Micro-pressure difference self-sealing box opening of airtight box

A technology for airtight boxes and box openings, applied in sealing, closing, packaging, etc., can solve problems such as loss of sealing effect, air leakage, deformation of sealing strips, etc., and achieve good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

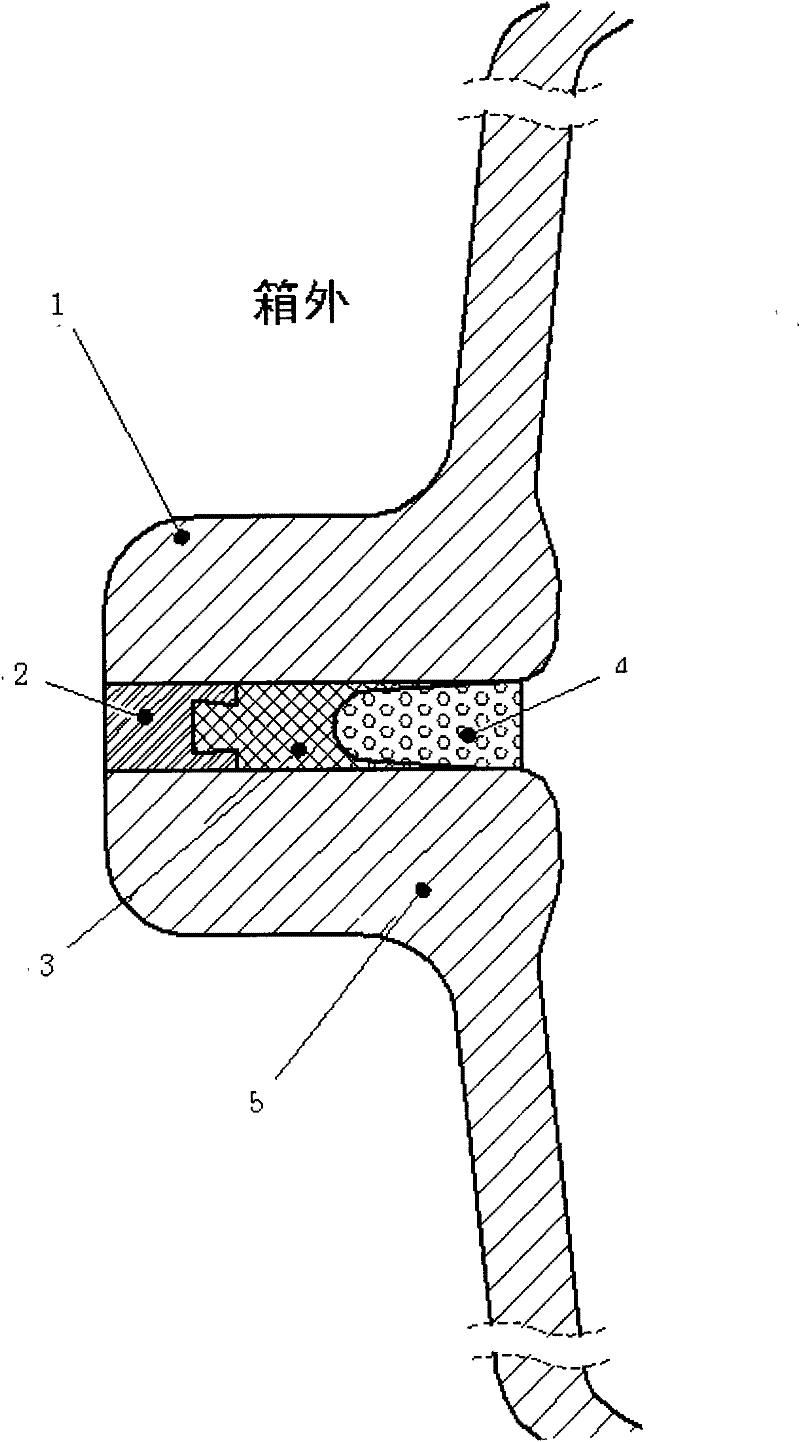

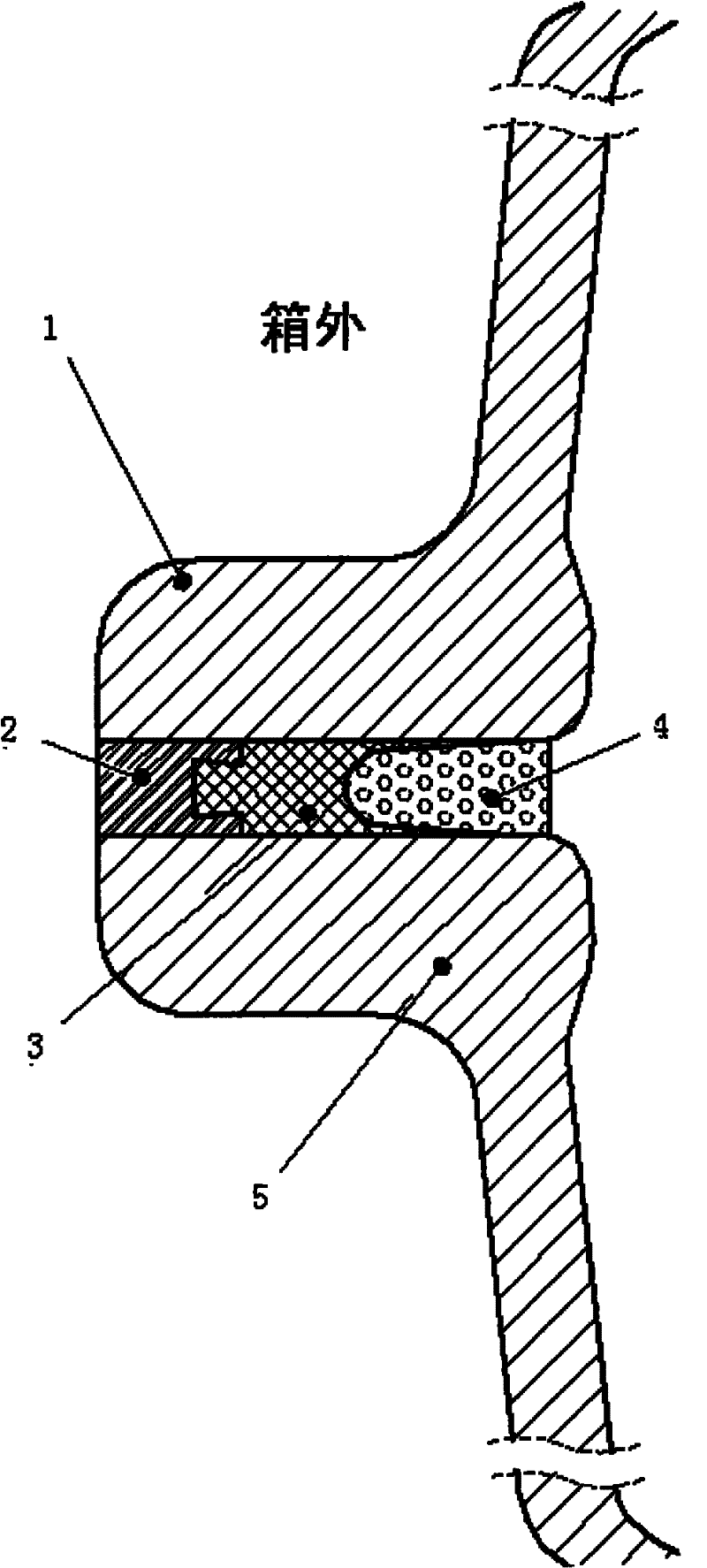

[0009] The sealing assembly is arranged on the box mouth 1 and 5, and the said sealing assembly is made of a hard plastic box mouth support member 2, a sealing strip 3 with upper and lower extended edges made of silicon rubber, and an extended edge support strip made of sponge 4 is combined in order from the outside to the inside, and the extended side support strip 4 is placed between the two extended sides of the sealing strip. When the contact surface of the box mouth support 2 and the sealing strip 3 is flat, adhesive connection can be used, or the box mouth support as shown in the figure is concave, and the sealing strip 3 is convex and inserted into each other. No glue required, easy to remove. The extended edge should be very thin to facilitate the creation of a pressure differential across the extended edge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com