Cleaning ball and washing machine

A technology of cleaning balls and spheres, which is applied to other washing machines, cleaning hollow objects, cleaning methods and appliances, etc., and can solve the problems of being easily bounced back between the inner and outer barrels, shortening the service life of cleaning balls, and easily damaging the surface of cleaning balls, etc. , to achieve the effects of physical form or magnetic stability, prolonging the service life and improving the collision efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

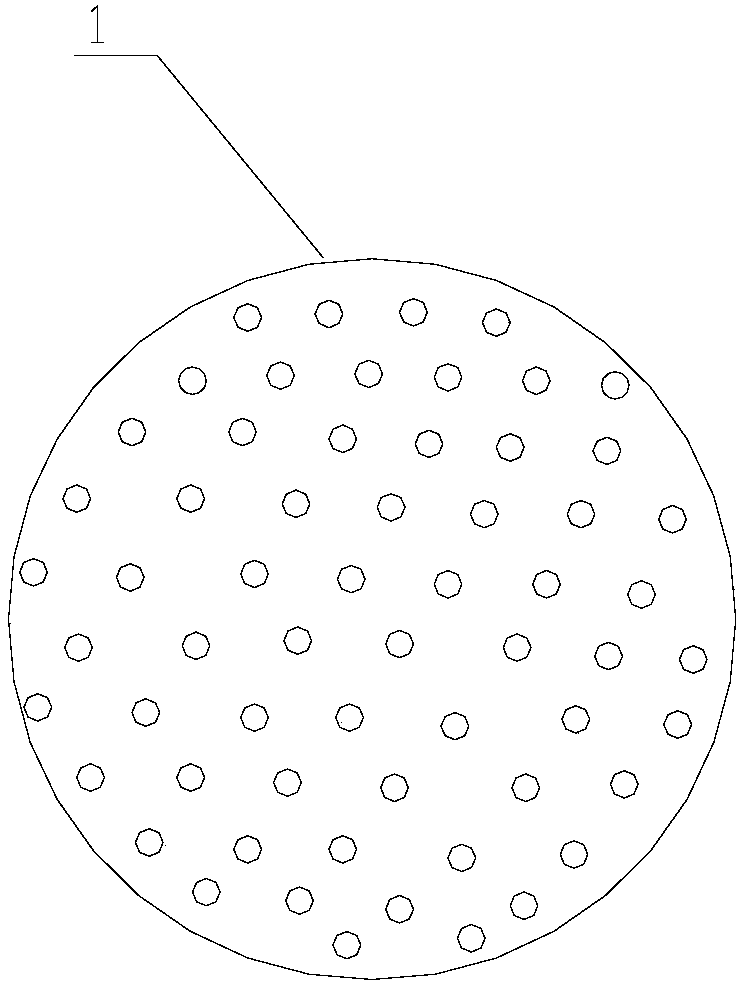

[0082] As attached figure 1 As shown, the cleaning ball 1 includes an outer rubber ball, and powder or granular magnetic materials are dispersed inside the rubber ball.

[0083] The distribution density of the magnetic material in different areas of the rubber sphere is the same or different. In order to improve the disorder of the movement of the cleaning ball 1, the magnetic material can be set to be different in different areas of the rubber ball to increase the probability of collision with different parts of the inner and outer tub walls of the washing machine, thereby further improving the cleaning effect of the cleaning ball 1.

[0084] The magnetic material is soft magnetic.

[0085] Soft magnetic materials are magnetic materials with low coercivity and high permeability. Soft magnetic materials are easy to magnetize and demagnetize, and are widely used in electrical and electronic equipment. The soft magnetic material can be iron-silicon alloy (silicon steel sheet) and var...

Embodiment 2

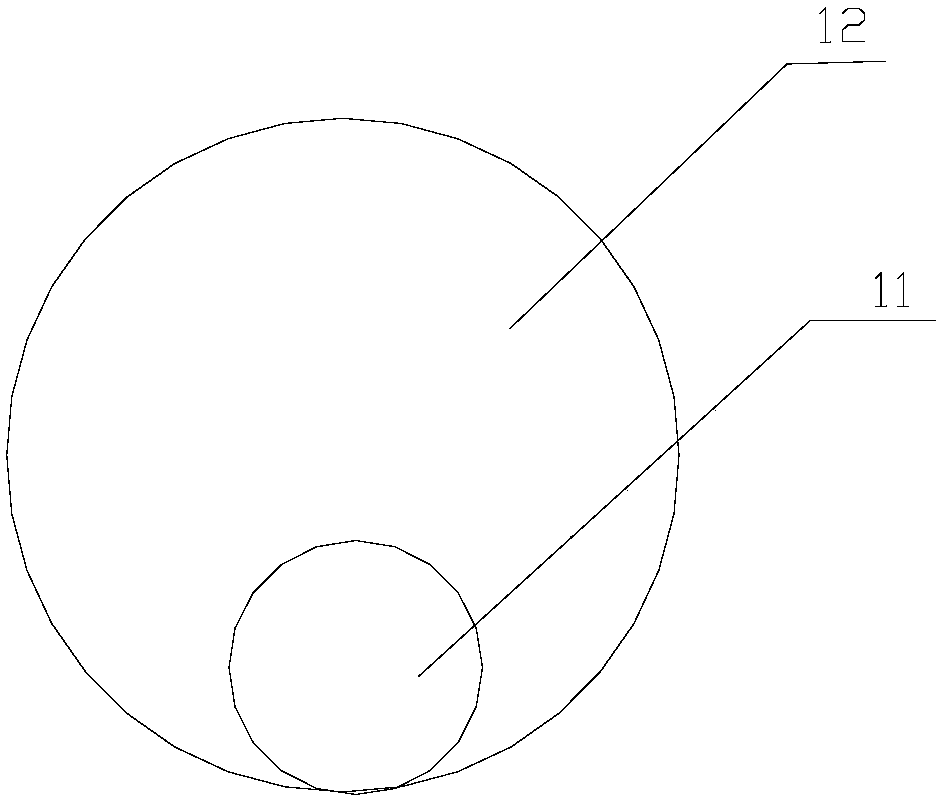

[0103] Such as figure 2 As shown, the cleaning ball includes an outer foamed rubber sphere 12, a magnetic sphere 11 built in the foamed rubber sphere 12, the center of the magnetic sphere 11 (that is, the center of the sphere) does not coincide with the center of the foamed rubber sphere 12, the magnetic sphere 11 is tangent to the foamed rubber ball 12.

[0104] The magnetic ball 11 is made of soft magnetic material.

[0105] The movement of the cleaning ball is more disorderly, the collision efficiency between the cleaning ball and the outer wall of the inner barrel and the inner wall of the outer barrel is improved, the cleaning effect can be significantly improved, and the time-consuming is shorter. And when the sphere or regular polyhedron is tangent to the rubber sphere, the cleaning ball is more likely to be attracted to the collection bin of the drain valve by the magnetic field during the dehydration process of the washing machine, and the adsorption is stronger, further ...

Embodiment 3

[0123] The difference between this embodiment and the second embodiment is:

[0124] The center of the foamed rubber sphere 12 coincides with the center of the magnetic sphere 11, and the radii of the magnetic sphere 11 and the foamed rubber sphere 12 are equal. The outside of the foamed rubber sphere 12 is coated with a magnetic material film layer, and the foamed rubber sphere 12 In different areas outside, the density of the magnetic material film layer is different, and the surface of the cleaning ball has multiple areas with different roughness.

[0125] Due to the different roughness, the same cleaning ball can clean a variety of stubborn dirt, and the cleaning effect is better. In addition, the amount of cleaning ball can also be reduced.

[0126] Another important object is to provide a washing machine having any one of the cleaning balls described above and a drain valve device capable of attracting and collecting the cleaning balls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com