Non-contact power supplying apparatus

A non-contact power supply and electric power technology, applied in circuit devices, along the running track devices, circuits, etc., to achieve strong electromagnetic coupling, high efficiency, significant effect and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

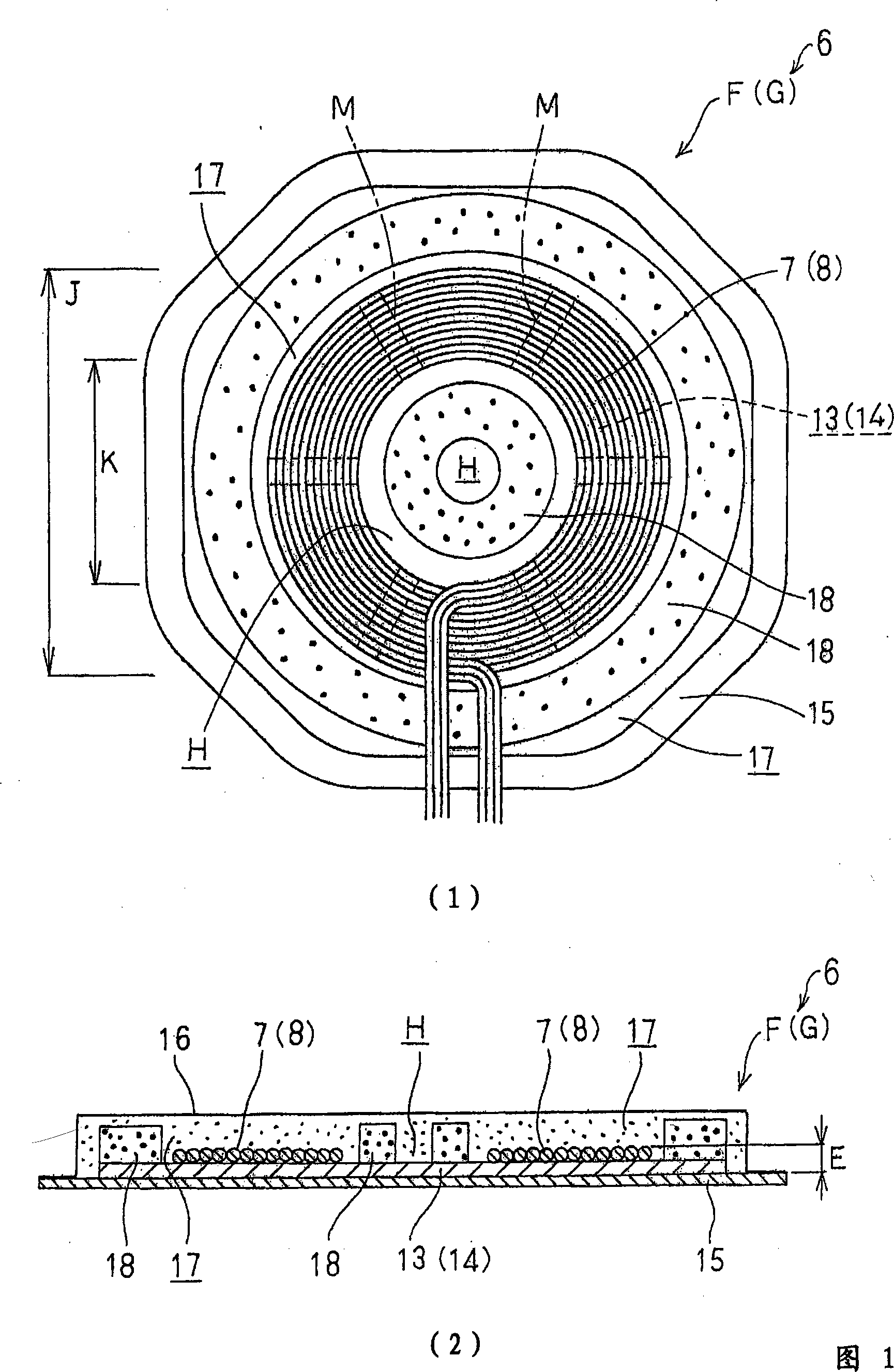

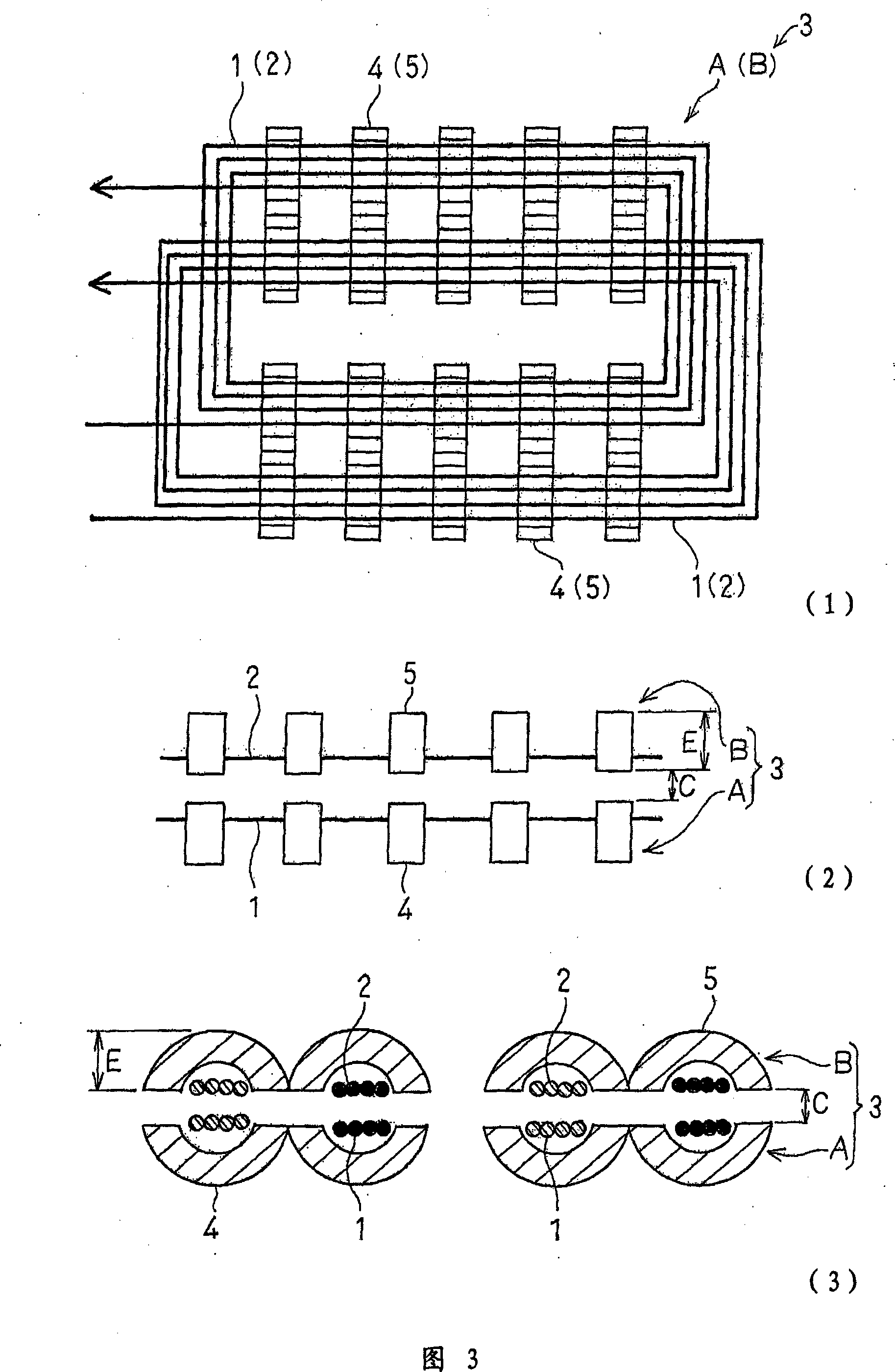

[0068] Hereinafter, the contactless power supply device of the present invention will be described in detail based on the preferred embodiments for implementing the present invention shown in the accompanying drawings.

[0069] FIG. 1 and FIG. 2 are for the description of the preferred embodiment for carrying out the present invention. 1 is a plan view of the primary side, that is, a view viewed from above (it is also a plan view of the secondary side, that is, a view viewed from above), and view (2) is a view of the primary side and the secondary side. A view is a cross-sectional view viewed from the front (side view, that is, viewed from a lateral direction).

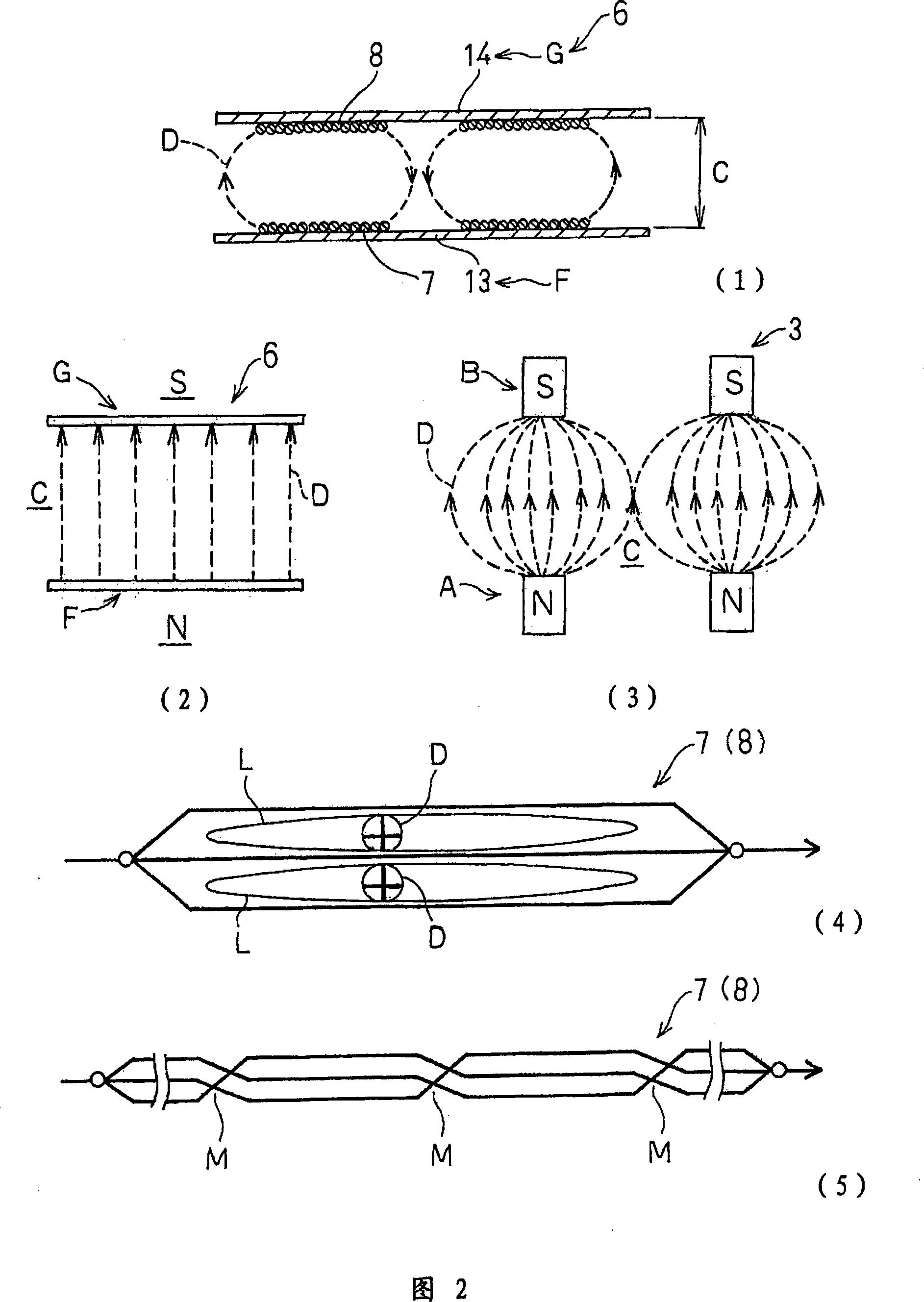

[0070] Fig. 2 (1) is a front view of the electromagnetic coupling, that is, a cross-sectional explanatory view viewed from the front (side view, that is, viewed from a lateral direction), (2) is a front view of the magnetic flux distribution, and (4) Fig. An explanatory plan view of the eddy current, and FIG. (5) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com