Air conditioner or compressor for refrigerator driven by permanent magnet synchronous motor

A permanent magnet synchronous and refrigerator technology, applied to synchronous motors with static armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit static parts, etc., can solve the problem of being susceptible to demagnetization and low winding efficiency , the complex winding process and other problems, to reduce costs, improve productivity, improve the effect of anti-demagnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

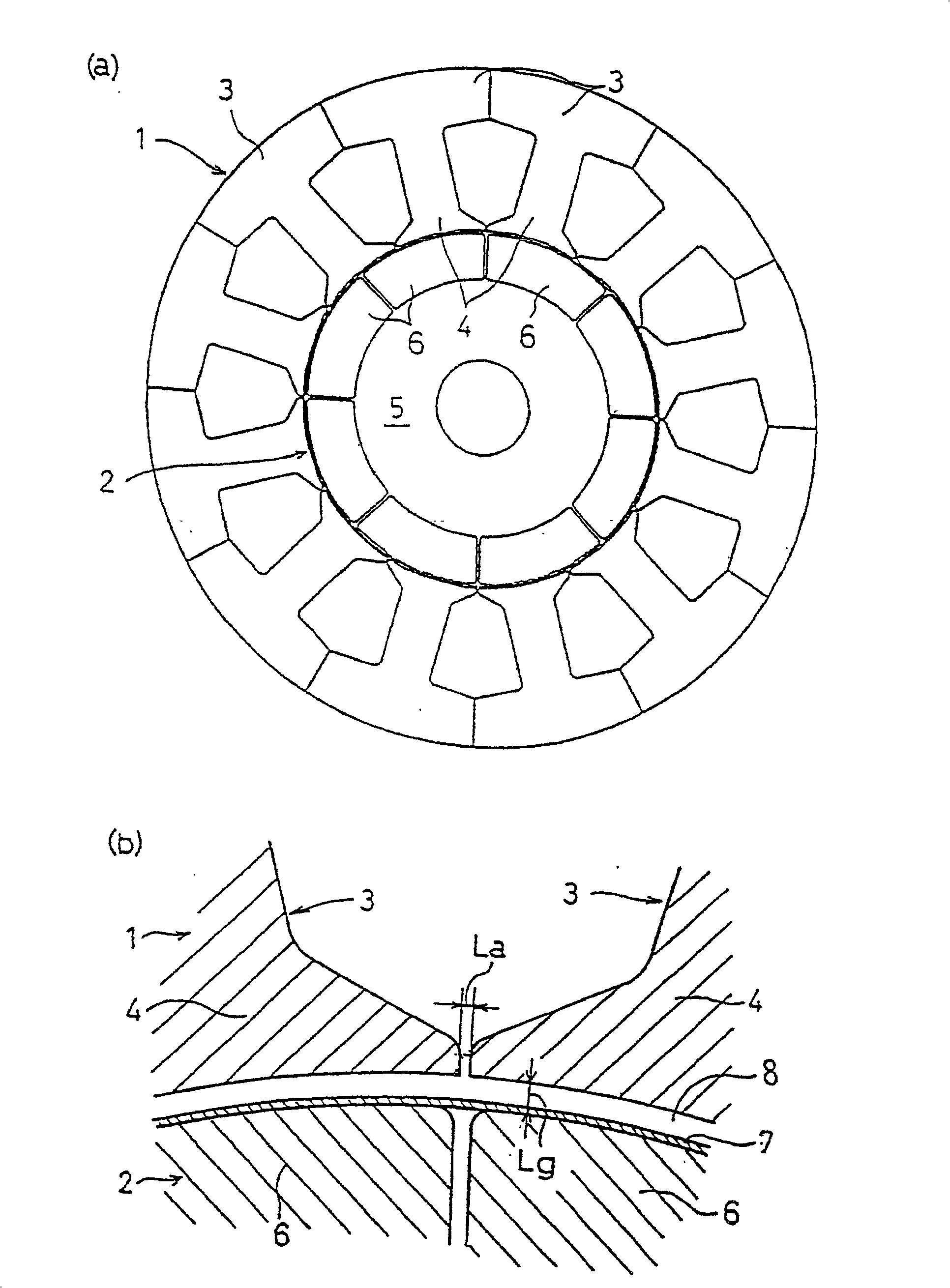

[0038] Refer to the following figure 1 , figure 2 , to illustrate Embodiment 1 of a permanent magnet synchronous motor, which is a motor for driving a compressor for an air conditioner or a refrigerator of the present invention.

[0039] exist figure 1Among them, 1 is the stator, and 2 is the rotor. The stator 1 is composed of split iron cores 3 corresponding to the number of slots, and windings (not shown) are independently wound on the pole shoes 4 of each split iron core 3, and the concentrated winding method is adopted. . The rotor 2 is formed by fixing a permanent magnet 6 composed of a plurality of ferrite magnets to the outer periphery of a rotor core 5 formed by laminating silicon steel sheets, and a rotating shaft (not shown) penetrating and fixed to the axial center is supported by a bearing. Can be turned freely. The outer circumference of the rotor 2 is covered with a thin plate cylinder 7 made of stainless steel, or a reinforcing belt is wound to ensure the...

Embodiment 2

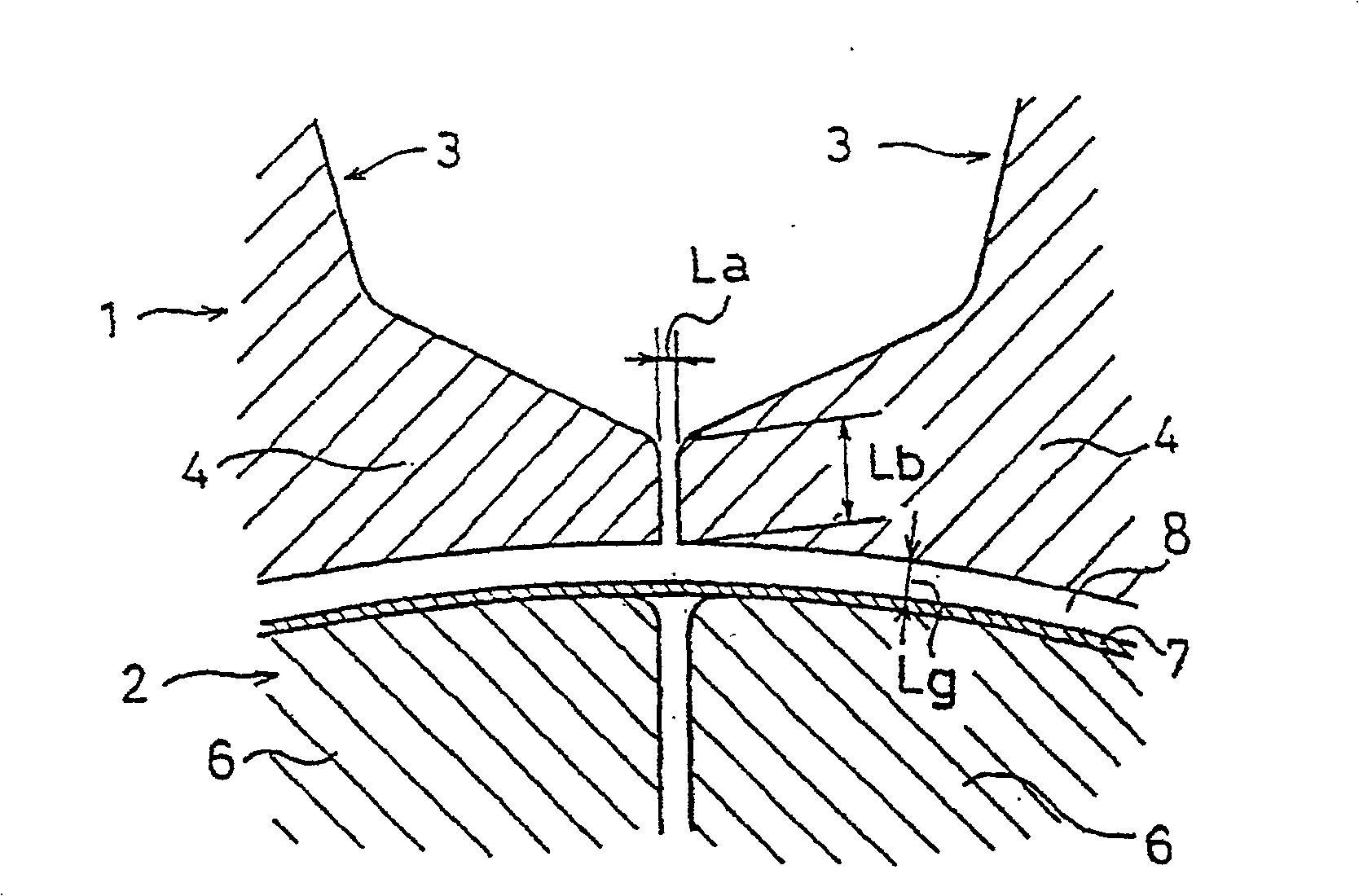

[0045] Then refer to image 3 , Figure 4 , to describe Embodiment 2 of the permanent magnet synchronous motor for driving the compressor of the present invention. In addition, the description of the same constituent elements as those of the first embodiment will be omitted, and only the points of difference will be described. The same applies to the following examples.

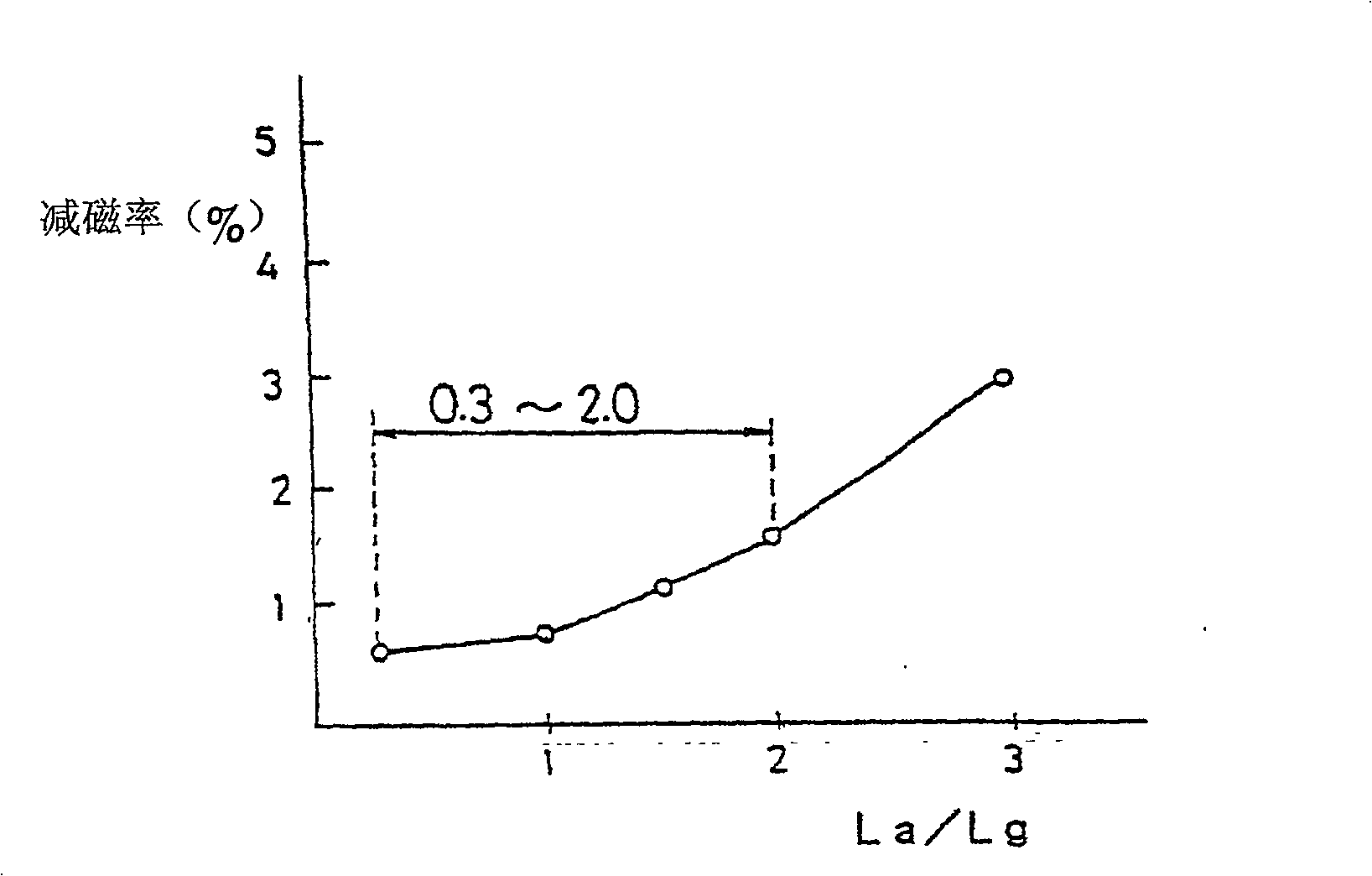

[0046] exist image 3 In the setting, the distance between the pole shoes 4 and 4 of the stator 1 is La, the end thickness of the pole shoes 4 of the stator 1 is Lb, and the size of the air gap 8 between the stator 1 and the rotor 2 is Lg, then it is set as 0.3Lg

[0047] In this way, since the thickness Lb of the end of the pole piece 4 of the stator 1 is larger than twice the air gap Lg between the stator 1 and the rotor 2 on the basis of the above-mentioned embodiment 1, the magnetic flux leakage can be further suppressed. By entering the rotor side, the ability to resist demagne...

Embodiment 3

[0051] Then refer to Figure 5 , Embodiment 3 of the permanent magnet synchronous motor for driving the compressor of the present invention will be described.

[0052] exist Figure 5 in the above image 3 On the basis of the structure of the shown embodiment 2, a cutout portion 9 (the end of the pole piece 4 and the rotor 2 is provided) on the side of the rotor 2 side at the opposite ends of the stator 1 adjacent to the pole pieces 4, 4. The interval between is represented by Lc).

[0053] The cutout portion 9 may be provided only at one end of the pole piece 4 of the stator 1 , that is, the end on the lower side in the rotation direction of the rotor 2 among the opposite ends of the adjacent pole pieces 4 , 4 .

[0054] By providing the cutout portion 9 in this way, the air gap at the end of the pole piece 4 can be enlarged, and the demagnetizing flux can be restrained from entering the rotor side, so that the same effect can be obtained.

[0055] Furthermore, in this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com