Semi-magnetic barrier type dual-field excitation linear synchronous generator

A linear synchronization and double excitation technology, applied in the direction of magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc., can solve the problems of cross-sectional area limitation, affecting efficiency, etc., and achieve the effect of increasing levitation force and thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention is further described below in conjunction with embodiment and accompanying drawing:

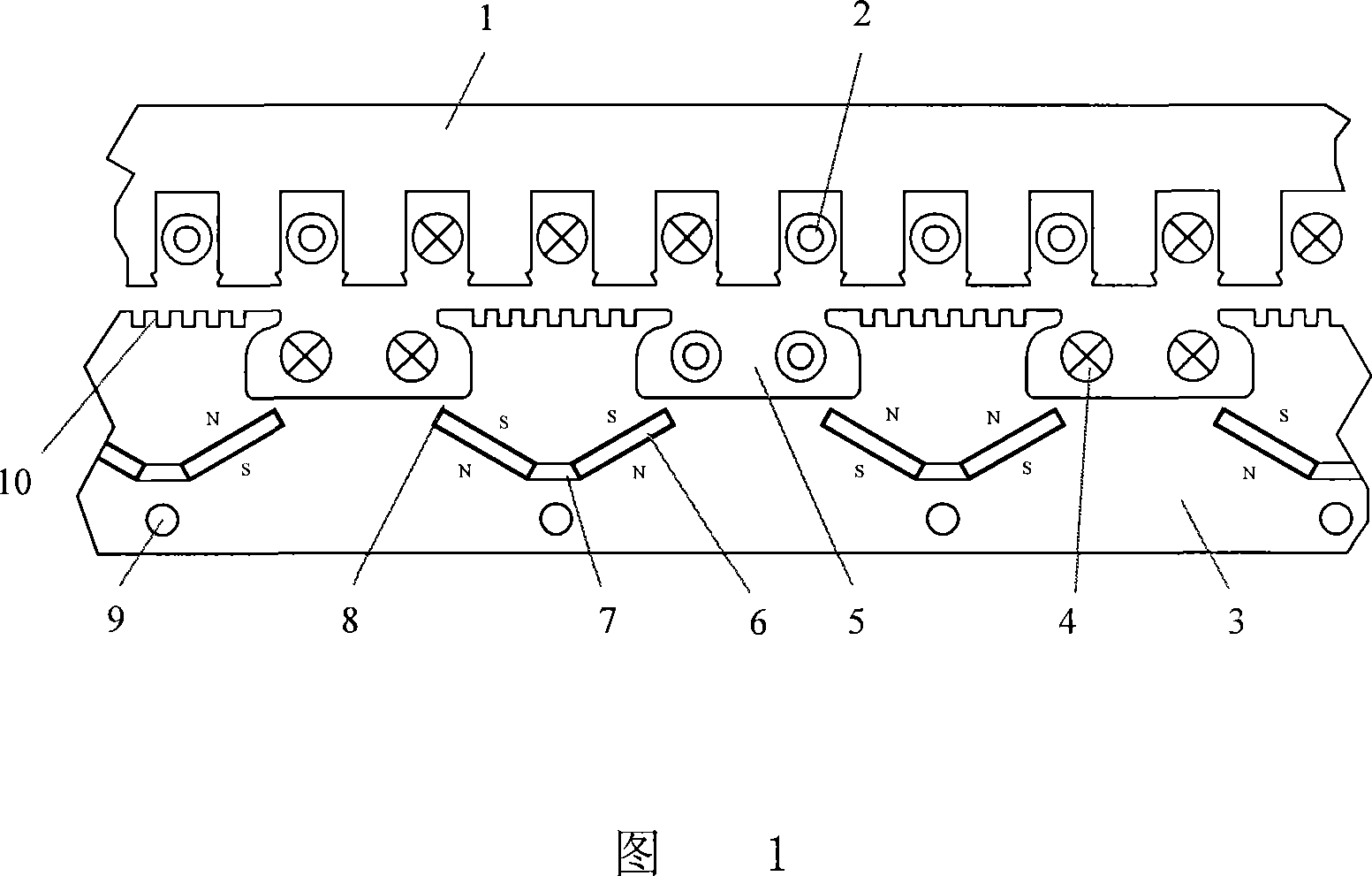

[0014] Fig. 1 is a schematic diagram of the basic structure of the semi-magnetic-isolated double-excitation linear synchronous motor of the present invention. It includes primary iron core 1, primary winding 2, secondary iron core 3, secondary excitation winding 4, secondary excitation winding slot 5, permanent magnet 6, tooth slot 10 where the generator and winding coil are located, and secondary excitation winding 4 wound on each secondary tooth, characterized in that there are two permanent magnets 6 for excitation under each magnetic pole, placed obliquely, corresponding to each other, fixed in the slot in the secondary yoke, and formed into each other The included angle of 120° is upward, and the corresponding ends of each pair of permanent magnets 6 are provided with magnetically isolated trapezoidal air slots 7; under the same magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com