Asphalt concrete steel bridge pavement structure and pavement method thereof

A technology for asphalt concrete and steel bridge decks, which is applied in bridges, bridge parts, bridge construction, etc. It can solve the problems of insufficient shear resistance of concrete, low viscosity of ordinary modified asphalt, and easy shifting, etc., to solve the problem of interlayer bonding problems, reduce pavement damage, and dry quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The preparation method of the modifier is as follows: 50% to 60% by weight of styrene-butadiene-styrene triblock copolymer, 12% to 41% by weight of petroleum resin, 0% to 26% Diatomaceous earth roasted products in weight percentage and 0-3% weight percentage of auxiliary agents are mixed evenly in a high-speed mixing equipment, and then mixed with 8%-37 weight percentage of aromatic oil, and extruded through a screw extruder , Cut into pellets, control the extrusion temperature at 120-200°C, and make it after cooling.

[0057] The aggregate consists of coarse aggregate and fine aggregate.

[0058] In the aggregate, the coarse aggregate (referring to the aggregate retained above the 4.75mm square hole sieve) is diabase, basalt or limestone; the fine aggregate (referring to the aggregate that can pass through the 4.75mm square hole ) is limestone;

[0059] The filler is limestone powder.

[0060] In the high-viscosity asphalt embedded compact graded concrete with a nom...

Embodiment

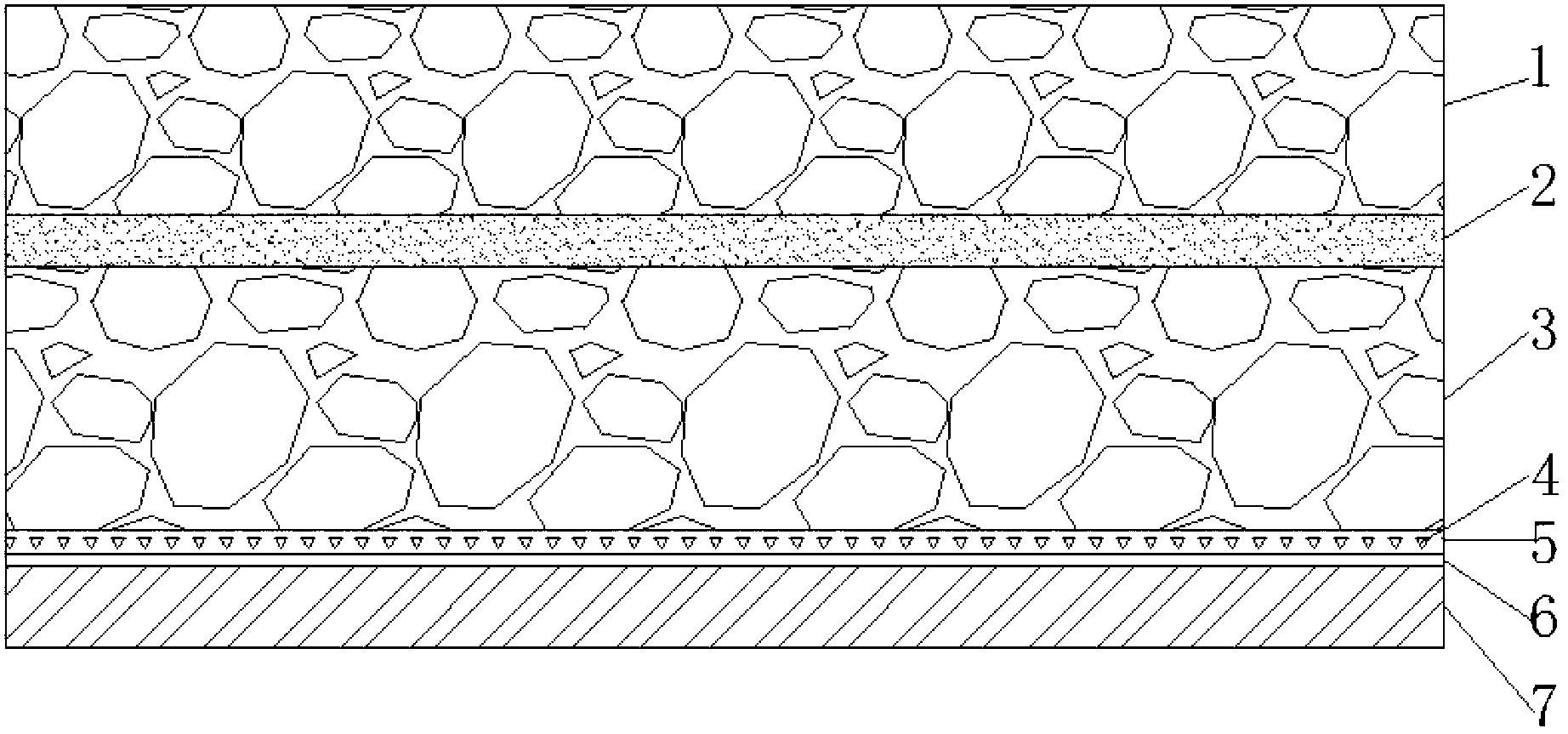

[0074] Steel bridge deck asphalt concrete pavement, consisting of bottom-up steel deck derusted by sandblasting 7, epoxy zinc-rich paint anti-corrosion layer 6, epoxy asphalt waterproof bonding layer 5, stone chip layer 4, nominal maximum The lower layer 3 of high-viscosity asphalt embedded densely graded concrete with a particle size of 16mm, the emulsified asphalt adhesive layer oil 2, and the upper layer 1 of high-viscosity asphalt embedded densely graded concrete with a nominal maximum particle size of 13.2mm. Epoxy asphalt waterproof bonding layer 5 is 0.8-1.0mm thick, high-viscosity asphalt embedded densely graded concrete lower layer 3 is 50mm thick, emulsified asphalt adhesive layer oil 2 is thick 0.8-1.0mm, high-viscosity asphalt embedded compacted graded compounding Congeal the above soil 1 thick 40mm.

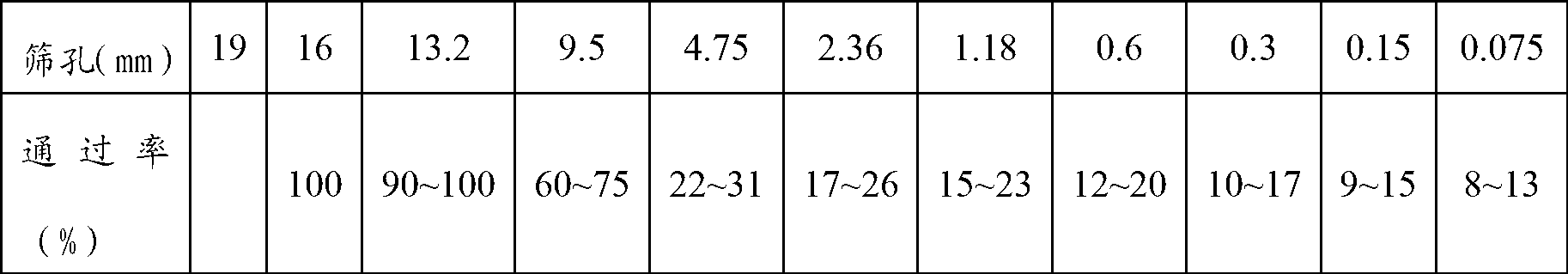

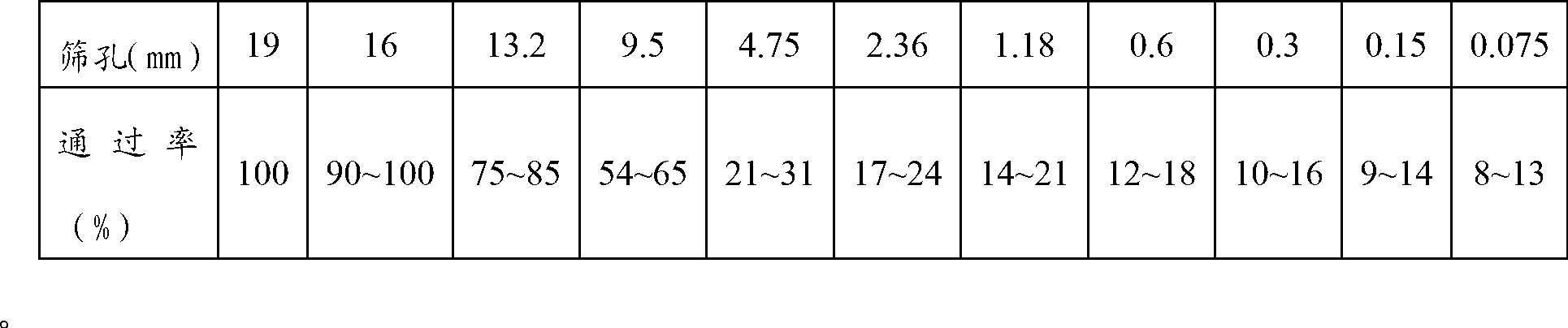

[0075] The lower layer of high-viscosity asphalt compacted compacted graded concrete with a nominal maximum particle size of 16 mm (abbreviated as PRAC-16, the same ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com