Photoelectric liquid sensor and water pump with same

A fluid sensor and photoelectric technology, which is applied to the components, pump components, machines/engines, etc. of the pumping device for elastic fluids, can solve the problems of difficult maintenance and replacement, loss of water diversion, insufficient sensitivity, etc., and achieves stable chemical properties, Long service life and small diffraction range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

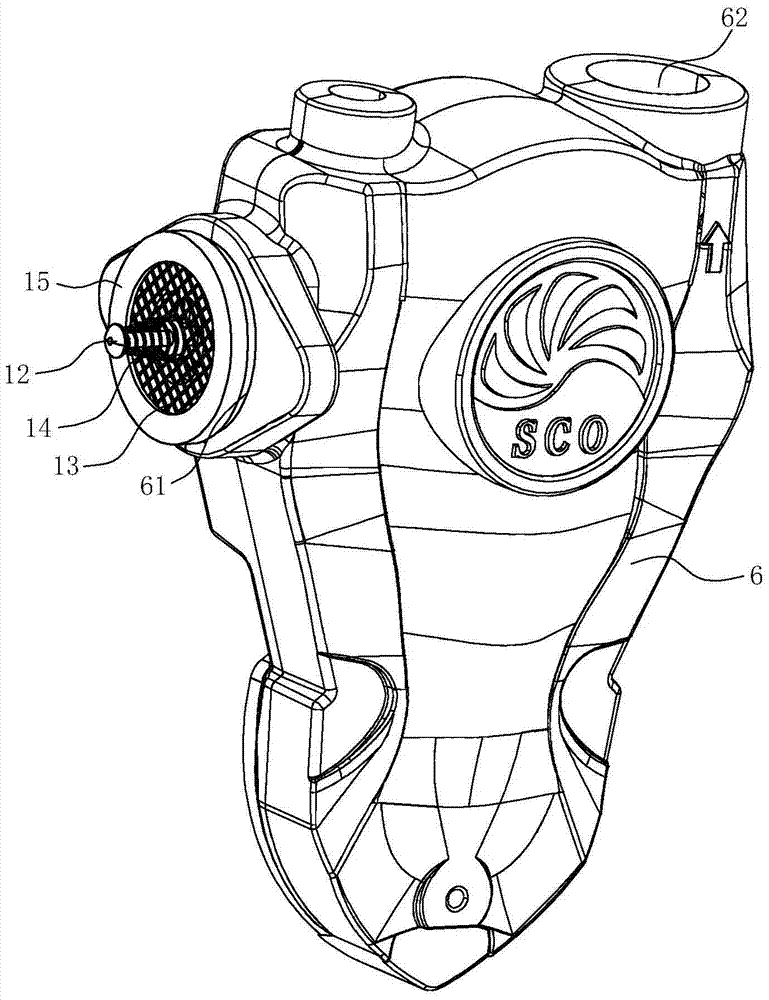

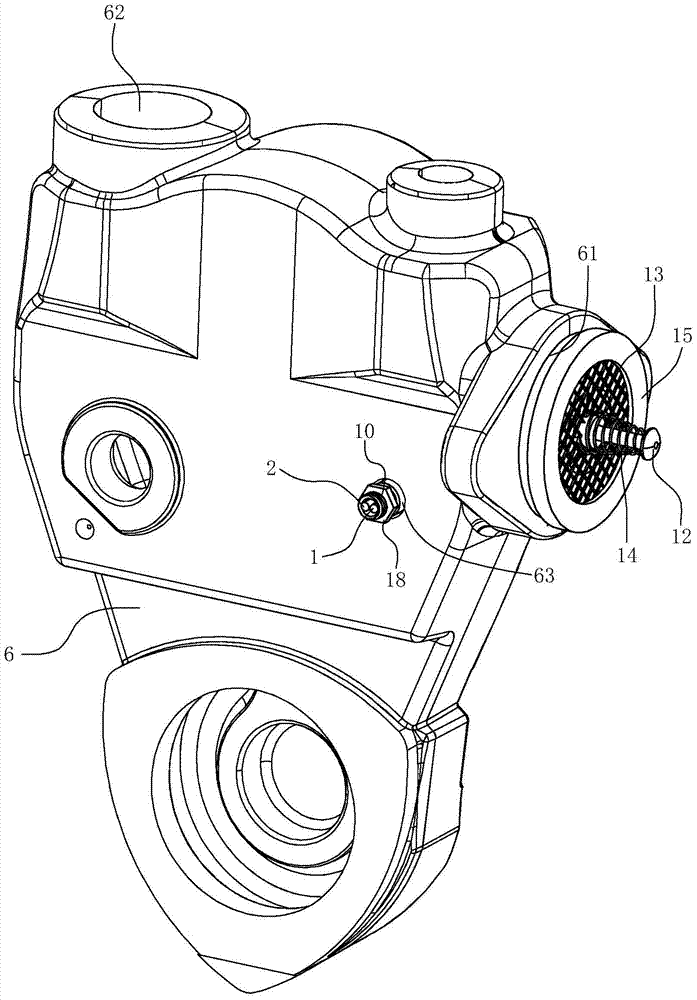

[0051] Such as figure 1 Shown is a preferred embodiment of the present invention.

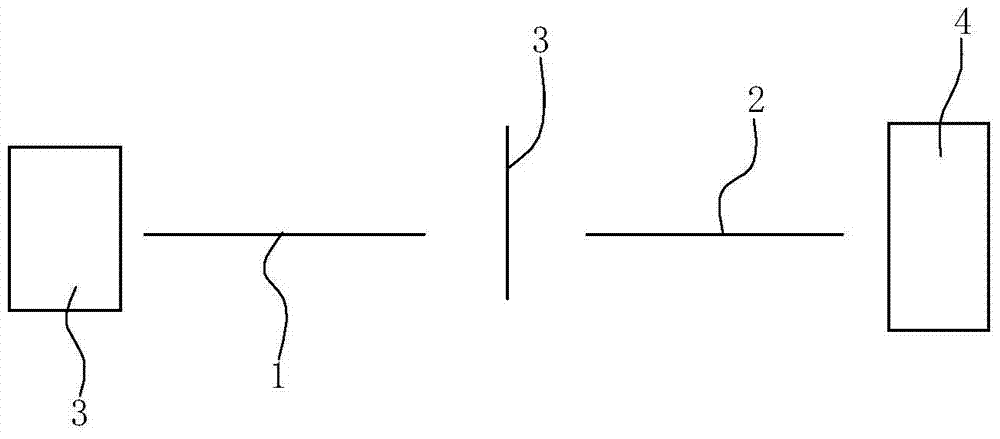

[0052] A photoelectric water flow sensor, including a sending optical fiber 1 and a receiving optical fiber 2 arranged at relative intervals on the left and right, the outer ends of the sending optical fiber 1 and the receiving optical fiber 2 are guided to the water body, and a photoelectric sensor is installed adjacent to the sending fiber 1 outside the water body. The light-emitting diode 3 of the sending fiber 1 is bright, the receiving fiber 2 can receive the light transmitted by the sending fiber 1 and transmit the received light to the photoelectric conversion module 4, and there is a moving part between the sending fiber 1 and the receiving fiber 2 under the action of water flow. The blocking member 5 determines whether it is blocked between the transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com