Magnetoresistance sensor and method of operating a magnetoresistance sensor

A magnetoresistive sensor, sensor technology, applied in the field of operating magnetoresistive sensors, program elements, and computer readable media, can solve the problem that AMR speed sensors cannot provide air gap capability, sensor head output signal reduction, signal processing and adjustment units are heavy requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The illustrations in the figures are schematic. In different drawings, similar or identical elements are indicated by similar or identical reference symbols.

[0035] In the following, reference will be made to Figure 1 to Figure 5 Some basic principles of a magnetoresistive sensor system according to example embodiments are described.

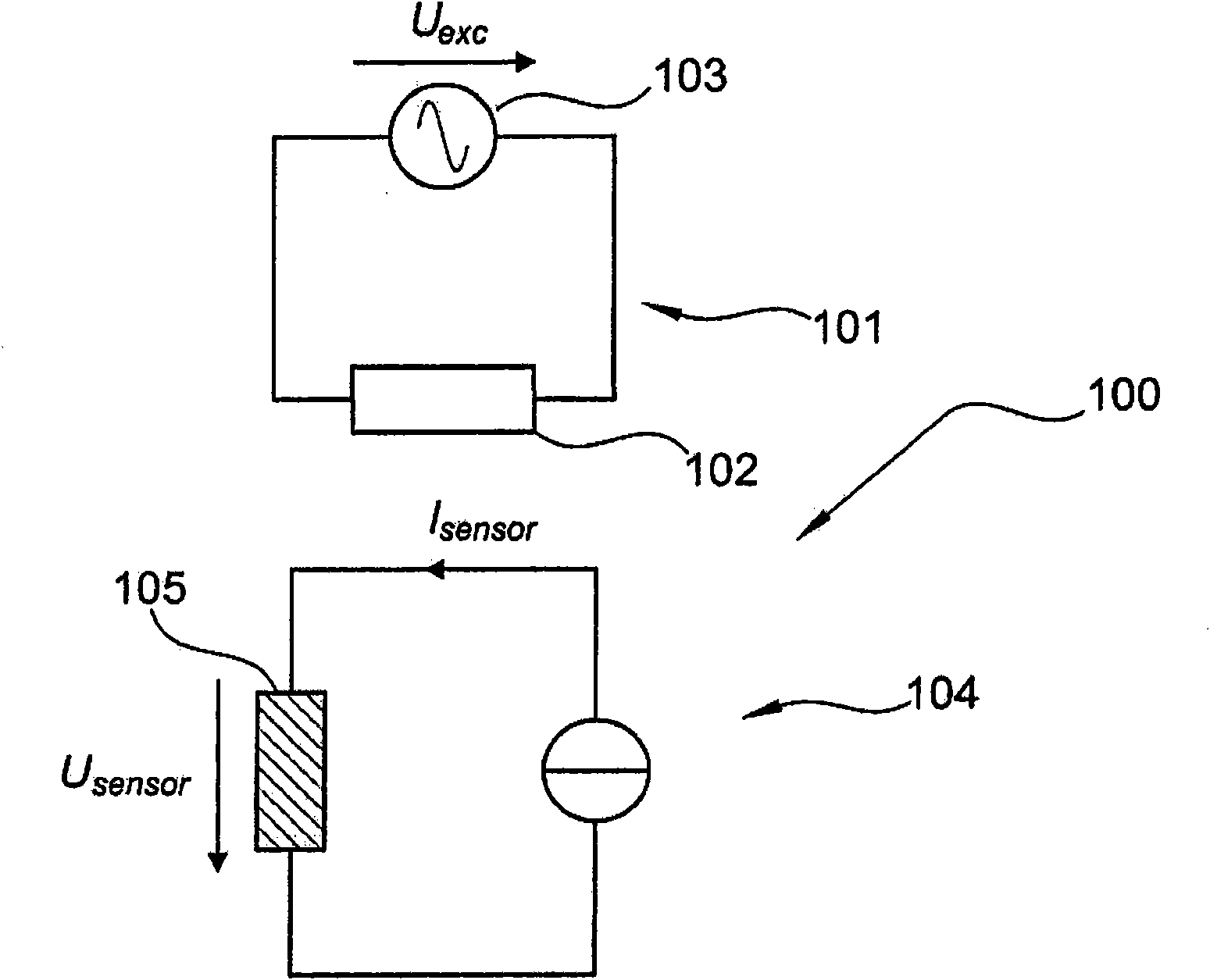

[0036] figure 1 A simplified circuit diagram representing a current fed anisotropic magnetoresistive sensor (AMR sensor) 100 with sinusoidal excitation. figure 1 A magnetic field source 101 comprising a drive coil 102 and an oscillating voltage source 103 (eg an oscillator) is shown in detail. also, figure 1 A magnetoresistive sensor 104 comprising an AMR element 105 is shown. Specifically, it should be noted that the easy axis of the AMR element 105 has figure 1 in a roughly vertical direction, that is, along the figure 1 The voltage shown in U sensor direction, while the direction of the magnetic field induced by the driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com