Patents

Literature

178results about How to "Improve resistance to demagnetization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high-coercivity sintered Nd-Fe-B permanent magnet

ActiveCN103839670AMaximize resource efficiencyResource efficiency is stableElectrolytic coatingsInductances/transformers/magnets manufactureAlloySolid matter

The invention discloses a method for preparing a high-coercivity sintered Nd-Fe-B permanent magnet. The method includes the following steps that firstly, the vacuum rapid hardening technology is used for preparing Nd-Fe-B alloy magnetic material blank; secondly, chamfering, cleaning, washing, surface modifying and washing are sequentially performed on the blank; thirdly, a processed permanent magnet is placed to a nickel / heavy rare earth composite coating for being electroplated; fourthly, a sintered Nd-Fe-B magnetic material is placed into a vacuum heat treatment furnace to receive heat treatment. With the technology of compositing heavy rare earth on a nickel-plate, heavy rare earth solid matter can be effectively utilized, and maximum benefits of rare earth resources are achieved. Meanwhile, it is ensured that the proportion of the content of the heavy rare earth in the nickel-plate is stable, volatile matter which is prone to decomposition does not exist in the nickel-plate in subsequent heat treatment to pollute a vacuum heat treatment system, a production device with infiltration of the heavy rare earth can be stable continuously, the application range of a technology is wider, and the method can be popularized and applied in an enterprise more easily.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

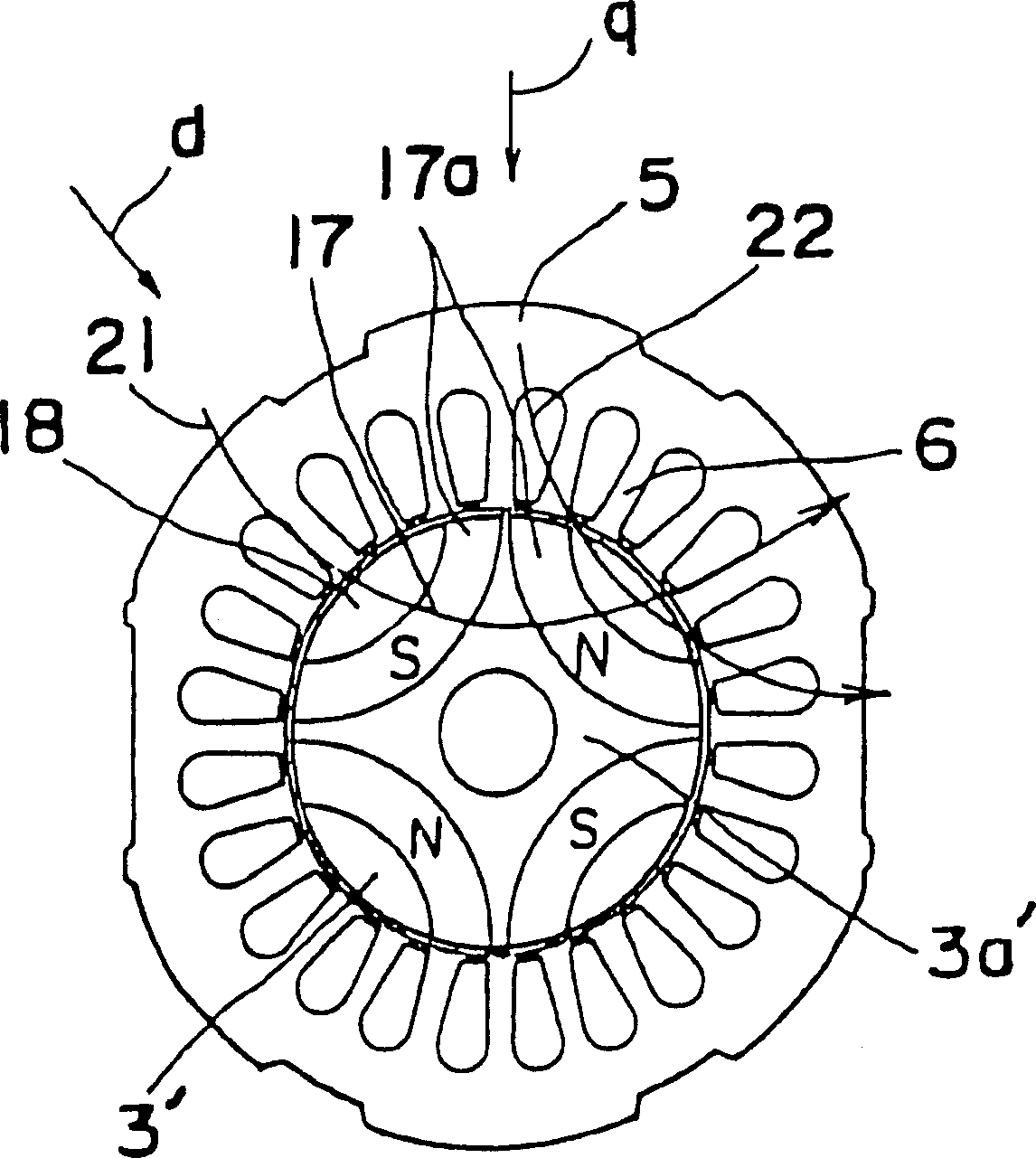

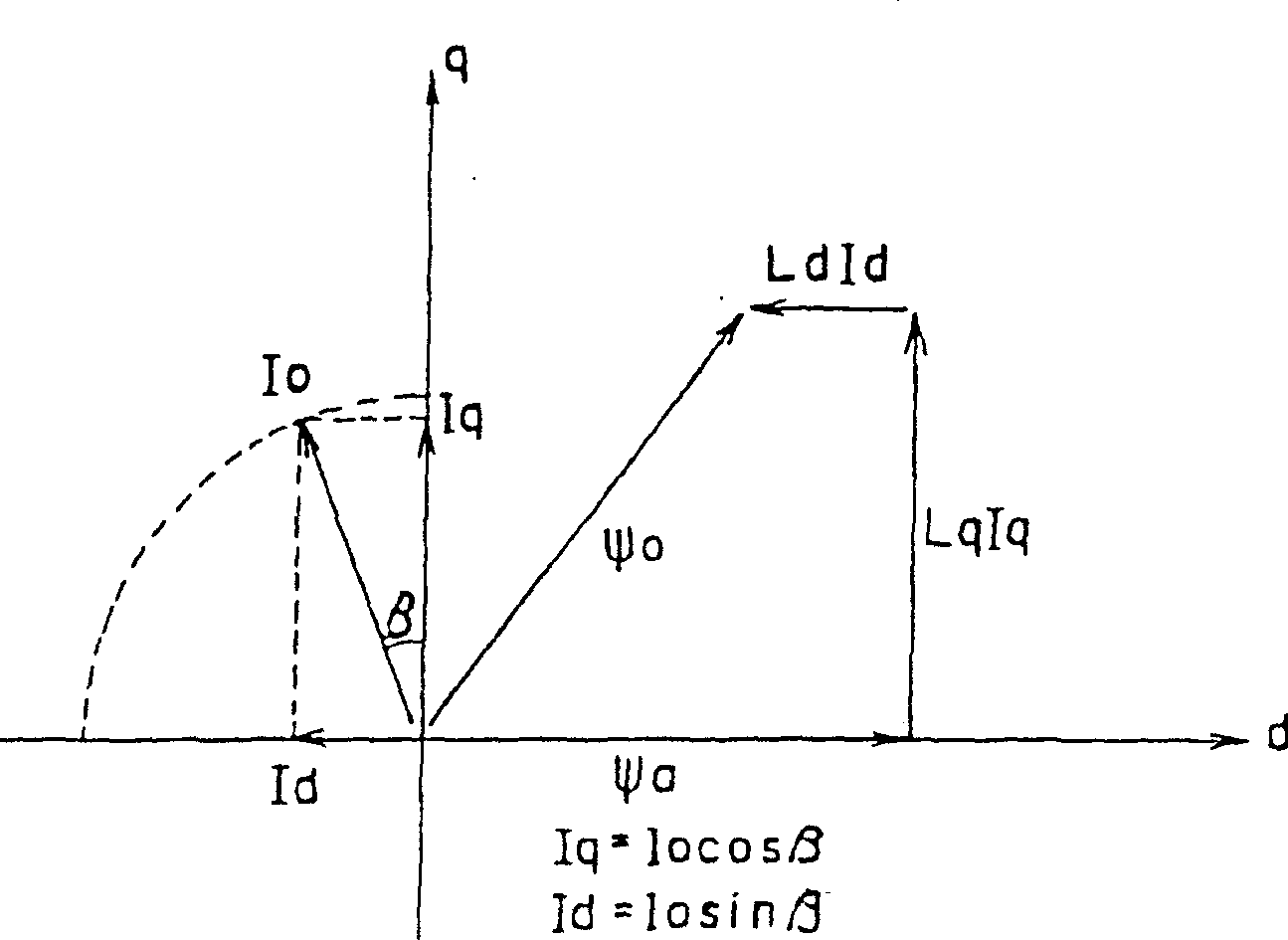

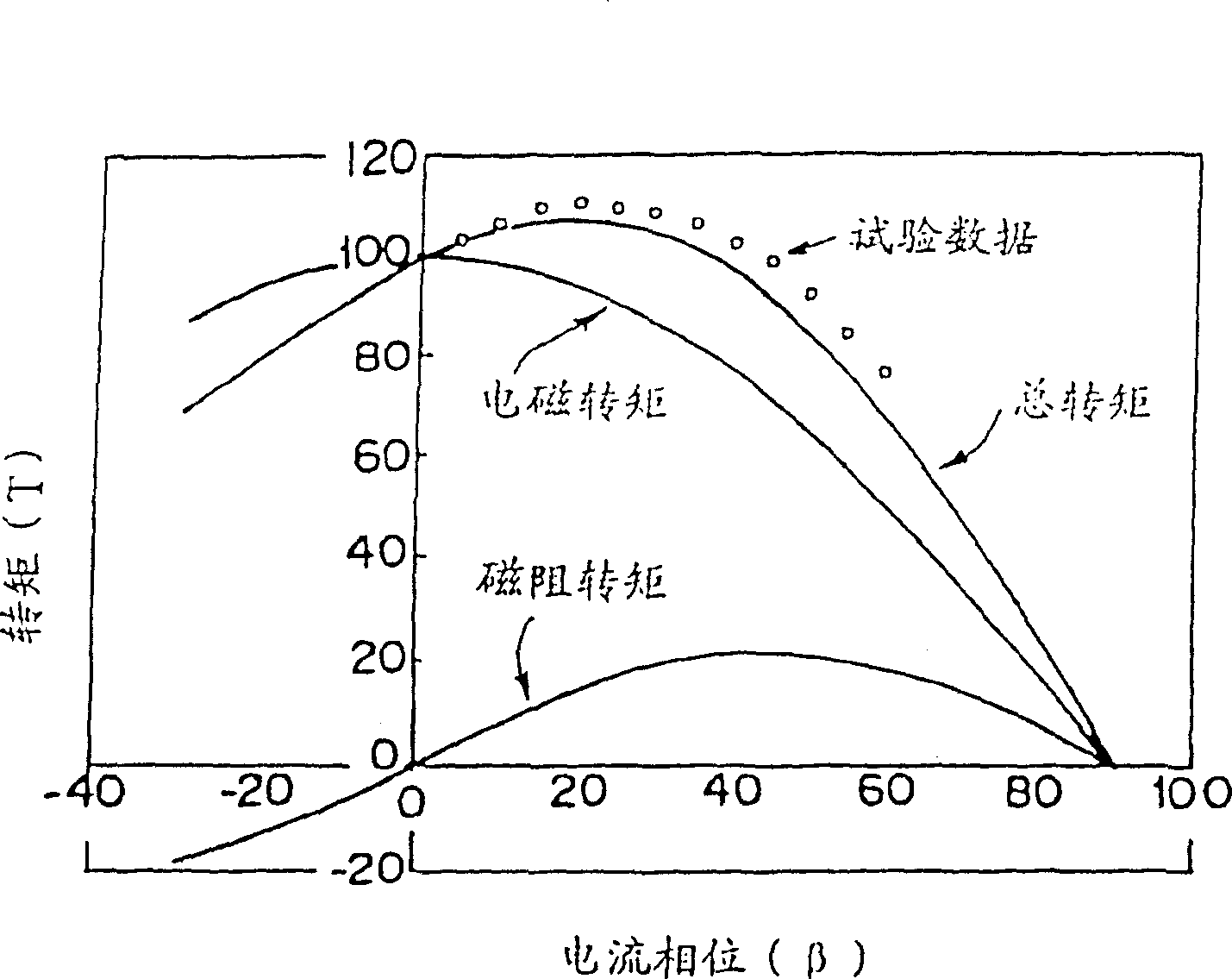

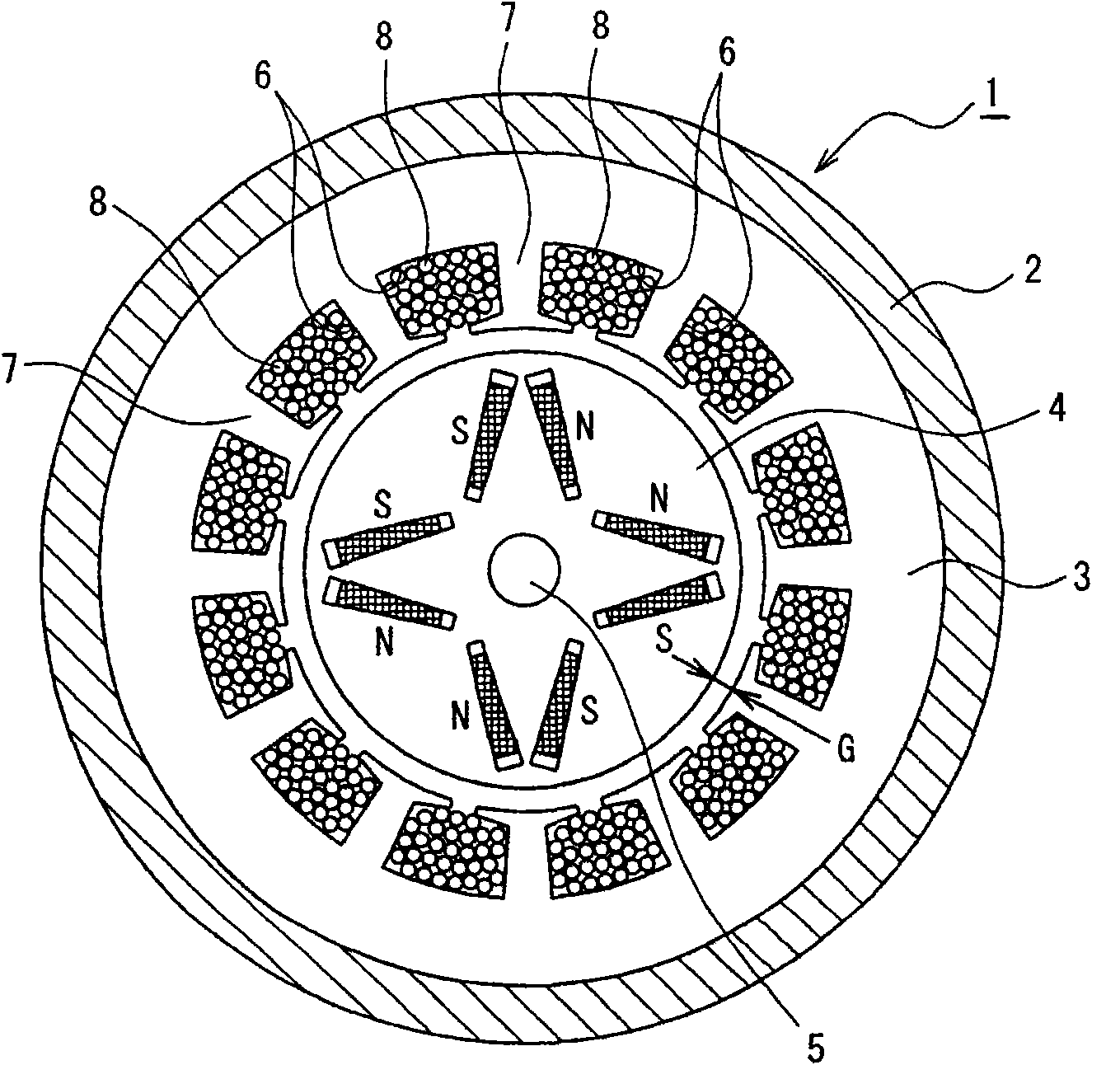

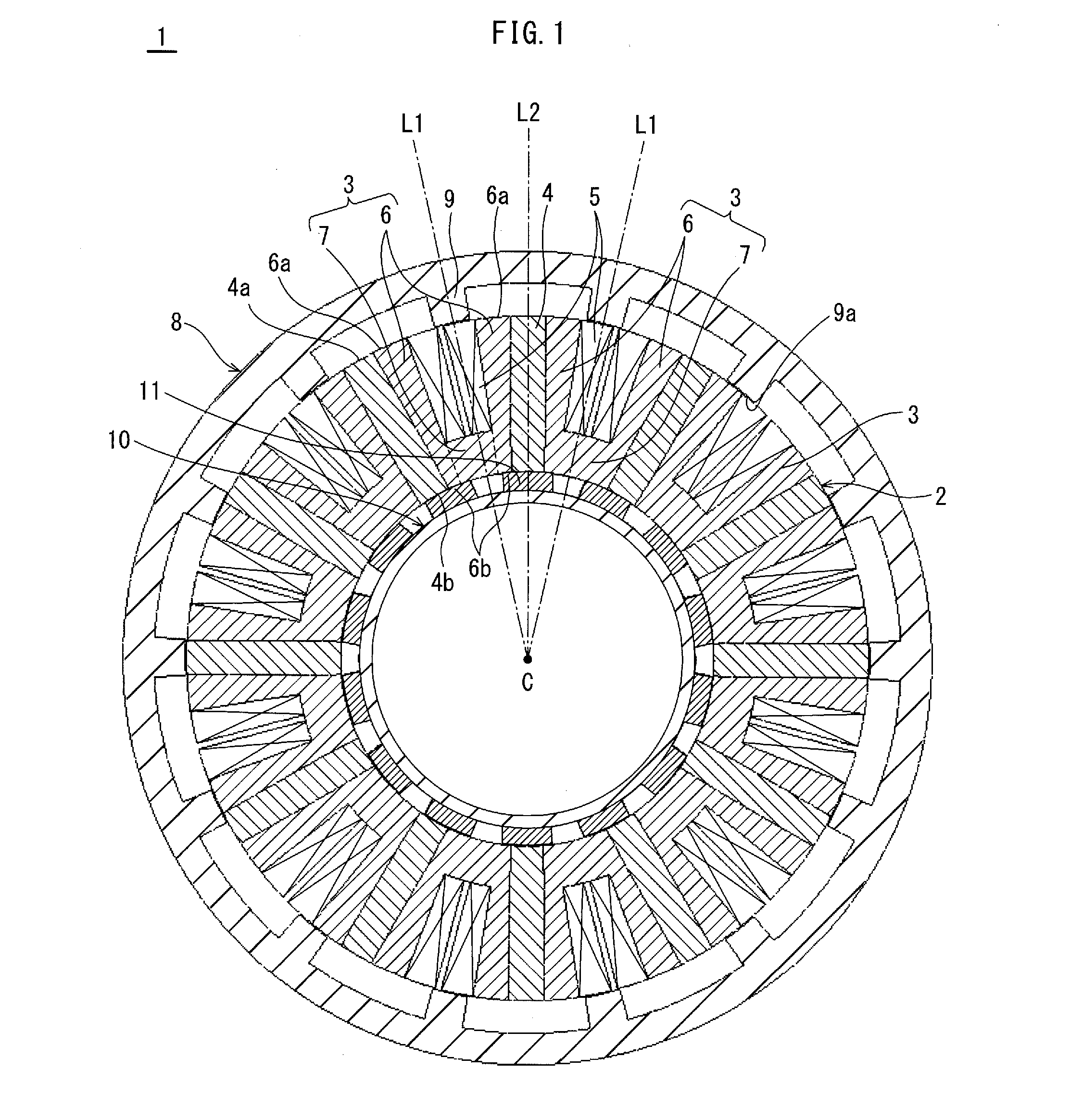

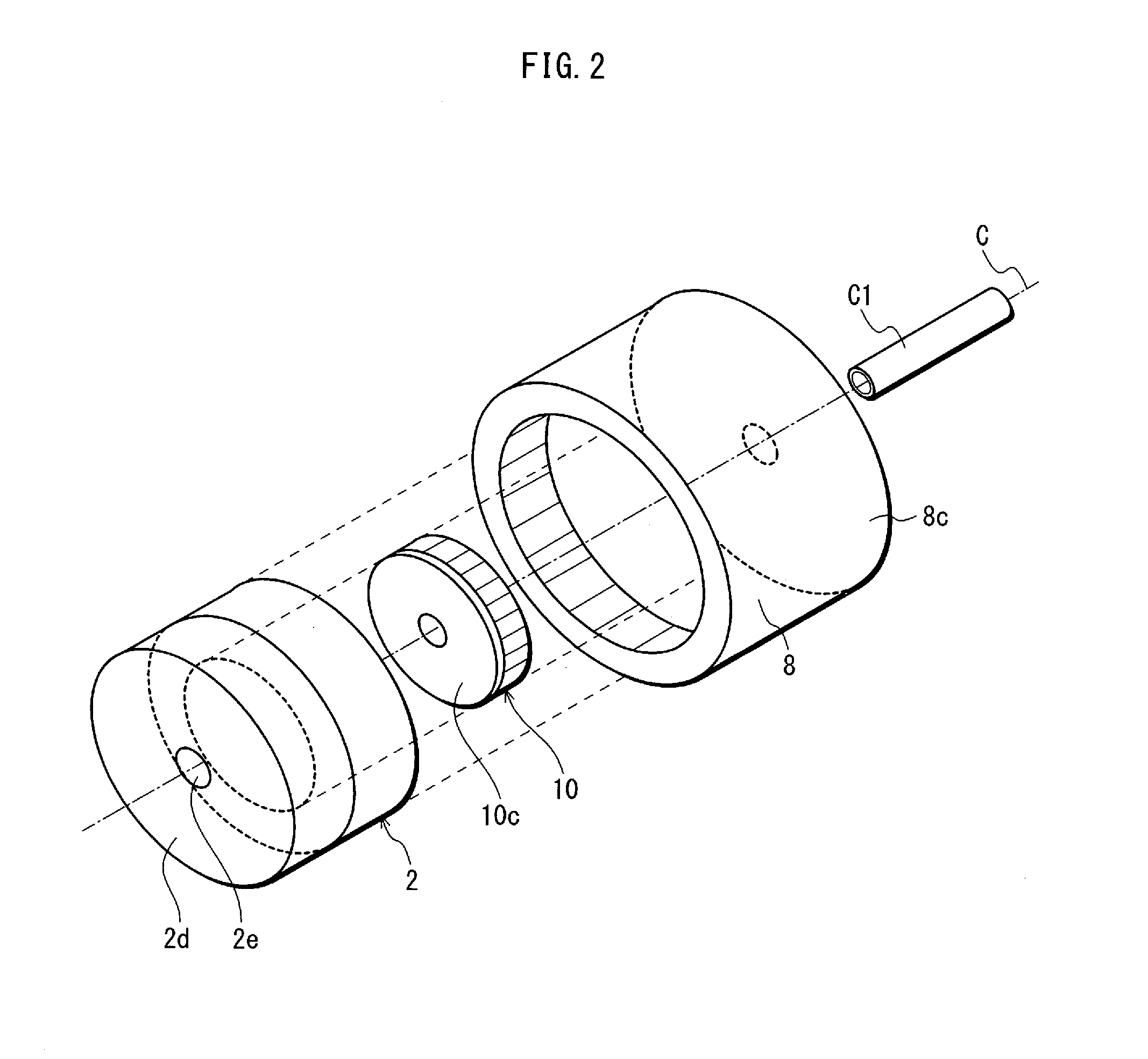

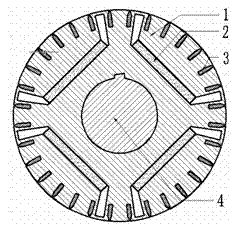

Motor with built-in permanent magnets

InactiveCN1505239AIncrease output powerImproved resistance to demagnetizationMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPhysicsMagnetic flux

A rotor of a motor includes a plurality of sets of permanent magnets 8a, 8b embedded in the rotor. Each includes a permanent magnet at an inner side and another permanent magnet at an outer side with a distance between them. Each permanent magnet 8a, 8b is formed like an arch projecting towards the center of the rotor. Magnetic flux flows easily through an interval between the permanent magnets at inner and outer sides, and the inductance in a q-axis is enlarged. Then, the reluctance torque is generated in addition to the magnet torque, and the motor has a high torque and a high output power.

Owner:PANASONIC CORP

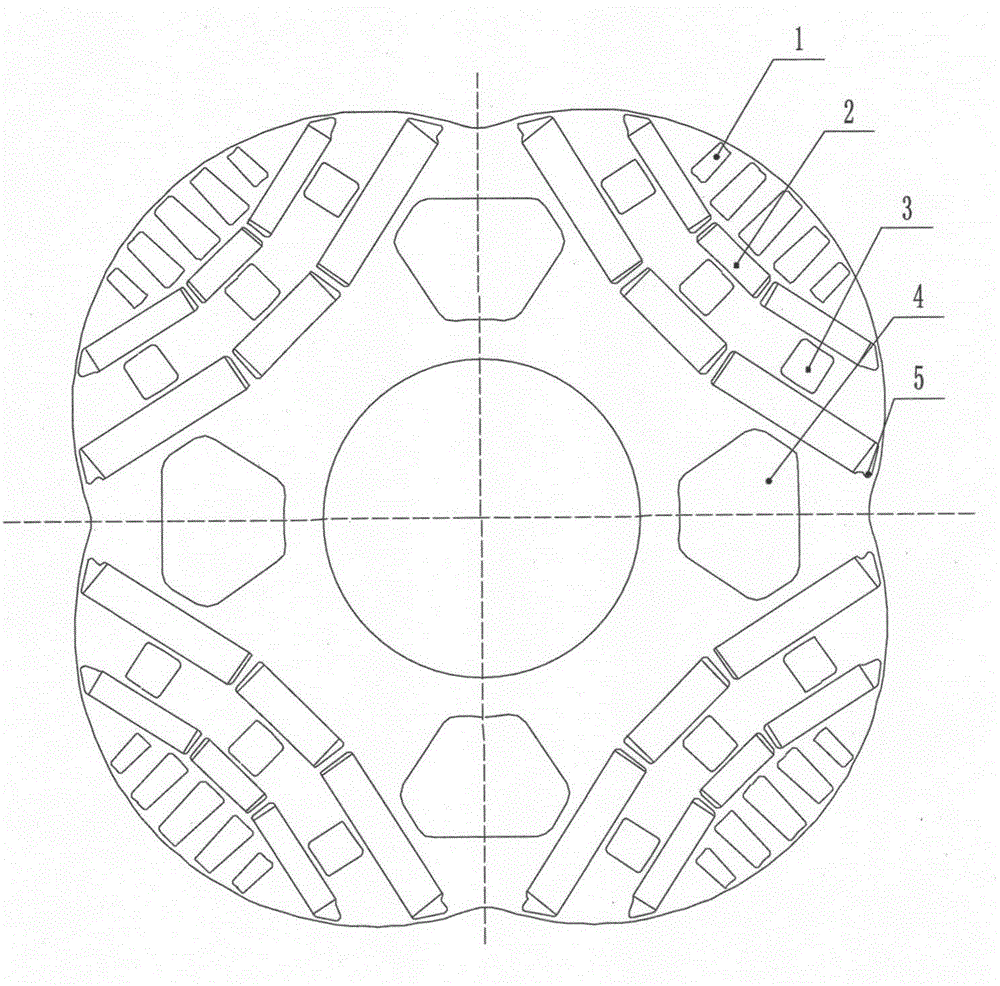

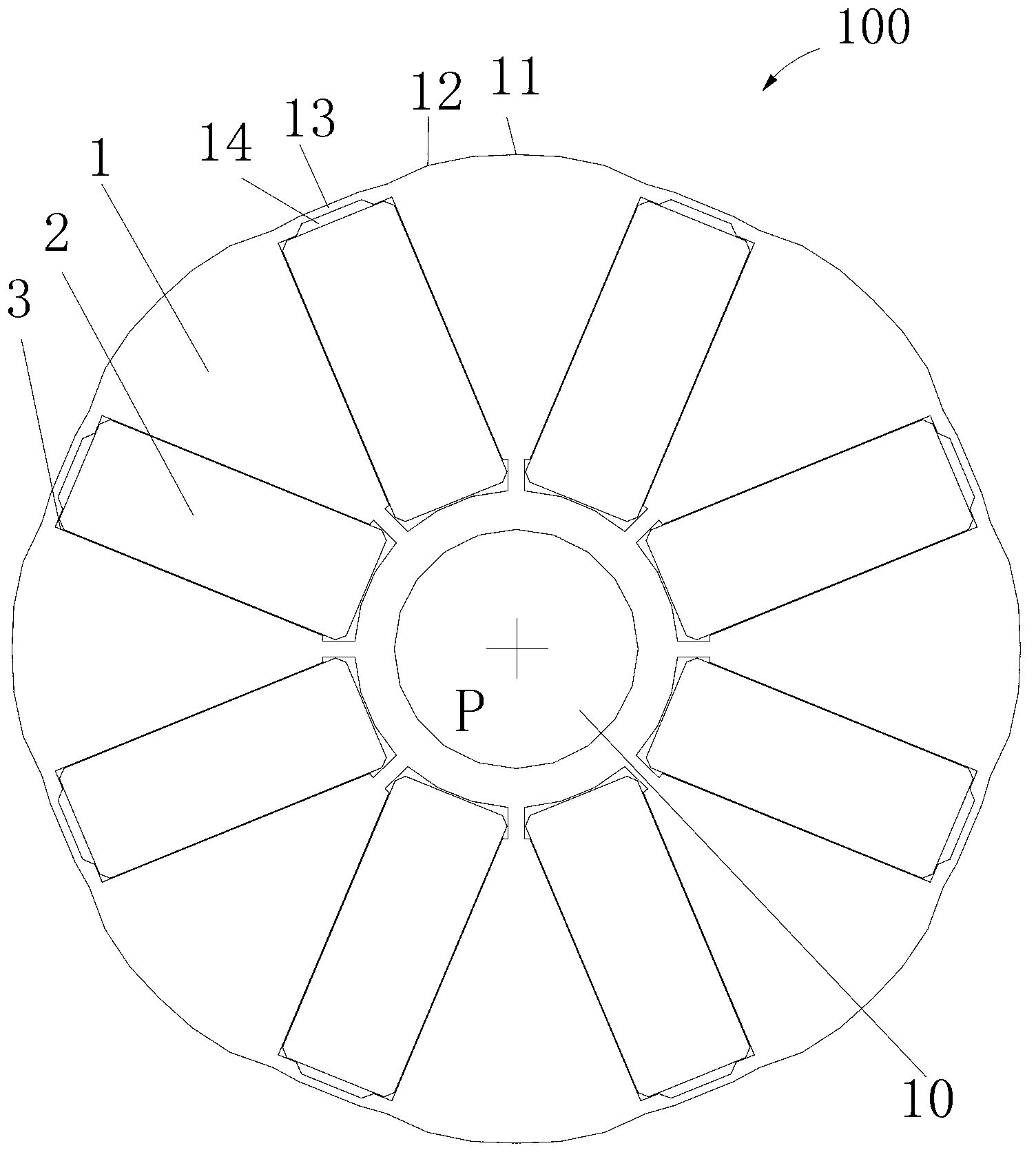

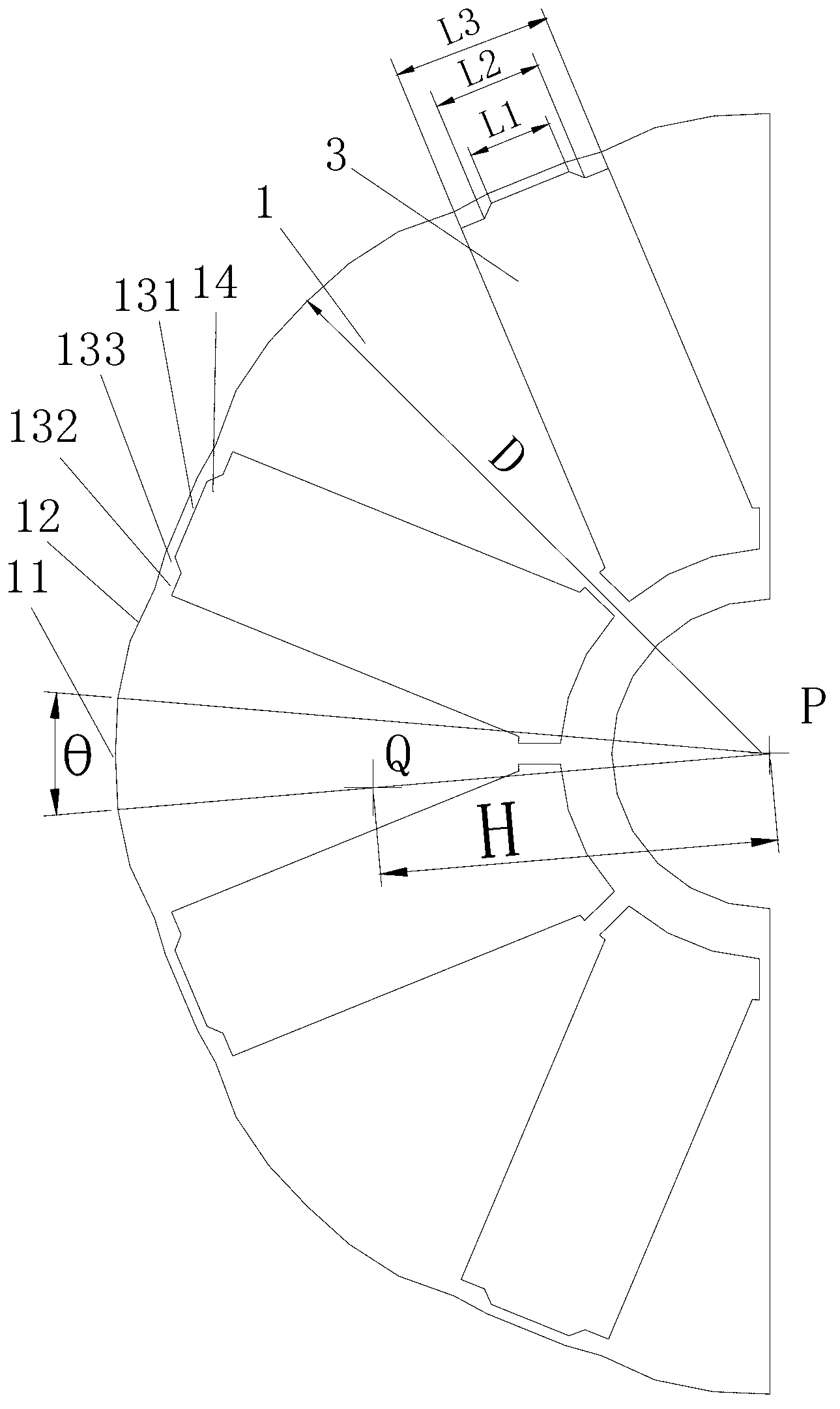

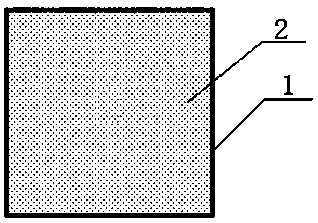

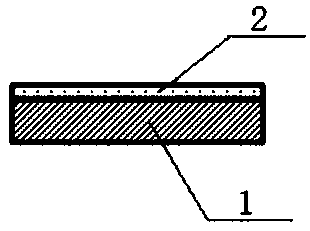

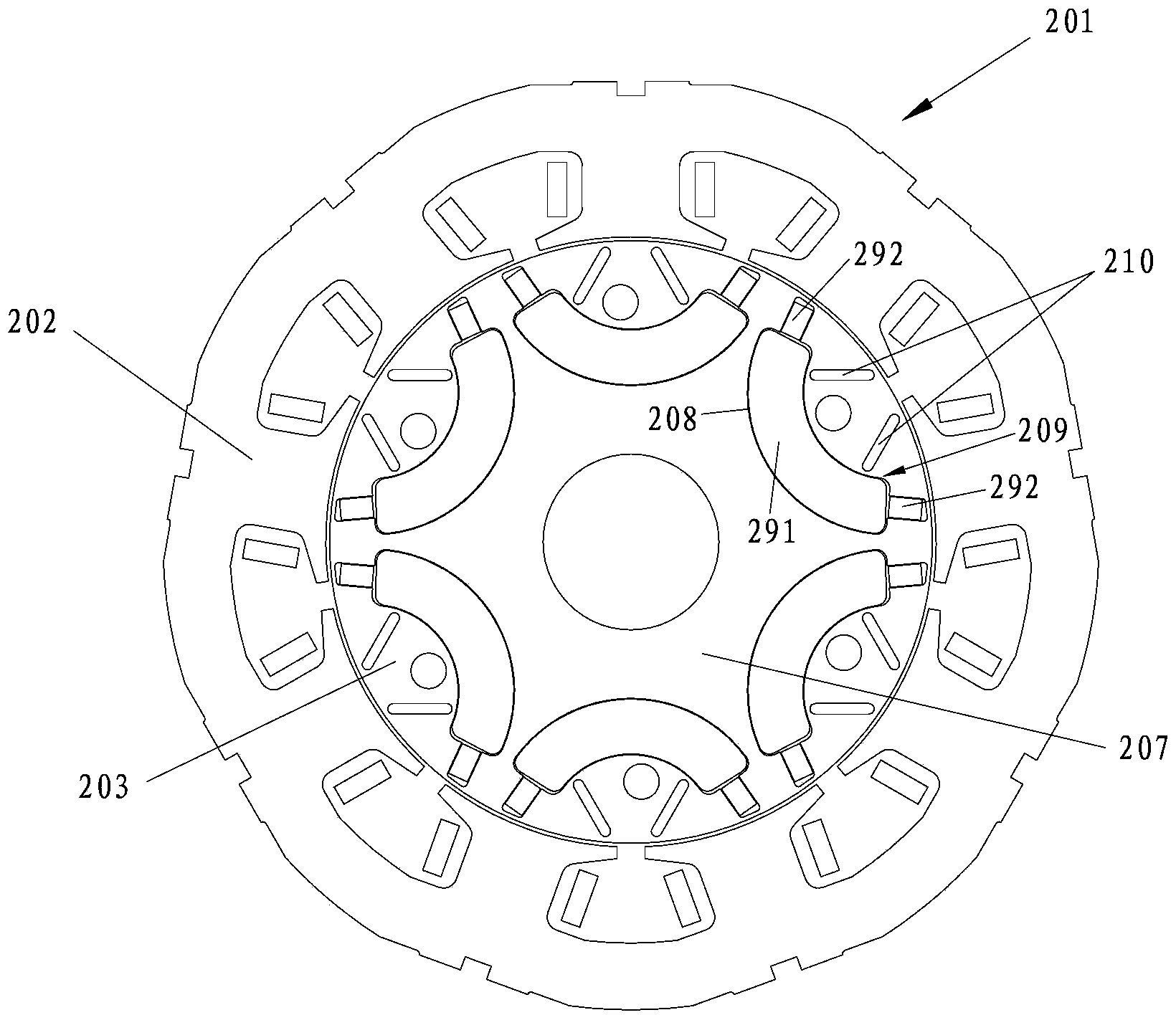

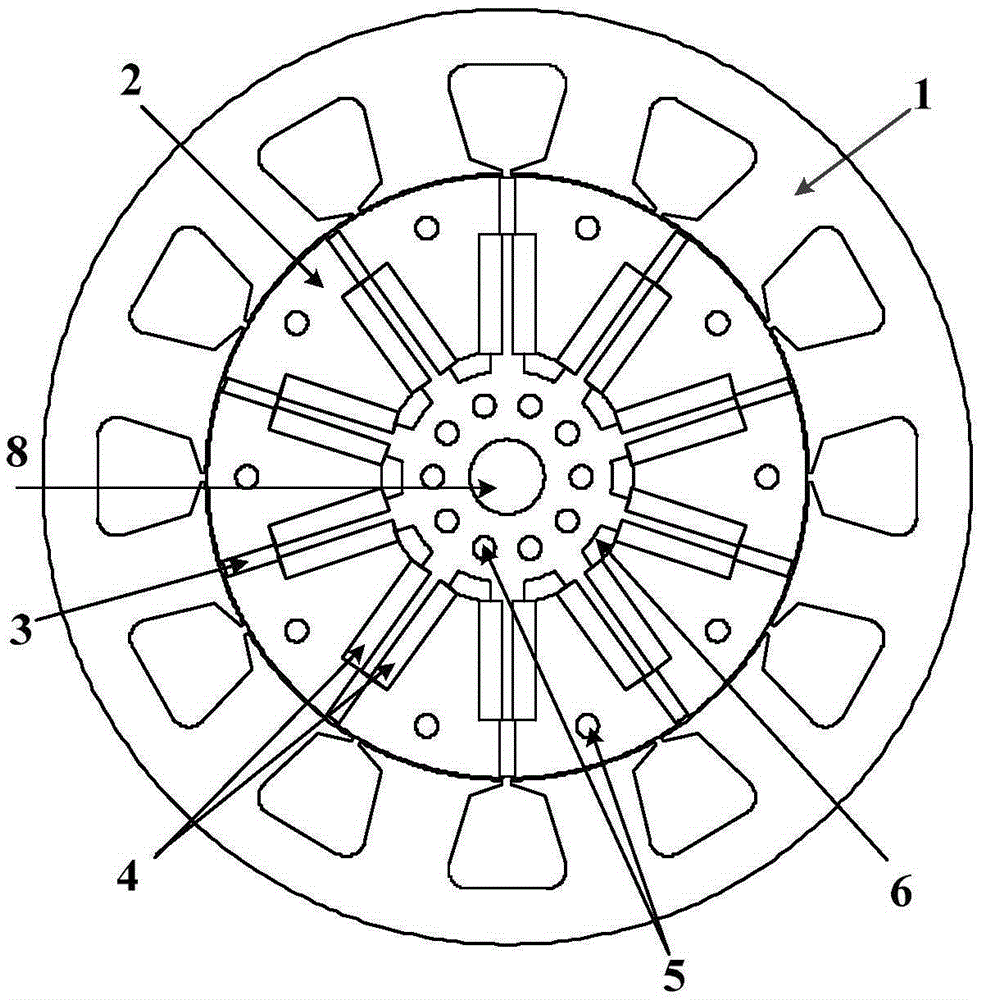

Rotor punching structure for permanent-magnet servo motor

ActiveCN104882981AImprove back EMF waveformReduce additional stray lossMagnetic circuit rotating partsPunchingCoupling

The invention provides a rotor punching structure for a permanent-magnet servo motor, and the structure comprises a rotor punching body. The peripheral surface of the rotor punching body is provided with permanent magnet tanks, and the interior of each permanent magnet tank is provided with a permanent magnet in an embedded manner. The external circle of the rotor punching body above the permanent magnet tanks is not concentric with the internal circle of a stator. The rotor punching body above the permanent magnet tanks is provided with magnetic isolation holes which are arranged horizontally, and the rotor punching body below the permanent magnet tanks is provided with an axial cooling channel. The permanent magnet tanks are radially arranged in a layered manner, and magnetic isolation tanks are respectively disposed between the adjacent permanent magnet tanks. Magnetic isolation bridges are disposed among the magnetic isolation tanks and the permanent magnet tanks. Through the improvement of the rotor punching structure and the control of the direction of a magnetic field, the nonlinear impact, caused by the coupling of quadrature-axis and direct-axis magnetic circuits, on motor parameters is reduced, and the space of a rotor punching is used fully for placing permanent magnets as many as possible. Moreover, the capability of resistance to demagnetizing and the overbearing capability of the permanent-magnet servo motor are improved, and the operation performance of the permanent-magnet servo motor is effectively improved.

Owner:SHANGHAI MOTOR SYST ENERGY SAVING ENG TECH RES CENT +2

Efficient electric machine

ActiveUS20150001980A1Reduce manufacturing costGuaranteed stable operationWindingsMagnetic circuit rotating partsElectric machineMagnet

An electric machine having a stator and a rotor which is mounted so as to be rotatable about a rotor axis and has a rotor body, in which at least two permanent magnets are arranged in receptacles, a first of which component magnets is associated with a first set of permanent magnets, and a second of which component magnets is associated with a second set of permanent magnets. The permanent magnets of the first set differ from the permanent magnets of the second set with respect to the material composition, In particular to the magnetic properties, and wherein at least one permanent magnet of the first or second set or at least one composite body has a contour, the cross-sectional face of which, being located perpendicularly with respect to the longitudinal axis, decreases within the respective receptacle towards that end thereof which is radially further to the outside.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

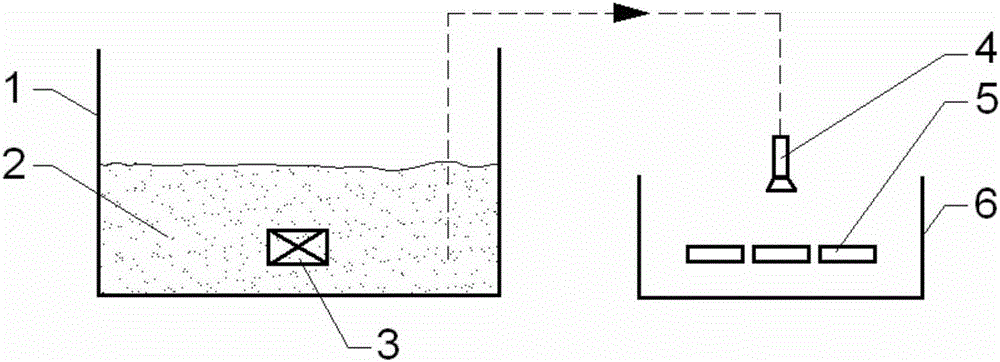

Preparation method of rare-earth permanent magnet material

ActiveCN105185501ACost-effectiveImprove coercive forceInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementSpray coating

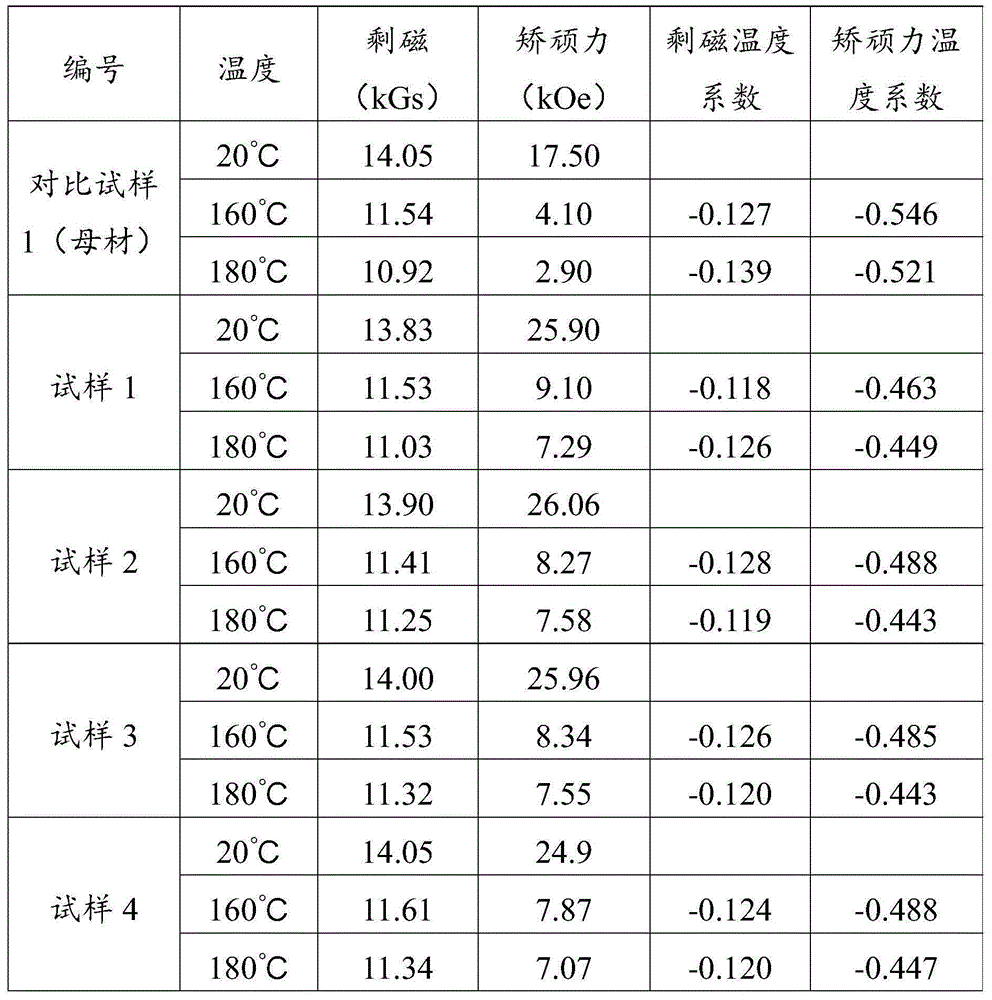

The invention provides a preparation method of a rare-earth permanent magnet material. The preparation method provided by the invention comprises an atomized spray coating process and a permeation process, wherein a sintered rare-earth magnet which is subject to atomized spray coating is put into a closed container before permeation; a solution containing a heavy rare-earth element is subjected to atomized spray coating on the surface of the sintered R1-Fe(Co)-B-A-X-M rare-earth magnet; and heat treatment is carried out after baking, so that the heavy rare-earth element which is subjected to spray coating permeates into a grain-boundary phase of the sintered rare-earth magnet. Compared with a traditional technology, according to the preparation method provided by the invention, the amount of the heavy rare-earth element is reduced; the production cost is reduced; in addition, the coercive force of the magnet can be greatly improved under the premise of slightly reducing the residual magnetism; the residual magnetism temperature coefficient and the coercive force temperature coefficient of the magnet are obviously lowered; and the anti-demagnetization capability of the magnet at high temperature is obviously improved.

Owner:BAOTOU TIANHE MAGNETICS TECH CO LTD

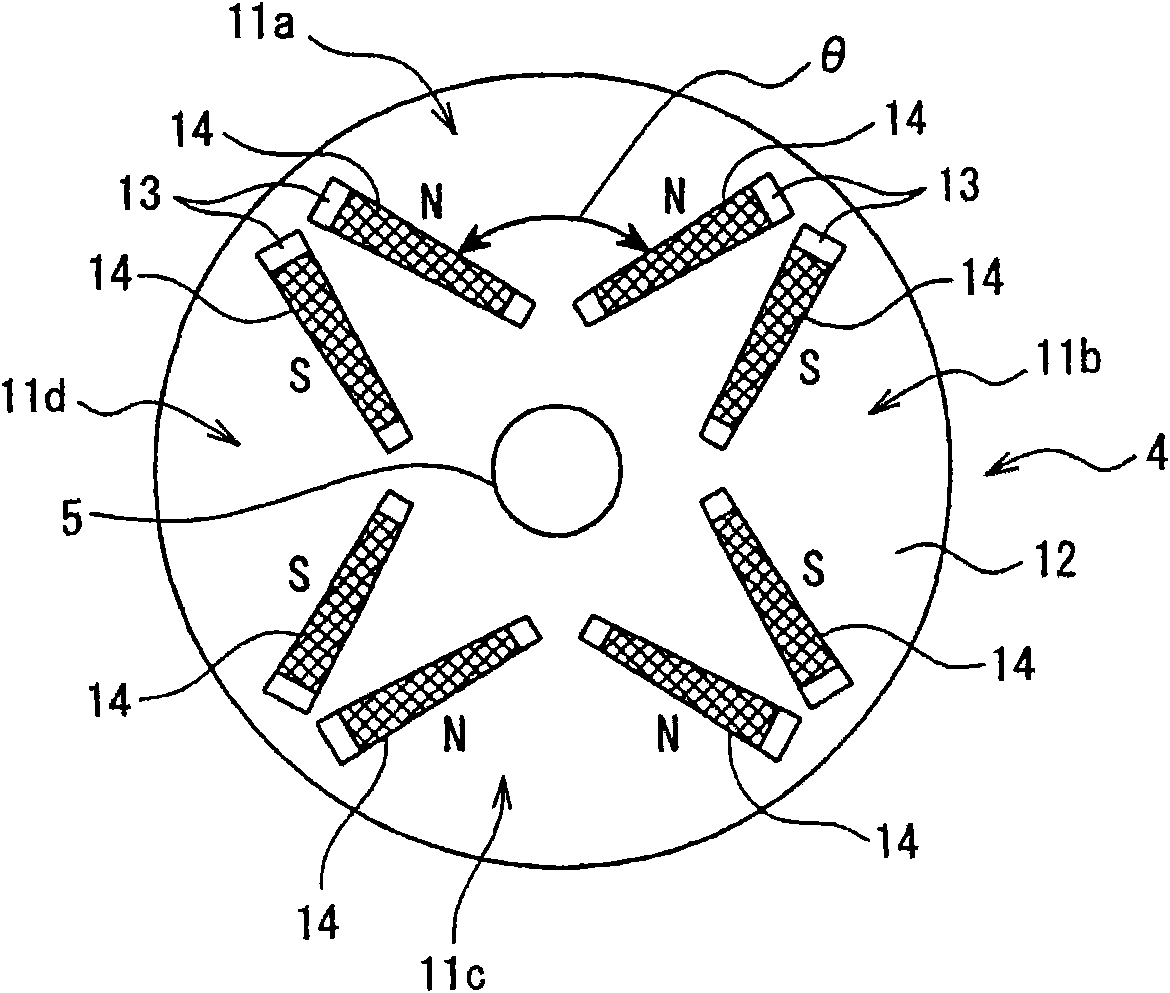

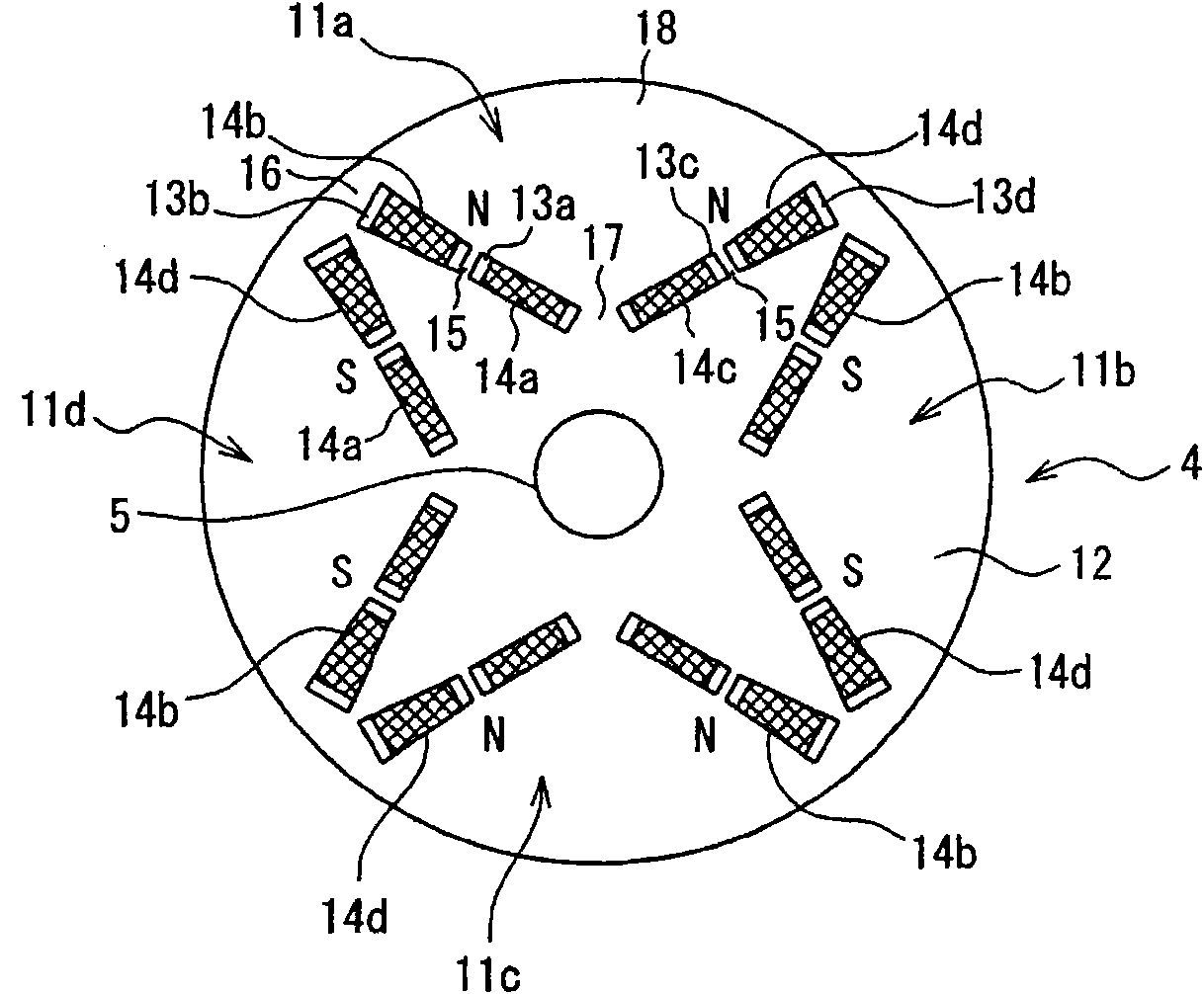

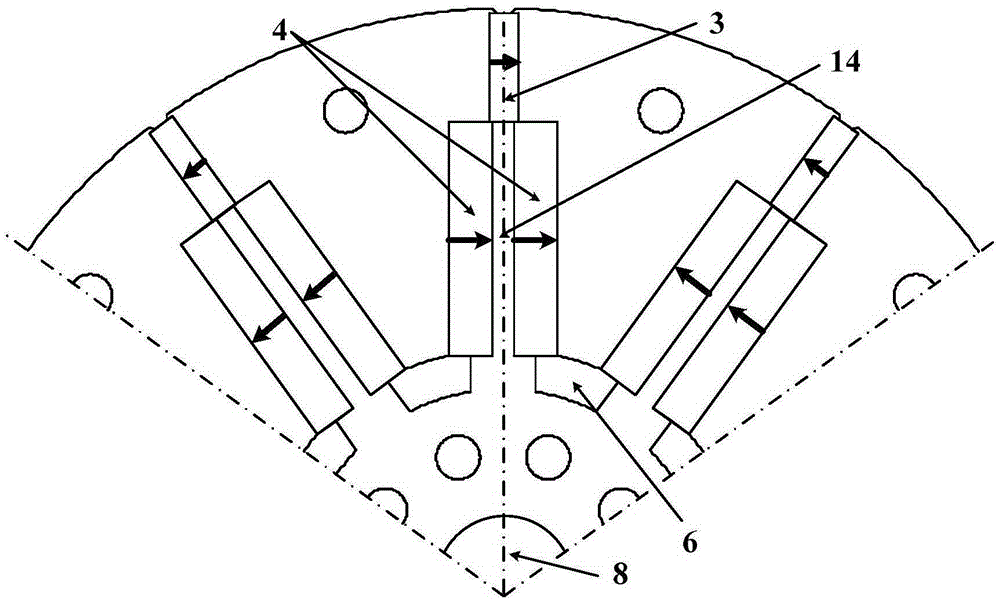

Permanent magnet rotary motor

ActiveCN102044944AEasy to manufactureImprove resistance to demagnetizationMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsMagnetic polesMagnetization

The present invention provides a permanent magnet rotary motor which can ensure manufacturing facility of a permanent magnet, restrains manufacturing cost increase and improves demagnetization resistance. The permanent magnet rotary motor comprises the following components: a stator (3) which is coiled by energizing coils (8), and a rotor (4) which is separated from the stator (3) for a certain clearance and rotates relatively. The rotor (4) is provided with the following components: a plurality of grooves (13) which are formed in an axial direction in a rotor core (12); and permanent magnets (14) which are inserted into the groove (13) with a mode that the adjacent magnet poles (11a-11d) that are adjacent in a circumferential direction are different. The magnetic poles (11a-11d) respectively have a V-shaped structure which configures a pair of grooves (13) to expand to the stator (3). The permanent magnets (14) respectively represent a trapezium shape in which the width of at least the stator side in a magnetization direction to the stator (3) is enlarged.

Owner:FUJI ELECTRIC CO LTD

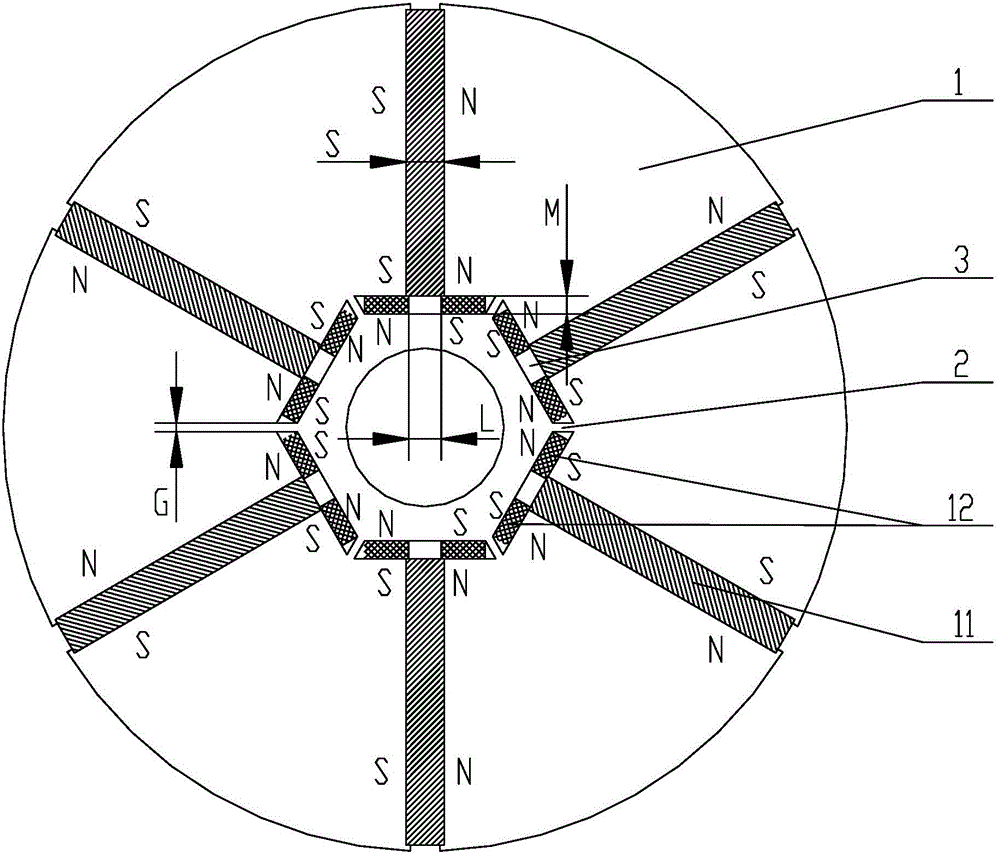

Rotor of permanent magnet synchronous motor and permanent magnet synchronous motor provided with same

ActiveCN104485762AHigh mechanical strengthReduce Flux LeakageSynchronous machine detailsMagnetic circuit rotating partsPermanent magnet synchronous motorPermanent magnet synchronous generator

The invention discloses a rotor of a permanent magnet synchronous motor and the permanent magnet synchronous motor, which belong to the technical field of the permanent magnet synchronous motors, and are designed in order to solve the problems of high leakage flux, low permanent magnet utilization rate, influence on motor performance and efficiency and the like in existing rotor of the permanent magnet synchronous motor. The rotor of the permanent magnet synchronous motor comprises a rotor core, wherein an even number n of tangential permanent magnets are distributed evenly in radial direction on the rotor core, and the same polarities of two adjacent tangential permanent magnets are opposite; radial permanent magnets are arranged symmetrically on two sides of one end of each tangential permanent magnet close to the inner side of the rotor core respectively; every two radial permanent magnets sandwiched between two adjacent tangential permanent magnets have the same polarity in the direction facing to a stator, and a magnetic isolating bridge is arranged between every two radial permanent magnets. The invention further discloses a permanent magnet synchronous motor provided with the rotor. By utilizing the rotor, the leakage flux of the tangential permanent magnets on the inner side of the rotor is reduced, the utilization rate of the permanent magnets is improved, and the motor efficiency and the motor structural intensity are enhanced.

Owner:GREE ELECTRIC APPLIANCES INC +1

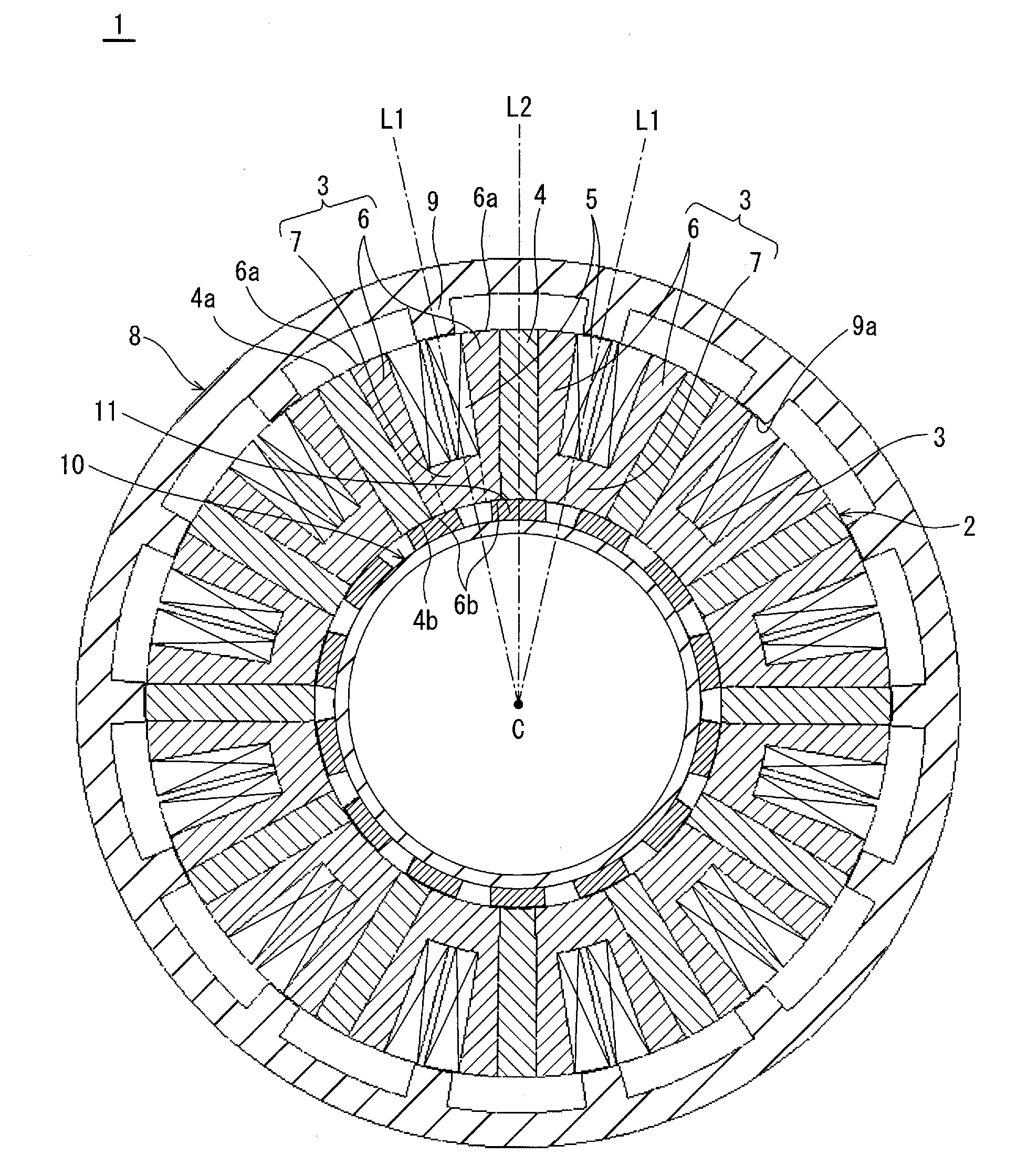

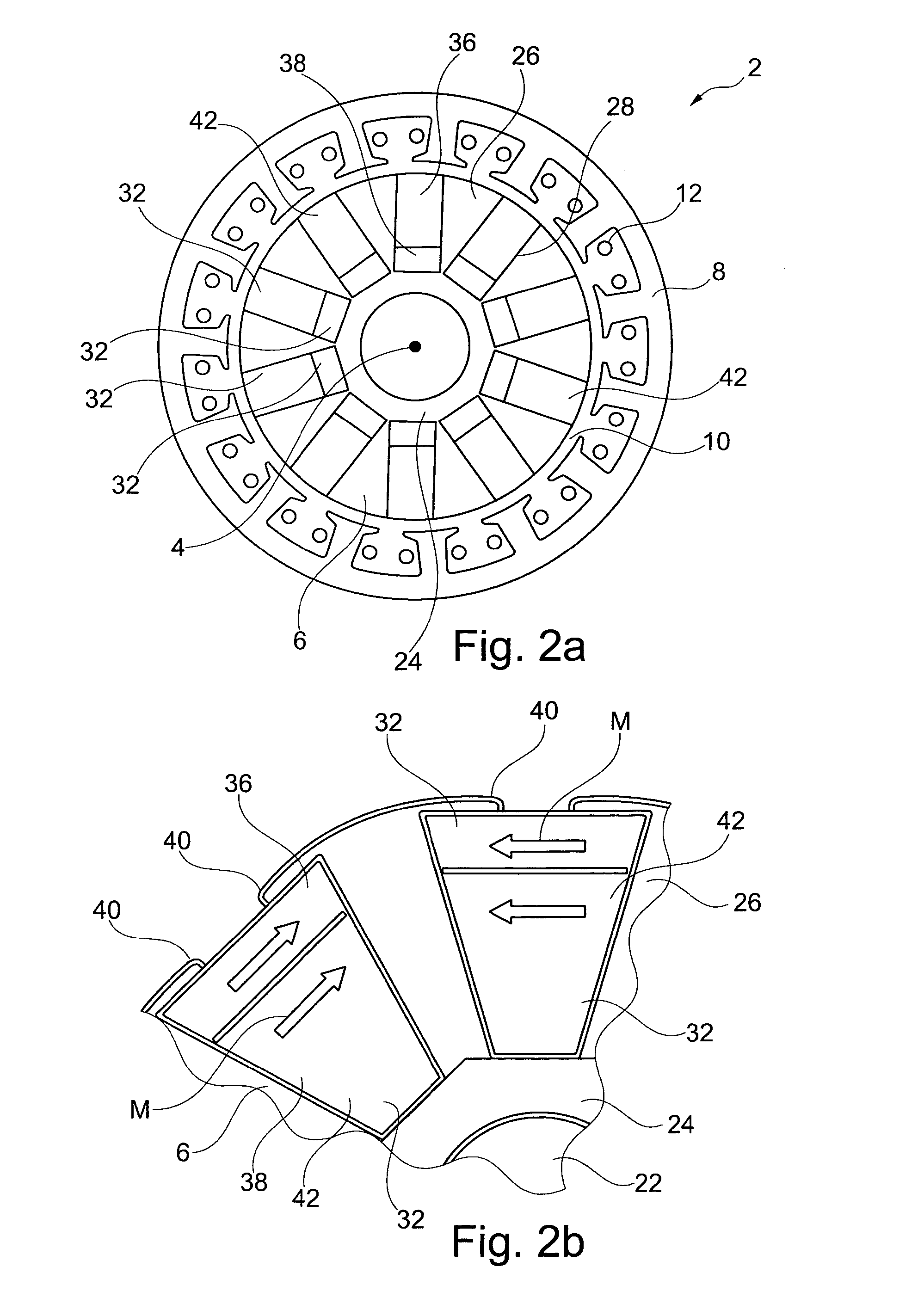

Motor

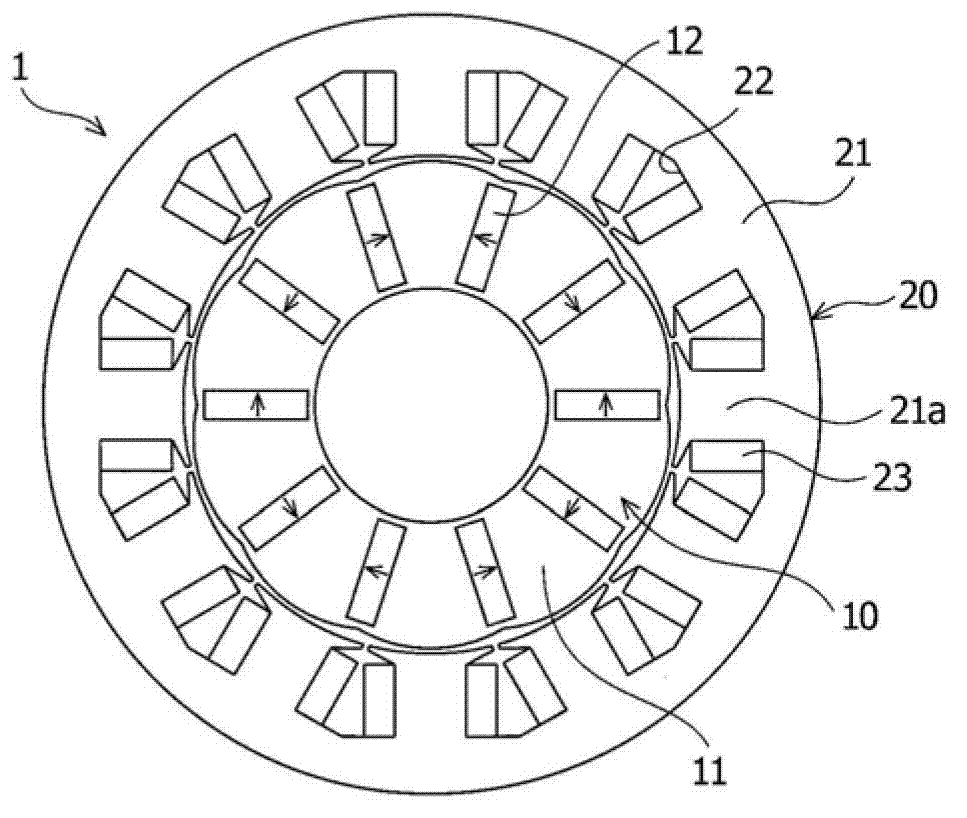

ActiveUS20130113318A1Increase permeance coefficientImprove demagnetization resistanceSynchronous generatorsWindingsPhysicsRotational axis

To provide a motor including: an annular stator including permanent magnets and stator cores that are alternately arranged circumferentially, and coils; an annular outer-rotor being arranged outside the stator, having a rotational axis coincident with a central axis of the stator, and having first salient poles; and an annular inner-rotor being arranged inside the stator, having a rotational axis coincident with the central axis to rotate in conjunction with the outer-rotor, and having second salient poles equal in number to the first salient poles, the magnets are magnetized circumferentially and extend radially, and each have respective ends that are opened toward the outer-rotor and toward inner-rotor in the radial direction, the coils are each wound by concentrated-winding on a tooth constituted from a different one magnet and respective parts of two stator cores adjacent to the magnet, and the first and second salient poles are arranged at offset positions circumferentially.

Owner:PANASONIC CORP

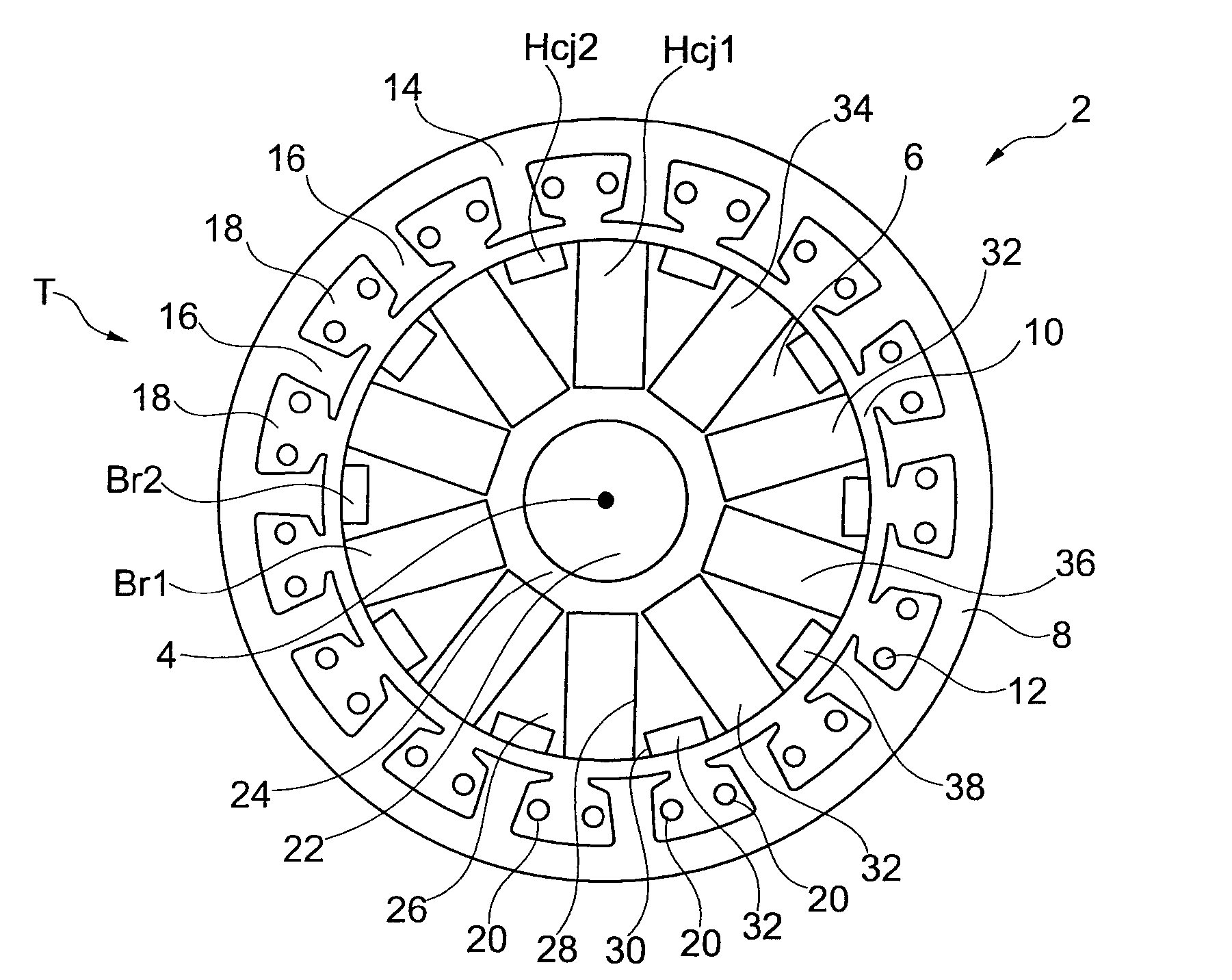

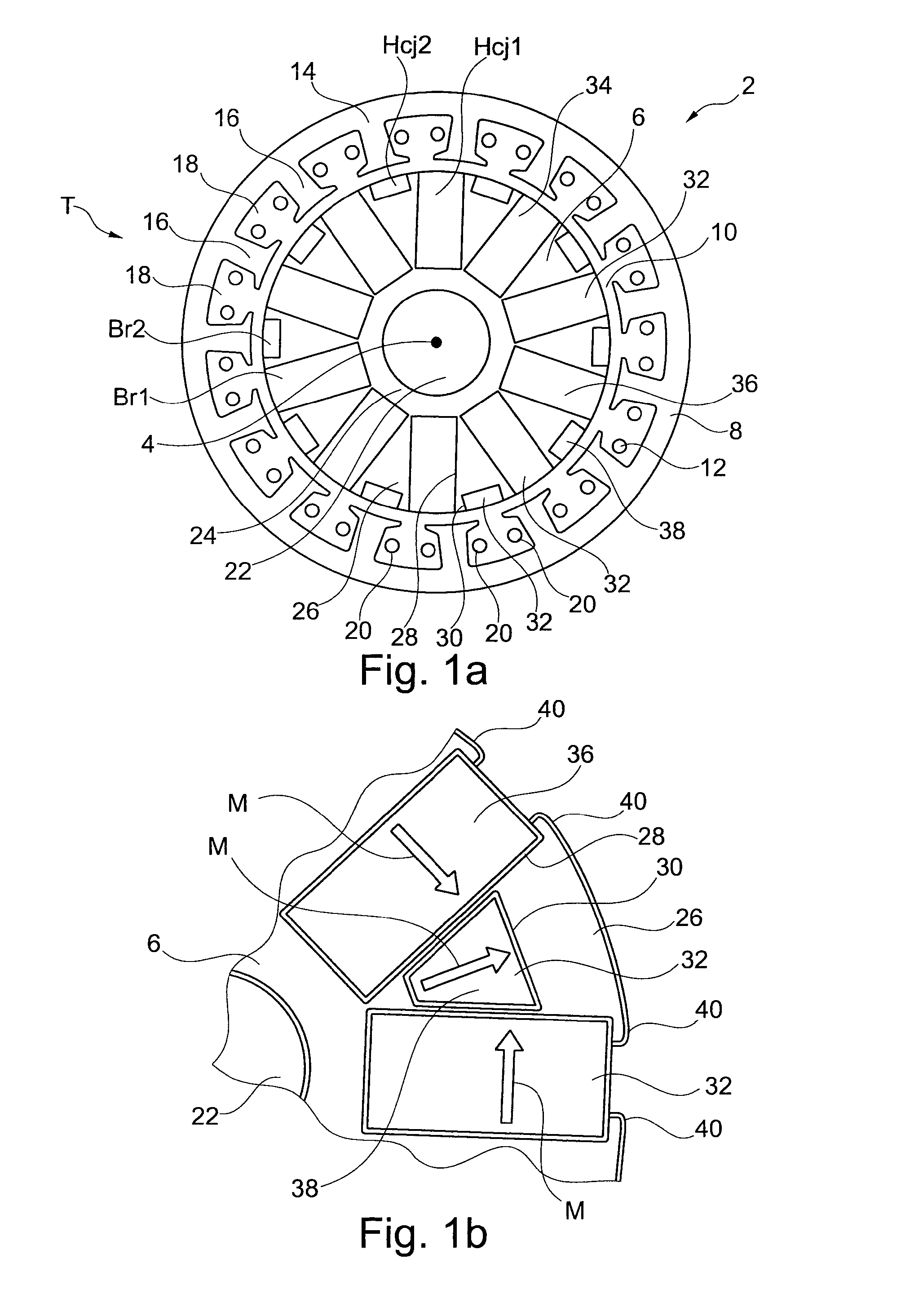

Electrical machine

InactiveUS20140375160A1Low priceImprove resistance to demagnetizationWindingsMagnetic circuit rotating partsElectric machineEngineering

An electrical machine, in particular an electric motor of a motor vehicle, having a stator and having a rotor which has a rotation axis. In this case, an electrical machine can be a brushless electric motor (DC motor) or a synchronous machine, but also a generator. The stator or the rotor has an electromagnet structure and the other has a permanent-magnet structure which comprises a first quantity of permanent magnets and a second quantity of permanent magnets. At an operating temperature, the magnetic coercive field strength of the first quantity is greater than the magnetic coercive field strength of the second quantity.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

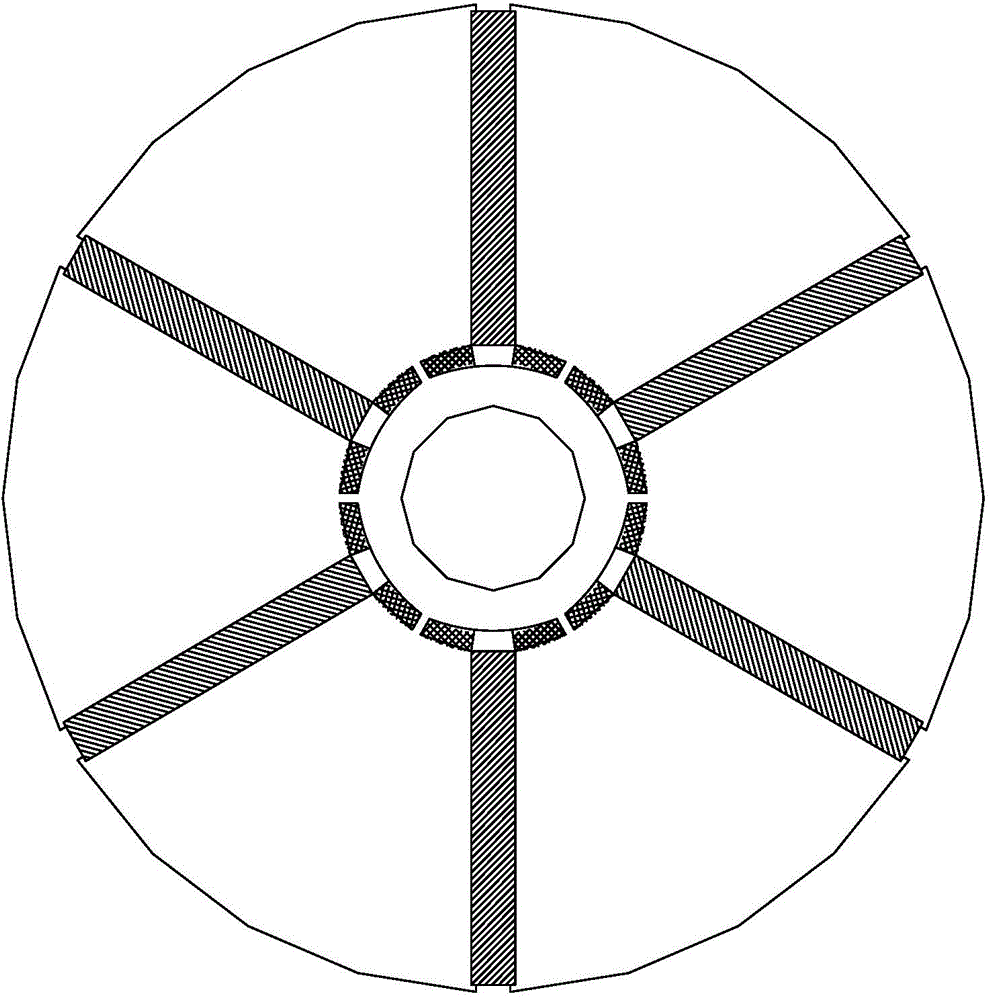

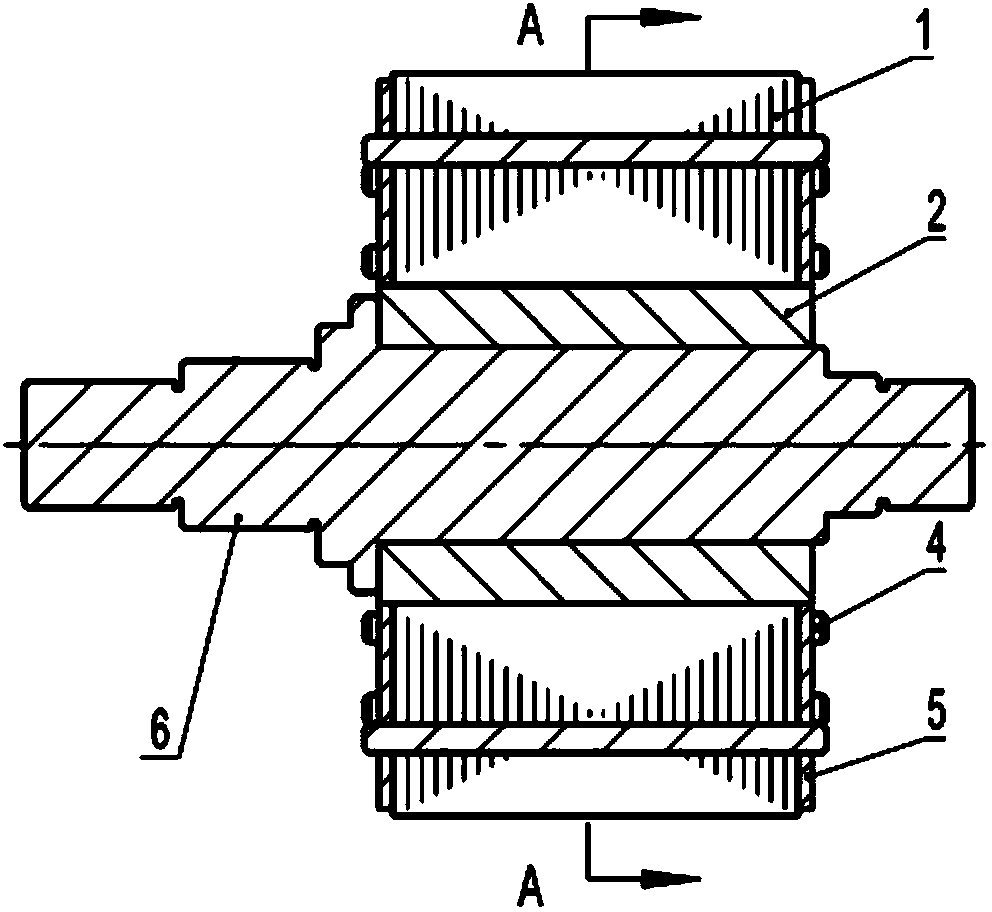

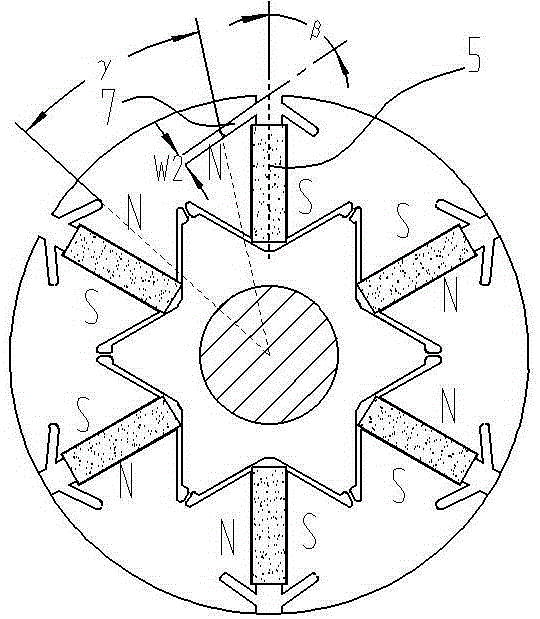

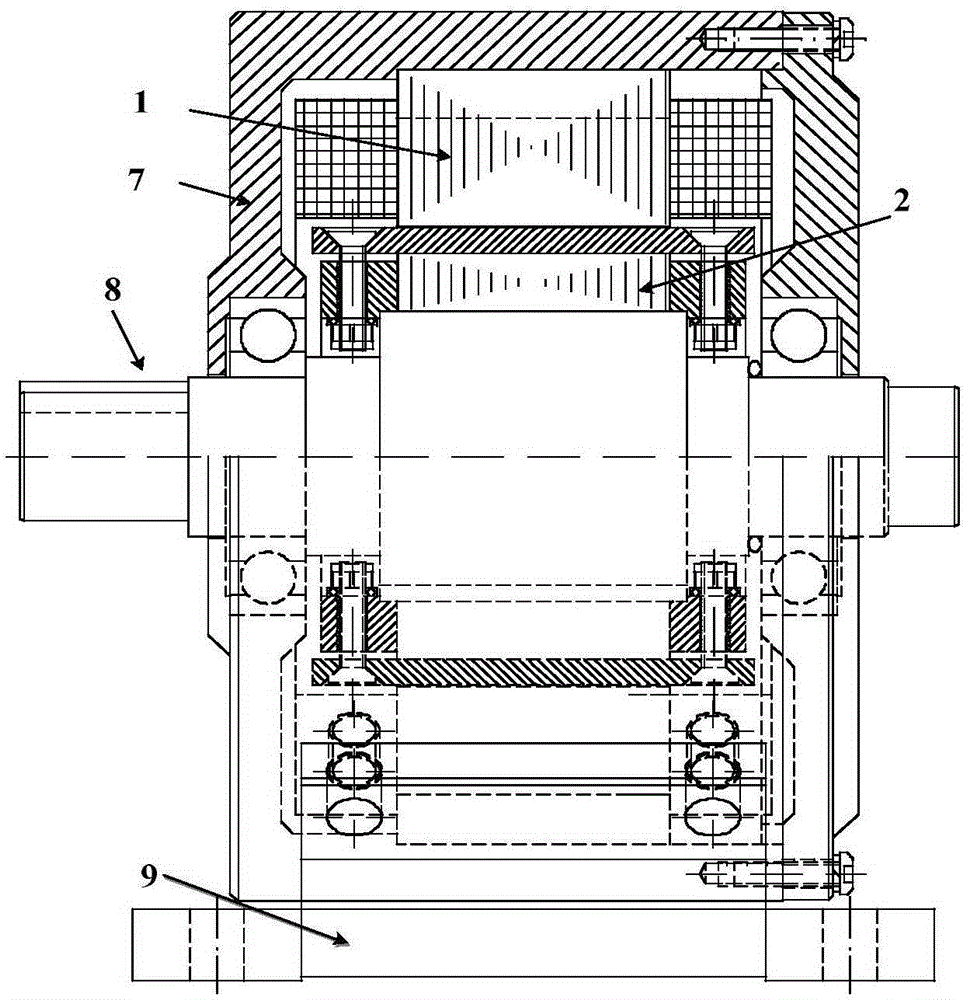

Spliced block type tangential magnetizing brushless motor rotor structure with built-in magnetic steel and method

ActiveCN103730969AImprove performanceImprove manufacturabilityMagnetic circuit rotating partsManufacturing stator/rotor bodiesBrushless motorsEngineering

The invention provides a spliced block type tangential magnetizing brushless motor rotor structure with built-in magnetic steel. The spliced block type tangential magnetizing brushless motor rotor structure with the built-in magnetic steel comprises rotor sheet assemblies, a supporting frame 2, the magnetic steel 3, rivets 4, partition plates 5 and a rotating shaft 6. The rotor sheet assemblies are mutually independent, and the magnetic steel 3 conducts tangential magnetizing inside the brushless motor rotor structure. The rotor sheet assemblies are mainly formed by interspersing and stacking a plurality of rotor sheets 1 through the rivets 4, the rotor sheets 1 are arranged on the supporting frame 2 in a spliced mode under the effect of the rivets 4, and flanges are arranged on the rotor sheets 1. The partition plates 5 are arranged on the two sides of the magnetic steel 3 respectively, and the rotating shaft 6 is arranged in a center hole of the supporting frame 2. The invention further provides a corresponding assembly method and a corresponding motor. Rotor leakage can be effectively reduced, the performance of the motor is improved, and the parts are firmly matched, so that the magnetic steel cannot be thrown away; the magnetic steel is not over against air gaps, demagnetization resistance is effectively improved, a traditional narrow side magnetism separation bridge is omitted, and manufacturability of the motor is obviously improved.

Owner:NEW ANANDA DRIVE TECHN SHANGHAI

Rotor of permanent magnet motor

ActiveCN103259356ASimple manufacturing processHigh mechanical strengthMagnetic circuit rotating partsLine segmentMagnet

The invention discloses a rotor of a permanent magnet motor. The rotor comprises a rotor core with a plurality of installation grooves and permanent magnets installed in the installation grooves. The rotor core is provided with a central hole and a plurality of sections of cylindrical surfaces, a magnetic bridge is connected between adjacent cylindrical surfaces, the outside surface of each magnetic bridge is much closer to the central hole of the rotor core relative to the cylindrical surfaces, the outside surface of each magnetic bridge is outwards concave from the installation grooves to form a groove in the magnetic bridge, and the widths of the grooves are smaller than that of those of the installation grooves. Compared with the prior art, the rotor of the permanent magnet motor has the advantages that the magnetic bridges and the grooves are arranged to allow a motor with the rotor to obtain low cogging torque, reversed electromotive force tending to the sine and low load torque pulsation. The rotor has the advantages of being simple in manufacturing process, high in mechanical strength, low in noise and high in demagnetization-resistance performance due to appropriate multi-section arc or the line-section magnetic bridges, and the rotor is applicable to motors of roller washing machines.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

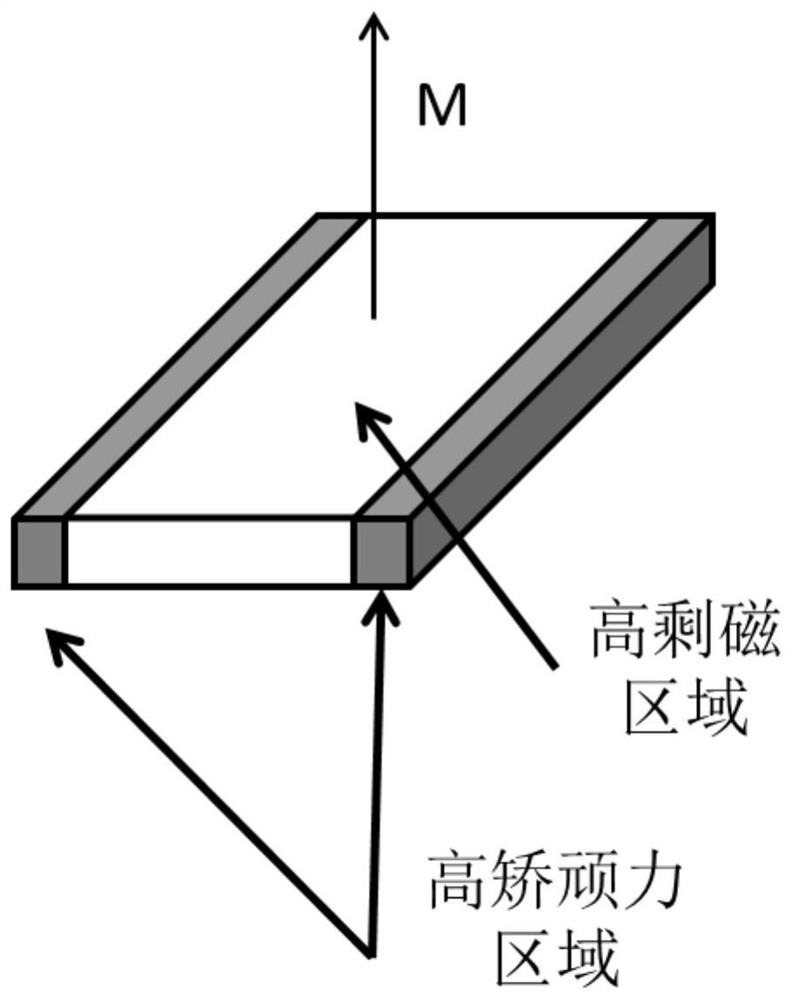

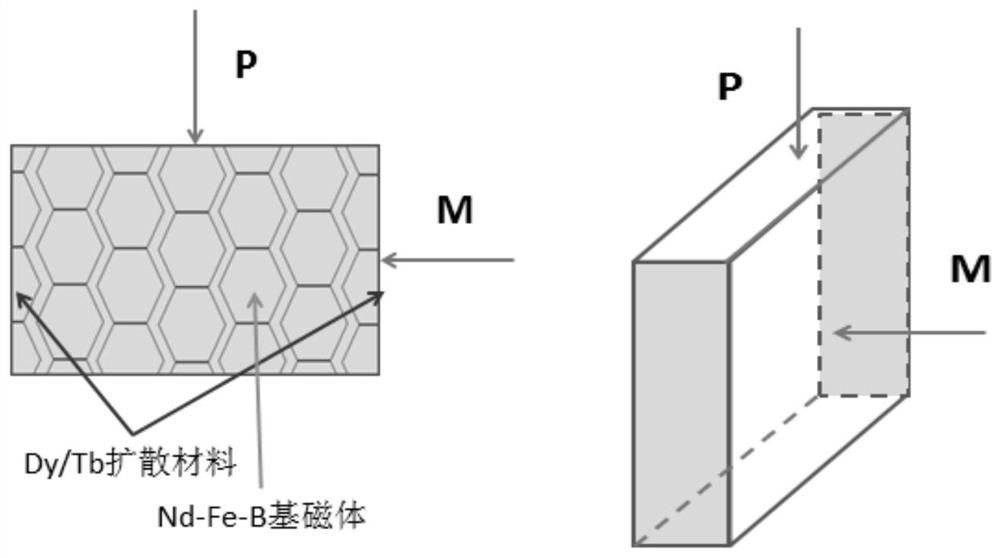

Gradient neodymium iron boron magnet and manufacturing method thereof

ActiveCN108899190AImprove coercive forceImprove resistance to demagnetizationPermanent magnetsInductances/transformers/magnets manufactureRare-earth elementMetallurgy

The invention discloses a gradient neodymium iron boron magnet and a manufacturing method thereof. The gradient neodymium iron boron magnet and the manufacturing method thereof are characterized in that a local area of a neodymium iron boron magnet sheet is covered with heavy rare earth elements and subjected to diffusion treatment to prepare the magnet with gradient change of performance; the gradient neodymium iron boron magnet can be divided into three different areas in the direction perpendicular to the magnetization direction according to the magnitude and change rule of coercive force,and the effect is achieved that the area close to the edge has the high coercive force, and the area close to the center has the low coercive force; the gradient neodymium iron boron magnet has the high coercive force by only conducting heavy rare earth diffusion treatment on the easy-to-demagnetize area at the edge of the magnet body without conducting diffusion treatment on other parts, and theuse quantity of the raw heavy rare earth material is low.

Owner:YANTAI DONGXING MAGNETIC MATERIALS INC

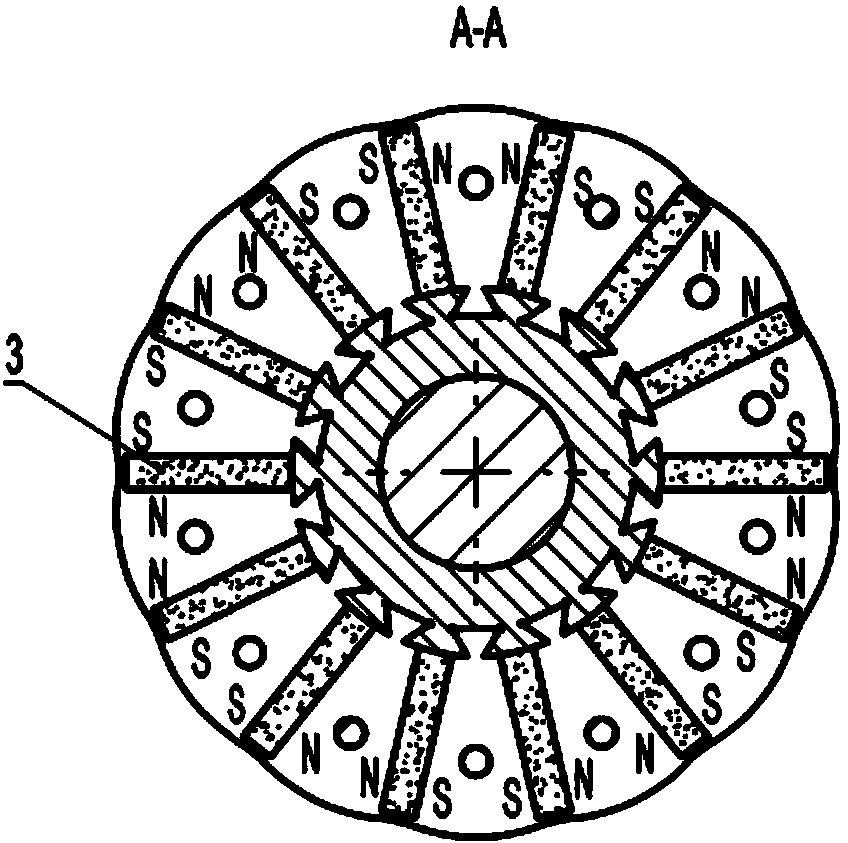

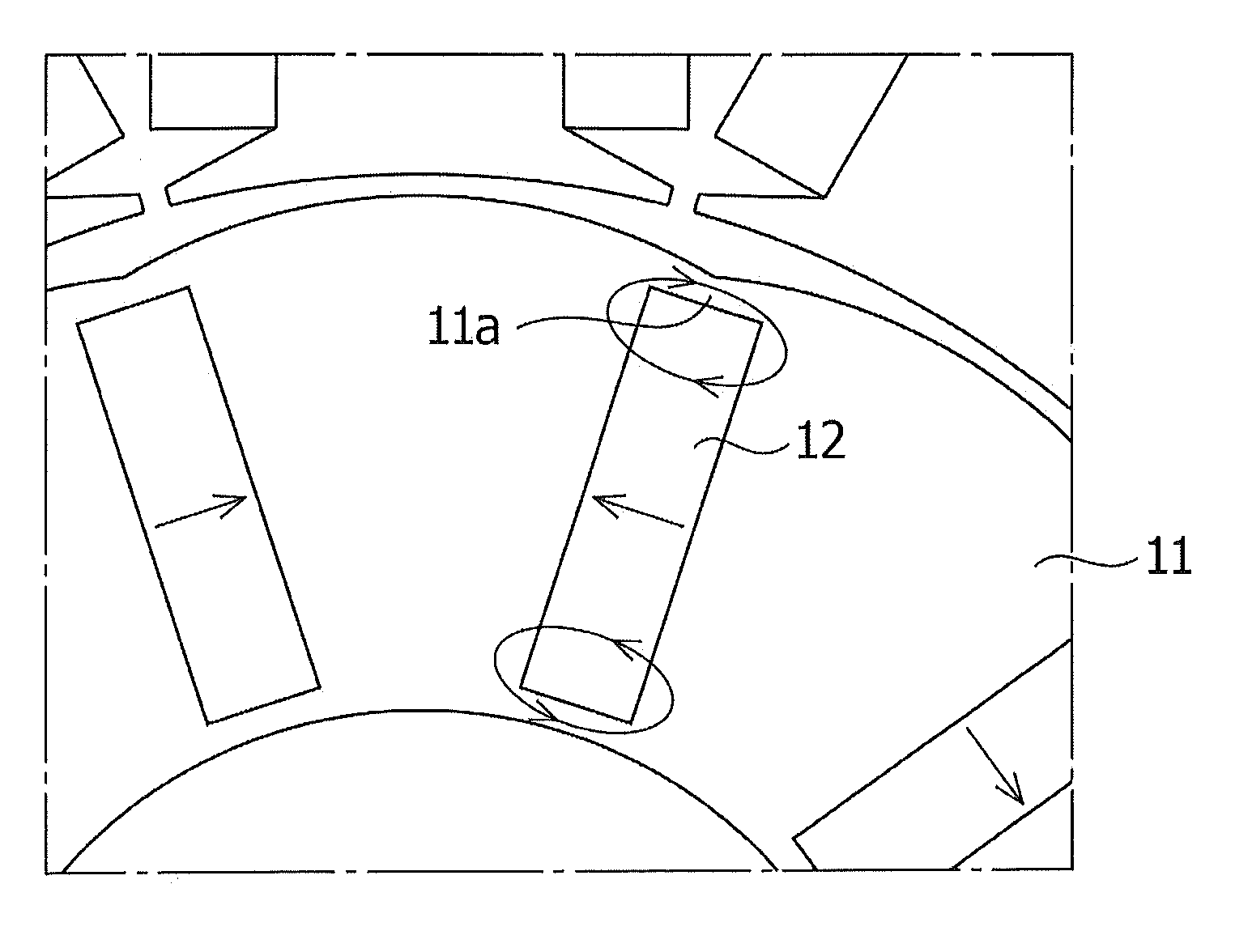

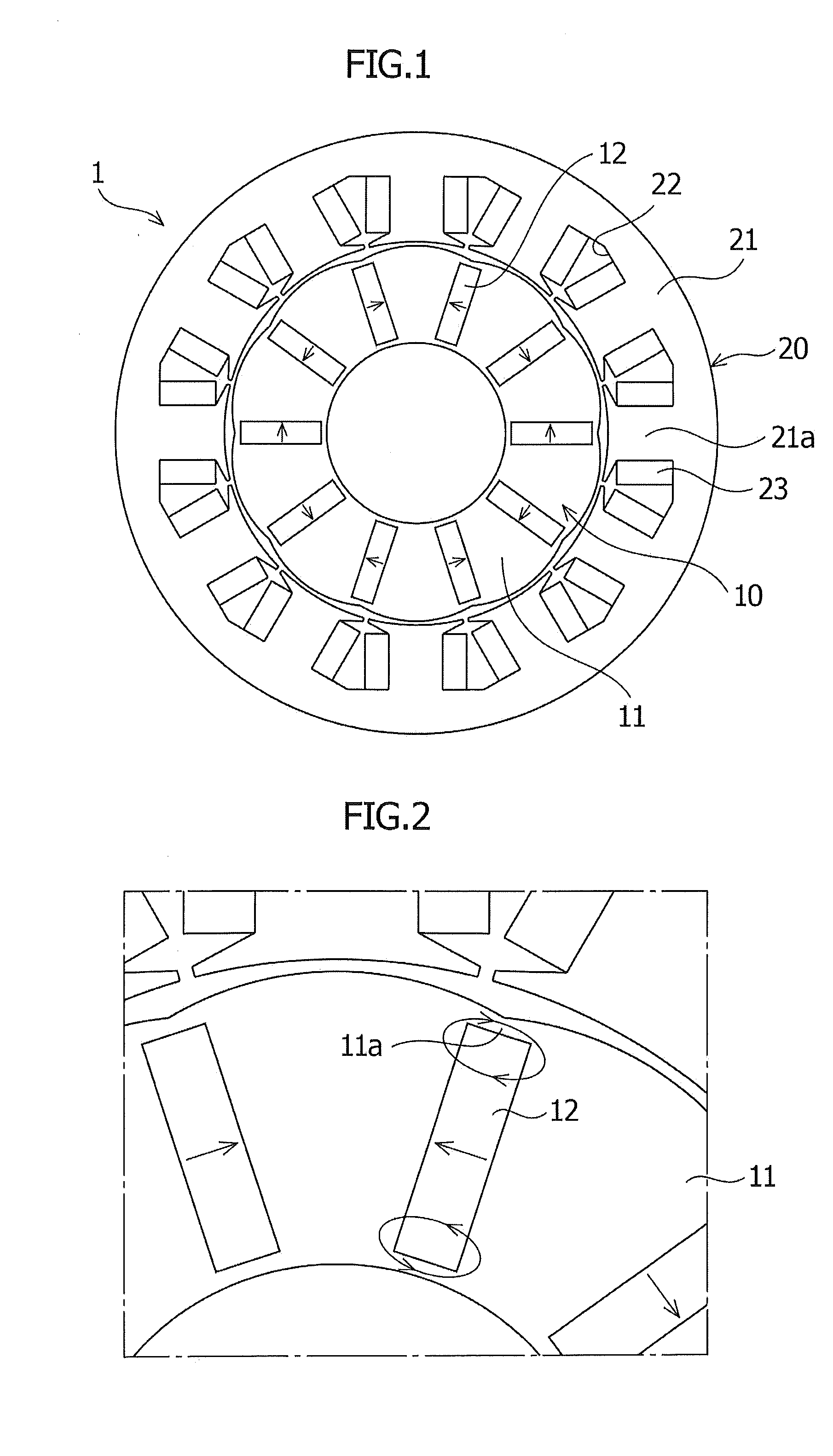

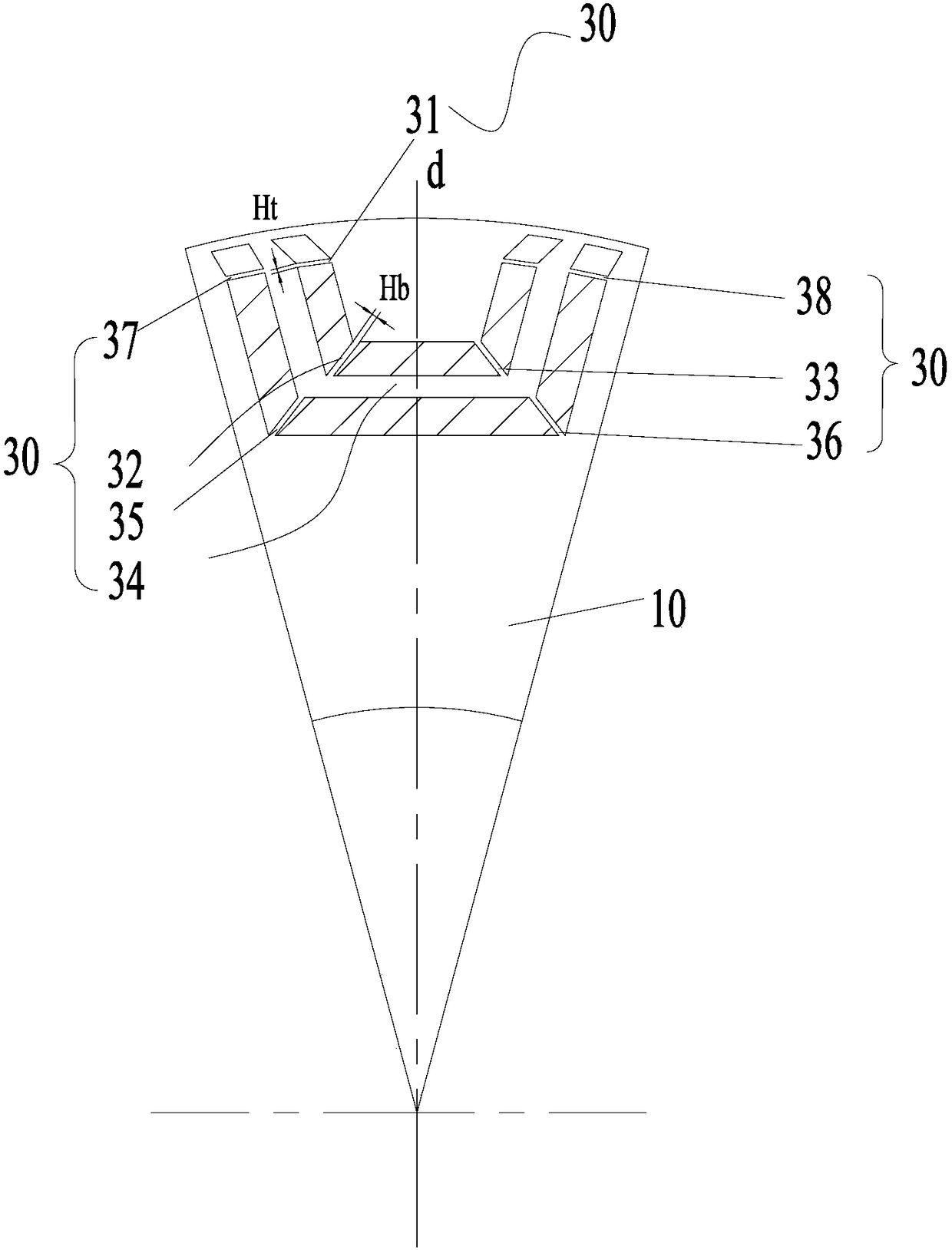

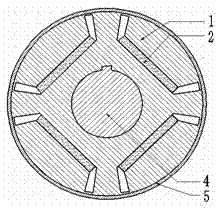

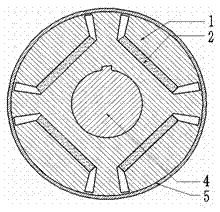

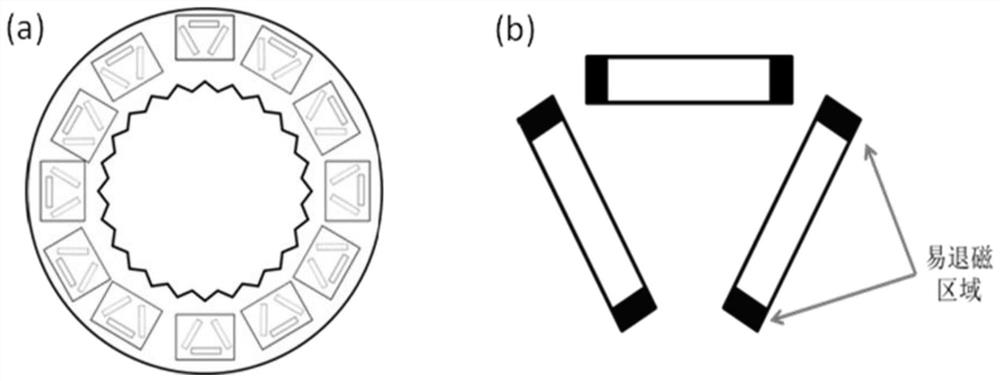

Rotor and permanent magnetic rotating machine

ActiveCN103117609AHigh residual flux densityImprove output characteristicsMagnetic circuit rotating partsElectric machinesMagnetPhysics

Disclosed are a rotor adapted for a permanent magnetic rotating machine and the permanent magnetic rotating machine having a high output and demagnetization resistance. Provided are a rotor adapted for a permanent magnetic rotating machine, the machine comprising a rotor and a stator comprising a stator core having two or more slots, and winding wires wound through the stator core, the rotor comprising: a rotor core having two or more insertion holes formed in the rotor core; and two or more permanent magnets in the two or more insertion holes; and each of the permanent magnets is in form of rectangle with two opposite sides substantially parallel to a radial direction of the rotor on a surface vertical to a rotation axis of the rotor, and is in form of rectangular parallelepiped with four longitudinal edges parallel to the rotation axis, and the permanent magnet has at least one angular portion of four angular portions containing the four longitudinal edges, which has stronger coercive force than a center within the rectangular parallelepiped, and is placed in the insertion hole in such a manner that one of the at least one angular portion is in a stator side and in the rear of a rotating direction of the rotor, and a permanent magnetic rotating machine comprising the rotor.

Owner:SHIN ETSU CHEM CO LTD

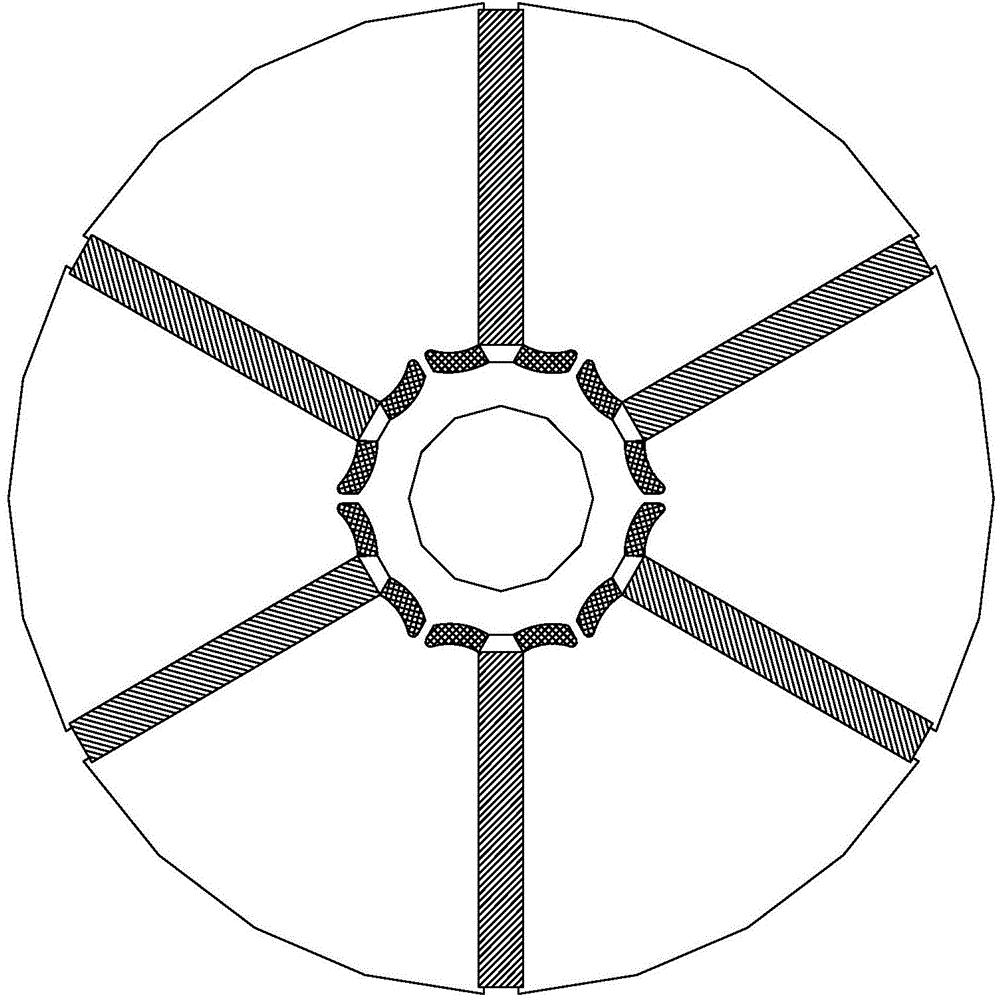

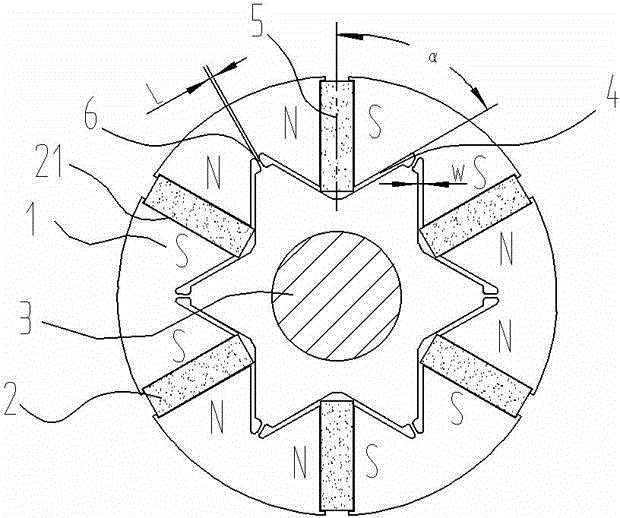

Rotor structure used for tangential permanent magnet direct current brushless motor, and tangential permanent magnet direct current brushless motor

InactiveCN105305760AIncrease working pointHigh torque/current ratioMagnetic circuit rotating partsBrushless motorsElectric machine

The invention discloses a rotor structure used for a tangential permanent magnet direct current brushless motor, and the tangential permanent magnet direct current brushless motor. The rotor structure comprises a rotor iron core, tangential permanent magnets and a rotation shaft; an even number of tangential permanent magnet grooves are formed in the circumference of the rotor iron core radially at the equal intervals; the tangential permanent magnets with the opposite polarities are arranged in the adjacent tangential permanent magnet grooves; the tangential permanent magnets are connected with or disconnected from the near air gap side; the central symmetry of the rotor iron core is maintained; the sides, close to the rotation shaft, of the tangential permanent magnet grooves are communicated with flux-insulation grooves on the two sides of the tangential permanent magnet grooves; the near air gap side of the flux-insulation grooves and the central line of the corresponding tangential permanent magnet grooves extend outwardly at an angle of alpha; and a radially-distributed flux-insulation bridge is formed between the adjacent flux-insulation grooves. The rotor structure used for the tangential permanent magnet direct current brushless motor is simple and compact in structure, small in magnetic leakage factor, high in mechanical strength, convenient to produce, low in manufacturing cost, higher in resistance to demagnetization, and high in overload capacity, so that the tangential permanent magnet direct current brushless motor is higher in torque / current ratio, torque / volume ratio and motor efficiency; and therefore, the rotor structure used for the tangential permanent magnet direct current brushless motor, and the tangential permanent magnet direct current brushless motor are brighter in the application prospects.

Owner:NANJING KANGNI ELECTRONICS TECH

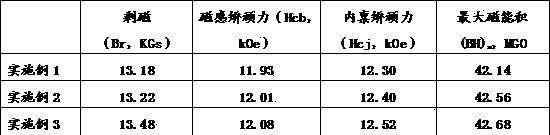

Novel sintered ndfeb permanent magnet and preparation method thereof

InactiveCN104347218AReduce material costsImprove overall performanceInorganic material magnetismInductances/transformers/magnets manufactureMagnetCost performance

The invention relates to a novel sintered ndfeb permanent magnet and a preparation method thereof. The composition expression of the sintered ndfeb permanent magnet is (Cex, Nd1-x)y-Mz-Fe100-y-zB0.9-1.05, wherein x is greater than or equal to 0.05 and smaller than or equal to 0.1, y is greater than or equal to 0.4 and smaller than or equal to 0.9, z is greater than or equal to 0.5 and smaller than or equal to 5, and M is one or several of Gd, Co, Al, Cu and Zr. After the composition of the sintered ndfeb permanent magnet is designed and the production technology is improved, the material cost of the product is reduced, the integrated performance is improved, the cost performance is increased comprehensively, and the magnetic property and the anti-demagnetization performance are improved; moreover, the manufacturing cost of the product is reduced effectively, and based on the current unit price of raw materials, the cost can be reduced by 16.5 yuan / kilo, and the power consumption can be reduced by 1 kwh / kilo.

Owner:浙江鑫盛永磁科技有限公司

Rotor and permanent magnetic rotating machine

InactiveUS20130119811A1Improve resistance to demagnetizationHigh Remanent Flux DensityMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsMagnetPhysics

Provided are a rotor adapted for a permanent magnetic rotating machine, the machine includes a rotor and a stator comprising a stator core having two or more slots, and winding wires wound through the stator core. The rotor includes a rotor core having two or more insertion holes formed in the rotor core; and two or more permanent magnets in the two or more insertion holes; and each of the permanent magnets is in form of rectangle with two opposite sides substantially parallel to a radial direction of the rotor on a surface vertical to a rotation axis of the rotor, and is in form of rectangular parallelepiped with four longitudinal edges parallel to the rotation axis, and the permanent magnet has at least one angular portion of four angular portions containing the four longitudinal edges.

Owner:SHIN ETSU CHEM IND CO LTD

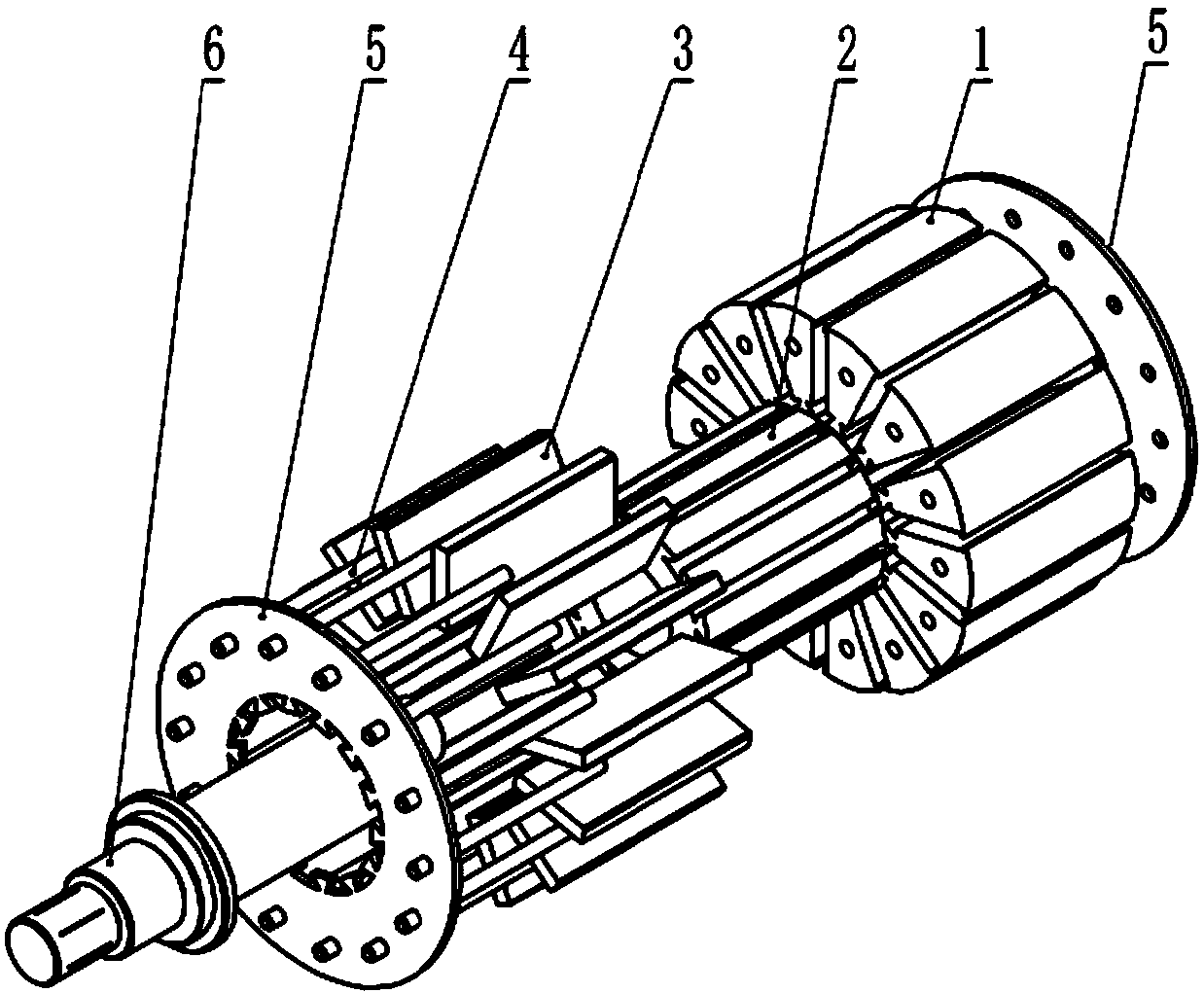

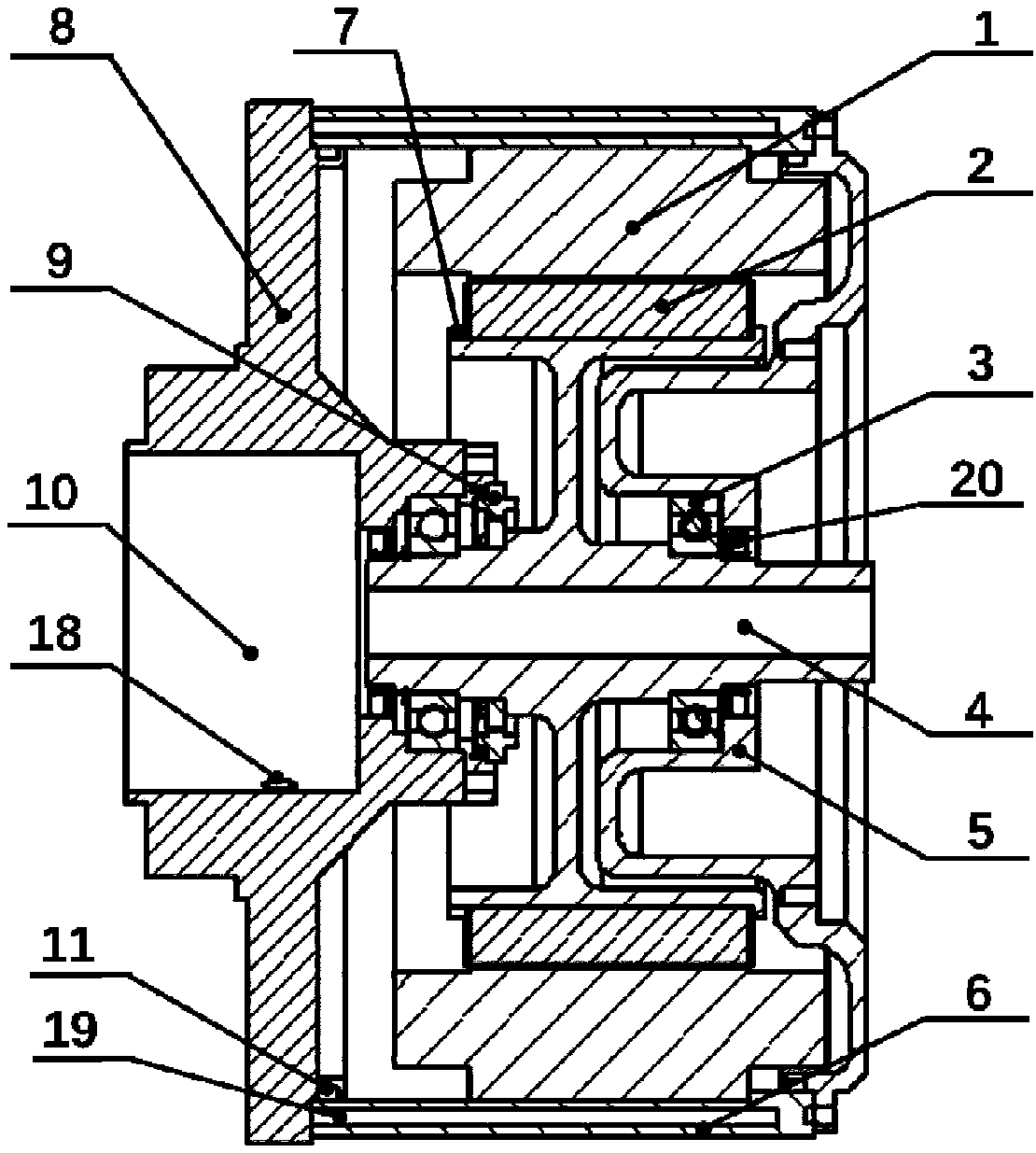

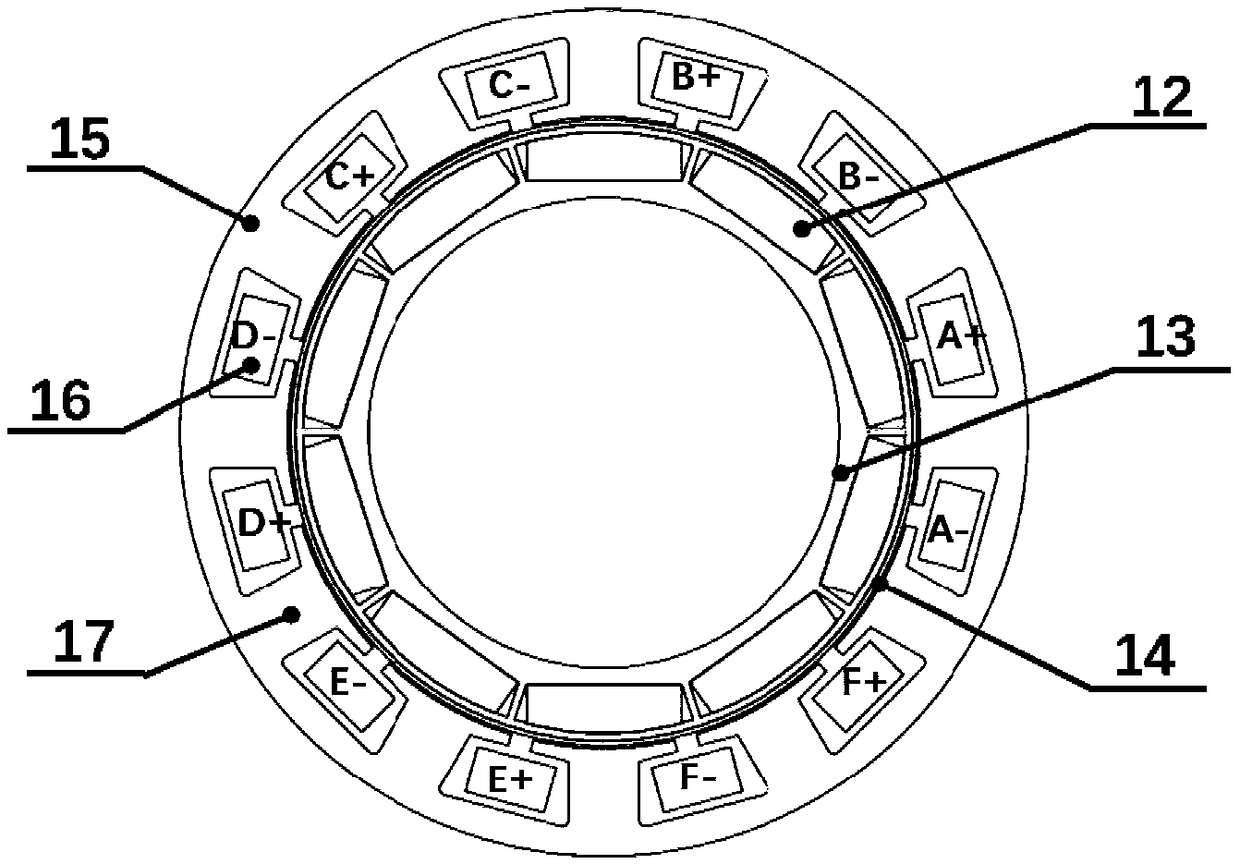

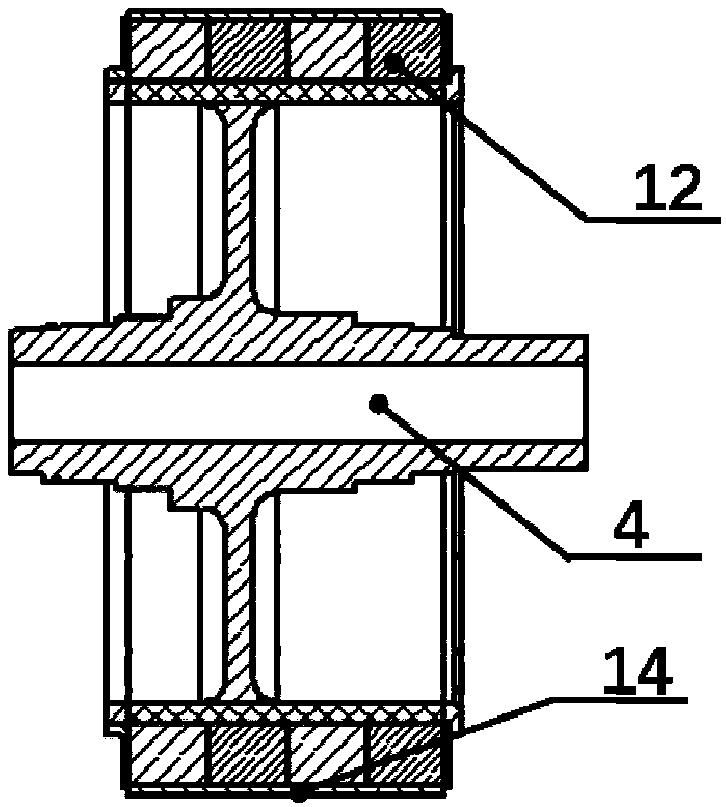

High-power high-reliability six-phase permanent magnet fault-tolerant hub motor used for electric armored vehicle

ActiveCN108631459AAdd direct axis inductanceImproving the speed-up capability of magnetic field weakeningMagnetic circuit rotating partsElectric machinesFiberPermanent magnet rotor

The invention discloses a high-power high-reliability six-phase permanent magnet fault-tolerant hub motor used for an electric armored vehicle. The high-power high-reliability six-phase permanent magnet fault-tolerant hub motor comprises a stator assembly, a rotor assembly, a rotary shaft, a bearing, a machine shell, front back end covers, and a position sensor; the six-phase windings in the stator assembly adopt a fractional-slot and concentrated single-layer winding structure embedded with partition teeth, so that an electrical fault-tolerant structure can be formed between the phase windings; meanwhile, by combination of the dimensional design of the stator toothed groove structure, the phase winding inductance of the electric motor is increased, the short circuit current is suppressedeffectively, and reliability and fault-tolerant performance of the hub motor are improved; the rotor assembly adopts an internal permanent magnet rotor structure, and the outer side of the rotor is wound with a carbon fiber protection sleeve, so that the mechanical structural strength of the rotor is improved; the stator winding adopts a monocrystal copper wire or silver wire, so that stator lossof the hub motor is lowered; the permanent magnet of the rotor assembly adopts eccentric design, and is subjected to circumferential or axial sectioning processing, so that the rotor loss of the hub motor is lowered effectively; a Z-shaped or spiral heat dissipation water path is formed in the machine shell, so that the heat dissipation capability of the hub motor is improved; and the hub motor has high fault isolation, anti-short-circuit and weak magnetic diffusion capability, so that the requirements of high reliability, high power and high rotary speed of the hub driving of the electric armored vehicle can be satisfied.

Owner:北京北航天宇长鹰无人机科技有限公司

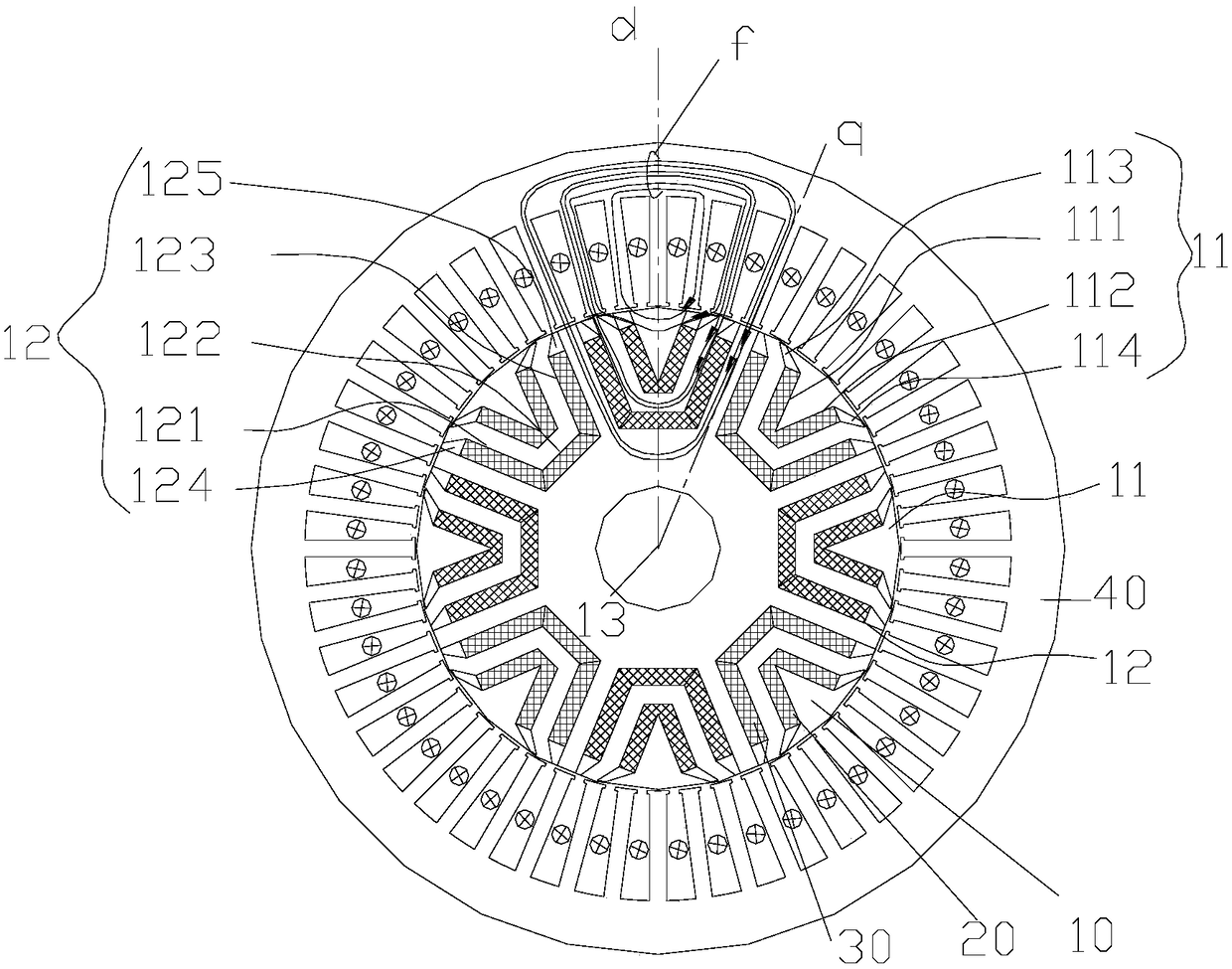

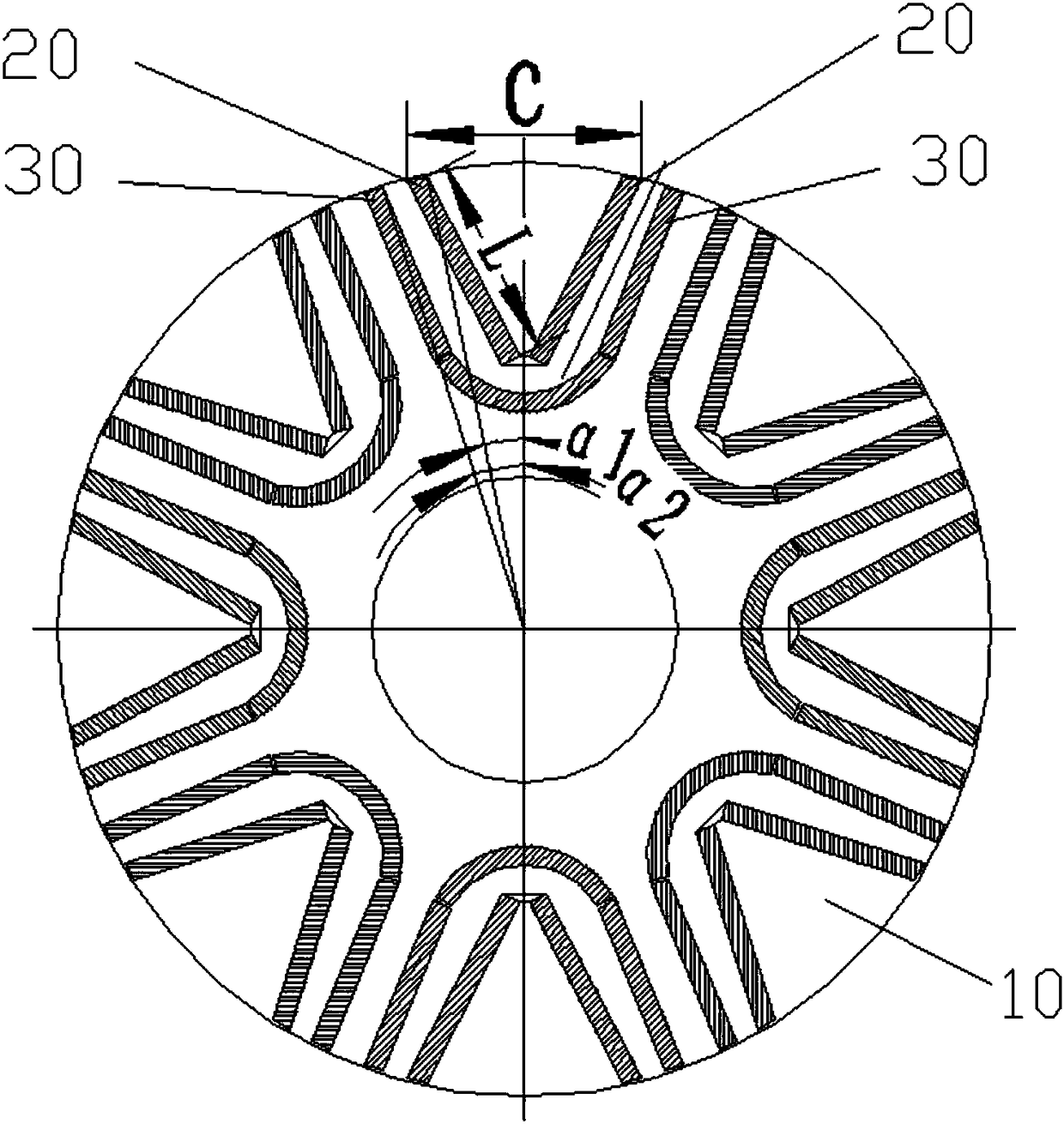

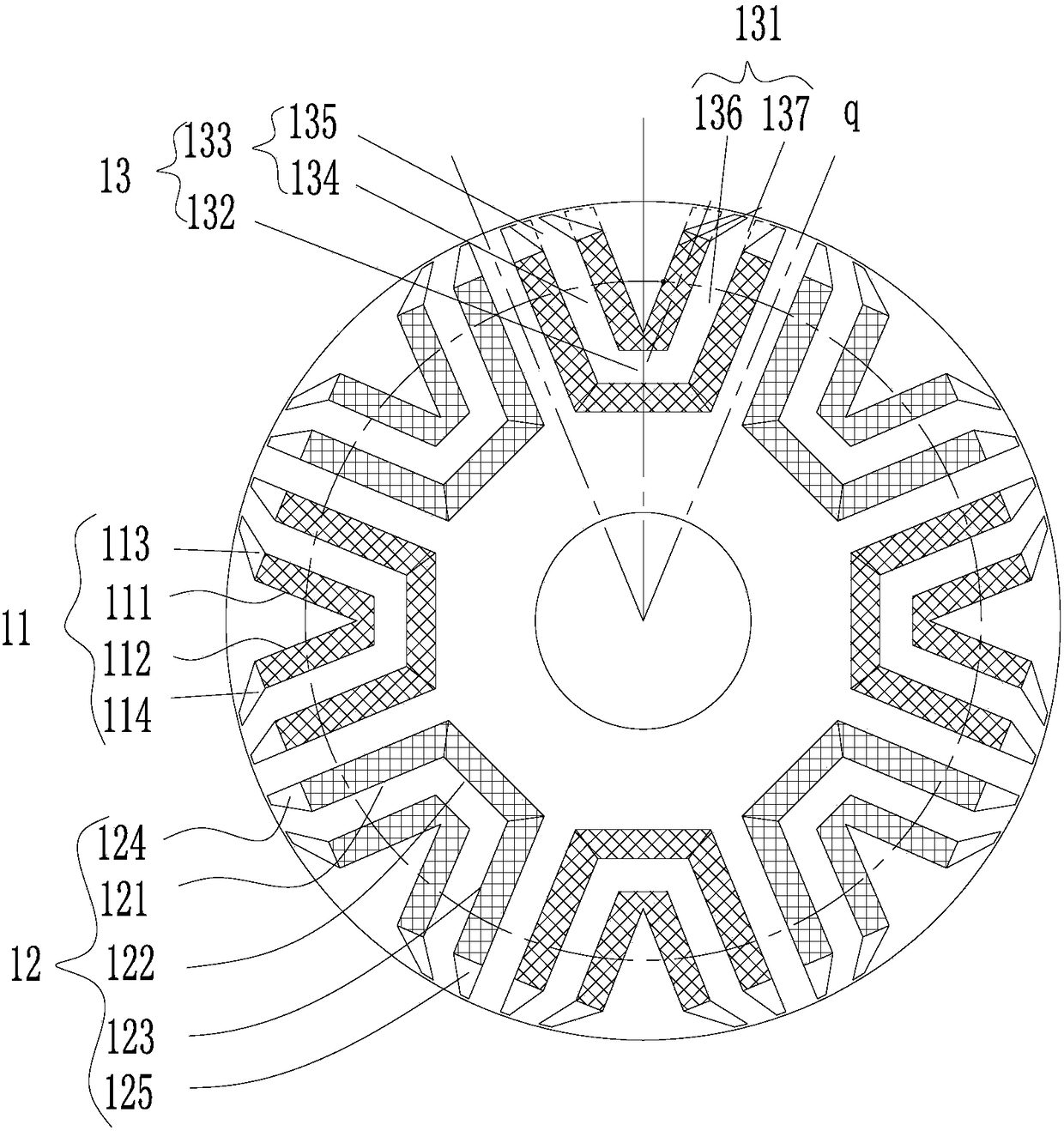

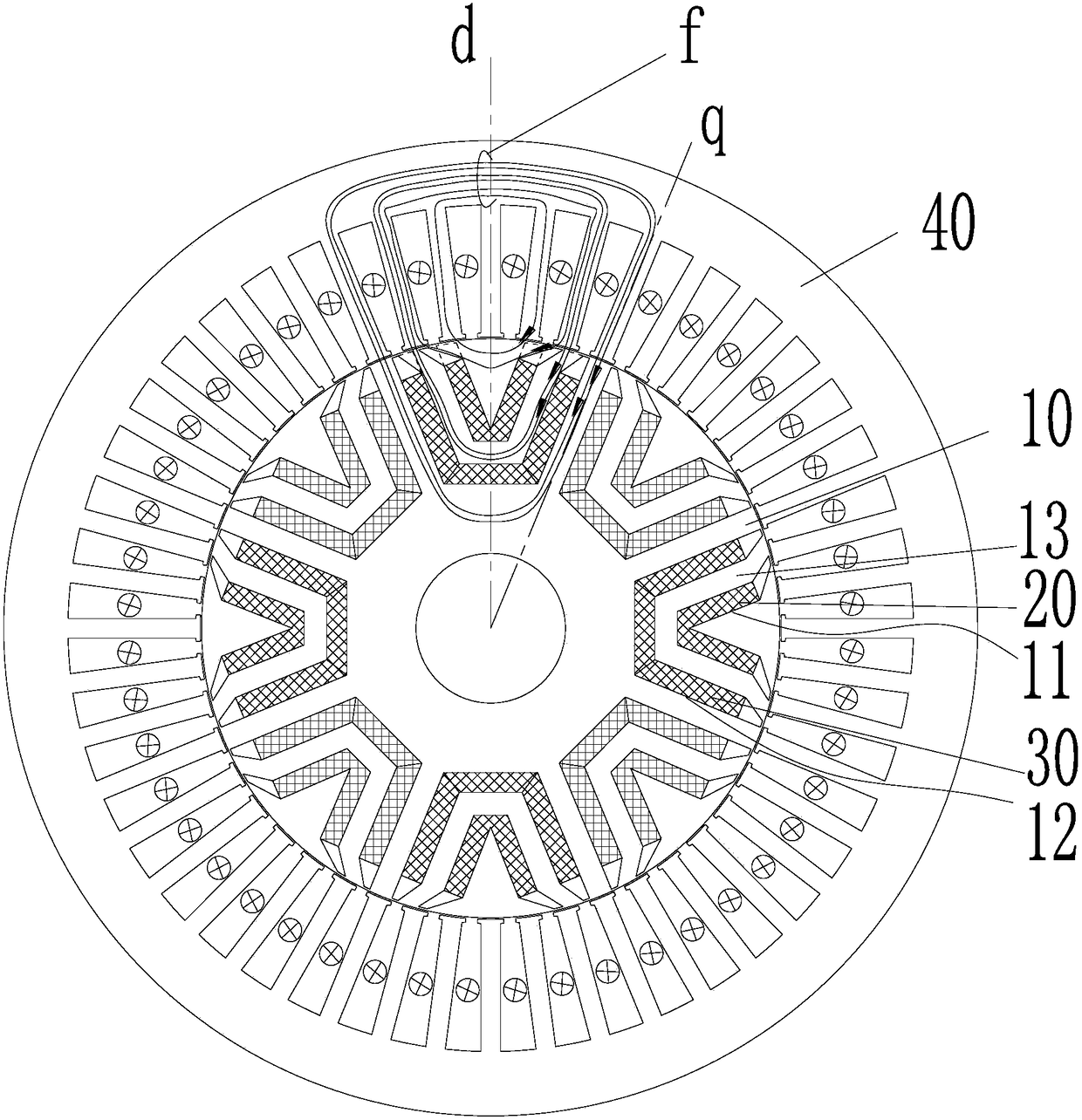

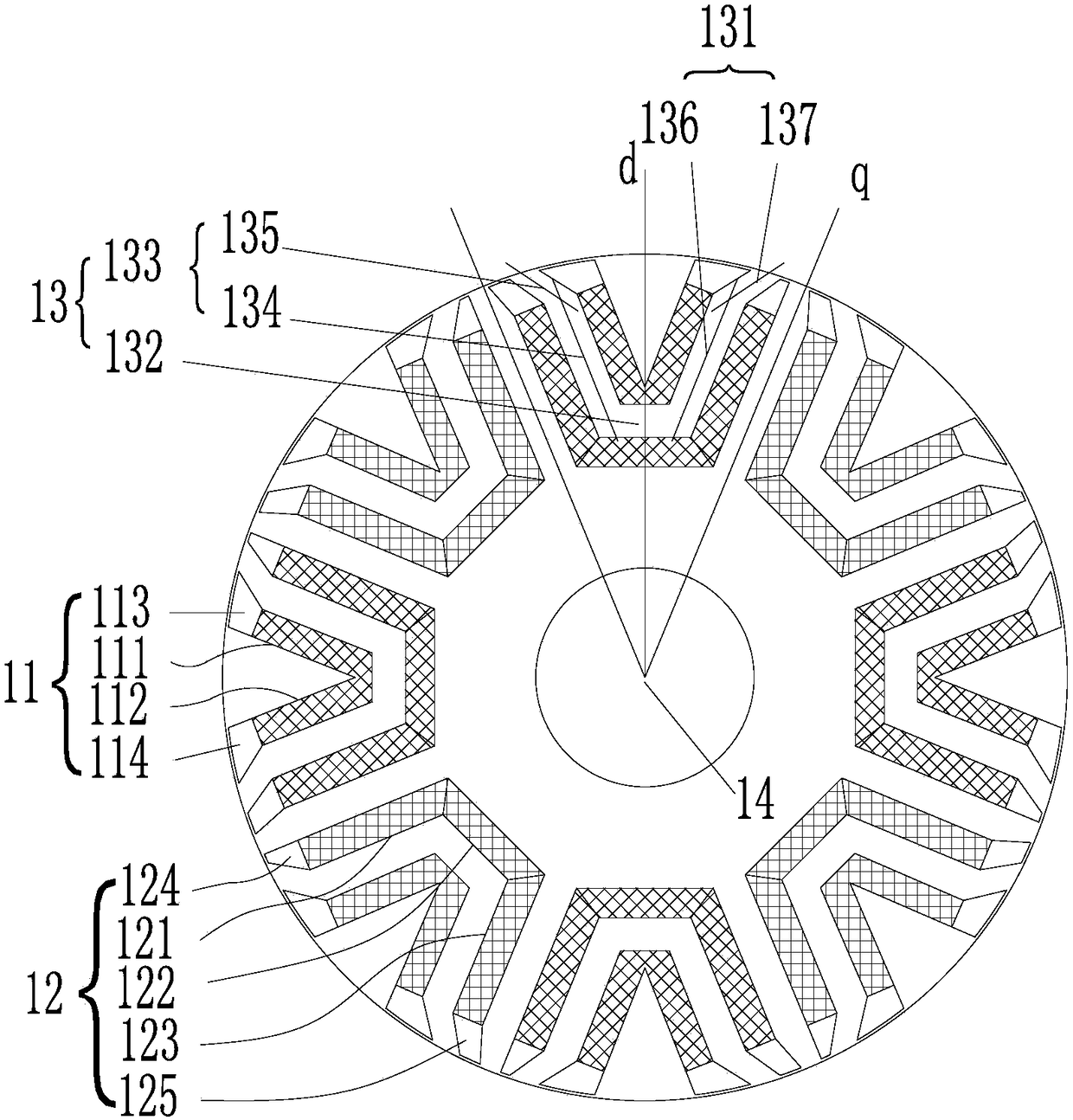

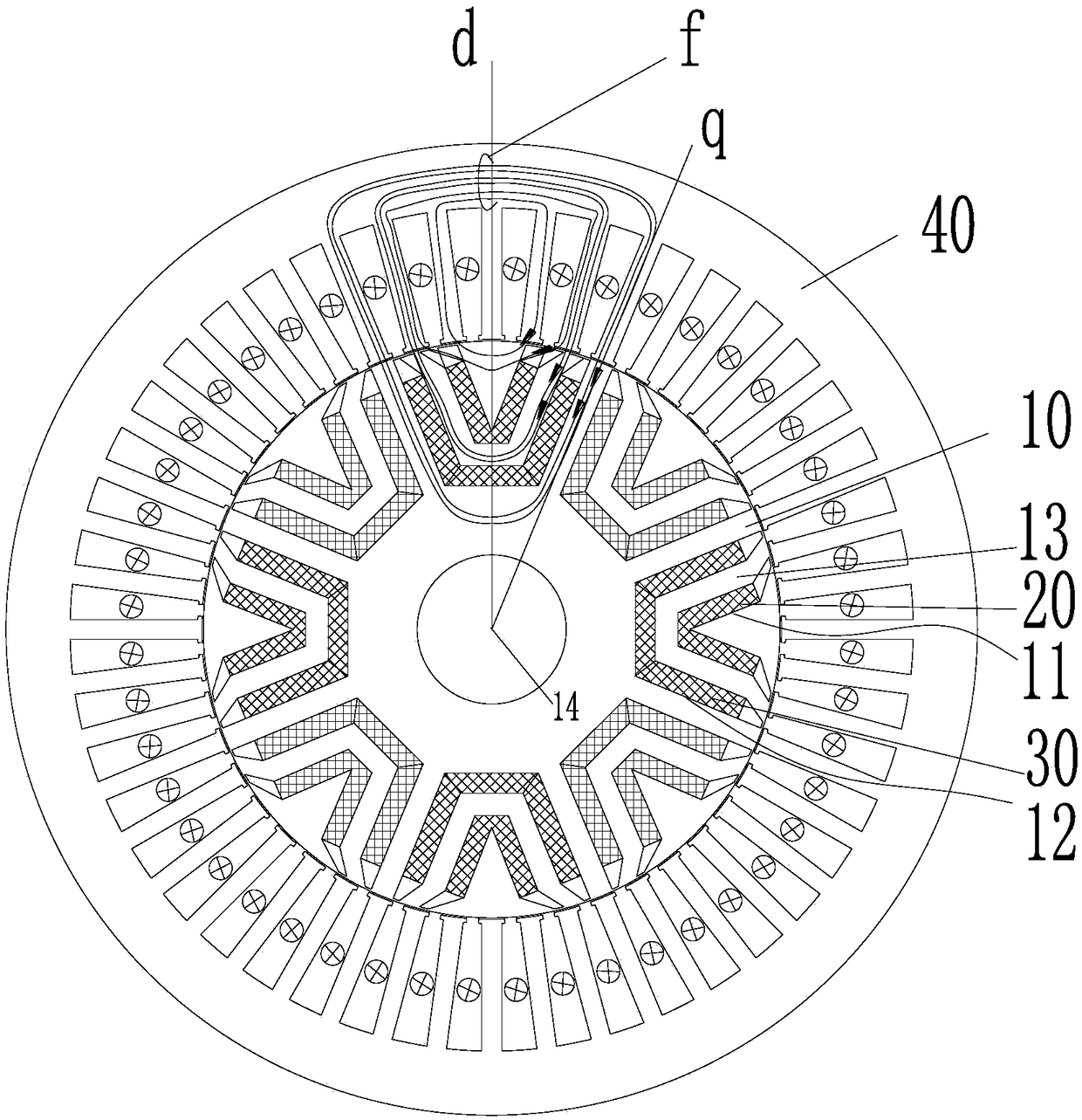

Rotor structure, permanent magnet auxiliary synchronous reluctance motor and electric vehicle

ActiveCN108336844AIncrease the q-axis inductanceImprove resistance to demagnetizationMagnetic circuit rotating partsElectric propulsion mountingSynchronous reluctance motorMotor vibration

The invention provides a rotor structure, a permanent magnet auxiliary synchronous reluctance motor and an electric vehicle. The rotor structure includes a rotor body and an outer layer permanent magnet. A magnetic steel groove group is disposed on the rotor body, and the magnetic steel groove group includes an outer magnetic steel groove. The outer magnetic steel trough includes a plurality of magnetic steel trough sections. At least two of the plurality of magnet steel trough segments are disposed opposite each other in the radial direction of the rotor body and are located on both sides ofthe straight axis of the rotor body. The outer permanent magnet is disposed in the magnetic steel slot section. Wherein the outer permanent magnets located in the two oppositely disposed magnetic steel trough sections have a length L, and the maximum distance between the two oppositely disposed magnetic steel trough sections is C, among them, 0.8 * C<= L. By arranging the outer magnetic steel troughs of the magnetic steel trough group on the rotor body, more permanent magnets are placed in the unit rotor volume, resulting in a larger permanent magnet torque, improving motor q-axis inductance,increasing motor efficiency, reducing motor torque ripple, motor vibration and noise, and improving motor demagnetization capability.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

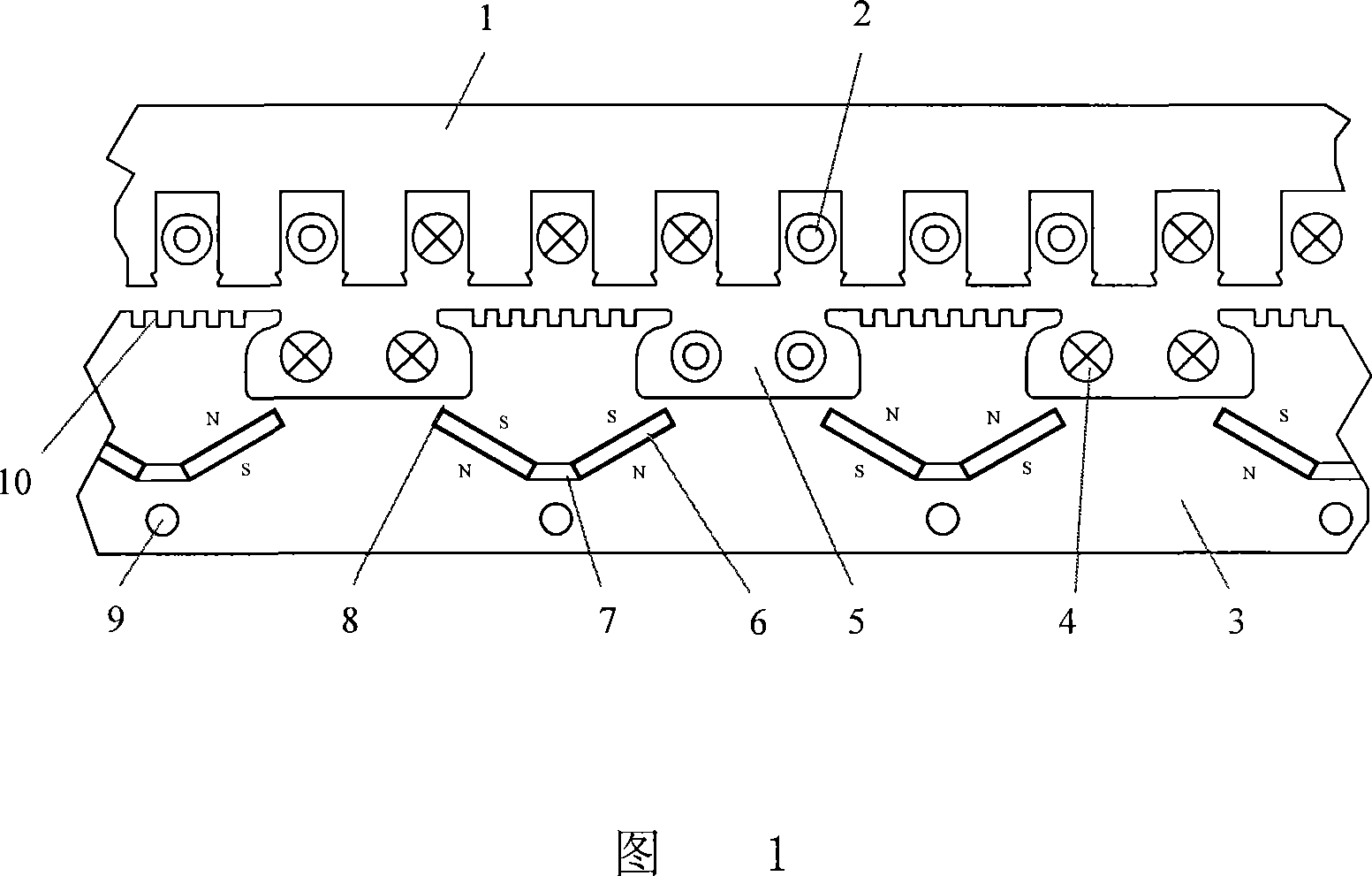

Semi-magnetic barrier type dual-field excitation linear synchronous generator

InactiveCN101179223AReduce Flux LeakageGood suspensionReciprocating/oscillating/vibrating magnetic circuit partsPropulsion systemsMagnetic barrierLevitation

The invention discloses a semi-magnet-isolated double-excitation linear synchronous motor. It includes primary iron core, primary winding, secondary iron core, secondary excitation winding, secondary excitation winding slot, permanent magnet, generator and cogging, and secondary excitation winding is wound on the core teeth and placed on the secondary excitation In the winding slot, the characteristic is that there are two permanent magnets for excitation under each magnetic pole, placed obliquely, corresponding to each other, fixed in the embedded groove in the middle of the secondary yoke, and facing upward at an angle of 120°. There is a trapezoidal magnetic isolation air between the adjacent ends of each pair of permanent magnets; the faces of the same polarity of the two permanent magnets under the same magnetic pole are facing the same direction, and the N and S magnetic poles are alternately distributed along the length direction of the secondary yoke; the permanent magnets The upper end is close to the secondary excitation winding slot and connected by the magnetic bridge of the secondary iron core. The integrity of the secondary iron core is good, and the levitation force and thrust of the motor are significantly increased under the same conditions. It is mainly used in various occasions of maglev transportation system drive and logistics line drive.

Owner:ZHEJIANG UNIV

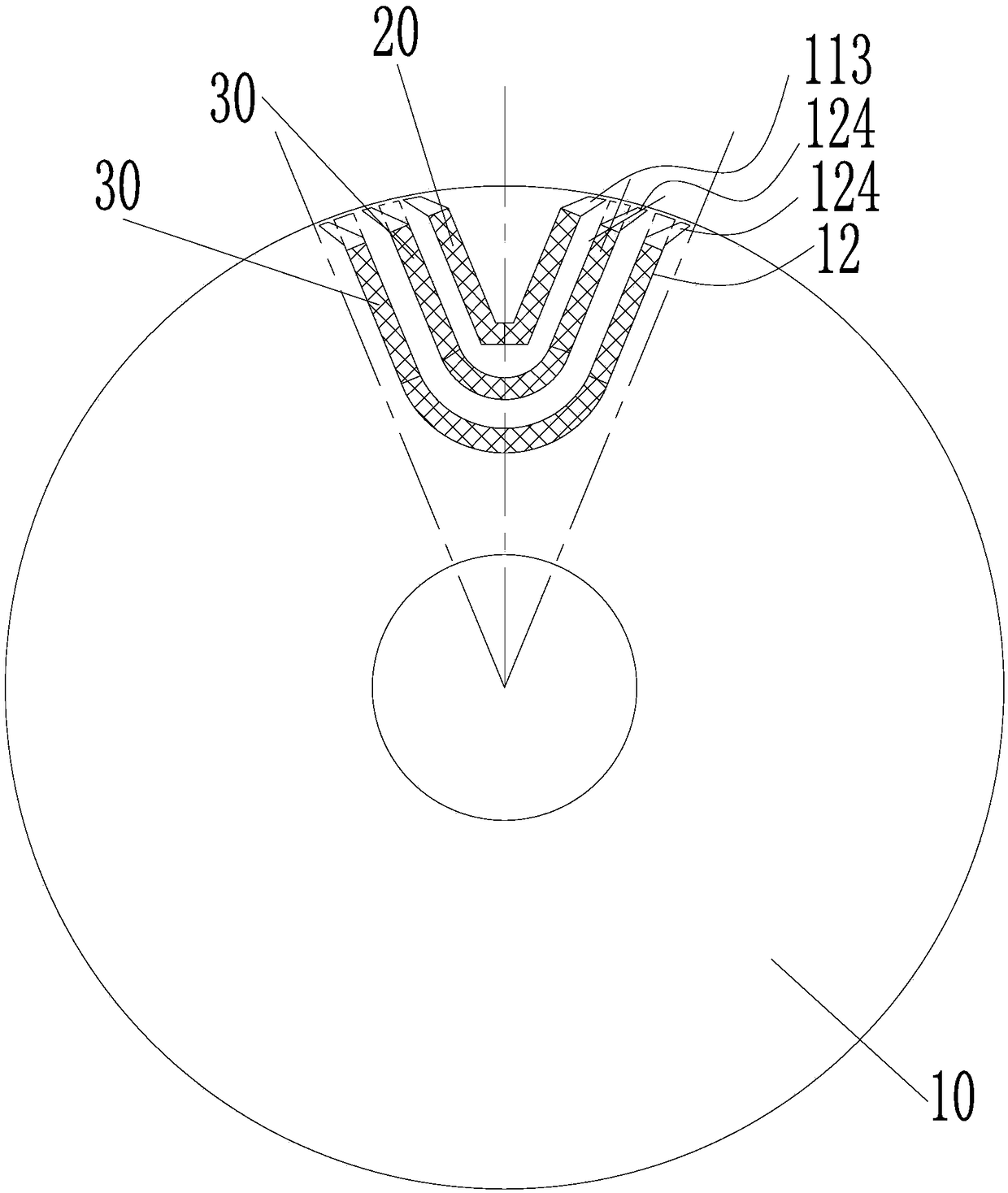

Rotor structure, permanent magnetism auxiliary synchronization magnetic resistance motor and electric vehicle

ActiveCN108321952AReduce demagnetizationReduce Flux LeakageMagnetic circuit rotating partsElectric machinesSynchronous reluctance motorElectric vehicle

The invention provides a rotor structure, a permanent magnetism auxiliary synchronization magnetic resistance motor and an electric vehicle; the rotor structure comprises a rotor body having a permanent magnet slot set; the permanent magnet slot set comprises an outer permanent magnet slot; the rotor body is also provided with a first air slot; a first end of the first air slot and the end portionof the outer permanent magnet slot are connected or adjacent to each other; a second end of the first air slot extends to the outer edge of the rotor body and gradually gets away from the straight axle of the rotor body; when the first end of the first air slot is adjacent to the end portion of the outer permanent magnet slot, a first magnetic conductive channel is formed between the first end ofthe first air slot and the end portion of the outer permanent magnet slot. The rotor body is provided with the air slot that decides the direction of a rotor magnetic path, thus reducing magnetic flux leakage in a process in which the stator magnetic field reaches the rotor via an air gap, improving the magnetic field utilization rate, increasing torque output, minimizing demagnetization effect on the permanent magnet by a demagnetization magnetic field, and enhancing the anti-demagnetization capability.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

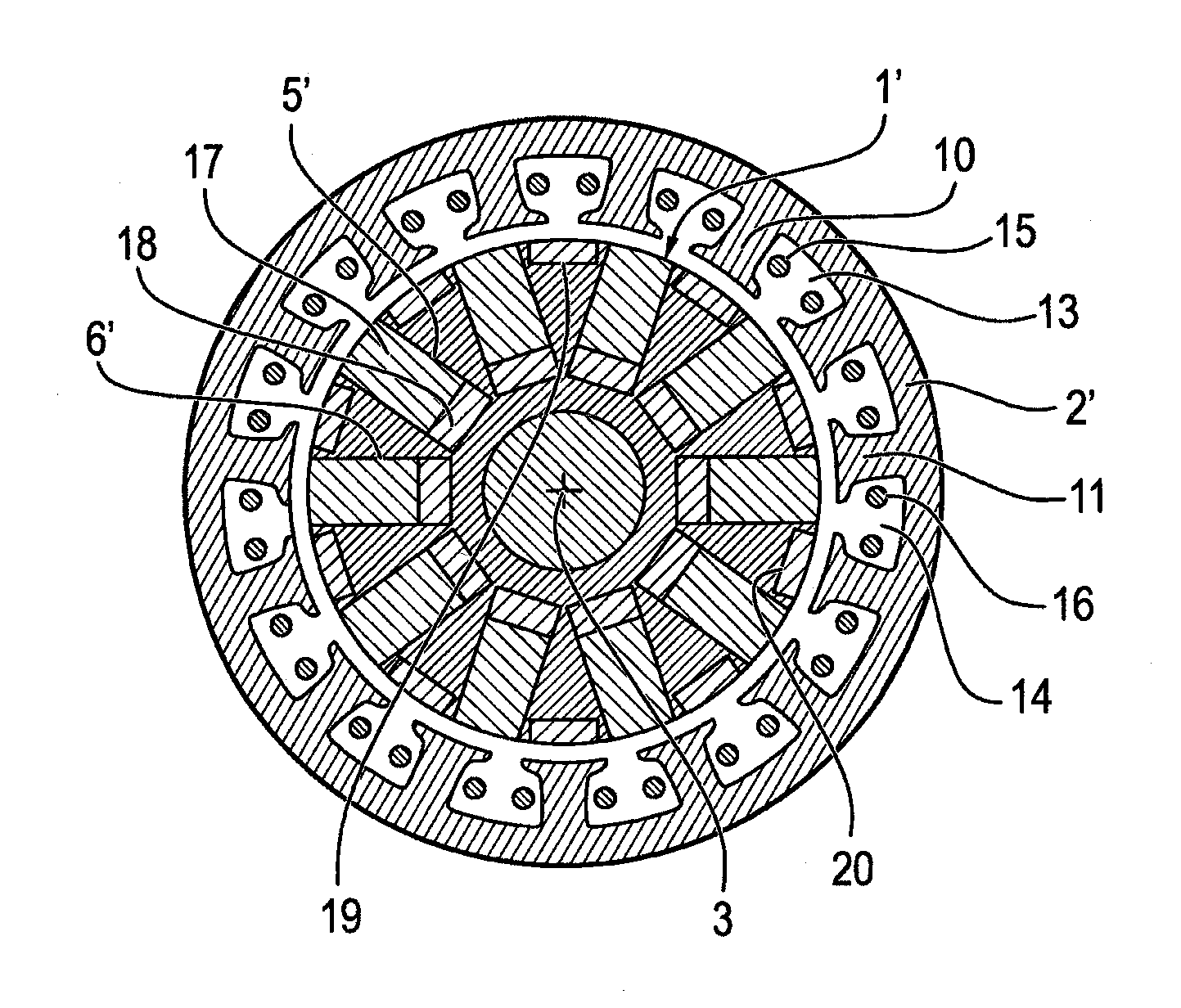

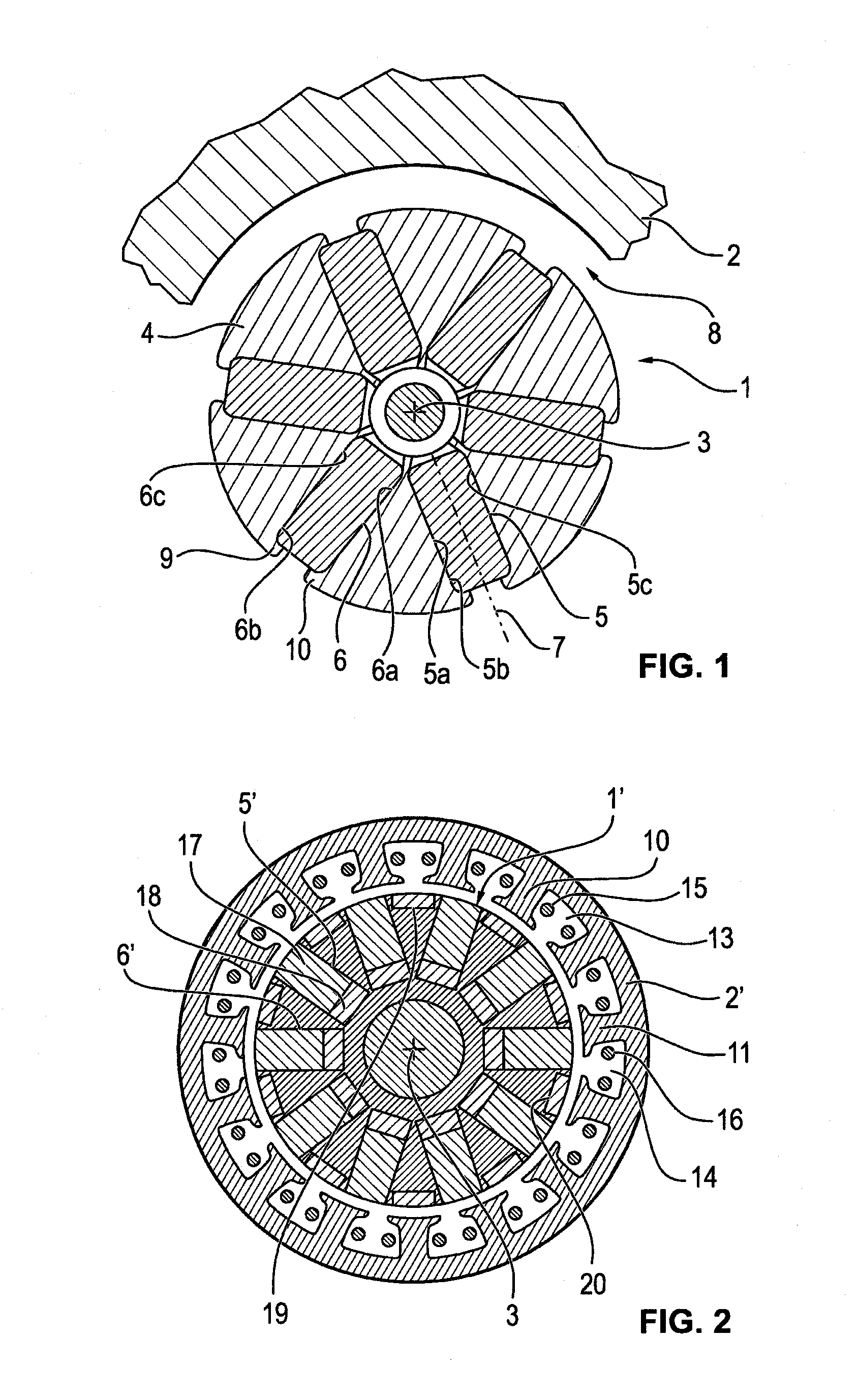

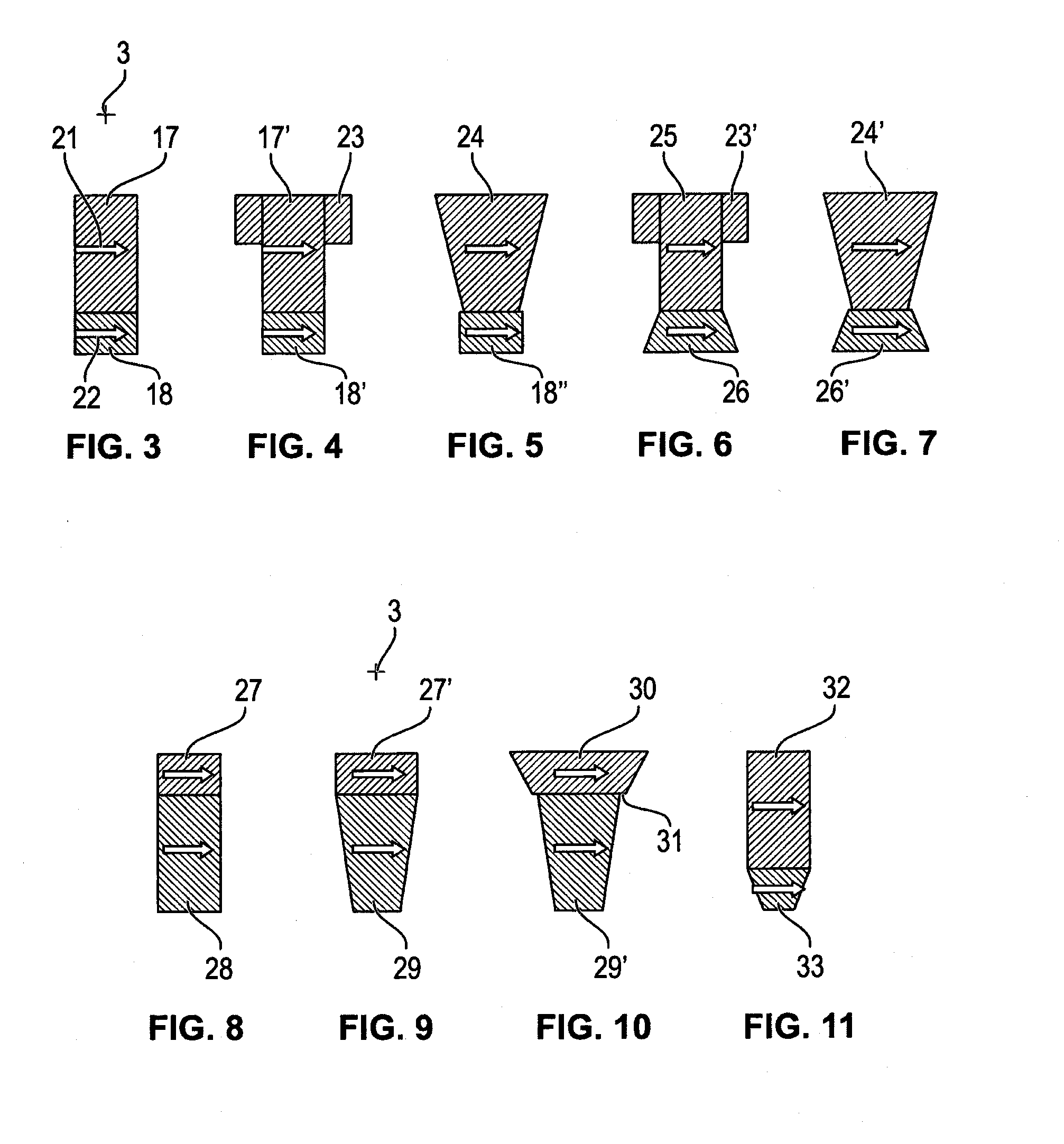

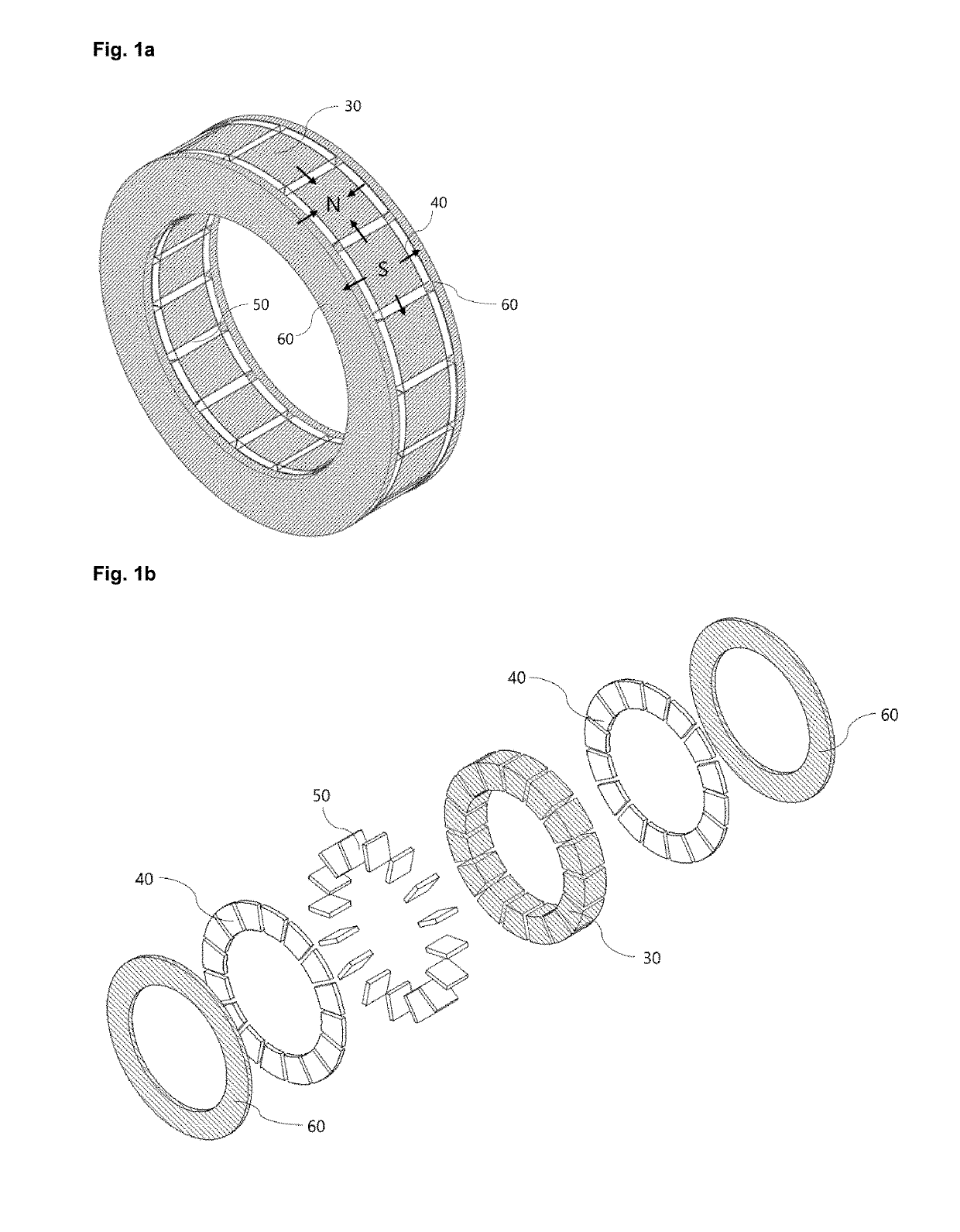

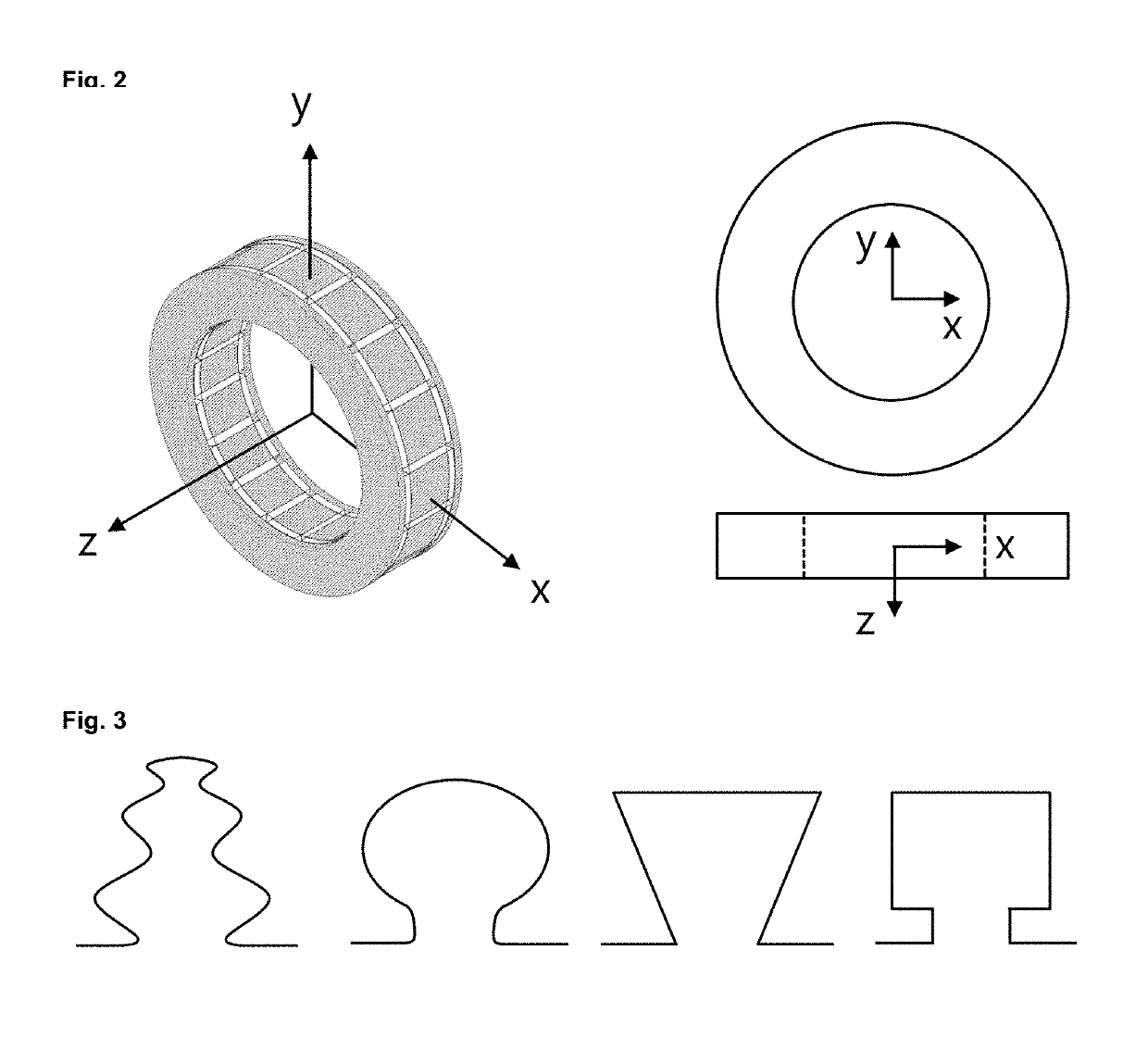

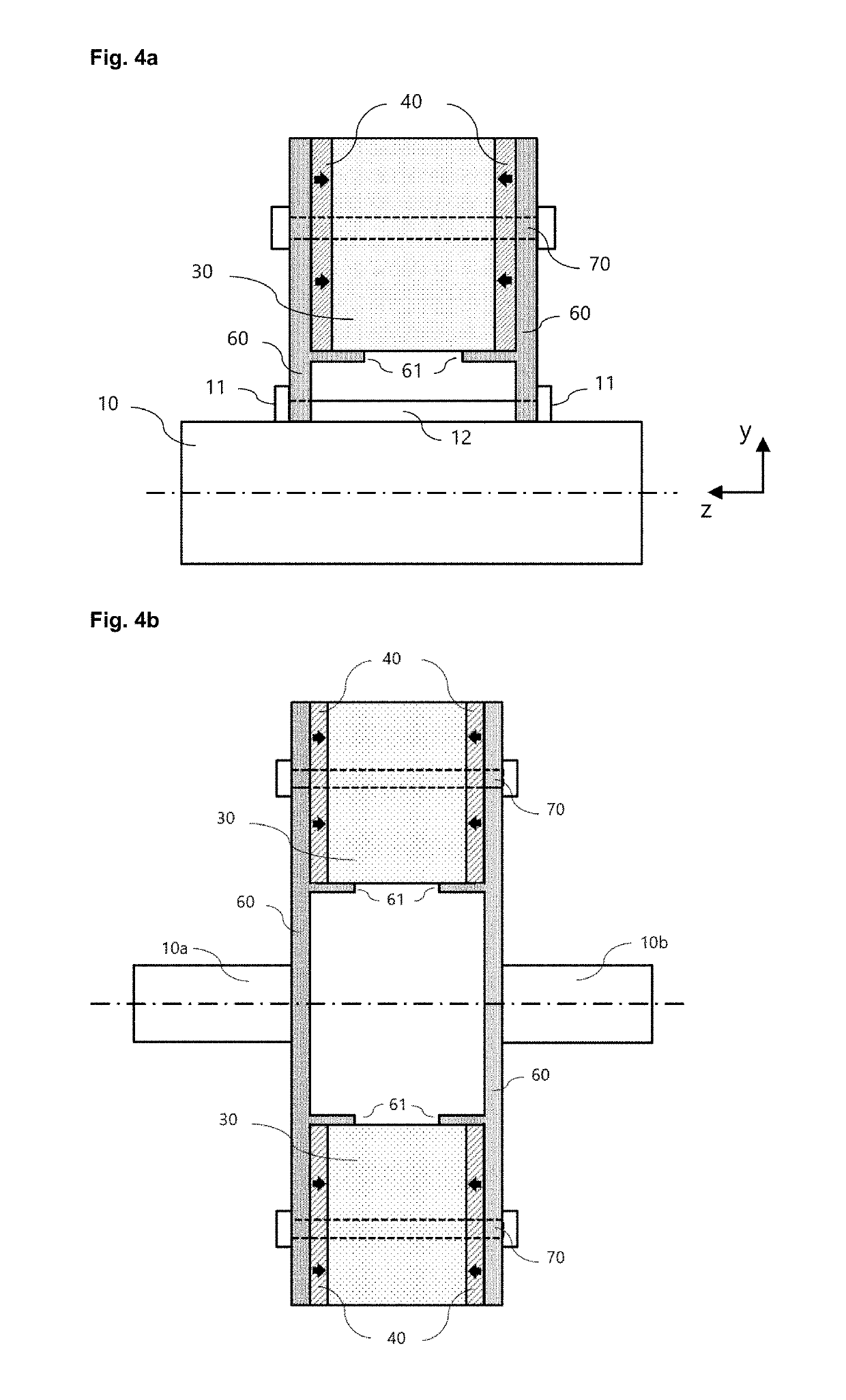

Motor

PendingUS20190103791A1Minimize power lossImproved mechanical robustnessMagnetic circuit rotating partsManufacturing stator/rotor bodiesPhysicsMagnetic flux

Construction of a permanent magnet rotor assembly having a plurality of magnetic poles and comprising a number of magnetic pole pieces arranged in circular array. Two sets of permanent magnets—one set magnetised in circumferential direction of the rotor and the second set providing flux in axial direction of rotor, generating a magnetic flux focused through the pole piece and interacting with the magnetic flux of the stator. End-plates made of magnetic material are present such there is an axial gap between the them and the array of magnetic pole pieces. Circumferentially magnetised magnets are placed in the circumferential gaps between the pole pieces, whereas the magnets providing flux in axial direction are placed in the gaps between the array of pole pieces and end-plates.

Owner:ROMAX TECH

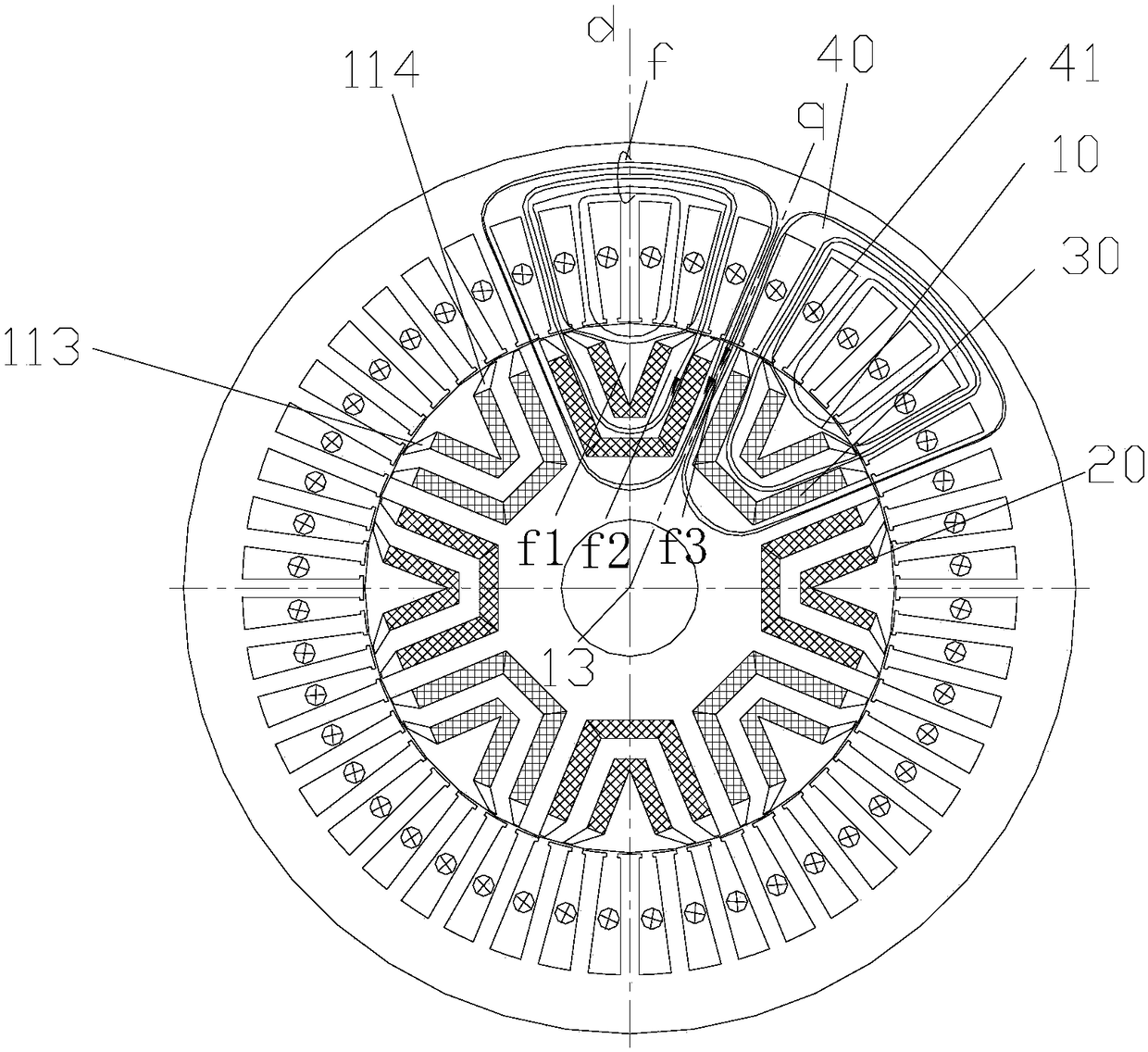

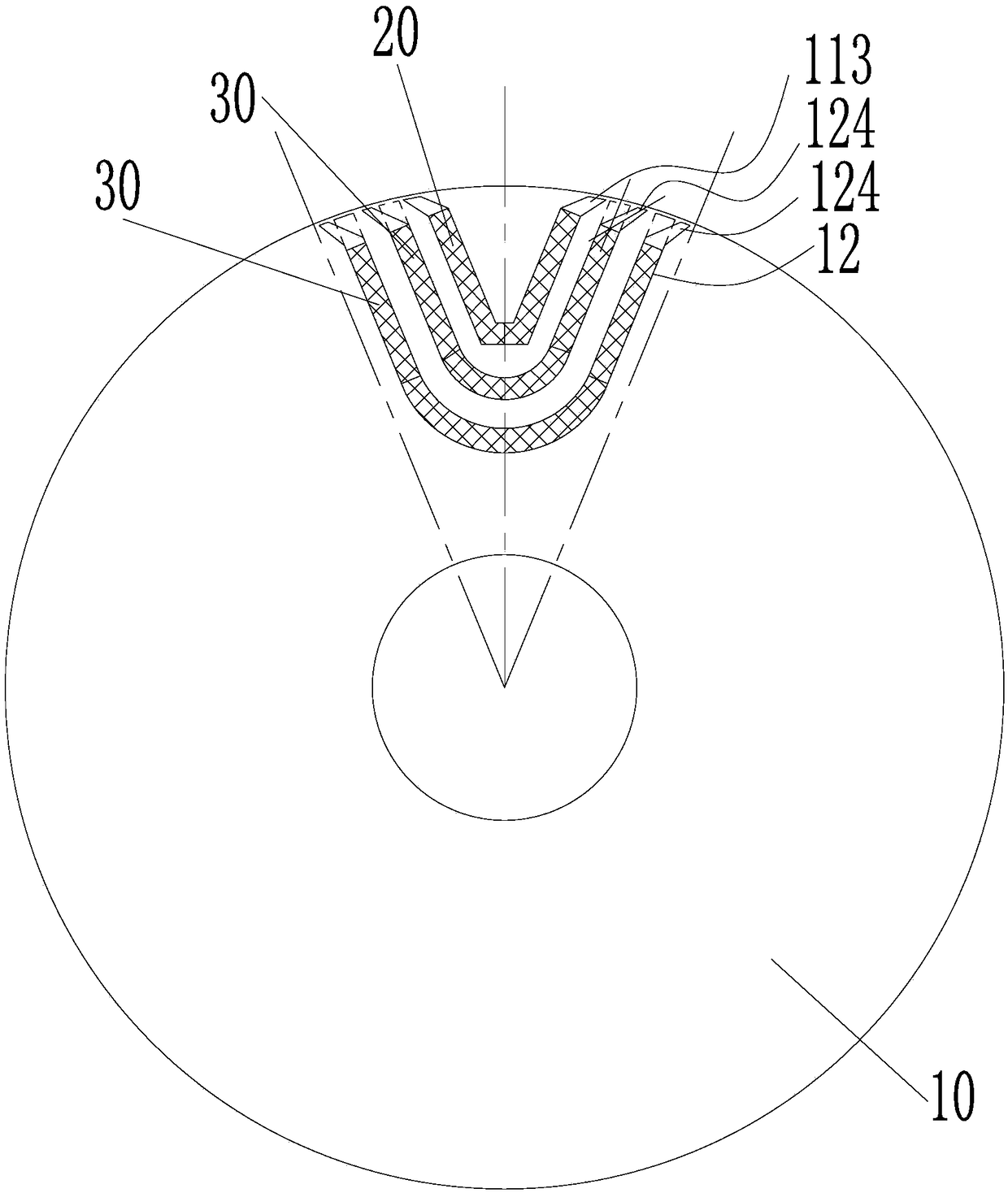

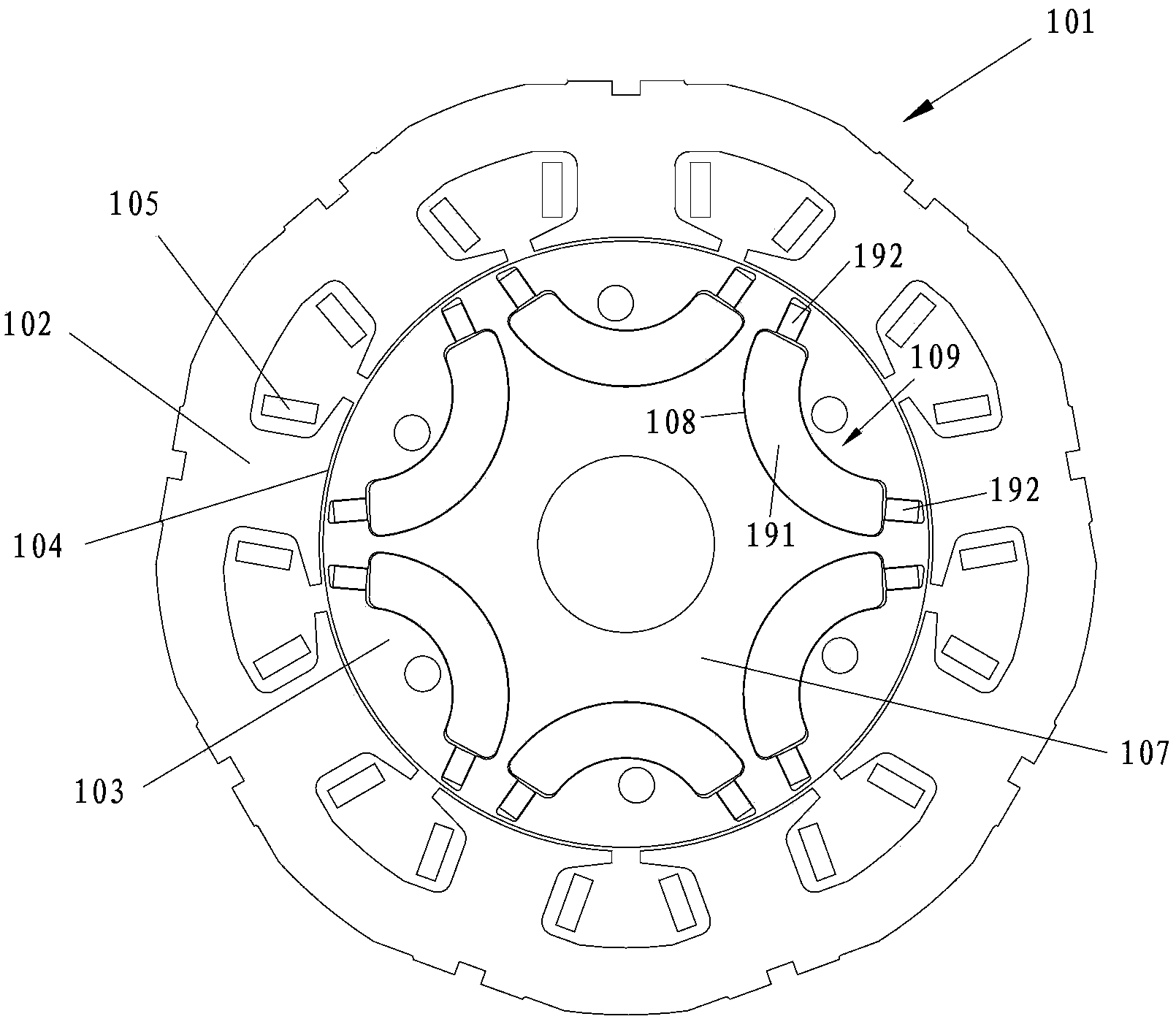

Rotor structure, permanent magnet auxiliary synchronous reluctance motor and electric vehicle

ActiveCN108336845AImprove resistance to demagnetizationOptimized magnetic circuitMagnetic circuit rotating partsElectric machinesSynchronous reluctance motorElectric machinery

The invention provides a rotor structure, a permanent magnet auxiliary synchronous reluctance motor and an electric vehicle. The rotor structure includes a rotor body. A permanent magnet slot group isdisposed on the rotor body. The permanent magnet slot group includes a plurality of permanent magnet slots. The multilayer permanent magnet slot includes a first permanent magnet slot. The first permanent magnet slot includes a first permanent magnet slot segment and a first hinge slot. The first end of the first chamfer is in communication with the second end of the first permanent magnet slot segment. A second end of the first chamfer extends toward an outer edge of the rotor body. A distance from a midpoint of the second end of the first chamfer adjacent the outer edge of the rotor body toa point at which the geometric centerline of the first permanent magnet slot intersects the outer edge of the rotor body is A. The width of the end of the second end of the first permanent magnet slot segment is M, where 0.6 M <=A. This arrangement optimizes the magnetic circuit of the rotor structure, so that the overall anti-demagnetization capability of the rotor structure is effectively improved, and the motor efficiency of the rotor structure with the structure is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

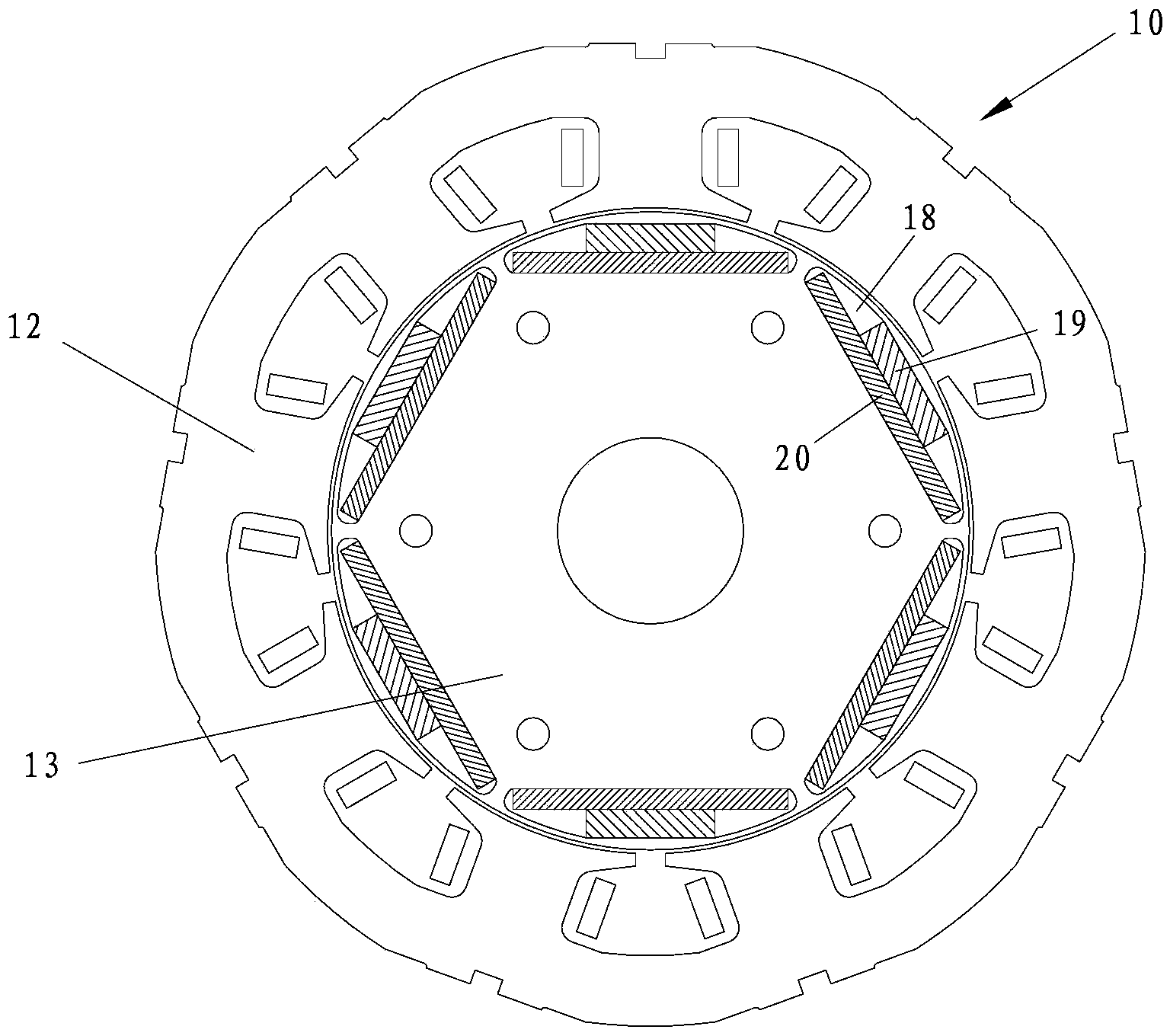

Rotor structure, permanent magnet auxiliary synchronous reluctance motor and electric vehicle

InactiveCN108566006AOptimized magnetic circuitIncrease reluctance torqueMagnetic circuit rotating partsElectric machinesSynchronous reluctance motorElectric machine

The present invention provides a rotor structure, a permanent magnet auxiliary synchronous reluctance motor and an electric vehicle. The rotor structure comprises a rotor body, the rotor body is provided with a permanent magnet slot group, the permanent magnet slot group comprises an outer layer of permanent magnet slot and an inner layer of permanent magnet slot, a magnetic conductive channel isformed between the adjacent outer layer of permanent magnet slot and inner layer of permanent magnet slot, at least one end of the magnetic conductive channel is provided with a deflection section, and a distance from the deflection section to a quadrature axis of the rotor body is gradually reduced outwards in a radial direction to allow the tail end of the magnetic conductive channel to be arranged close to the quadrature axis. The at least one end of the magnetic conductive channel is provided with the deflection section and the distance from the deflection section to the quadrature axis ofthe rotor body is gradually reduced outwards in a radial direction to optimize the magnetic circuit of the rotor structure and improve the reluctance torque of the motor, the shape of the permanent magnet slot is further improved to allow the whole demagnetization-resistant capacity of the rotor permanent magnet to be improved, reduce the motor torque pulsation, reduce the vibration and noise ofthe motor and improve the demagnetization-resistant capacity of the motor.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

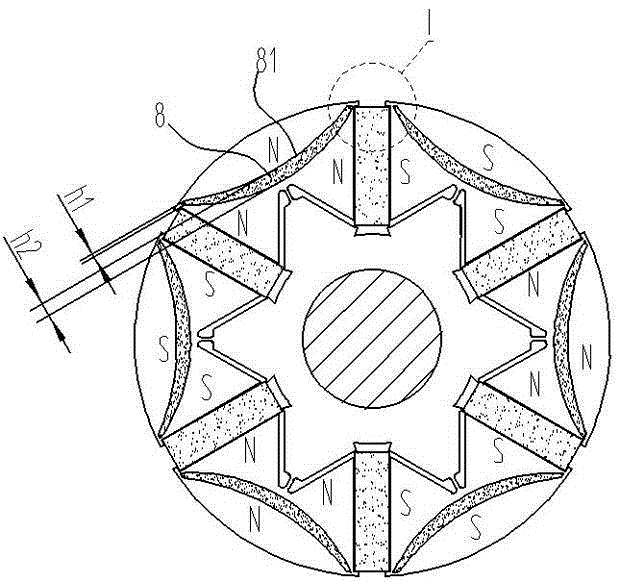

Hybrid permanent magnet rotor assembly and corresponding motor

ActiveCN103580327AOvercoming the problem of easy demagnetizationExtended service lifeMagnetic circuit rotating partsPermanent magnet rotorElectric machine

The utility model relates to a hybrid permanent magnet rotor assembly, comprising a rotor core, a plurality of magnet containing grooves disposed in the rotor core, and a plurality of groups of hybrid permanent magnets disposed in the magnet containing grooves, wherein each group in the plurality of groups of hybrid permanent magnets comprises ferrite permanent magnets disposed on central positions of the magnet containing grooves and rare earth permanent magnets disposed on two side ends of the magnet containing grooves. The hybrid permanent magnet rotor assembly can effectively overcome a problem that a permanent magnet motor rotor in the prior art is easy to demagnetize, and through using the ferrite permanent magnets as a main part of the motor rotor permanent magnet, material cost of the motor rotor is greatly reduced. The utility model also relates to a motor using the hybrid permanent magnet rotor assembly.

Owner:EMERSON CLIMATE TECH (SUZHOU) CO LTD

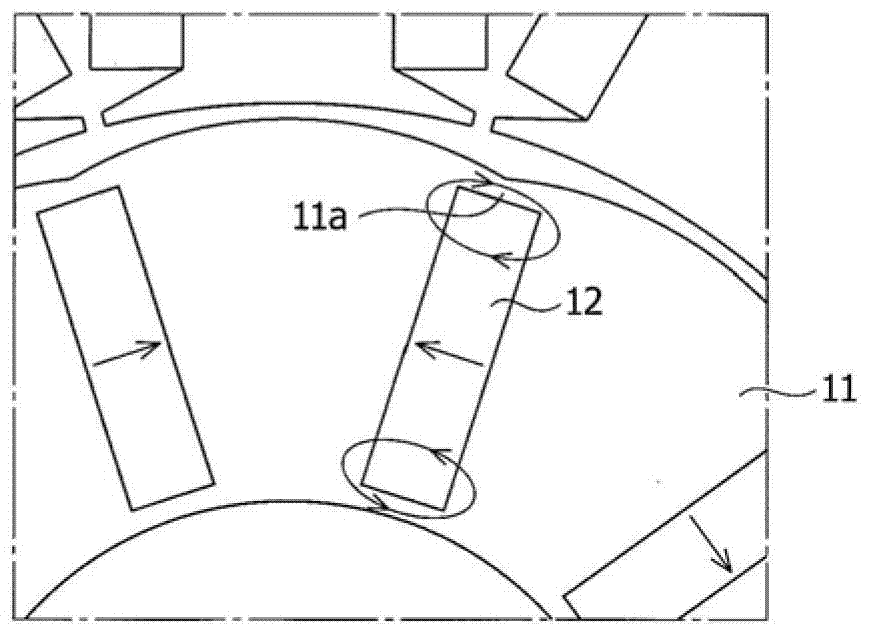

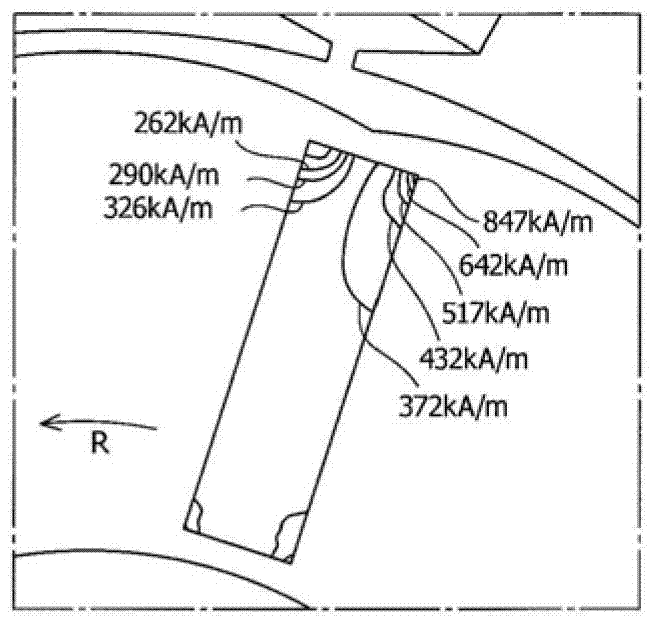

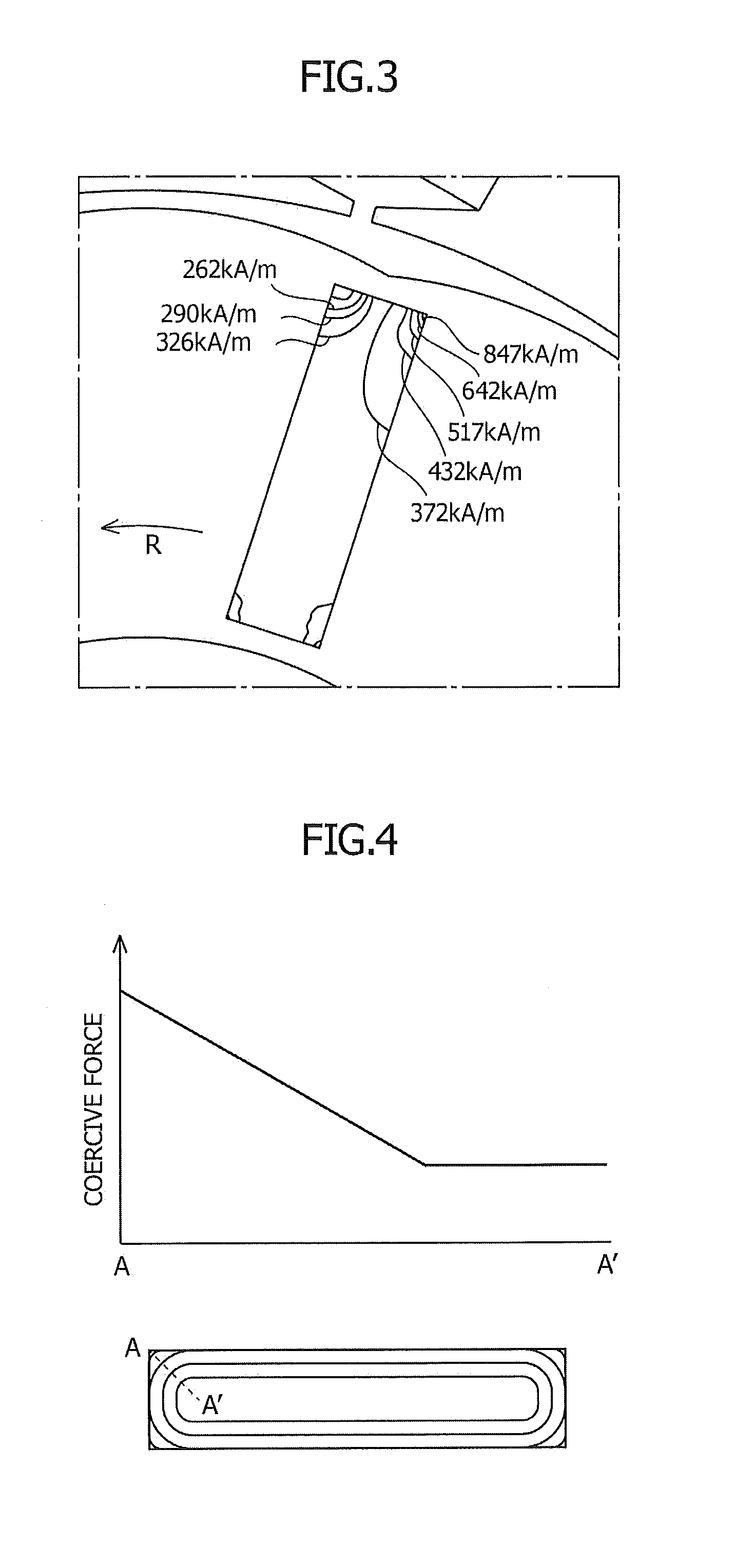

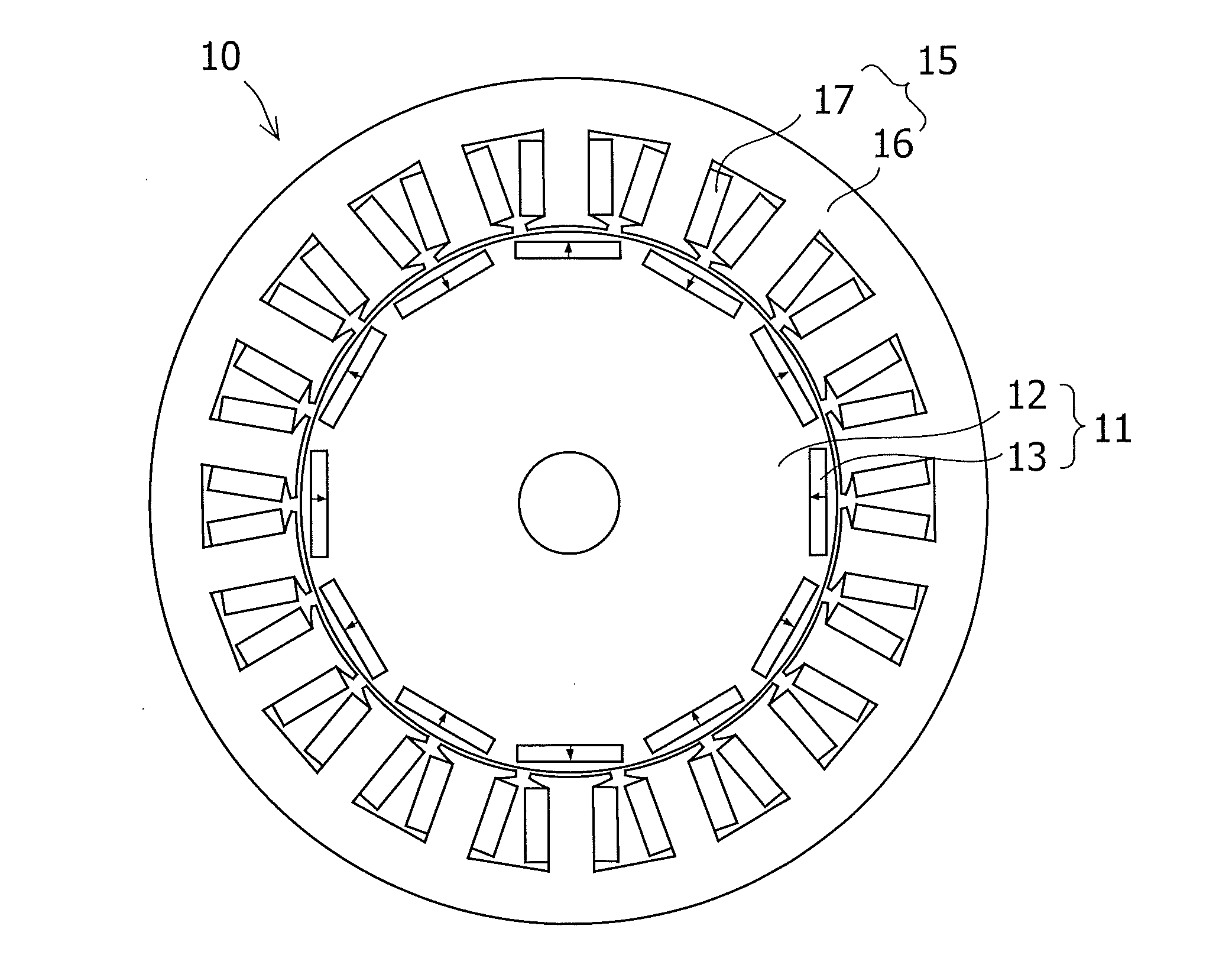

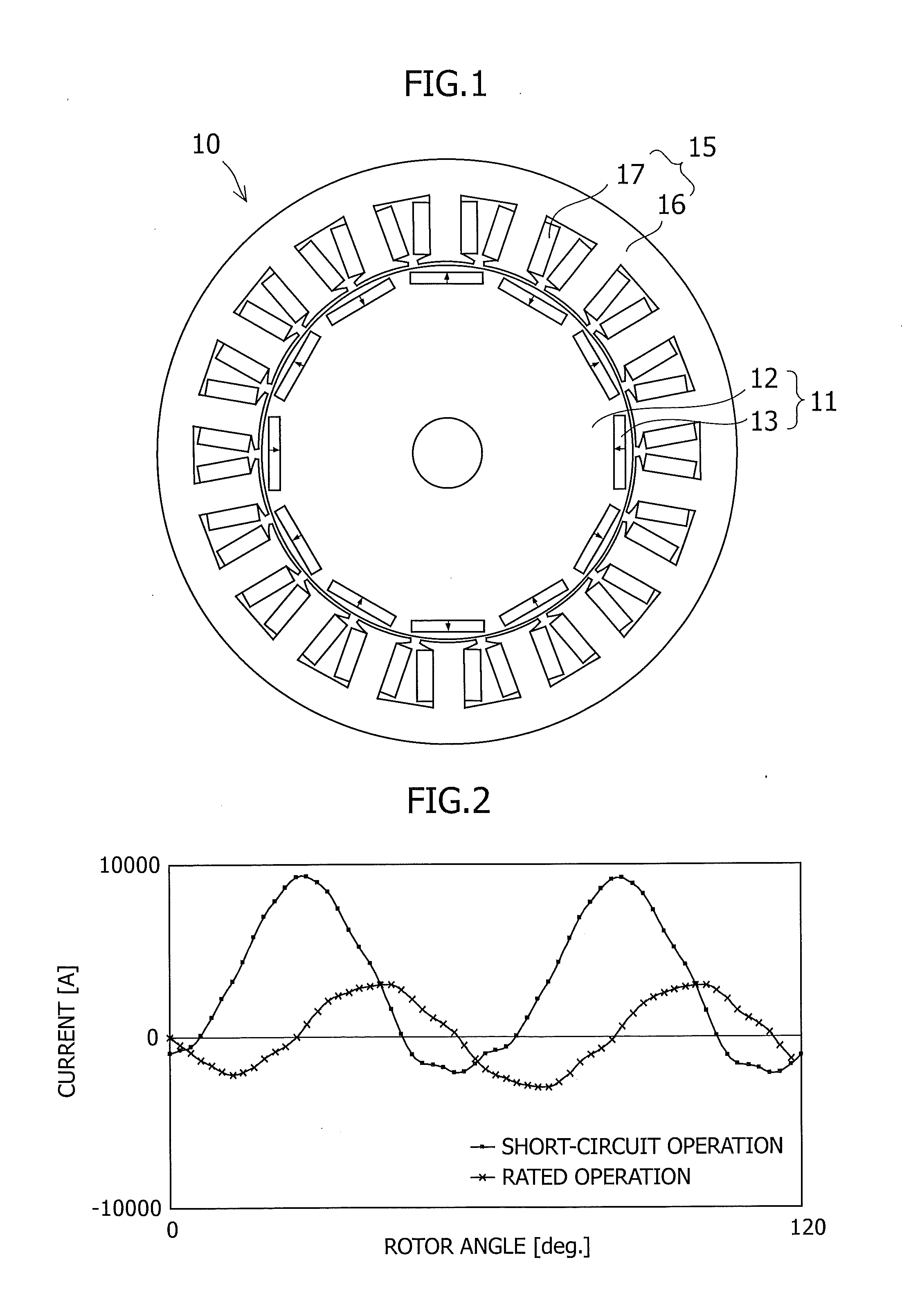

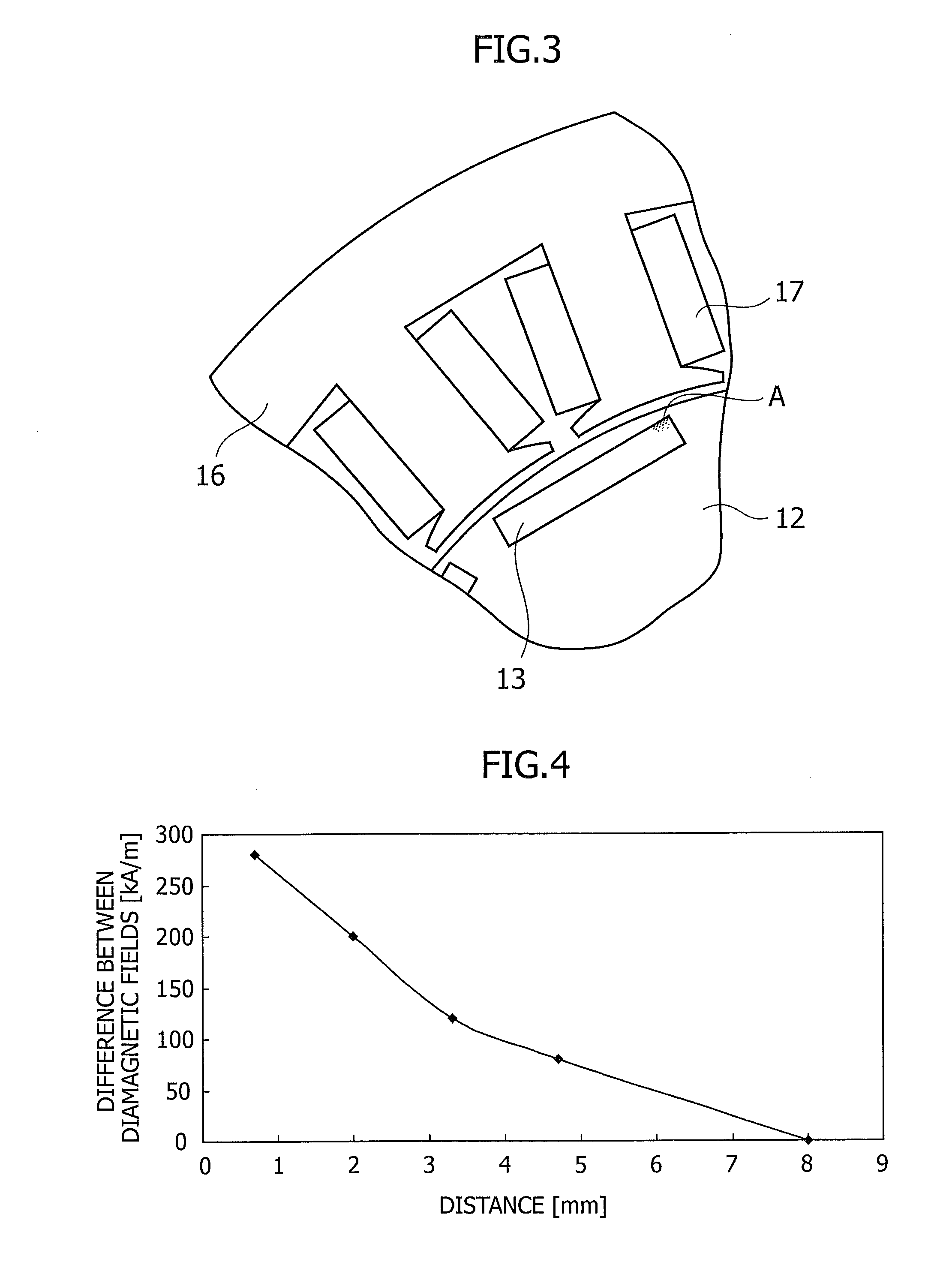

Rotor and permanent magnet rotating machine

ActiveUS20110234038A1Increase forceReduce the possibilityMagnetic circuit rotating partsManufacturing dynamo-electric machinesConductor CoilMagnet

A rotor adapted for a large permanent magnet rotating machine having high output and demagnetization resistance and the permanent magnet rotating machine are provided. More specifically, there is provided a rotor adapted for a permanent magnet rotating machine, the machine comprising the rotor and a stator disposed with a clearance from an outer peripheral face of the rotor and formed by winding a winding wire through a stator core having two or more slots, the rotor comprising one or more permanent magnets in each of two or more insertion holes, the insertion holes being formed in a circumferential direction in a rotor core, wherein a magnetic coercive force in a stator-side surface region of each of the permanent magnets is greater than that in an inner central portion by 300 kA / m or more, the inner central portion being an inner portion at a depth of at least 5 mm from every outer shape face of the permanent magnet. There is also provided the permanent magnet rotating machine comprising this rotor and a stator disposed with a clearance from an outer peripheral face of the rotor and formed by winding a winding wire through a stator core having two or more slots.

Owner:SHIN ETSU CHEM IND CO LTD

Self-starting permanent magnet synchronous motor rotor adopting conductive sleeve

InactiveCN102545432AEasy to startLower resistanceMagnetic circuit rotating partsElectrical conductorPermanent magnet synchronous motor

The invention discloses a self-starting permanent magnet synchronous motor rotor adopting a conductive sleeve. The self-starting permanent magnet synchronous motor rotor comprises an iron core, a permanent magnet, a shaft and the conductive sleeve, wherein the conductive sleeve is wrapped at the outer side of the iron core of the rotor to form a rotor starting winding; and the conductive sleeve is made of a non-magnetic good conductor material. Compared with the prior art, the self-starting permanent magnet synchronous motor rotor has the beneficial effects: 1, the equivalent air gap length of a motor is increased by means of the conductive sleeve, and the influence of magnetomotive force of stator current demagnetization on the permanent magnet is weakened; 2, the resistance of the conductive sleeve is lower and the equivalent winding of the rotor is enhanced; 3, the air gap length of the motor is increased by means of the conductive sleeve, and internal eddy-current loss and stray loss of the motor are favorably reduced; 4, the mechanical strength of the rotor can be enhanced by means of the conductive sleeve, a magnetic isolation bridge inside the rotor can be made to be narrower, and high enough utilization rate of the permanent magnet is ensured; and 5, the torque pulsation caused by slotting on the surface of the rotor during steady-state running is reduced, and vibration and noise of the motor are restricted.

Owner:ZHEJIANG UNIV

Neodymium-iron-boron magnet and preparation method and application thereof

ActiveCN111653404AImprove high temperature demagnetization resistanceReduce fluxTransformersVacuum evaporation coatingRare-earth elementRemanence

The invention provides a neodymium-iron-boron magnet and a preparation method and application thereof. The neodymium-iron-boron magnet is represented by a chemical formula R1-R2-Fe-M-B, and the neodymium-iron-boron magnet has a composite structure of a high-coercivity region and a high-remanence region, wherein R1 is a rare earth element at least containing Nd, R2 is a heavy rare earth element atleast containing Dy and / or Tb, and M is a transition metal element at least containing Co. The magnet can adopt a small amount of Dy / Tb, the high-temperature demagnetization resistance of the magnet is greatly improved, the reduction of the magnetic flux of the magnet is inhibited, and the magnet is suitable for an embedded high-speed motor. The method for preparing the magnet can also greatly improve the utilization rate and the production efficiency of the material, and has mass production feasibility.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL CO LTD

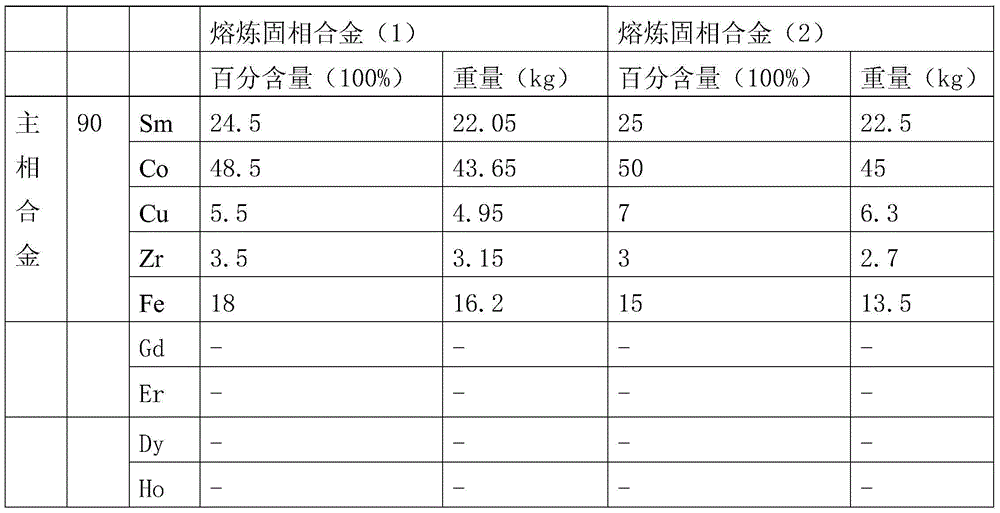

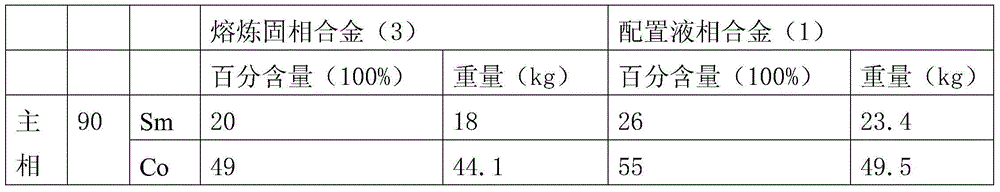

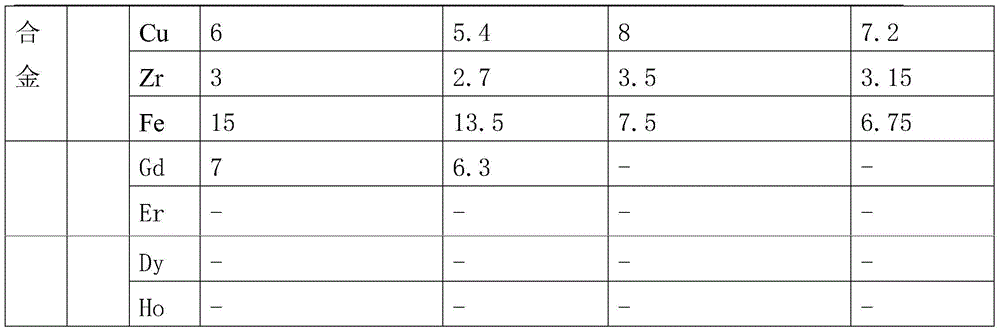

Rare earth permanent magnetic material Sm2(CoFeCuZr)17 and preparation method thereof

The invention provides a rare earth permanent magnetic material Sm2(CoFeCuZr)17 which comprises the following components by weight percentage: 87-100% of main phase alloy, 0-10% of Gd or Er, and 0-3% of Dy or Ho, wherein the main phase alloy is a 2:17 sintered samarium cobalt based rare earth permanent magnetic material and comprises the following components by atomic weight percentage: 20-40% of Sm, 40-65% of Co, 0-10% of Cu, 0-5% of Zr and 10-20% of Fe. Compared with the prior art, the rare earth permanent magnetic material Sm2(CoFeCuZr)17 has the benefits that all properties can be covered by a preparation method according to different material property requirements of users without changing pulverization, forming, sintering or aging treatment, the production cycle is shortened, and the raw material cost and labor cost are lowered as compared with the common sintered 2:17 permanent magnet.

Owner:CHENGDU 899 SCI & TECH

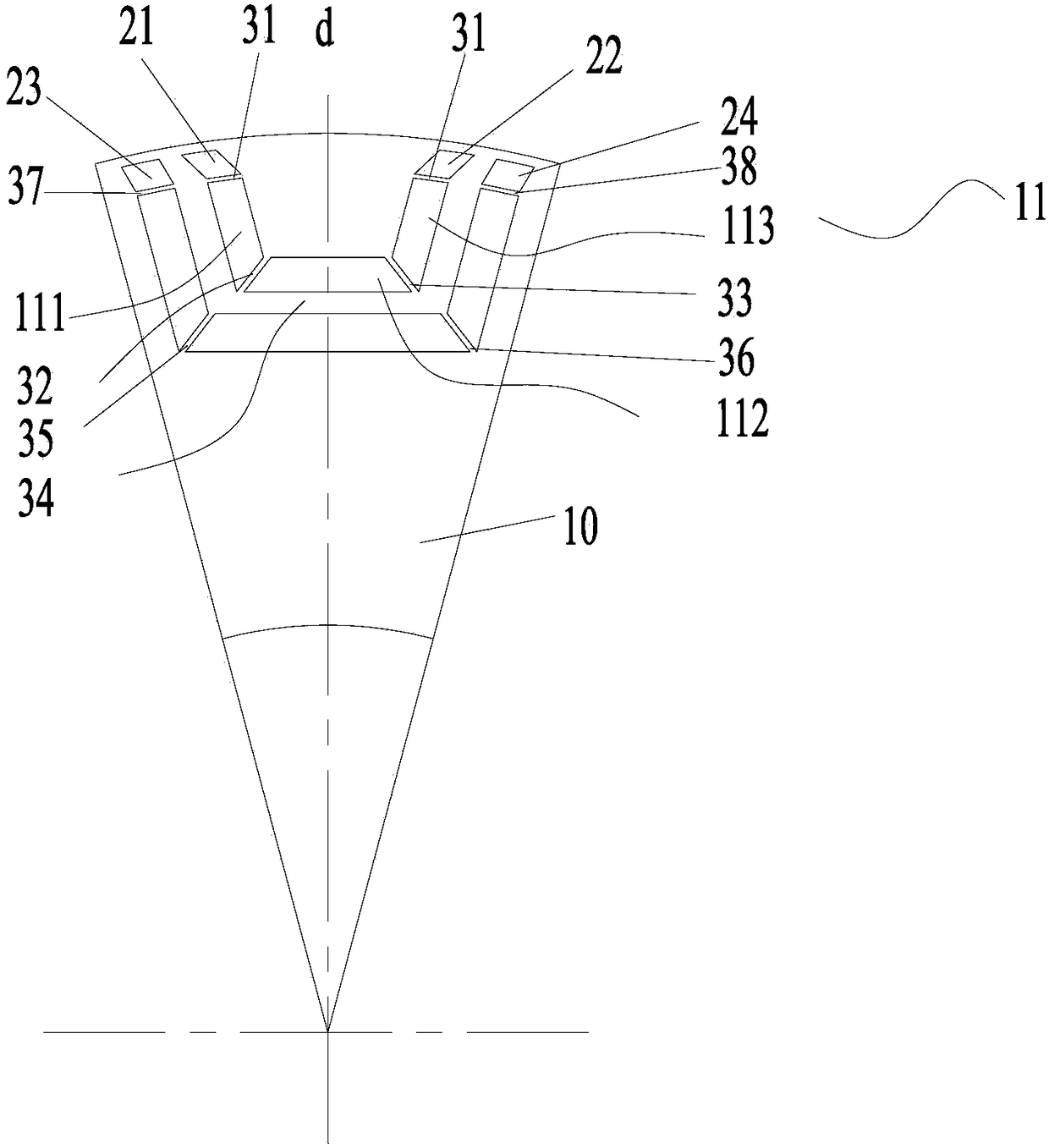

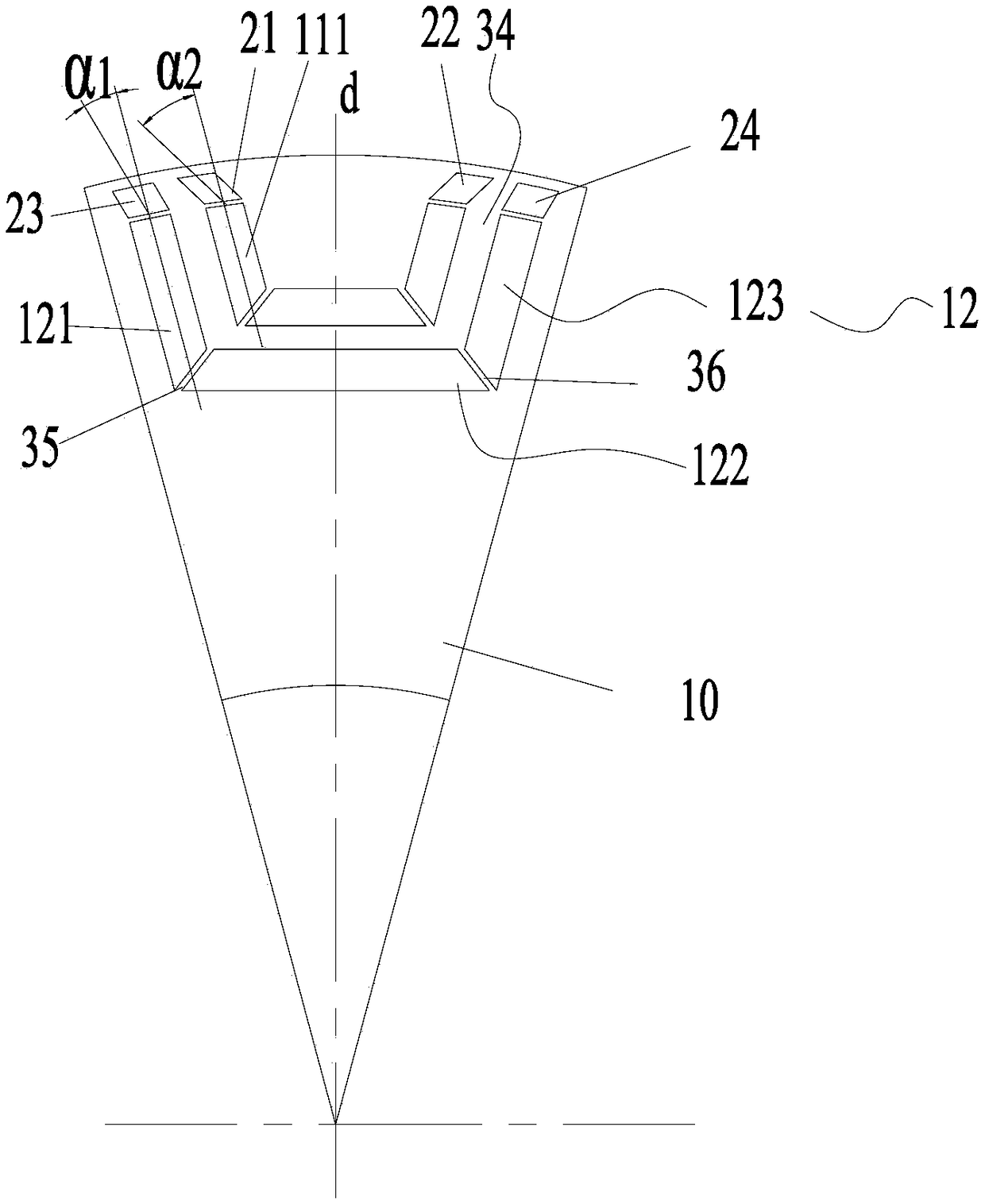

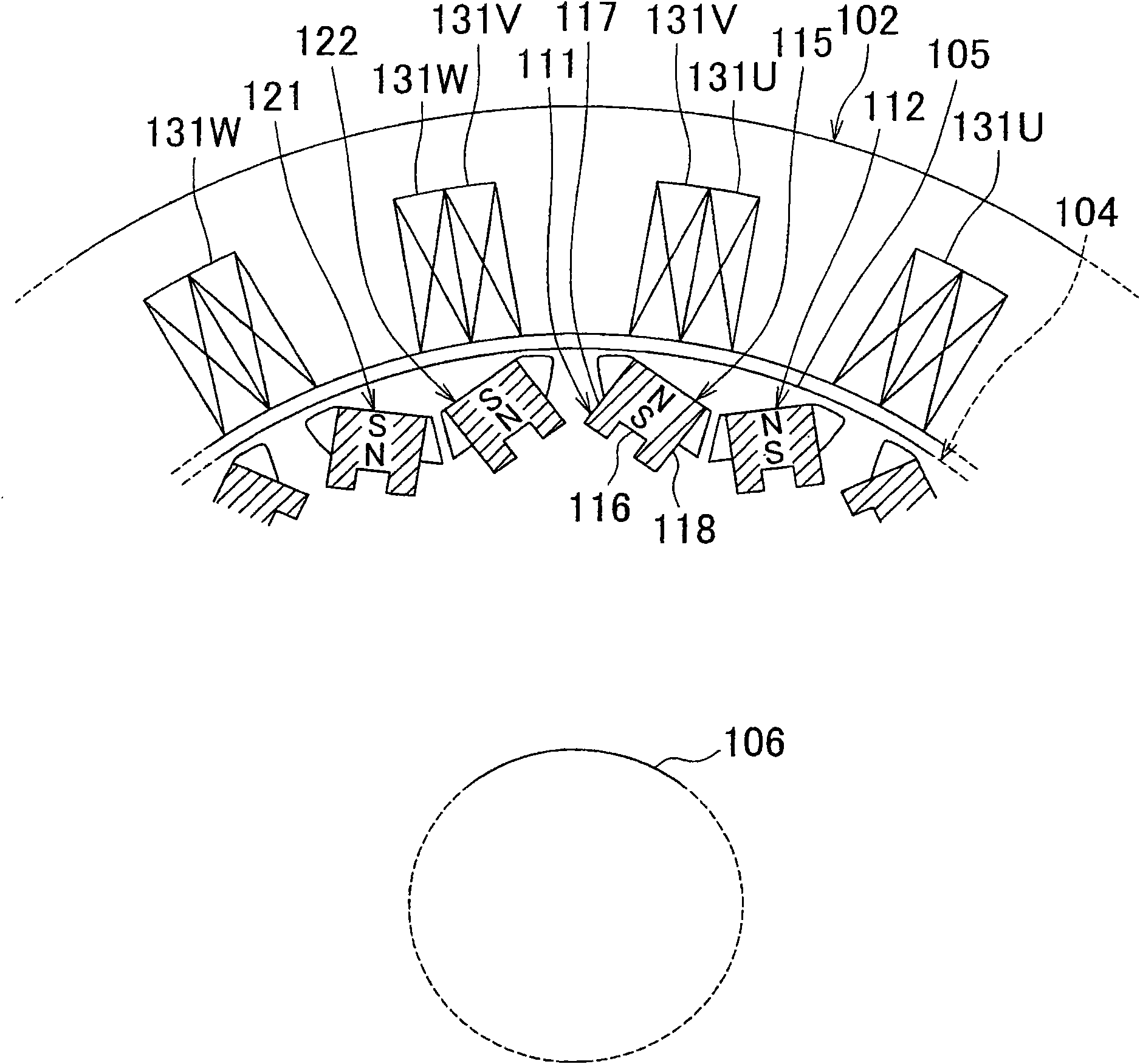

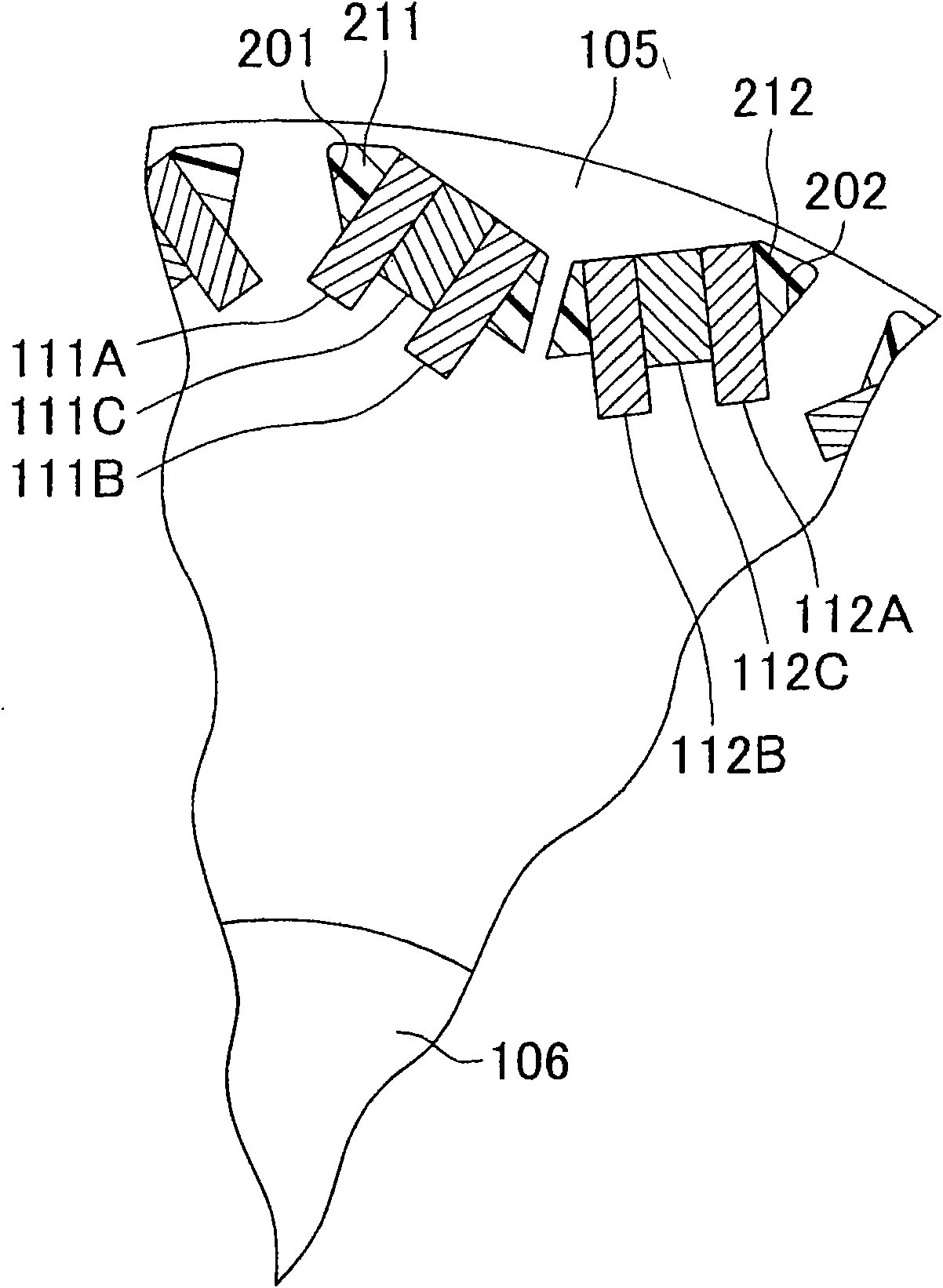

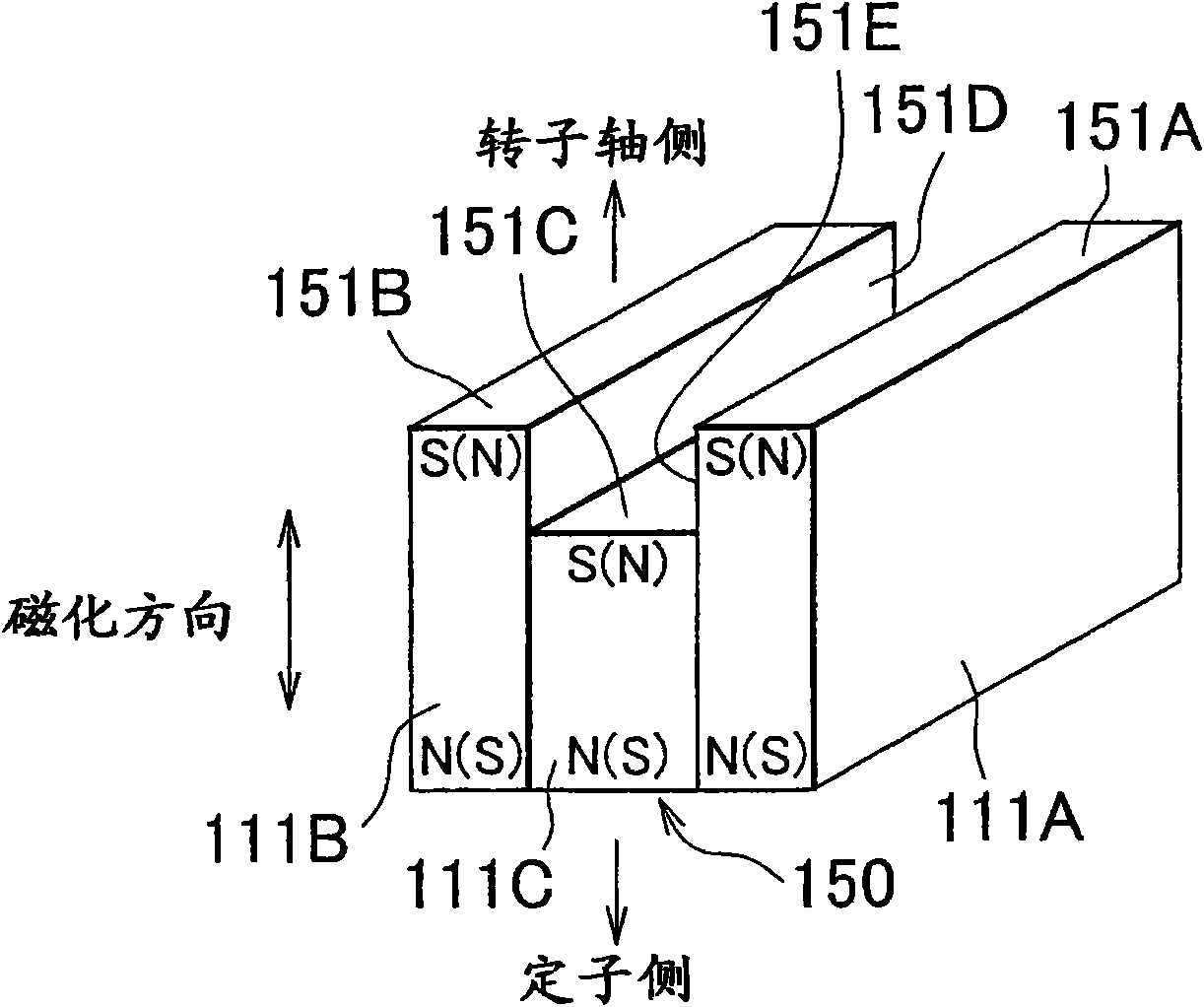

Rotor of rotary electric machine, and production method therefor

InactiveCN101682221ALow costImprove resistance to demagnetizationMagnetic circuit rotating partsManufacturing stator/rotor bodiesElectric machineMagnetization

A rotor (104) includes a rotor core (105) and permanent magnets (111, 112, 121, 122) embedded in the rotor core (105). The permanent magnet (111) includes a first surface that is a flat surface facinga stator side, and a second surface that is opposite from the first surface. A center position of a middle portion of the permanent magnet (111) which is a center in the magnetization direction of the permanent magnet (111) is positioned in a stator side of a center position of two opposite end portions of the permanent magnet (111) in a direction orthogonal to the magnetization direction which is a center in the magnetization direction.

Owner:TOYOTA JIDOSHA KK

Split type combined permanent magnet brushless motor for electric vehicle

ActiveCN105322744ALow costImprove power densityMagnetic circuit rotating partsElectric machinesBrushless motorsRare earth

The invention discloses a split type combined permanent magnet brushless motor for an electric vehicle. A rotor is coaxially positioned in the internal of a stator; a rectangular neodymium iron boron permanent magnet steel and two same rectangular ferrite permanent magnet steels are fixedly embedded in each pole of the rotor; the neodymium iron boron permanent magnet steels are close to air gaps and are symmetrical relative to the central line of the rotor poles; the two ferrite permanent magnet steels are close to a rotation shaft, are distributed on the two sides of the central line of the rotor poles and are symmetrical relative to the central line of the rotor poles; a magnetic conductive bridge is between the two ferrite permanent magnet steels; the permanent magnet steel on each pole is magnetized along the tangential direction of the circumference; the magnetizing directions on the same pole are the same, and the magnetizing directions on the adjacent two poles are opposite; the rare earth permanent magnet material and the non-rare-earth ferrite permanent magnet material are adopted at the same time; on the basis of ensuring the power density and the torque density of the permanent magnet motor with a small amount of rare earth, the cost of the motor is reduced by more than 50%; and in addition, the requirements on the torque and the power in the electric vehicle applications can be met on the premise of keeping the relatively high power density and the torque density.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com