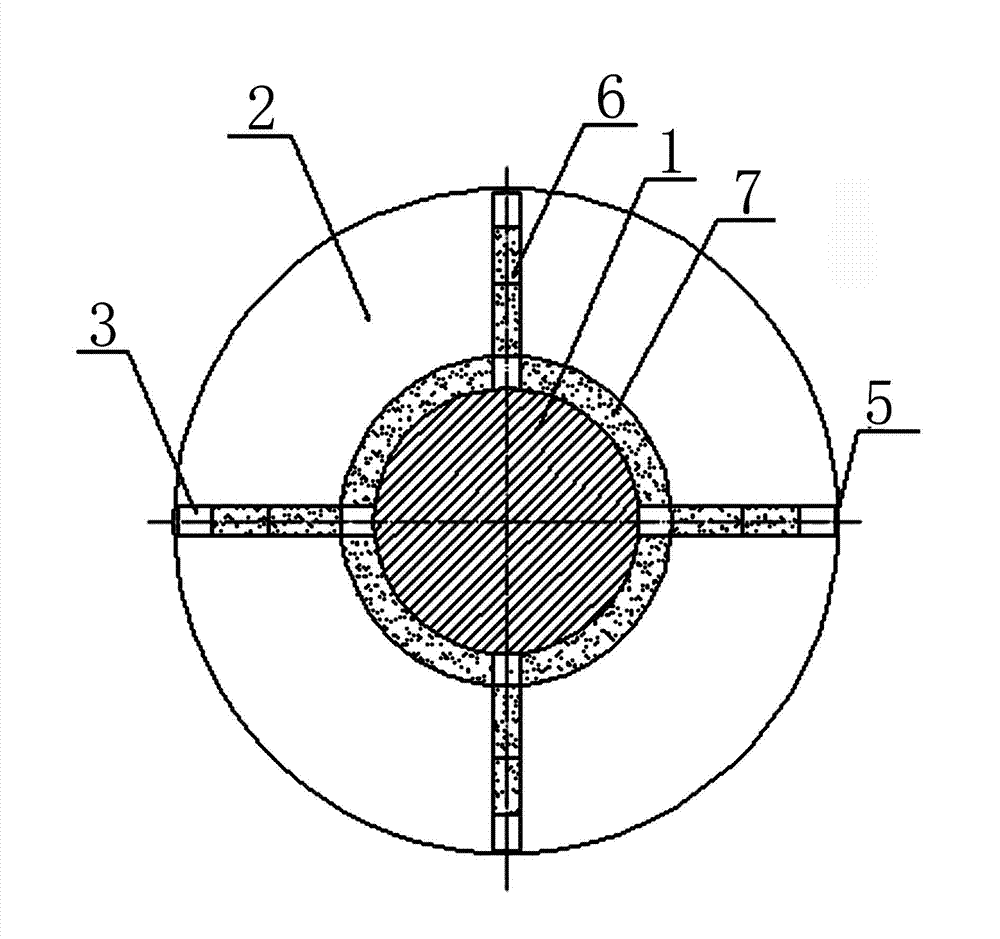

High-temperature-resistant electric control hoisting electro permanent magnet

InactiveCN104276506AOvercome sensitivityStrong suctionLoad-engaging elementsIntermediate frequencyMagnetic poles

The invention discloses a high-temperature-resistant electric control hoisting electro permanent magnet which comprises chains connected with hoisting equipment, lifting lugs arranged at the bottom ends of the chains, and an electro permanent magnet body fixedly connected to the bottom ends of the lifting lugs, wherein the electro permanent magnet body is of a sealed integrated structure consisting of a top plate, side plates, an end plate, an inner magnetic plate and a heat insulation plate; an iron core is arranged in the middle in the electro permanent magnet body; main excitation coils sleeve the outside of the iron core; a plurality of groups of magnetic steel are respectively arranged in the middle of the iron core; demagnetization coils respectively sleeve the outside of the multiple groups of magnetic steel; an outer magnetic pole is arranged at the bottom end outside the electro permanent magnet body; the top plate, the side plates, the outer magnetic pole, the inner magnetic plate, the iron core and the multiple groups of magnetic steel form a magnetic loop. According to the high-temperature-resistant electric control hoisting electro permanent magnet, current meeting different demands is generated by using electric control energy; during excitation, the high direct current is supplied; during demagnetization, the intermediate-frequency alternating current is supplied to the demagnetization coils; and therefore, extremely good and convenient control can be realized.

Owner:马鞍山起劲磁塑科技有限公司

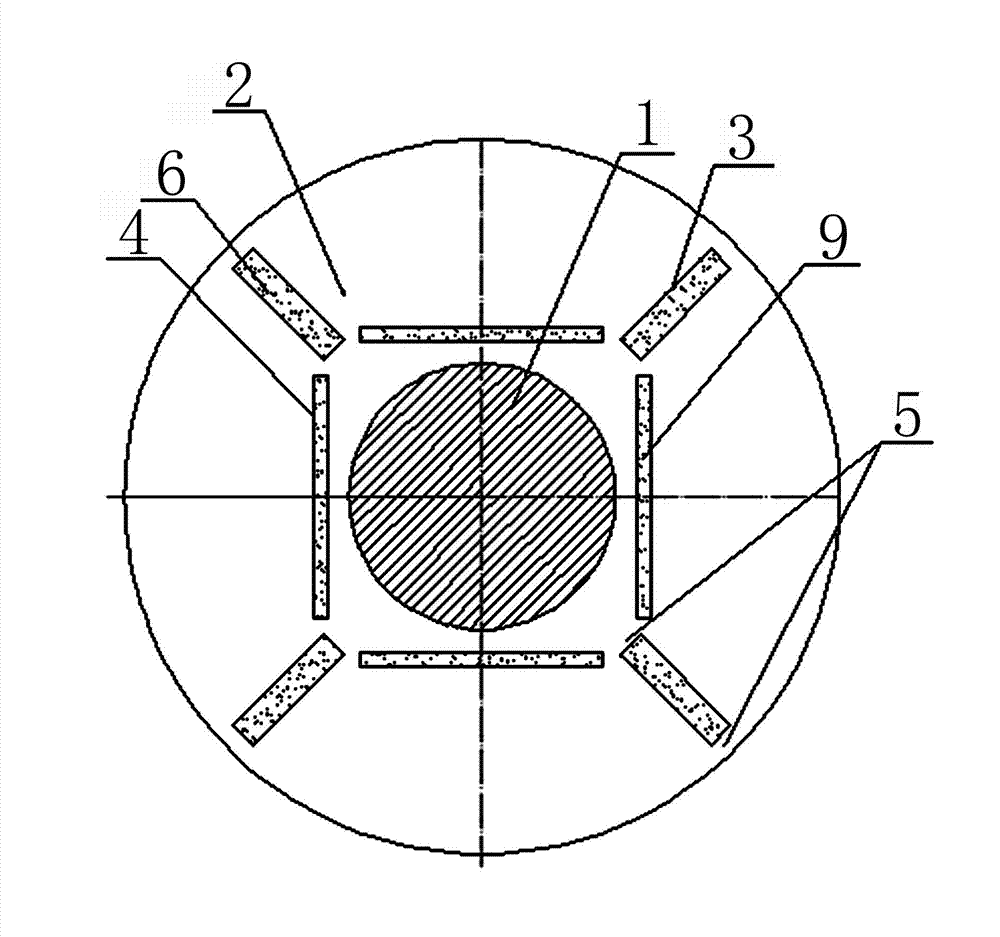

Mixed permanent magnet synchronous motor rotor

InactiveCN102769347AEasy to demagnetizeLow costMagnetic circuit rotating partsElectric machinePermanent magnet synchronous motor

The invention relates to a permanent magnet synchronous motor, and in particular relates to a mixed permanent magnet synchronous motor rotor. The problems that the existing permanent magnet synchronous motor rotor is low in mechanical strength and high in magnetic leakage factor and the cost of the motor is high are solved. The mixed permanent magnet synchronous motor rotor comprises a steel shaft and a rotor core, wherein even radial permanent magnet slots are uniformly distributed on the section of the rotor core; a radial permanent magnet is arranged in each radial permanent magnet slot; even tile-shaped permanent magnets are uniformly distributed on the steel shaft according to the polarity; adjacent two tile-shaped permanent magnets have different polarities; a gap is reserved between adjacent two tile-shaped permanent magnets; the inner end of each radial permanent magnet slot is provided with an opening; each opening respectively corresponds to each gap; and the inner ring of the rotor core is pressed on the outer side face of each tile-shaped permanent magnet. The mixed permanent magnet synchronous motor rotor is suitable for various permanent magnet synchronous motors.

Owner:岳群生

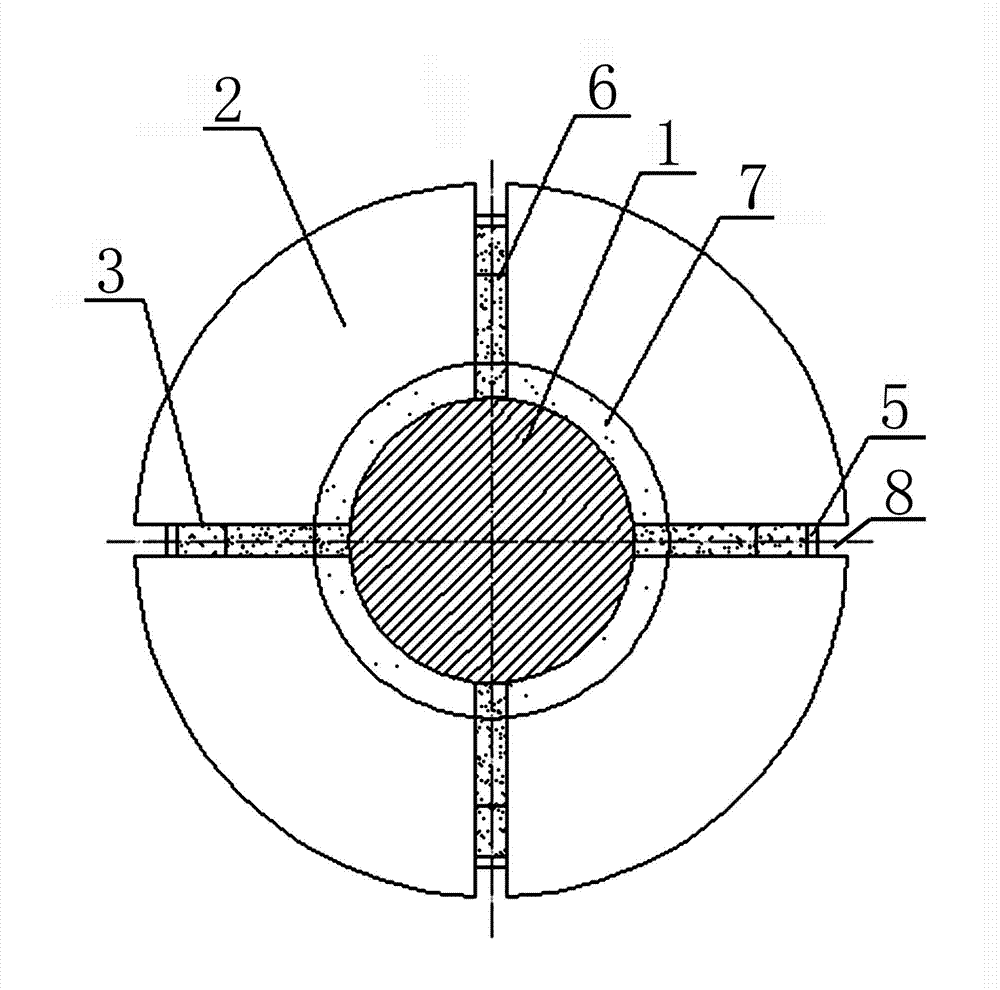

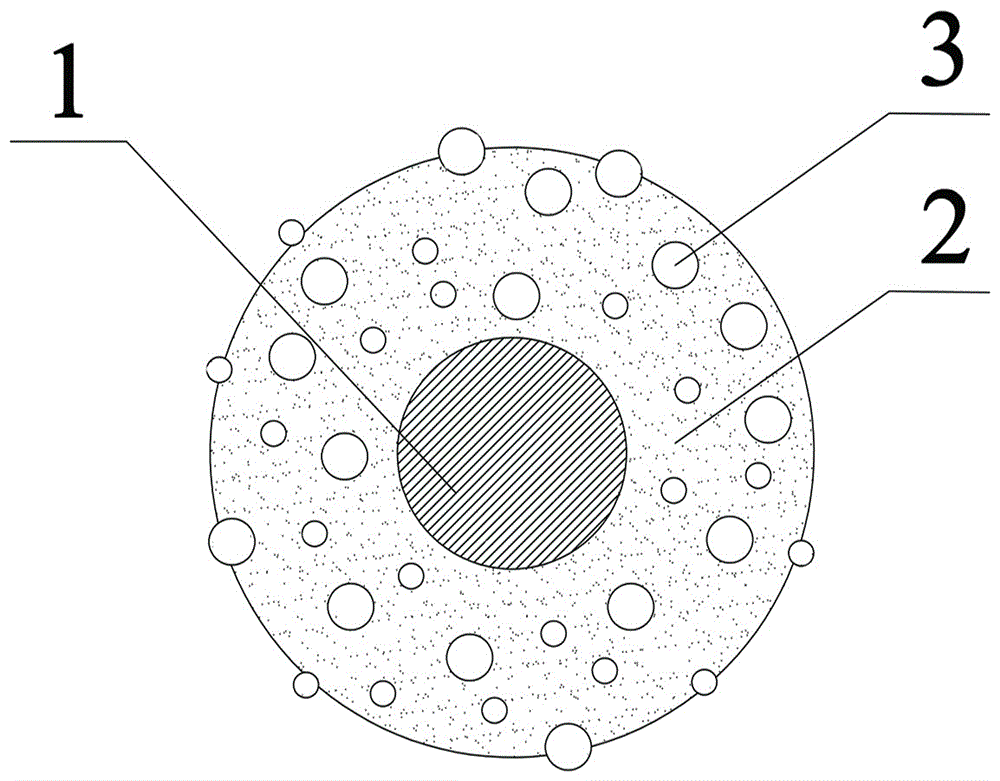

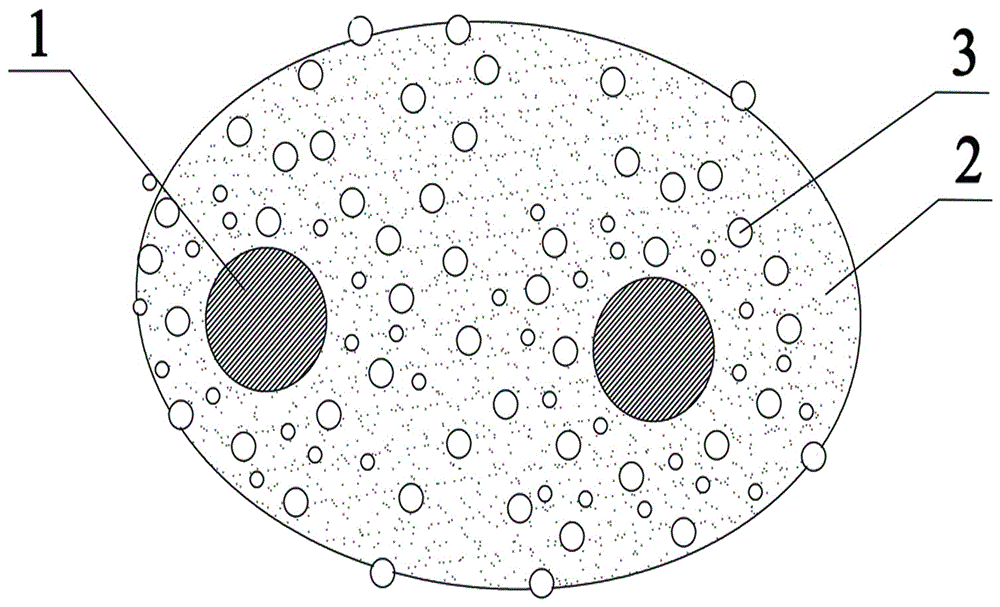

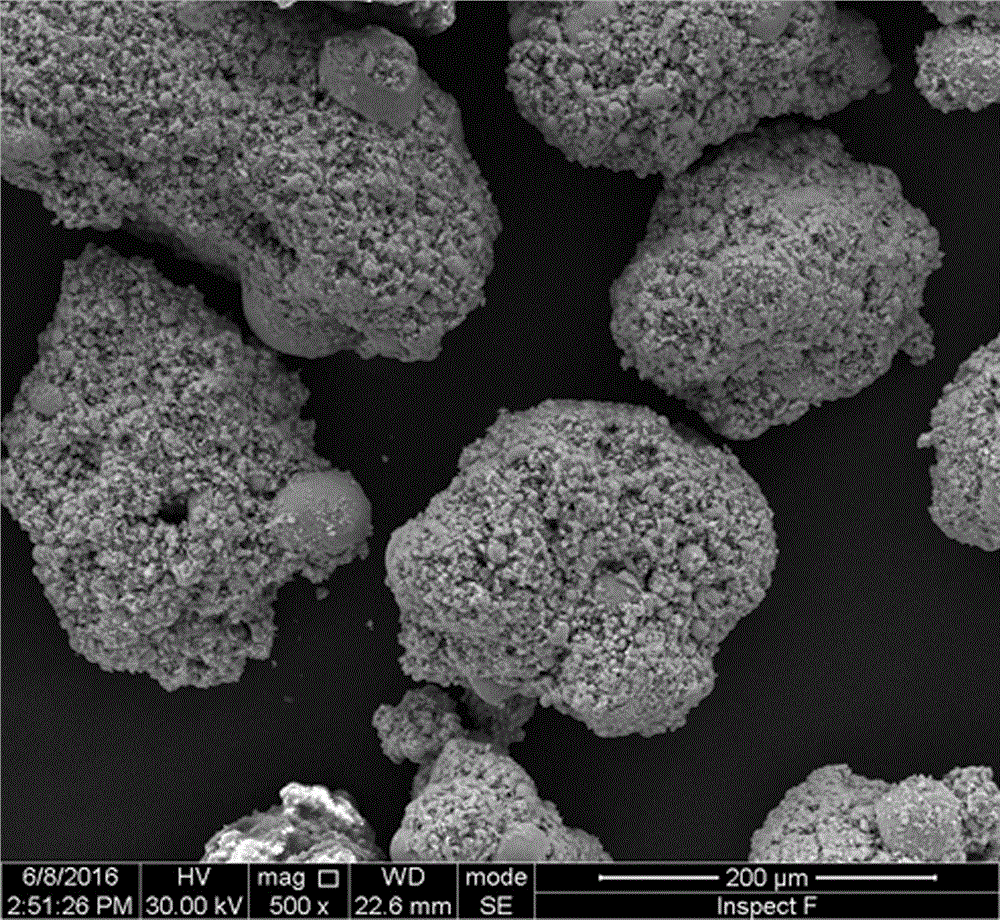

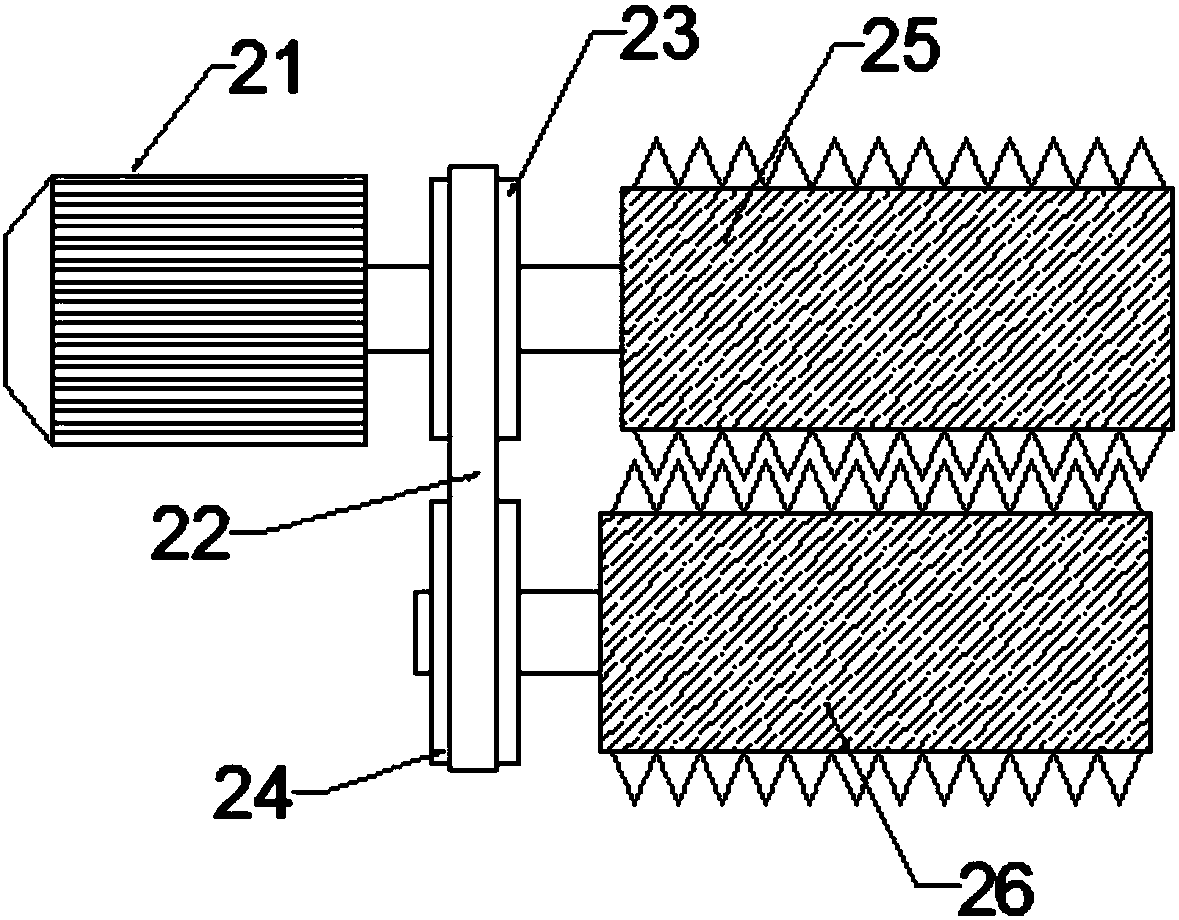

Magnetic grinding material and preparation method thereof

ActiveCN106753241AExtended service lifePreserve self-sharpeningOther chemical processesHot meltWork in process

Owner:ZHENGZHOU HONGJI ABRASIVE TECH CO LTD

Rotor of an electric machine with embedded permanent magnets and electric machine

ActiveUS8896175B2Raise the ratioHigher reluctance torqueMagnetic circuit rotating partsMagnetic circuit characterised by insulating materialsElectric machineMagnetic poles

A rotor for an electric machine excited by magnetic poles formed by one or more embedded permanent magnets includes a magnetic body and the one or more embedded permanent magnets associated with the magnetic body defining first magnetic poles and second magnetic poles of alternating magnetic polarity along a rotor direction. For at least one of the one or more embedded permanent magnets a rotor segment is arranged between the one or more embedded permanent magnets and a first surface of the magnetic body. At least one retainer element connects the rotor segment to a portion of the magnetic body.

Owner:VOLVO TRUCK CORP

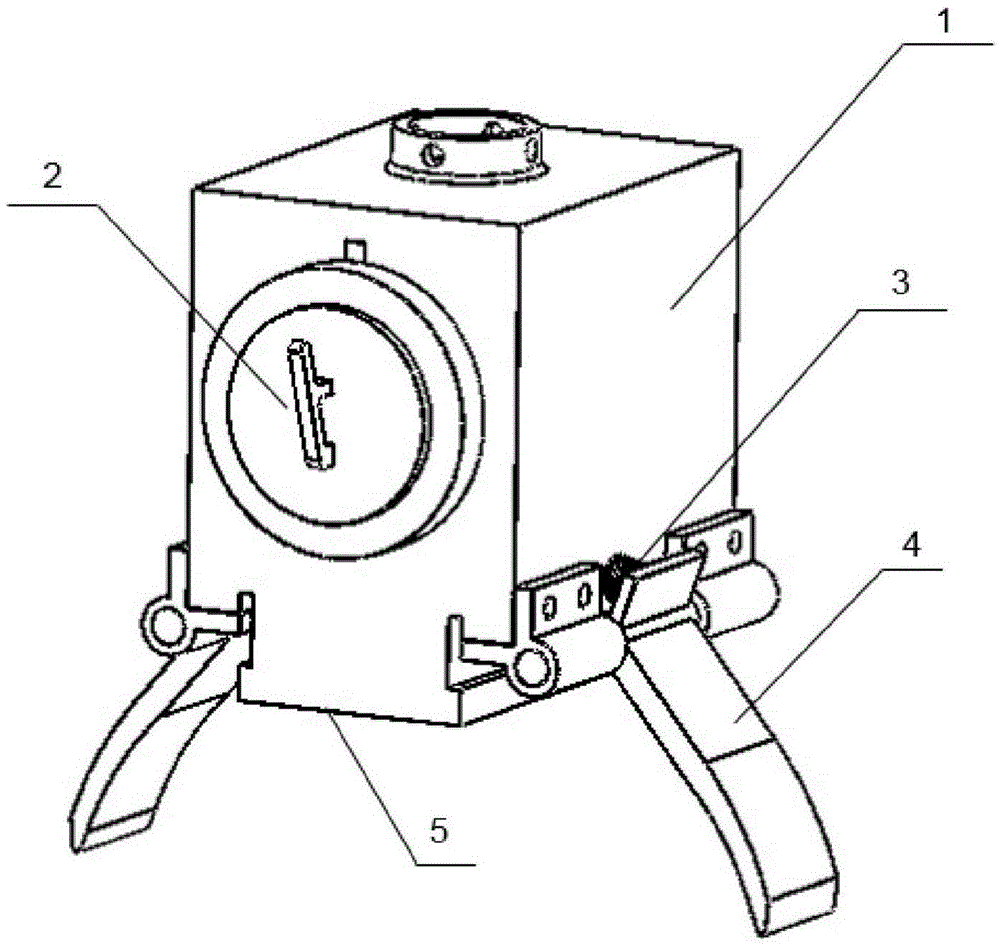

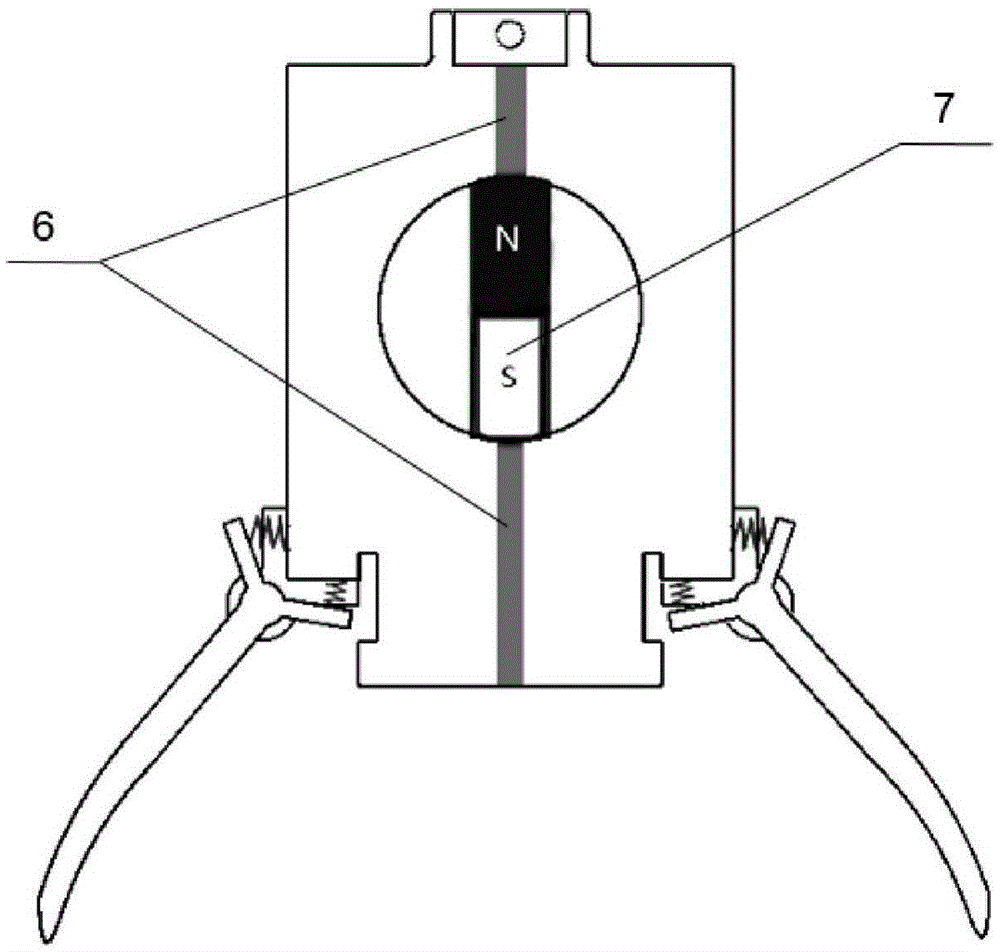

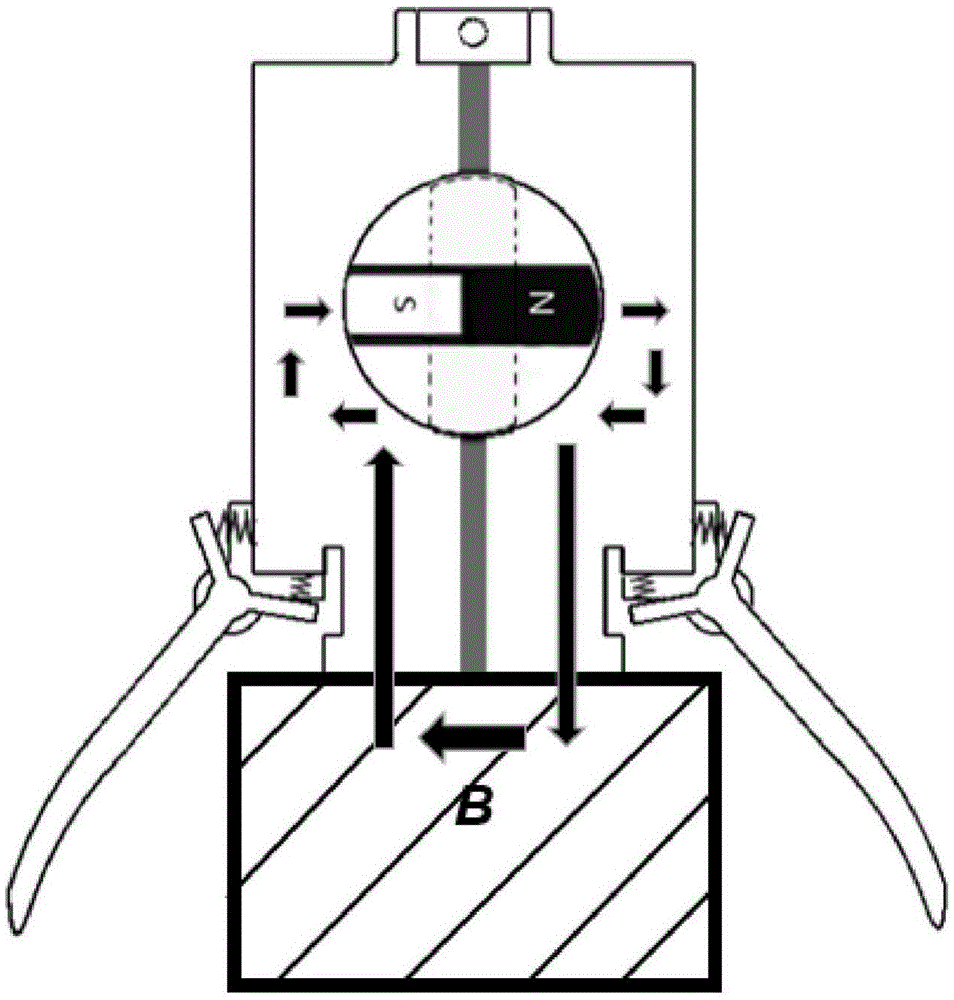

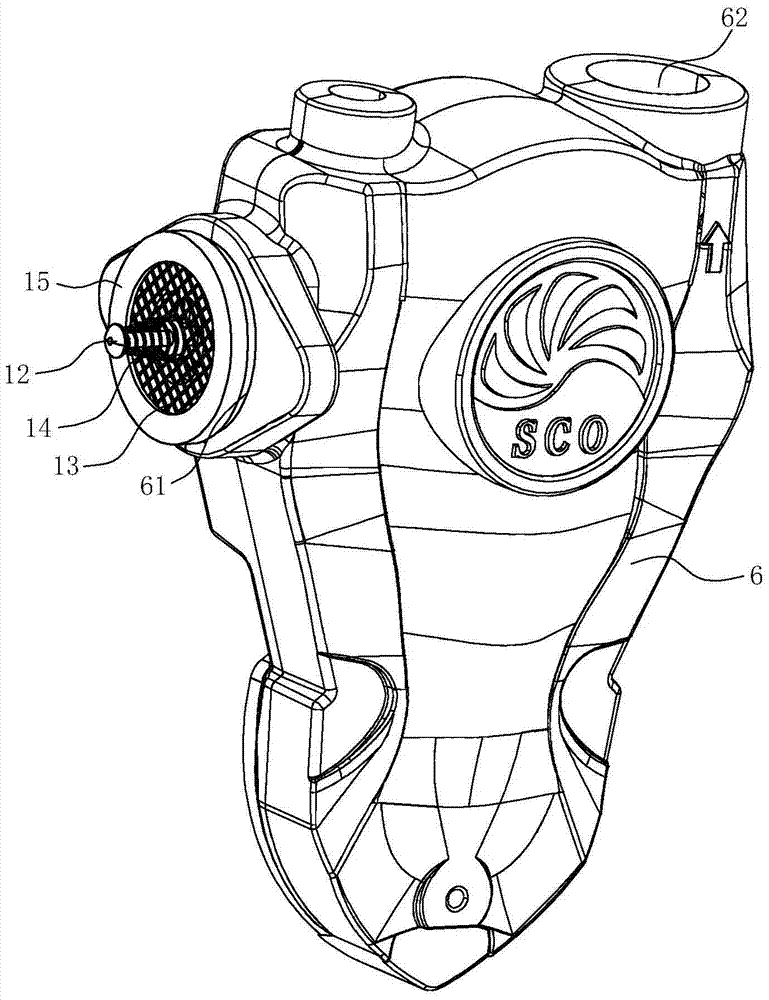

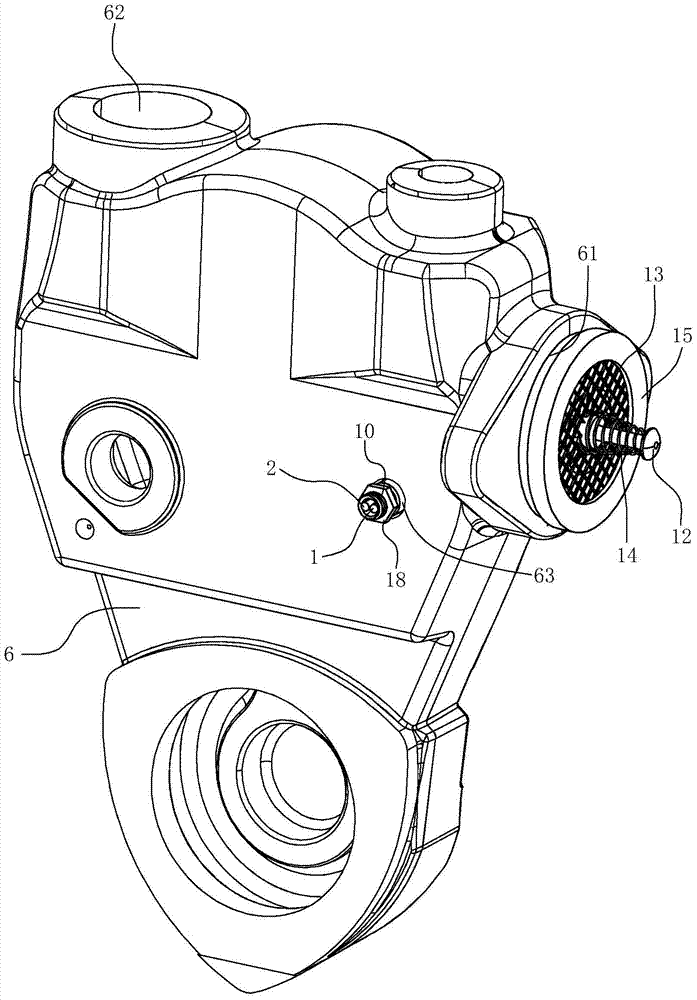

Magnetic manipulator adopting magnetic frame principle

The invention discloses a magnetic manipulator adopting the magnetic frame principle. The magnetic manipulator comprises a main rack with a sealed inner cavity, a hollow cylindrical barrel made of soft magnetic materials is horizontally arranged in the main rack, and a strip-shaped permanent magnet is arranged in the hollow cylindrical barrel and rotates around the axis of the hollow cylindrical barrel. A rotating switch in rigid connection with the permanent magnet and a steering engine output shaft is arranged at one end of the hollow cylindrical barrel. A brass bar equally dividing the main rack into a left part and a right part is further vertically arranged in the main rack, and the inner cavity of the main rack is filled with soft magnetic materials. According to the magnetic manipulator, the permanent magnet is rotated to control existence and absence of magnetism, and therefore a target object is grabbed or released; by means of the characteristics of easy magnetization and quick demagnetization of the soft magnetic materials, the functions of grabbing and releasing the target object are achieved, and the magnetic manipulator is easy and convenient to manufacture and high in feasibility.

Owner:SOUTH CHINA UNIV OF TECH

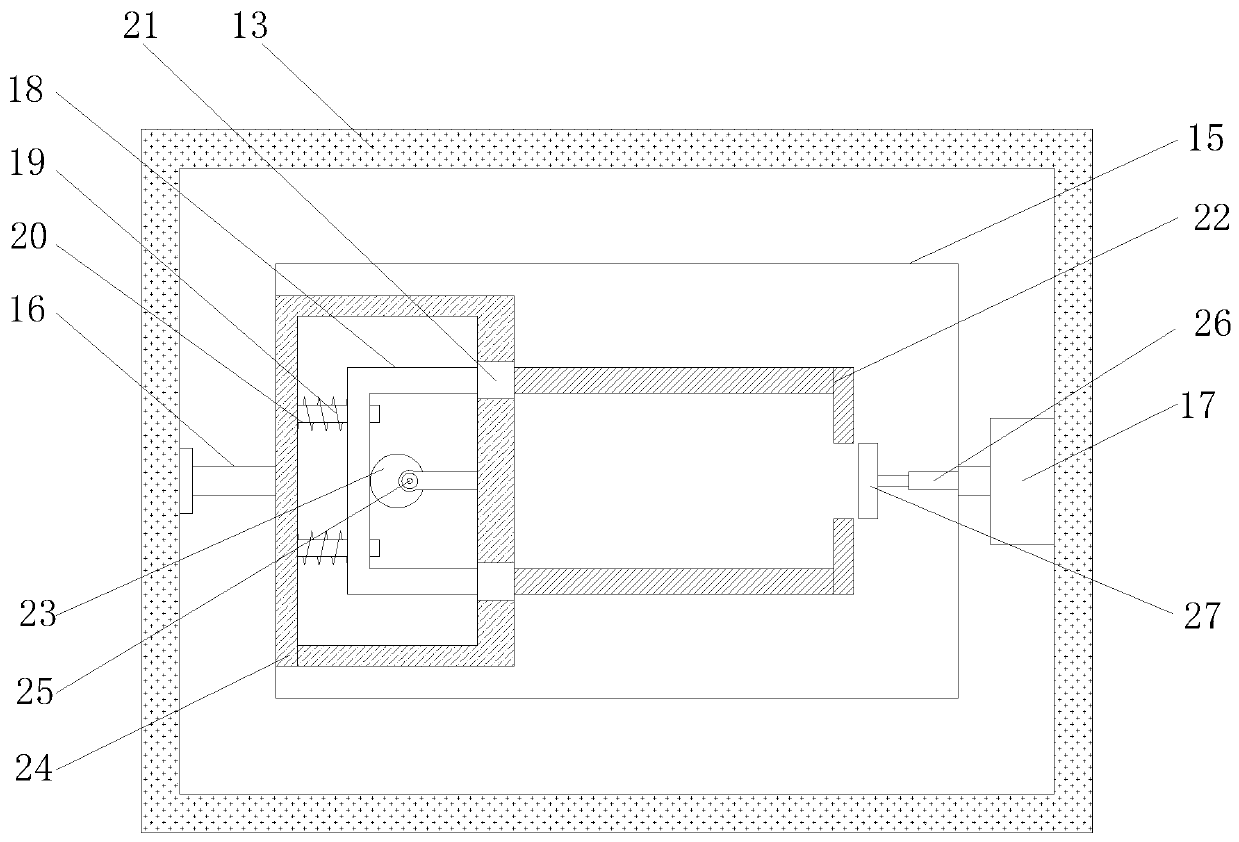

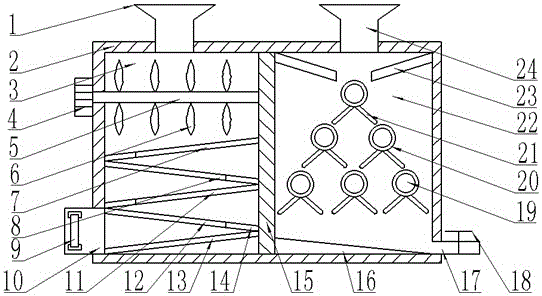

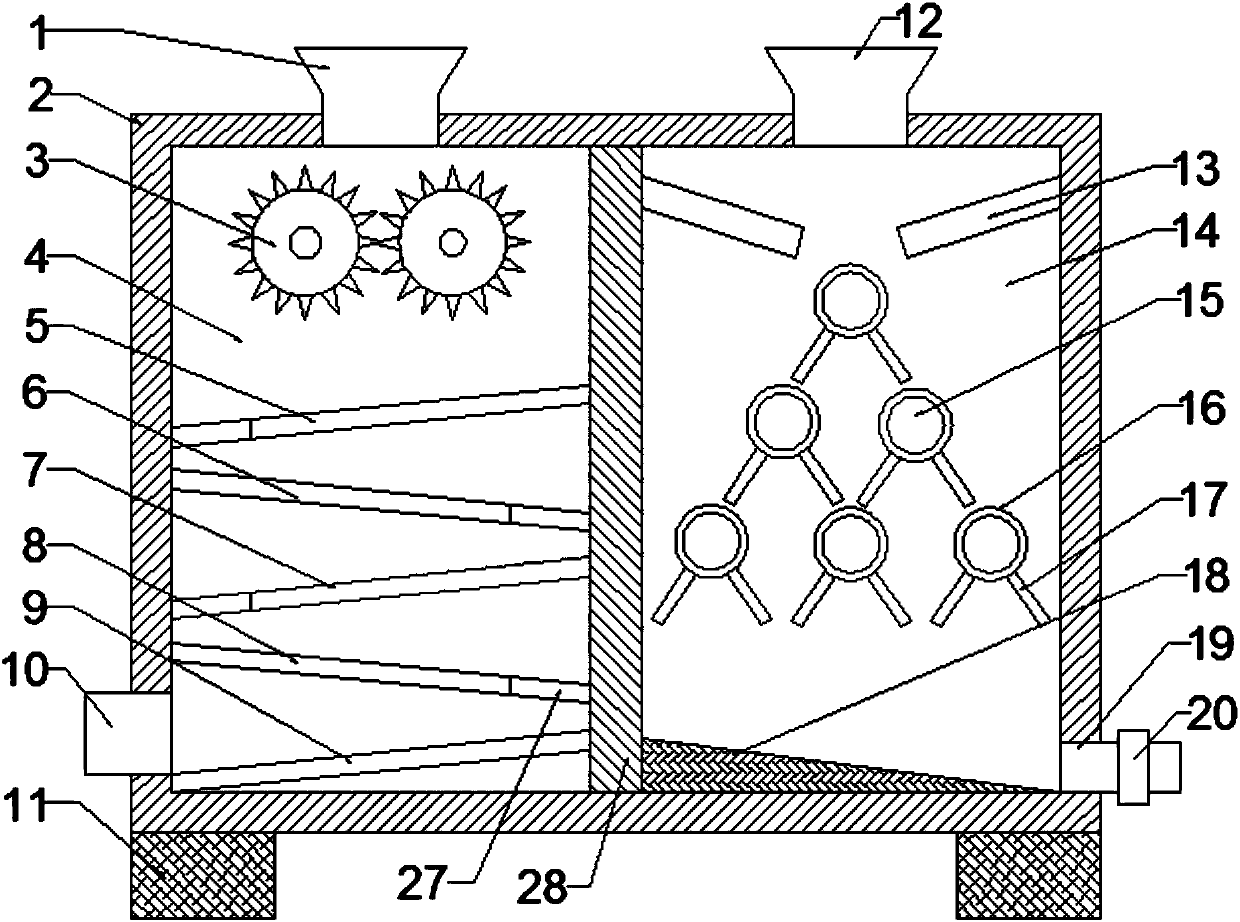

Dual-purpose magnetism-removal smashing device for solid-liquid electrode material

ActiveCN106807515AGuaranteed divisibilityEasy to demagnetizeMagnetic separationGrain treatmentsDrive motorEngineering

The invention provides a dual-purpose magnetism-removal smashing device for a solid-liquid electrode material. The dual-purpose magnetism-removal smashing device comprises a box body, wherein the box body comprises a solid magnetism-removal cavity, an intermediate partition board and a liquid magnetism-removal cavity; the solid magnetism-removal cavity is internally provided with a graphite feed hopper, a smashing device, magnetism removing devices and a box door; the smashing device comprises a drive motor and a rotating shaft; a first magnetism removing device comprises a first magnetism removing plate, a second magnetism removing plate, a third magnetism removing plate, a fourth magnetism removing plate and a fifth magnetism removing plate; the box door is arranged at the left lower end of the solid magnetism-removal cavity, and a handle is arranged on the box door; the intermediate partition board is arranged between the solid magnetism-removal cavity and the liquid magnetism-removal activity; the liquid magnetism-removal activity is internally provided with an inclined base plate, a discharge tube, a second magnetism removing device, a flow guide plate and a liquid feed hopper; the second magnetism removing device comprises a cylinder and a flow guide rod; a magnet rod is arranged in the cylinder in a sleeving manner; and the liquid feed hopper is arranged at the upper end of the liquid magnetism-removal cavity. According to the device, the magnetism is removed in a circulating manner, and the magnetism removal is thorough; and solid magnetism removal and liquid magnetism removal can be carried out simultaneously, so that the efficiency is high.

Owner:ZHEJIANG THREETE ELECTRONICS TECH

Photoelectric liquid sensor and water pump with same

ActiveCN104847960AShorten the separation distanceLight wavelength shortValve arrangementsPositive displacement pump componentsFiberWater flow

The invention relates to a photoelectric liquid sensor. The photoelectric liquid sensor is characterized by comprising a transmitting optical fiber and a receiving optical fiber which are bilaterally oppositely arranged at an interval, the outer end of the transmitting optical fiber and the outer end of the receiving optical fiber are led out of a fluid, a light-emitting diode used for lighting the transmitting optical fiber is arranged at the position, adjacent to the transmitting optical fiber, out of the fluid, the receiving optical fiber is capable of receiving the light transmitted by the transmitting optical fiber and transmitting the light to a photoelectric conversion module, a shielding piece capable of moving under the action of the fluid is arranged between the transmitting optical fiber and the receiving optical fiber, and whether the receiving optical fiber can receive the light transmitted from the transmitting optical fiber or not is determined by vertical motion of the shielding piece. The diameter of the transmitted light is quite small due to the features of the light transmitted by the fiber, the light can be sensed if only the shielding piece slightly moves by a distance, and sensitivity is quite high. Compared with a traditional magnetic water flow sensor, the photoelectric liquid sensor has the advantages of freeness from affection of external magnetic field, operation is stable, the fiber is less prone to damage, and the part easy to be damaged is the light-emitting diode which is quite convenient to maintain. The invention further relates to a water pump provided with the above sensor.

Owner:ZHEJIANG SINCONTROL PUMP IND

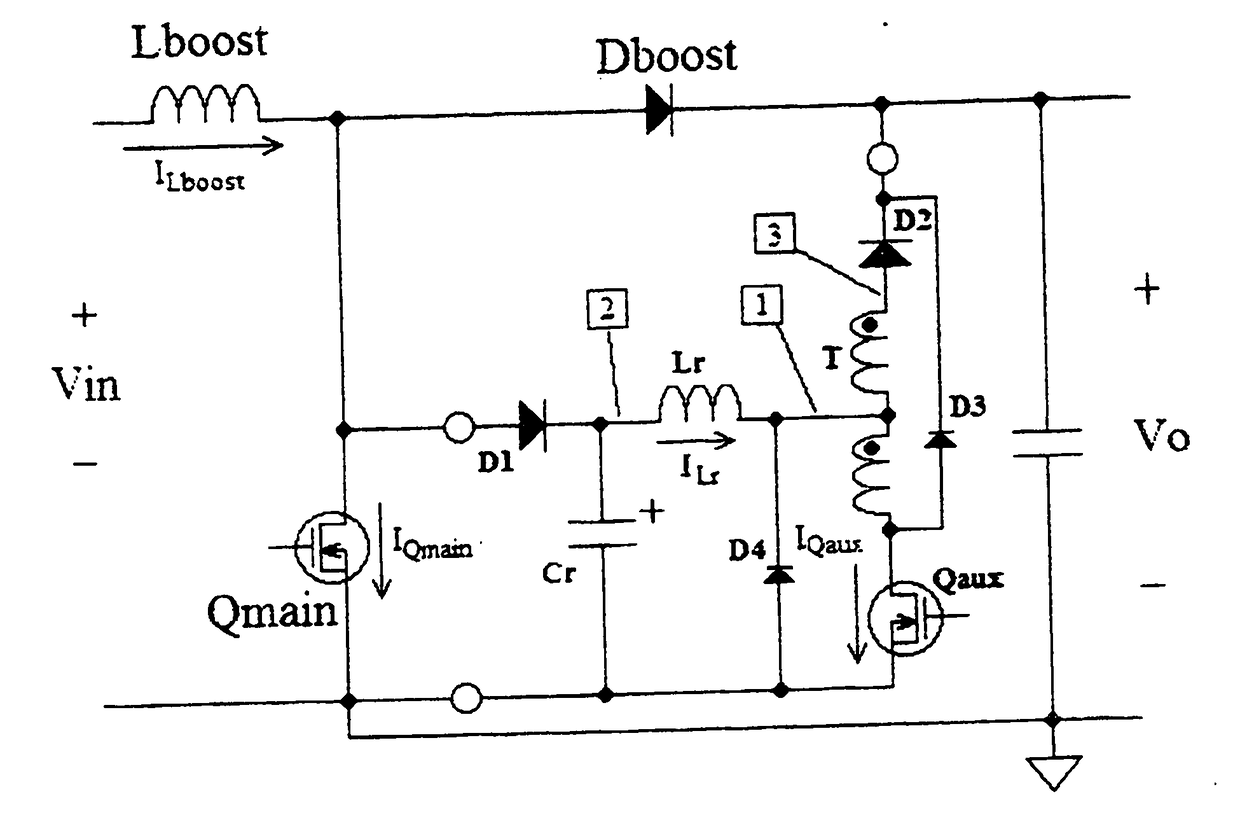

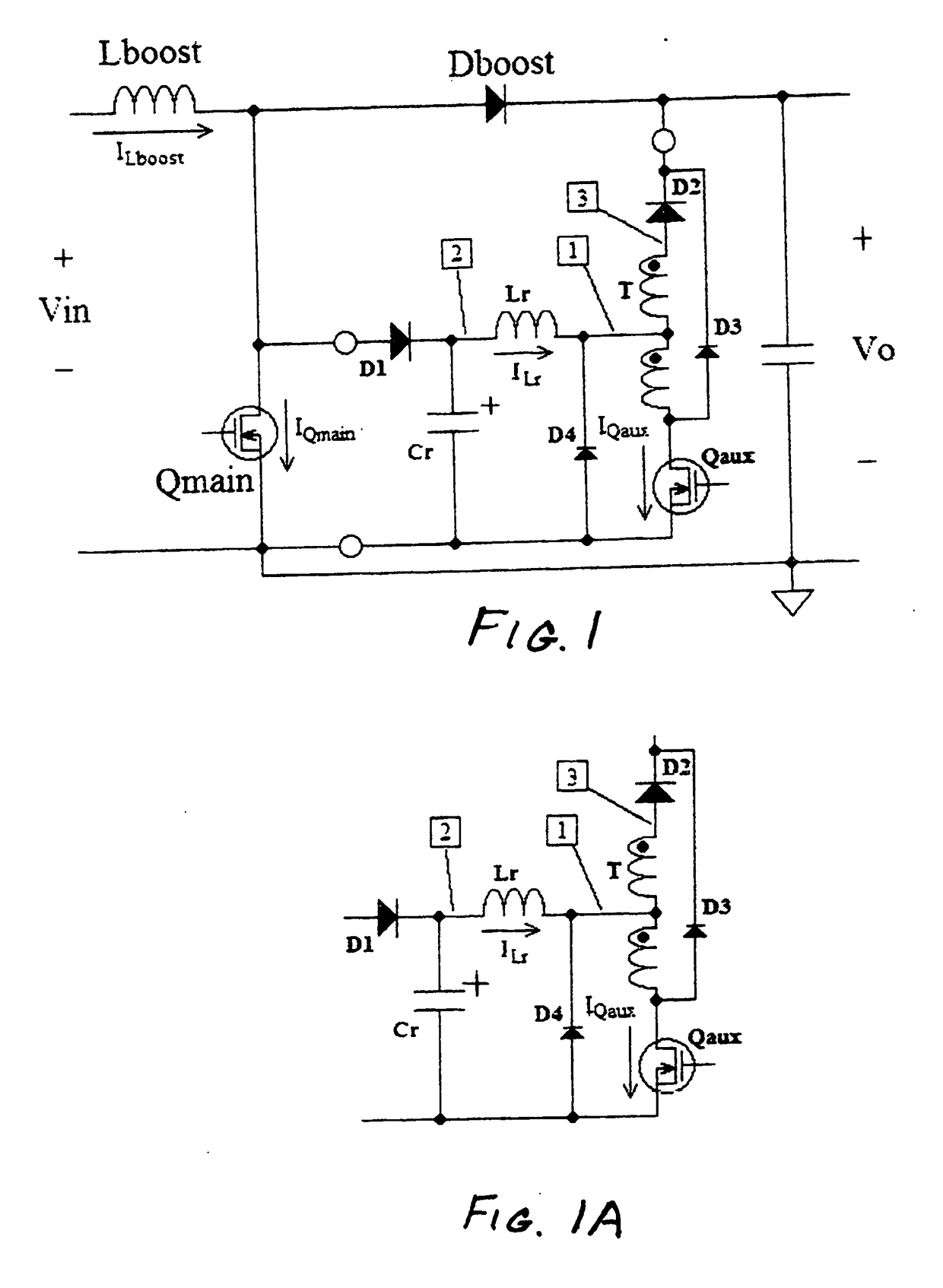

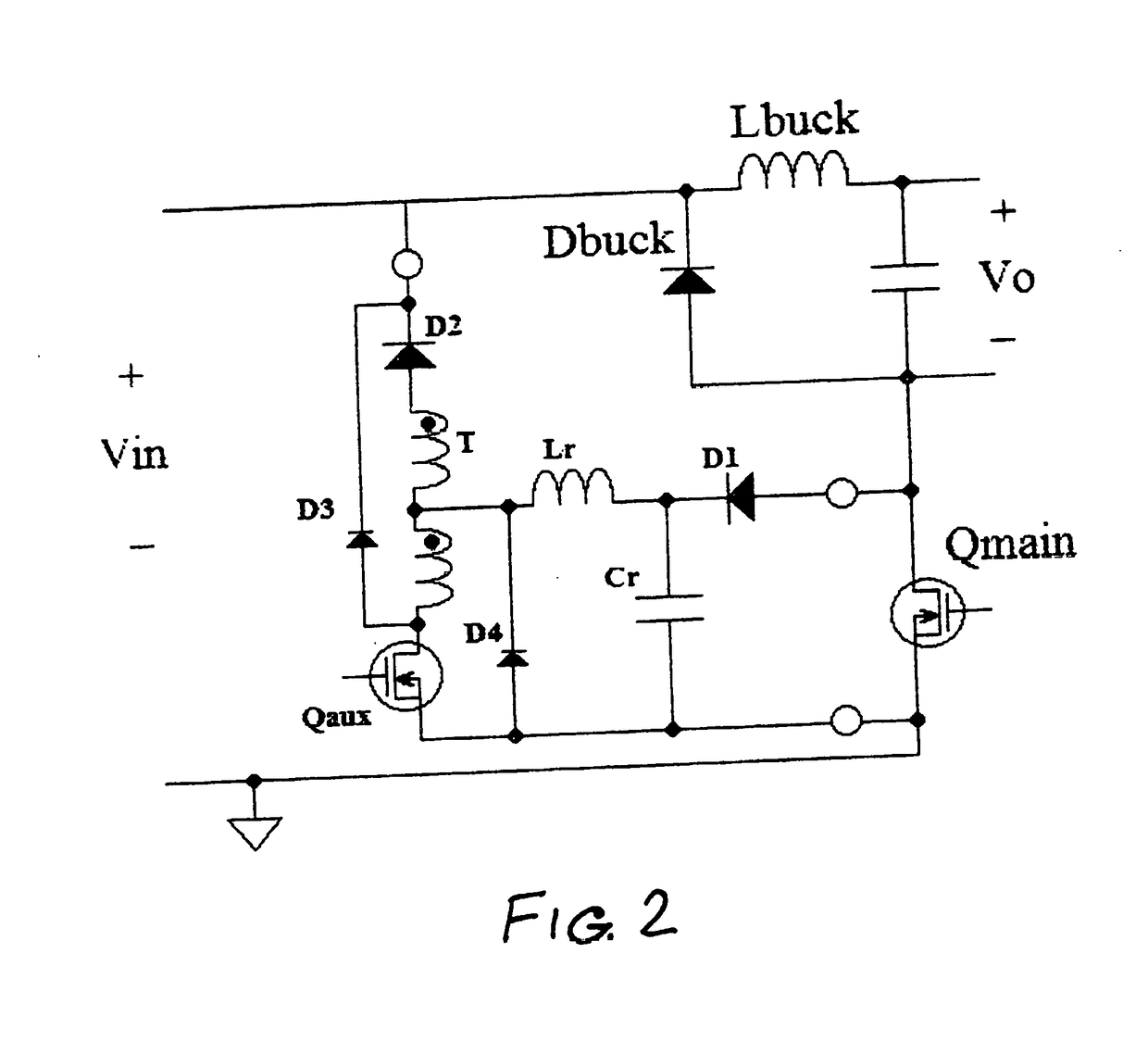

Soft-switching for high-frequency power conversion

InactiveUS20180323713A1Improves EMI emission levelLessens turn-off lossEfficient power electronics conversionConversion using Cuk convertorsSoft switchingHigh frequency power

A power converter designed for operation at high frequencies includes a soft-switching cell comprising a split inductor, a resonant inductor, a resonant capacitor, two diodes and a controlled semiconductor. Alternatively, the power converter includes a soft-switching cell comprising a transformer having isolated windings, a resonant inductor, a resonant capacitor, two diodes and a controlled semiconductor.

Owner:EMD TECH

MRI apparatus with high-resistance magnet

InactiveUS20070159171A1Improve the immunityEasy to demagnetizeMagnetic measurementsThin material handlingHigh resistanceMagnetic field gradient

Eddy current generated around a magnetic circuit in an MRI apparatus is one of the causes of deviation from an ideal magnetic field gradient waveform and causes image distortion, loss of strength, ghost generation, loss of signal, and spectral distortion. An object of the present invention is to suppress the generation of the eddy current. In an MRI apparatus, a ferromagnetic material formed from powder is used in a part of a magnetic circuit: the powder mainly comprising a mother phase containing iron or cobalt and showing ferromagnetism; and a high-resistance layer having a resistance not less than ten times as high as the mother phase and a Vickers hardness lower than that of the mother phase being formed in layers along parts of the surface of the powder on parts or the entire of the surface.

Owner:HITACHI LTD

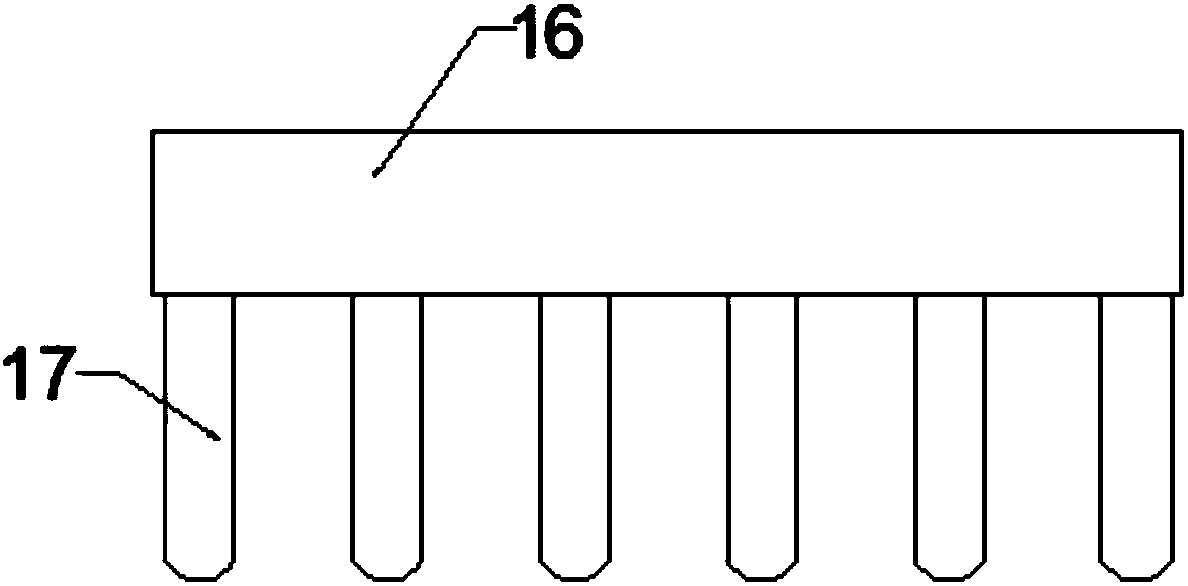

Solid-liquid dual-purpose chemical raw material demagnetization crushing device

InactiveCN108031517AEasy to demagnetizeGuaranteed divisibilityMagnetic separationGrain treatmentsDual purposeEngineering

The invention discloses a solid-liquid dual-purpose chemical raw material demagnetization crushing device, and belongs to the field of chemical production equipment. The device comprises a box, a solid demagnetization chamber and a liquid demagnetization chamber; a sealing separation plate is vertically arranged in the center in the box, and is fixedly connected with the inner wall of the box; a first demagnetization plate is low in left end and high in right end; an unloading port is formed in the left end of the first demagnetization plate; the liquid demagnetization chamber is arranged in the box on the right side of the sealing separation plate; a liquid inlet hopper, a guide plate, a magnet rod, a cylinder, a guide rod, an inclined baseplate and a liquid discharge pipe are arranged inthe liquid demagnetization chamber; the liquid inlet hopper is arranged in the center of the top end of the liquid demagnetization chamber, and is fixedly connected with the box; the magnet rod is sleeved with the cylinder; and the inclined baseplate is arranged at the bottom end of the liquid demagnetization chamber, and is high in left end and low in right end. The device is reasonable in structural design, circular in demagnetization and thorough in demagnetization, and can synchronously perform solid-liquid dual-purpose demagnetization to achieve high efficiency.

Owner:TIANJIN KECHUANG FUXIN TECH CONSULTING CO LTD

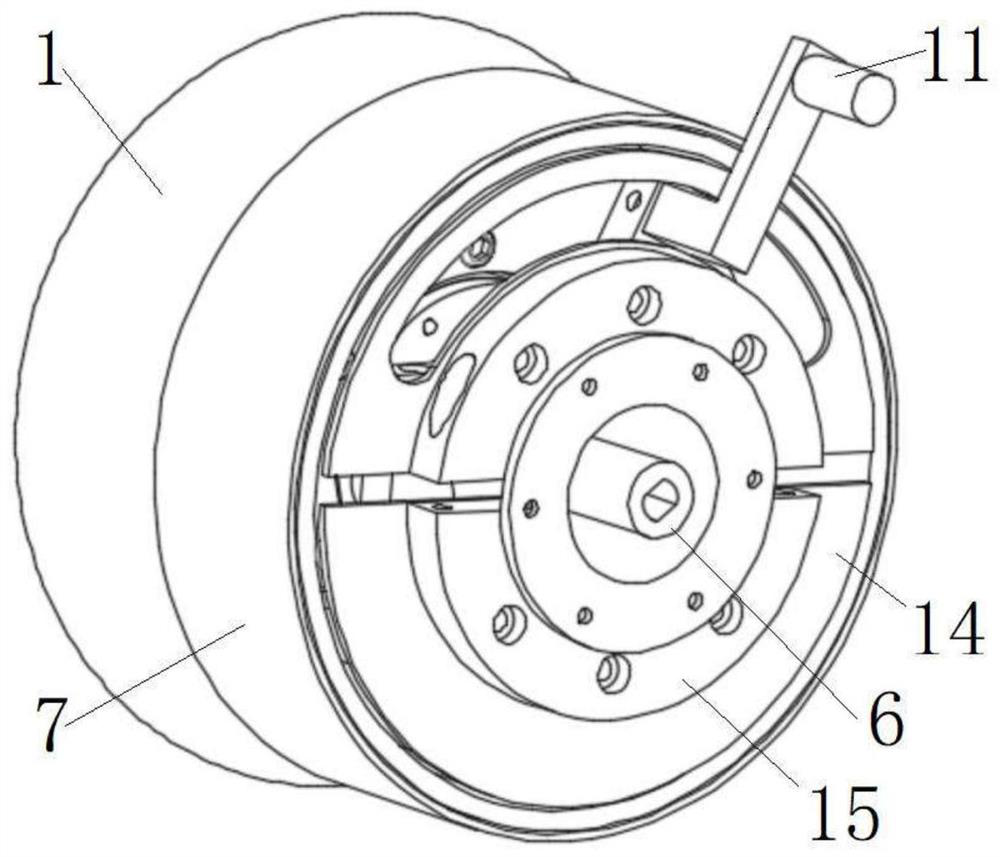

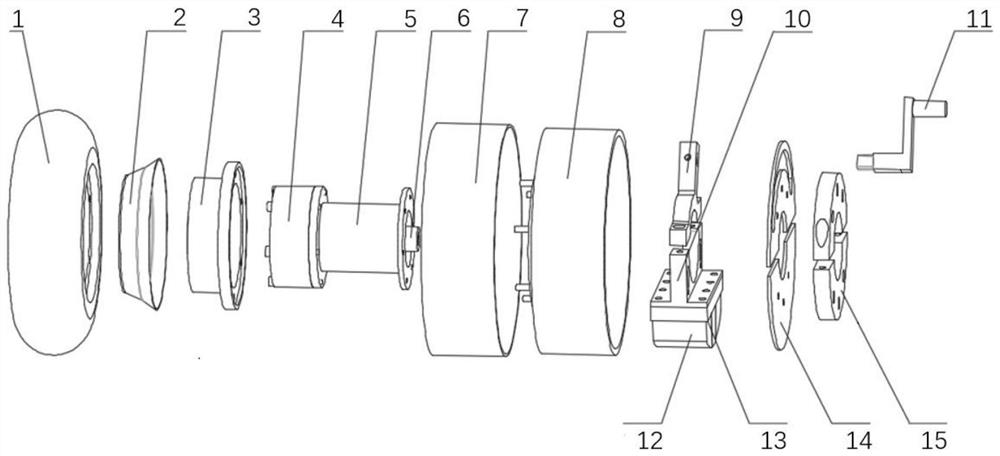

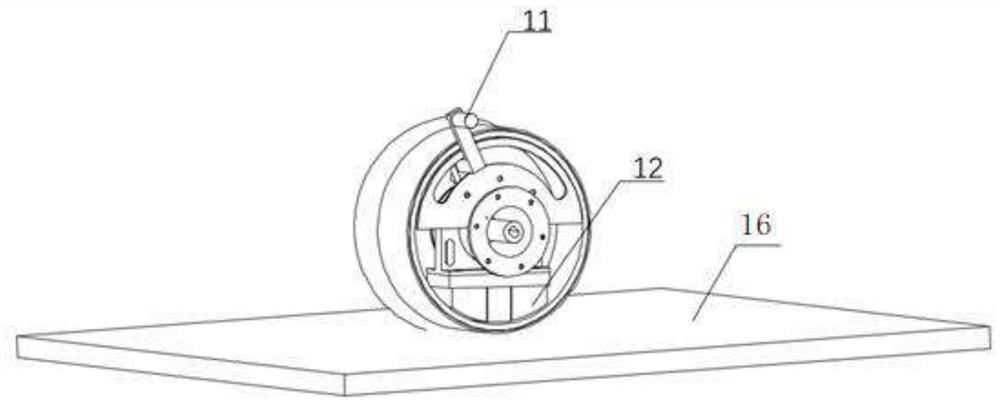

Permanent magnet adsorption wheel used for magnetic conductive wall surface and capable of realizing rapid magnet unloading

PendingCN113002653ALimit the amount of compressionIncrease contact areaInflatable tyresWheelsReduction driveElectric machinery

The invention discloses a permanent magnet adsorption wheel used for a magnetic conductive wall surface and capable of realizing rapid magnet unloading. A pneumatic tire is fixed outside a wheel hub, the wheel hub is fixedly connected with a harmonic reducer, the harmonic reducer is fixedly connected with a motor connecting shaft, the motor connecting shaft is sleeved with a bearing sleeve, and the bearing sleeve is sleeved with a synchronous pulley; the magnet fixing part and the magnet connecting plate are fixedly connected through a long screw and arranged on the bearing sleeve in a sleeved mode, the magnet connecting plate is fixedly connected with the yoke, the magnet is directly attracted to the yoke, the magnet check ring and the magnet limiting part are sequentially arranged on the outer side of the magnet connecting plate and the outer side of the magnet fixing part in a sleeved mode, the bearing sleeve is installed on the synchronous belt wheel, and the synchronous belt is arranged on the synchronous belt wheel in a sleeved mode. The synchronous belt wheel is fixed to a wheel hub through a screw, the pneumatic tire is clamped in the wheel hub through inflation of the pneumatic tire, and one end of the magnet unloading handle is fixedly connected with the magnet fixing piece. The magnet module is good in performance, the magnetic force can be adjusted, magnet unloading is convenient, and the magnetic conduction wall face can be effectively protected.

Owner:彼合彼方机器人(天津)有限公司

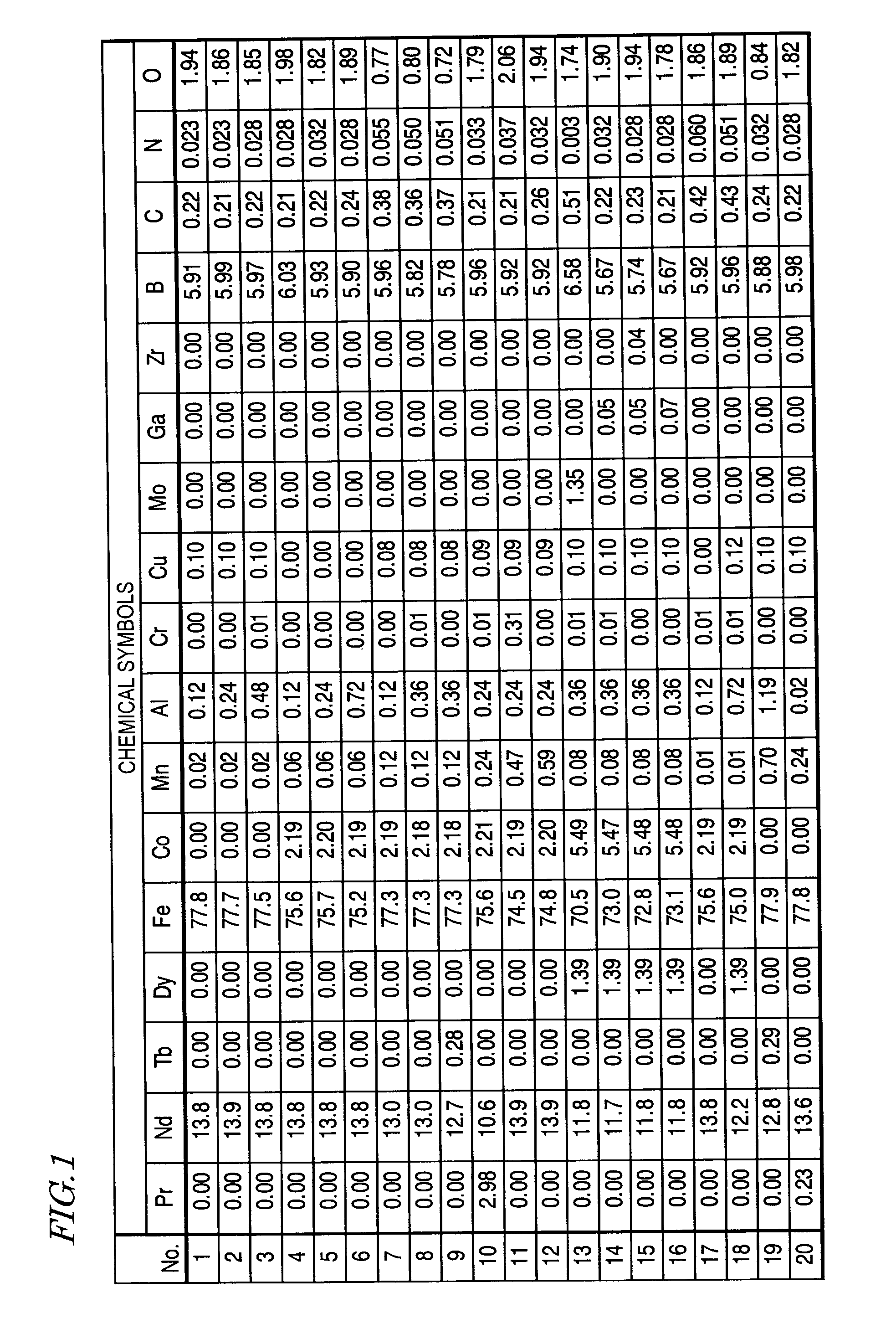

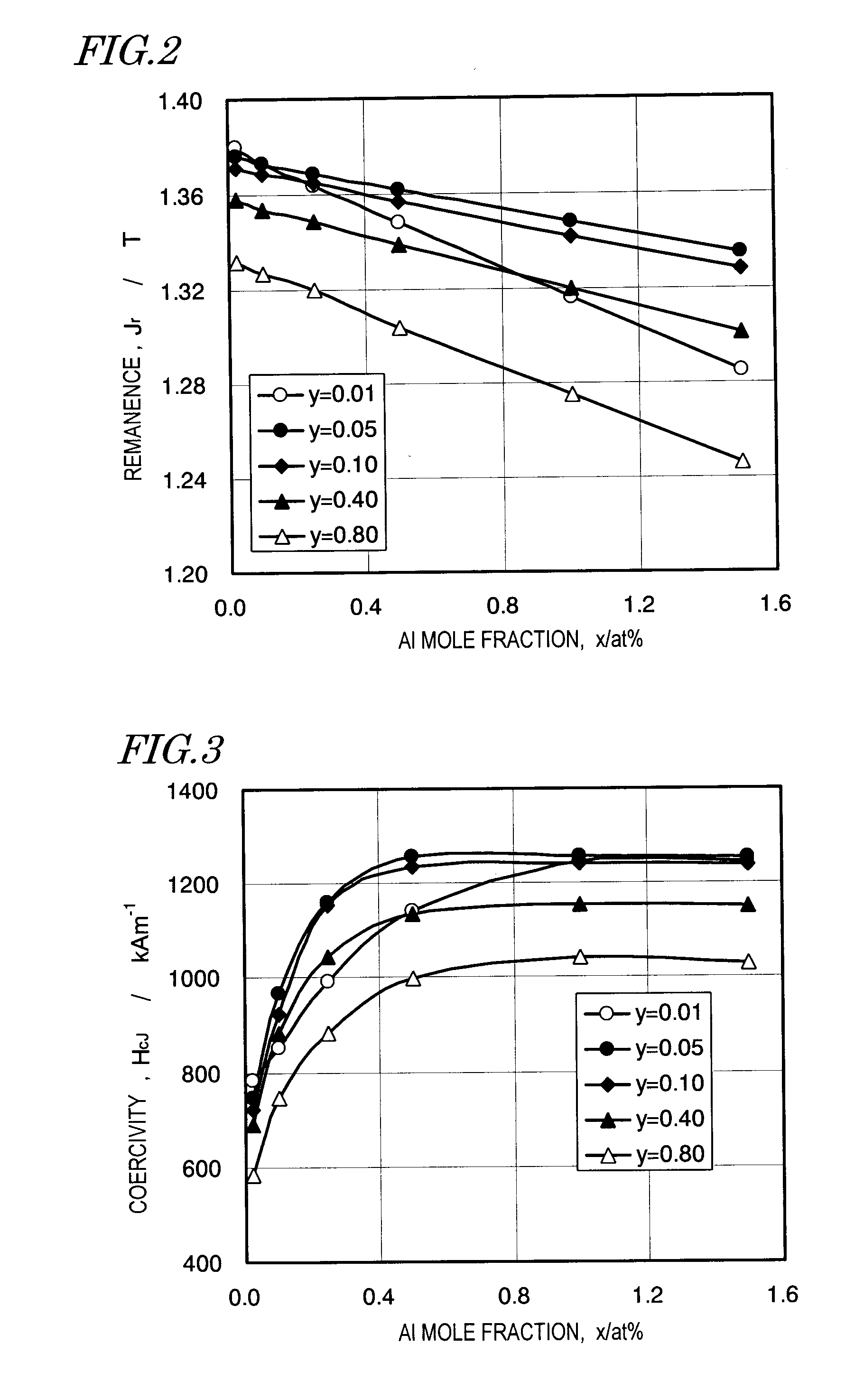

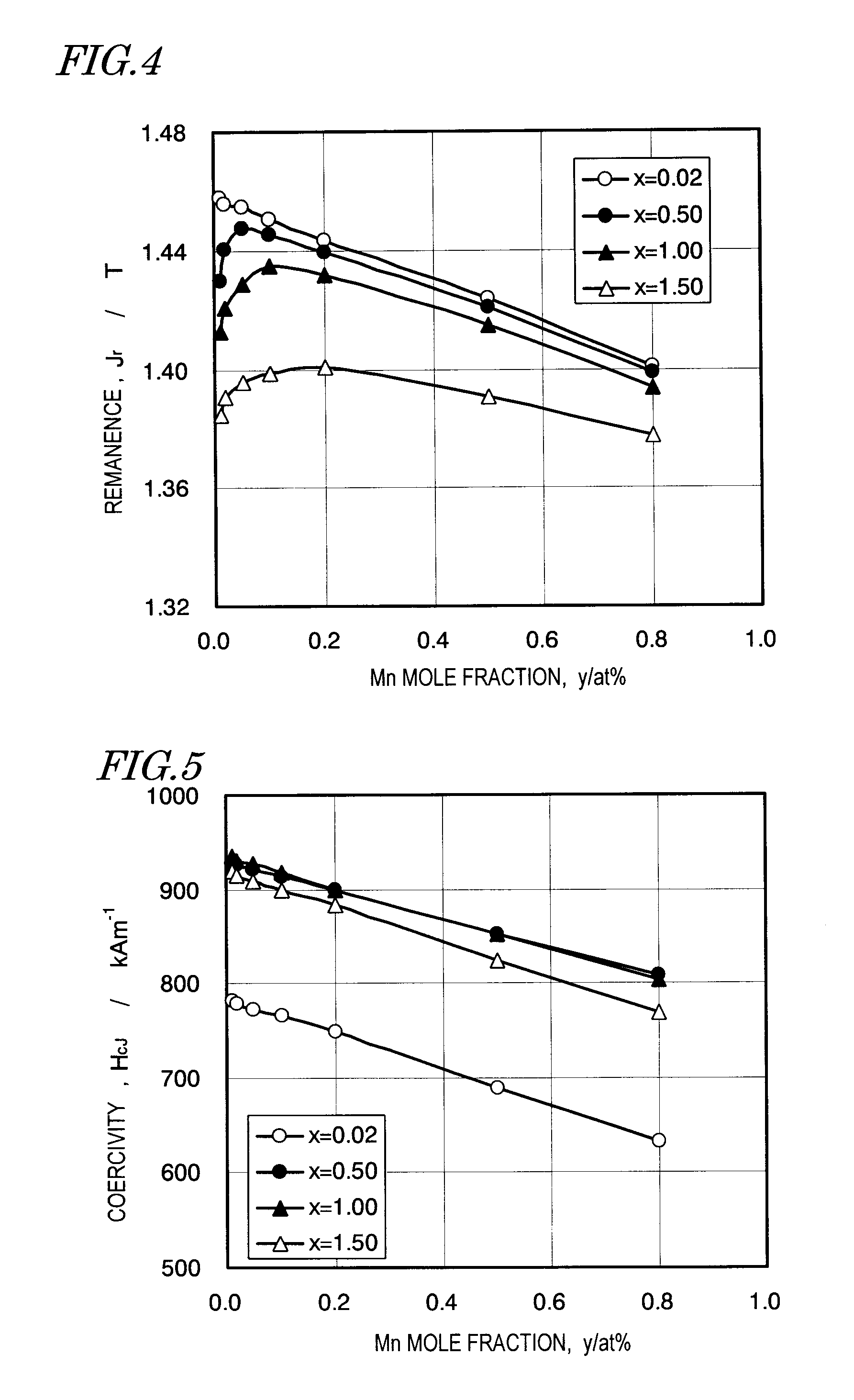

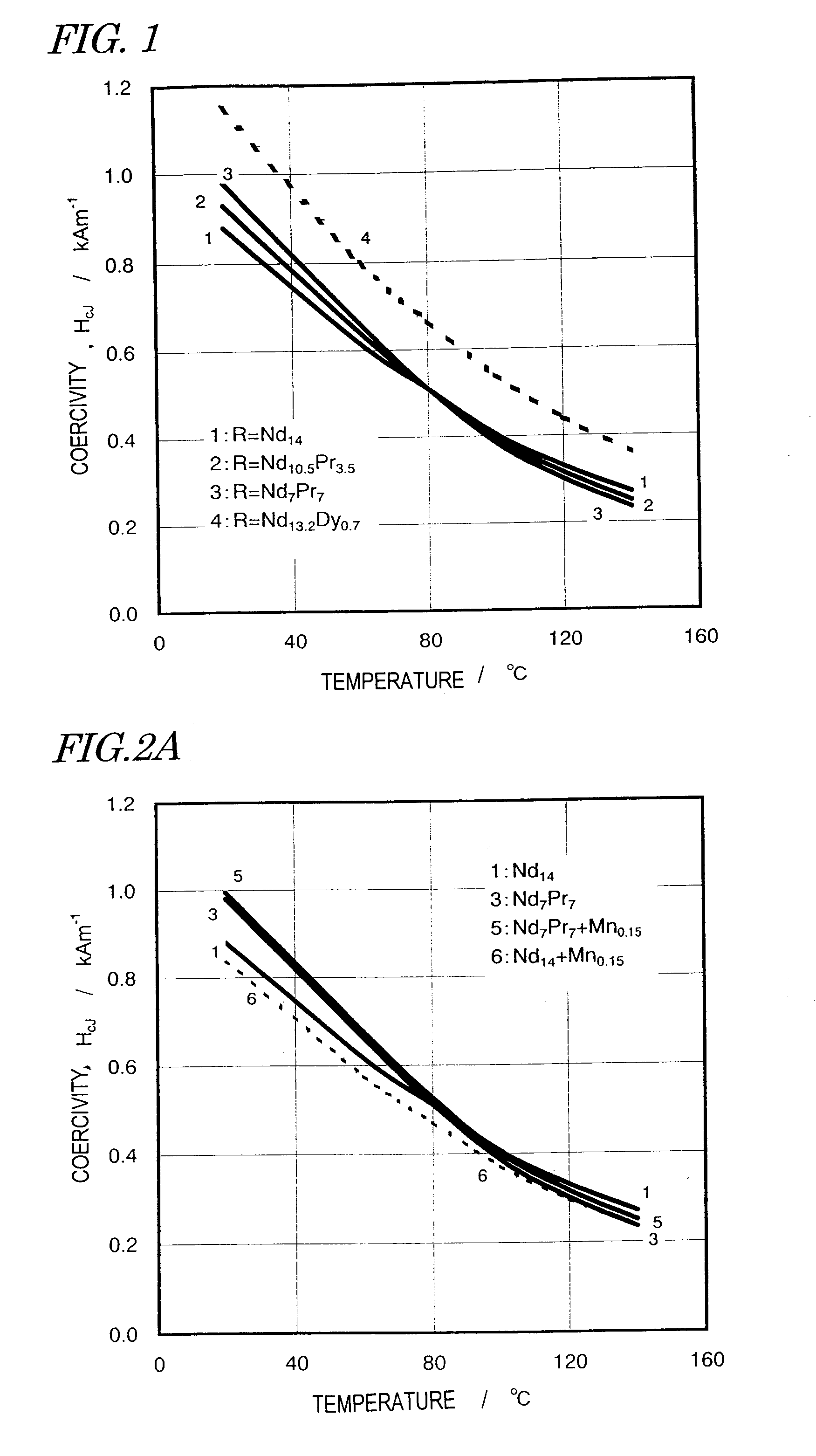

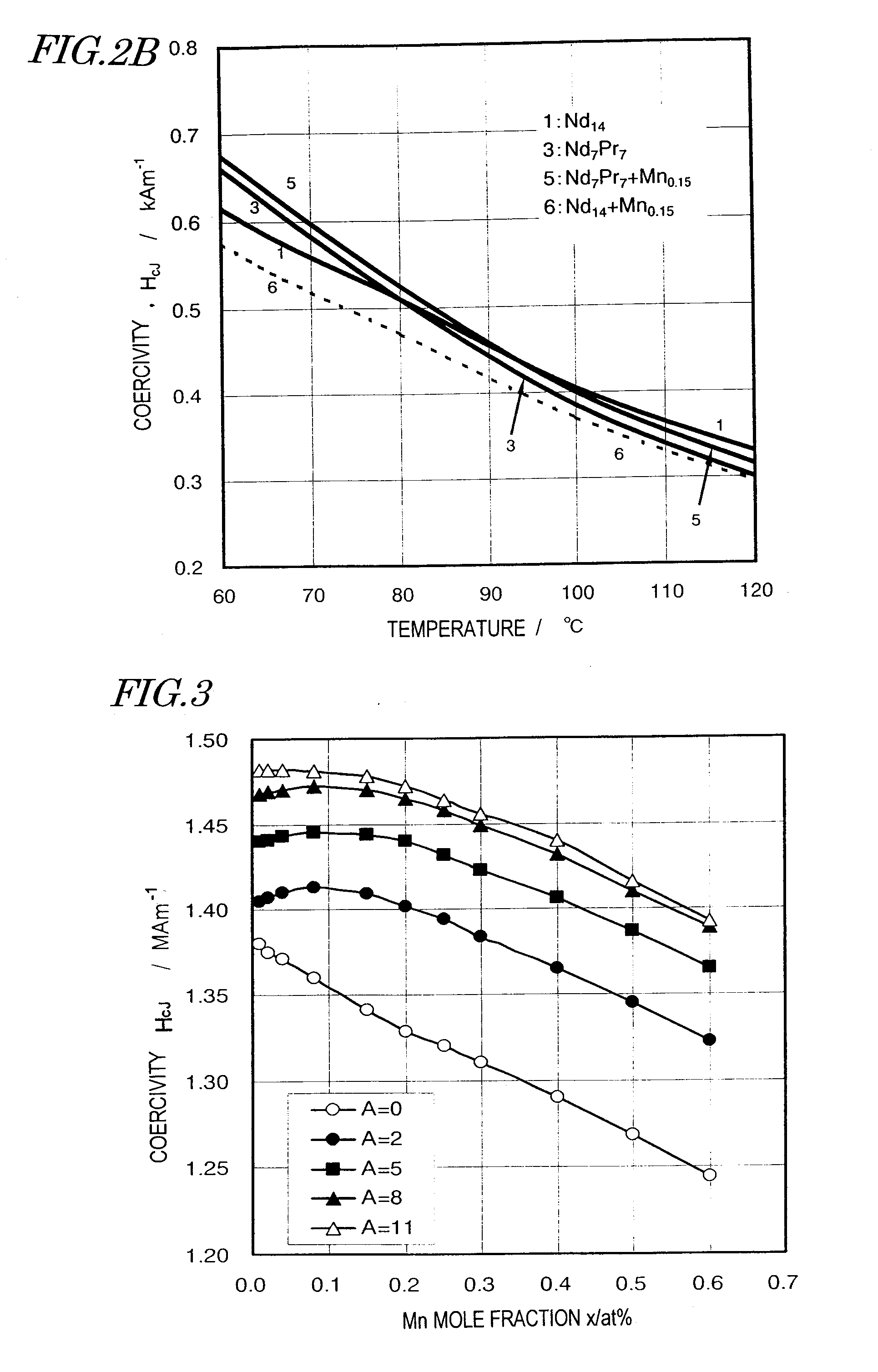

R-t-b based sintered magnet

ActiveUS20100003160A1Increase in coercivityDeterioration of magnetic propertyInorganic material magnetismRare-earth elementMetallurgy

An R-T-B based sintered magnet according to the present invention has a composition comprising: 12 at % to 15 at % of a rare-earth element R; 5.0 at % to 8.0 at % of boron B; 0.1 at % to at % of Al; 0.02 at % to less than 0.2 at % of Mn; and a transition metal T as the balance. The rare-earth element R is at least one element selected from the rare-earth elements, including Y (yttrium), and includes at least one of Nd and Pr. The transition element T includes Fe as its main element.

Owner:HITACHI METALS LTD

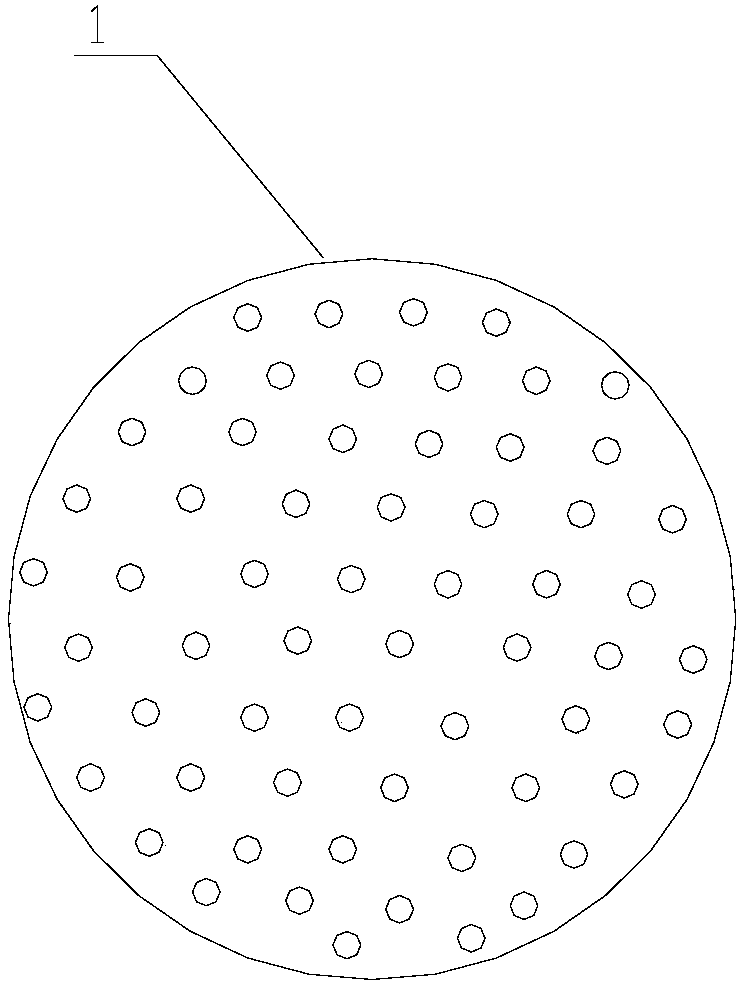

Cleaning ball and washing machine

InactiveCN108568437AReduce wearReduce noise pollutionHollow article cleaningOther washing machinesWater infusionFree state

The invention belongs to the technical field of the decontamination device and washing machine, and particularly relates to a cleaning ball and washing machine. The cleaning ball comprises a magneticmaterial, and the cleaning ball can be attracted by a magnetic field and demagnetize when the magnetic field disappears. The cleaning ball can be relatively stably collected in the drain valve deviceused in the laundry dehydration process, so as to avoid the cleaning ball bounce back between the inner and outer barrels, and the noise that occurs frequently between the inner and outer barrel wallsduring the dehydration process can be avoided because the cleaning ball is bounced back into the inner and outer barrels; after the dehydration is completed, the cleaning ball returns to the free state, and returns to the inner and outer barrels of the washing machine with the water infusion process, and continues to clean the inner and outer barrels. The cleaning ball not only extends the service life of cleaning ball, but also improves the cleaning effect of the inner and outer barrels of the washing machine, and the noise is low, which improves the user experience.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

R-t-b based sintered magnet

ActiveUS20100008814A1Improve coercive forceImprove responseMagnetic materialsRare-earth elementMetallurgy

An R-T-B based sintered magnet according to the present invention comprises: 12 at % to 15 at % of a rare-earth element R; at % to 8.0 at % of boron B; 0.02 at % to 0.2 at % of Mn; and a transition metal T as the balance. The rare-earth element R is at least one element selected from the rare-earth elements, including Y (yttrium), and includes 0.2 at % to 8 at % of Pr. And the transition element T includes Fe as its main element.

Owner:HITACHI METALS LTD

A stirring bar to prevent contamination

The invention provides a stirring bar for preventing pollution. The stirring bar is composed of a stirring bar core and an outer covering layer. Among them, the stirrer core is made of soft magnetic material, and the outer cladding layer is made of polymer or glass material. The stirrer core and the outer covering material are prepared by hot melting, molding and thermoforming. The soft magnetic material used in the stirrer core is easy to magnetize and demagnetize. The stirrer rotates and stirs under the magnetic field of the magnetic stirrer. When the stirring is stopped and the magnetic field is left, all or most of the magnetism obtained will disappear, thus avoiding There are magnetic impurities such as iron, nickel, cobalt and their alloys adsorbed on the surface of the stirrer during storage and use to pollute chemical synthesis, biological experiments, pharmaceutical separation and purification, and material and substance analysis processes.

Owner:MINJIANG UNIV

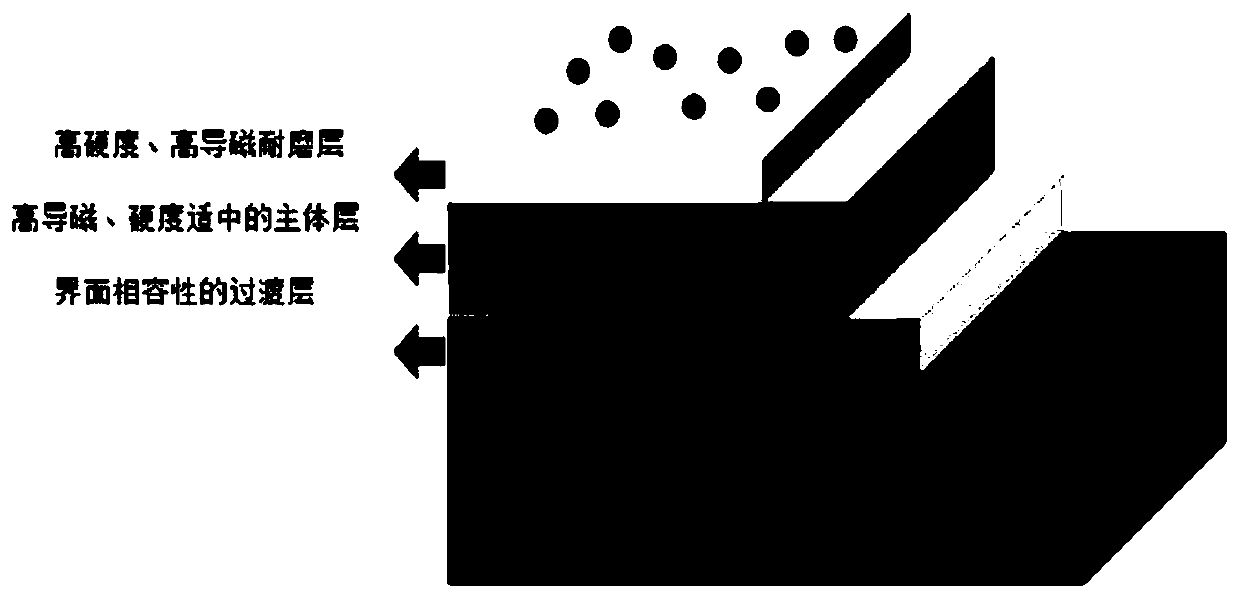

Titanium alloy surface high-magnetic-conductivity wear-resistant coating material for magnetic fluid sealing, preparation method thereof and application thereof

ActiveCN111593344AHigh hardnessImprove magnetic permeabilityEngine sealsTransportation and packagingConductive coatingHigh wear resistance

The invention belongs to the technical field of surface protection and magnetic conductive coatings, and discloses a titanium alloy surface high-magnetic-conductivity wear-resistant coating material for magnetic fluid sealing, a preparation method of the titanium alloy surface high-magnetic-conductivity wear-resistant coating material and application of the titanium alloy surface high-magnetic-conductivity wear-resistant coating material. The titanium alloy surface high-magnetic-conductivity wear-resistant coating material sequentially comprises a wear-resistant layer, a body layer and a transition layer. The transition layer is located between a substrate and the body layer. The transition layer comprises 85%-97% of iron-cobalt-vanadium alloy, 1%-5% of Si and 1%-5% of B. The body layer comprises 85-95% of iron-cobalt-vanadium alloy, 2%-5% of Si, 2%-5% of B and 1%-5% of WC. The wear-resistant layer comprises 70%-80% of iron-cobalt-vanadium alloy, 1%-5% of Si, 1%-5% of B and 10%-20% ofWC. The coating material integrates multiple functions of the high hardness, the high wear resistance and the high magnetic conductivity. A laser cladding method is adopted to manufacture the coatingmaterial, and the coating material can serve as a titanium alloy part of a magnetic fluid sealing system to be applied to the field of aerospace.

Owner:GUANGDONG UNIV OF TECH +1

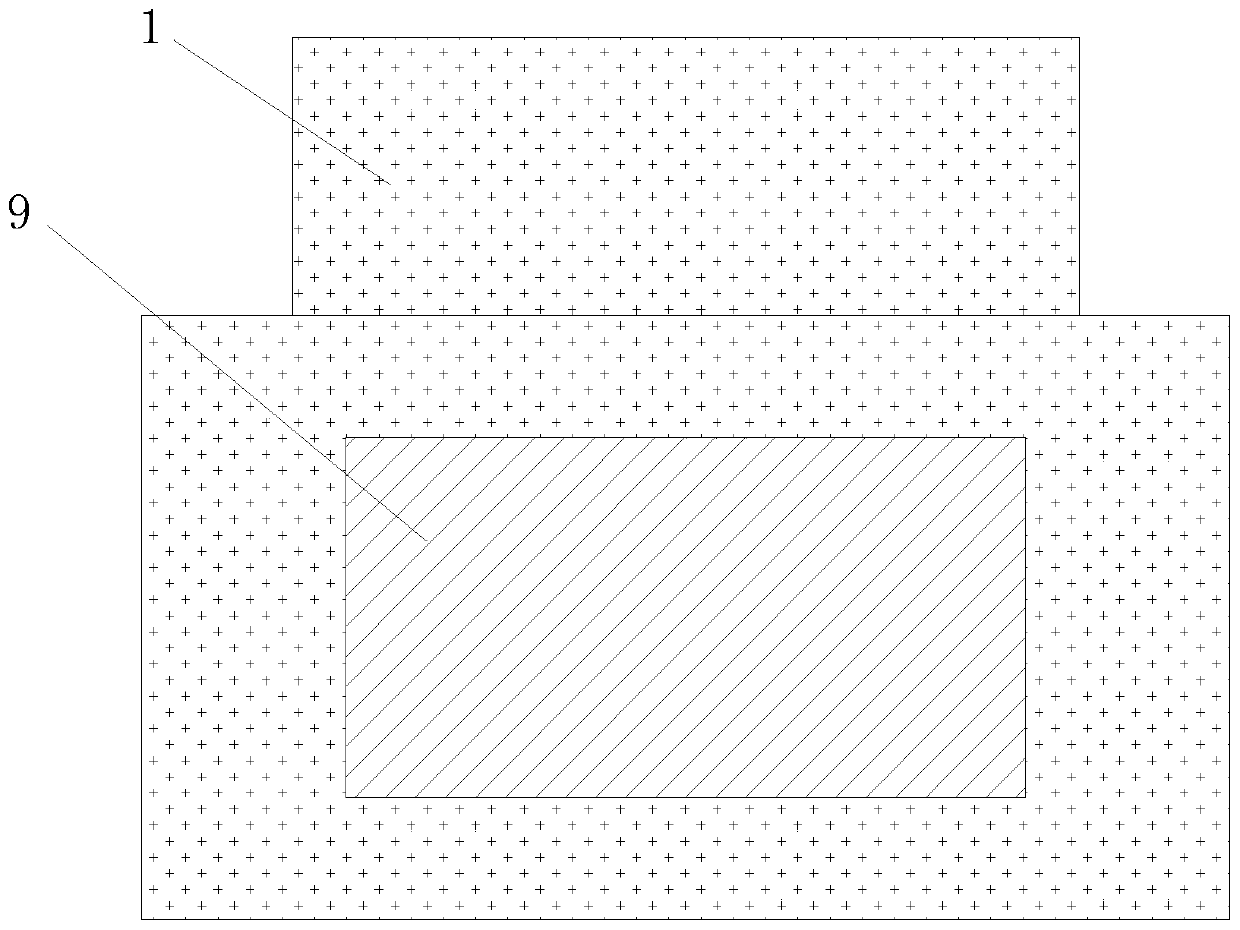

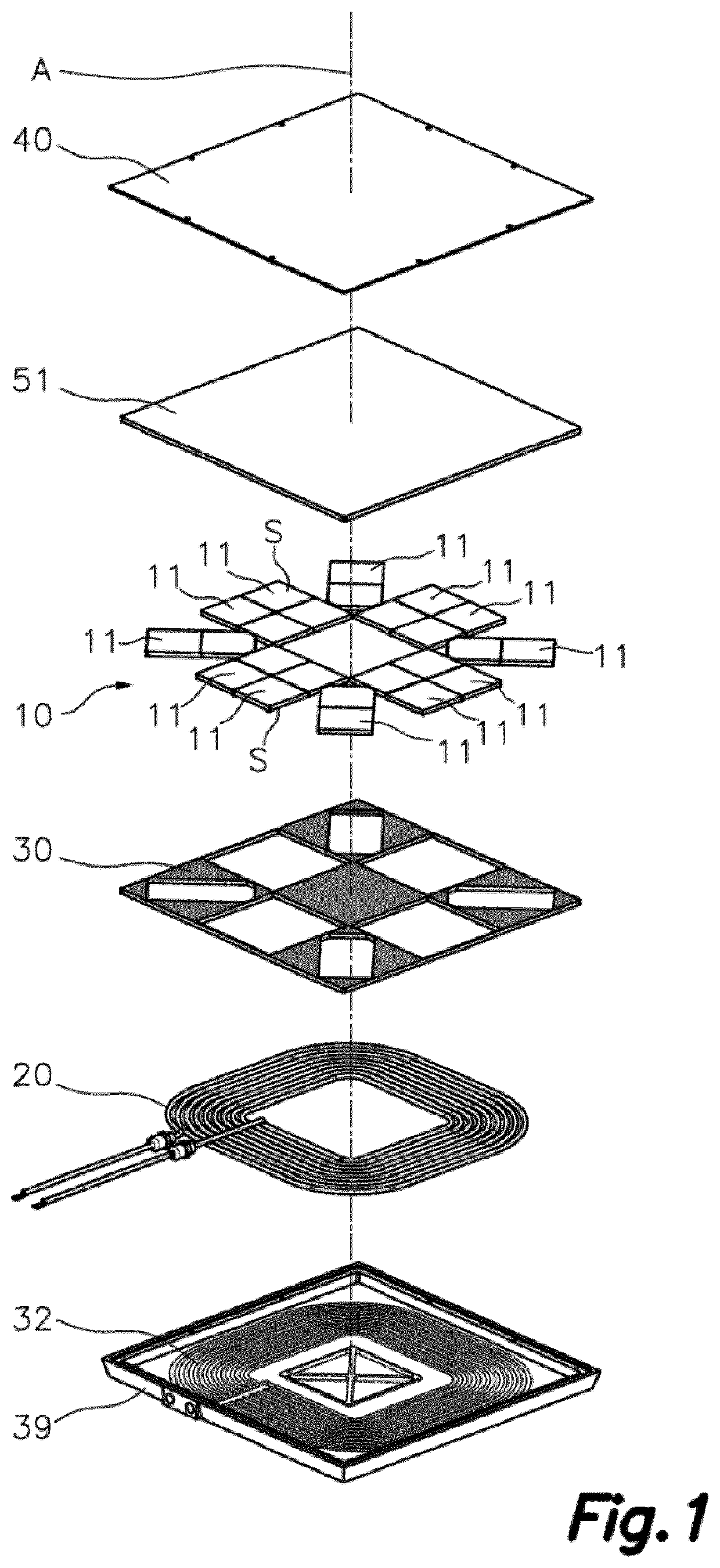

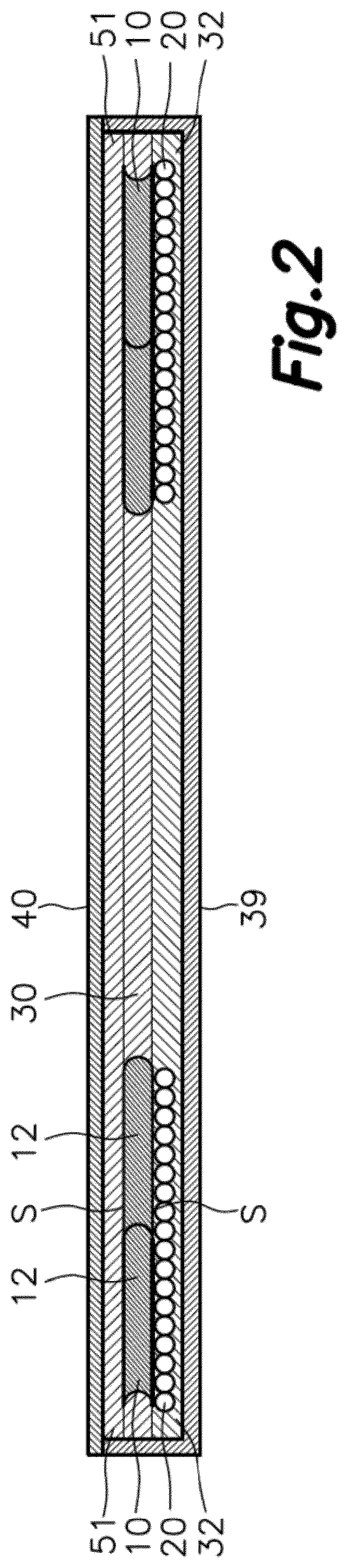

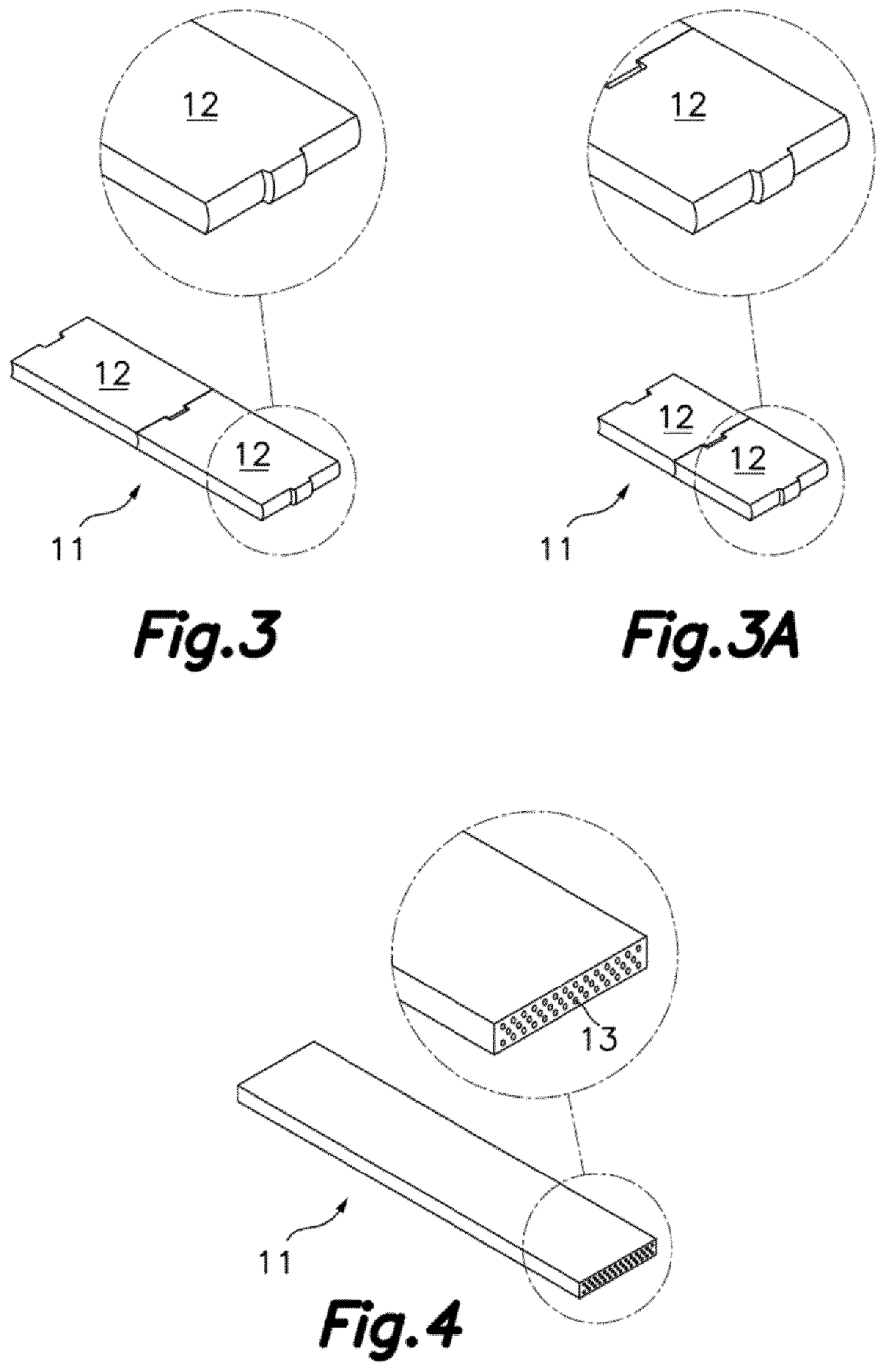

Inductive energy emitter/receiver for an inductive charger of an electric vehicle

PendingUS20210193382A1Enhance and/or channel the flux produced by the conductive coilEasy to demagnetizeCharging stationsTransformersEngineeringInductor

Inductive energy emitter / receiver including a planar-shaped magnetic core with two opposed main surfaces is provided having at least one conductive coil wound around an axis perpendicular to the main surfaces of the planar-shaped magnetic core, the conductive coil being overlapped to one of the main surfaces of the magnetic core; an inductor casing being attached to the planar-shaped magnetic core and at least one conductive coil. The inductor casing is at least partially made of flexible polymer bonded soft magnetic material, and the planar-shaped magnetic core is a made of a plurality of flexible elongated partial cores, forming a flexible planar-shaped magnetic core.

Owner:PREMO

Air conditioner or compressor for refrigerator driven by permanent magnet synchronous motor

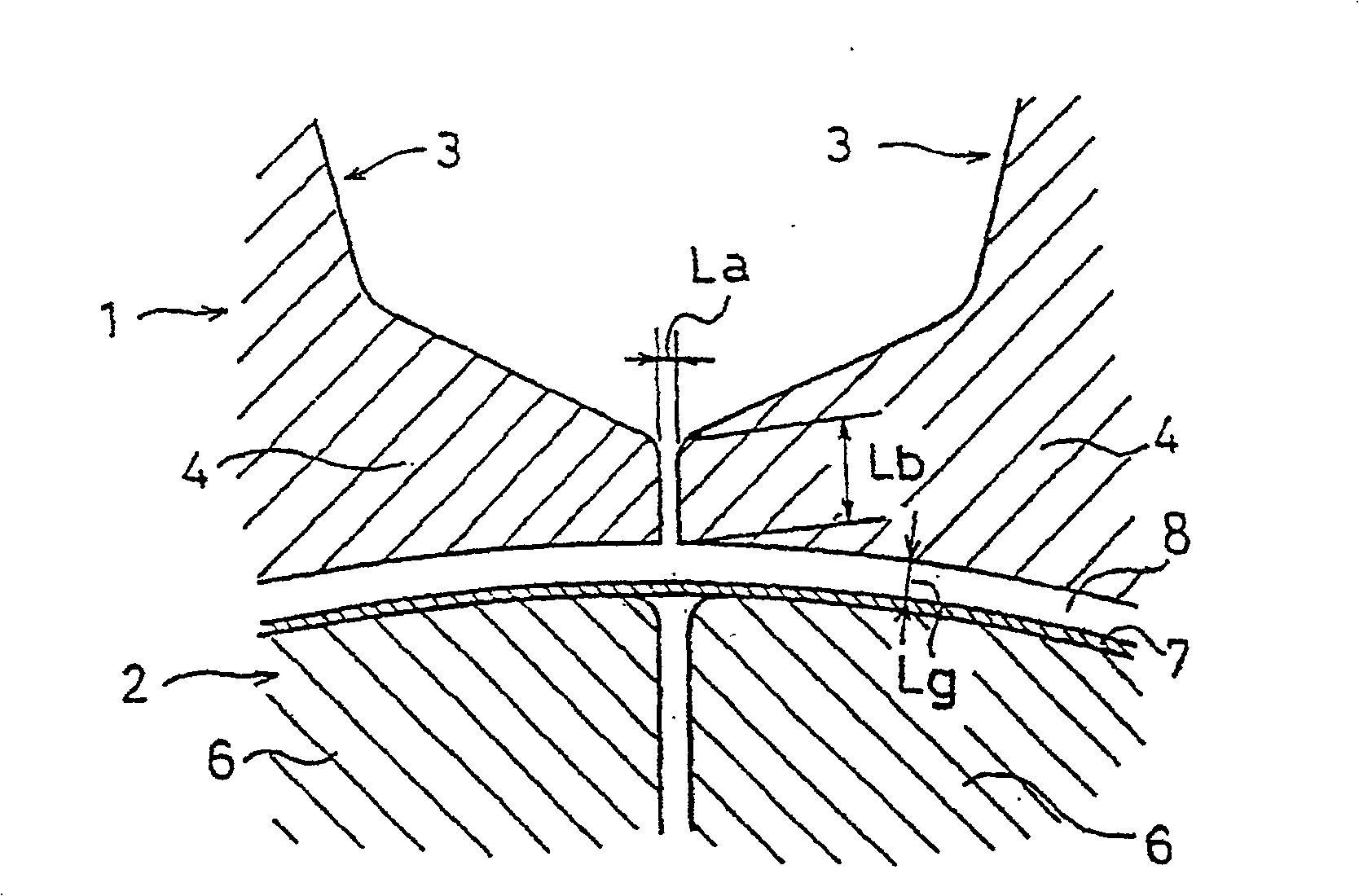

InactiveCN100541986CImprove resistance to demagnetizationIncreased leakage fluxMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet synchronous motorPole piece

An air conditioner or a refrigerator compressor is driven by a permanent magnet synchronous motor with a stator of a concentrated winding mode, the interval between the pole pieces of the stator (1) is La, the stator (1) and the rotor (2 ) is Lg, so that 0.3Lg<La≤2.0Lg, or, assuming that the pole shoe end thickness of the permanent stator (1) is Lb, the air gap between the stator (1) and the rotor (2) is Lg , and make 2Lg<Lb<5Lg. In addition, the outer peripheries of both circumferential end portions of the permanent magnets (6) provided on the outer peripheral portion of the rotor (2) may be formed in a concave shape that is recessed radially inward from the outer periphery of the rotor. In this way, it is difficult for the demagnetization field to act on the permanent magnet (6), thereby improving the demagnetization resistance of the permanent magnet (6).

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com