Method for producing rare earth magnet

A manufacturing method and technology of rare earth magnets, applied in the direction of inductance/transformer/magnet manufacturing, magnetic objects, magnetic materials, etc., can solve the problems that are not suitable for the manufacture of multi-variety or a small amount of magnet products, and achieve suppression of eddy current, crack suppression, The effect of increasing the residual magnetic flux density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

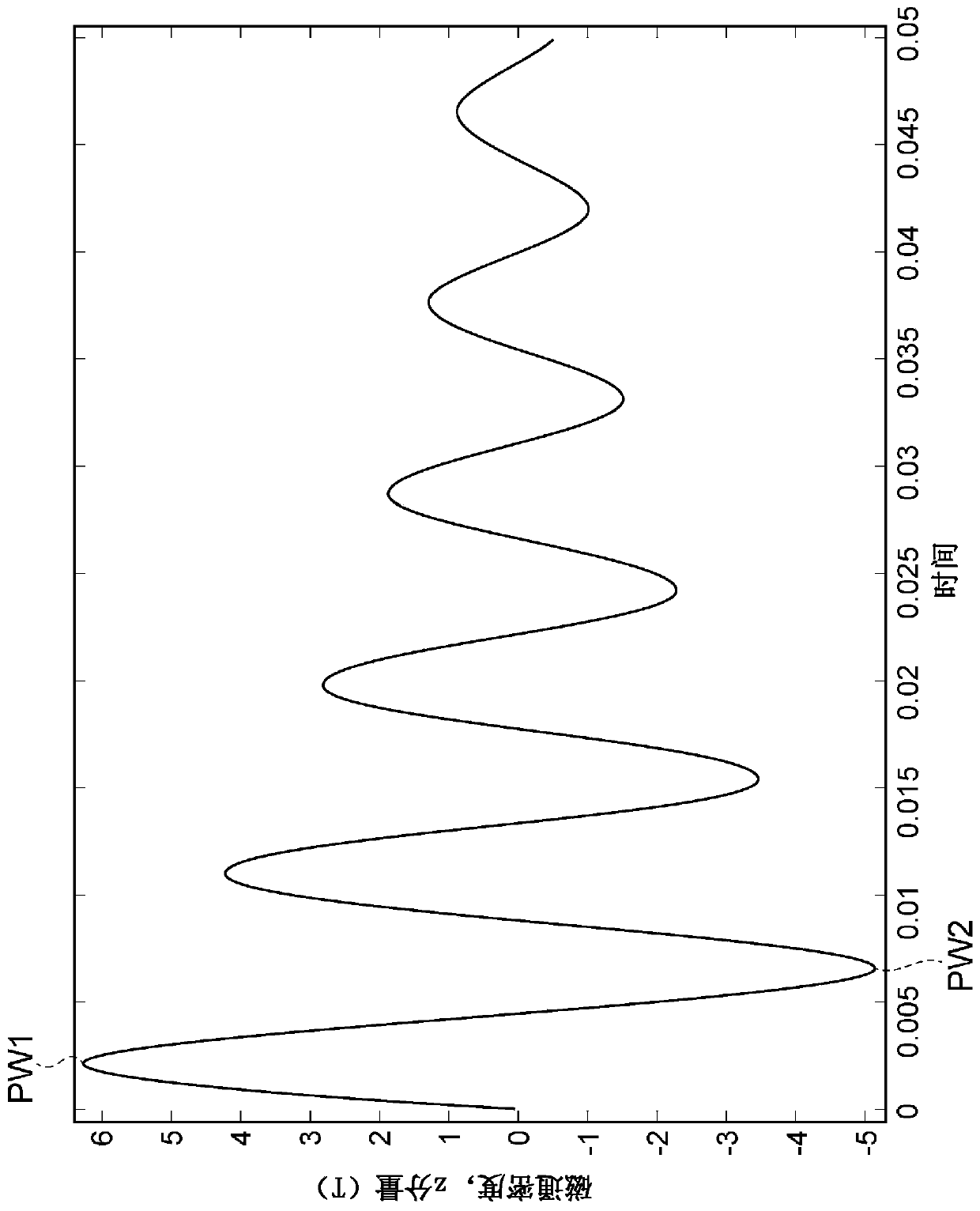

[0086] As described below, the orientation process of Example 1 was simulated by simulation using a computer. The simulation is based on the finite element method. As the simulation, COMSOL Multiphysics, which is a software manufactured by COMSOL Corporation, was used.

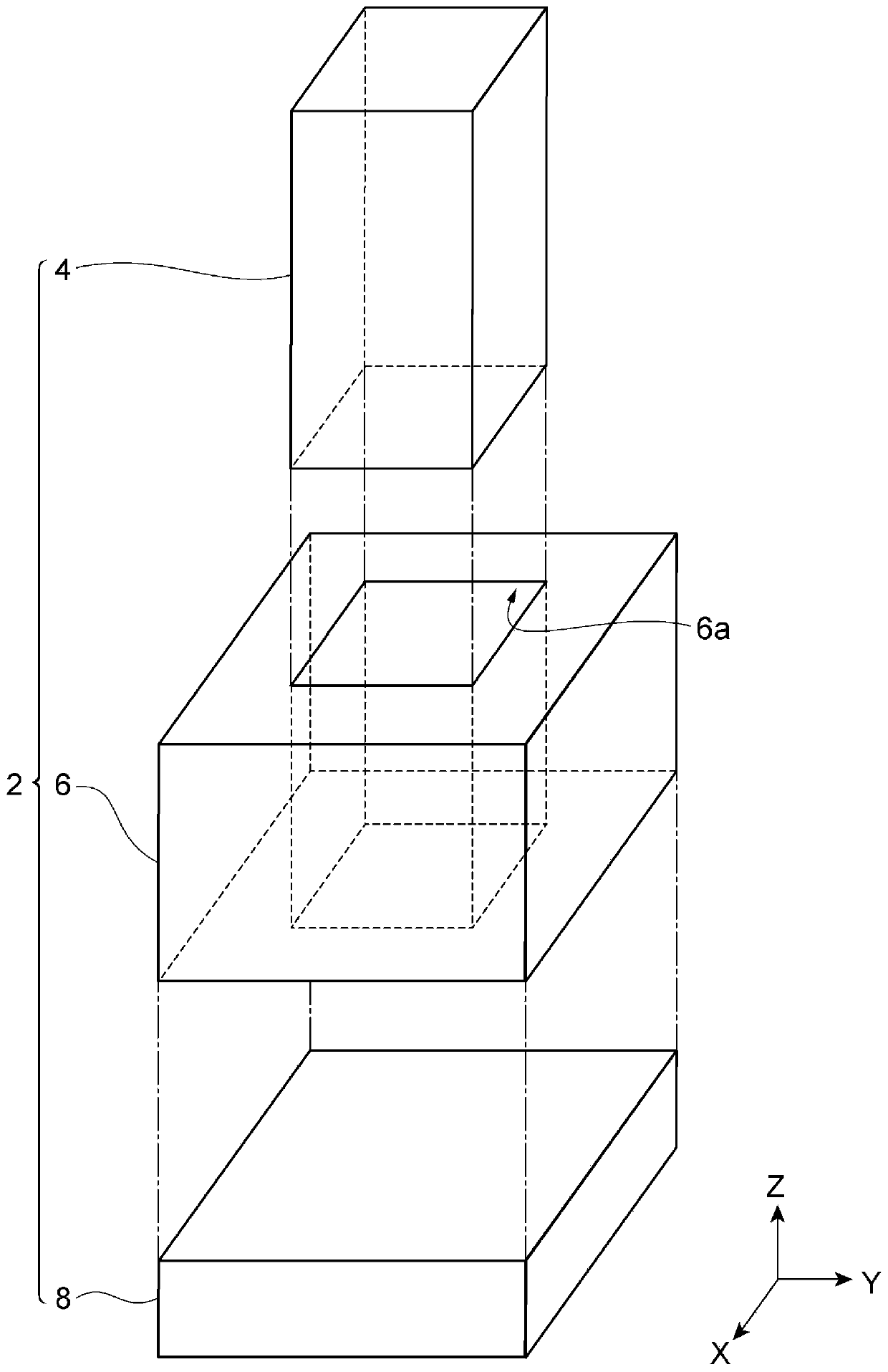

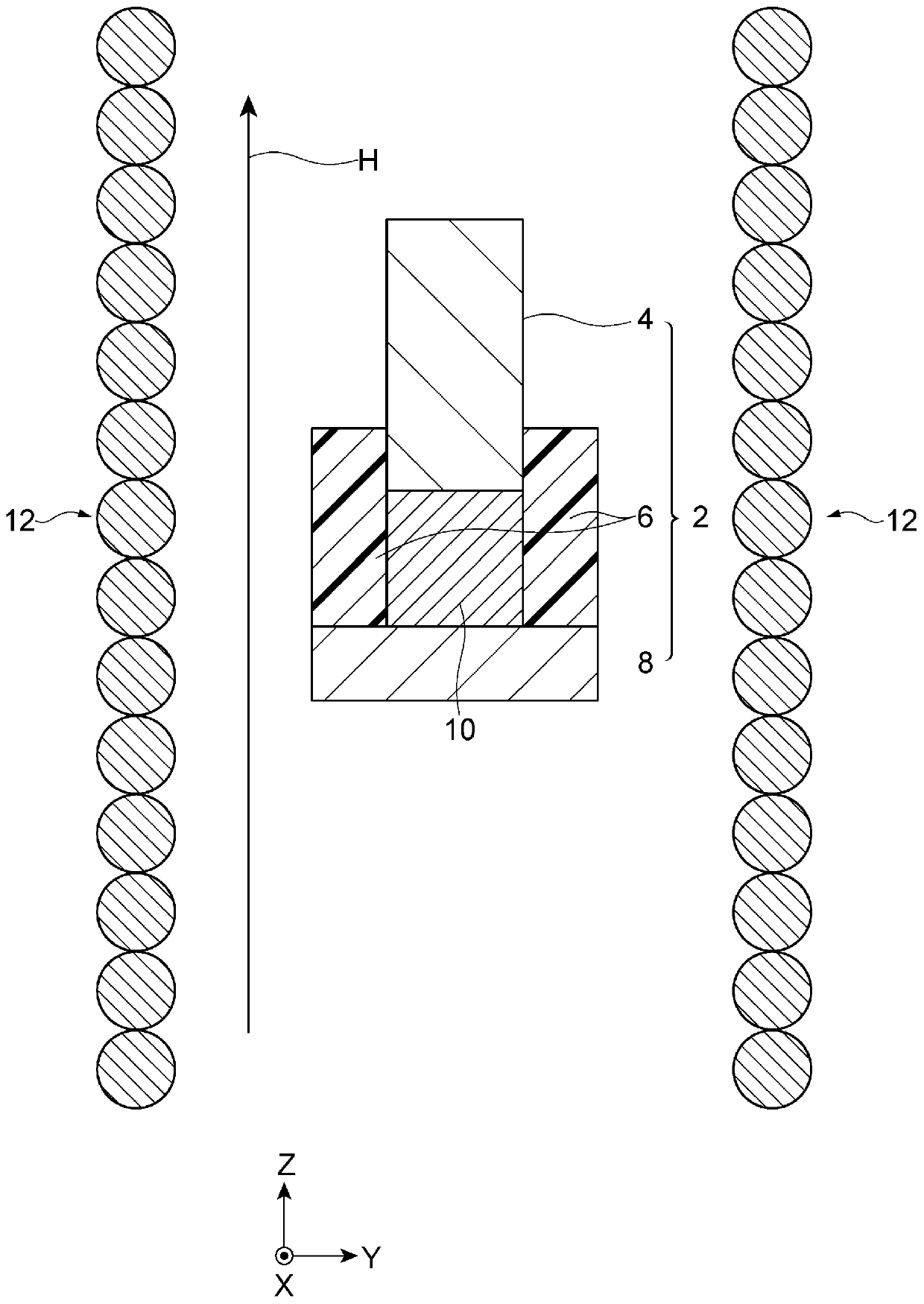

[0087] Such as Figure 4 As shown, in the orientation process of Example 1, a cylindrical side mold 6 made of acrylic resin was used. The side mold 6 and the cylindrical molded body 10 filled in the side mold 6 are arranged inside the hollow coil 12. Then, the pulse magnetic field H generated by the air-core coil 12 is applied to the side mold 6 and the molded body 10. The surface of the side mold 6 in contact with the molded body 10 (ie, the inner wall of the side mold 6) is parallel to the pulse magnetic field H. The side mold 6 and the molded body 10 are arranged at the center of the air-core coil 12 in the direction of the pulse magnetic field H. Inner diameter of side mold 6 (The diameter of the molded ...

Embodiment 2

[0154] Through thin strip continuous casting, the composition is Nd in weight fraction 29 Dy 1 Fe bal. B 1 The flaky alloy. The alloy is coarsely pulverized by the hydrogen adsorption method to obtain coarse powder. Add oleic acid amide (lubricant) to the coarse powder. Next, the coarse powder is pulverized in an inert gas by a jet mill to obtain a fine powder (metal powder containing rare earth elements). The particle size D50 of the fine powder was adjusted to 4 μm. The oxygen content in the fine powder is 5000 mass ppm or less. The nitrogen content in the fine powder is 500 mass ppm or less. The carbon content in the fine powder is 1000 mass ppm or less.

[0155] In the molding process, the fine powder to which oleic acid amide is added is fed into the mold to form a molded body. The details of the molding process are as follows.

[0156] The mold includes a rectangular lower mold, a rectangular parallelepiped side mold arranged on the lower mold, and an upper mold arran...

Embodiment 3~9、 and comparative example 2 and 3

[0168] In Examples 3 to 9 and Comparative Examples 2 and 3, the molding pressure was adjusted to the value shown in Table 2 below. In Examples 3-9 and Comparative Examples 2 and 3, the density of the molded body immediately after the molding process was adjusted to the value shown in Table 2 below by changing the quality of the fine powder supplied into the mold and the molding pressure . In each of Examples 3 to 9 and Comparative Examples 2 and 3, the density of the molded body immediately before the sintering process was substantially the same as the density of the molded body immediately after the molding process (density 1). Except for these matters, the same method as in Example 2 was used to produce molded bodies and rare earth magnets of Examples 3 to 9, and Comparative Examples 2 and 3, respectively.

[0169] In the same manner as in Example 2, the residual magnetic flux density Br of each of the rare earth magnets of Examples 3 to 9 and Comparative Examples 2 and 3 was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com