Patents

Literature

145results about How to "Increase the air gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

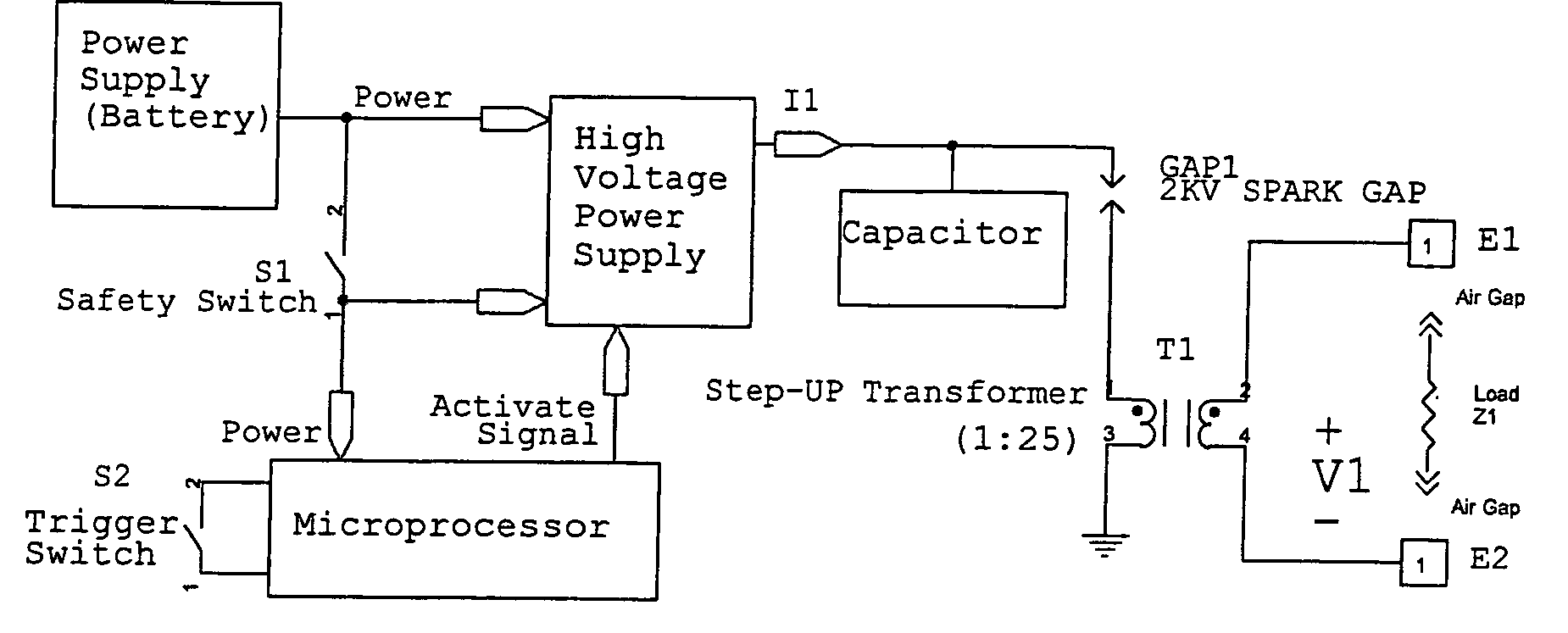

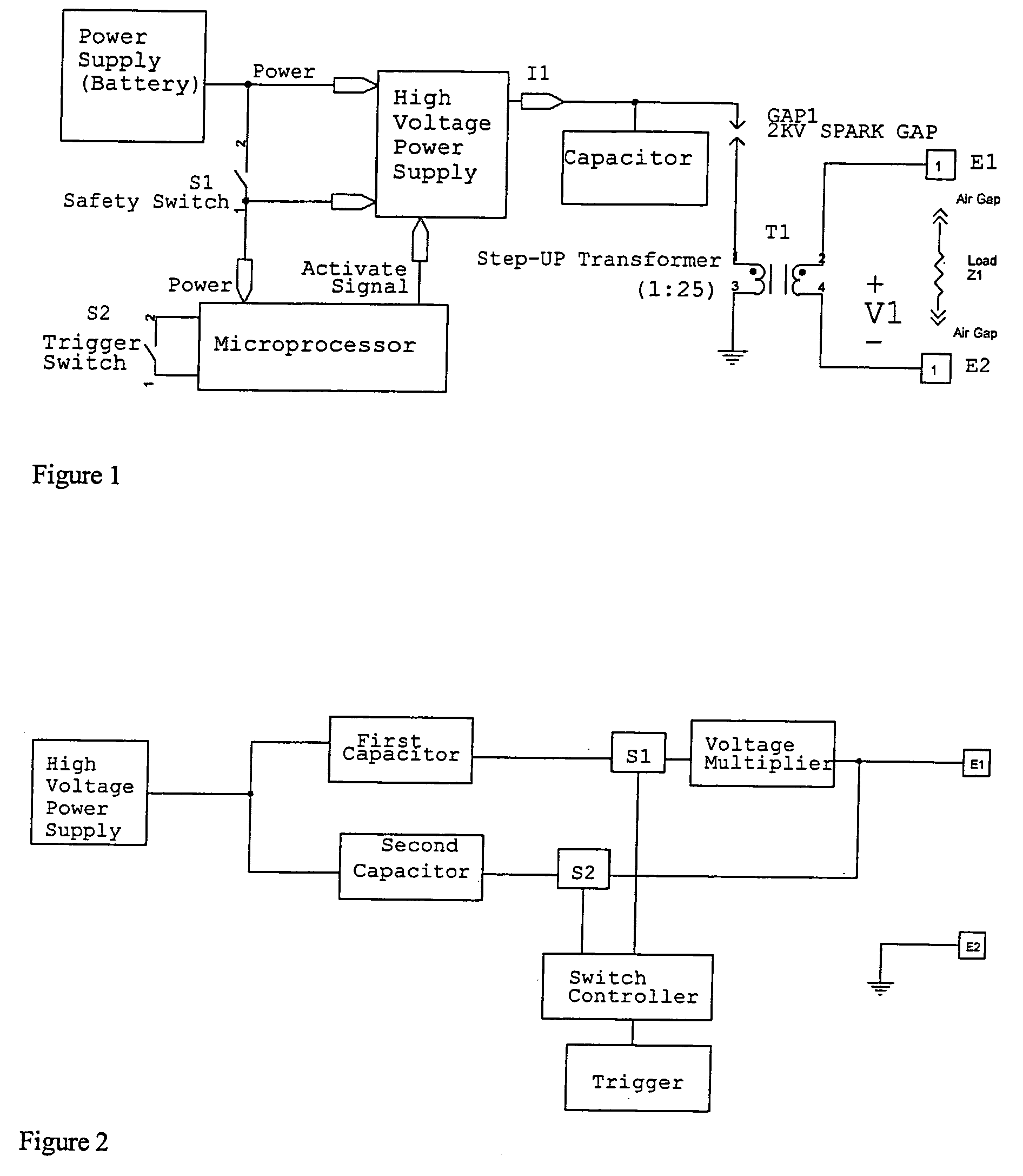

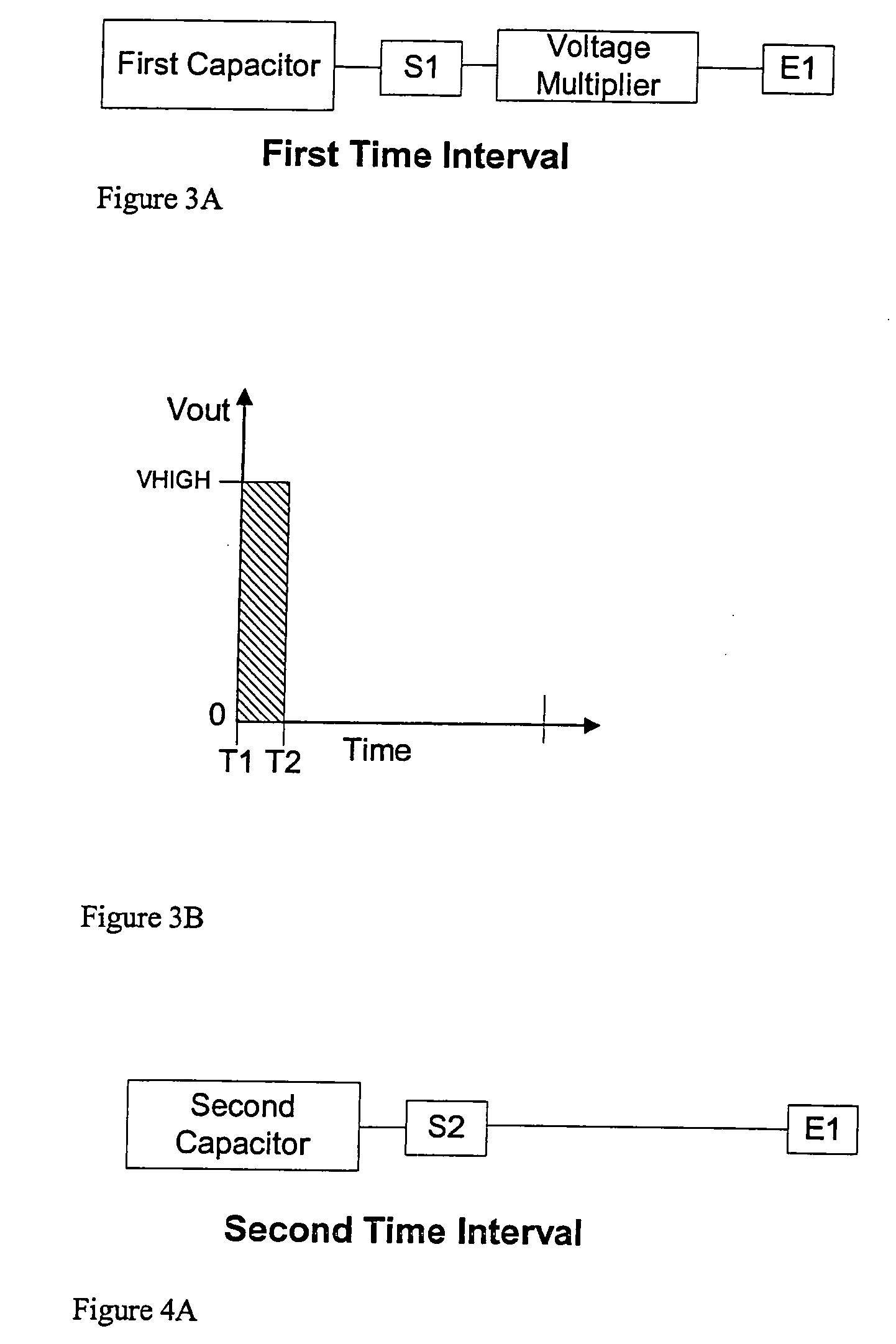

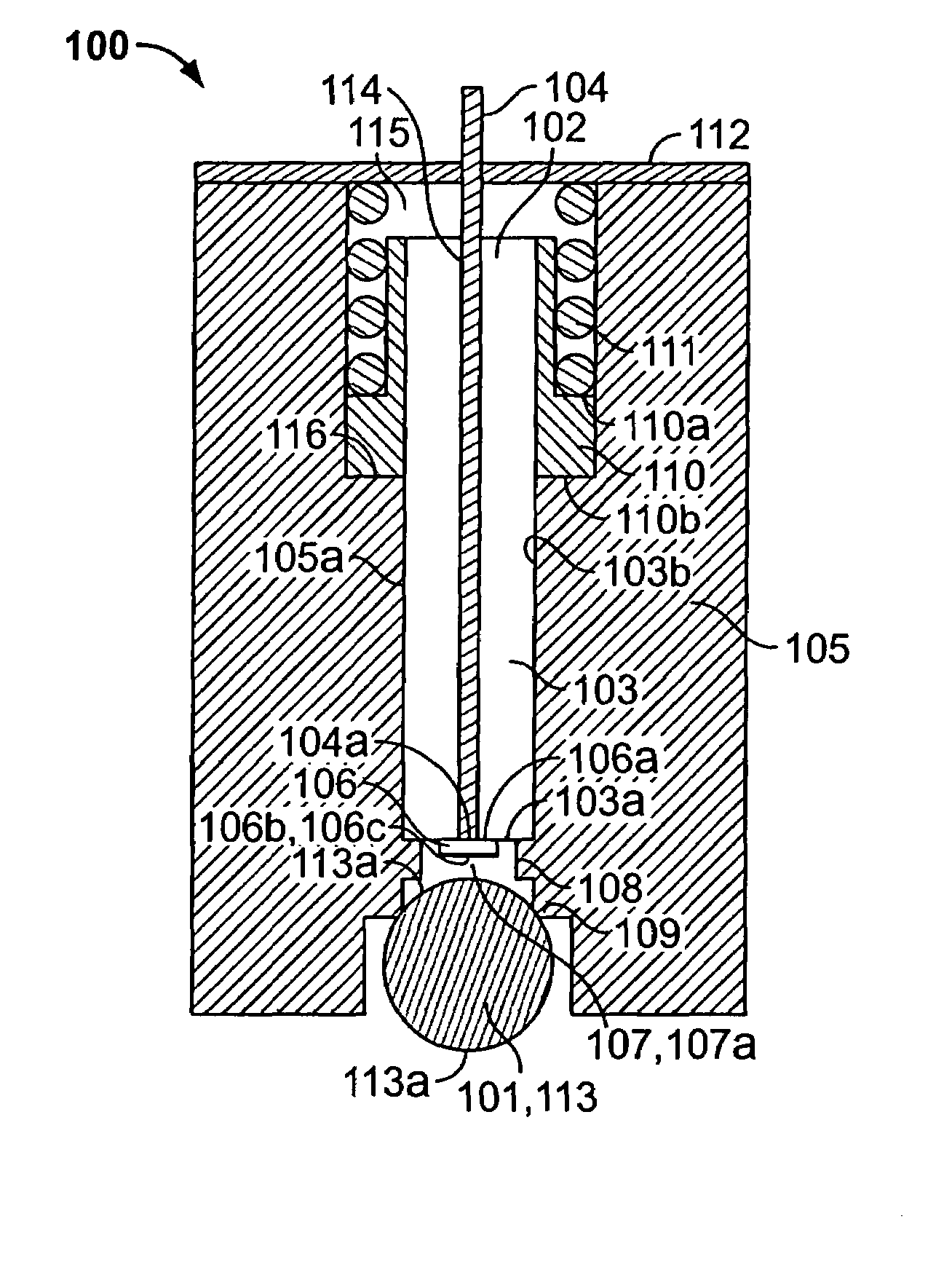

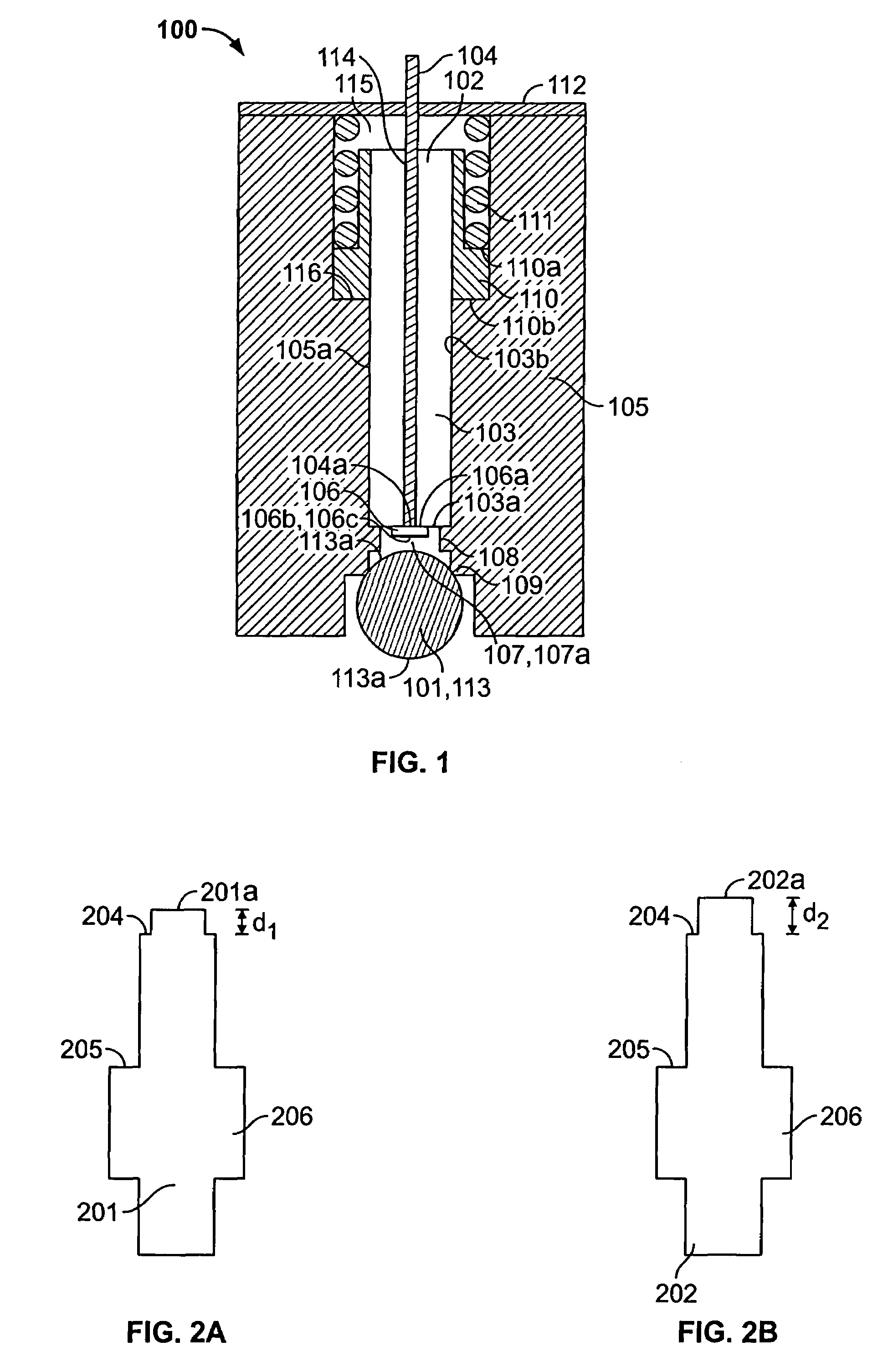

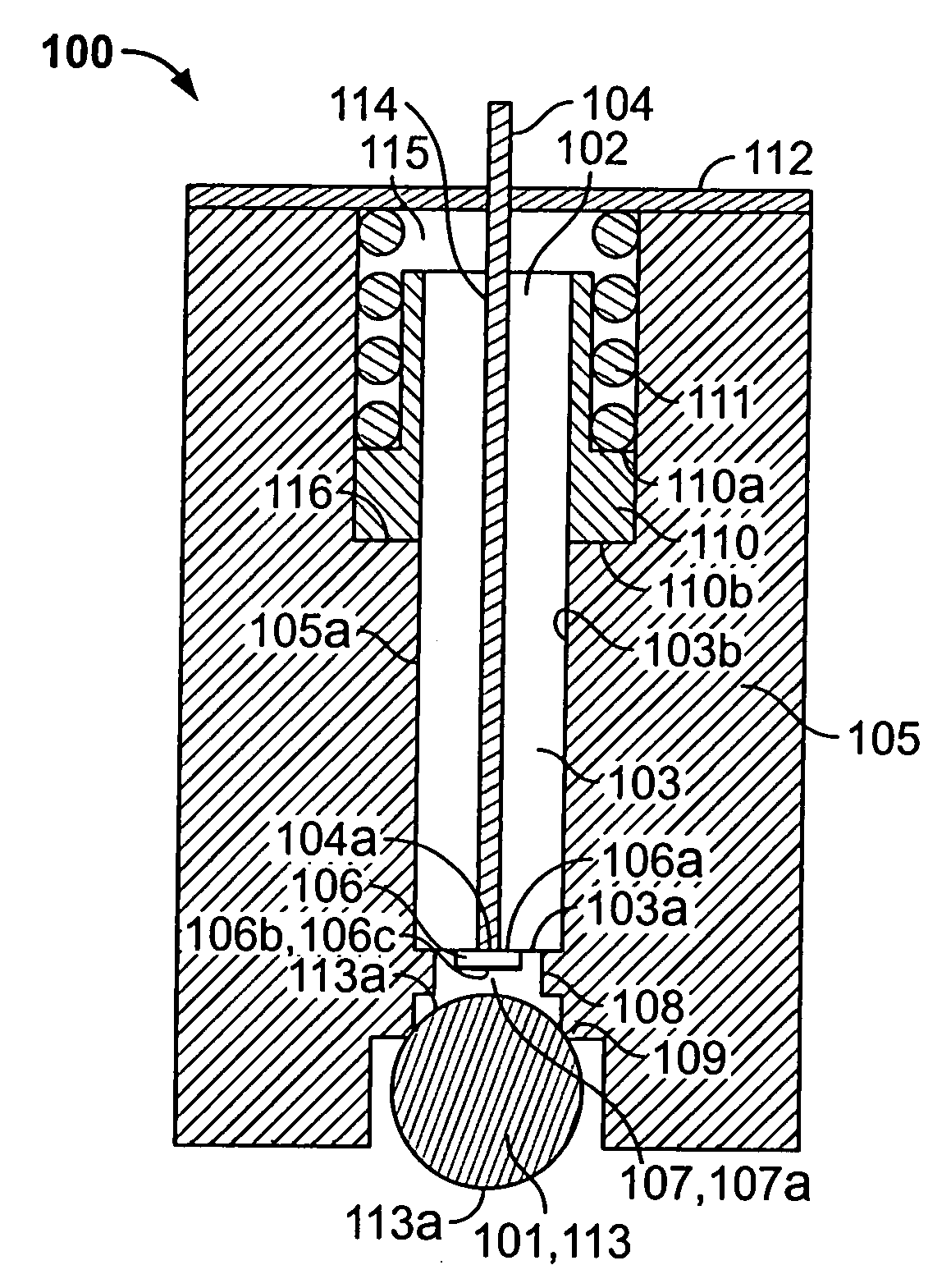

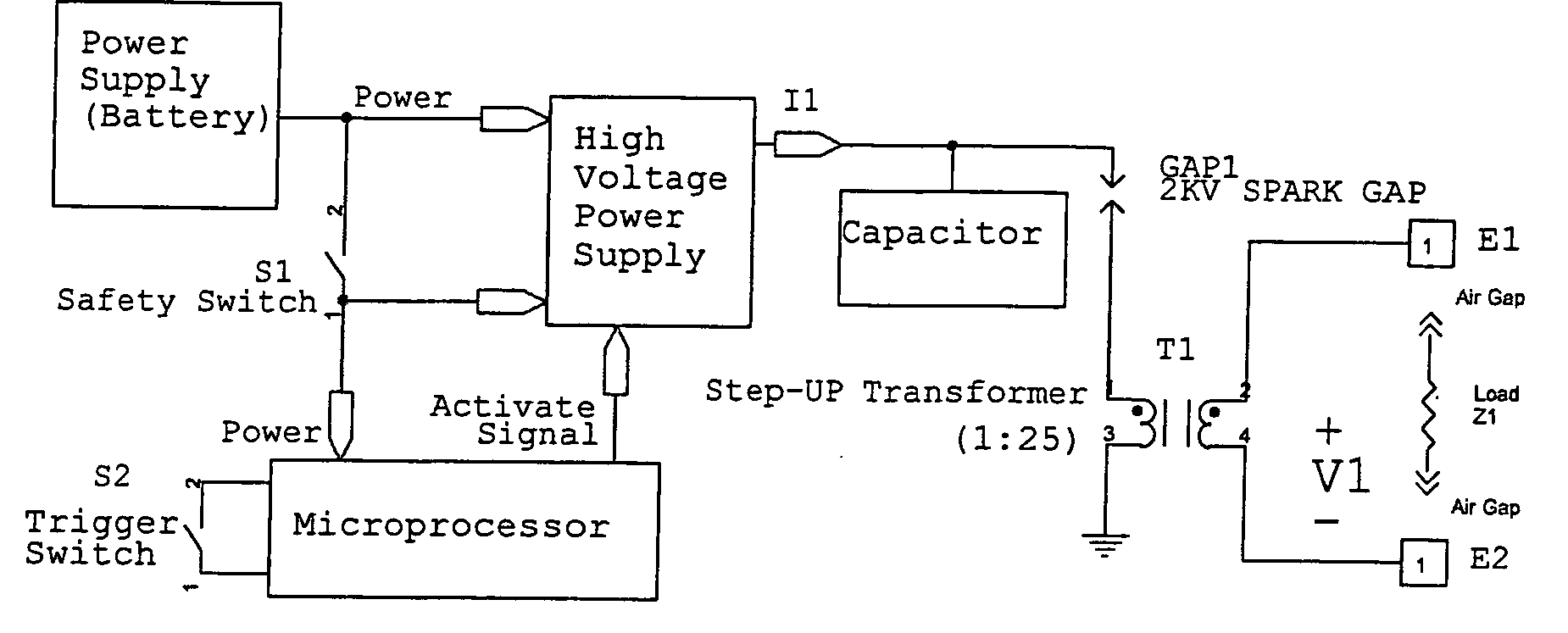

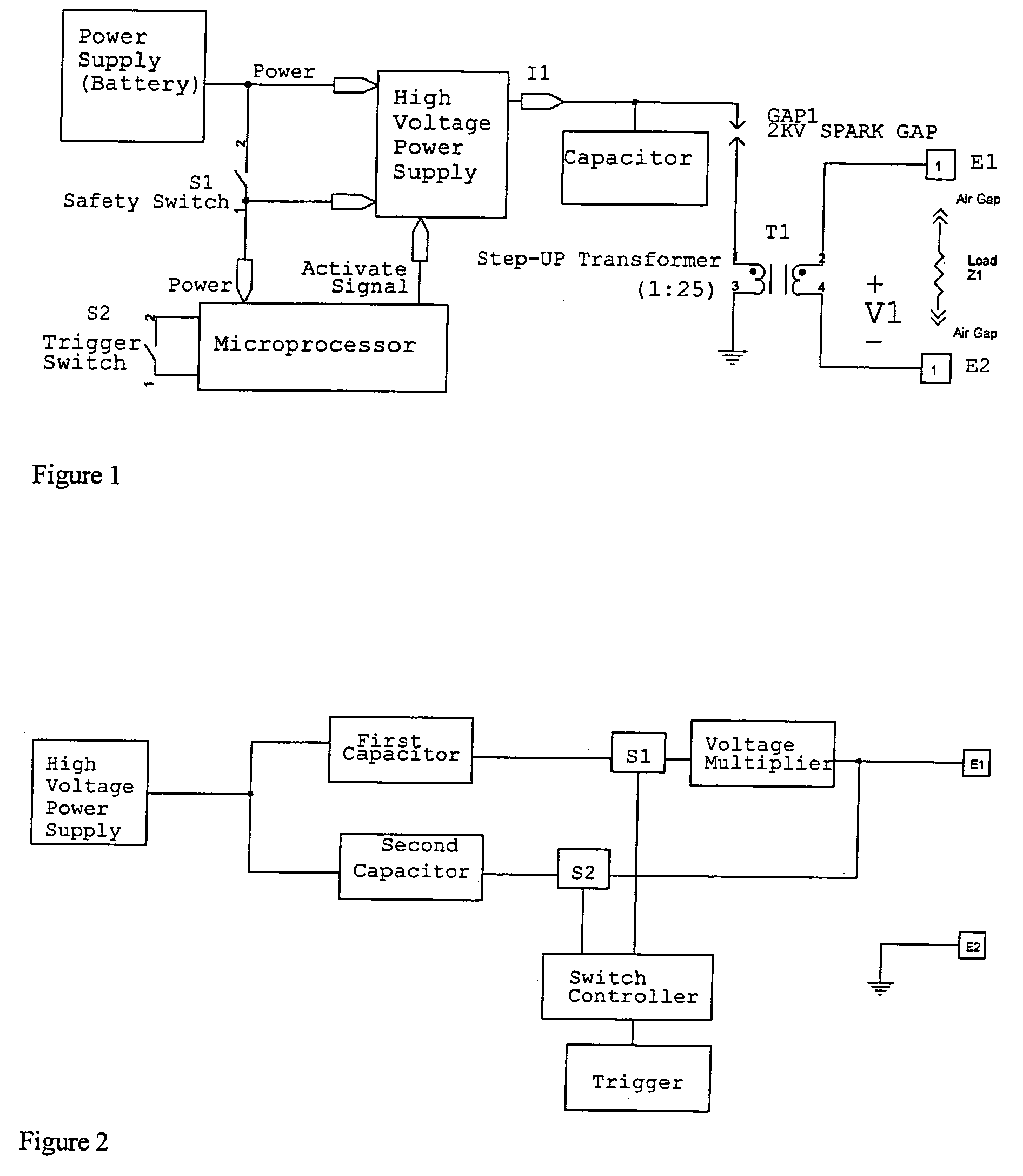

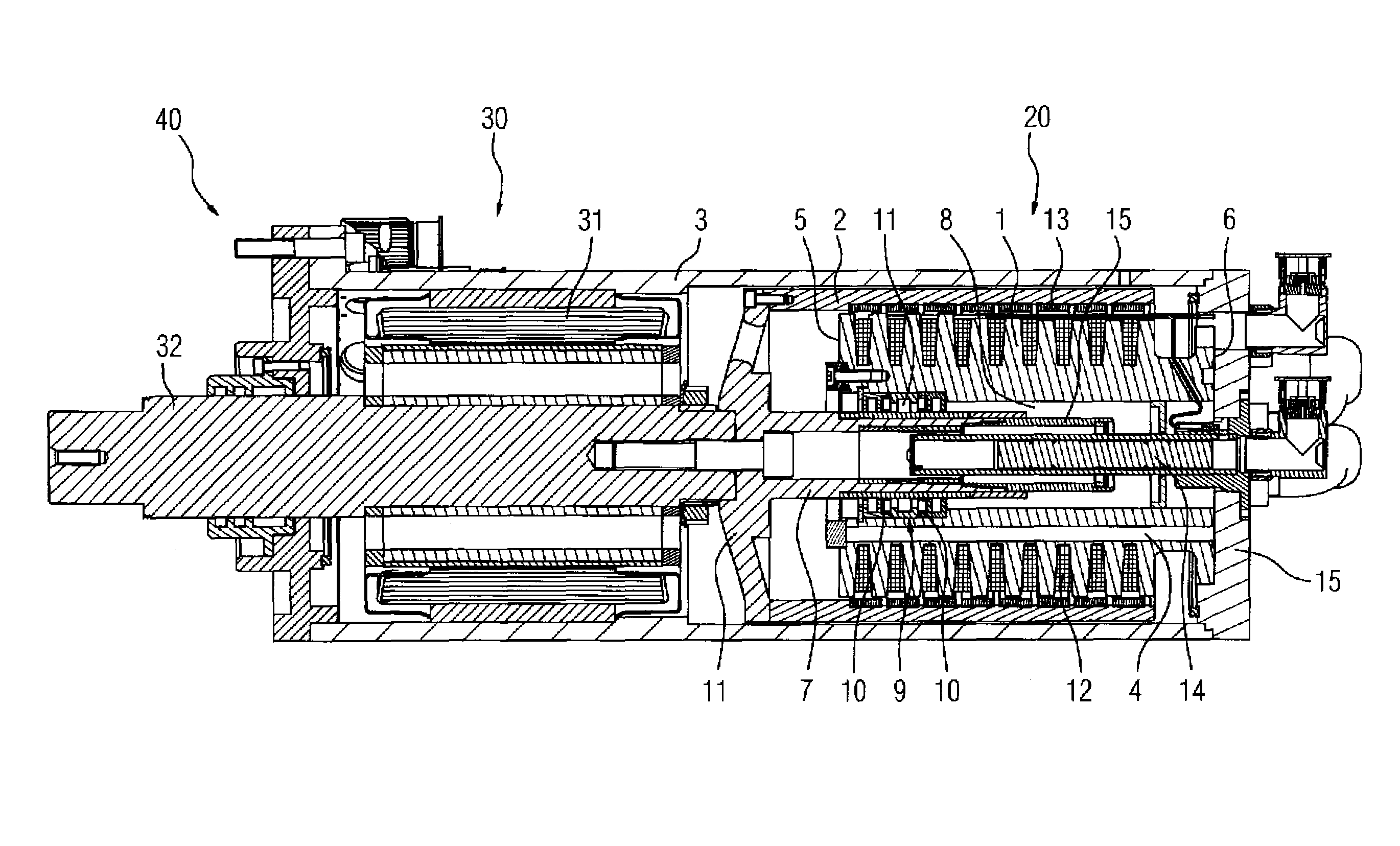

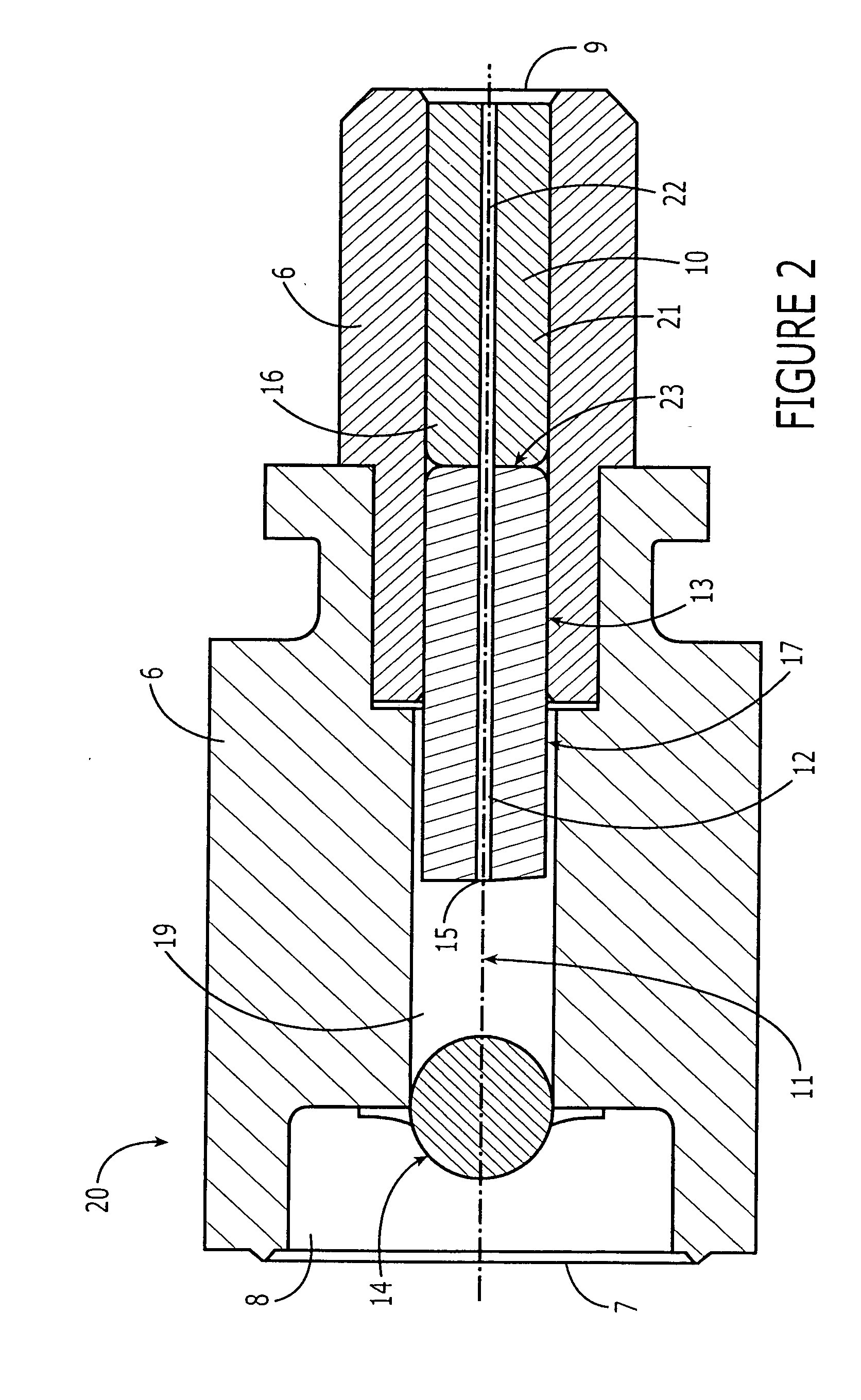

Dual operating mode electronic disabling device for generating a time-sequenced, shaped voltage output waveform

InactiveUS6999295B2Increase the air gapHigh impedanceElectric shock equipmentsPistolsLow voltageEngineering

Owner:AXON ENTERPRISE INC

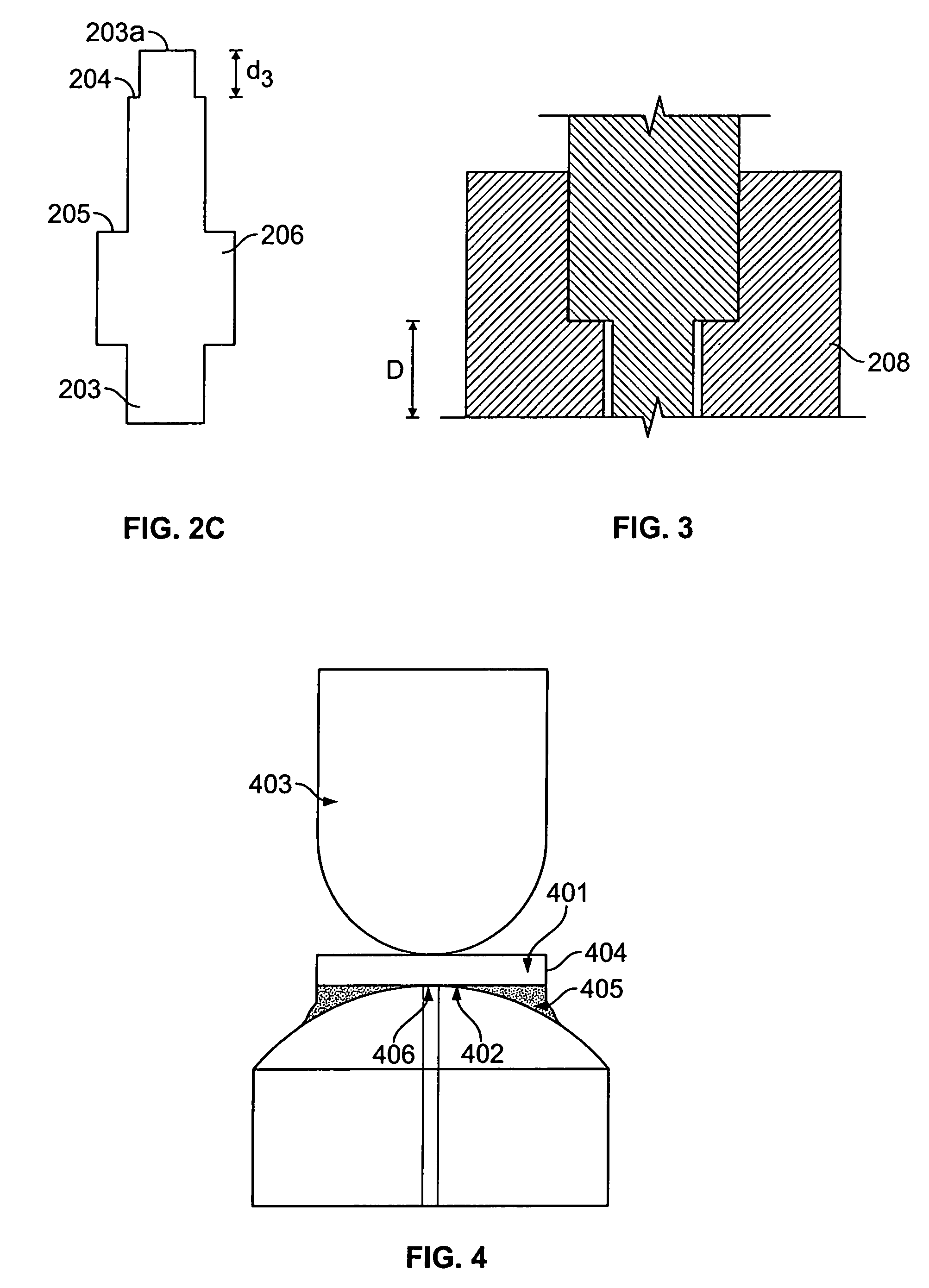

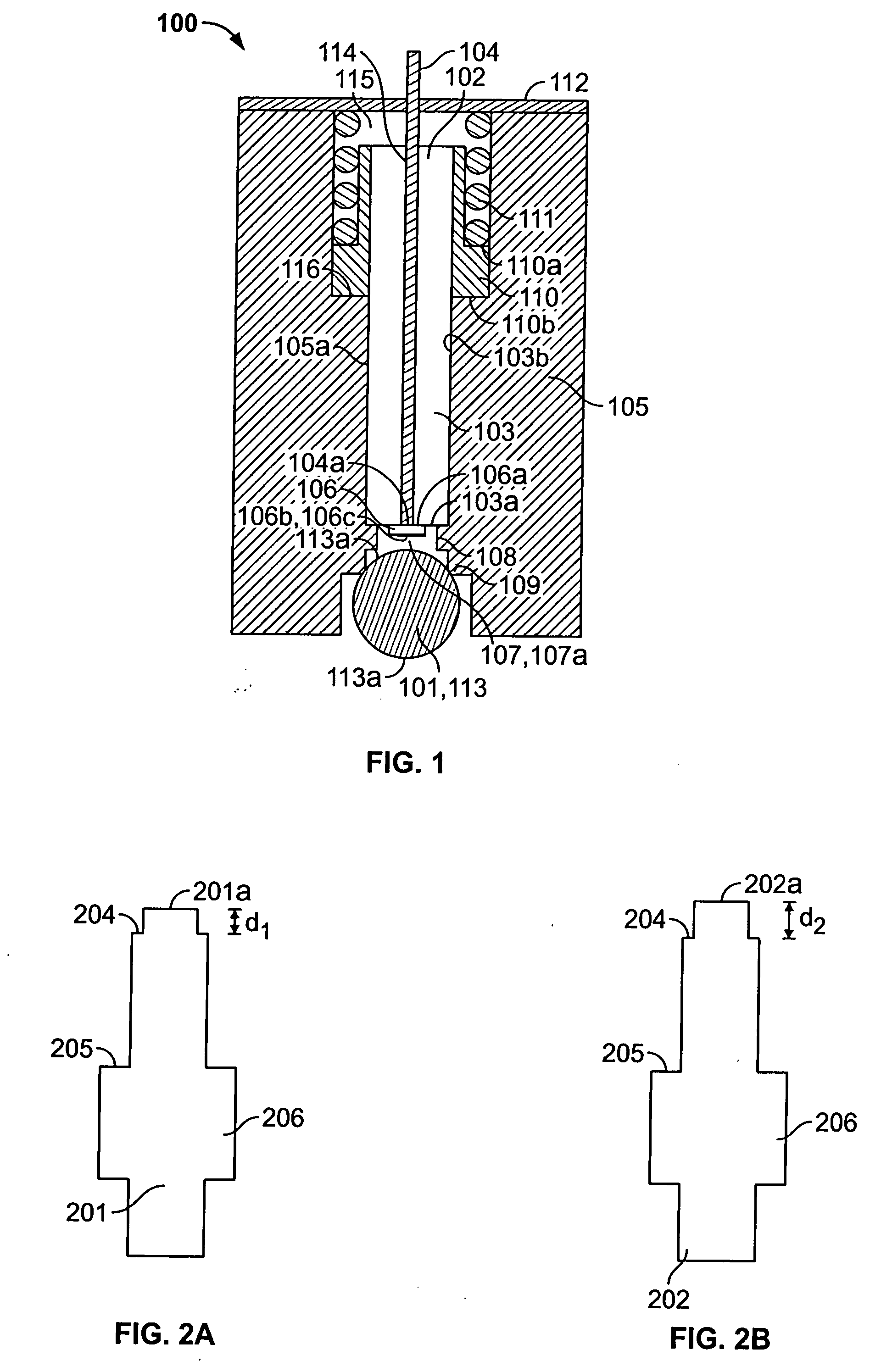

Expanded beam connector

Owner:TE CONNECTIVITY CORP

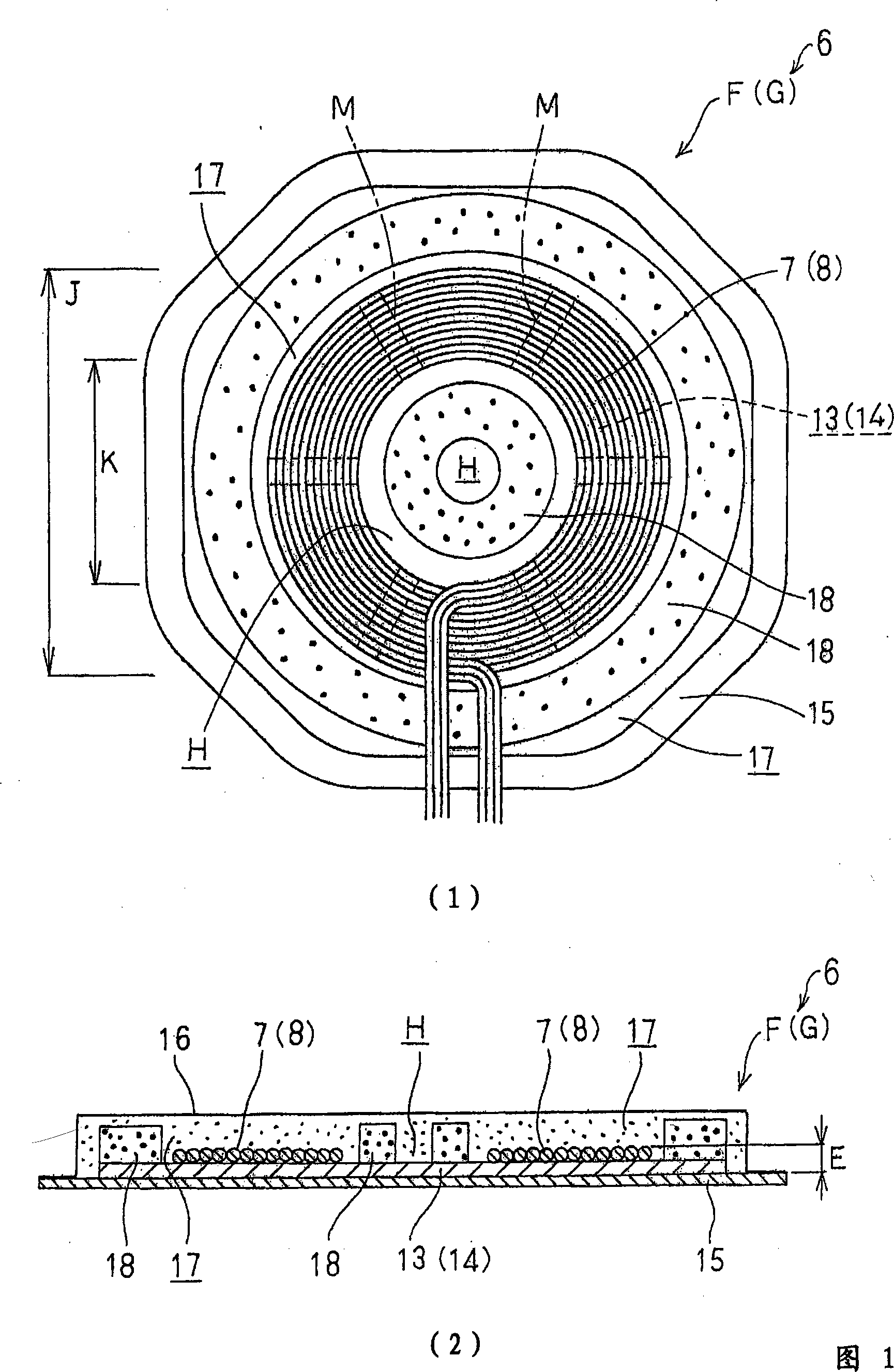

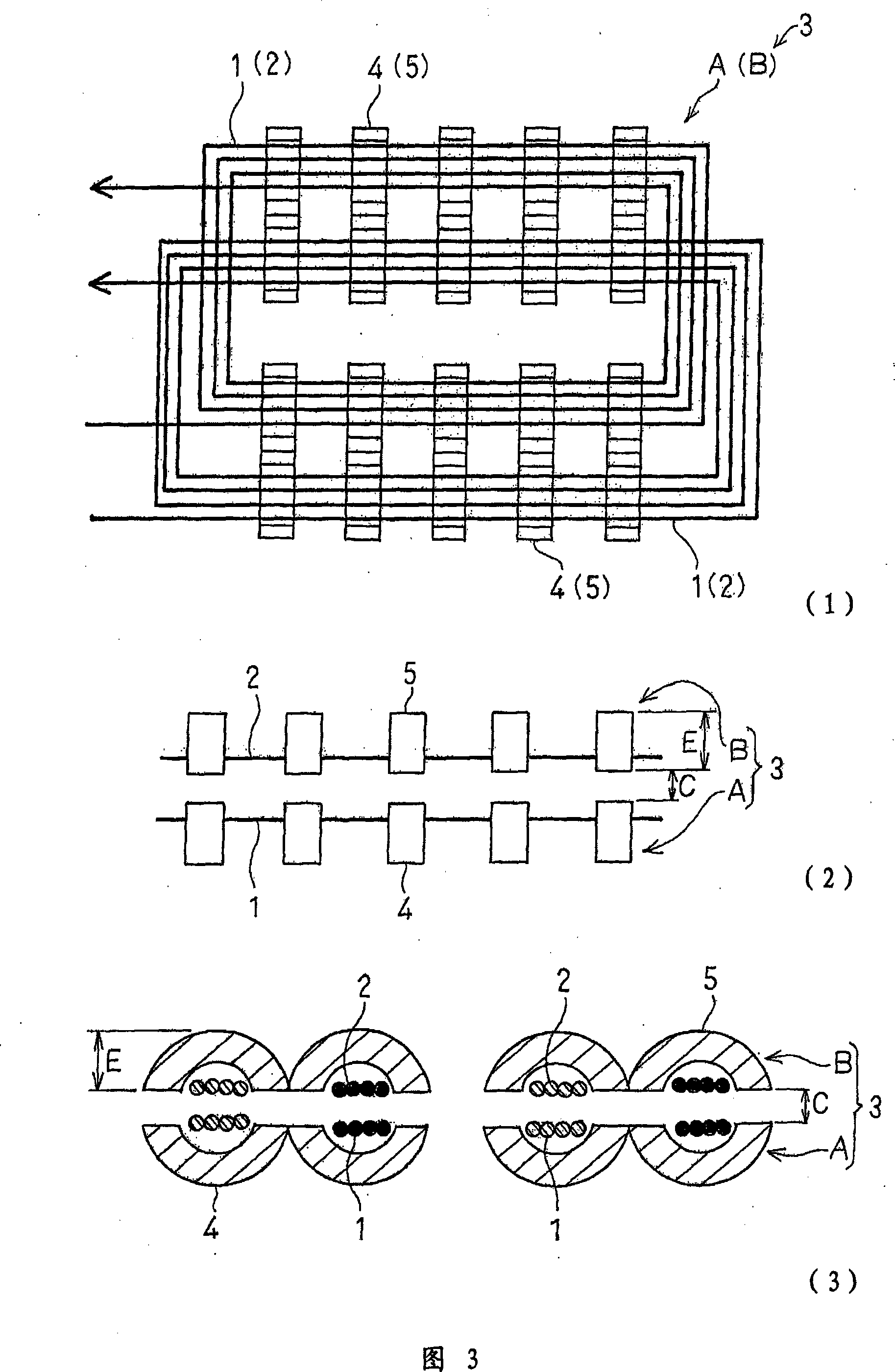

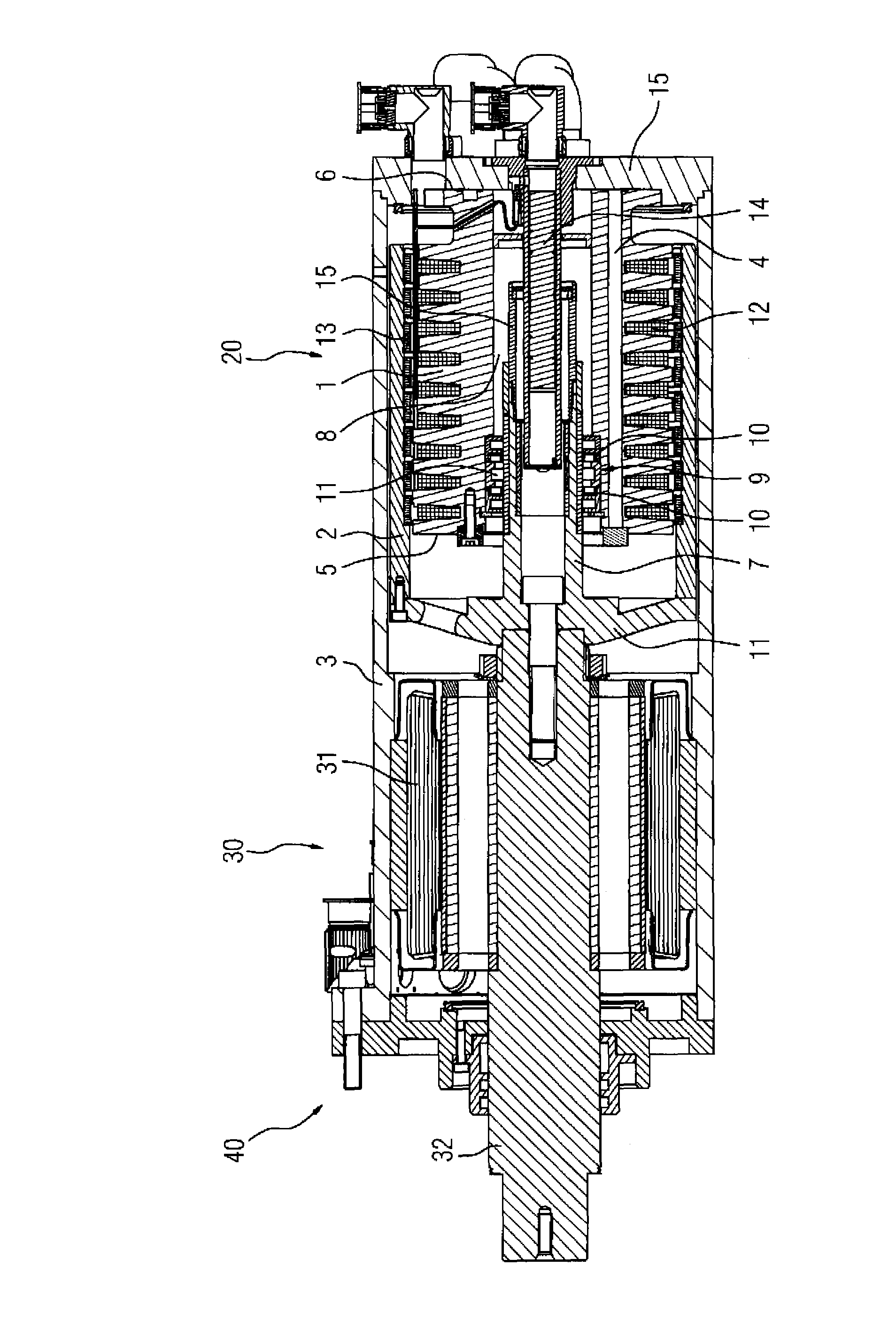

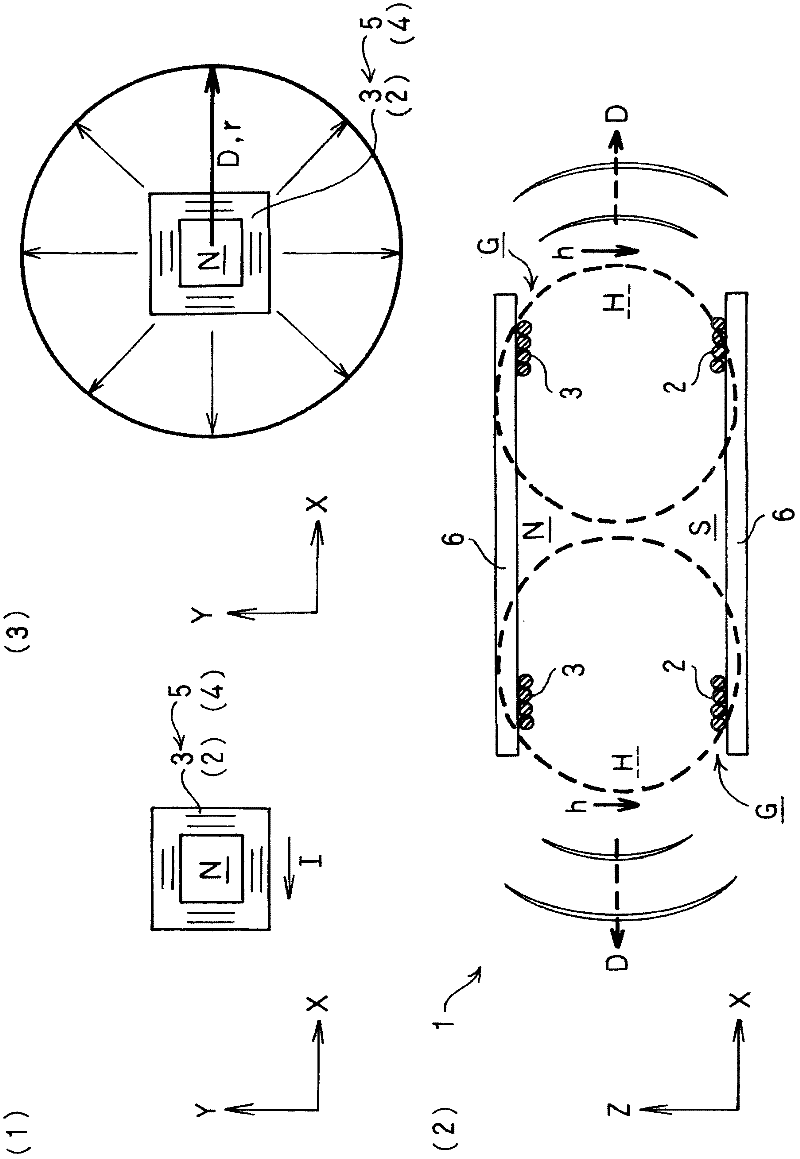

Non-contact power supplying apparatus

ActiveCN101179208AImprove coupling coefficientStrong electromagnetic couplingRail devicesCharging stationsMagnetic coreElectrical battery

This non-contact electric power supply device 6 is used to charge, for example, a battery of an electric vehicle, and electric power is supplied from a primary side, i.e., a primary coil 7 on an electric power supply side to a secondary side, i.e., a secondary coil 8 on an electric reception side based on a mutual induction effect of electromagnetic induction. The primary coil 7 and the secondary coil 8 are flatly and spirally wound in one plane, respectively, (by) making a plurality of parallel conducting wires a set and are twisted at a regular pitch interval along the way. A primary magnetic core 13 and secondary magnetic core 14 on which the primary coil 7 and the secondary coil 8 are disposed are made of ferrite and the like and are formed in a tabular shape. Outer surfaces of the primary coil 7 and the primary magnetic core 13 and outer surfaces of the secondary coil 8 and the secondary magnetic core 14 are covered and secured by molded resin 17, respectively. Foamed materials 18 are mixed in the molded resin 17.

Owner:SHOWA AIRCRAFT INDUSTRY +1

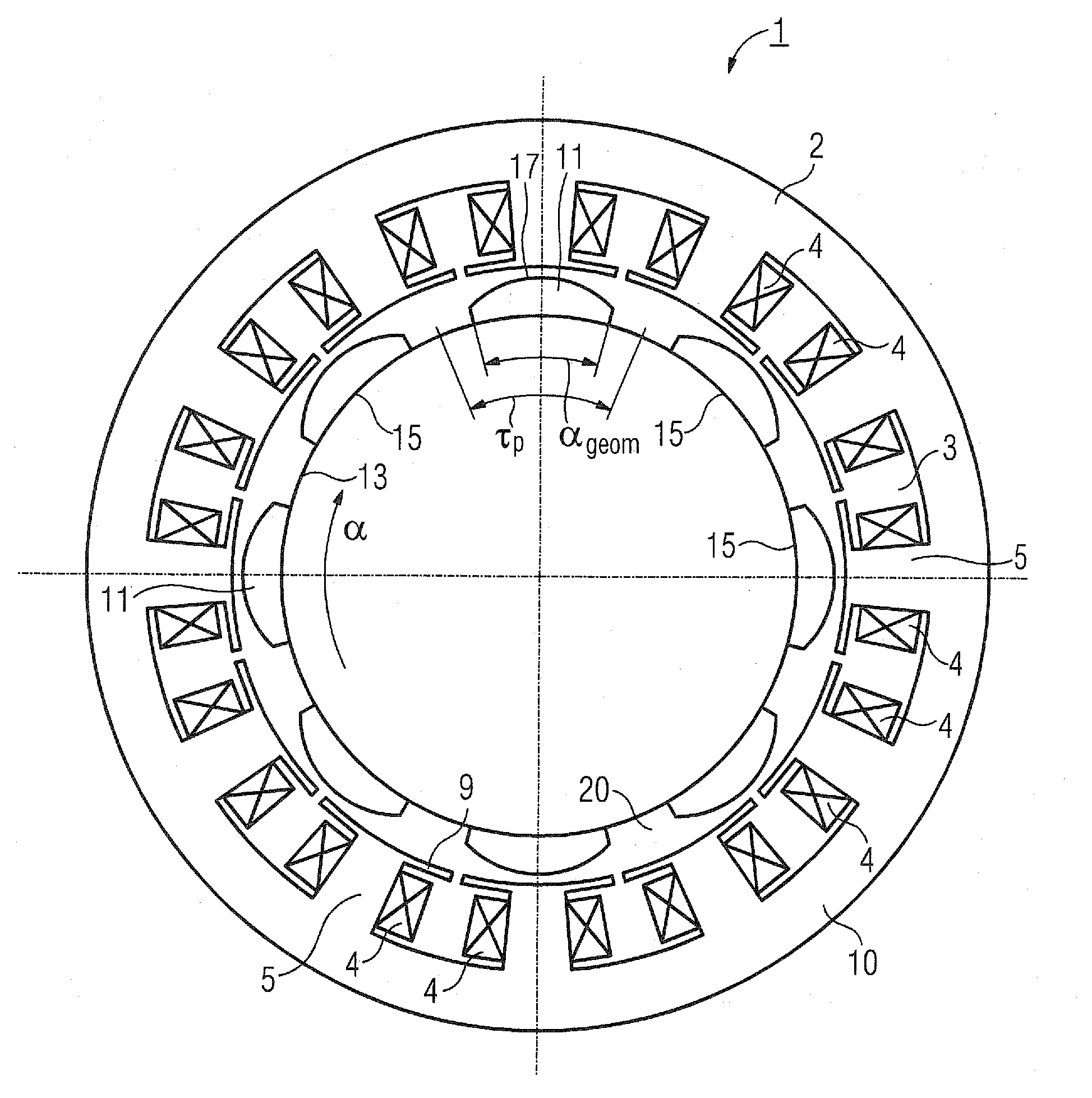

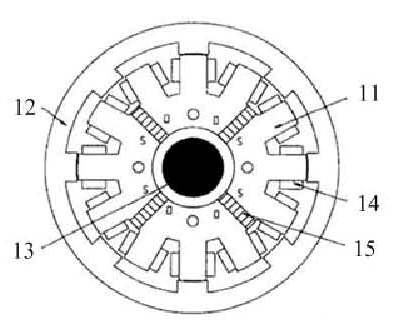

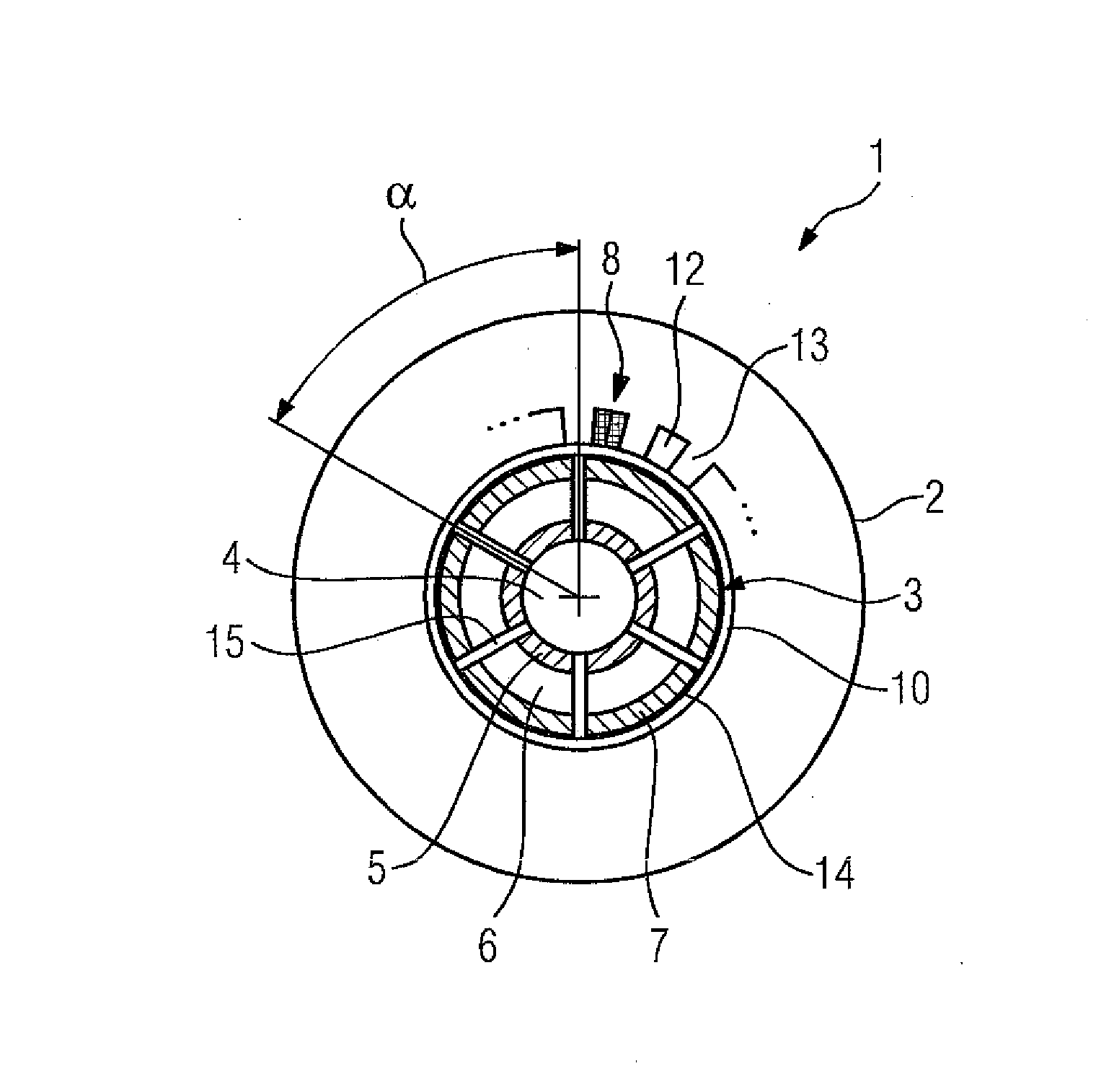

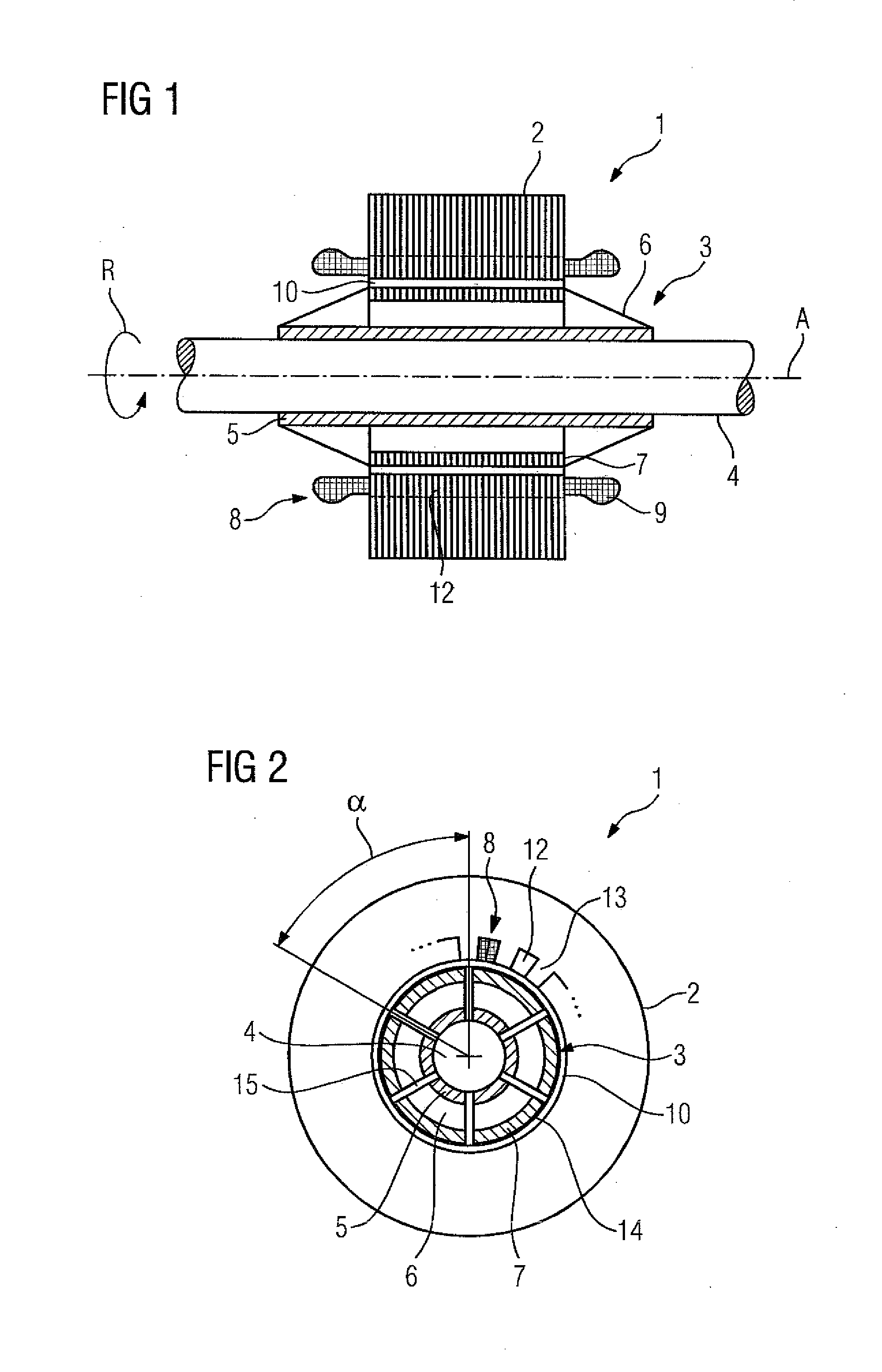

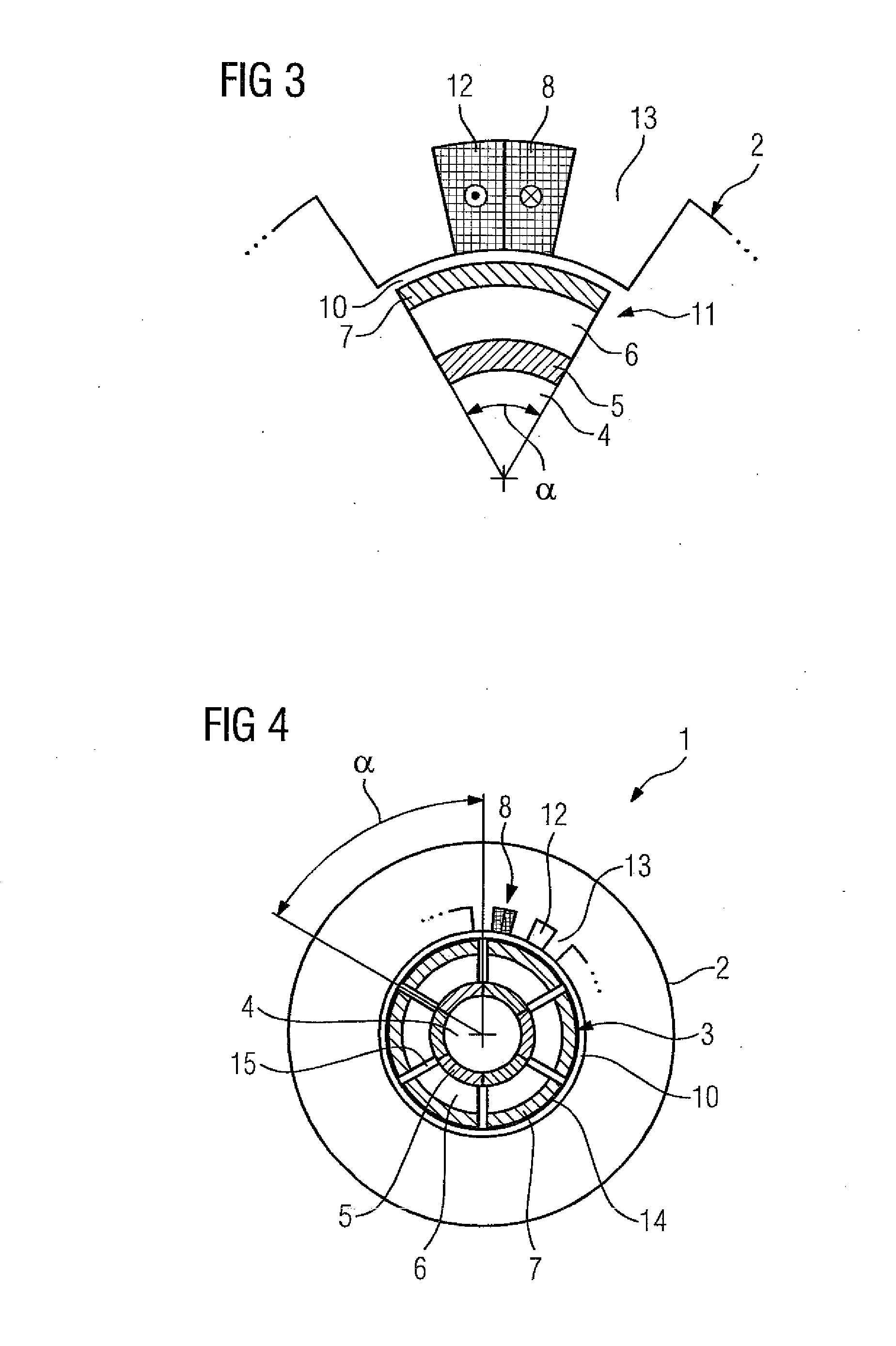

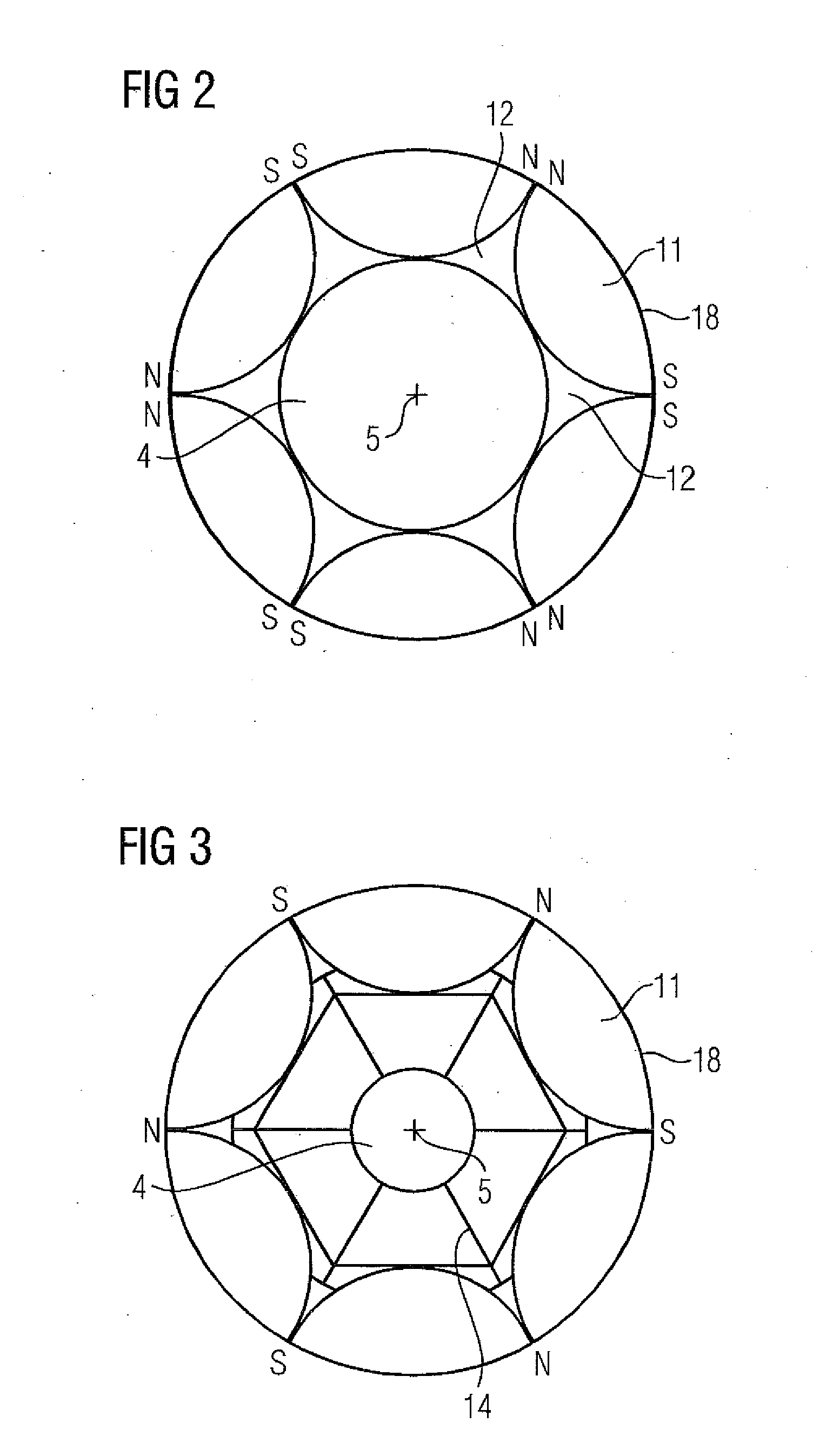

Three-phase dynamoelectrical permanently excited synchronous machine

InactiveUS20100133940A1Reduce edgeReduction in detentMagnetic circuit stationary partsSynchronous machines with stationary armatures and rotating magnetsWind systemThree-phase

A three-phase dynamoelectrical permanently excited synchronous machine includes a stator with teeth which point to a rotor, wherein twelve slots are formed between the teeth. The slots have coil sides of coils of a winding system in such a manner that two coil sides of different coils are situated in each slot. The rotor has a cylindrical support structure which is provided with permanent magnets defined by an inner radius which corresponds to a radius of the support structure, and by an outer radius which is smaller than their inner radius. The permanent magnets are formed with ten magnet poles when viewed in a circumferential direction.

Owner:SIEMENS AG

Expanded beam connector

InactiveUS20080050073A1Increase the air gapReduce inventory costsCoupling light guidesFiberEngineering

An optical connector comprising: (a) a lens; (b) a ferrule assembly comprising a ferrule with an endface and at least one fiber in the ferrule having a fiber end presented at the endface; (c) a housing for holding the ferrule assembly and the lens in a certain axial and radial relationship; and (d) a glass element having a first and second surface, the first surface affixed to the endface such that it is in physical contact with the fiber end, the second surface having an AR coating and defining a space between it and the lens.

Owner:TE CONNECTIVITY CORP

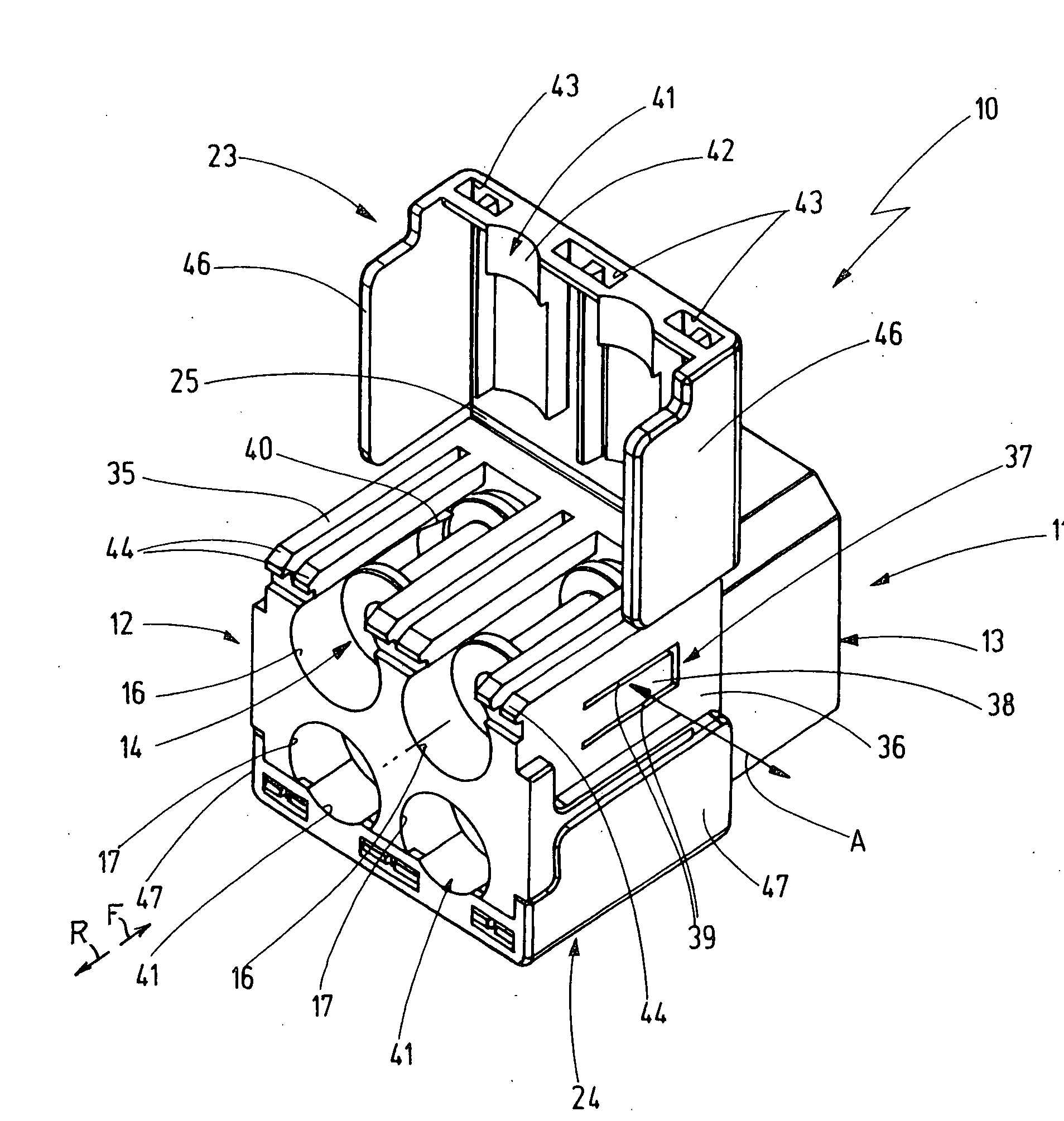

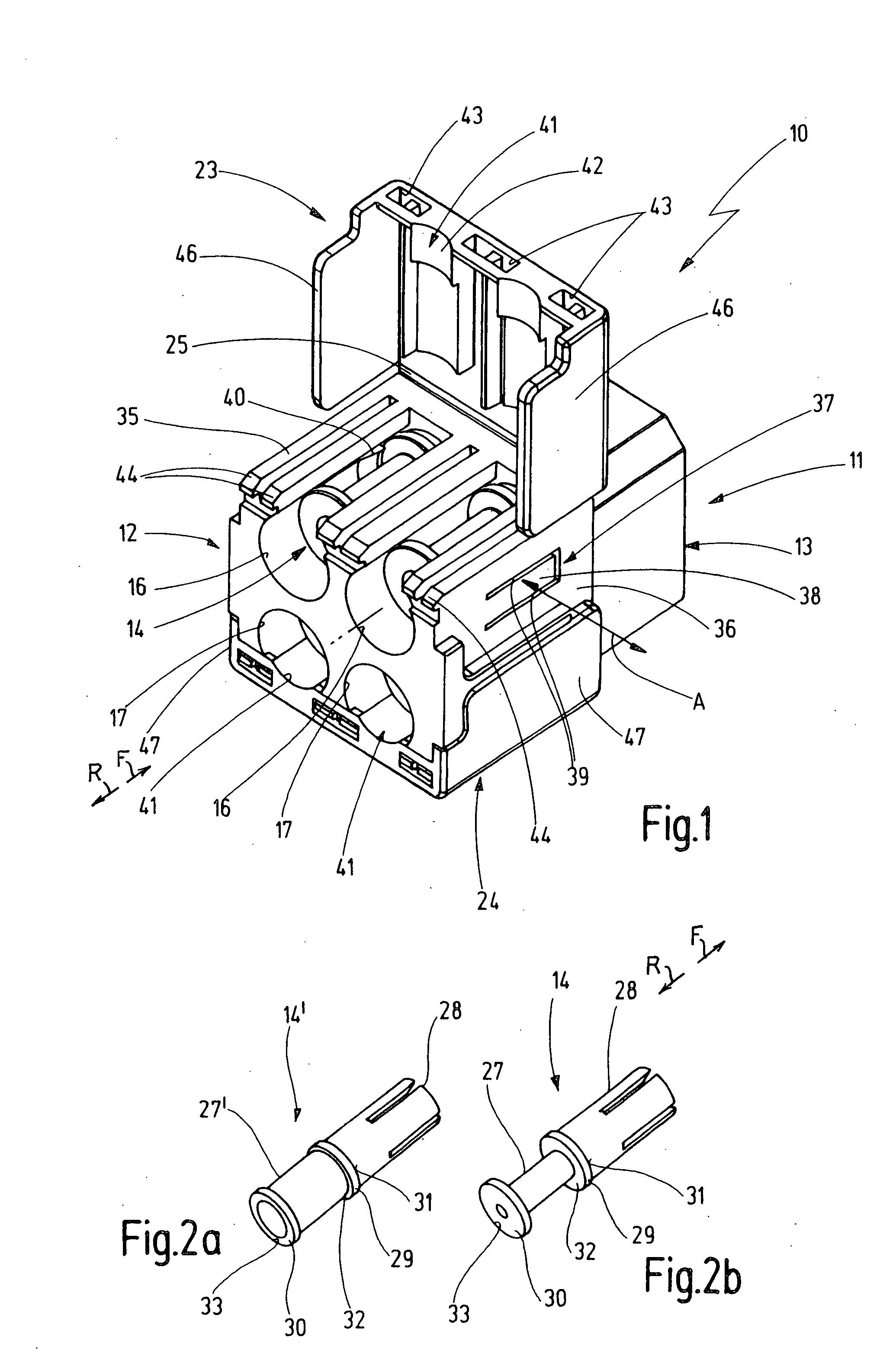

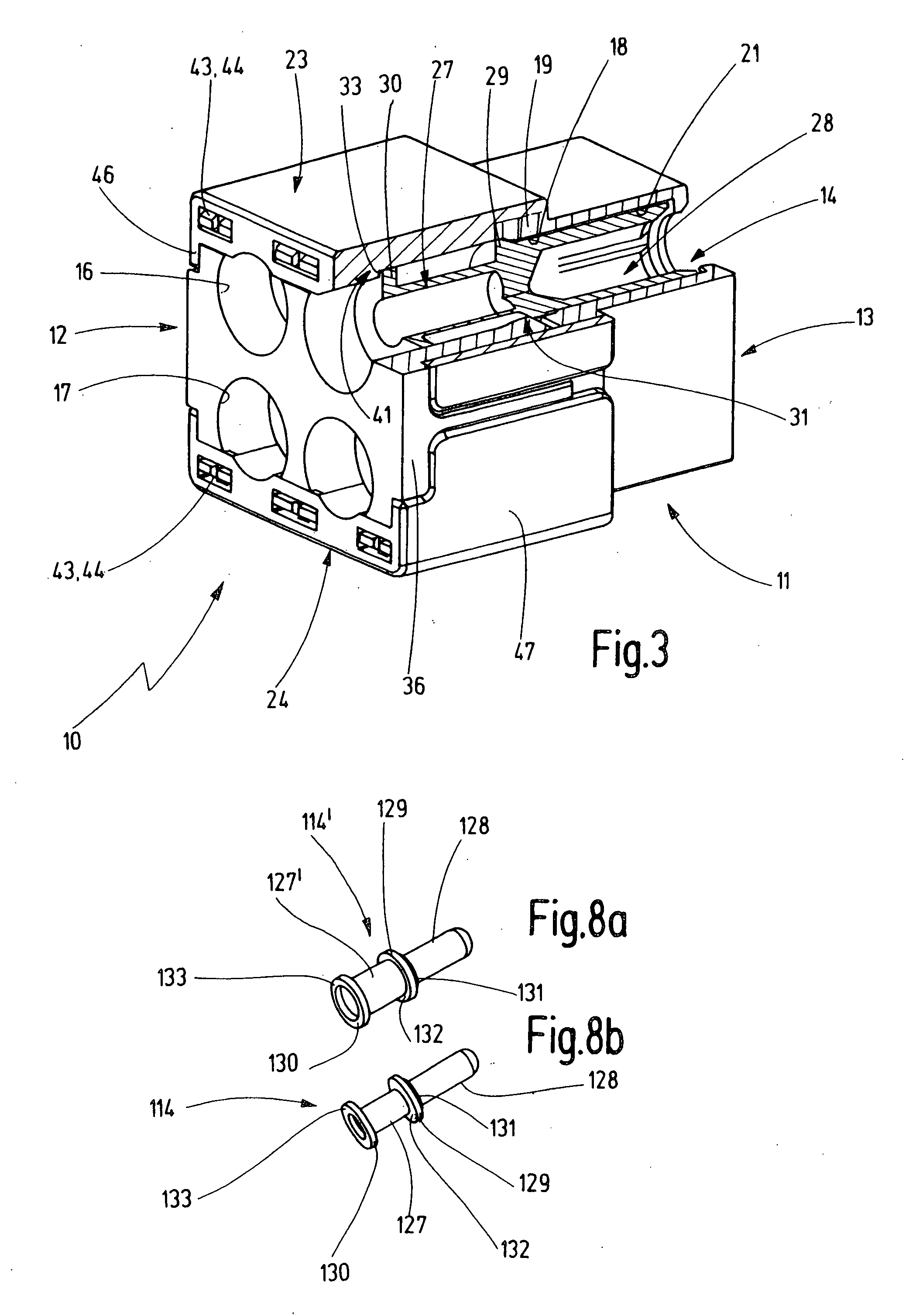

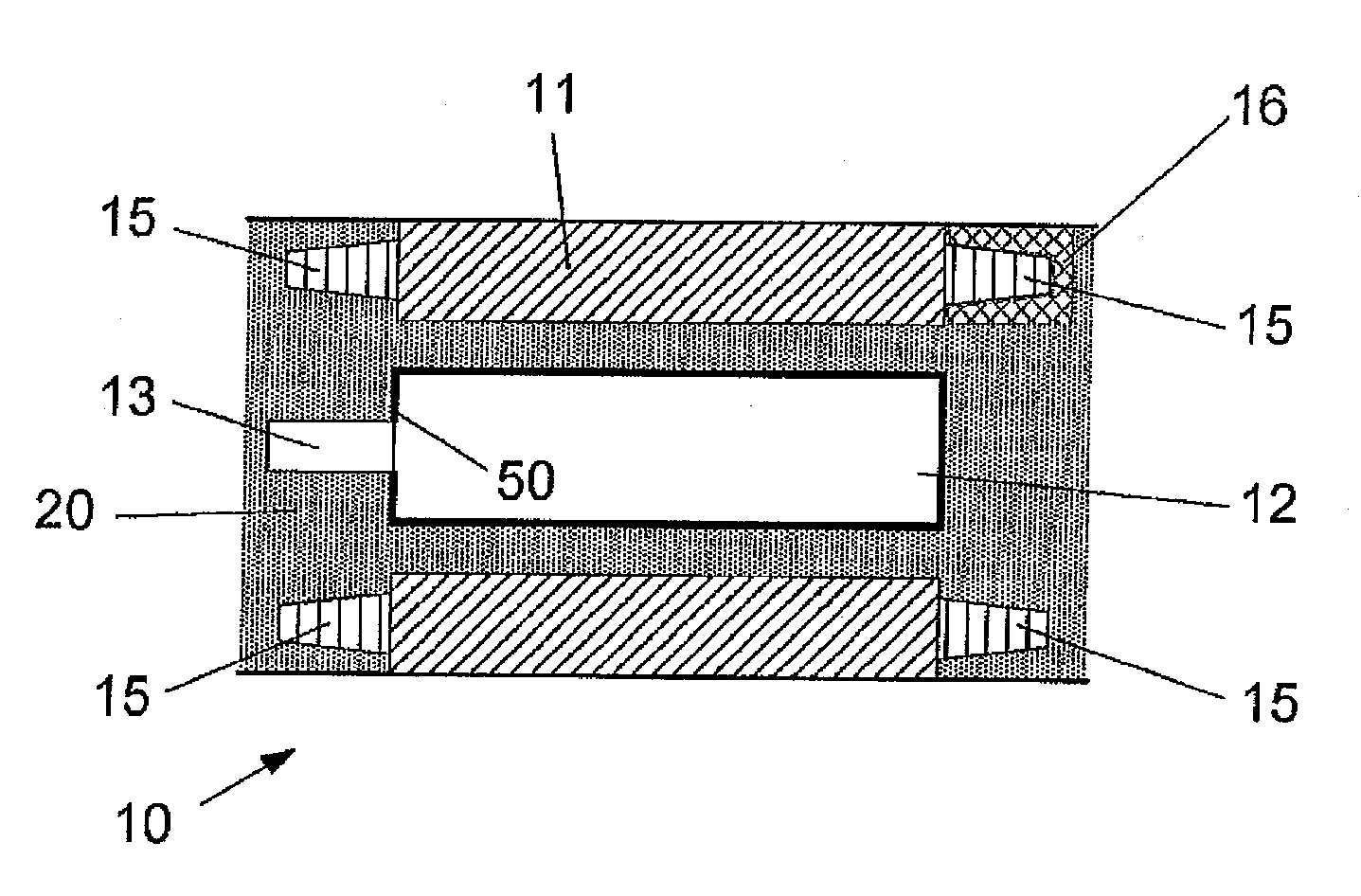

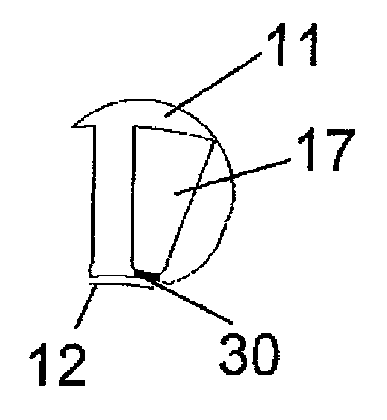

Plug-and socket connector

ActiveUS20070232117A1Increase the air gapPrevent movementSecuring/insulating coupling contact membersConnections effected by permanent deformationEngineeringMechanical engineering

Owner:ITT MFG ENTERPRISES LLC

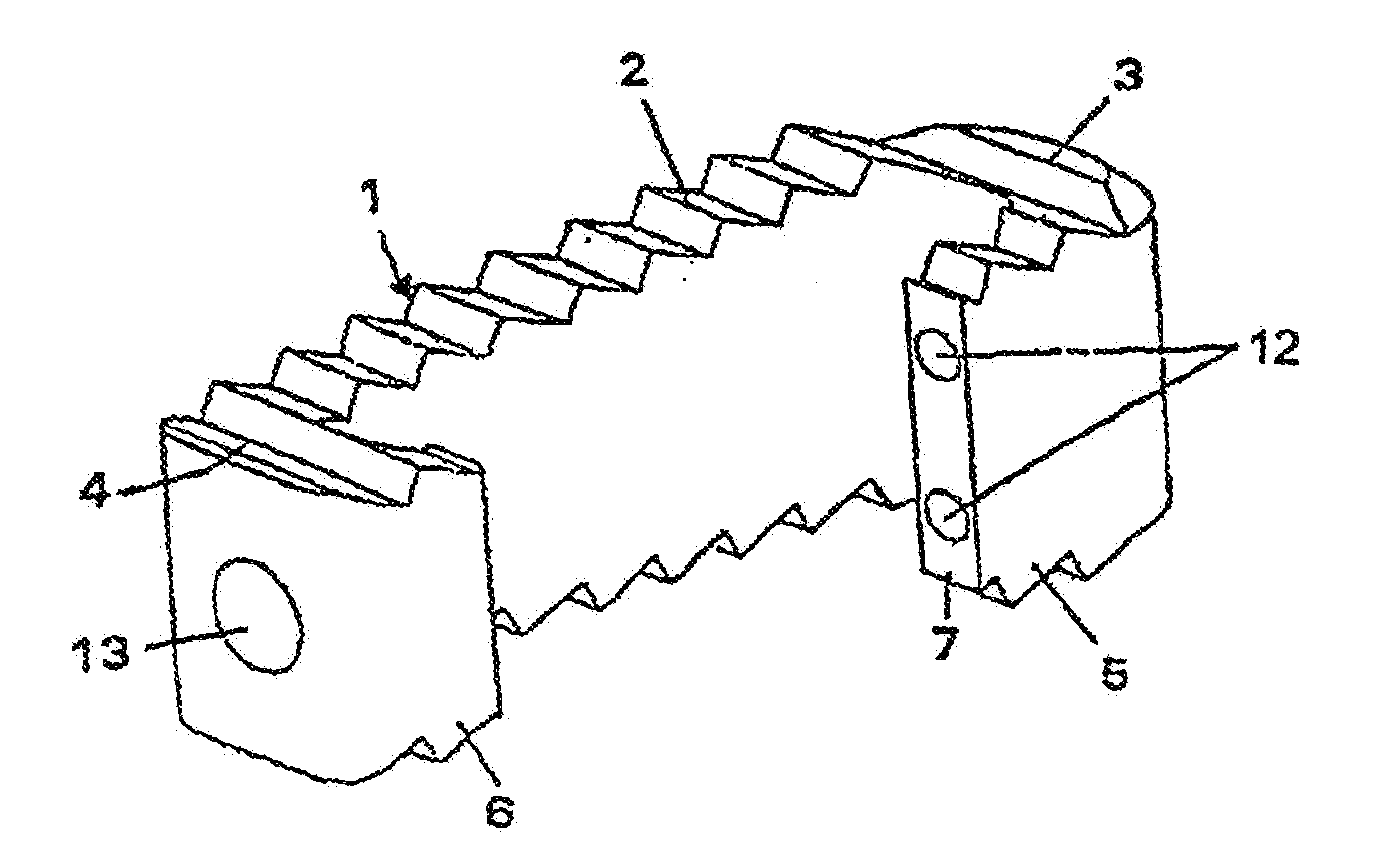

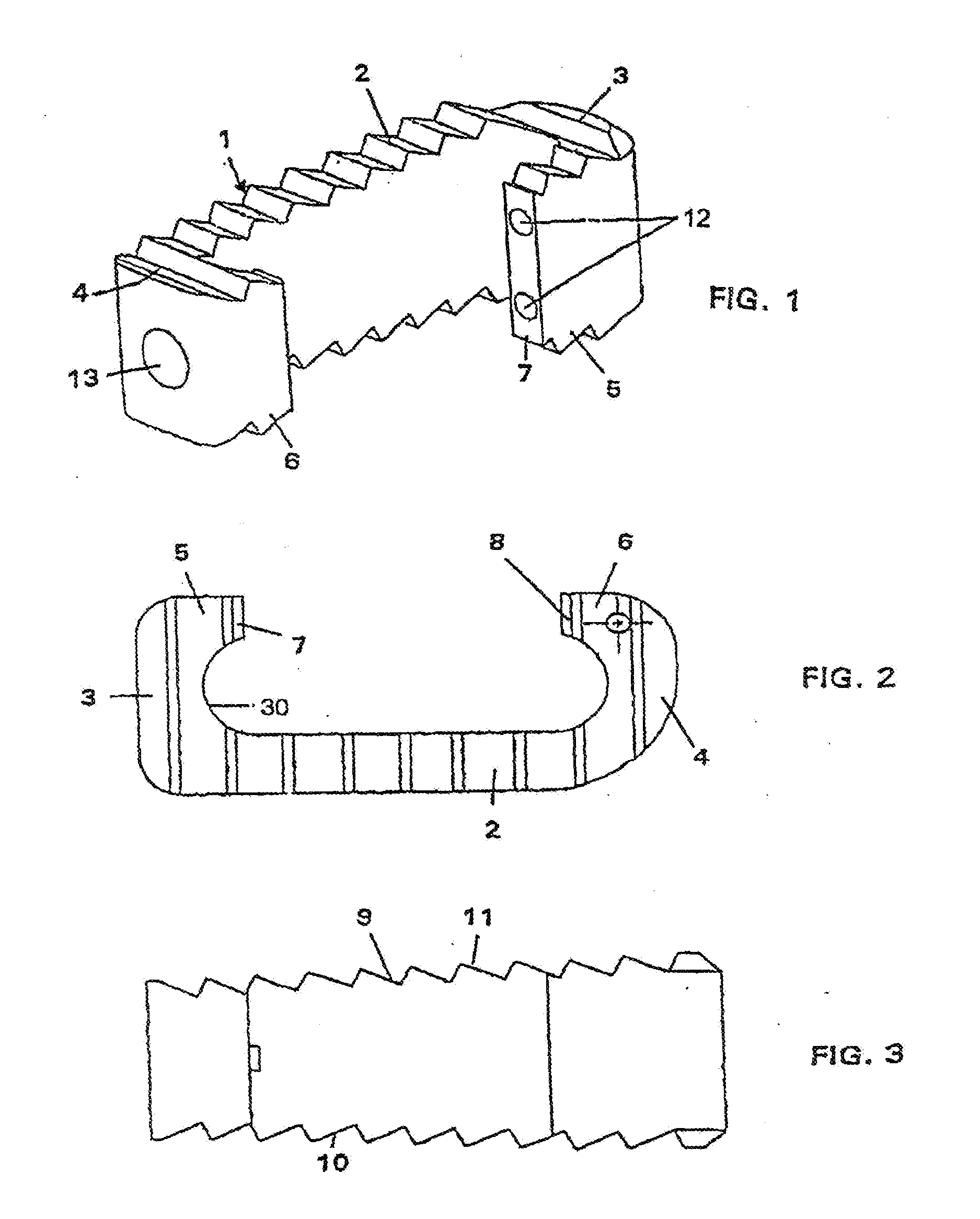

Intersomatic cage with unified grafts

InactiveUS20080021562A1Promote growthImprove the immunityBone implantJoint implantsEngineeringMechanical engineering

Owner:LDR MEDICAL SAS

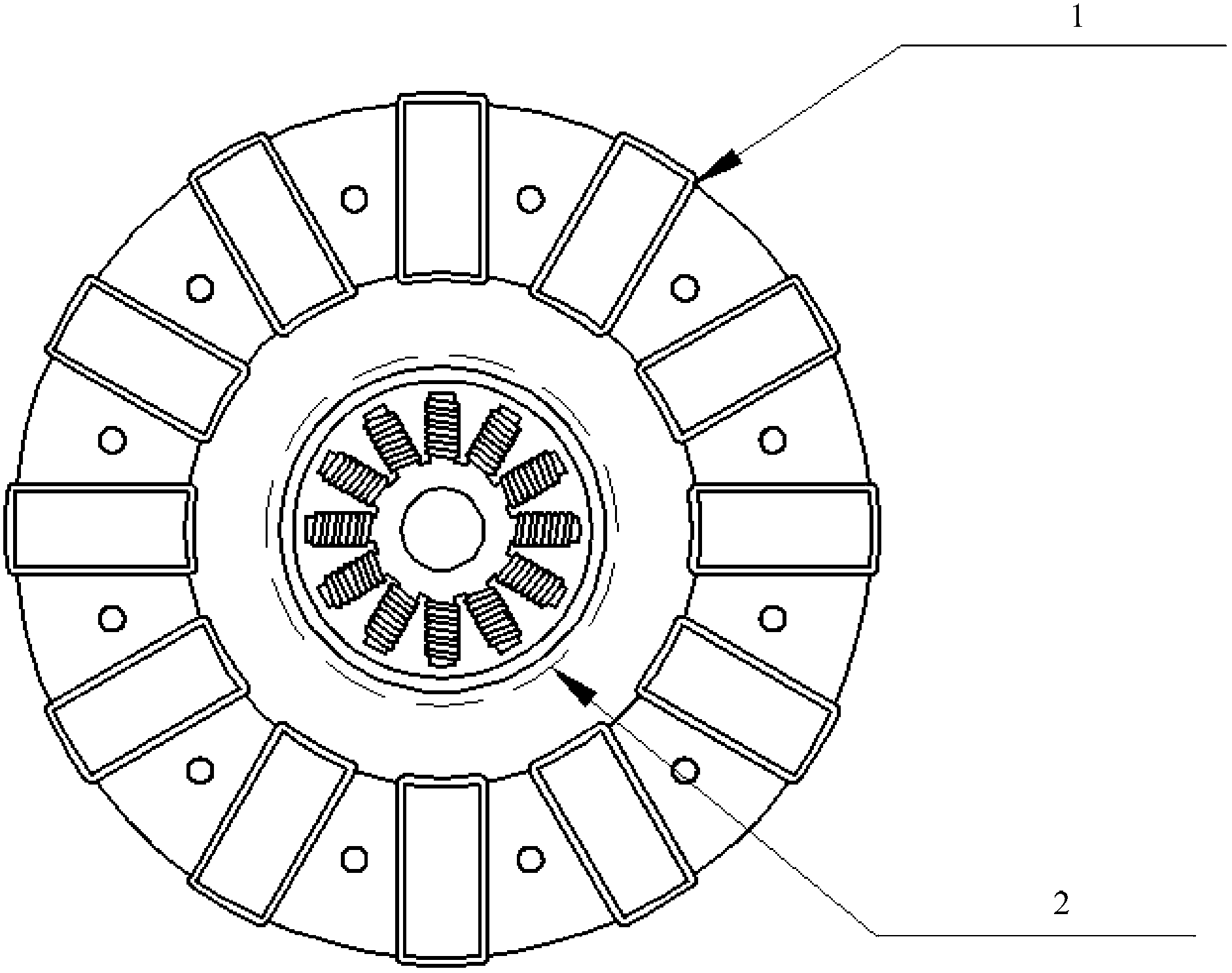

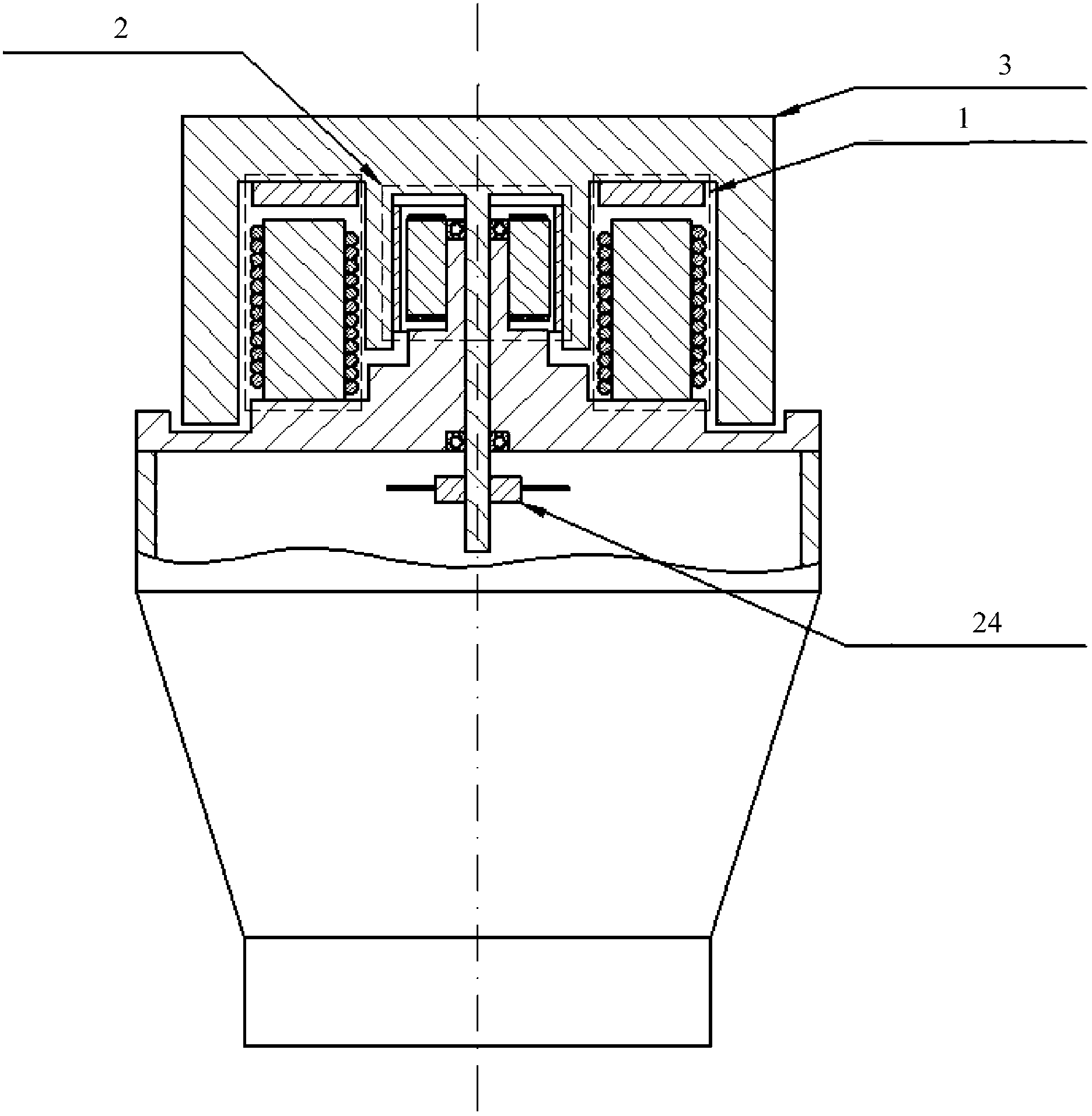

Rotor iron core and permanent magnet synchronous motor with same

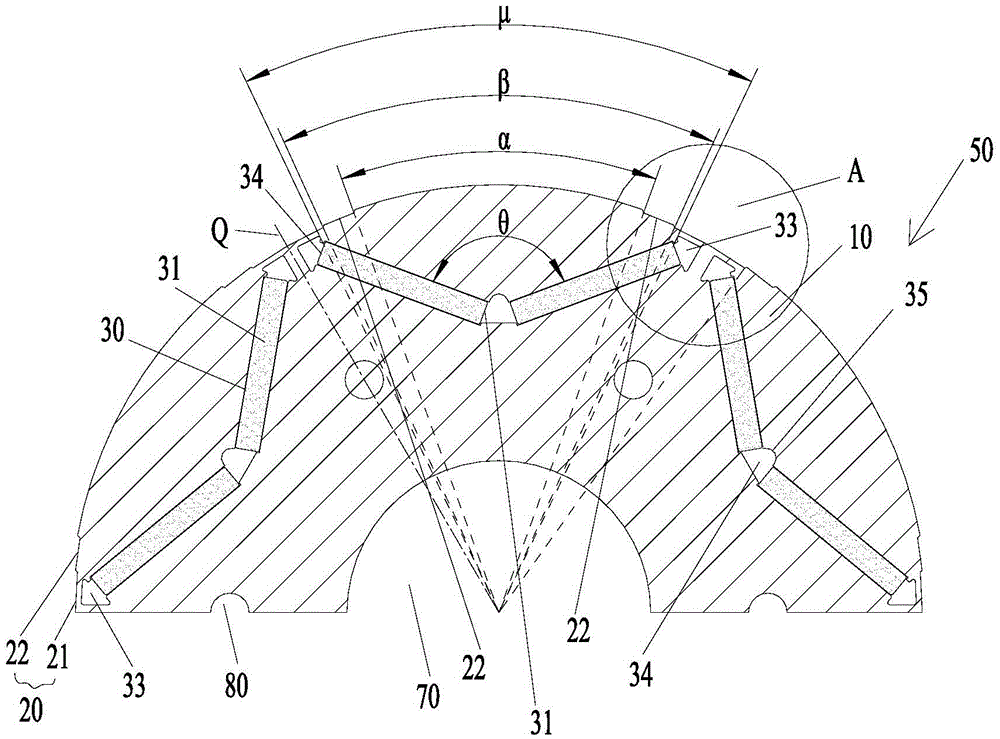

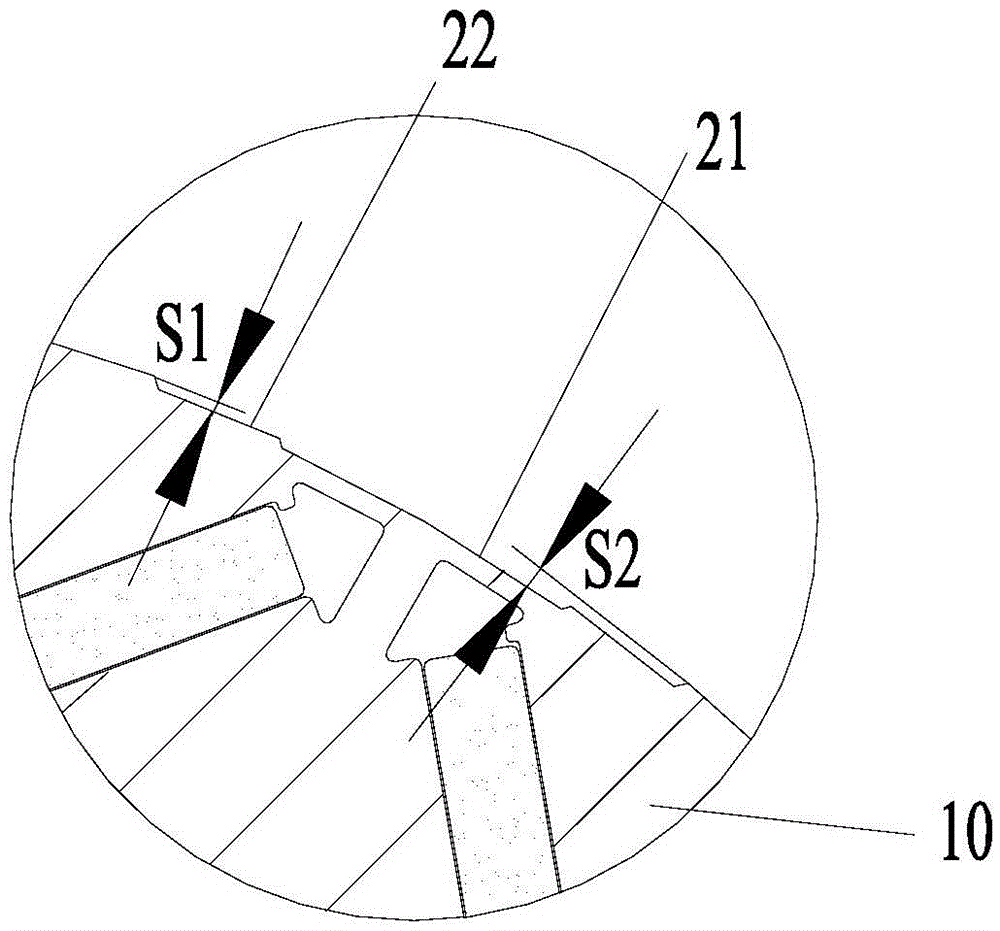

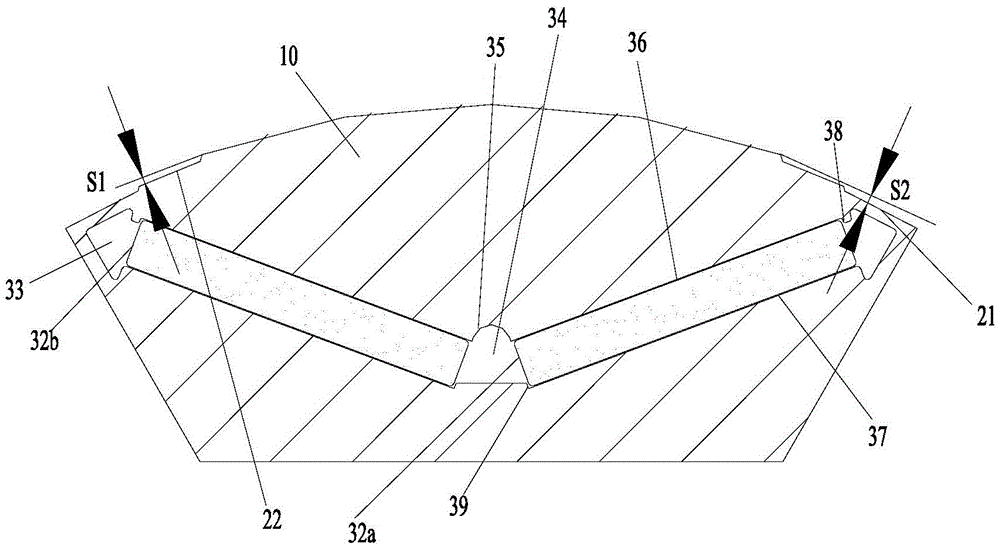

ActiveCN105553143AGreat effortHarmonic reductionMagnetic circuit rotating partsSynchronous machinesHarmonicPermanent magnet synchronous motor

The invention provides a rotor iron core and a permanent magnet synchronous motor with the same. The rotor iron core comprises an iron core body, wherein grooves are formed on the peripheral wall of the iron core body in an axial direction of the iron core body; the grooves comprise a first groove and a second groove which are communicated mutually; and a depth of the first groove in a radial direction of the iron core body is greater than that of the second groove in the radial direction of the iron core body. At the position of the first groove, an air gap is the largest, magnetic resistance is high, an air gap flux density is small, and an applied moment fluctuation with a stator tooth socket is reduced; the first groove and the second groove have different depths; by transition of the second groove, a fundamental wave magnetic field is increased and is closer to sine; a torque of the tooth socket is reduced, so that a motor output is increased, a harmonic wave is reduced, and an electromagnetic force and operation vibration voice of the motor are reduced.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Permanent magnet generator

InactiveUS20130069604A1Increase speedFew flux lineEmergency protective circuit arrangementsSynchronous machinesCouplingPermanent magnet synchronous generator

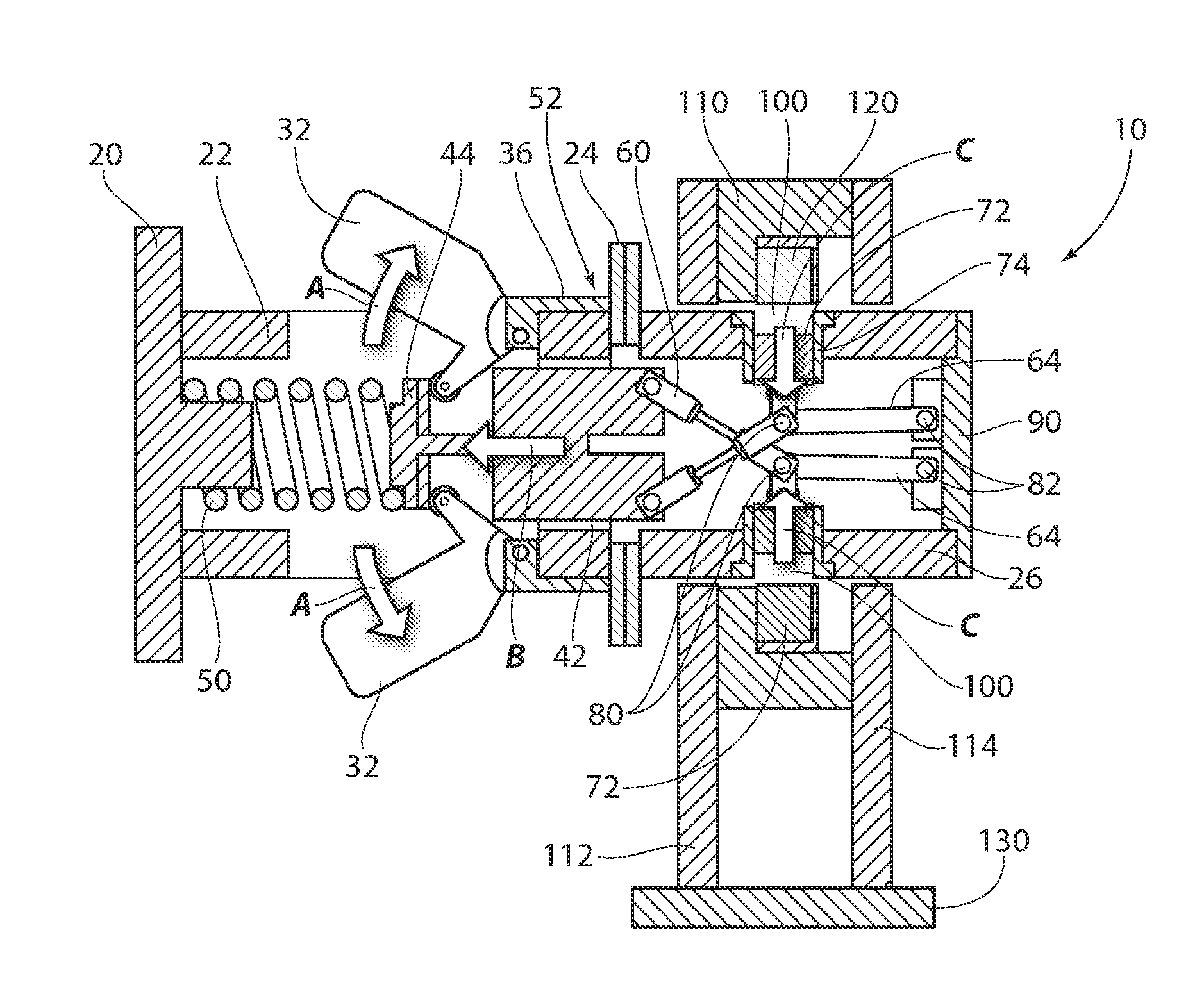

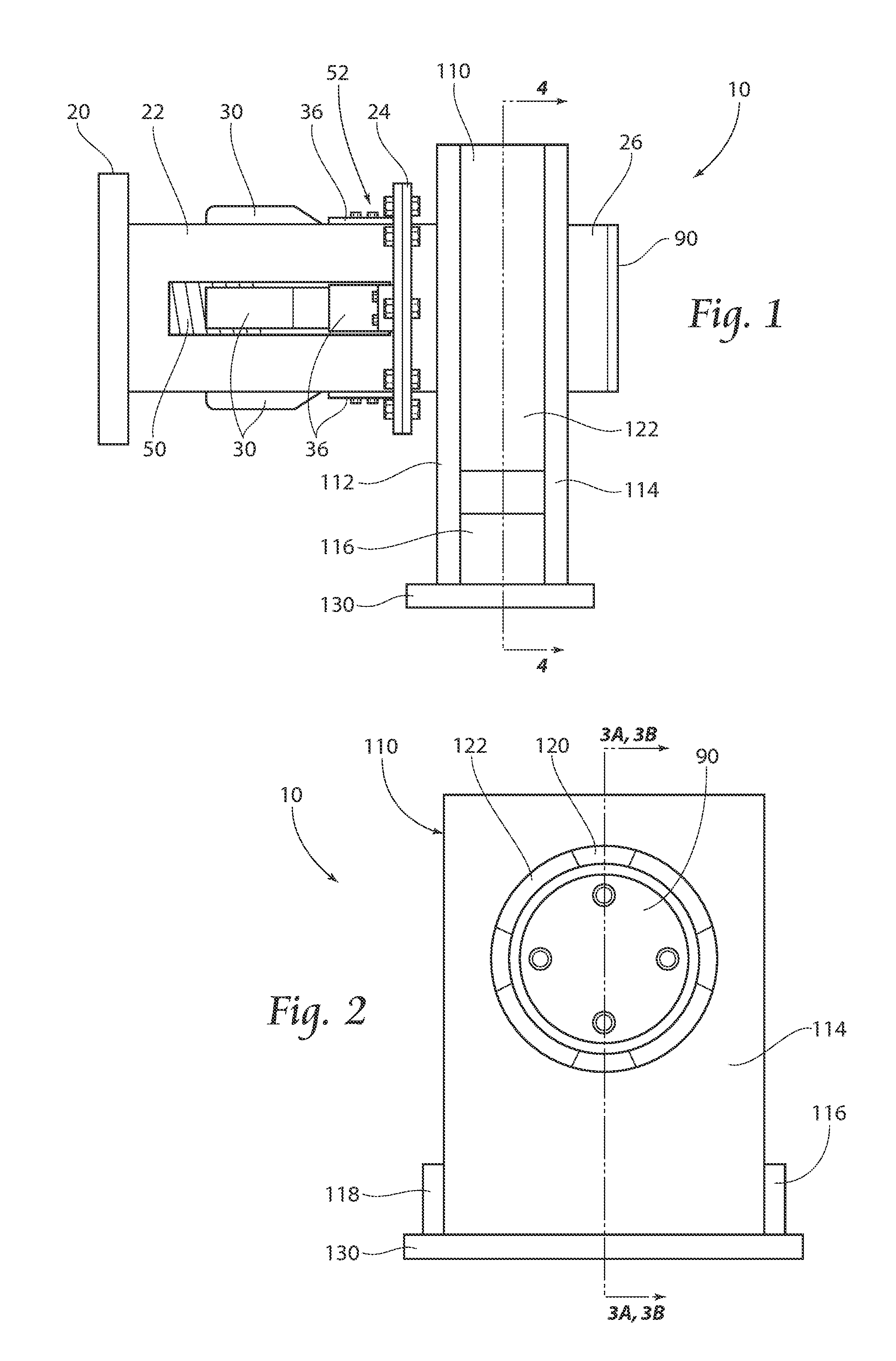

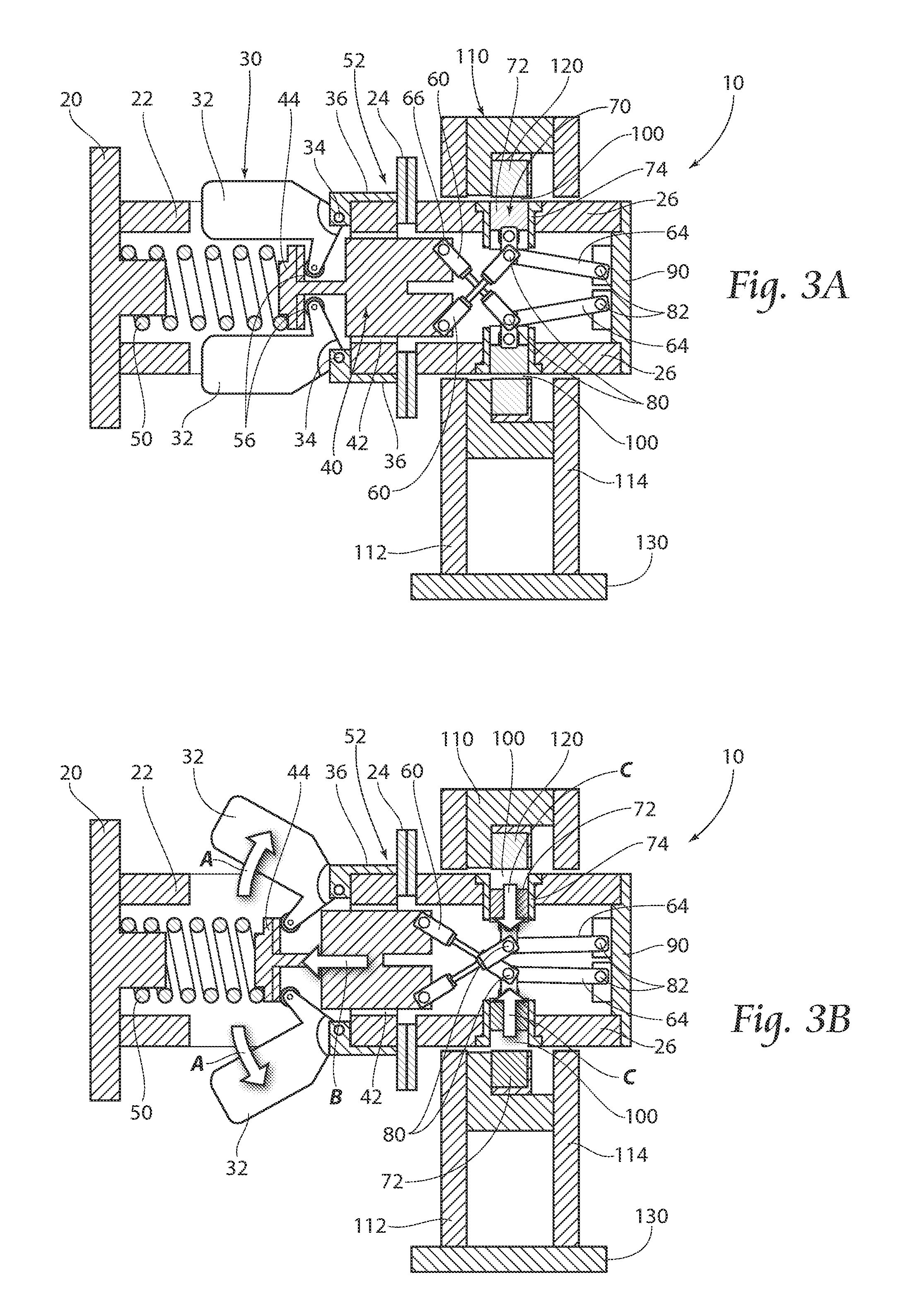

A permanent magnet generator having the unique feature of a speed proportionally adjusted air gap for self-regulation of coil output voltage over a wide range of operating rotational speed of a steam turbine to which the invention is coupled. The Permanent Magnet Generator rotor is supported by the turbine end shaft and the stator is supported by a bracket bolted to the turbine pedestal base or other rigid structure. The speed proportional air gap is accomplished through the use of a plurality of centrifugal flyweights in mechanical coupling to a spool piece under spring load and to corresponding rare earth magnets via linkage such that increasing rotor speed extends the flyweights outward from the rotor center of rotation and draws the rare earth magnets closer to the rotor center of rotation and thus increases the air gap.

Owner:LOVEJOY CONTROLS

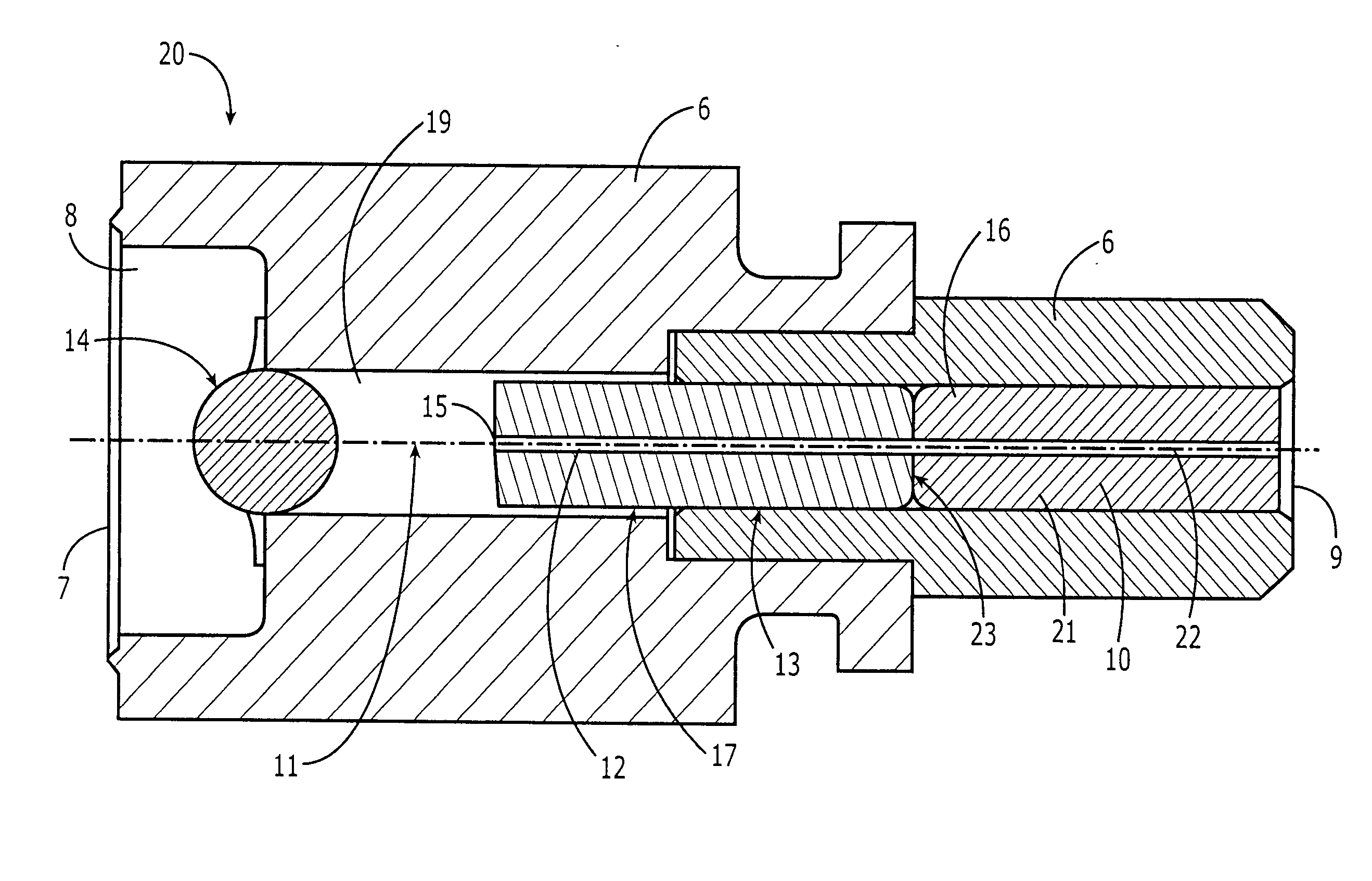

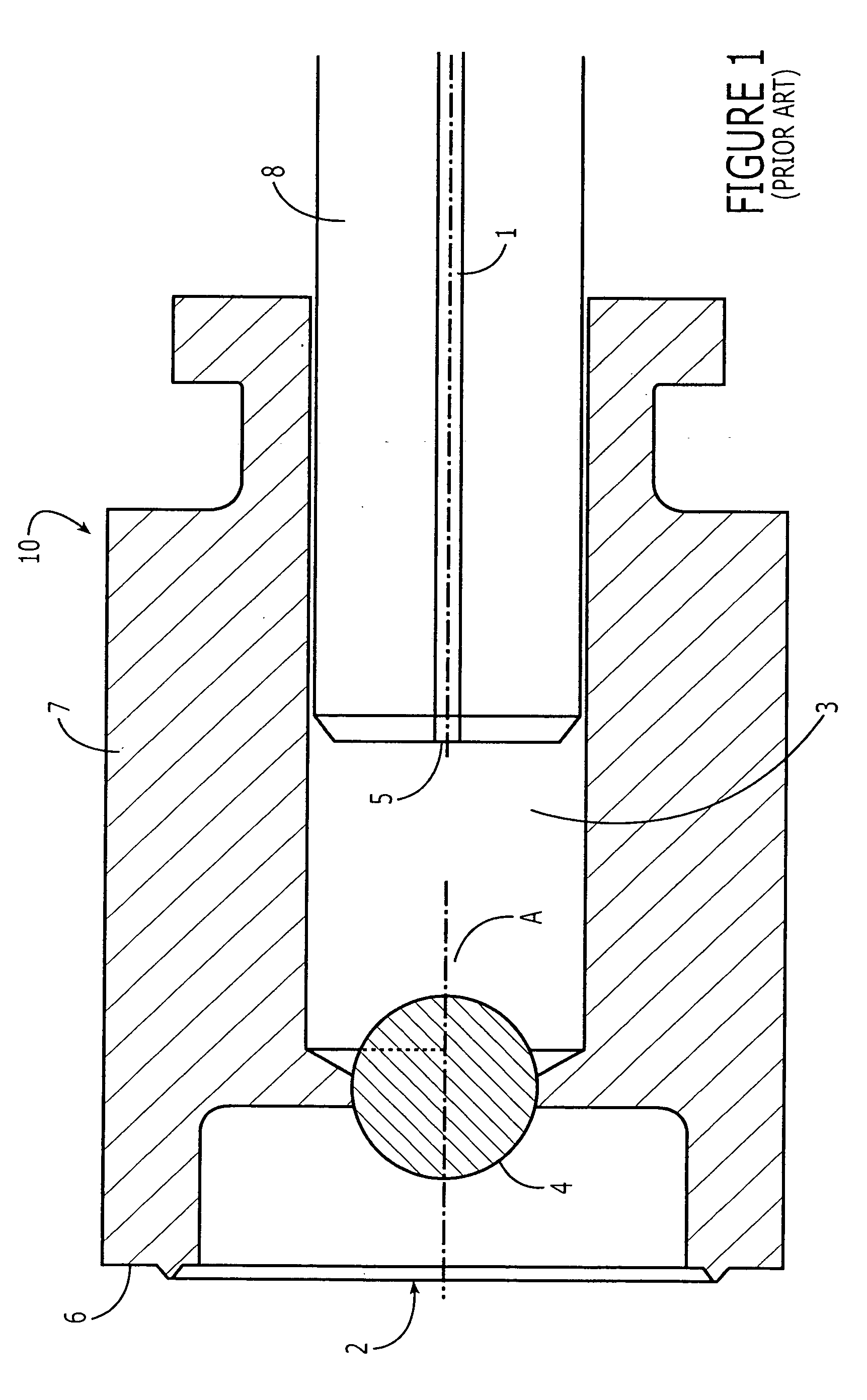

Dual operating mode electronic disabling device for generating a time-sequenced, shaped voltage output waveform

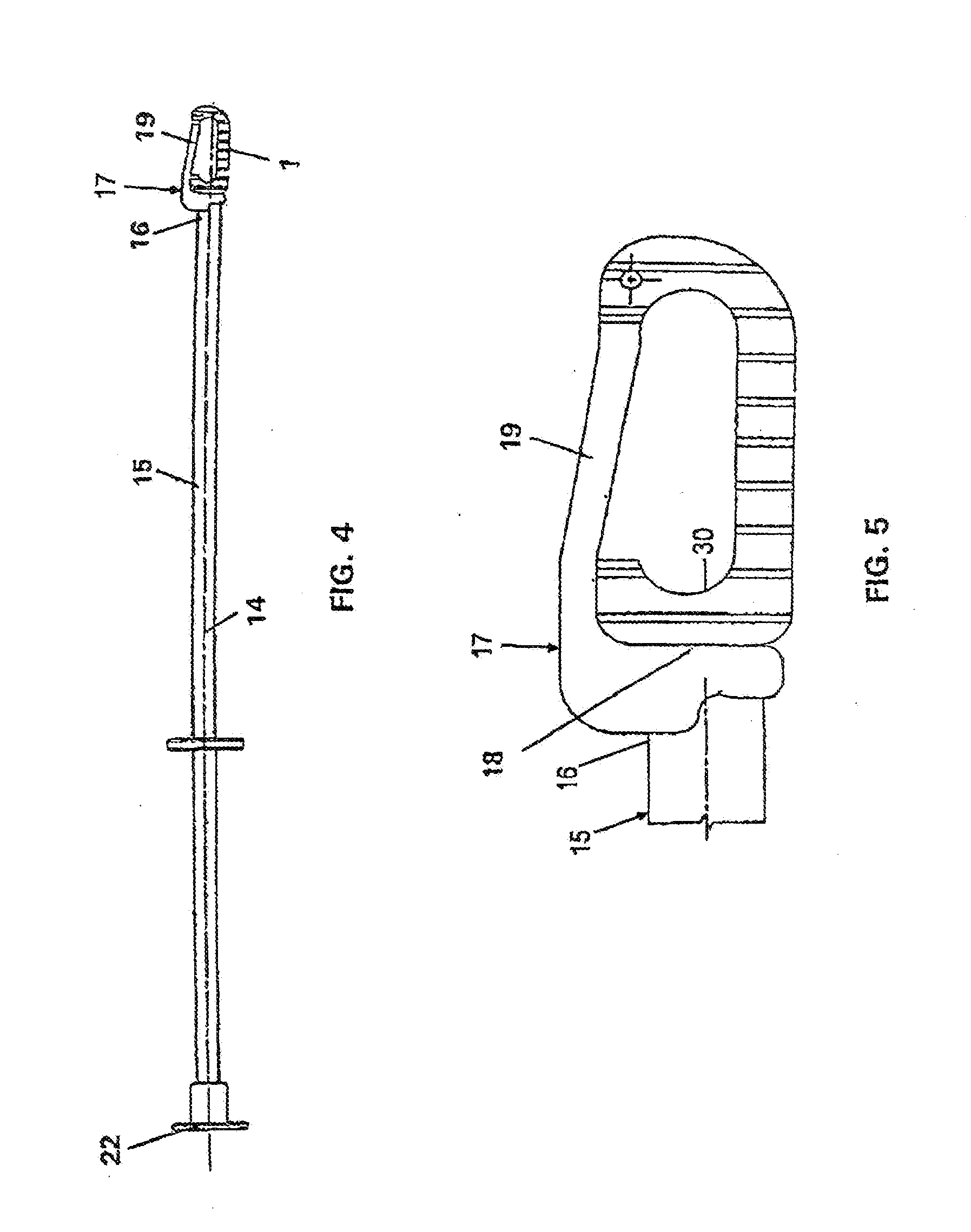

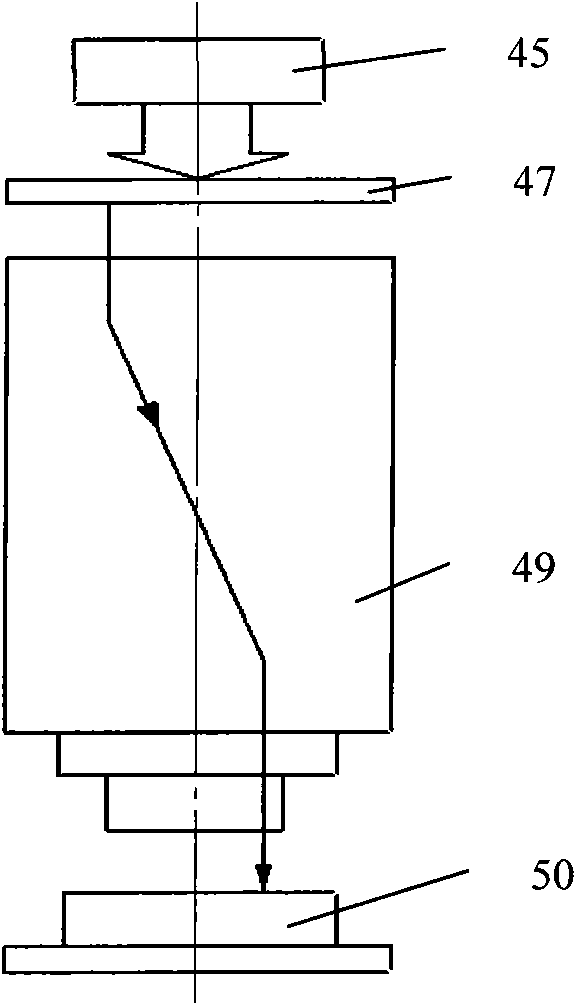

InactiveUS20050188888A1Reduce high impedanceIncrease the air gapAmmunition projectilesElectric shock equipmentsShort durationHigh impedance

An electronic disabling device includes first and second electrodes positionable to establish first and second spaced apart contact points on a target having a high impedance air gap existing between at least one of the electrodes and the target. The power supply generates a first high voltage, short duration output across the first and second electrodes during a first time interval to ionize air within the air gap to thereby reduce the high impedance across the air gap to a lower impedance to enable current flow across the air gap at a lower voltage level. The power supply next generates a second lower voltage, longer duration output across the first and second electrodes during a second time interval to maintain the current flow across the first and second electrodes and between the first and second contact points on the target to enable the current flow through the target to cause involuntary muscle contractions to thereby immobilize the target.

Owner:AXON ENTERPRISE INC

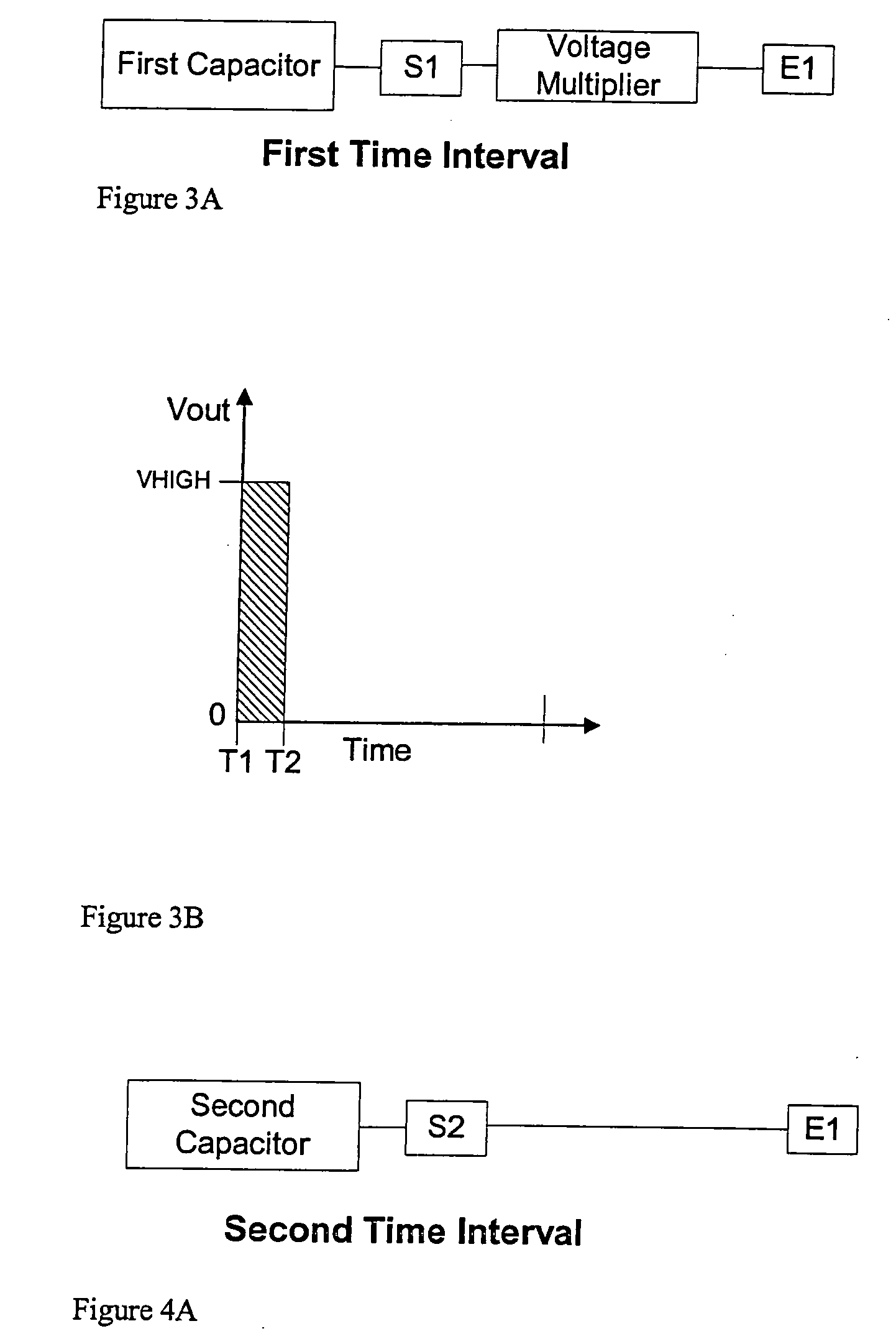

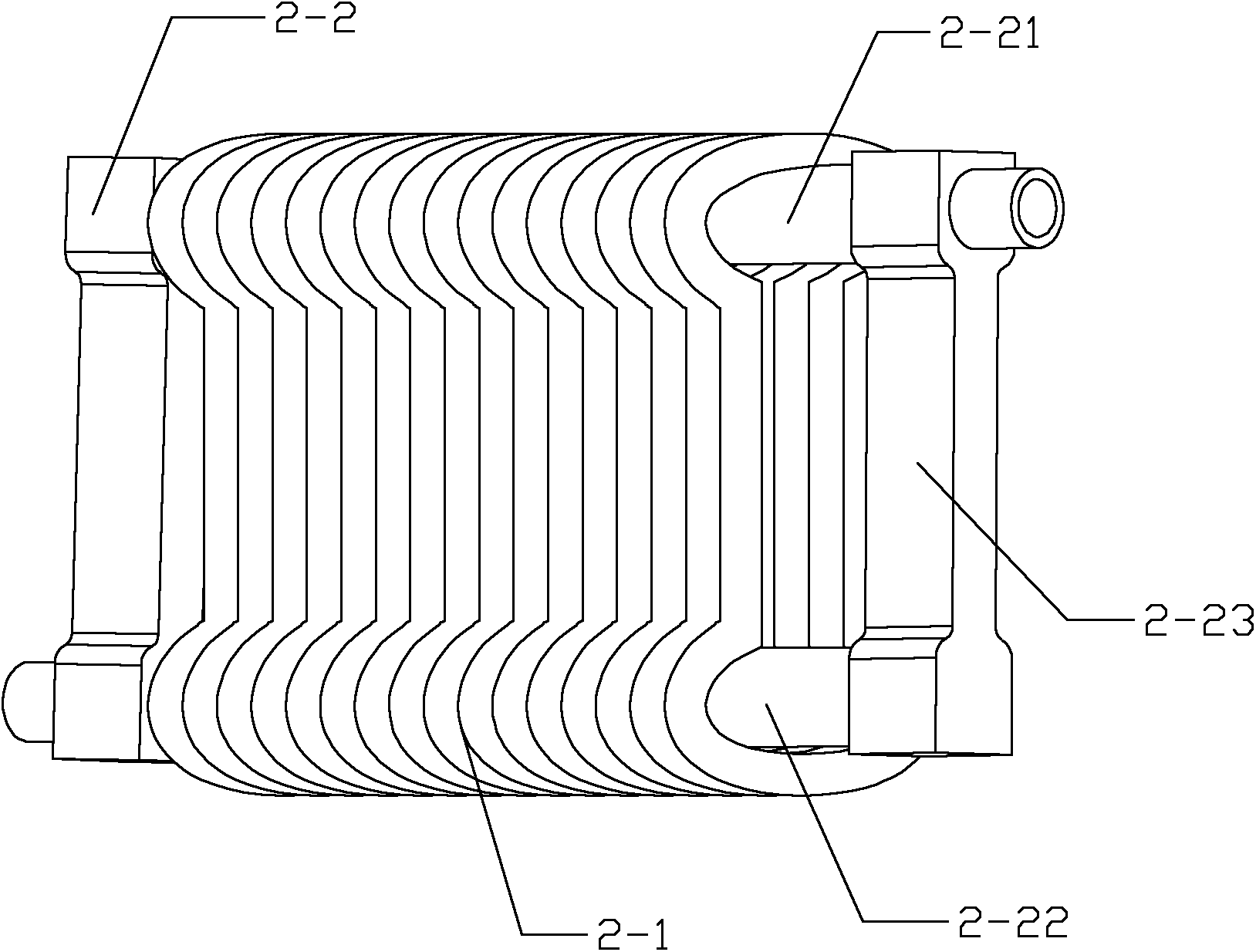

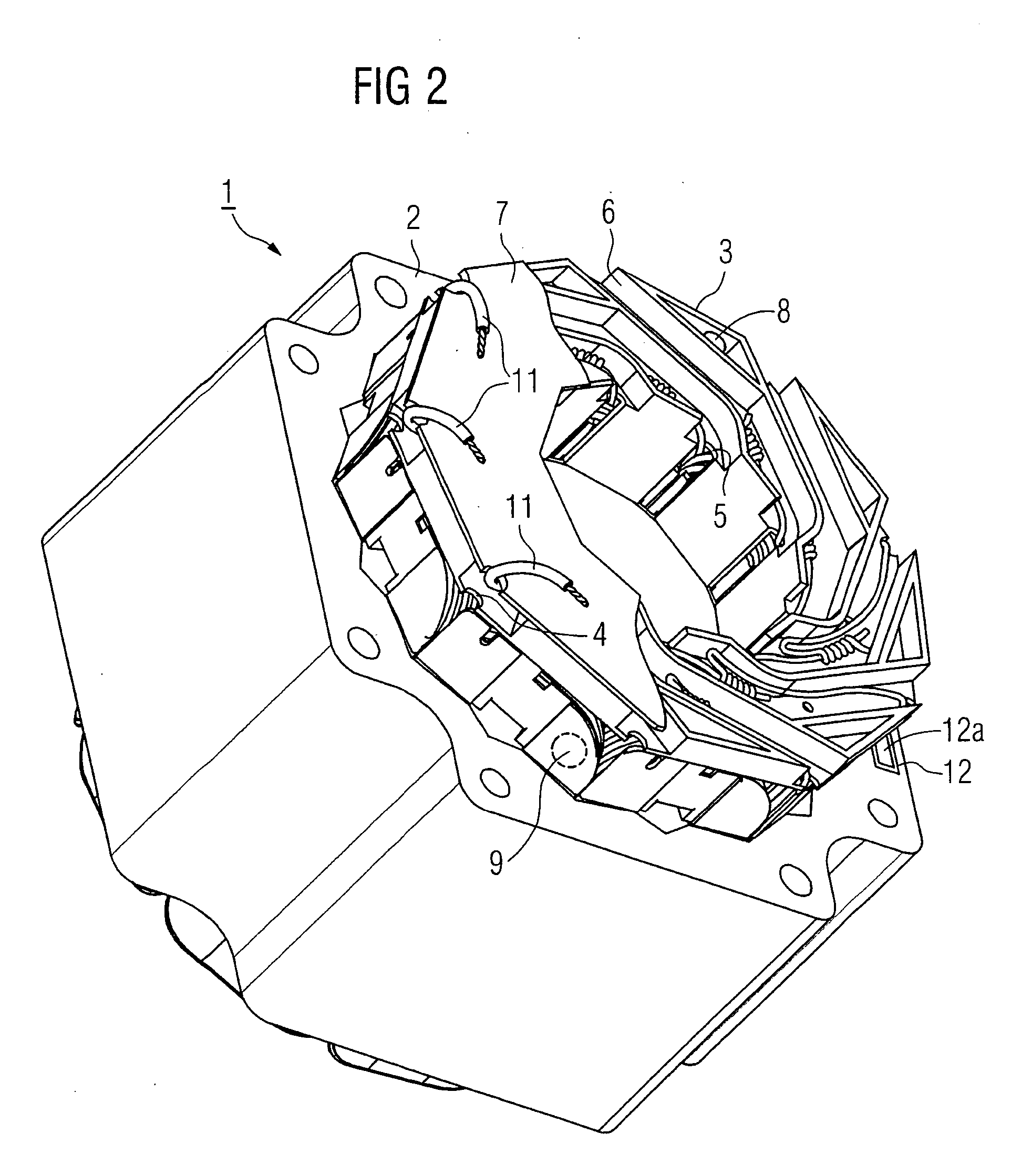

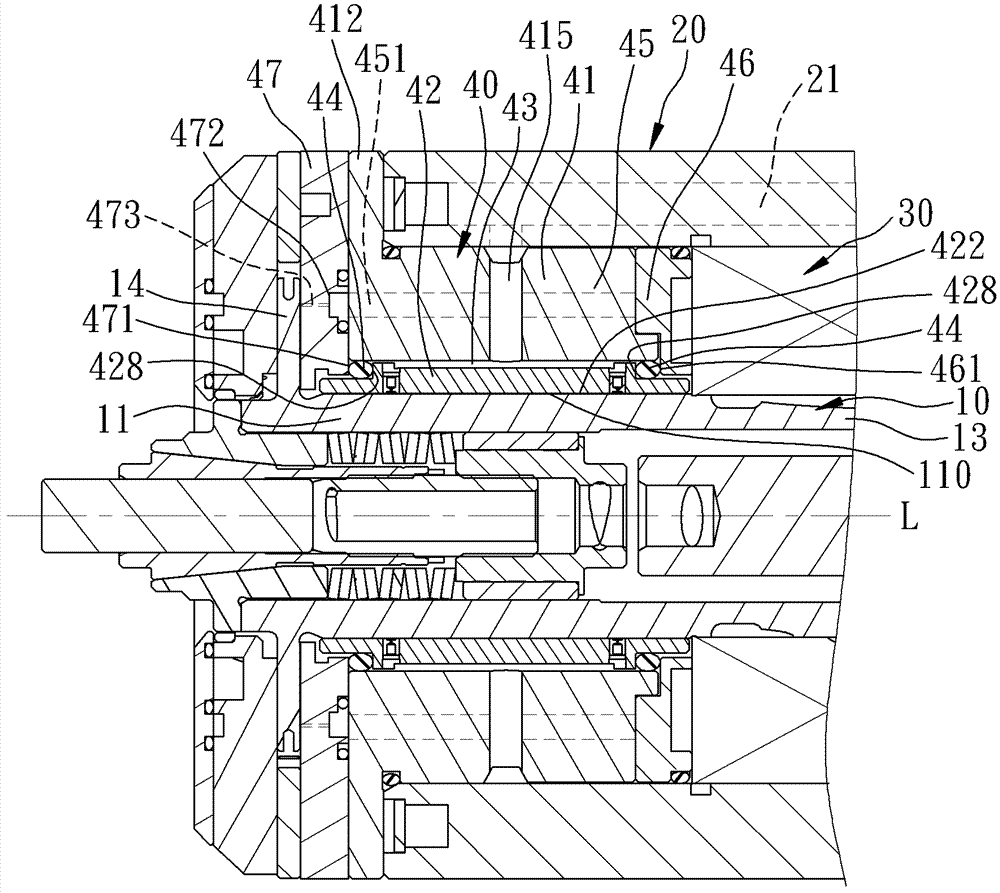

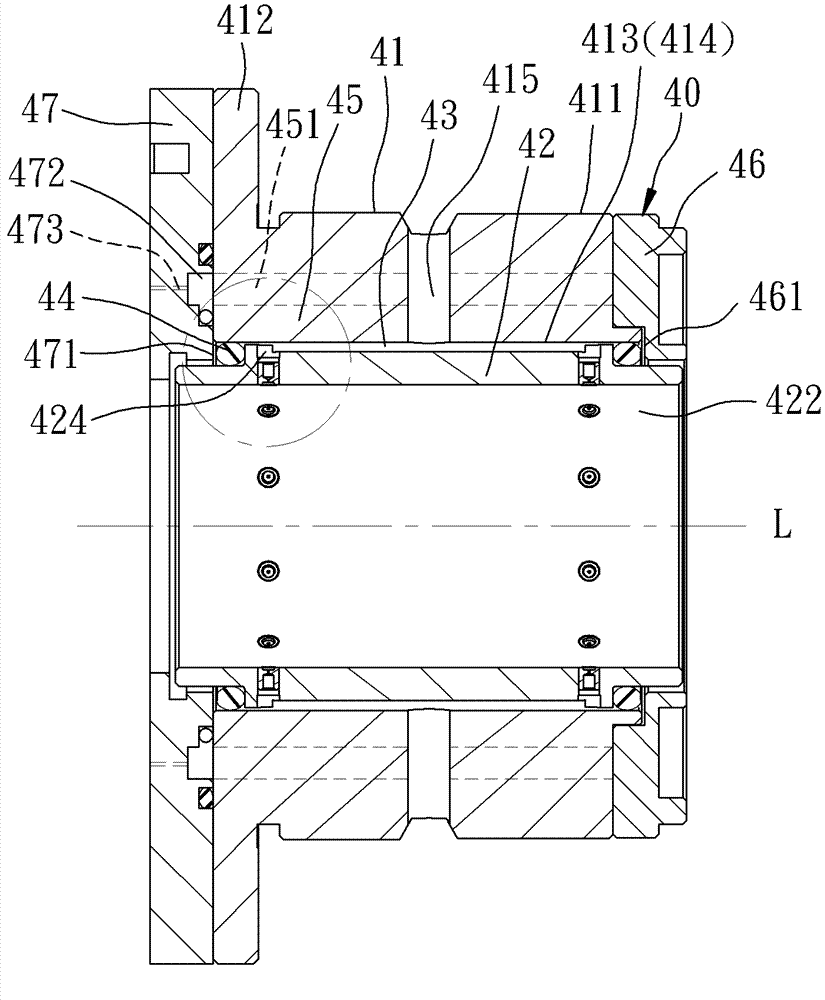

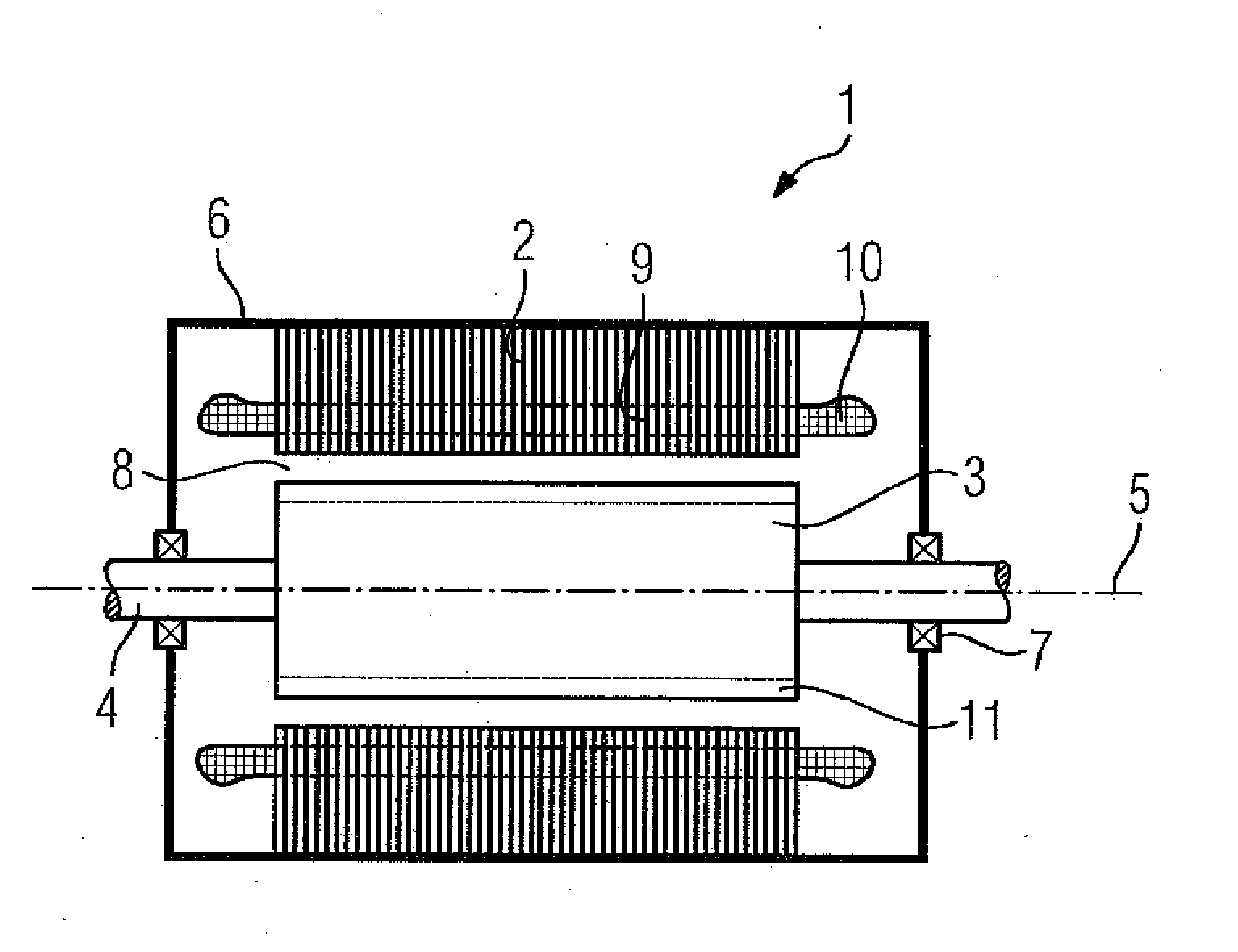

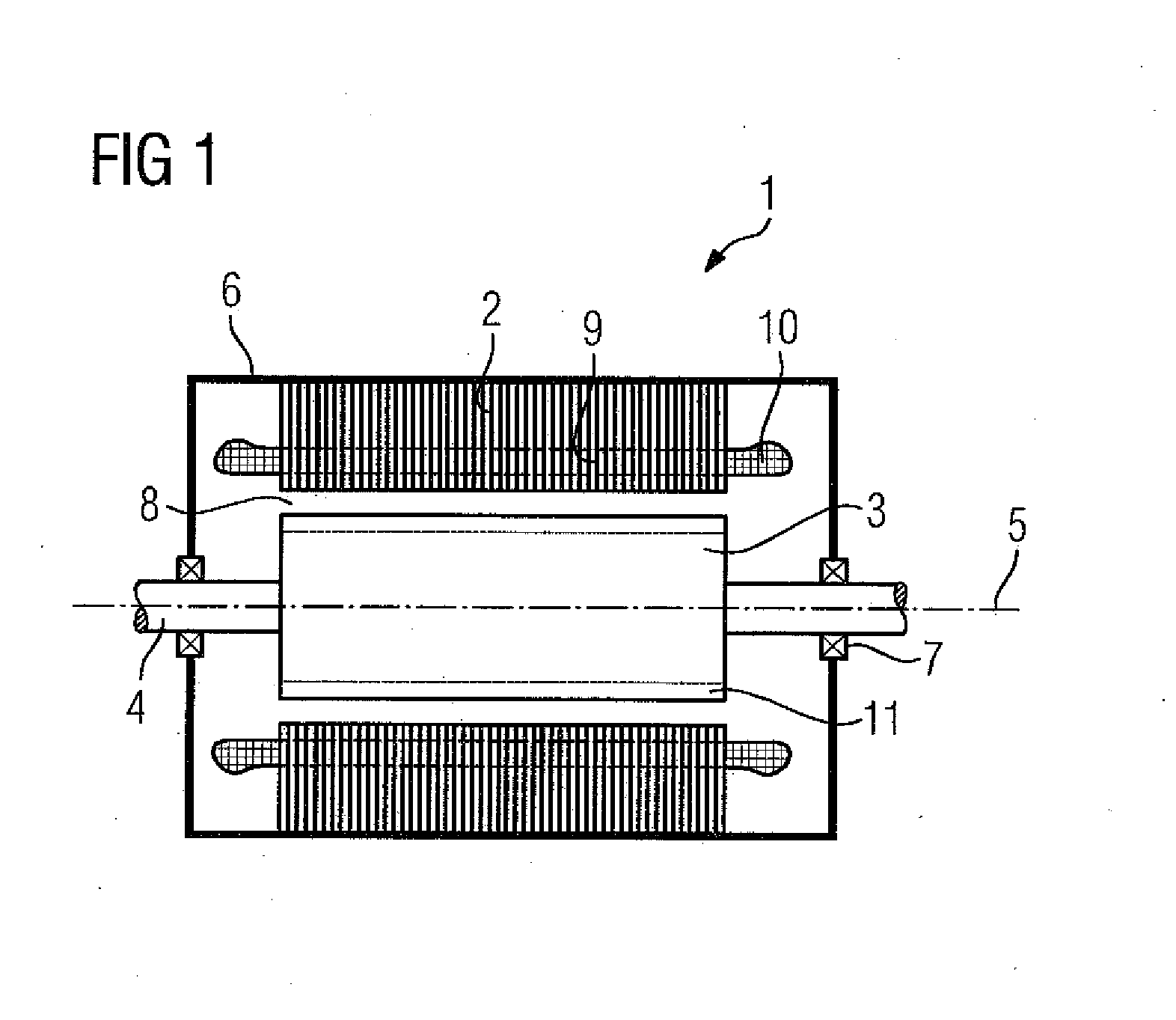

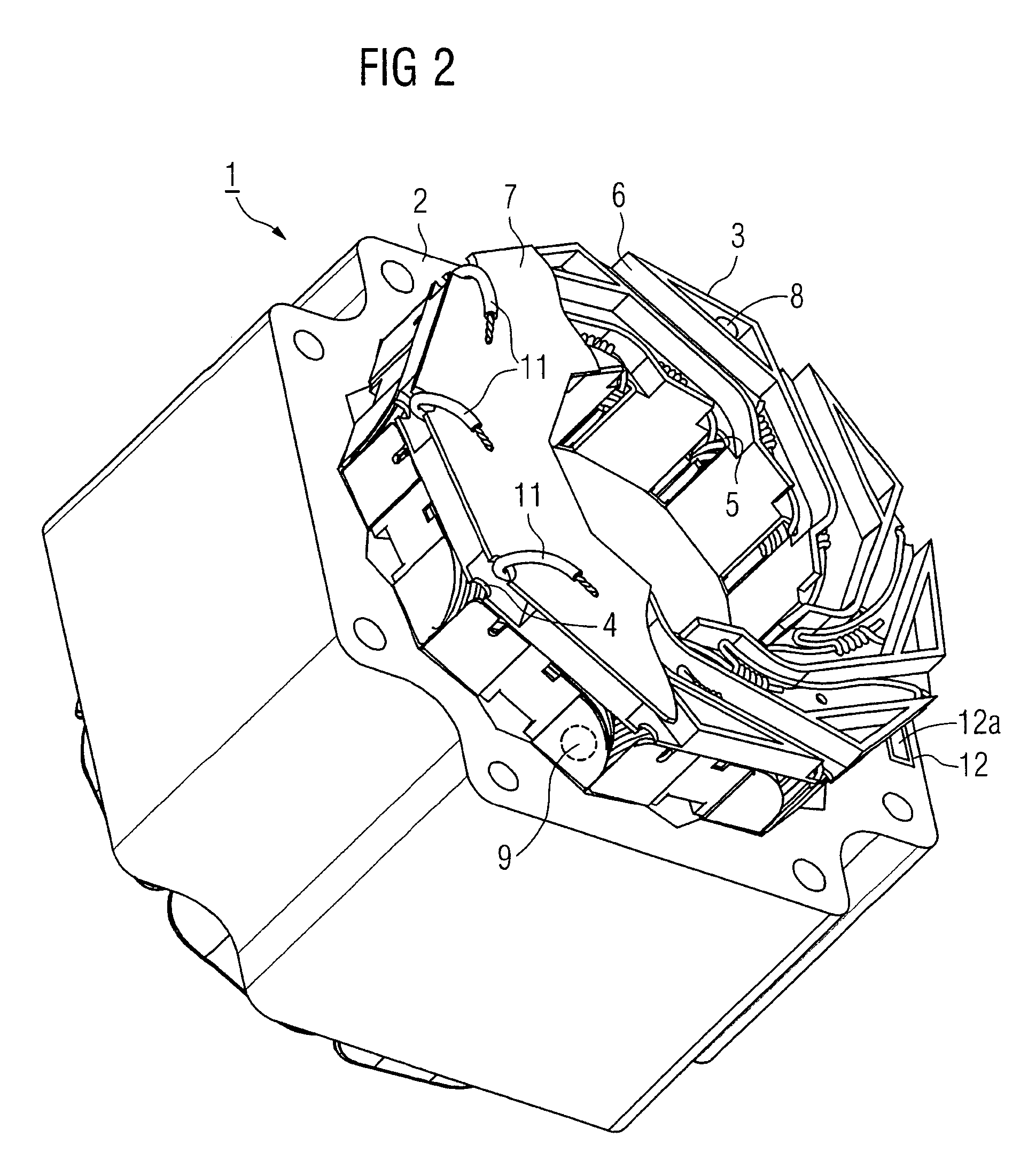

Electric machine having a rotary and a linear actuator

InactiveUS8026640B2High feed forceHigh strengthMagnetic circuitMechanical energy handlingLinear motionMachine parts

The invention relates to an electric machine which comprises a first machine part (30), comprising a stator element (31) and a rotor element (32) and being configured as a rotary actuator which interacts with a rotary movement of the rotor element (32). The electric machine (40) also comprises a second machine part (20), comprising a primary part (1) and a secondary part (2) and being configured as a linear actuator which interacts with a linear movement of the secondary part (2). The rotor element (32) of the first machine part (30) and the secondary part (2) of the second machine part (20) are interlinked. The secondary part (2) of the second machine part (20) can be rotated and is configured as an external rotor. Such a secondary part (2) allows to generate a higher power of a secondary machine part (20) acting as the linear motor. The secondary part (2) is mounted in the center thereof in relation to the primary part (1).

Owner:SIEMENS AG

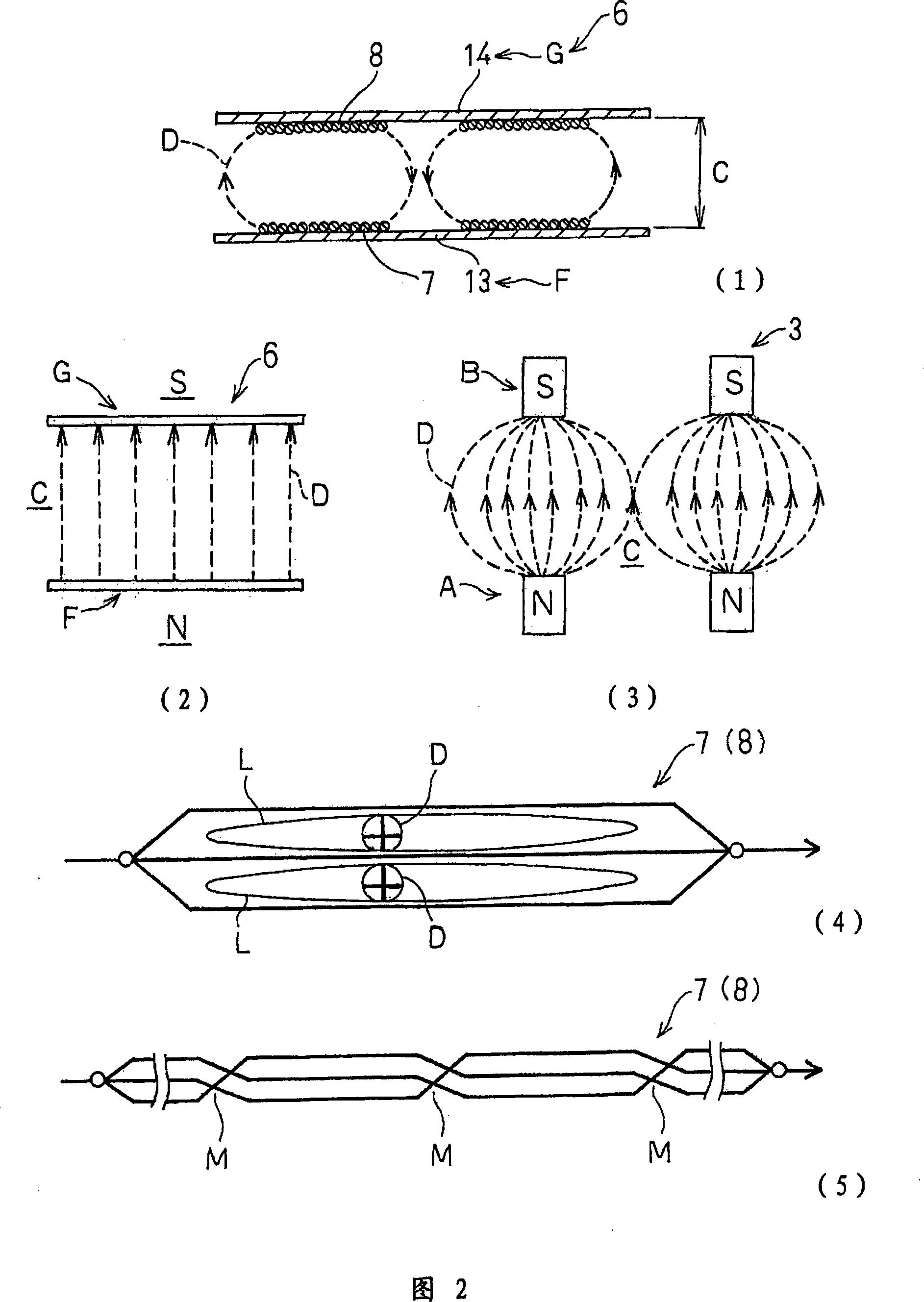

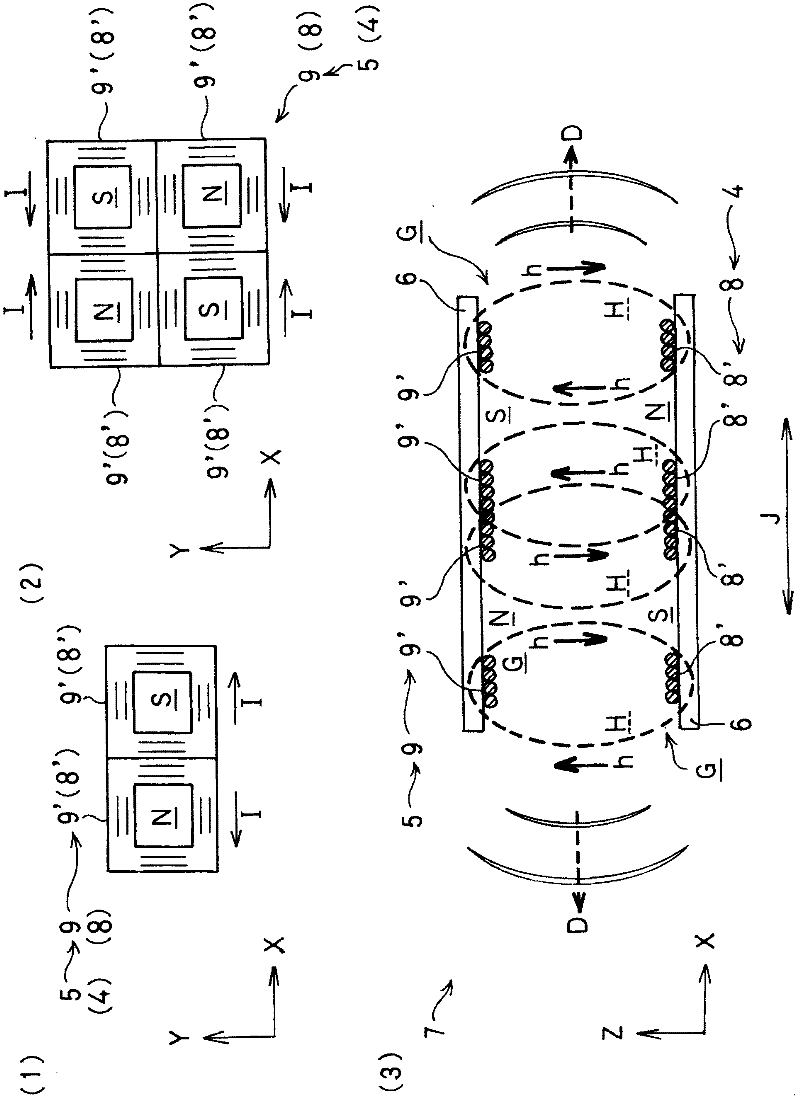

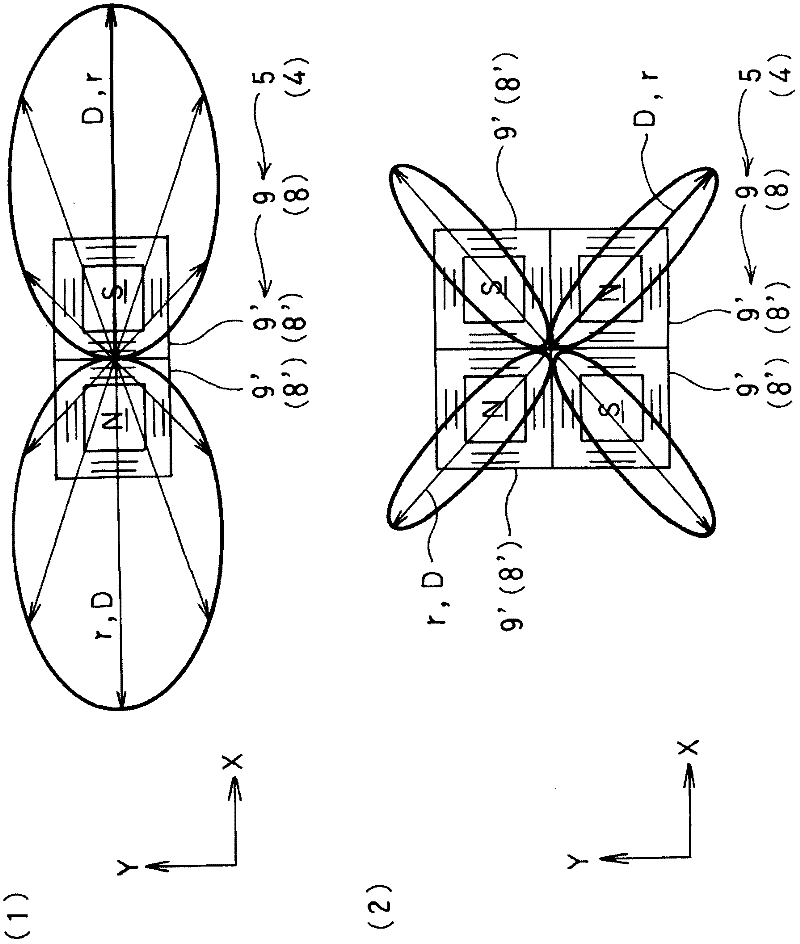

Non-contact power feeding apparatus

InactiveCN102545393AAvoid damageReduce intensityRail devicesElectromagnetic wave systemElectricityPower flow

In a non-contact power feeding apparatus 7 of the present invention, power is fed through an air gap G from a power transmission coil 8 of a power feeding side circuit 4 to a power receiving coil 9 of a power receiving side circuit 5, which are closely located to face each other, based on a mutual induction effect of electromagnetic induction. The power transmission coil 8 and the power receiving coil 9 are respectively composed of a planar assembly of a number of unit coils 8' and 9'. Each unit coil 8' (9') is formed in a spirally wound flat structure, wherein the direction of an electric current I is set in reverse to make the north and south magnetic poles reverse between each unit coil 8' (9') which is juxtaposed to another to directly come into line. As a result, the unit coils 8' (9'), which are juxtaposed to another to directly come into line, are provided in such a manner that an overlapping area of a respectively formed magnetic field H cancels another out to be offset.

Owner:SHOWA AIRCRAFT INDUSTRY

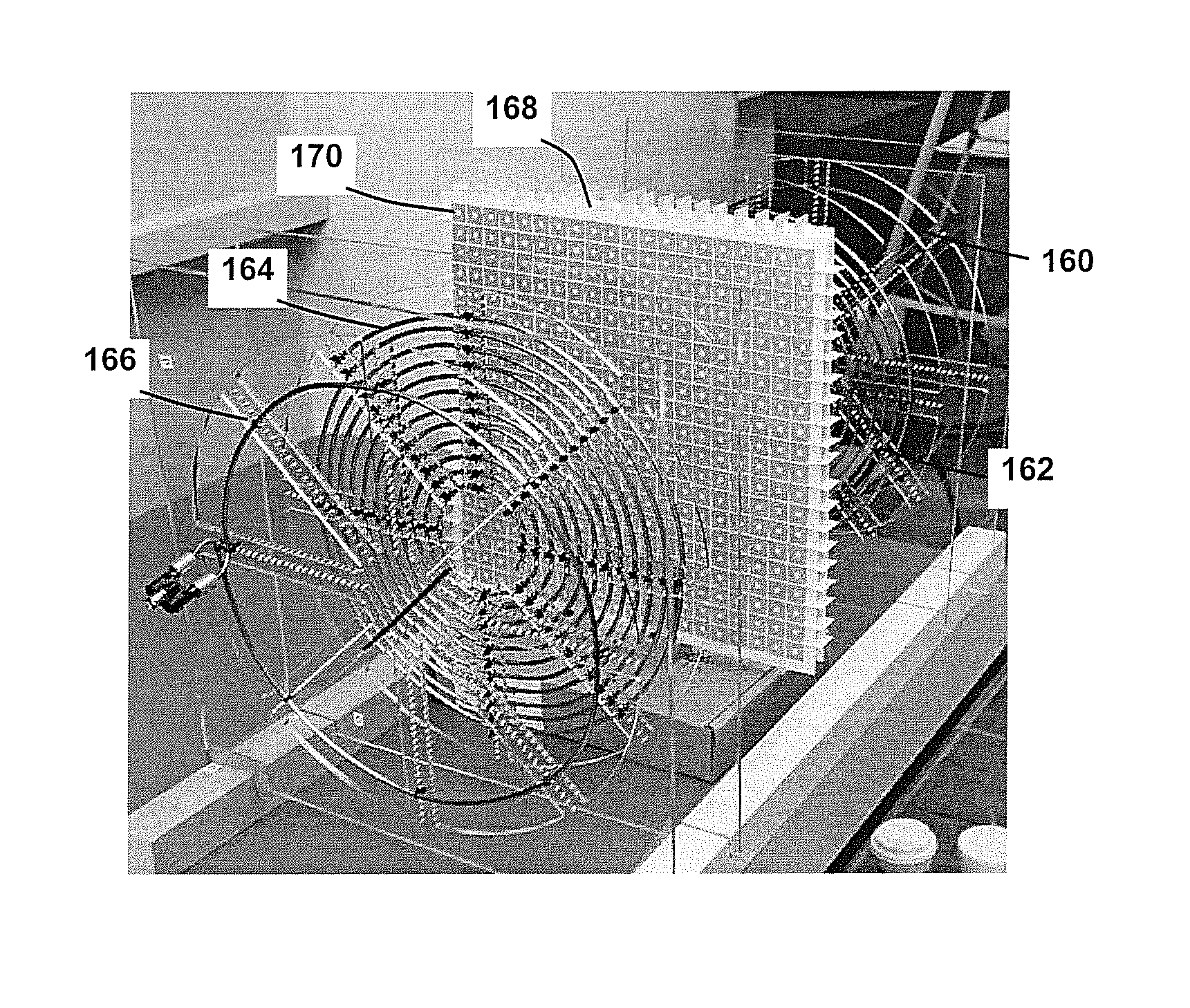

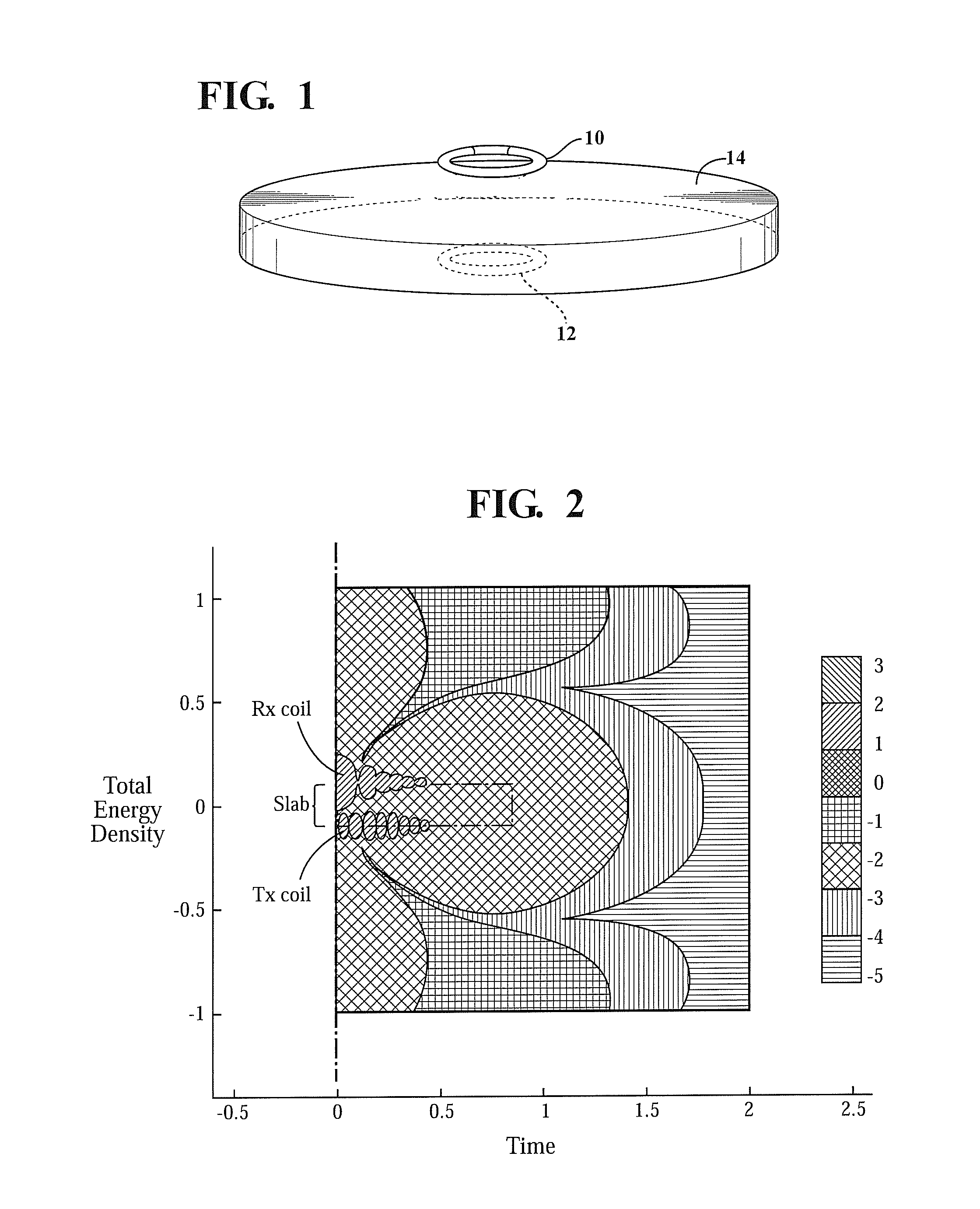

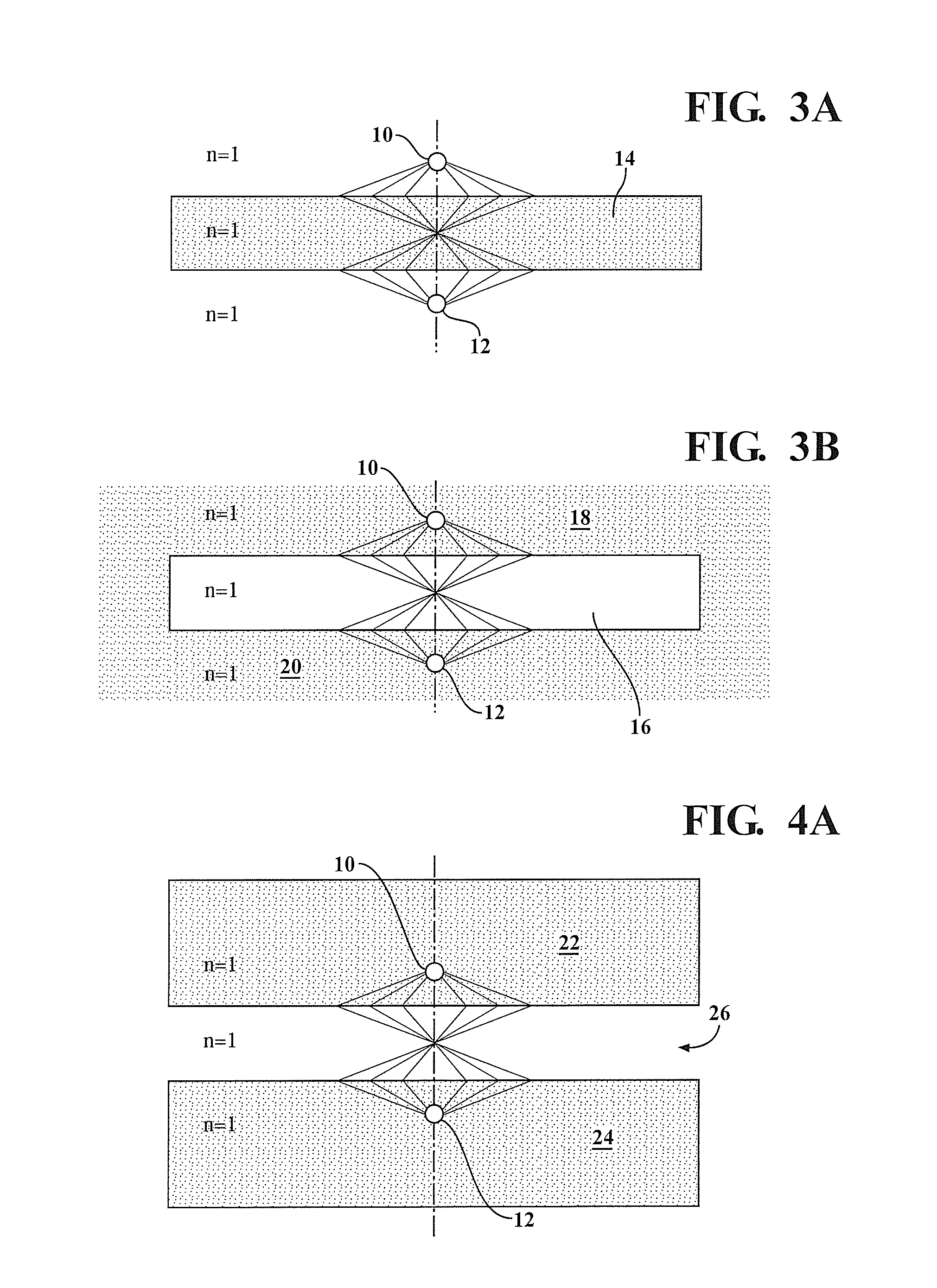

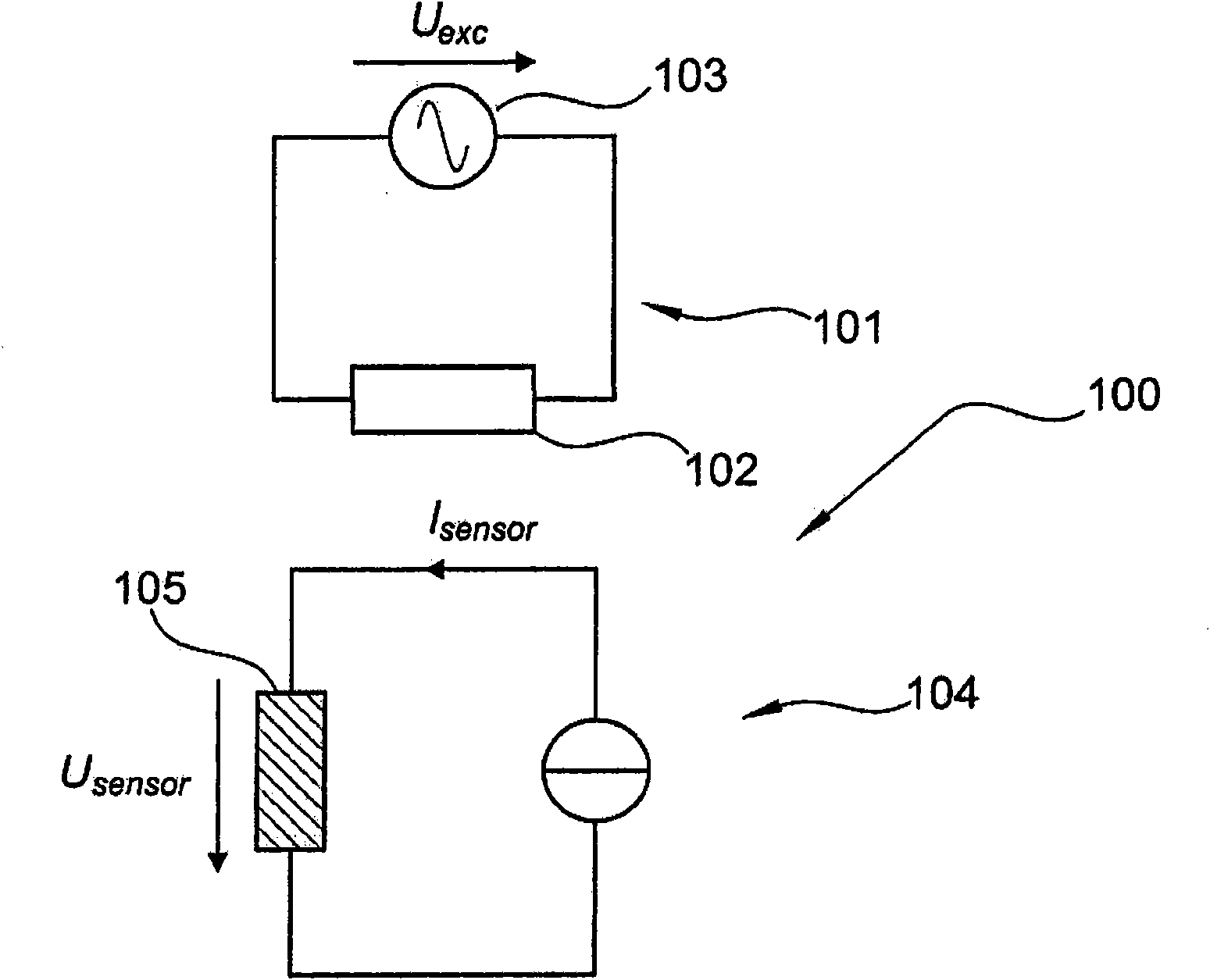

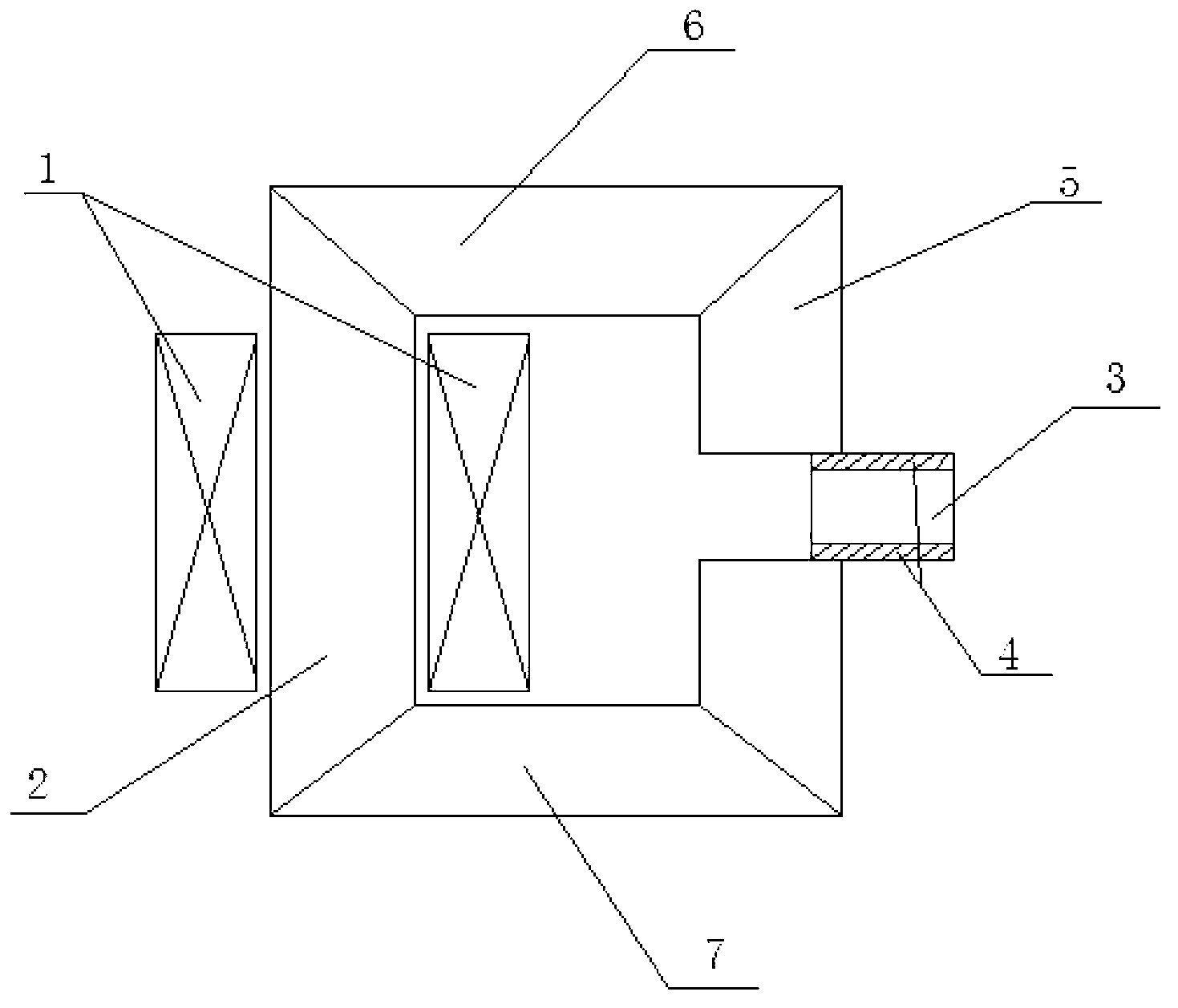

Wireless power transfer using air gap and metamaterial

ActiveUS20140159479A1Increasing efficiency of wireless power transferImprove efficiencyCharging stationsElectromagnetic wave systemTransmitter coilTransmitted power

Examples of the invention include methods and apparatus for wirelessly transmitting power to a vehicle using electromagnetic radiation. An example apparatus includes a transmitter coil associated with a first metamaterial lens, and a receiver coil associated with a second metamaterial lens, the receiver coil being located within the vehicle. The metamaterial lenses each have a negative magnetic permeability, and are separated by a lens spacing including an air gap. The first and second metamaterial lenses (and the lens spacing) act cooperatively to focus the electromagnetic radiation from the transmitter coil on the receiver coil.

Owner:TOYOTA JIDOSHA KK

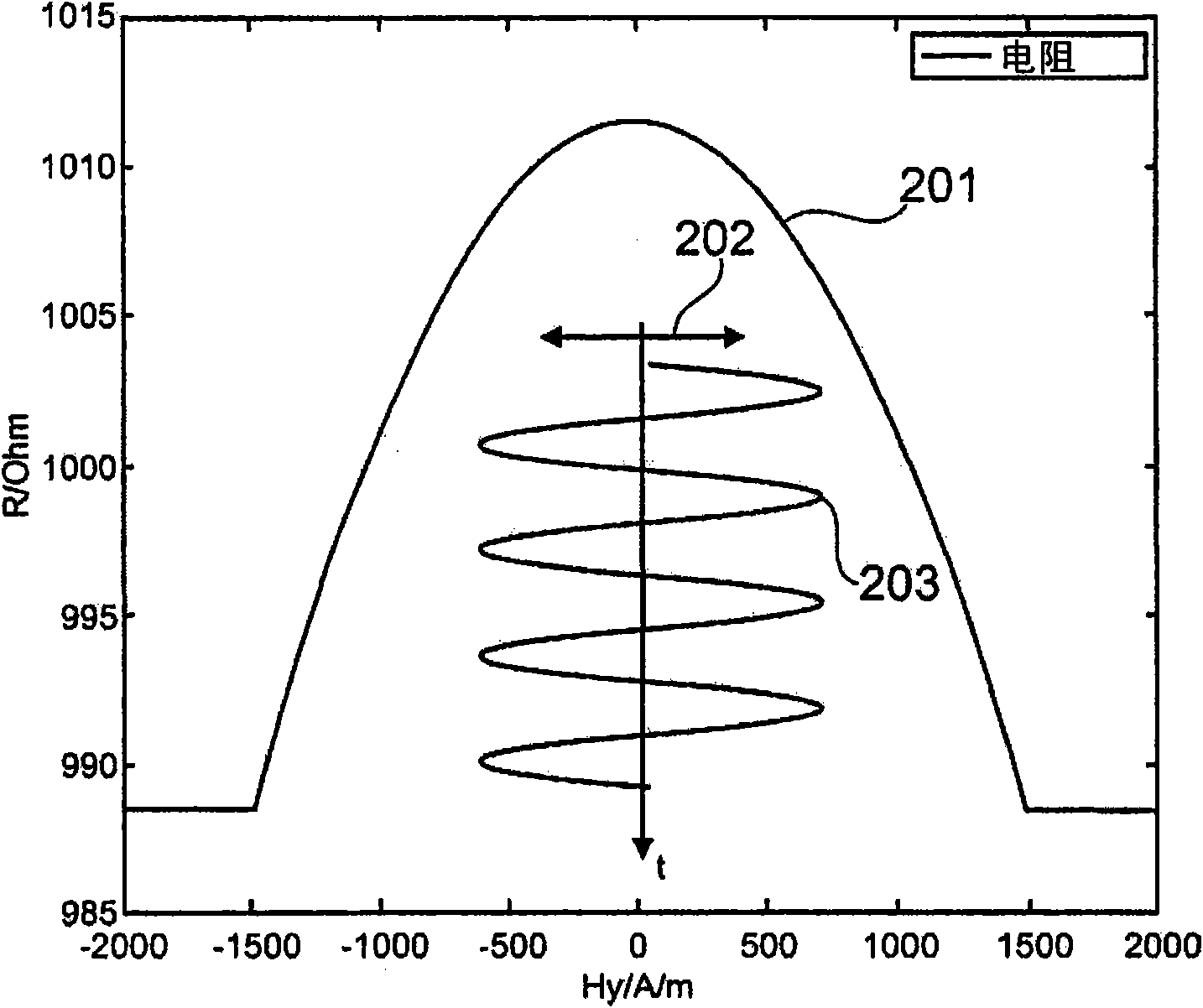

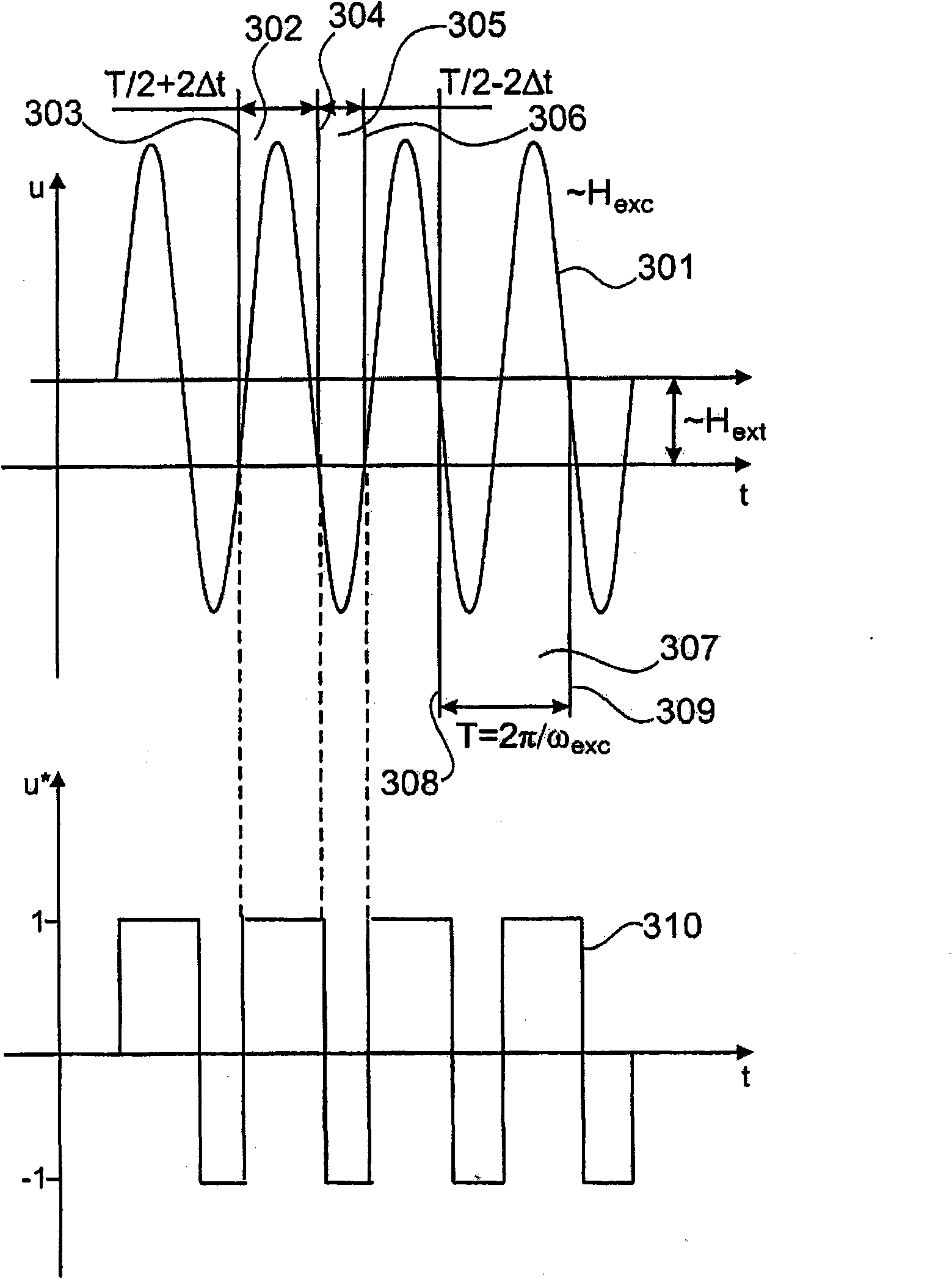

Magnetoresistance sensor and method of operating a magnetoresistance sensor

InactiveCN101855563AHigh sensitivityReliable measurementNanomagnetismMagnetic measurementsElectrical resistance and conductanceSensor system

Amagnetoresistive sensor system (400) is provided, wherein the system comprises a magnetic field source (402), a magnetoresistive sensor (403) having an easy axis, and a differentiation element (404), wherein the magnetic field source (402) is adapted to emit an auxiliary magnetic field generated from an oscillating input signal (401), wherein the auxiliary magnetic field is orthogonal to the easy axis of the magnetoresistive sensor (403), wherein the magnetoresistive sensor (403.) is adapted to sense a signal associated to a superposition of an external magnetic field and the auxiliary alternating magnetic field, and wherein the differentiation element (404) is adapted to differentiate the sensed signal.

Owner:NXP BV

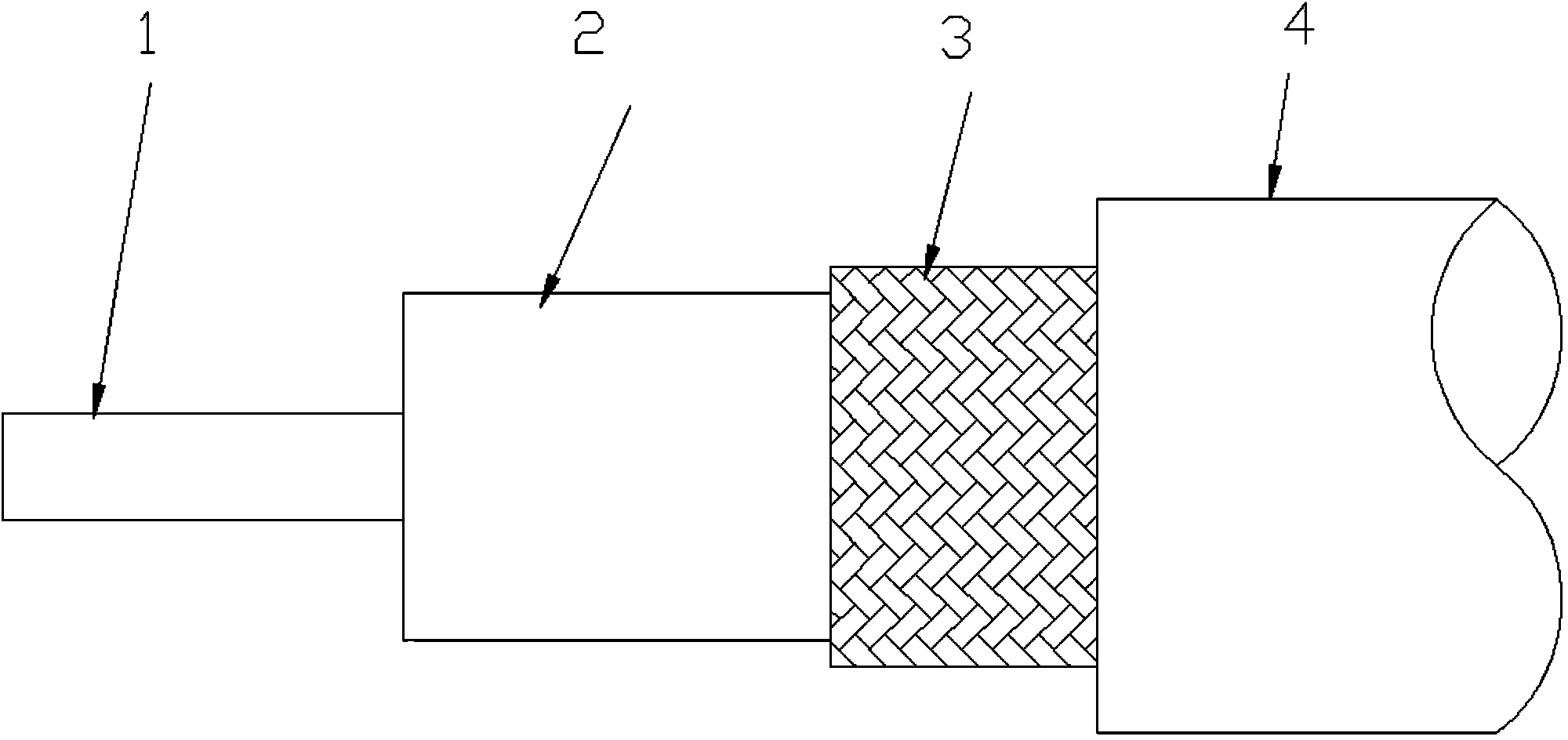

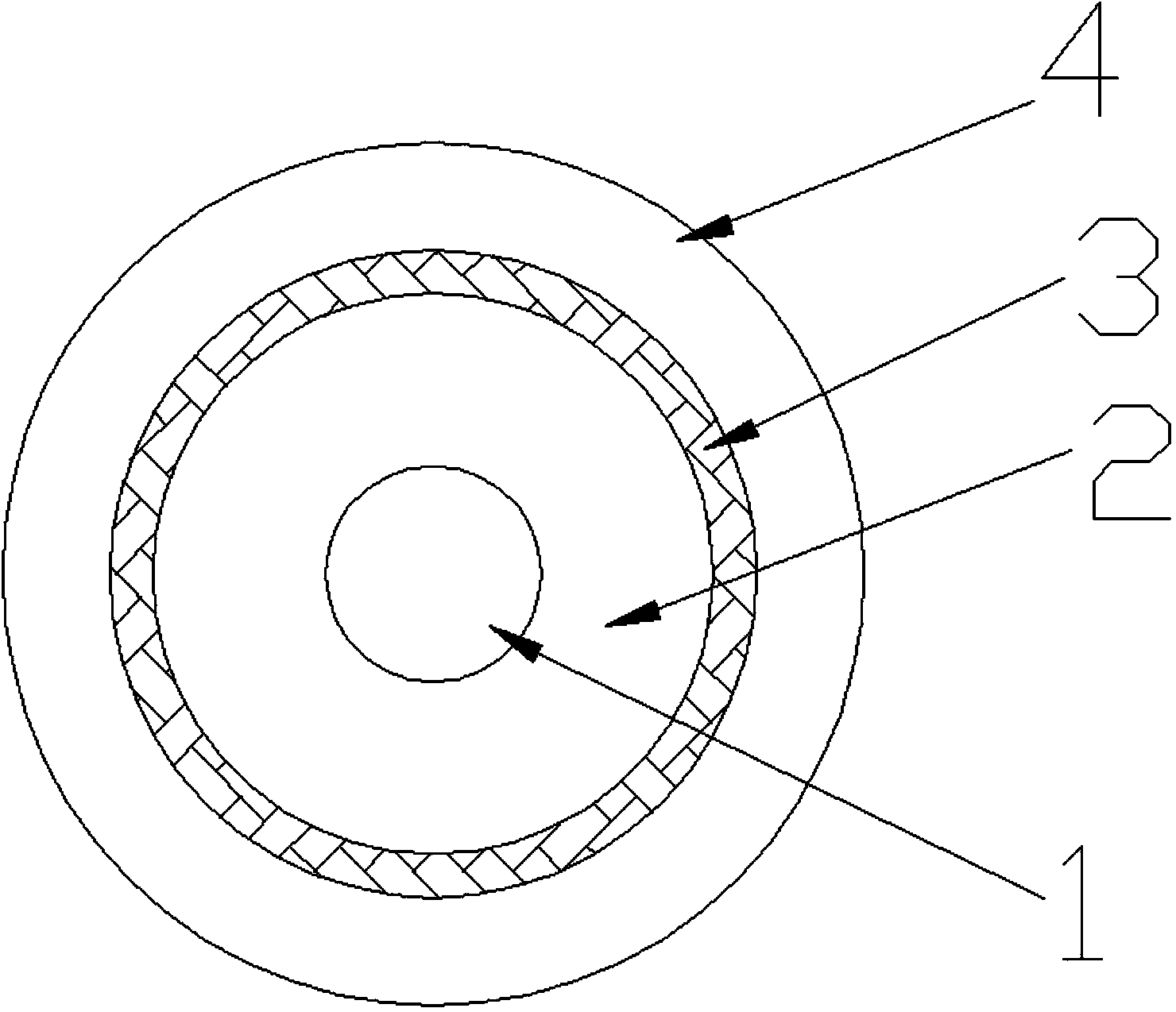

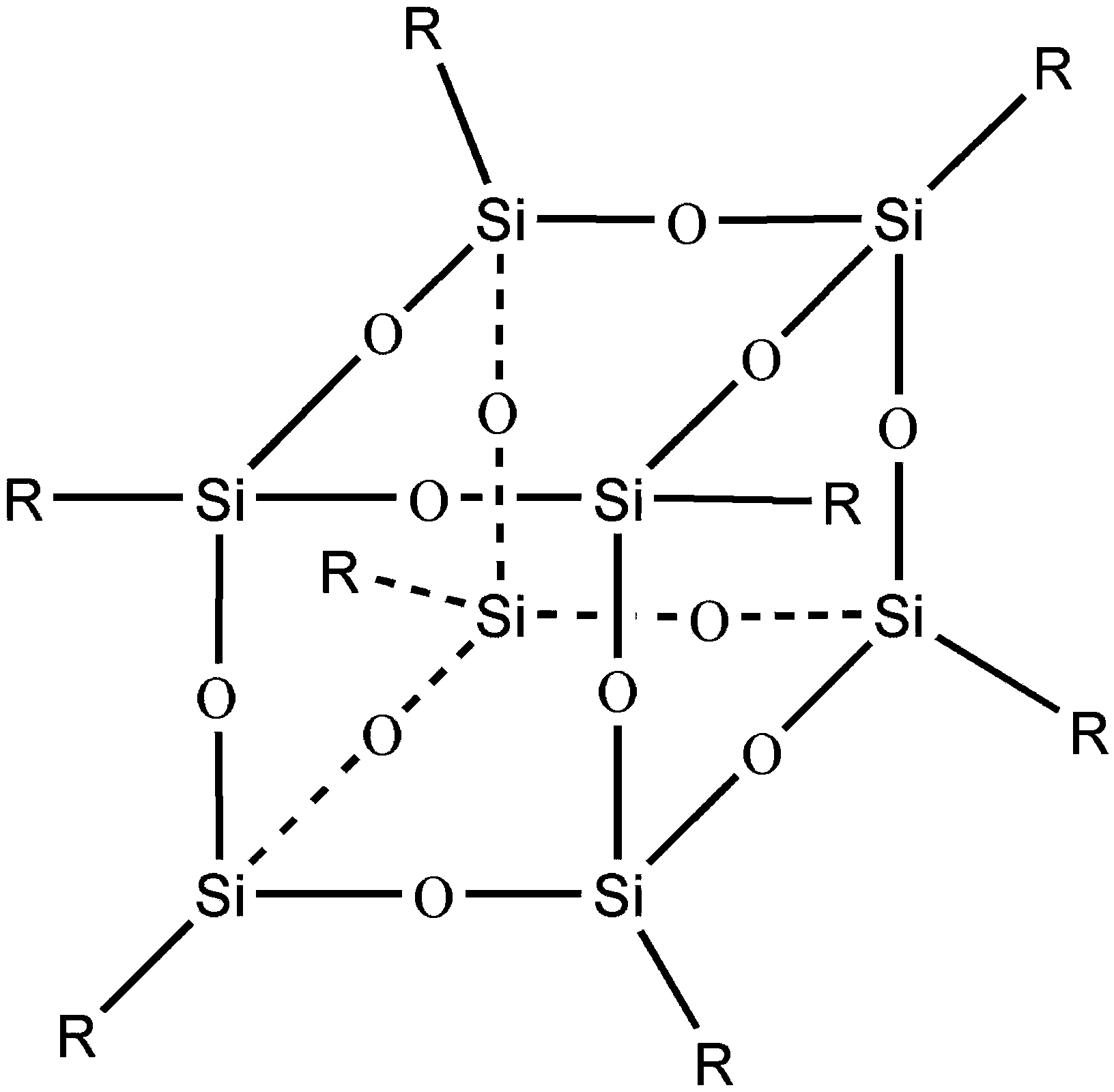

High-temperature-resistant low-loss compound insulation coaxial cable

InactiveCN104319008AImprove high-frequency communication performanceLow densityCoaxial cables/analogue cablesInsulated cablesPolytetrafluoroethyleneOrganic inorganic

Provided is a high-temperature-resistant low-loss compound insulation coaxial cable. The high-temperature-resistant low-loss compound insulation coaxial cable is characterized in that a solid or stranded inner metal conductor (1), a polytetrafluoroethylene micropore compound insulation layer (2), an outer conductor (3) and a sheath layer (4) are arranged from inside to outside in sequence, the solid or stranded inner metal conductor (1) longitudinally extends along the central axis of the cable, the outer conductor (3) is formed by knitting metal or is additionally provided with an inner shielding layer, the sheath layer (4) is made of FEP copolymer or low-smoke halogen-free flame retardant polyolefin, and the inner metal conductor (1) and the outer conductor (3) are separated by the polytetrafluoroethylene micropore compound insulation layer (2); the polytetrafluoroethylene micropore compound insulation layer (2) is made of modified polytetrafluoroethylene organic-inorganic nanocomposites filled with nano polyhedral oligomeric silsesquioxanes (POSS). According to the coaxial cable, the dielectric constant of the insulation layer of the cable is reduced. A traditional solid polytetrafluoroethylene insulation dielectric constant is reduced to 1.2-1.6 from 2.1 and is reduced by about 24 percent to 43 percent, and the signal attenuation of cable high-frequency communication is reduced.

Owner:JIANGSU TRIGIANT TECH

Double-stage switching system of photoetching machine wafer stage

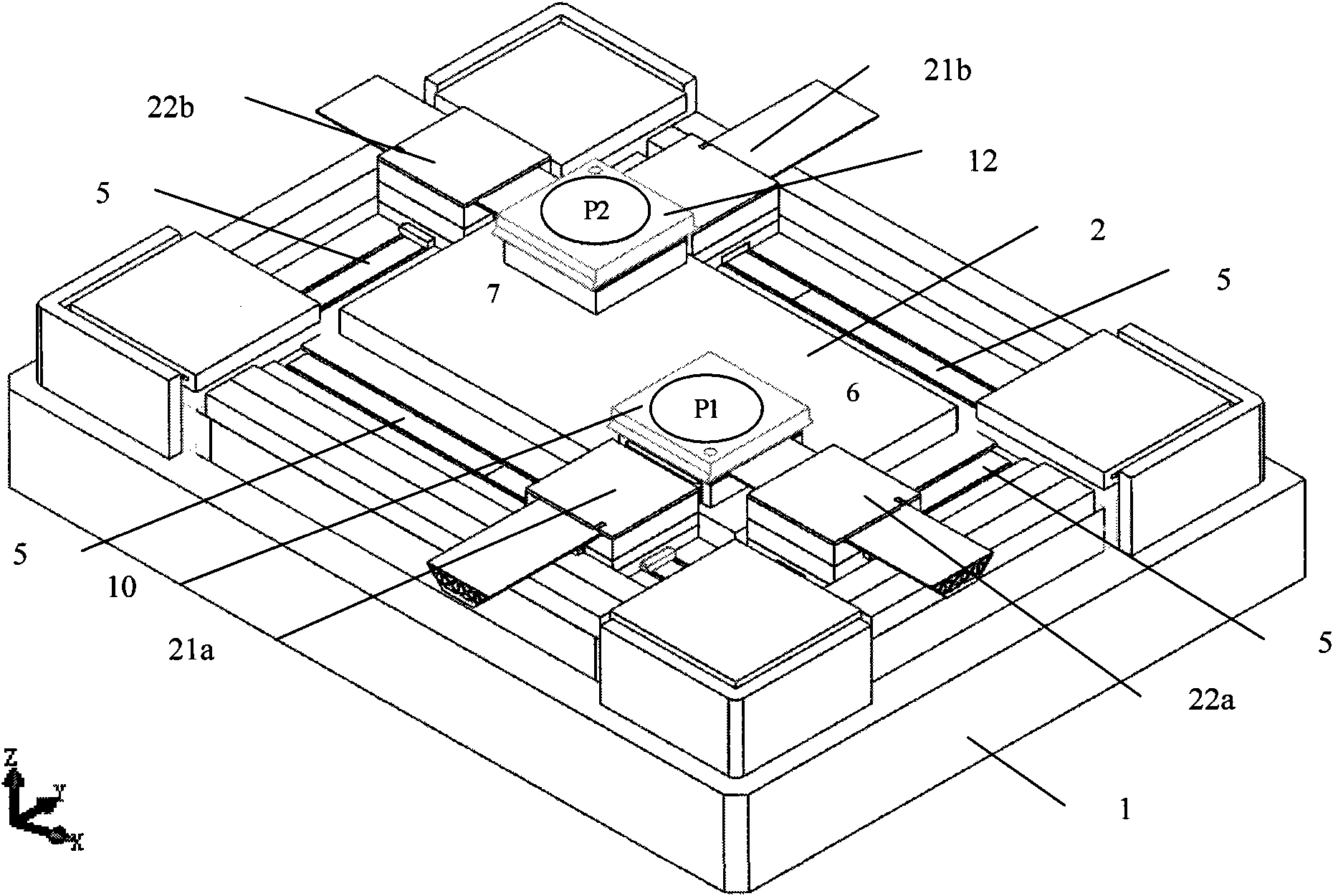

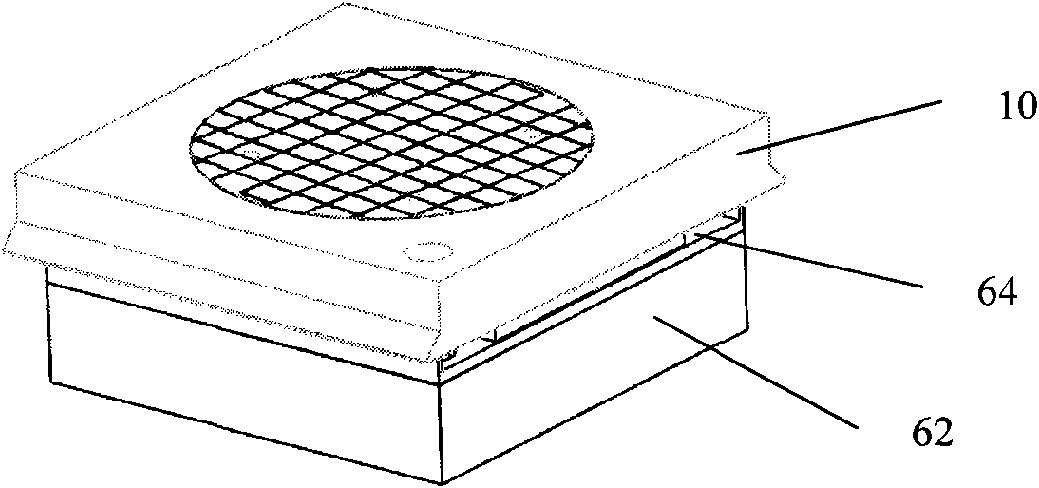

ActiveCN101551598ALow installation accuracy requirementsAvoid extremely high precision requirementsSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusButt jointStator coil

The invention provides a double-stage switching system of photoetching machine wafer stage, wherein the system comprises a wafer stage operating on exposure station and a wafer stage operating on preprocess station, each wafer stage is bore by a six-freedom-degree microchecker, one wafer stage and one six-freedom-degree microchecker compose a wafer stage group, the two wafer stage groups is fixed on a rectangular base station. a group of double-freedom-degree driving units is fixed on each edge of the base station respectively, the two wafer stage groups suspends on surface of the base station by air-float bearings; the six-freedom-degree microchecker has upper and lower two layers, capable of implementing six-freedom-degree control, the double freedom degree driving units on edges of the base station is connected with the casing of the microchecker for driving the whole wafer stage group on a horizontal plane, the double-freedom-degree units on short edges of the microchecker are connected with the stator coil framework of the upper layer for driving the six-freedom-degree microcheckers moving on a horizontal plane of the upper layer stator coil. The invention avoids defects of high require process and assembly precision because of employing butt joint of guiding rails and need of butt joint auxiliary device increase, thereby greatly simplifying system structure.

Owner:TSINGHUA UNIV +1

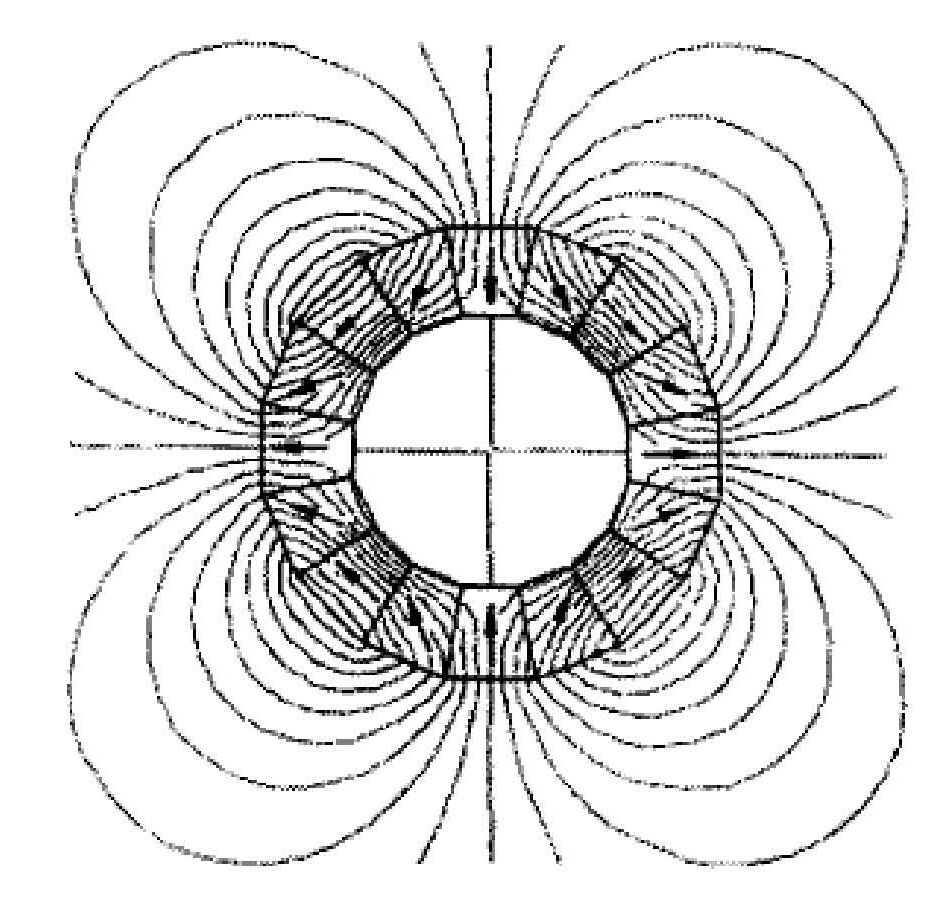

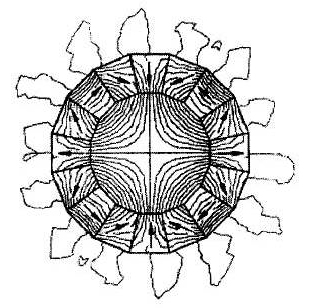

Halbach outer rotor doubly salient motor

InactiveCN102005835AIncrease the air gapIncrease air gap flux densityMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic sourceElectric machine

The invention provides a magnetizing outer rotor doubly salient motor with a radial structure, which is characterized by comprising a stator, a rotor, an air gap between the stator and the rotor, a rotating shaft and the like, wherein, the stator comprises a stator permanent magnet support arranged around the rotating shaft, permanent magnets arranged around the stator permanent magnet support, and a stator core arranged around the permanent magnet; the permanent magnets adopt a radial magnetizing or parallel magnetizing mode; the stator core is composed of stator core components; air gaps exist among the stator core components; and the permanent magnets and the stator core components are contacted with each other and have equal number. The magnetizing outer rotor doubly salient motor takes the magnetizing body with a radial / parallel structure as a magnetic source and has simple manufacturing process and less magnetic leakage on an end part; and the magnetizing outer rotor doubly salient motor can be widely applied to fields such as wind power generation, an automobile hub and the like.

Owner:SHANGHAI DIANJI UNIV

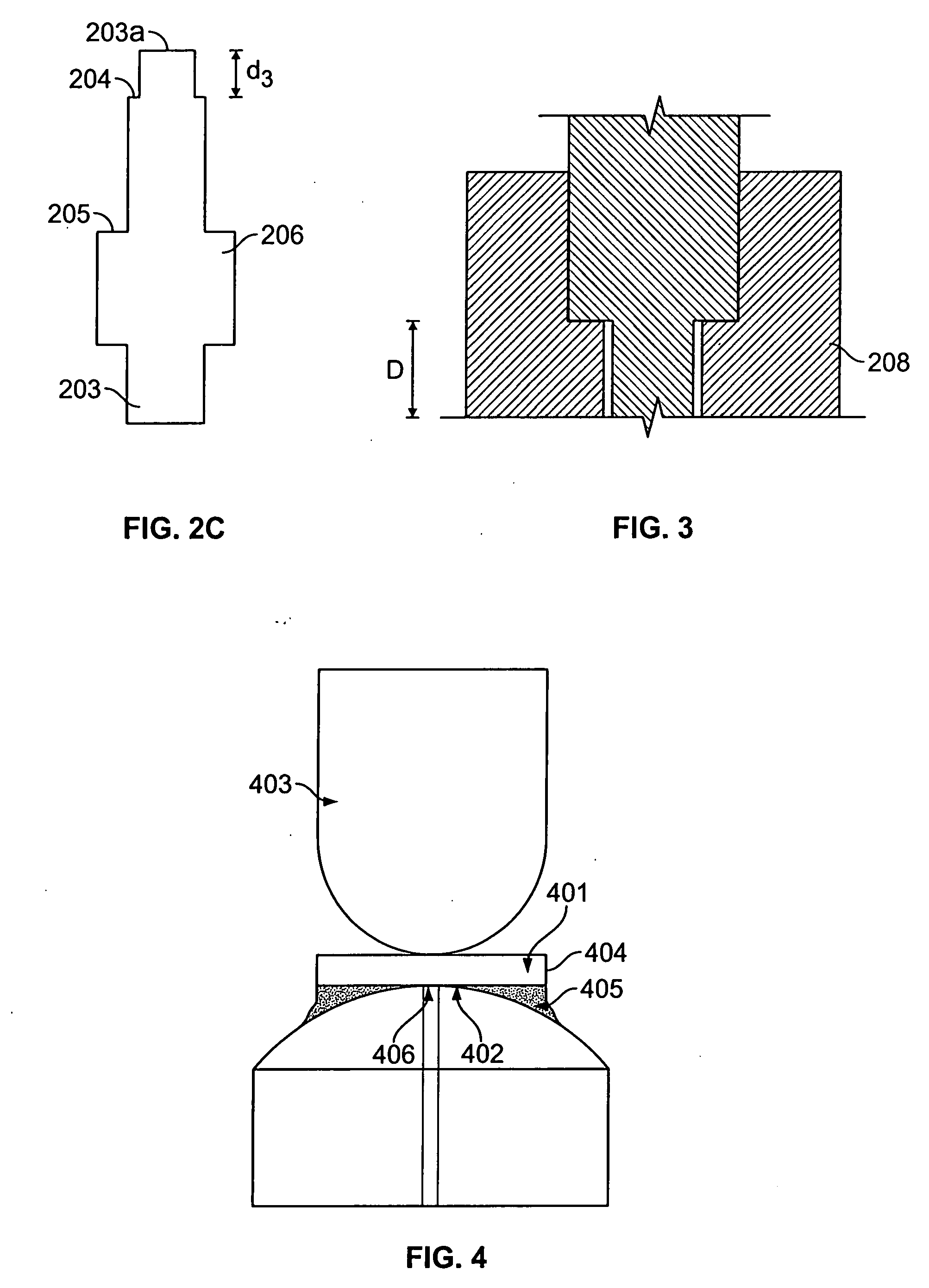

Low reflectance optical coupling

InactiveUS20050220410A1Easy to optimizeReduce reflection lossCoupling light guidesOptical axisEngineering

An optical coupling comprising: (a) a housing having first and second ends and having an optical axis, the first end having a first cavity for receiving an optical component, the second end having a second cavity for receiving a single mode fiber along the optical axis; and (b) a section of a multimode fiber disposed within the housing and along the optical axis between the first and second cavities, the multimode fiber having a first fiber end and a second fiber end, the first fiber end interfacing with air, the second fiber end being polished to optically couple with the single mode fiber through physical contact.

Owner:TE CONNECTIVITY CORP

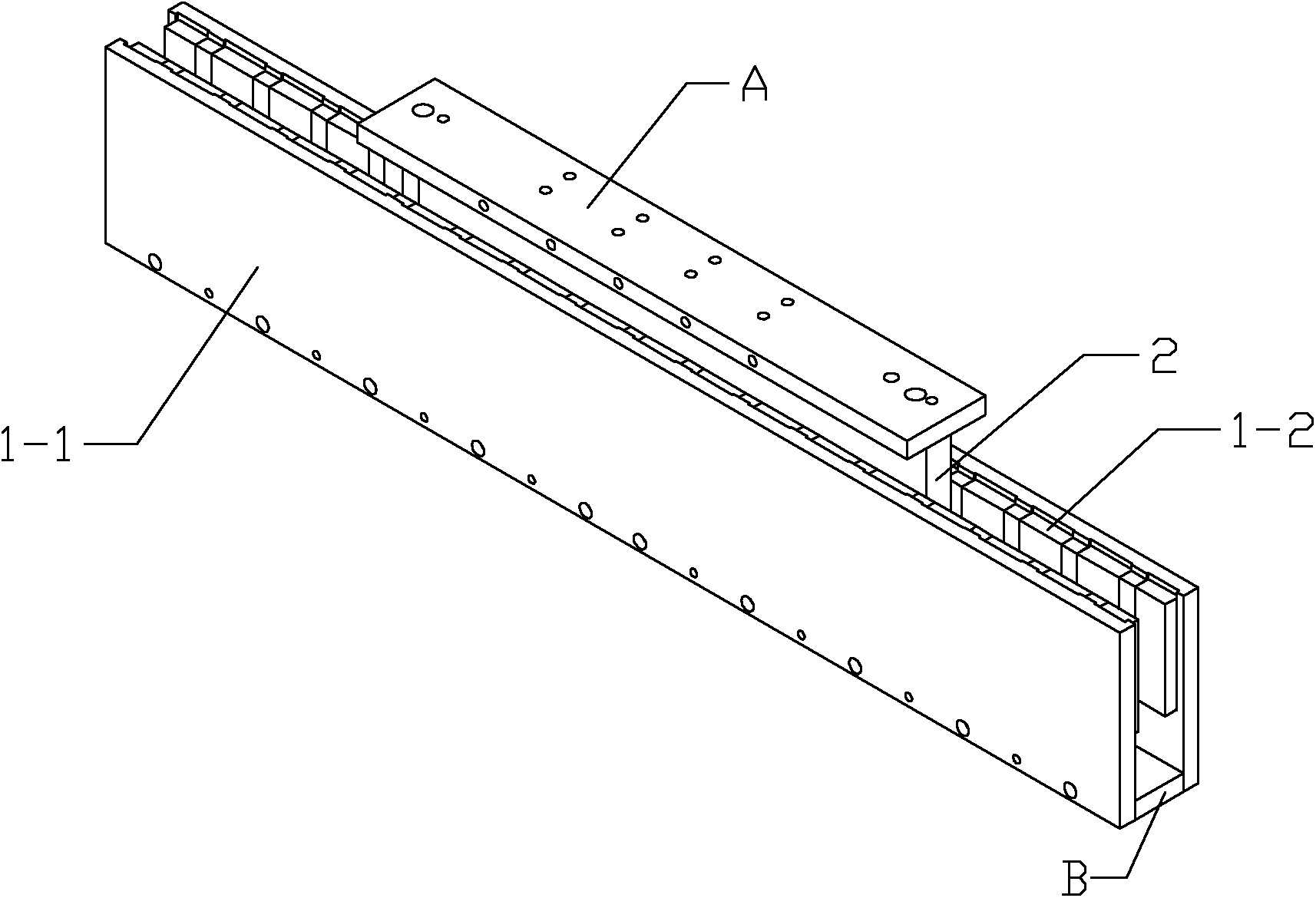

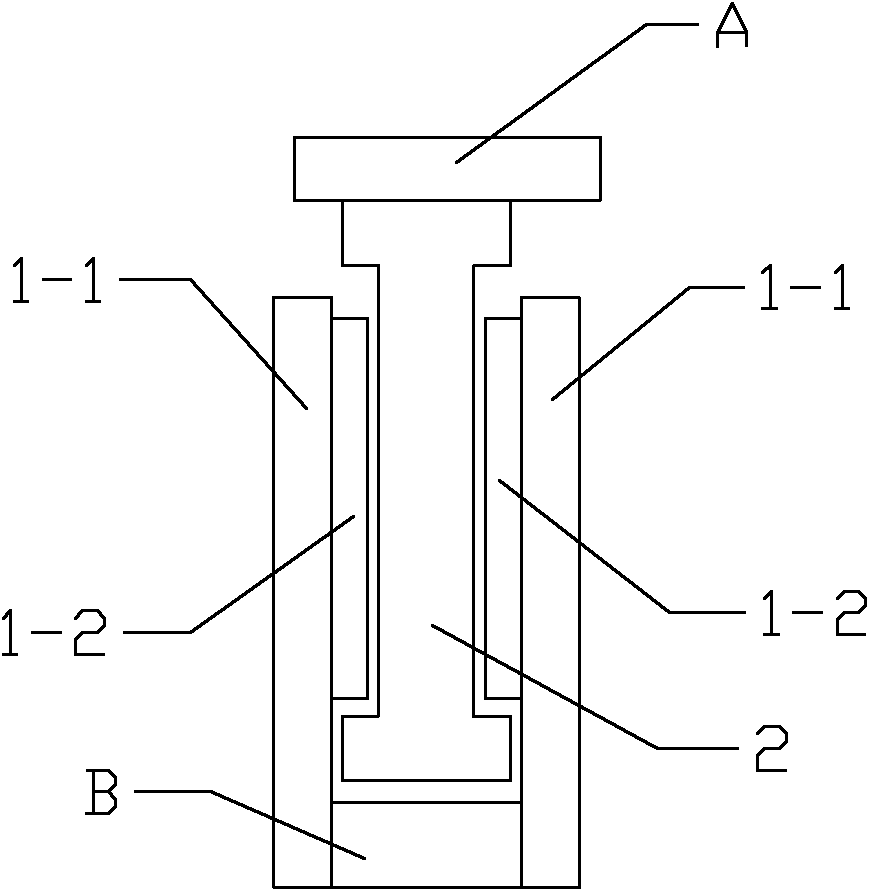

Coreless permanent magnet linear motor with cooling structure, manufacturing mould for winding coil thereof and machining process for winding coil

ActiveCN102255469ASimple structureEasy to manufactureMagnetic circuit rotating partsManufacturing dynamo-electric machinesPermanent magnet linear motorControl theory

The invention relates to a coreless permanent magnet linear motor with a cooling structure, a manufacturing mould for a winding coil thereof and a machining process for the winding coil and belongs to the technical field of linear motors. The coreless permanent magnet linear motor with the cooling structure is used for solving the radiation problem of a coreless permanent magnet linear motor. Stators of the coreless permanent magnet linear motor with the cooling structure are mirror-symmetrically arranged at the two sides of a rotor, wherein the rotor comprises an armature winding and a cooling pipeline; the cooling pipeline is composed of an upper pipeline, a lower pipeline and two connectors; the upper pipeline passes through an arc-shaped through hole which is formed on the upper end part of the armature winding; and the lower pipeline passes through an arc-shaped through hole which is formed on the lower end part of the armature winding. The manufacturing mould for the winding coil of the coreless permanent magnet linear motor with the cooling structure is composed of two winding shape-fixing components, a coil dislocation moving component and two base plates. The machining process for the winding coil by using the manufacturing mould for the winding coil is used for realizing the dislocation of upper and lower coil edges of the winding coil and preventing a winding from falling into pieces. The machining process provided by the invention is suitable for the coreless permanent magnet linear motor.

Owner:HARBIN INST OF TECH

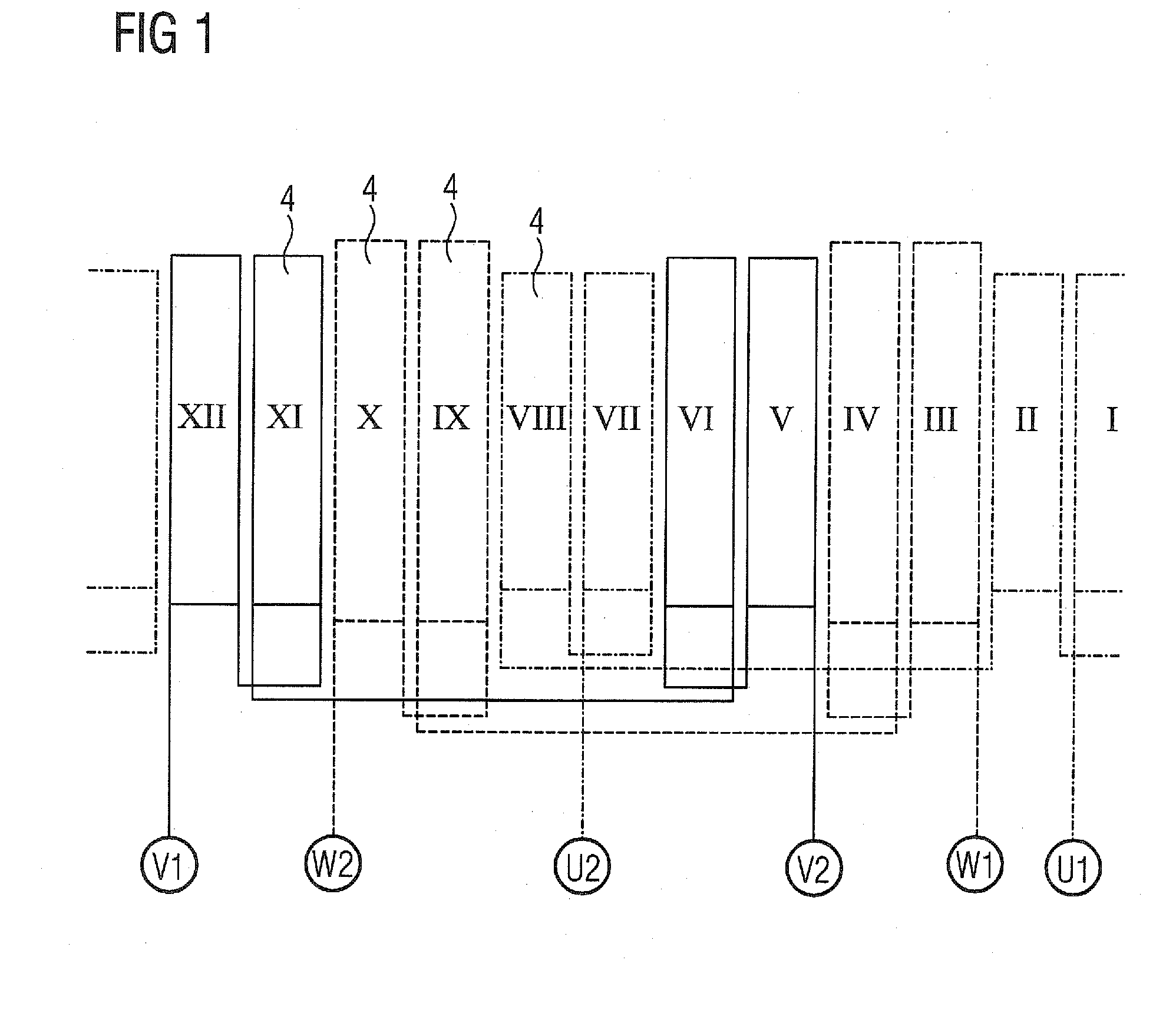

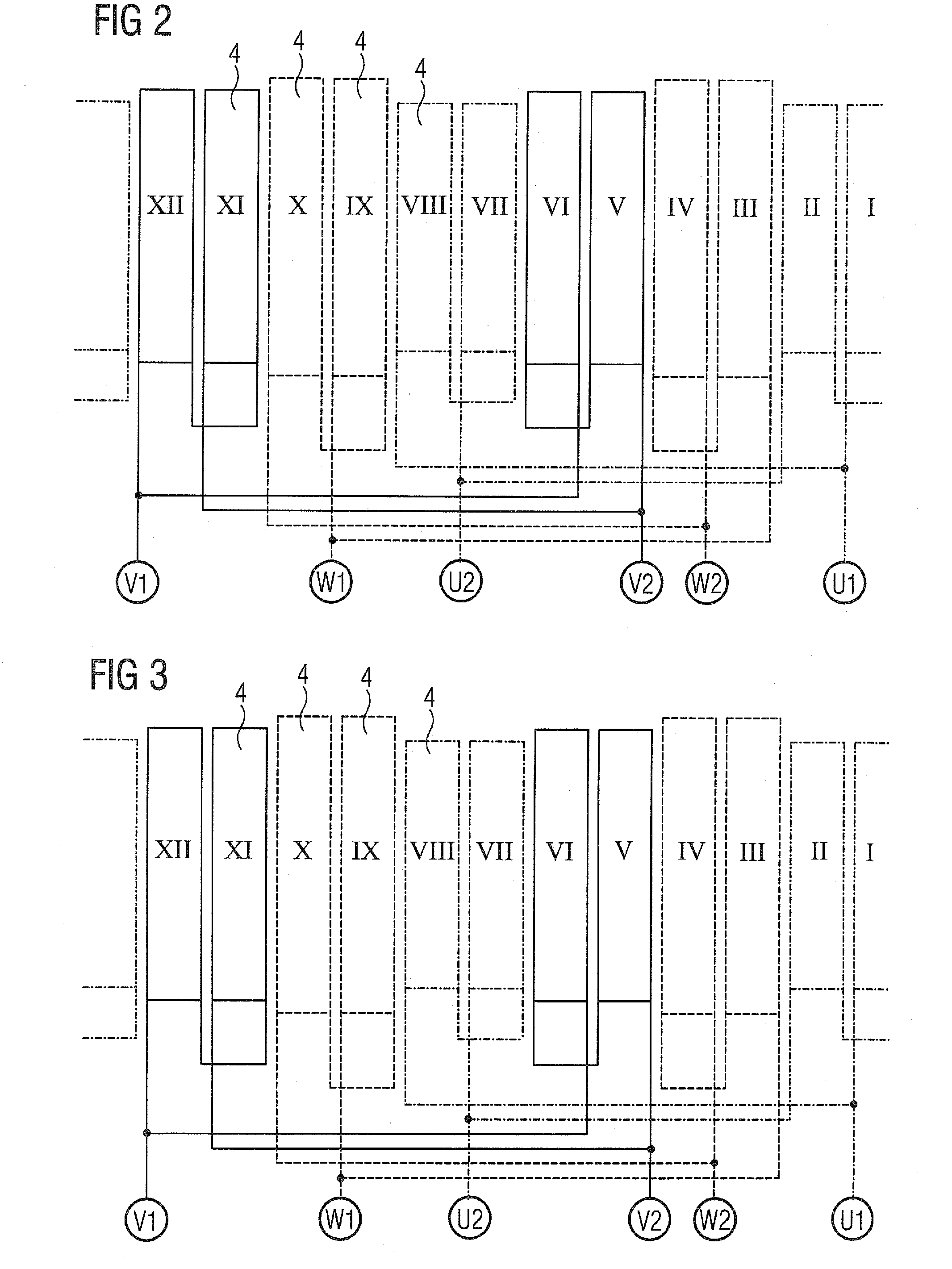

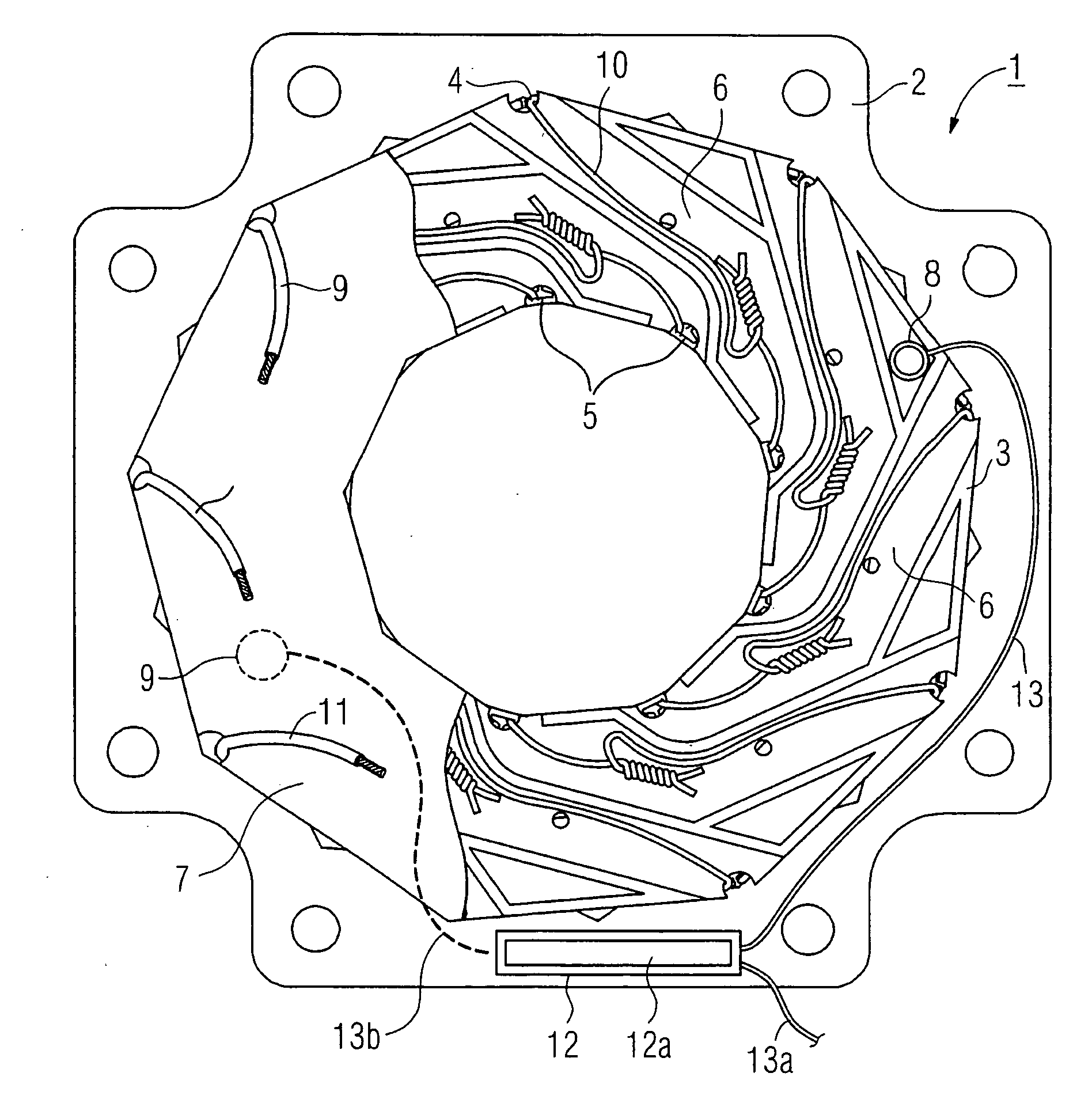

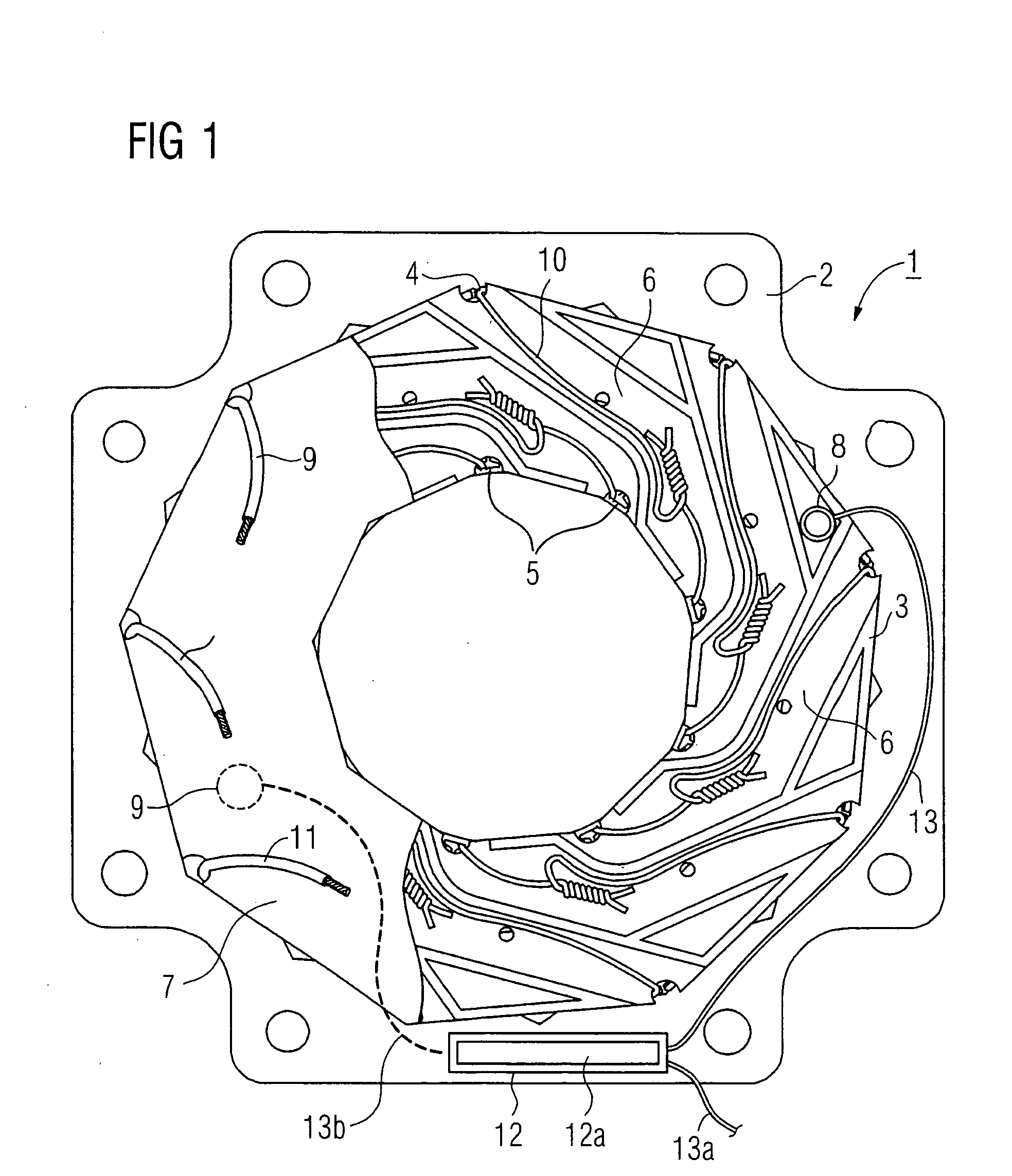

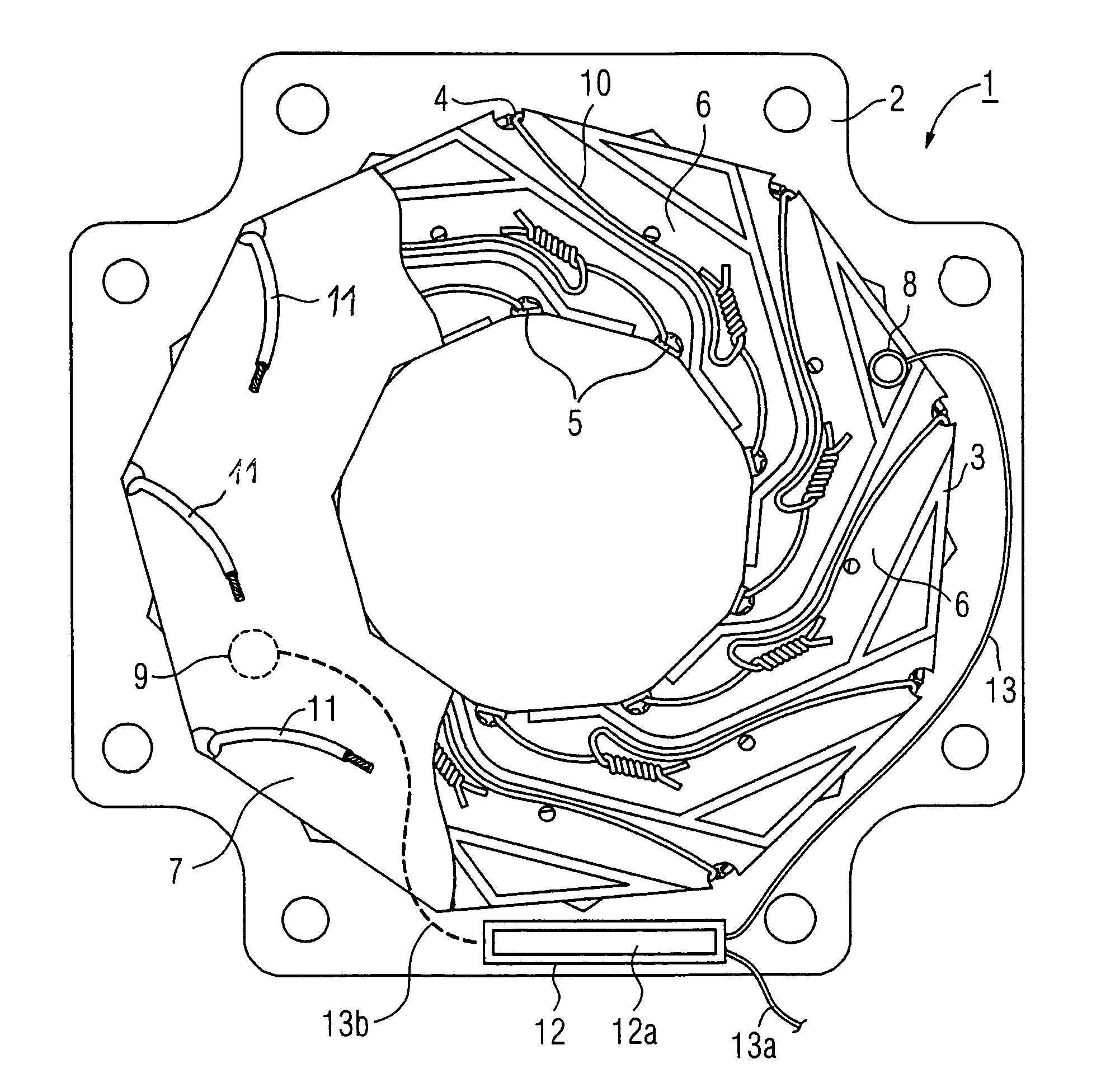

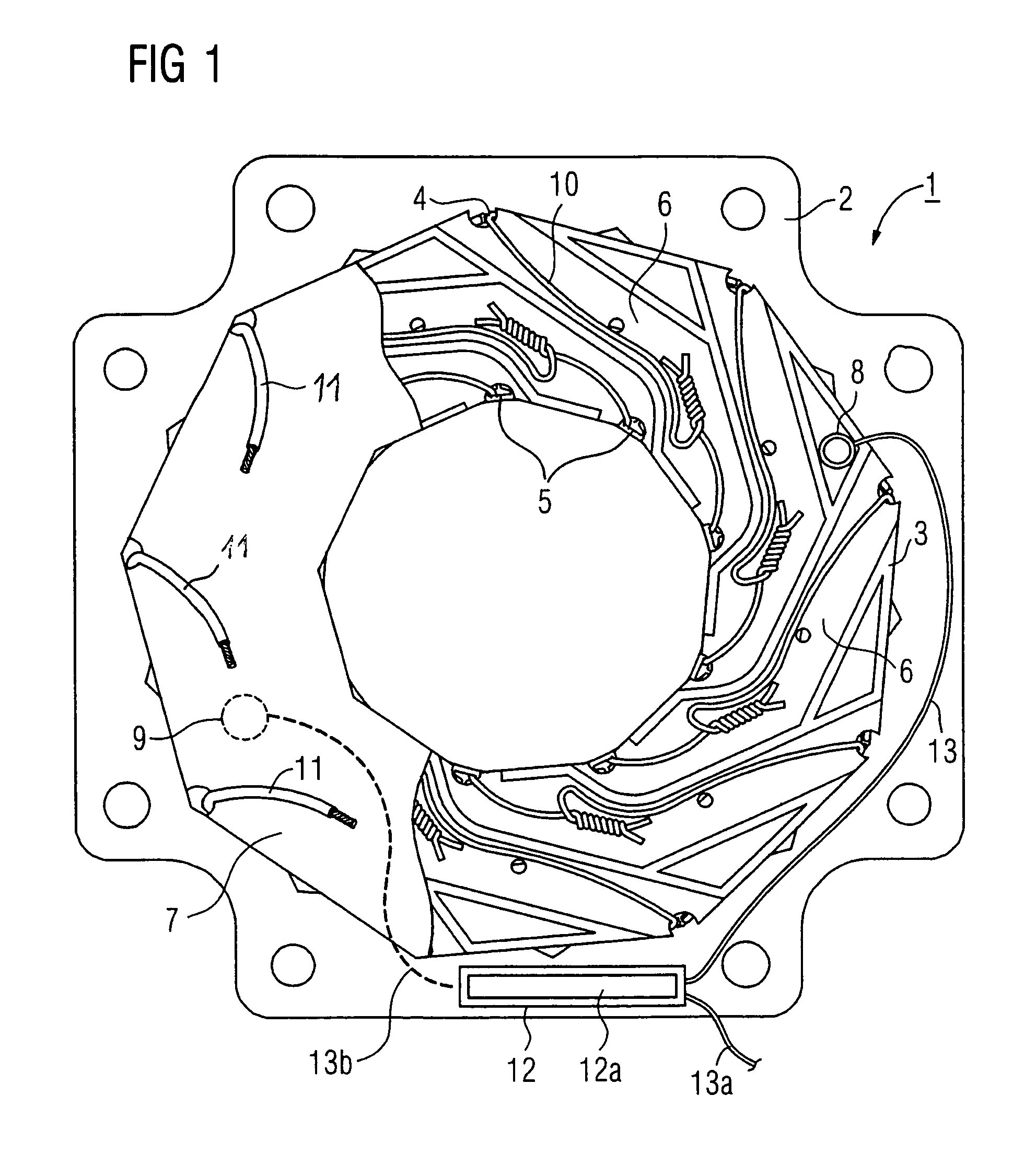

Electric machine with a winding support assembly and a measuring system

ActiveUS20050082940A1Well definedGain is not constantSynchronous generatorsWindingsElectric machineEngineering

An electric machine, in particular a motor, includes a winding support assembly and a measuring system, preferably an infrared measuring system, The measuring system has at least one sensor and an evaluation unit, whereby the measuring system is integrated in the winding support assembly. The infrared sensor, which operates without making contact with the winding support assembly, provides almost instantaneously a measurement value that is proportional to the actual temperature of the winding system, thereby significantly improving motor protection. The sensor can be embedded and sealed in the winding support assembly.

Owner:SIEMENS AG

Bushing type air bearing and main shaft device

ActiveCN103244559AImprove high-speed running stabilityImprove running stabilityBearing coolingBearingsAir bearingMechanical engineering

The invention relates to a bushing type air bearing and a main shaft device. The air bearing comprises an outer ring seat, an inner bushing sleeved in the outer ring seat, an annular space disposed between the outer ring seat and the inner bushing, and two buffering leakproof rings respectively arranged between the outer ring seat and the inner bushing, wherein the outer ring seat is provided with at least one air-entraining hole; the inner bushing is provided with a plurality of gas ports capable of communicating with the air-entraining holes through the circular space; and the buffering leakproof rings can make the circular space isolated from an the outside world. Besides, the main shaft apparatus is provided with the air bearing. Thereby, the air bearing provides a mandrel unit stable support.

Owner:OFUNA TECH

Electromagnetic drive type magnetic suspension rotating platform

ActiveCN102710181ASolve wear and tearSolve the carrying capacityMagnetic holding devicesPermanent magnet rotorEngineering

The invention discloses an electromagnetic drive type magnetic suspension rotating platform which comprises an electromagnetic suspension structure positioned on an outer ring and an electromagnetic drive structure positioned on an inner ring, wherein a rotating platform casing is arranged outside the electromagnetic suspension structure and the electromagnetic drive structure; the electromagnetic suspension structure comprises an annular electromagnetic suspension iron core; a plurality of teeth are symmetrically arranged on the annular electromagnetic suspension iron core along the circumference; an electromagnetic suspension winding is wound on each tooth; a high-precision air gap sensor is arranged at the clearance between every two teeth; an annular suspension conductor plate is arranged above the annular electromagnetic suspension iron core; the electromagnetic suspension structure comprises an annular electromagnetic drive iron core; three groups of teeth are symmetrically arranged on the outer side of the electromagnetic drive iron core along the circumference; the electromagnetic suspension windings are continuously wound on each group of teeth; each group of electromagnetic drive winding is in a link type structure; an annular permanent magnet rotor is arranged outside the annular electromagnetic drive iron core; and a photoelectric encoder is arranged on a rotating shaft of the rotating platform casing. The assembly difficulty is reduced and the manufacturability is improved.

Owner:TIANJIN UNIV

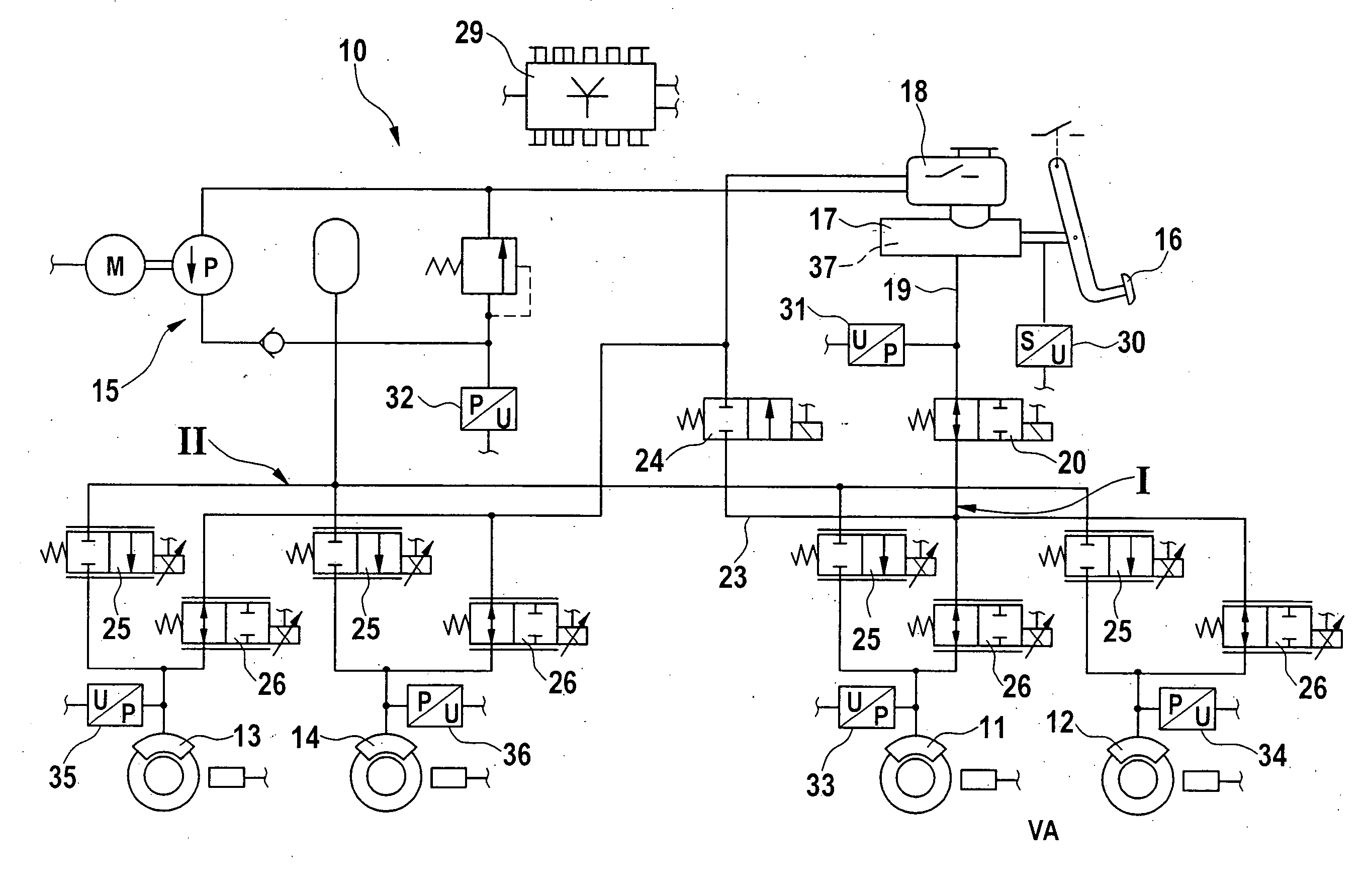

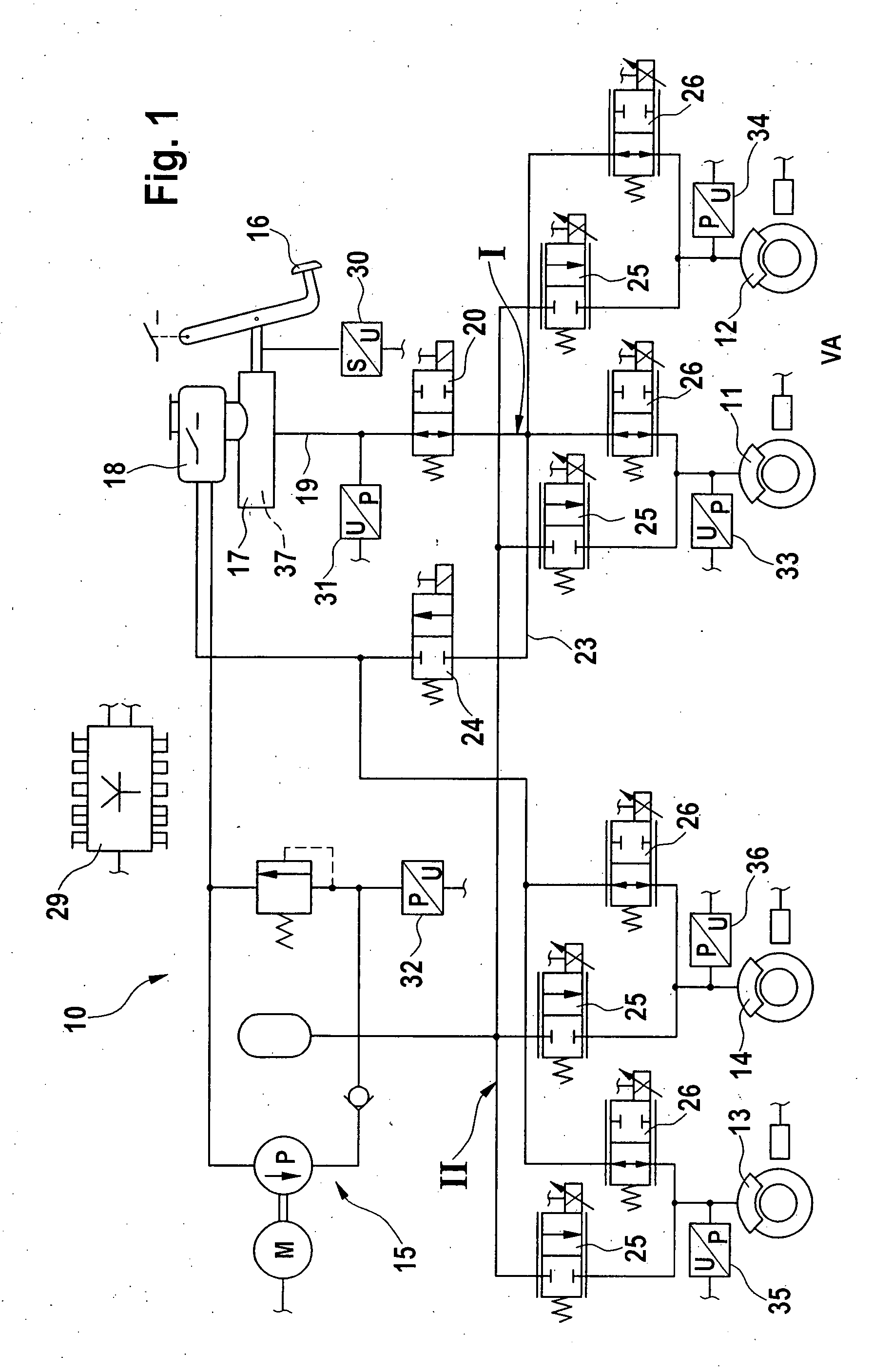

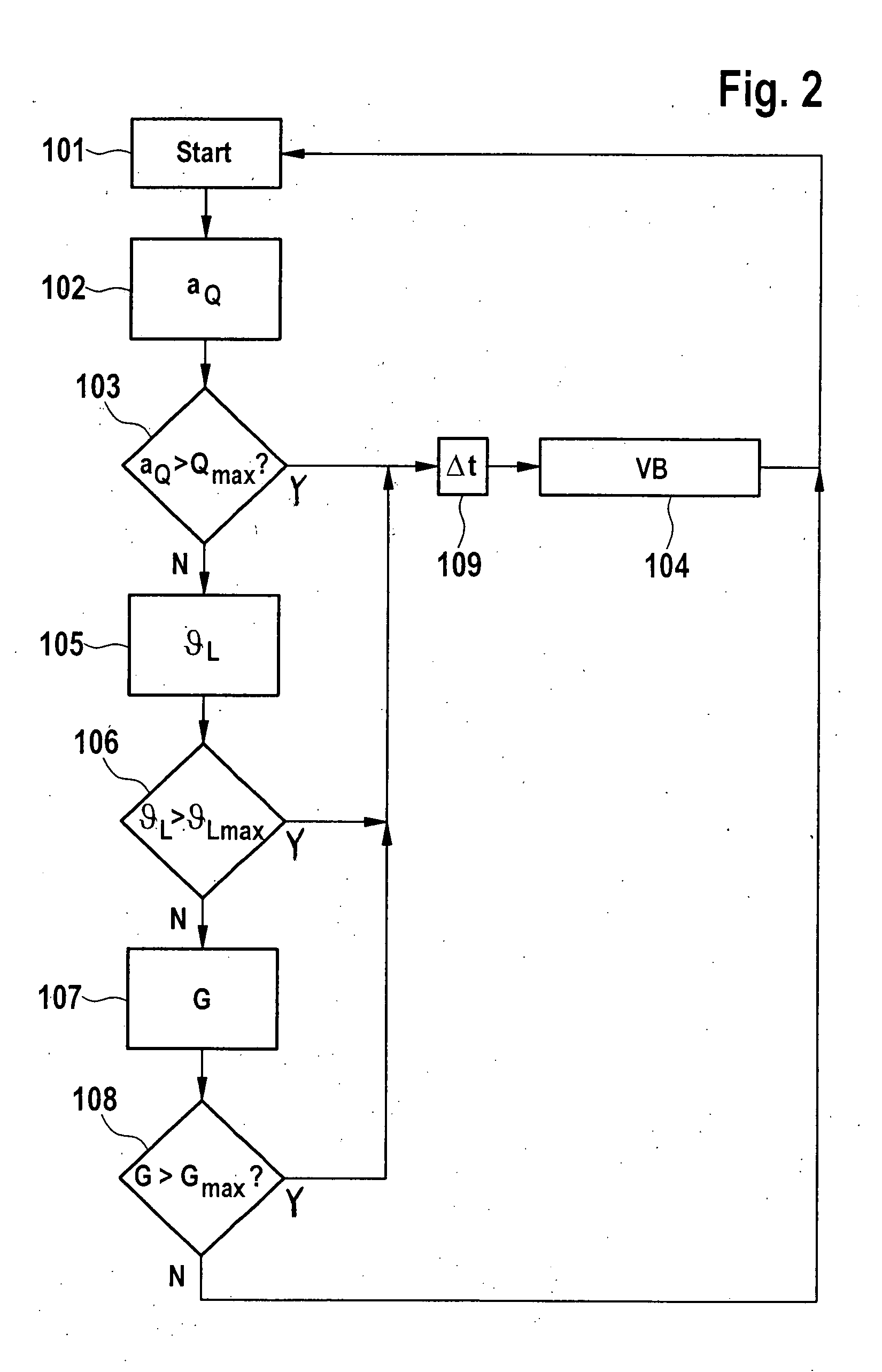

Method for operating a brake system of a motor vehicle

InactiveUS20080058162A1Improve responseReduce distanceBraking action transmissionEngine controllersMobile vehicleMotorized vehicle

A method for operating a brake system of a motor vehicle, prefilling taking place to at least partially overcome an air gap of one wheel brake or a plurality of wheel brakes if the air gap of at least one wheel brake is increased, in particular as a result of dynamic influences of the vehicle motion.

Owner:ROBERT BOSCH GMBH

Permanently excited synchronous machine with ferrite magnets

ActiveUS20140070655A1Reduces torque rippleReduce heatMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsWind systemMagnetic poles

A permanently excited synchronous machine includes a stator; a winding system arranged in grooves of a laminated core of the stator and forming winding overhangs on end faces of the laminated core, and a rotor connected in fixed rotative engagement to the shaft and having ferrite magnets which extend axially beyond the end faces of the laminated core. The rotor electromagnetically interacts with the stator across an air gap there between during operation of the permanently excited synchronous machine to cause a rotation about an axis of rotation. A flux concentration element is provided radially across each of the ferrite magnets of a magnetic pole and bundles magnetic field lines of the ferrite magnet onto an axial length of the laminated core of the stator. The flux concentration elements and held by a fixing element on the ferrite magnets of a magnetic pole.

Owner:SIEMENS AG

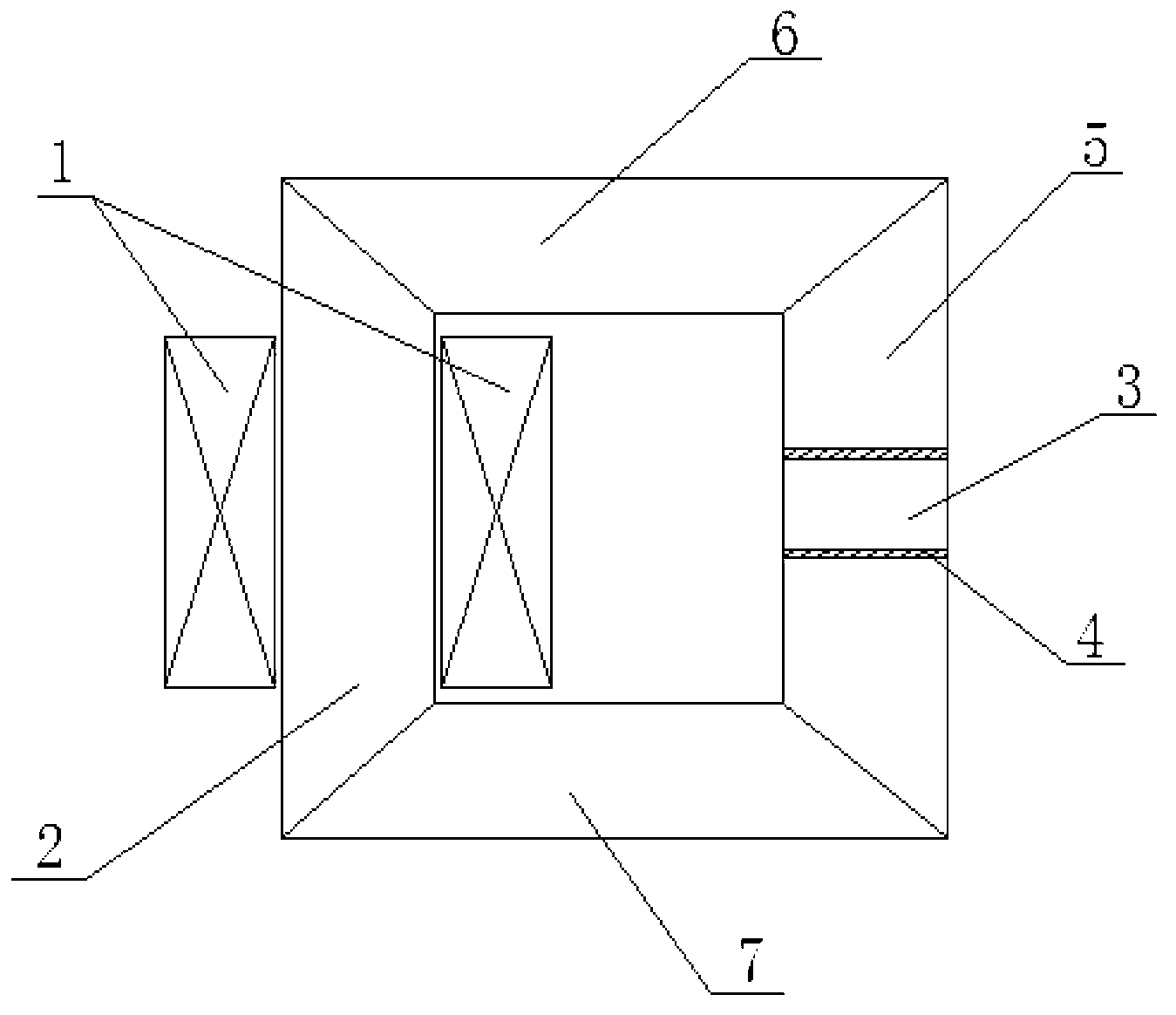

Adjustable reactor with magnetic wedge

InactiveCN102938289AEasy to adjustOvercoming gravityTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresAlternating currentConductor Coil

The invention relates to an adjustable reactor with a magnetic wedge, which belongs to the technical field of adjustable reactor manufacturing and aims to solve the problems that the conventional reactor is inconvenient to adjust and poor in linearity. The adjustable reactor comprises a rectangular main magnetic circuit frame, an alternating current winding, the magnetic wedge and two nonferromagnetic insulating plates, wherein the rectangular main magnetic circuit frame is composed of a winding iron core, a lower iron yoke, an iron core with an air gap and an upper iron yoke which are sequentially connected with one another end to end; the lower iron yoke and the upper iron yoke are opposite in the horizontal direction; the alternating current winding spirally wraps the winding iron core; the horizontal air gap is formed in the center of the iron core; the magnetic wedge is embedded in the horizontal air gap; the nonferromagnetic insulating plates are respectively arranged between the magnetic wedge and the two side walls of the horizontal air gap; and the magnetic wedge and the two nonferromagnetic insulating plates are clamped and fixed in the horizontal air gap. The technical scheme of the adjustable reactor disclosed by the invention can be applied to manufacturing of reactors.

Owner:HARBIN UNIV OF SCI & TECH

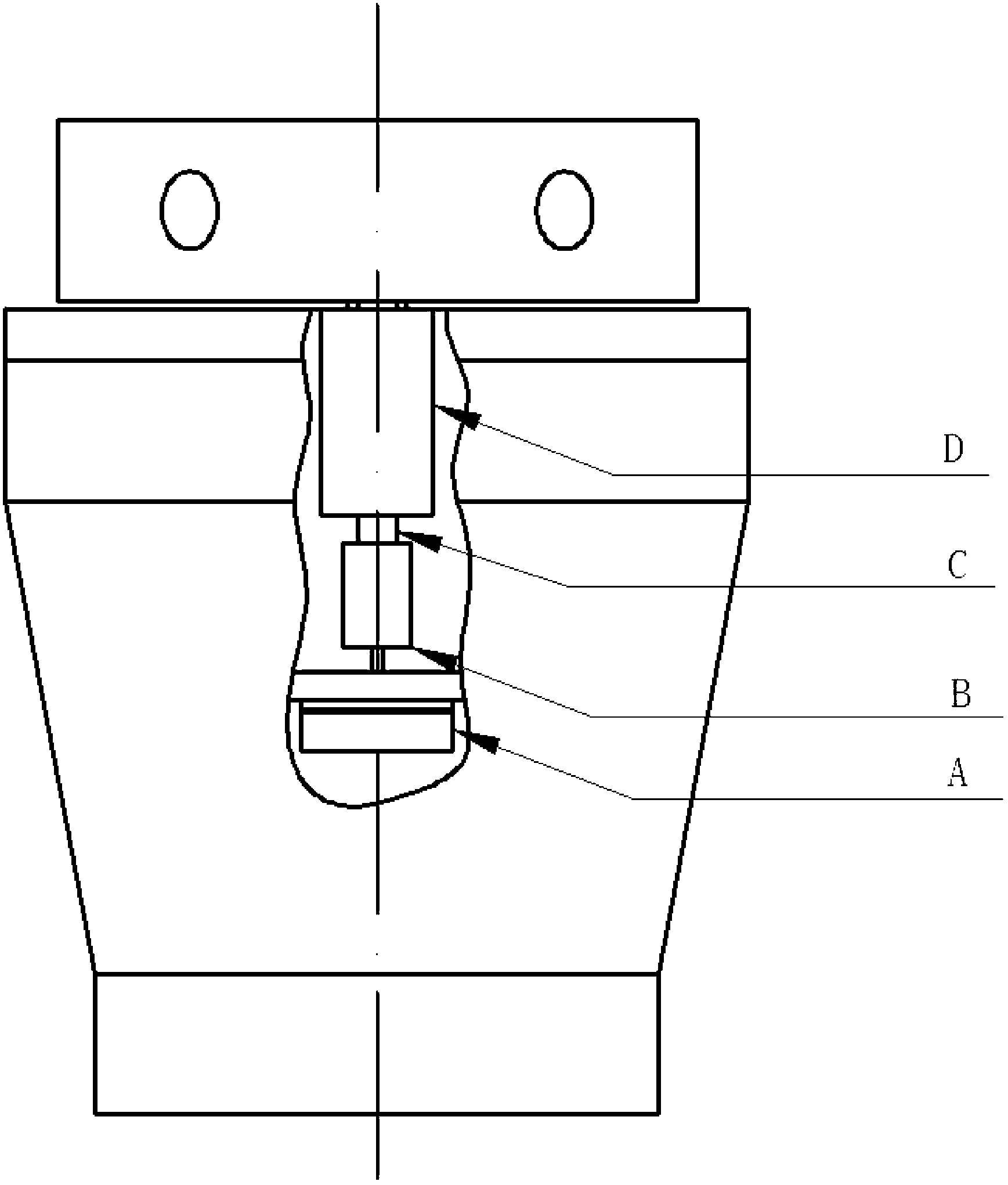

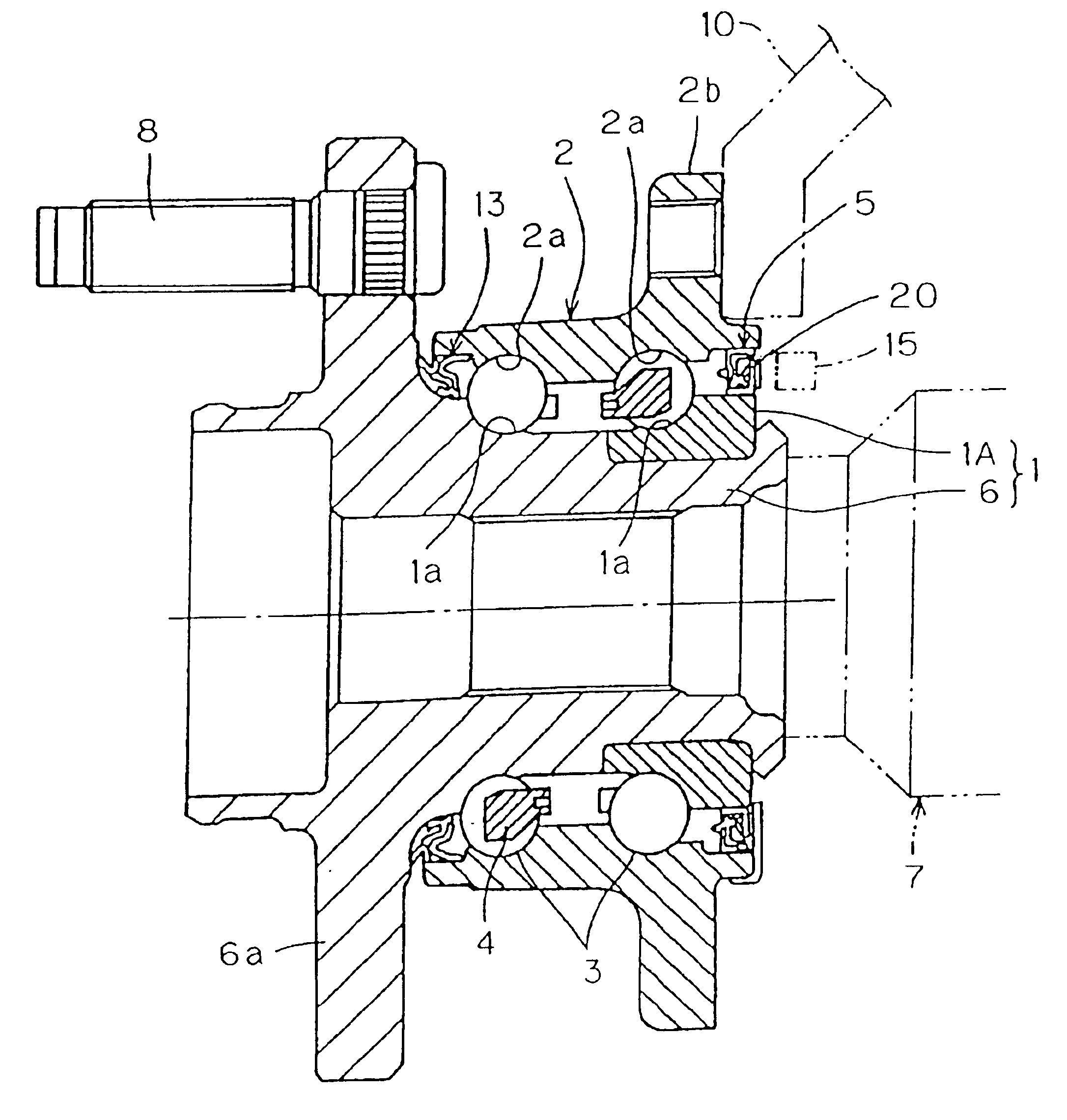

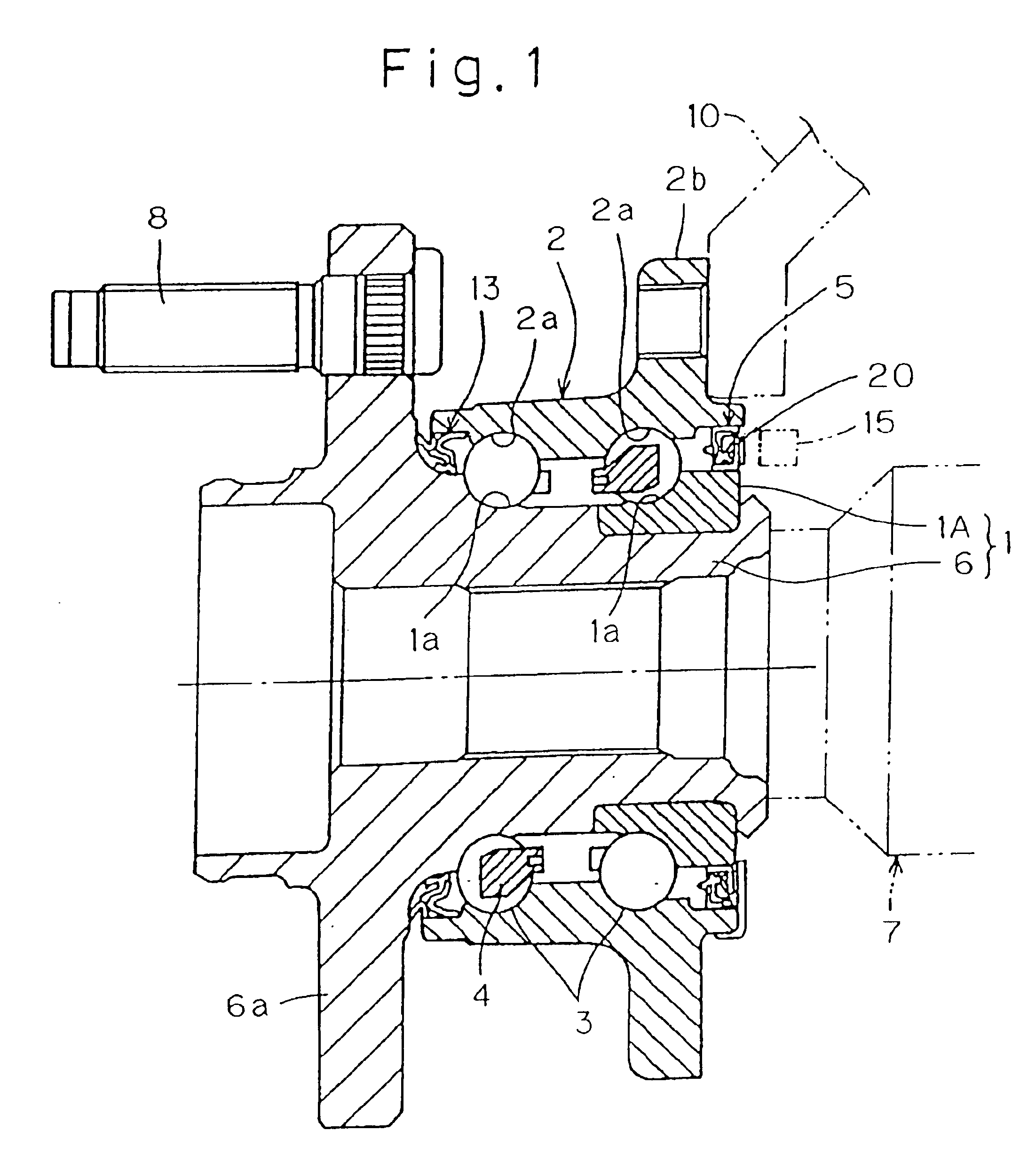

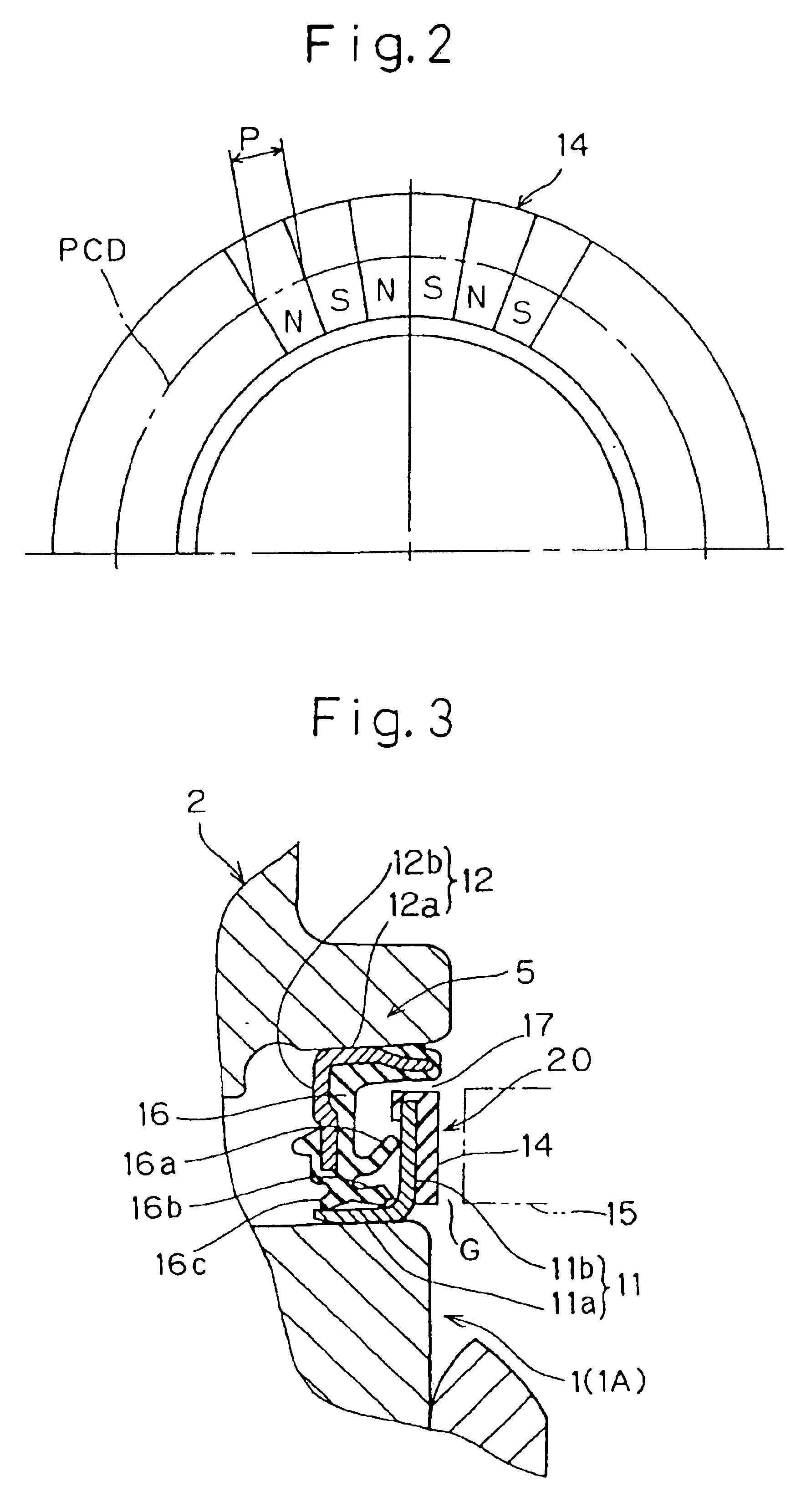

Magnetic encoder and wheel bearing assembly using the same

To provide a magnetic encoder in which an air gap between it and a magnetic sensor can be increased and the magnetic force generated thereby can be easily quality-controlled, and a wheel bearing assembly having the magnetic encoder, the magnetic encoder 20 includes a core metal 11 and an elastic member 14 integrated with the core metal 11 in a ring-shaped configuration. The elastic member 14 is made from an elastic material mixed with a powder of magnetic material and has a plurality of different magnetic poles alternating in a direction circumferentially thereof. The elastic member 14 also has a Shore hardness of not lower than Hs 90. A wheel bearing assembly is also provided, which makes use of the magnetic encoder 20 as a component part of a sealing unit 5.

Owner:NTN CORP

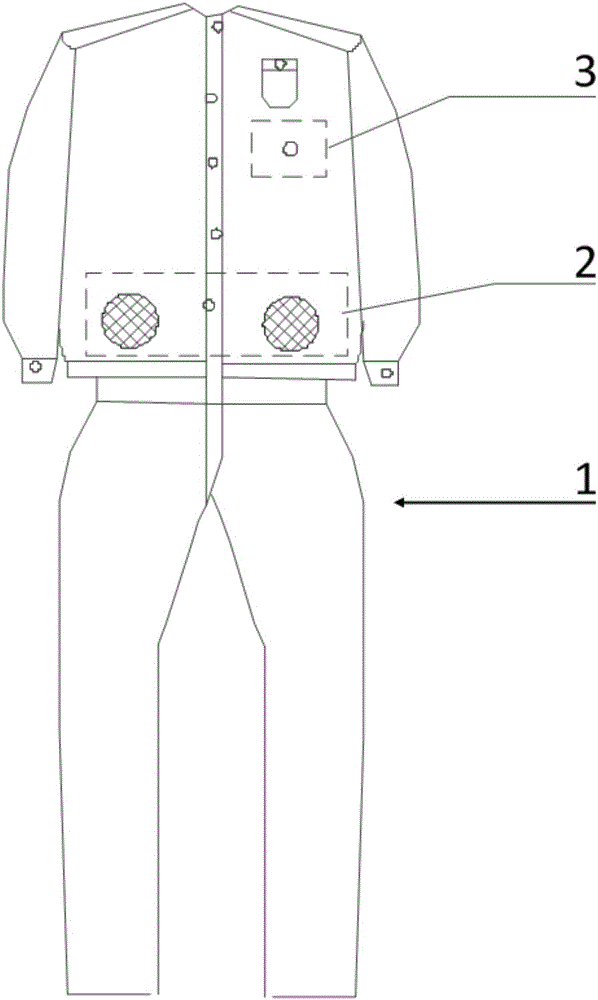

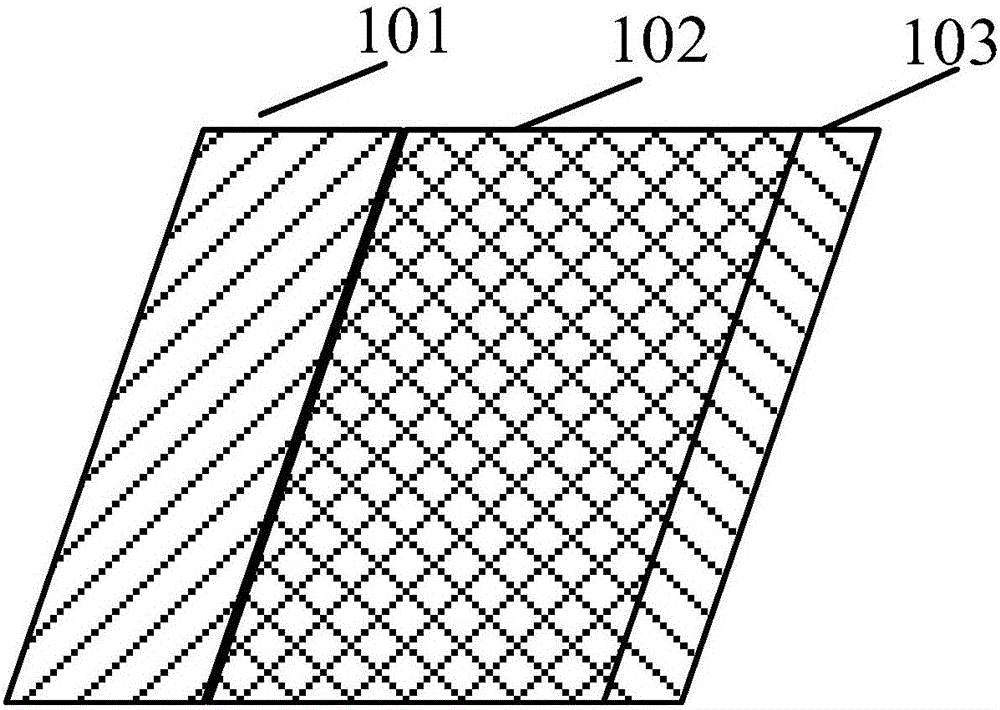

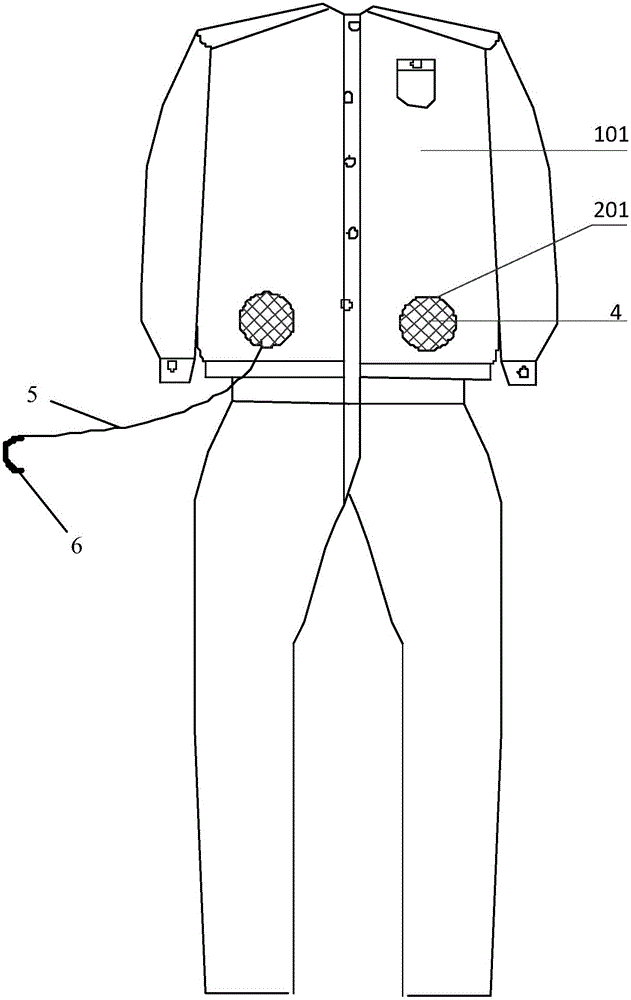

Extra-high-voltage cooling shielding clothes for live working

ActiveCN105054390AWill not affect normal useEasy to removeProtective garmentSpecial outerwear garmentsAir volumeEvaporation

The invention provides extra-high-voltage cooling shielding clothes for live working. The shielding clothes comprise a shielding clothes body, cooling assemblies arranged on the shielding clothes body, and a detecting unit. The shielding clothes body comprises a conduction outer lining, a cooling inner lining, and a ventilating layer sandwiched between the conduction outer lining and the cooling inner lining. The number of the cooling assemblies is at least four. Each cooling assembly comprises one air guide opening and a minitype fan connected with the air guide opening, and the air guide openings are formed in the same position on the shielding clothes body. The shielding clothes are convenient to assemble and disassemble without damaging the whole shielding efficiency of the shielding clothes; while the electric integrity of the shielding clothes is ensured, air volume is conveyed uniformly, and effective cooling is ensured; meanwhile, mobility of airflow is improved, the coverage area is increased, and the temperature of the human body under the high-temperature condition is reduced effectively by means of evaporation of sweat; the situation that due to the unsmooth airflow, the clothes are fluffy and swell, and inconvenience is brought to operation of an operator is avoided, and the safety of equipment and the personal safety of the operator are ensured.

Owner:CHINA ELECTRIC POWER RES INST +2

Synchronous reluctance motor and underwater pump

InactiveCN104285360AEliminate air gapsEliminate power lossMagnetic circuit rotating partsPrevention/reducing eddy-current losses in winding headsSynchronous reluctance motorUnderwater

The present invention relates to a synchronous reluctance motor for an underwater pump having a stator and a rotor which comprises a fluid barrier section for forming one or more magnetic pole pairs, wherein the airgap between the rotor (12) and the stator (11) is at least partially filled with a ferrofluid (20). A further partial aspect of the invention relates to an underwater pump with such a synchronous reluctance motor for driving the pump.

Owner:KSB AG

Permanently-excited dynamoelectric machine

ActiveUS20160065016A1Increase polarityIncrease the air gapMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetStator

A permanently-excited dynamoelectric machine includes a stator and a rotor supported for rotation about an axis. The stator has a winding system, which is embedded in grooves of a material forming a magnetic return path and interacts electromagnetically with permanent magnets of the rotor via an air gap between the stator and the rotor. The permanent magnets are disposed on the rotor, with each individual permanent magnet, on a side facing towards the air gap, having a North and South pole. The rotor, viewed in the circumferential direction, has a pole coverage by the permanent magnets of 100%, i.e. that the permanent magnets viewed in the circumferential direction, are arranged substantially without gaps.

Owner:SIEMENS AG

Electric machine with a winding support assembly and a measuring system

ActiveUS7501728B2Guaranteed uptimeReliably securedSynchronous generatorsMagnetic circuit rotating partsElectric machineEngineering

An electric machine, in particular a motor, includes a winding support assembly and a measuring system, preferably an infrared measuring system, The measuring system has at least one sensor and an evaluation unit, whereby the measuring system is integrated in the winding support assembly. The infrared sensor, which operates without making contact with the winding support assembly, provides almost instantaneously a measurement value that is proportional to the actual temperature of the winding system, thereby significantly improving motor protection. The sensor can be embedded and sealed in the winding support assembly.

Owner:SIEMENS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com