Double-stage switching system of photoetching machine wafer stage

A technology for exchanging systems and wafer stages, which is applied in the field of dual-stage exchanging systems for lithography machine wafer stages, can solve problems such as complex structure, high processing and assembly precision, achieve large air gap, reduce installation accuracy requirements, and avoid extreme The effect of high precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

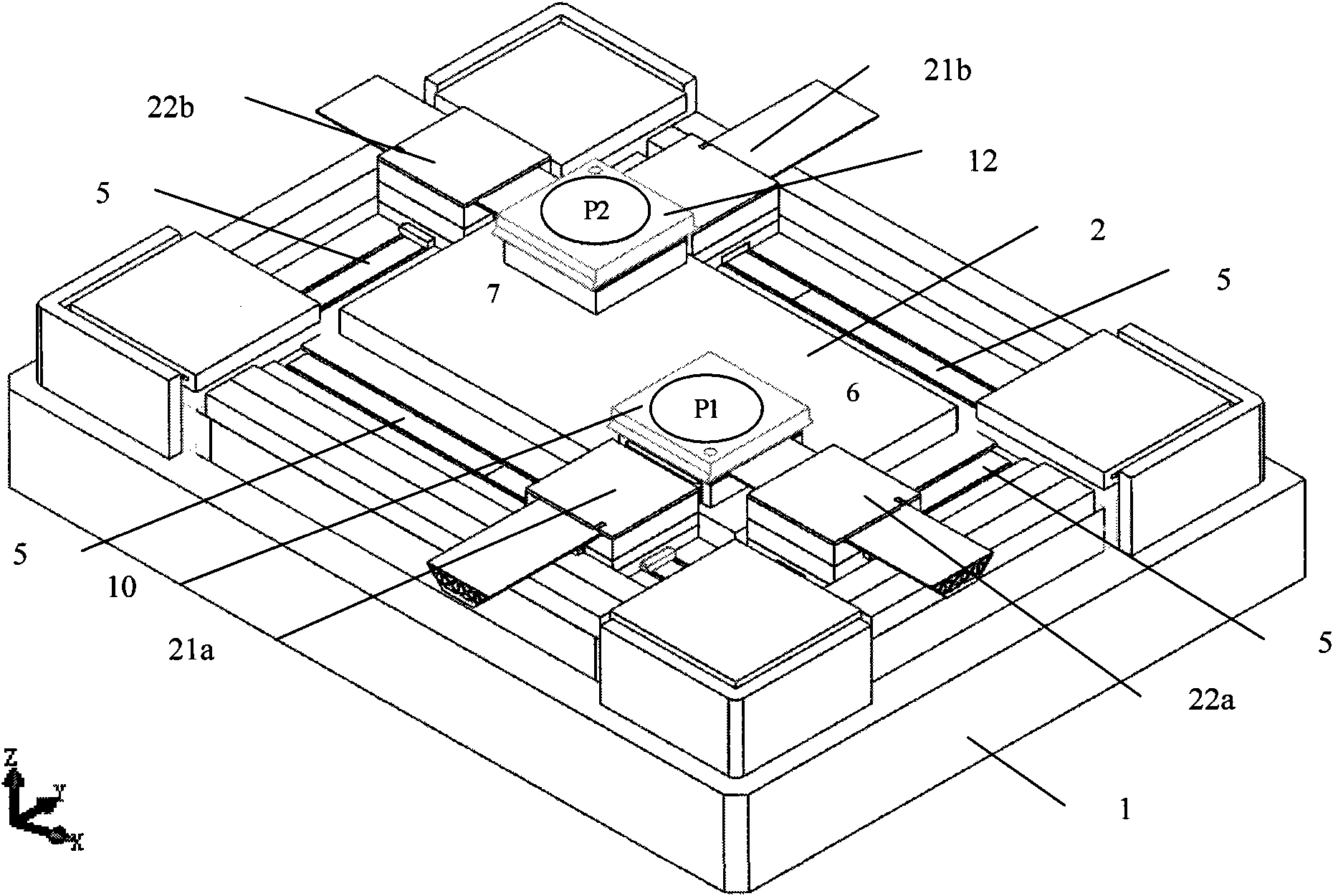

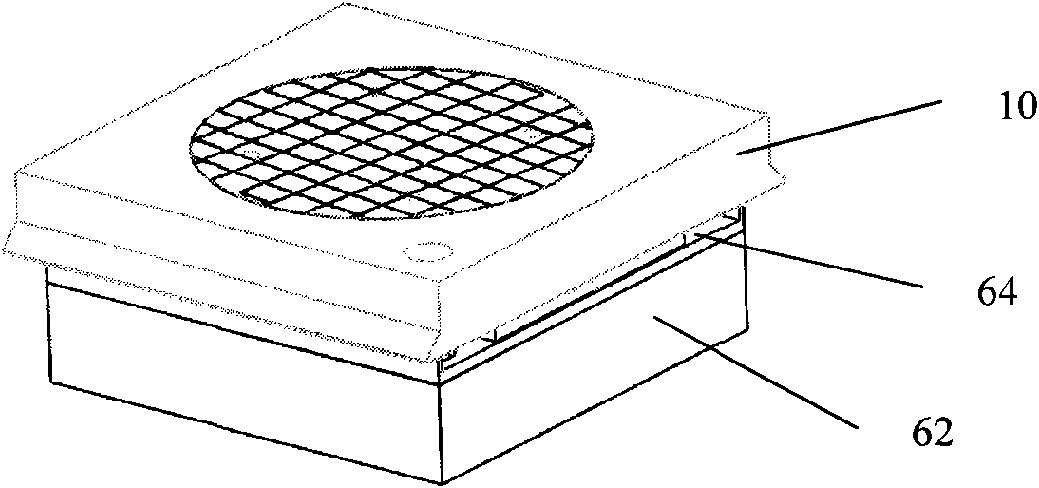

[0028] figure 2 It shows the structural schematic diagram of the dual wafer stage exchange system of the lithography machine. The system includes the base 1, the long side of the base is in the X direction, the short side is in the Y direction, and there is the first wafer stage running in the exposure station 6 10, the second wafer stage 12 running in the pre-processing station 7, and four dual-degree-of-freedom drive units arranged on the edge of the platform along the X-direction and Y-direction. The two silicon wafer stages are located in the space surrounded by four dual-degree-of-freedom drive units, and are suspended on the upper surface of the base stage through air bearings. The push rod of the first two-degree-of-freedom drive unit 21a in the X direction is fixed to the six-degree-of-freedom micro-motion table base 62 of the wafer stage, and the push rod of the first two-degree-of-freedom drive unit 22a in the Y direction is connected to the six-degree-of-freedom mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com