Motor with built-in permanent magnets

A permanent magnet and motor technology, applied in the field of motors, can solve the problem that the difference in inductance cannot be made larger, and achieve the effect of improving anti-demagnetization and high output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

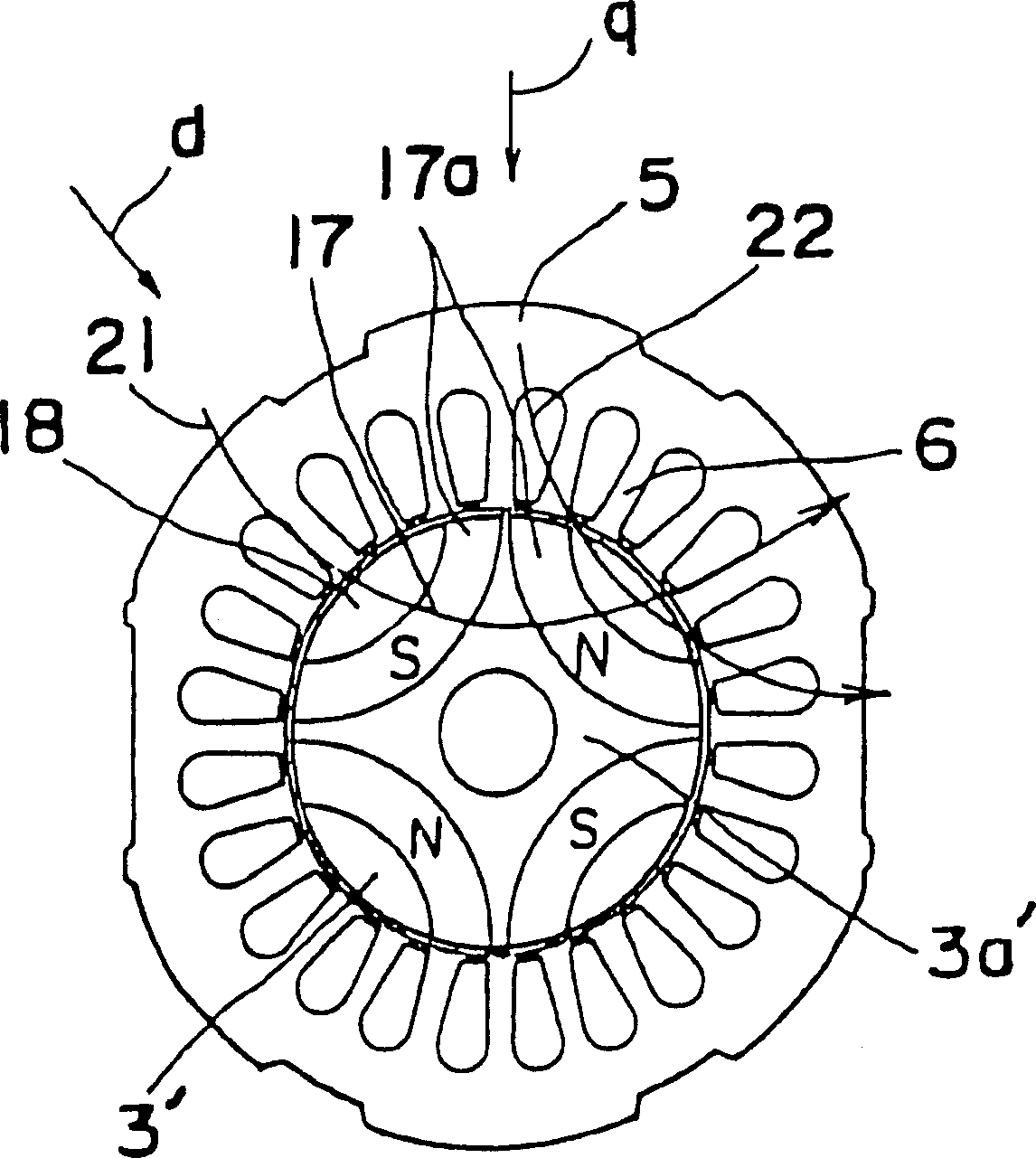

[0055] Referring now to the drawings, wherein the same or corresponding parts are denoted by the same reference numerals throughout the drawings, embodiments of the present invention will be described in detail with reference to the drawings. Figure 4 and 5 A motor with built-in permanent magnets of 4 poles is shown in the first embodiment. The motor includes a rotor 3 fixed on a rotating shaft 7 and a stator 2 on which the rotor 3 is installed.

[0056] The rotor 3 includes 4 sets of 2-layer permanent magnets 8a, 8b embedded in a rotor core 3a made of high magnetic permeability material. The 2-layer permanent magnet group is composed of an outer permanent magnet 8a and another inner permanent magnet 8b, and 4 sets of 2-layer permanent magnets 8a and 8b are arranged with alternating N and S poles on their outer peripheral sides. The inner and outer sides are defined in a radial direction with respect to the center of the rotor. Seen in a different way, the one-pole permane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com