Rotor and permanent magnetic rotating machine

A permanent magnet, rotating machine technology, applied in the magnetic circuit shape/style/structure, magnetic circuit, motor and other directions, can solve problems such as motor output deterioration, and achieve the effect of high anti-demagnetization and high output characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

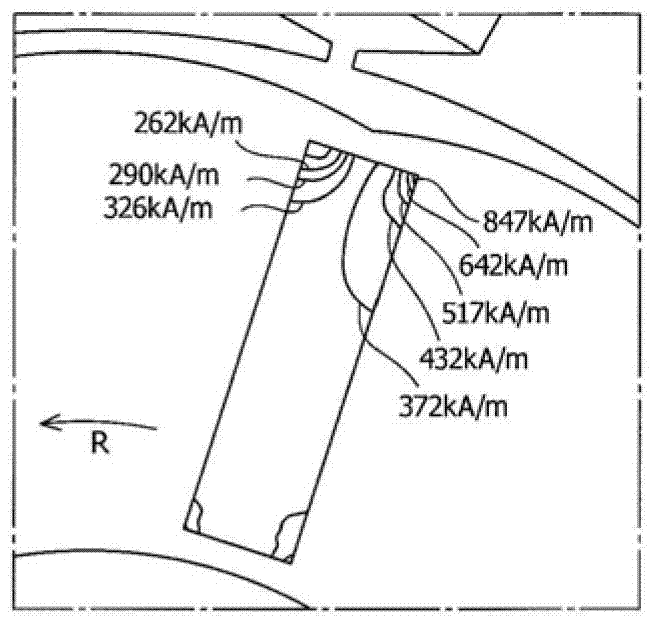

[0045] As the magnet, a rectangular parallelepiped Nd-based rare earth sintered magnet Nd 2 Fe 14 B, wherein the residual magnetic flux density is 1.32T, the coercive force is 1000kA / m, the size is 12mm length×3mm width×50mm height, and the width direction is the magnetization direction. Two or more magnets are provided and diffused. As diffusion, granular dysprosium fluoride having an average particle diameter of 5 μm was mixed with ethanol at a weight ratio of 1:1, the magnet was immersed in the mixture, and thereafter, heat treatment was performed at 900° C. for 1 hour in an Ar atmosphere. For one of the diffused magnets, a cube of 1 mm on each side was cut from the corner containing the vertices of the magnet and the coercivity was determined by using a BH tracer. As a result, the coercive force of the magnets at the corners was 1600 kA / m. Therefore, the coercivity increases by 600 kA / m.

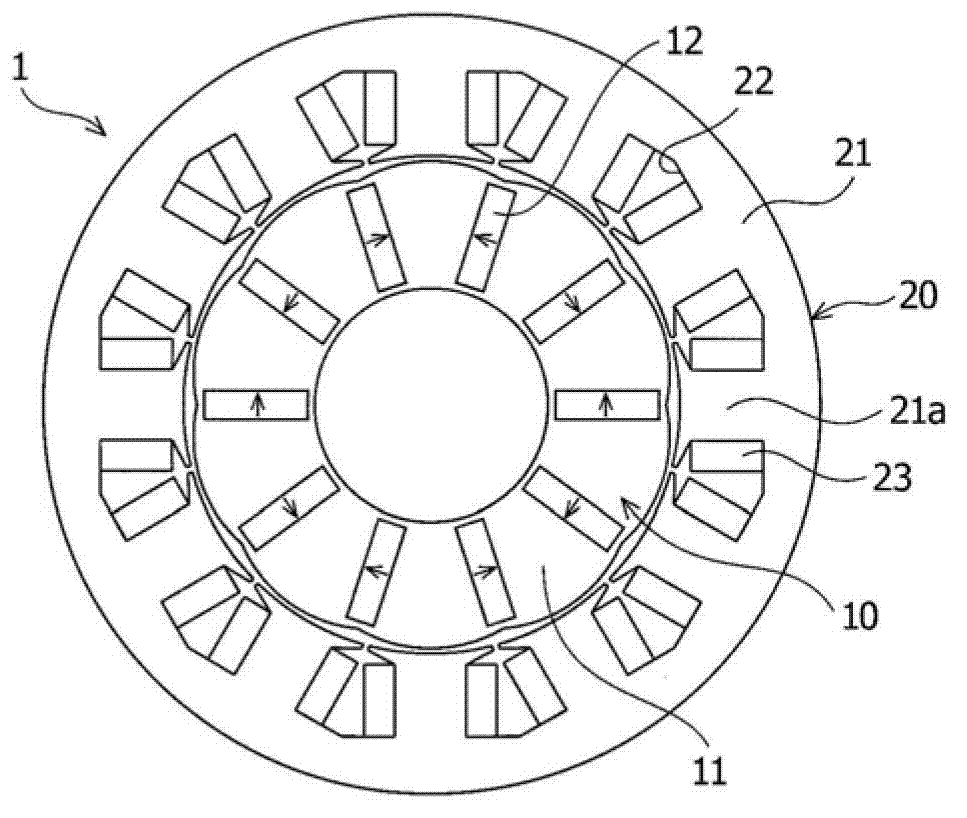

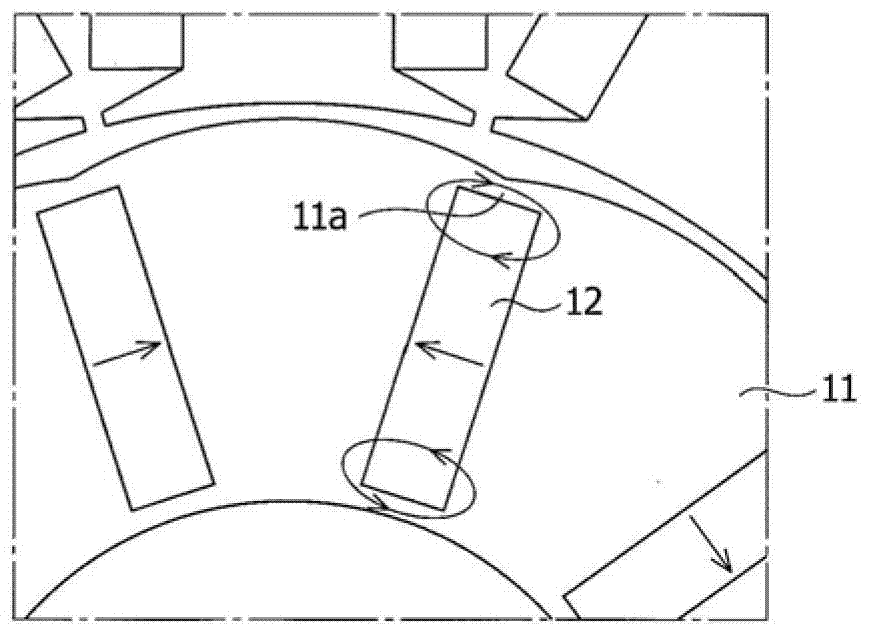

[0046] like figure 1 As shown, the magnets were installed in a rotating machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com